Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Guaranteed production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

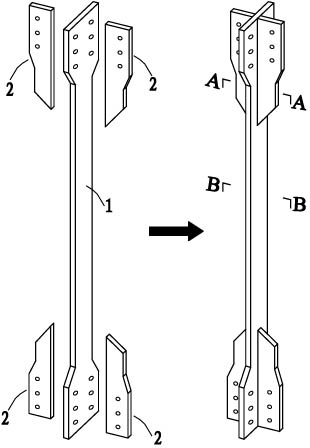

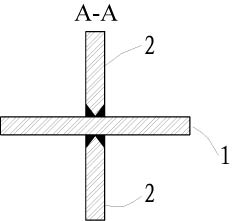

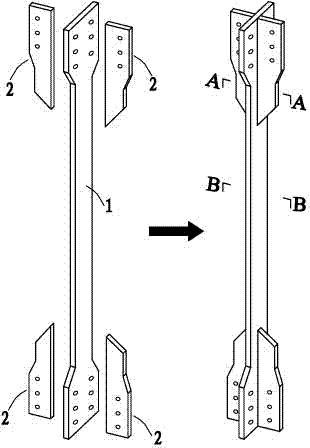

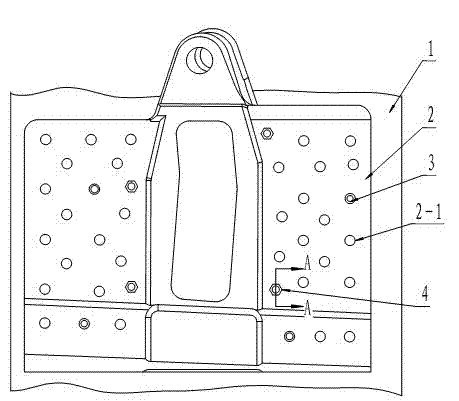

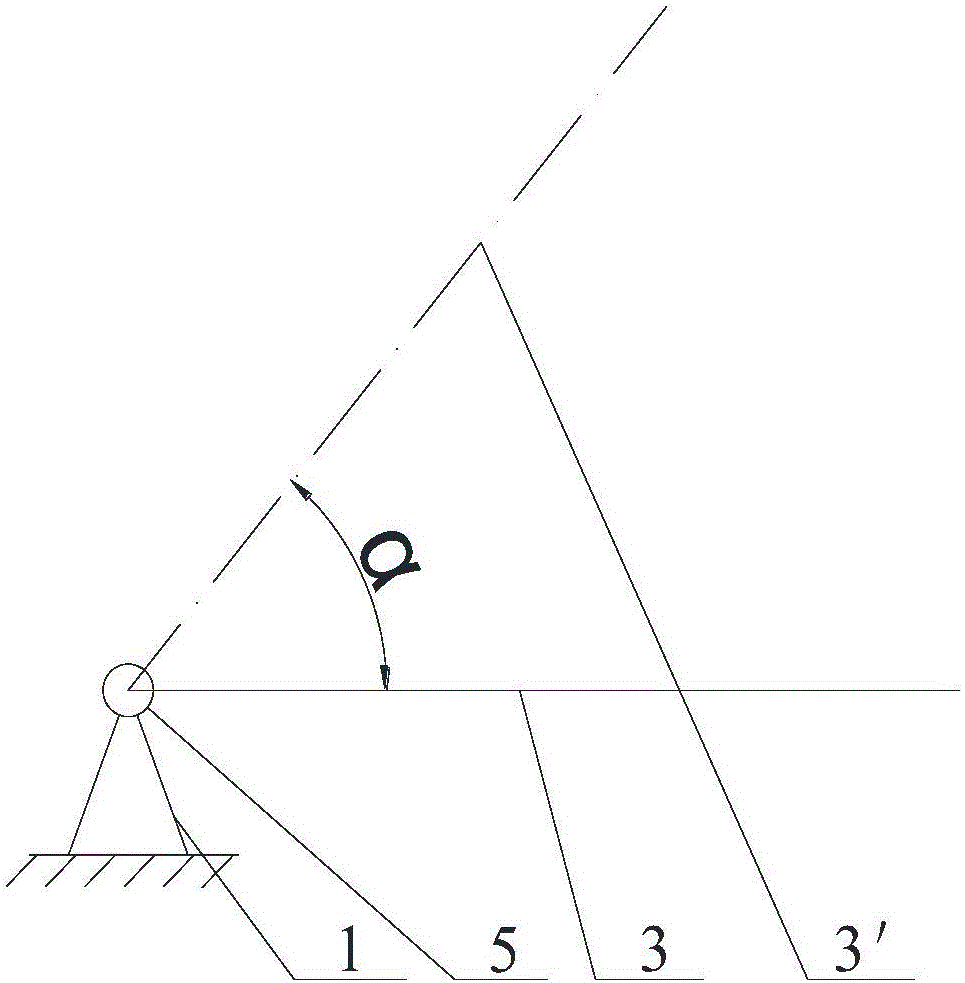

Combined steel pipe-encased concrete type buckling-restrained brace member

InactiveCN101798851AEasy production and constructionReduce manufacturing costShock proofingSteel tubeBuckling-restrained brace

