Section-steel-column support frame construction method for super-high-rise-building frame column

A construction method and support frame technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of insufficient anchor bolt precision, poor support structure stability, and the influence of key construction procedures, so as to achieve easy construction quality and good construction quality. Simple and convenient, guarantee the effect of pre-embedded quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

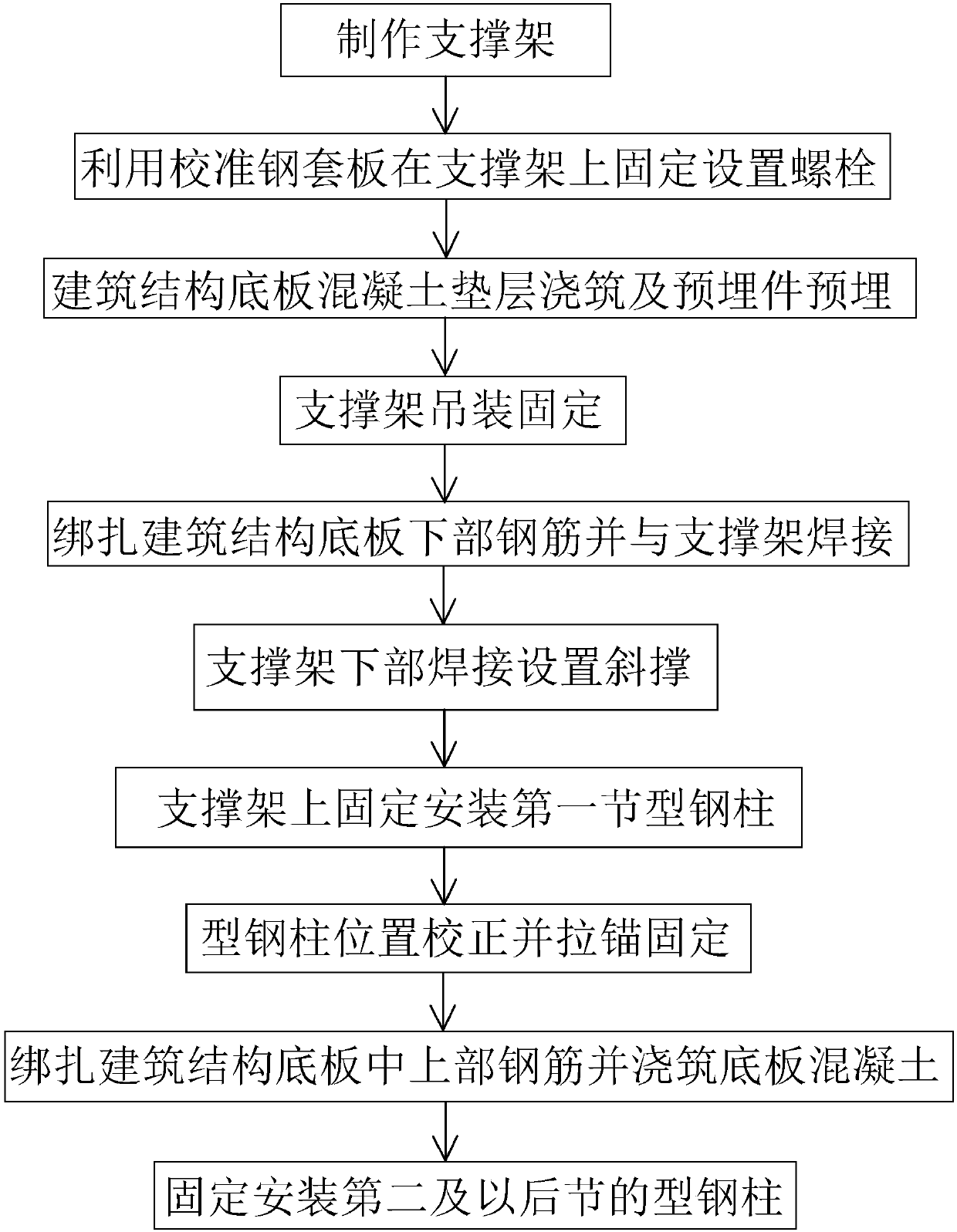

[0031] See figure 1 , the construction method of the shaped steel column bracing frame of the super high-rise building frame column of the present embodiment, it is mainly implemented by the following steps:

