Integral fixed installation method of embedded steel pipe on roof of coal furnace foundation

An installation method and coke oven technology, applied in the furnace foundation, infrastructure engineering, construction and other directions, can solve the problems of low installation accuracy of pre-embedded steel pipes, changes in the relative position of pre-embedded steel pipes, and no guarantee of strength and rigidity. The construction method is convenient and fast, the cost is reduced, and the operation is easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further understand the invention content, characteristics and effects of the present invention, the implementation of Xingtai Xuyang 2 million ton coke oven project is taken as an example, and the present invention is further described in detail in conjunction with the accompanying drawings:

[0048] The invention discloses a method for integrally fixing and installing the pre-embedded steel pipe on the top plate of the coke oven foundation:

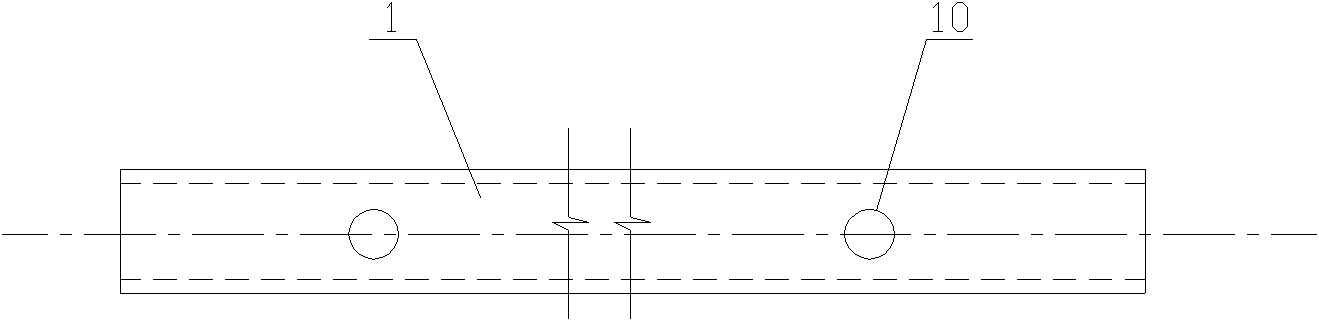

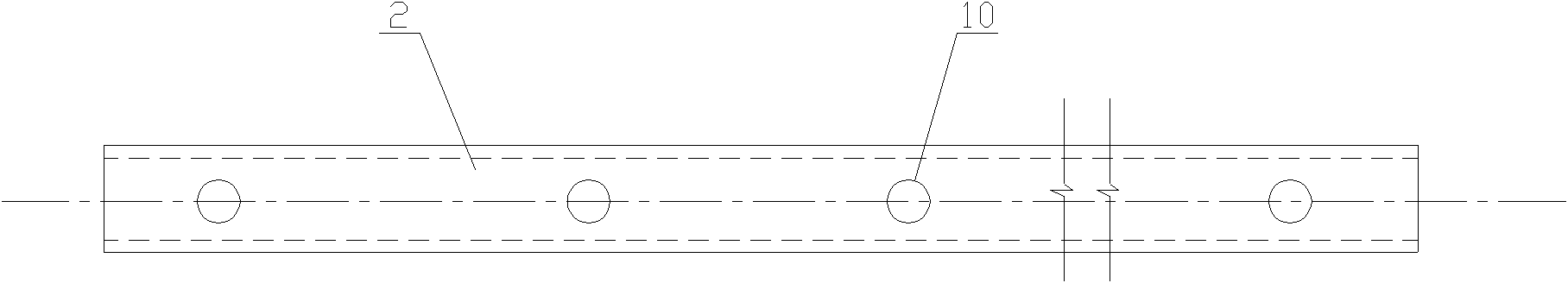

[0049] Such as figure 2 and image 3 As shown, first according to the diameter and the spacing of the embedded pipe 9 required by the drawing, the positioning hole 10 is processed on the channel steel with a drilling machine, and the horizontal beam fixing frame 1 and the horizontal longitudinal beam fixing frame 2 are manufactured in sections. The positioning hole 10 should satisfy that its diameter is greater than the diameter of the corresponding embedded pipe 9, but the difference must not be greater than the max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com