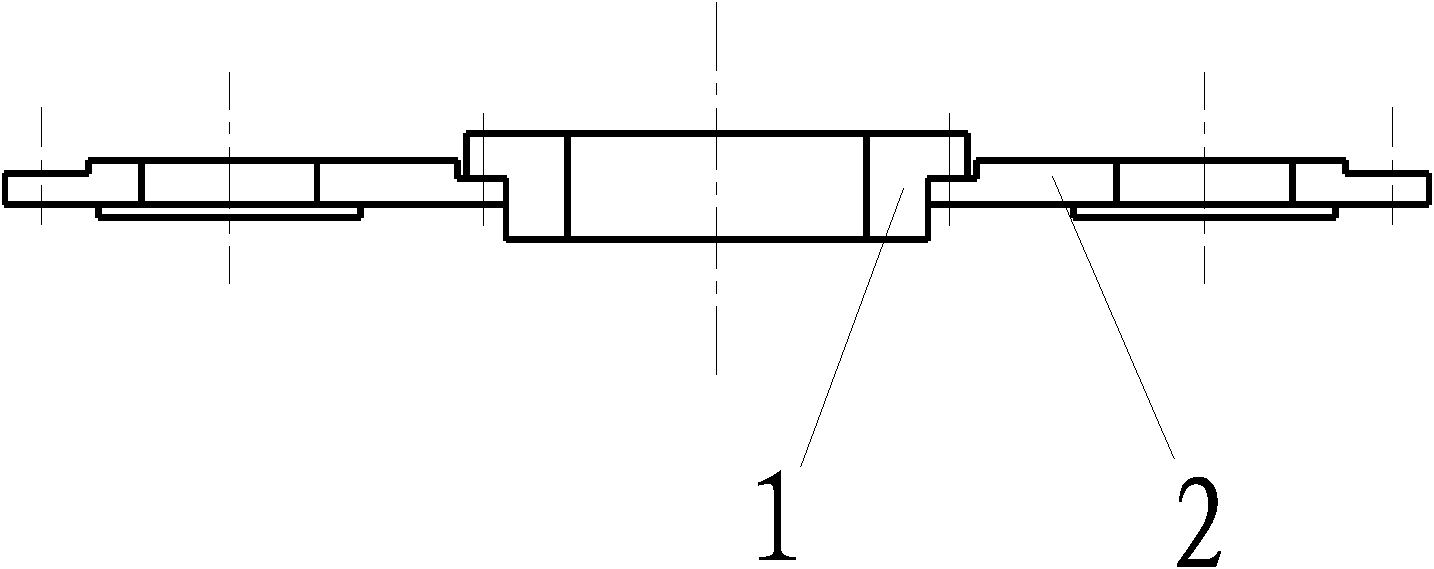

The invention relates to a buckling-restrained brace member, in particular to a combined steel pipe-encased concrete type buckling-restrained brace member. The invention solves the problems that the processing cost of the in-line brace inner core in the existing buckling-restrained brace member is high, the reliable low-cycle fatigue performance cannot be ensured, the cast-in-situ construction and the vibrating construction of mortar or concrete are apt to cause special soft material plates to be displaced and non-binder material plates to be locally damaged, and the production cycle is long. Technical scheme one: the in-line brace inner core and two first backing plates are clamped between two rectangular steel pipes filled with mortar or concrete blocks, each first backing plate is respectively and fixedly connected with outer walls which face to the two rectangular steel pipes and each backing plate is fixedly connected with an external restraining member; and technical scheme two: the in-line brace inner core and third backing plates are clamped between two rectangular steel pipes filled with mortar or concrete blocks, and the third backing plates are connected with pairs of bolt seats through a plurality of bolts. The combined steel pipe-encased concrete type buckling-restrained brace member can be used in the side force resisting component in the field of building structure engineering.

