Engine cylinder sleeve press-fitting detection device

A technology for engine cylinders and detection devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low detection efficiency and high labor intensity, and achieve the effects of low labor intensity, improved motion precision, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

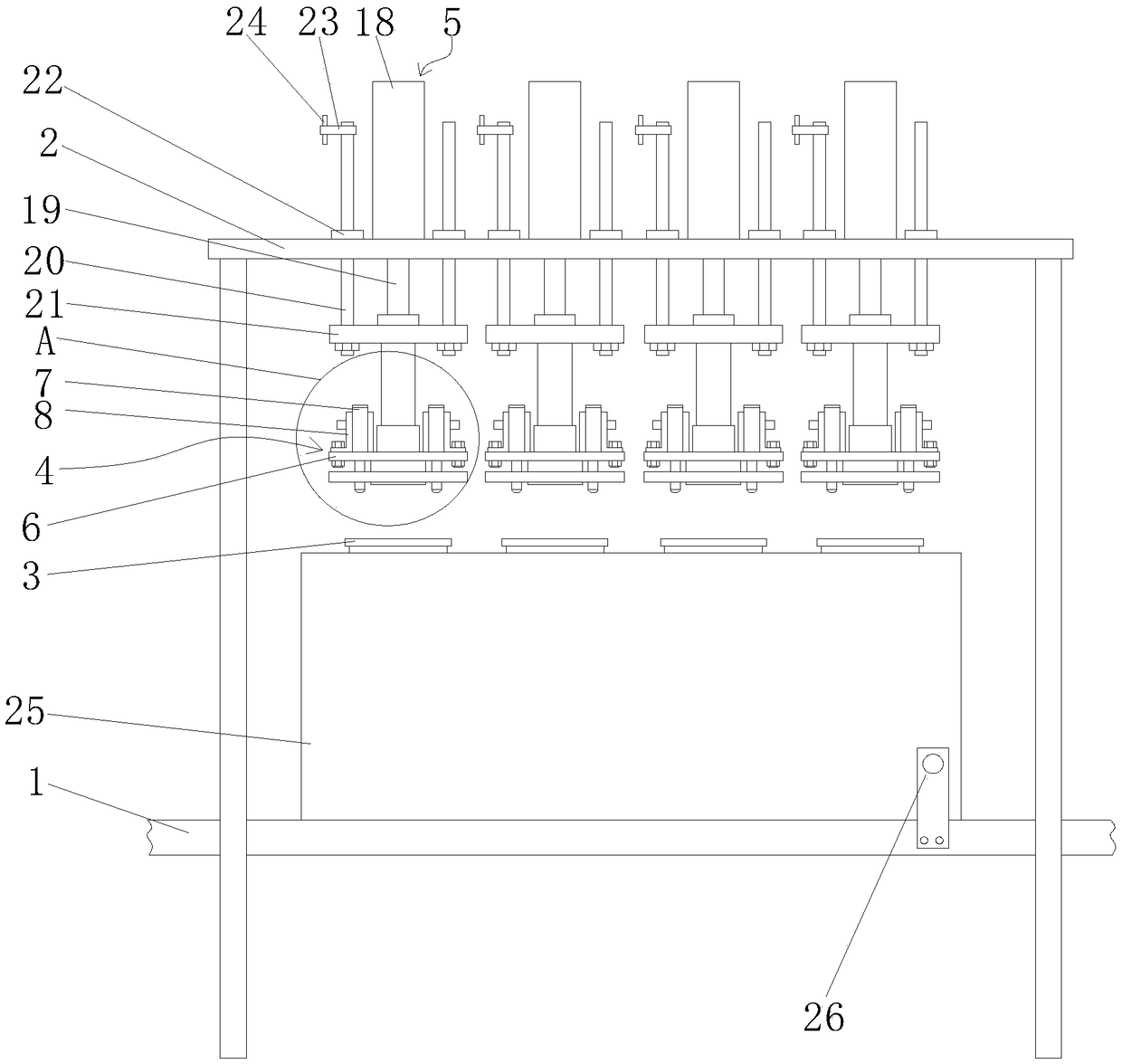

[0024] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

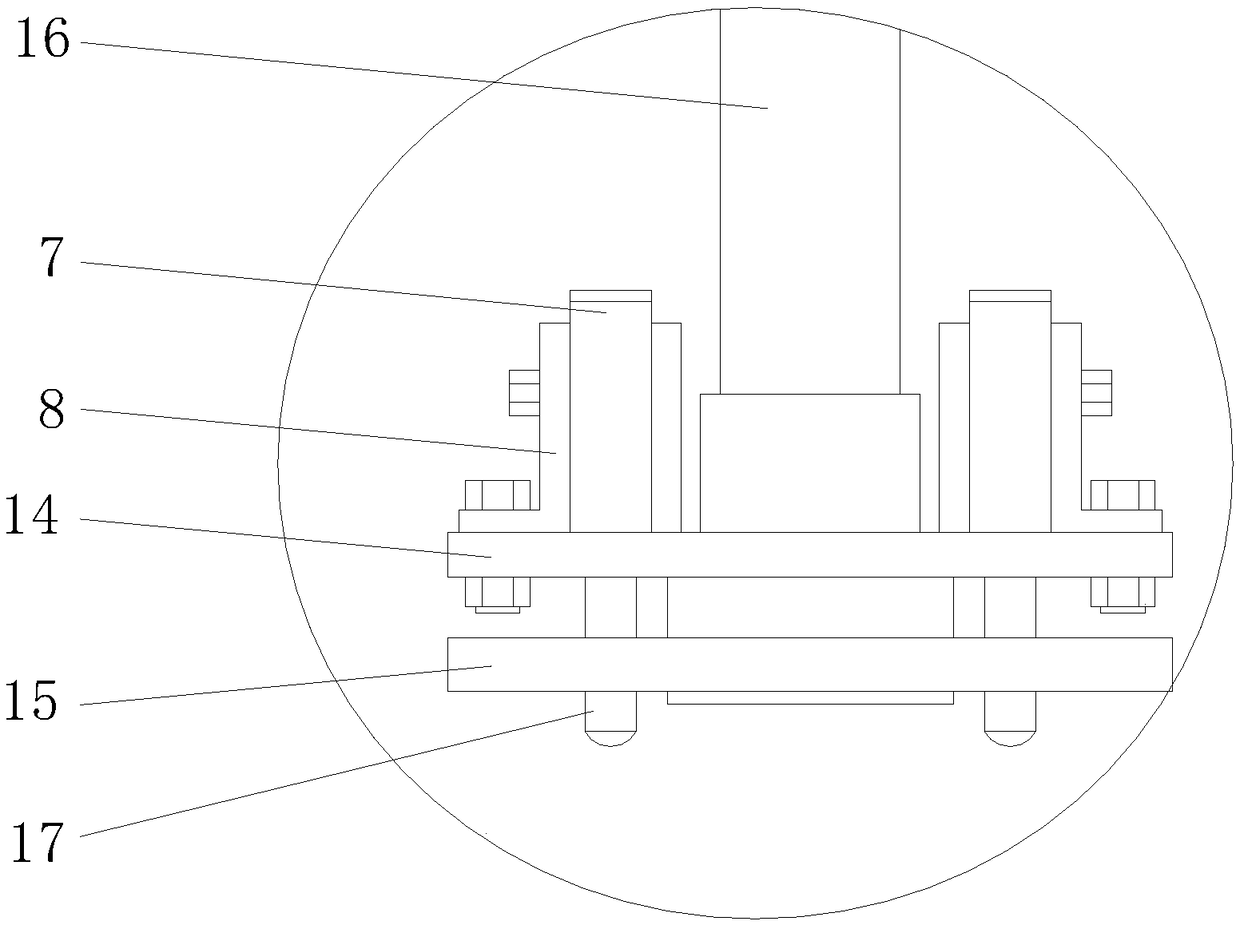

[0025] refer to Figure 1-3 , an engine cylinder liner press-fit detection device, including a bracket 2 erected above the conveyor belt 1, at least one detection head 4 for detecting the flatness of the engine cylinder liner 3 is arranged between the bracket 2 and the conveyor belt 1, which can The detection head 4 corresponding to the number of engine cylinder liners 3 is set to improve detection efficiency. The support 2 is provided with a linear motion mechanism 5 for driving the detection head 4 to move up and down. The detection head 4 includes a base 6 and at least 3 displacement sensors 7. Sensor 7 can be contact type, as grating ruler displacement sensor or electronic ruler displacement sensor, also can be non-contact type, as laser displacement sensor, displacement sensor 7 is arranged on the periphery of base 6 evenly around the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com