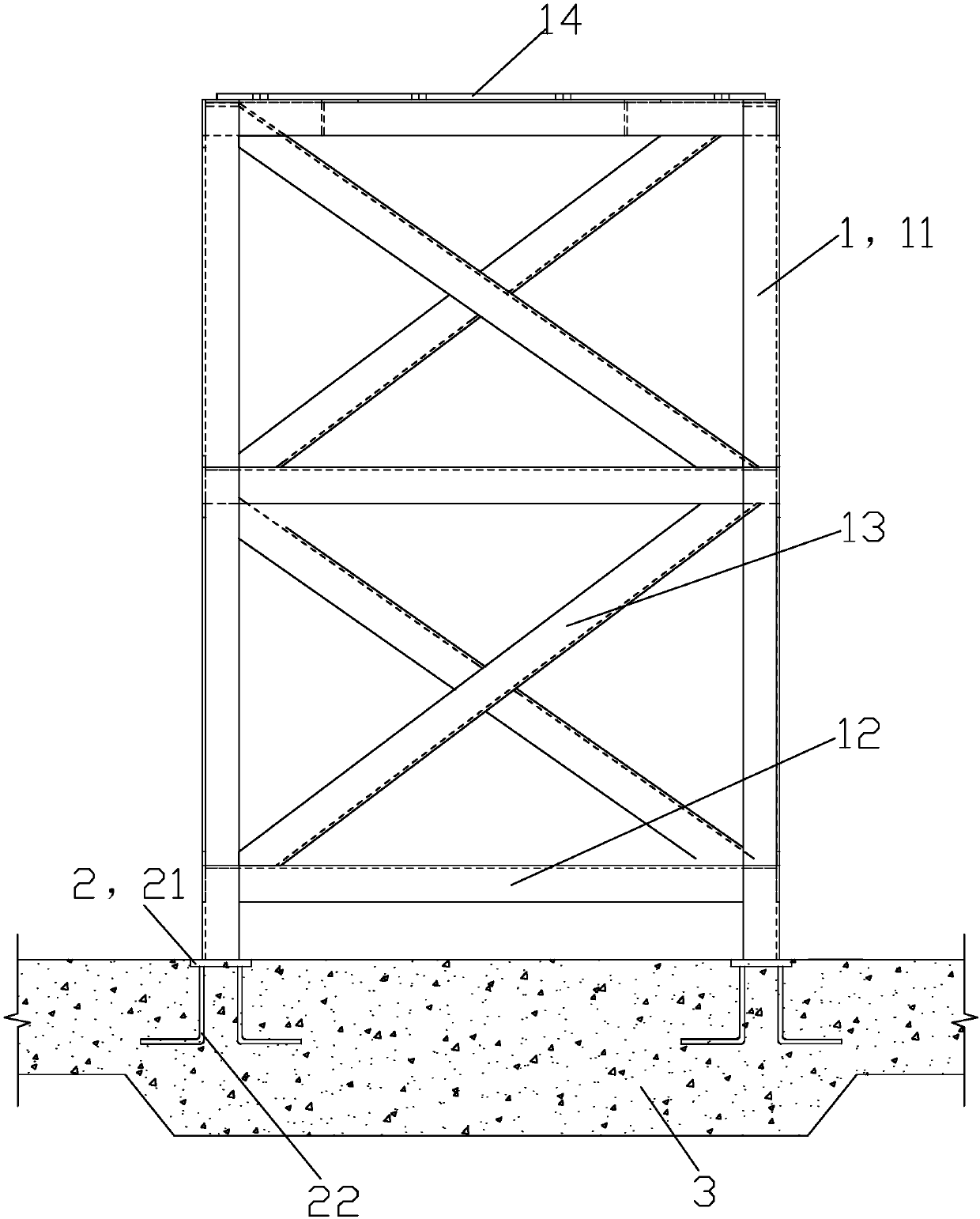

[0032] ① Make the support frame: make the support frame 1 according to the design size, and the manufactured support frame 1 is a truss type support frame, such as figure 2 As shown, the support frame 1 is composed of vertical bars 11, cross bars 12, oblique bars 13 and top plate 14; the vertical bars 11 are vertically arranged with 4, and the horizontal bars 12 are arranged with 12 horizontal bars. The 12 horizontal bars are divided into upper, middle, and The lower three floors are set up, and each floor is provided with four. The four horizontal bars 12 on the upper floor connect the tops of the four vertical bars 11 in turn; the four horizontal bars 12 on the middle layer connect the middle parts of the four vertical bars 11 in turn. The bottoms of the four vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com