Owner:HARBIN INST OF TECH

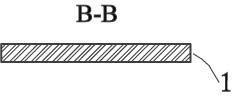

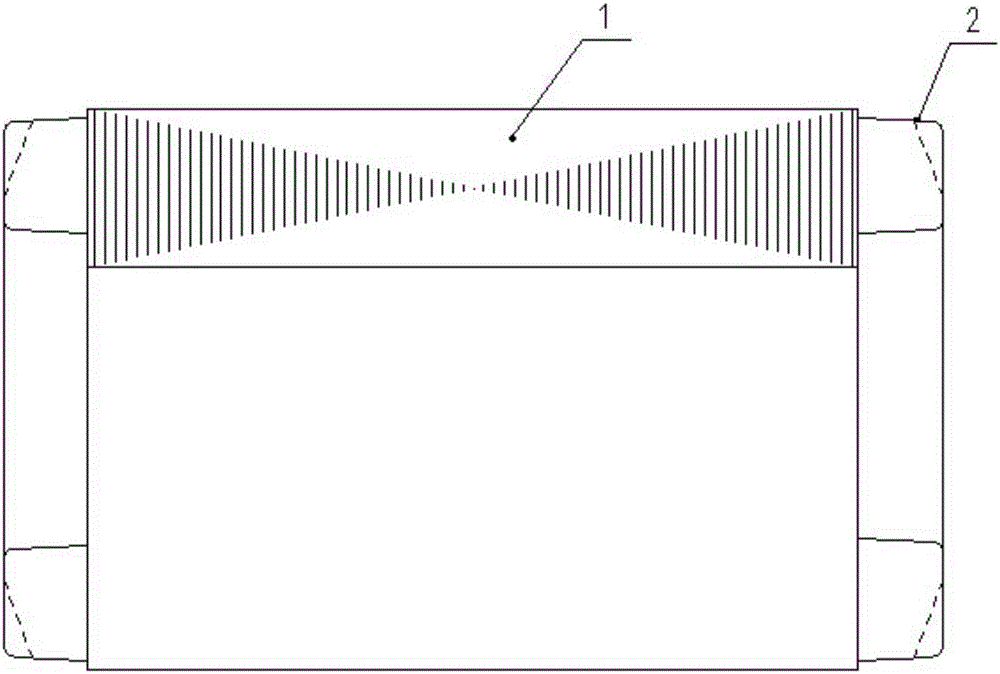

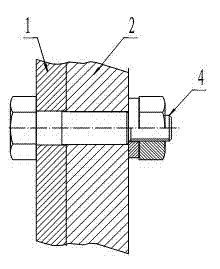

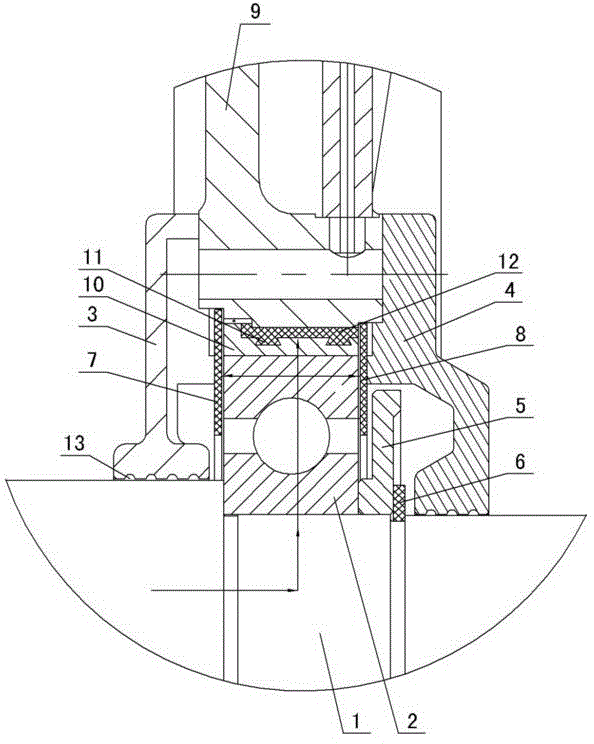

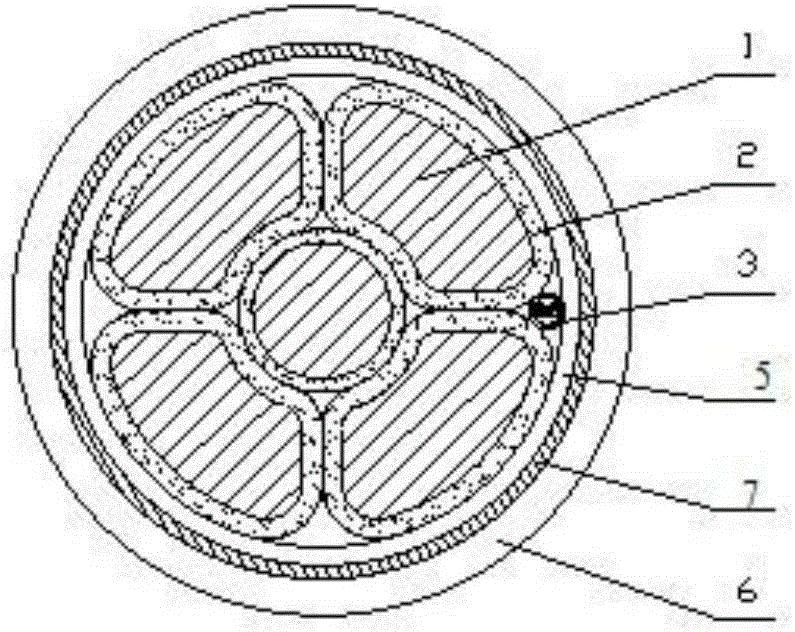

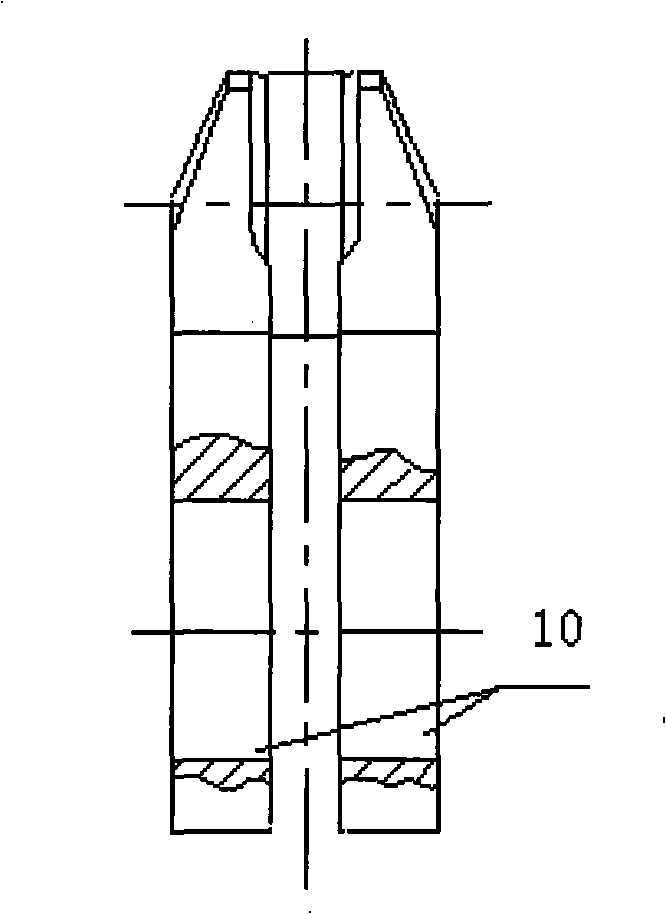

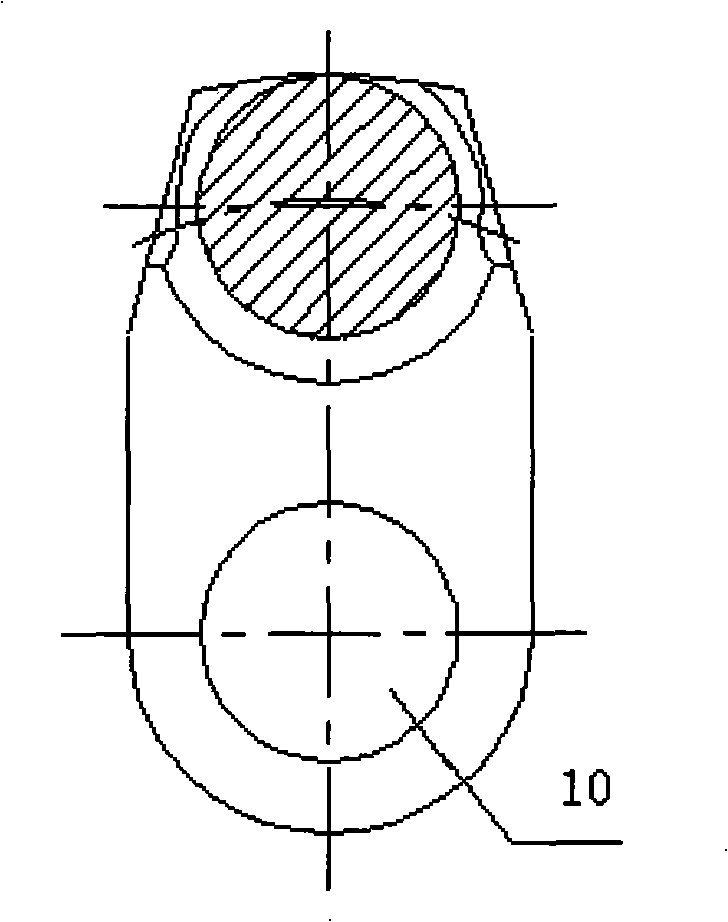

High-power variable frequency motor insulation bearing sleeve

ActiveCN103023190AReduce manufacturing costSimple structureSupports/enclosures/casingsGlass fiberInsulation layer

A high-power variable frequency motor insulation bearing sleeve comprises a motor shaft, a bearing, a bearing inner cap, a bearing outer cap, an oil baffle ring and a baffle ring, wherein an insulation sleeve is arranged out of the bearing. The high-power variable frequency motor insulation bearing sleeve is characterized in that the insulation sleeve comprises an inner insulation spacer arranged between the bearing and the bearing inner cap, an outer insulation spacer arranged between the bearing and the bearing outer cap, a rear end cap arranged out of the bearing, and a gap insulation strip and a glass fiber insulation layer arranged between the rear end cover and a bearing seat. Three insulation strips are respectively arranged on the left side, the right side and the outer circle of the bearing, can effectively cut off a loop of a motor shaft current, and prevent the motor shaft current from forming a current loop through a motor bearing end cap and a motor base to destroy bearing balls, raceway surface roughness and oil film, and furthermore the bearing is protected. In addition, the insulation strips are simple in structure, convenient to manufacture, low in cost, and convenient to replace, and therefore manufacturing cost of a motor is reduced, and production cycles of motor forming products are guaranteed.

