Two-wheel-driven bidirectional heavy-pipe deep stirring ground wall connecting machine

A technology of deep stirring and wall machine, applied in the direction of drill pipe, casing, sheet pile wall, etc., can solve the problems such as the cement content of the wall does not reach the due index, the drill pipe is slurried, and the quality of the wall is affected. Eliminate pulp phenomenon, ensure verticality, and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

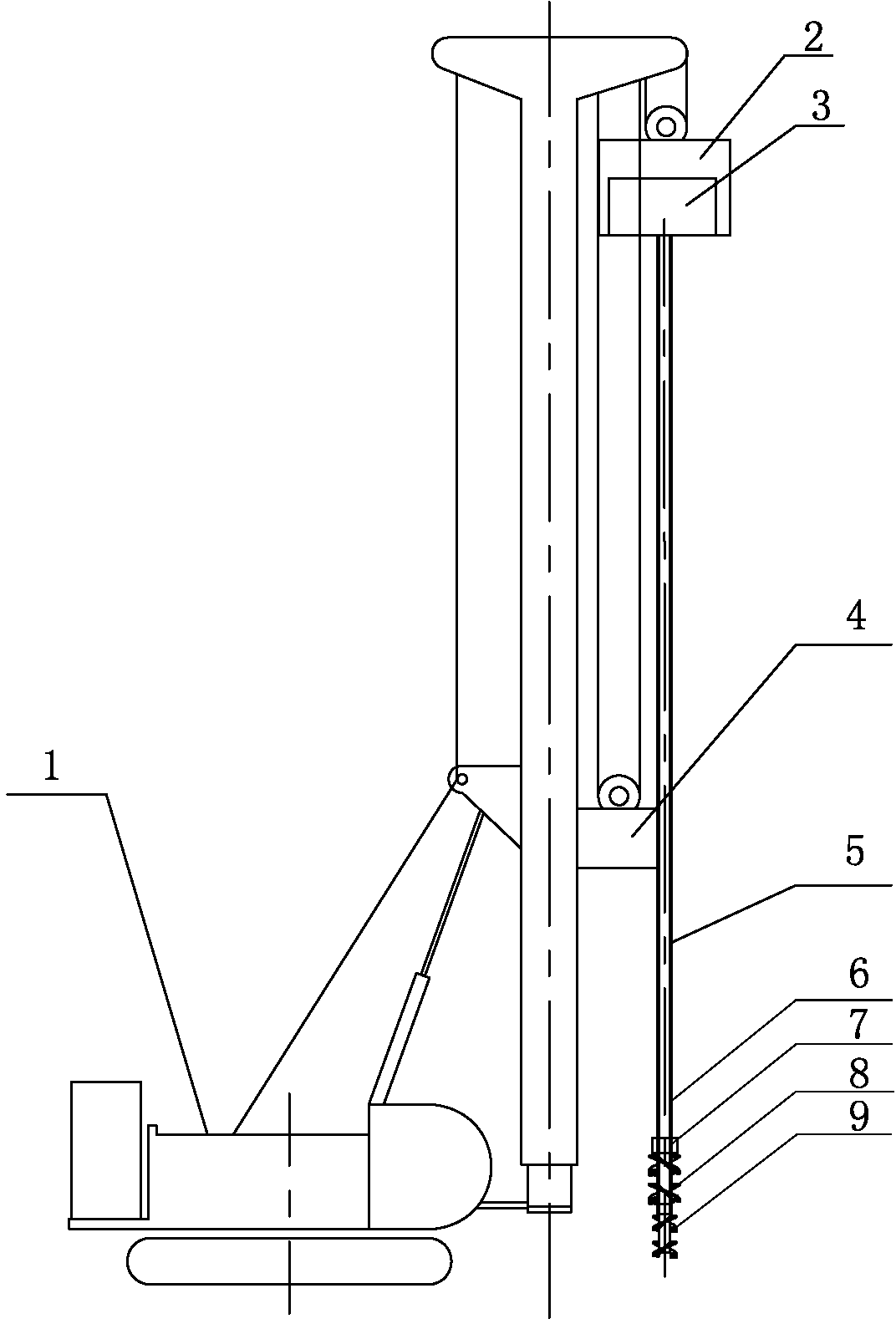

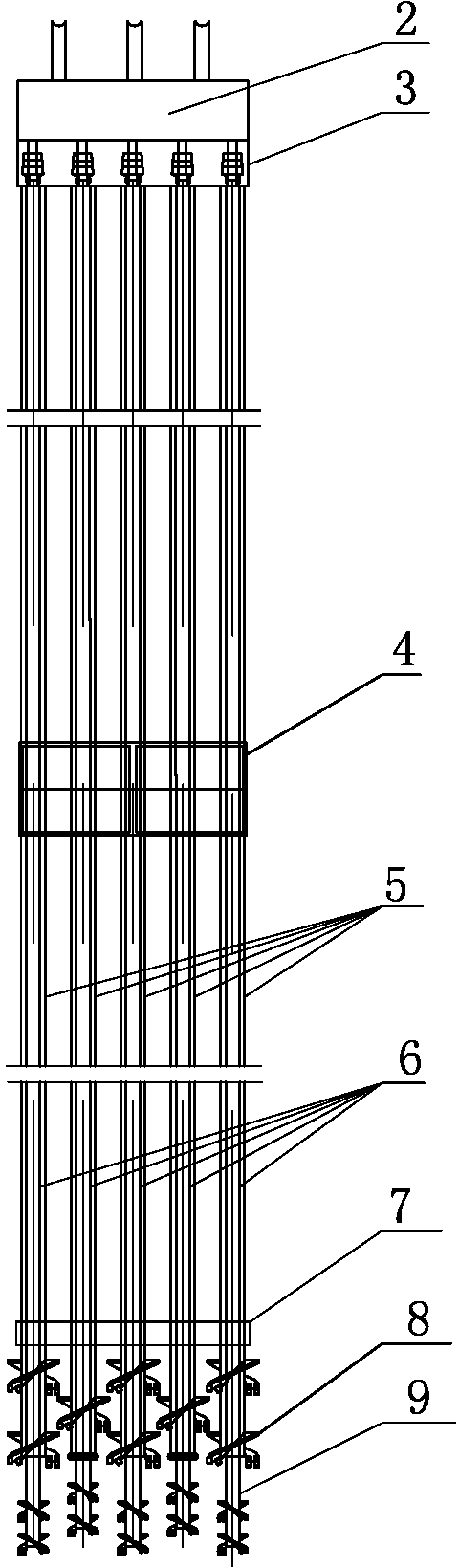

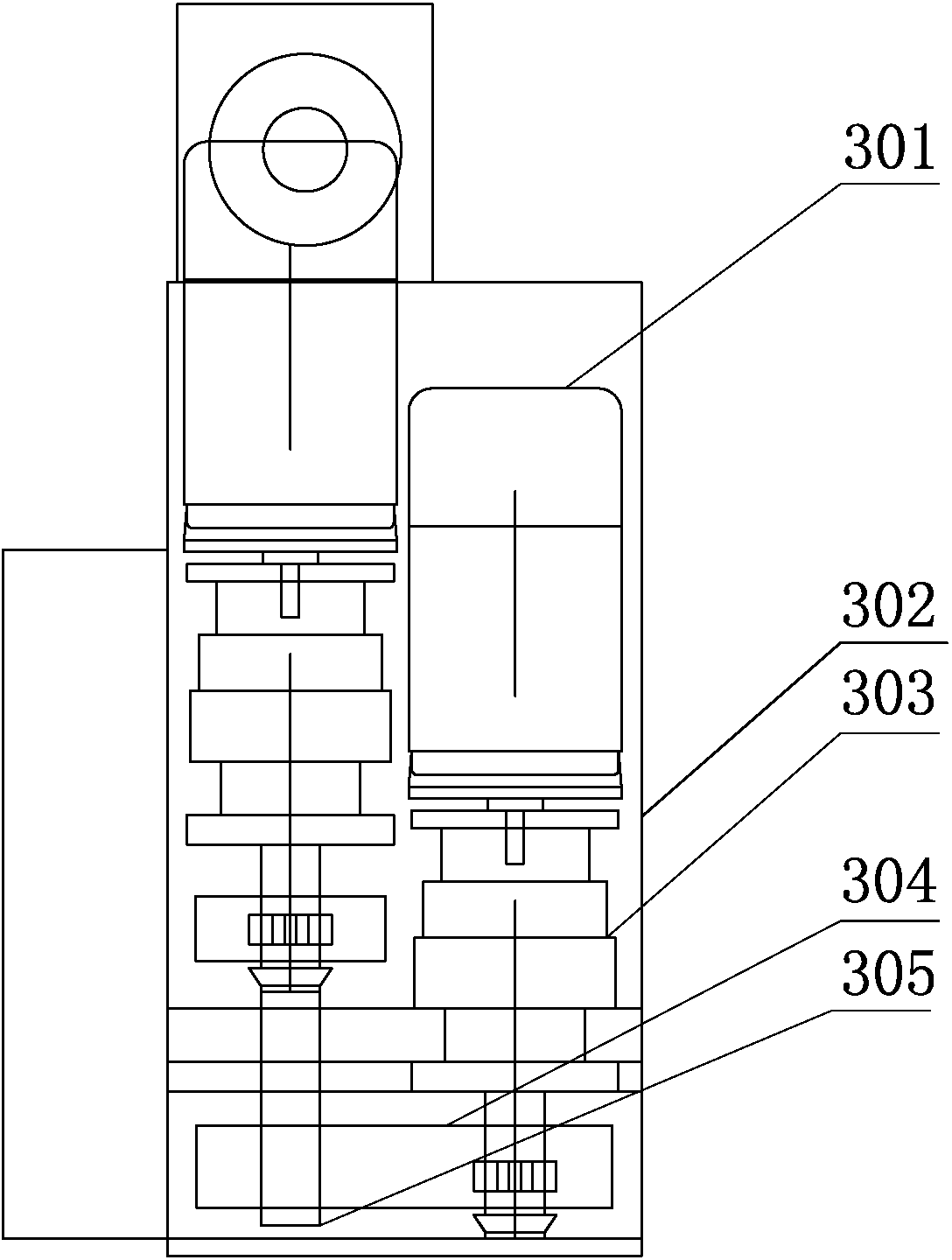

[0029] Such as figure 1 — Figure 5 Shown is the two-drive two-way heavy-pipe deep-stirring ground-wall connecting machine of the present invention, including drill pipes. In this embodiment, the drill pipes are 5 groups arranged parallel to each other. The lower parts of each drill pipe respectively pass through the cage 7, and the drill pipes The top is provided with a lifting platform 2, and the drill rods include a hollow inner drilling rod 6 and an outer drilling rod 5 which are arranged concentrically and can rotate in opposite directions. The inner drilling rod 6 and the outer drilling rod 5 are rotatably connected below the lifting platform 2, and the lifting platform 2 is provided with a top drive mechanism 3 for driving the rotation of the inner drill rod 6, and the lifting table 2 is suspended on the support machine 1 through a wire rope; the middle part of the outer drill rod 5 is provided with a middle drive mechanism 4 for driving the rotation of the outer drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com