Owner:ZHEJIANG JINLONG ELECTRICAL MASCH CO LTD

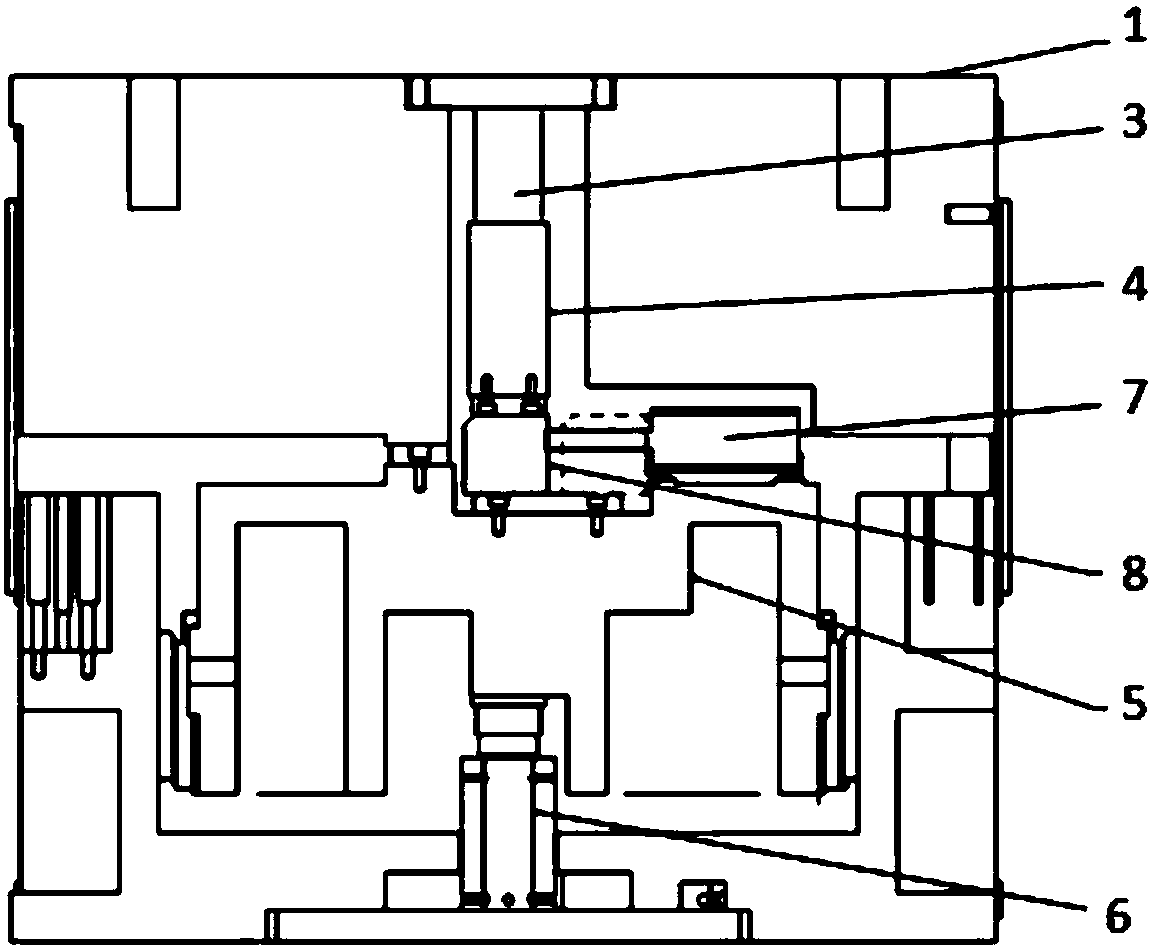

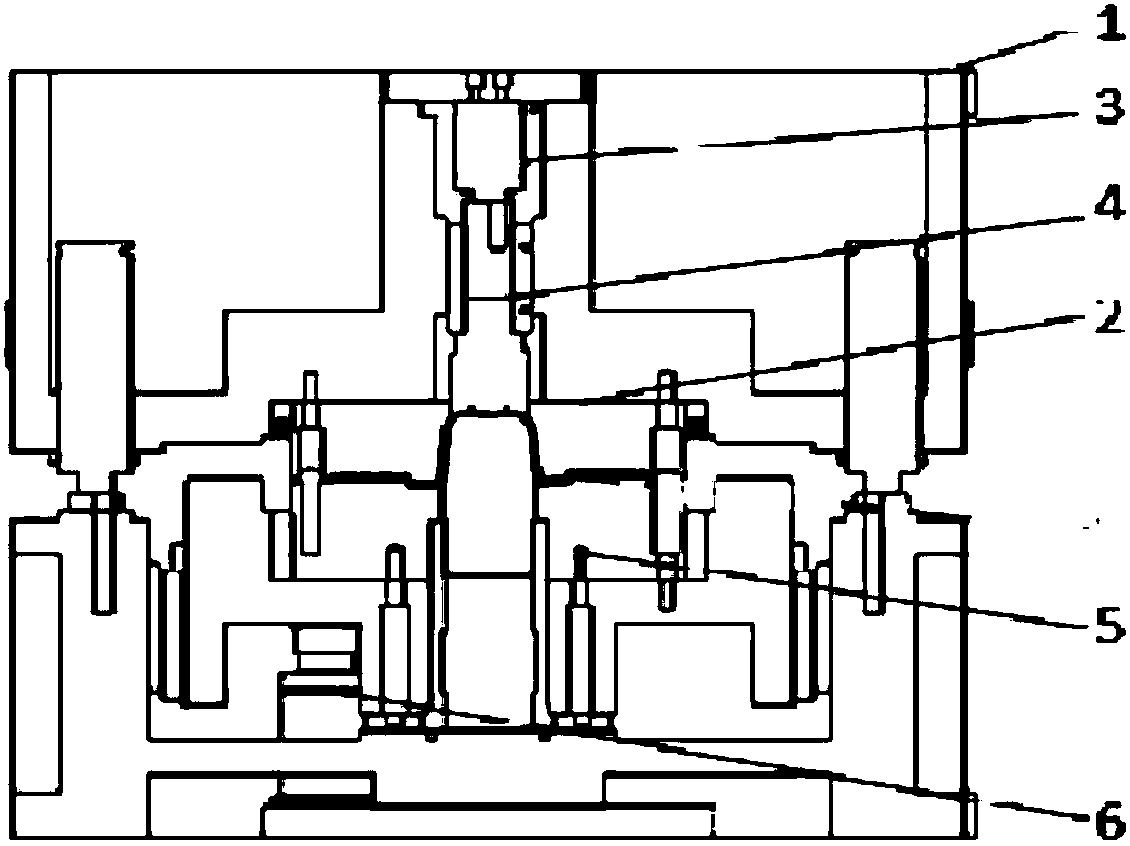

Secondary ejecting mechanism of automobile door panel injection mold

The invention relates to a secondary ejecting mechanism of an automobile door panel injection mold. The secondary ejecting mechanism of the automobile door panel injection mold comprises a mold seat board, wherein the mold seat board is provided with a movable mold through a mold leg, an ejector pin board and an ejector pin ventral board which are driven to do vertical motion by an oil cylinder are arranged between the mold seat board and the movable mold, the ejector pin board is fixedly provided with a top rod, mesh pull rods are fixedly arranged on the ejector pin board and the ejector pin ventral board, the movable mold is provided with a concave pit, the concave pit is internally provided with a mesh ejector pin board, the mesh ejector pin board is fixedly provided with a mesh ejector pin which is used for ejecting a mesh opening of an automobile door panel, a mesh ejecting spring which is used for supplying power for ejecting the mesh ejector pin board is arranged in the pit, the upper ends of the mesh pull rods are fixedly arranged on the mesh ejector pin board, the lower ends of the mesh pull rods are provided with rod caps in bulged ring shapes, the ejector pin ventral board is provided with a guide hole which is in size match with the rod cap, and the rod cap is positioned in the guide hole and can slide vertically. The secondary ejecting mechanism of the automobile door panel injection mold, disclosed by the invention, has the advantage that the breaking (bending) probability of the ejector pin is reduced to a large extent.

Owner:ZHEJIANG TAIZHOU MEIDUO MOLD CO LTD

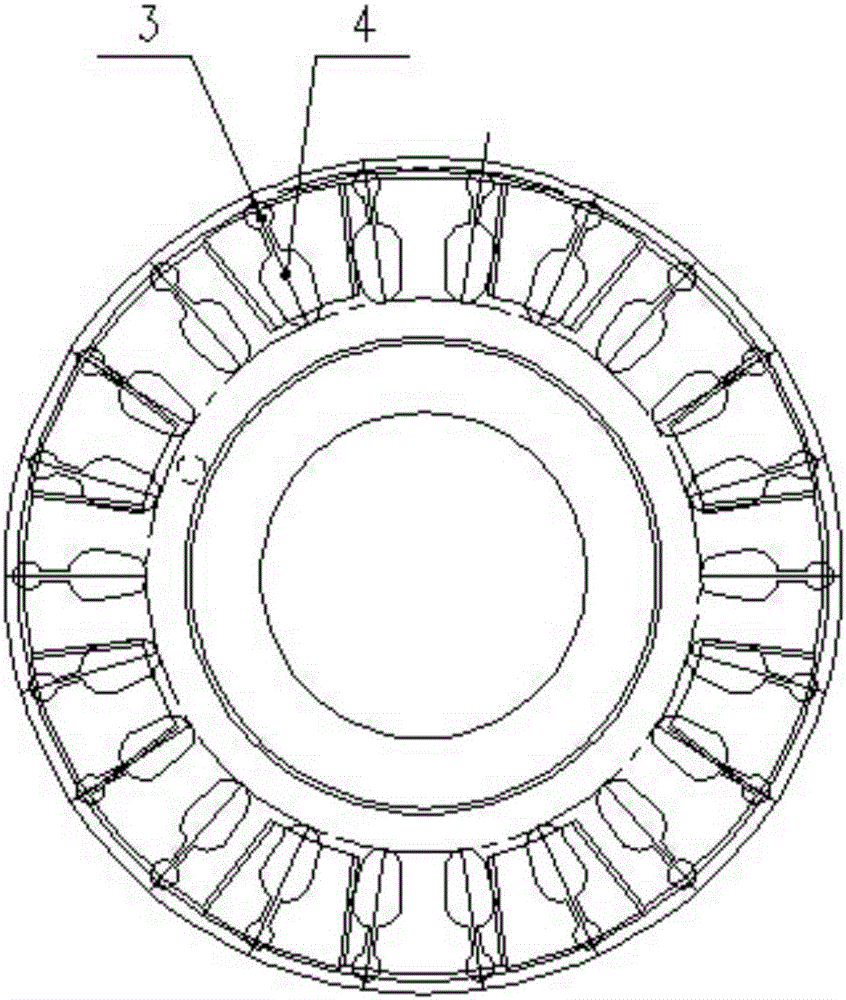

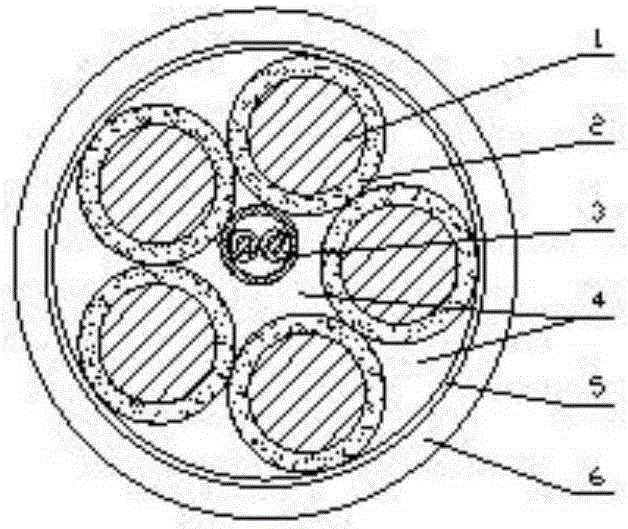

Highly-efficient composite cage bar motor rotor and preparation method thereof

InactiveCN106787554AMeet assembly requirementsIncreased assembly requirementsAsynchronous induction motorsManufacturing cage rotorsPunchingPower factor

The invention provides a highly-efficient composite cage bar motor rotor. The highly-efficient composite cage bar motor rotor comprises a rotor, and is characterized in that the rotor comprises a set of rotor punching sheets, inner and outer squirrel cage slots are formed in the rotor punching sheets; inner squirrel cage bars are inserted in the inner squirrel cage slots; a silicon aluminum outer squirrel cage which comprises outer squirrel cage bars and an end ring is cast in the outer squirrel cage slots once; the end ring comprises blades and balance columns; two ends of each of the inner squirrel cage bars and the outer squirrel cage bars are connected with the end ring integrally. The highly-efficient composite cage bar motor rotor disclosed by the invention is reasonable and simple in structure, scientific and advanced; when the highly-efficient motor rotor of high-speed pressed copper-aluminum double-squirrel cage composite cage bars is started, the starting current is concentrated on the outer squirrel cage due to a skin effect, equivalently, an effective section is small, the effective resistance is large, and power factors are increased, so that the starting current of a motor is reduced, and the starting torque is increased.

Owner:XUZHOU DAYUAN ELECTROMOTOR

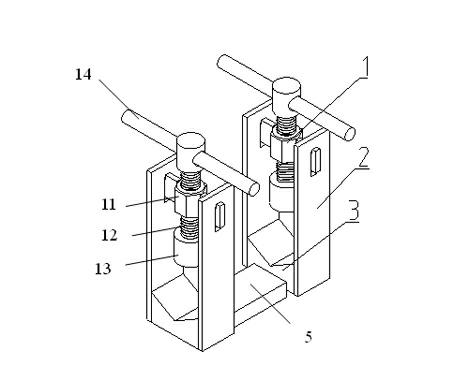

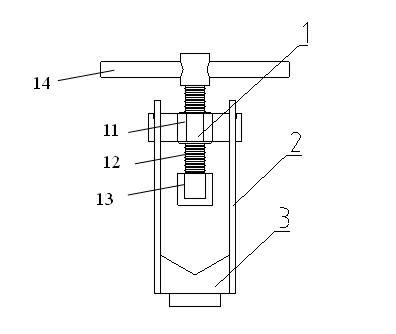

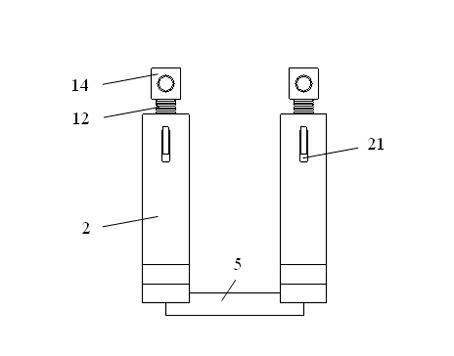

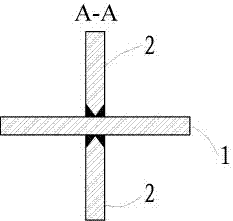

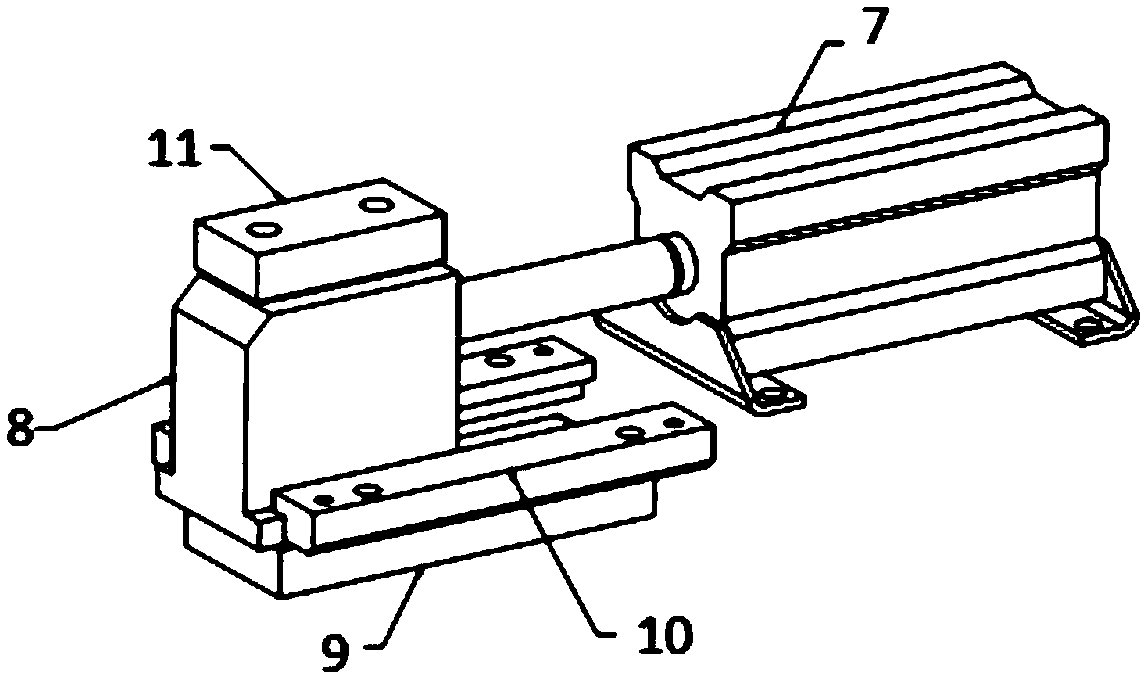

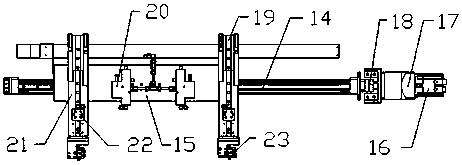

Fitting clamp for fine-pitch tube bundle

ActiveCN102390009ACompact structureEasy to install and disassembleWelding/cutting auxillary devicesAuxillary welding devicesManufacturing qualityEngineering

The invention relates to a fitting clamp for a fine-pitch tube bundle, which comprises two fitting clamp assemblies concentrically connected through a connecting plate; each fitting clamp assembly comprises two insertion plates, a tray and a fastening device, wherein the tray is arranged between the bottom ends of the two insertion plates; the fastening device is arranged between the top ends of the two insertion plates; the thickness of each insertion plate is less than a gap between two adjacent pipes; and the spacing width between the two insertion plates and the pitch of the adjacent pipes are correspondingly arranged. The fitting clamp for the fine-pitch tube bundle can be suitable for the concentric fitting operation on the end part of the fine-pitch tube bundle in an integrated gasification combined cycle (IGCC) gasification furnace or a large-capacity circulating fluid bed (CFB) boiler, is convenient for welding and is capable of effectively ensuring the product manufacturing quality and cycle.

Owner:SHANGHAI BOILER WORKS

Method for making Salicornia bigelovii Torr capsules

InactiveCN102551118AImprove sensory qualityMaintain sensory qualityFood preparationHuman bodyVitamin C

The invention discloses a method for making Salicornia bigelovii Torr capsules. The method comprises the following steps of: (1) harvesting tender stems of Salicornia bigelovii Torr; (2) cleaning; (3) blanching; (4) performing composite desalting, namely performing vacuum penetration treatment, and desalting by using ultrasonic waves; (5) draining water; (6) performing combined drying, namely performing vacuum freeze-drying, and drying by using hot air; (7) performing metal detection and X-ray detection; (8) performing superfine comminution; and (9) packaging. A composite desalting technology is adopted, so that the desalting efficiency is improved, and the Salicornia bigelovii Torr well maintains chlorophyll, vitamin C (VC) and sensory quality; by the combined drying, the production cycle is shortened, the production cost is reduced, the nutrition, sensory quality and functional characteristics of the product are improved, and particularly the loss of heat-sensitive nutrient components and biological active functional components is greatly reduced; and by the mutual synergistic cooperation of the composite desalting, the combined drying and the superfine comminution, the prepared capsules are favorable for the absorption of human bodies, the quality guarantee period of the product is long after the product is packaged into the capsules, and the product is convenient to carry and eat.

Owner:慈溪市蔬菜开发有限公司 +2

Combined steel pipe-encased concrete type buckling-restrained brace member

InactiveCN101798851BShorten the production cycleGuaranteed production cycleShock proofingBuckling-restrained braceSoft materials

The invention relates to a buckling-restrained brace member, in particular to a combined steel pipe-encased concrete type buckling-restrained brace member. The invention solves the problems that the processing cost of the in-line brace inner core in the existing buckling-restrained brace member is high, the reliable low-cycle fatigue performance cannot be ensured, the cast-in-situ construction and the vibrating construction of mortar or concrete are apt to cause special soft material plates to be displaced and non-binder material plates to be locally damaged, and the production cycle is long.Technical scheme one: the in-line brace inner core and two first backing plates are clamped between two rectangular steel pipes filled with mortar or concrete blocks, each first backing plate is respectively and fixedly connected with outer walls which face to the two rectangular steel pipes and each backing plate is fixedly connected with an external restraining member; and technical scheme two:the in-line brace inner core and third backing plates are clamped between two rectangular steel pipes filled with mortar or concrete blocks, and the third backing plates are connected with pairs of bolt seats through a plurality of bolts. The combined steel pipe-encased concrete type buckling-restrained brace member can be used in the side force resisting component in the field of building structure engineering.

Owner:HARBIN INST OF TECH

Cooling process of czochralski single-crystal method

ActiveCN102978688AQuality assuranceGuaranteed crystallization rateBy pulling from meltThermodynamicsCzochralski method

The invention provides cooling process of a czochralski single-crystal method. During cooling, cooling gas is stopped being introduced in a furnace body, at the same time, a vacuum pump is closed, and therefore sealed space is formed. Gas in the furnace body serves as a medium and transmits more heat to flowing water of a furnace wall, and therefore cooling efficiency is high. On the condition that quality, the crystal rate and the production period of czochralski single-crystal bars are guaranteed, the cooling process enables czochralski method cooling process to be remarkably efficient, greatly lowers use amount of the cooling gas, and therefore lowers production cost of the czochralski method to a large extent.

Owner:新疆仕邦光能科技有限公司

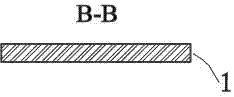

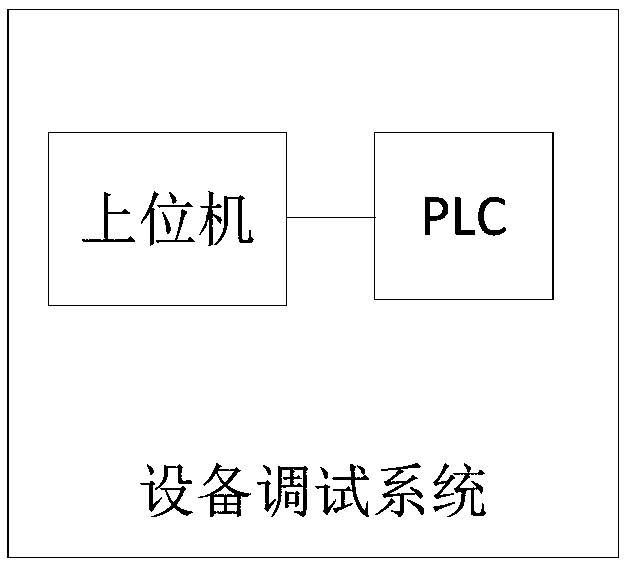

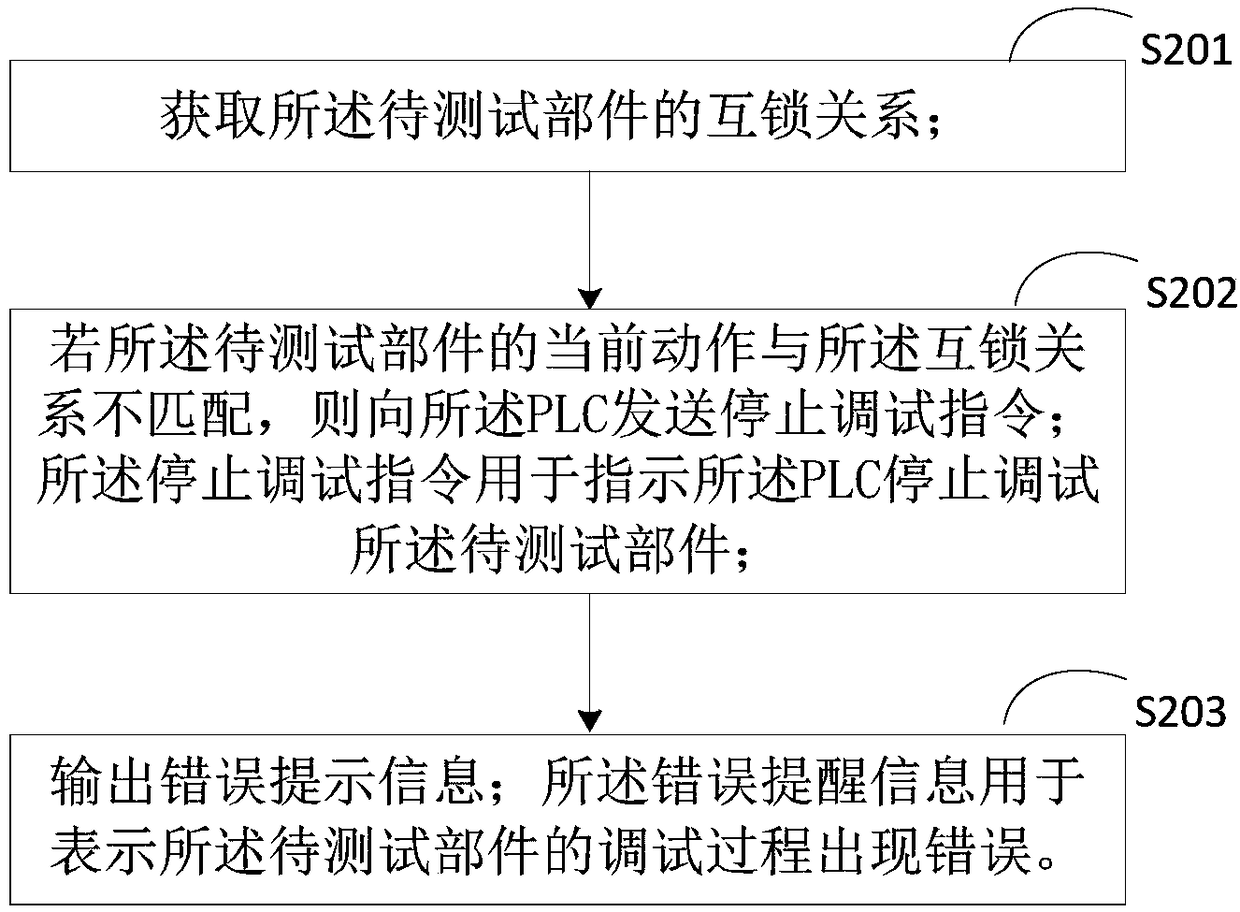

Device debugging method, system and apparatus, computer device and storage medium

InactiveCN109032060ASave time spent on debuggingShorten the development cycleElectric testing/monitoringProgramme control in sequence/logic controllersAnimationComputer engineering

The invention provides a device debugging method, system and apparatus, a computer device and a storage medium. The method comprises the following steps: determining a to-be-tested component of a device through an upper computer, obtaining an identifier of the to-be-tested component, correspondingly determining an interface identifier corresponding to the to-be-tested component, and then sending,by the upper computer, the interface identifier to a PLC that communicates with the upper computer. In this way, a real action effect is simulated by a simulation component of the to-be-tested component of the device in the upper computer, the operation condition of the to-be-tested component under the control of a PLC program is visually reflected through animation, so that the debugging personnel can be effectively helped to complete the debugging task, and the debugging program of the method is more sufficient as a result. The PLC is under the control of the upper computer, only the upper computer and the PLC are adopted, the device can be debugged in advance without connecting the real device the production site, so that the subsequent time occupied by the debugging of the PLC programis greatly shortened, and the research and development cycle of a project is shortened, so that a normal production cycle is ensured.

Owner:BEIJING JUNTAIINNOVATION TECH CO LTD

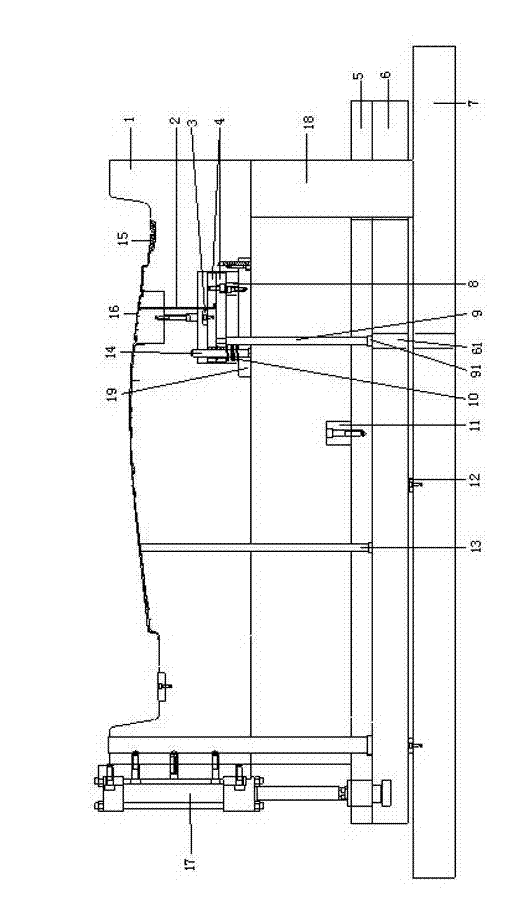

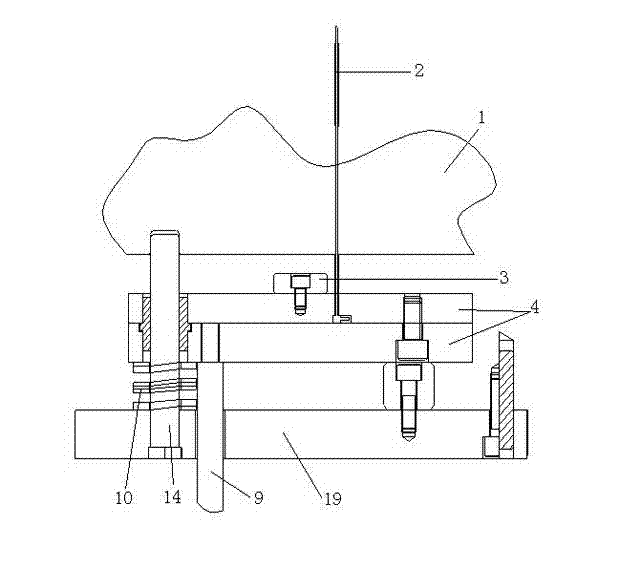

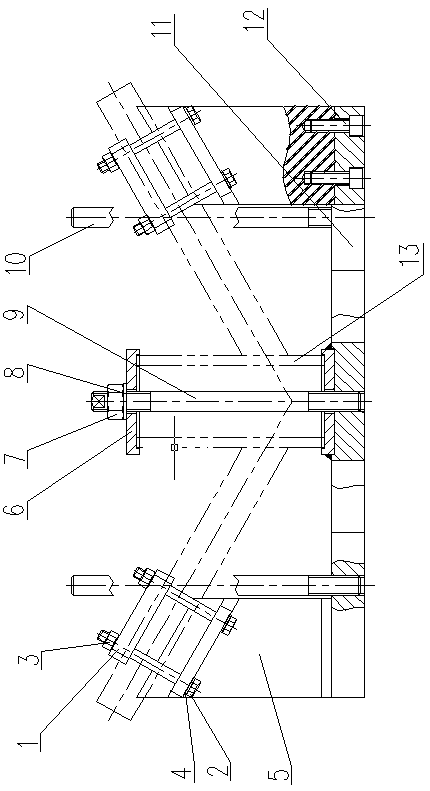

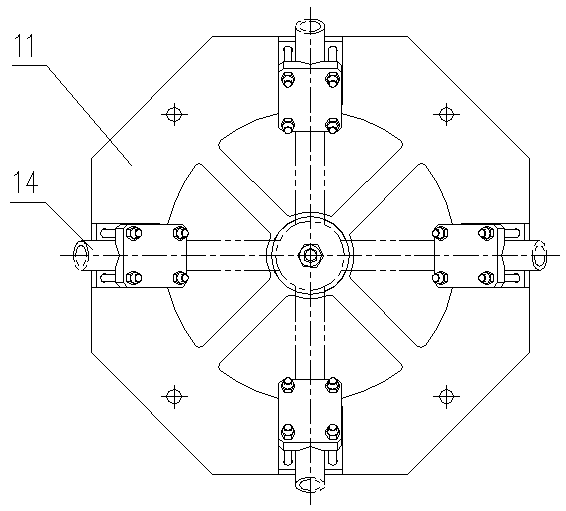

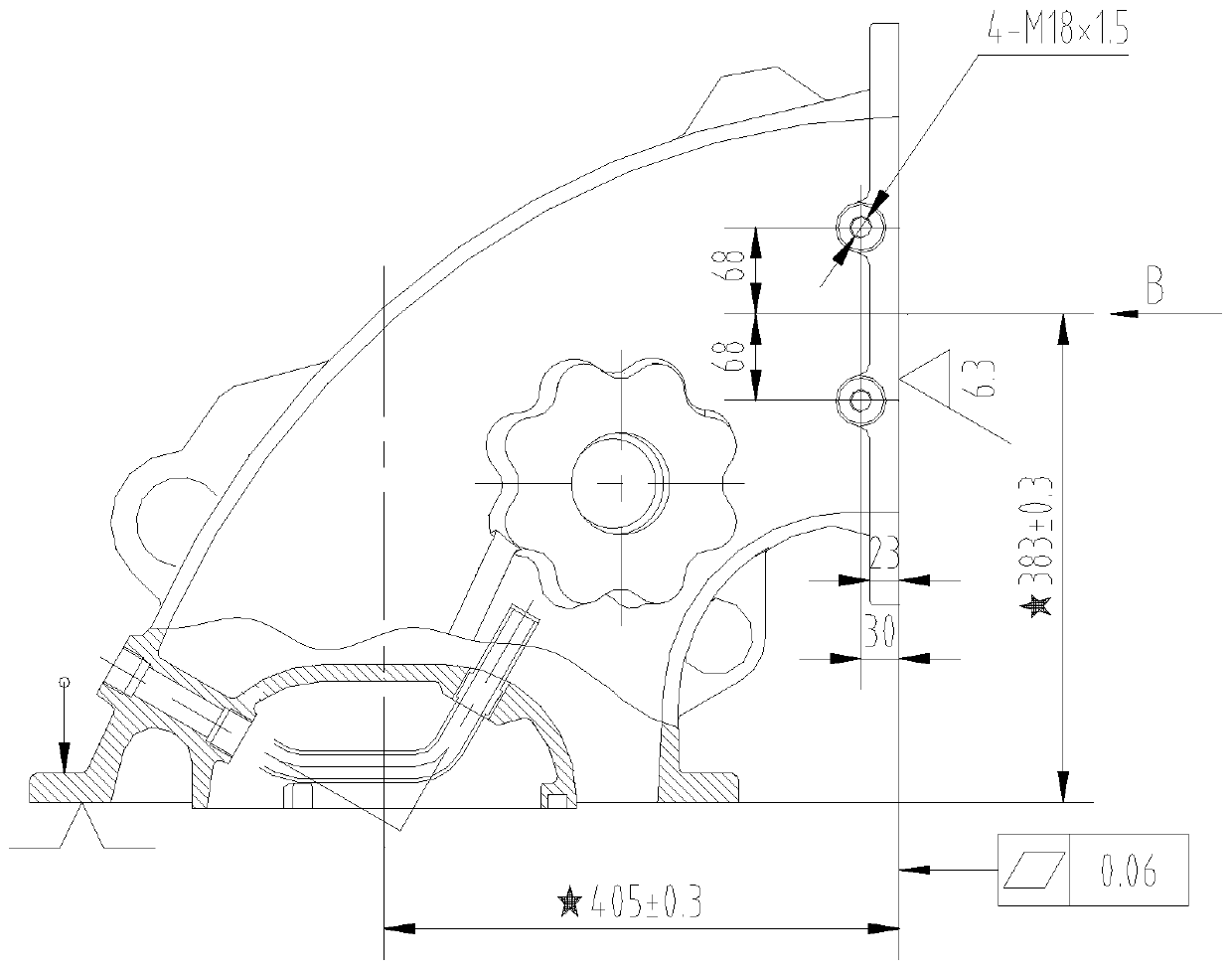

Tree-shaped structure pipe welding anti-deformation device and positioning method thereof

InactiveCN110253205AGuaranteed 60-degree angle welding deformation problemGuaranteed production cycleWelding/cutting auxillary devicesAuxillary welding devicesStructure of the EarthEngineering

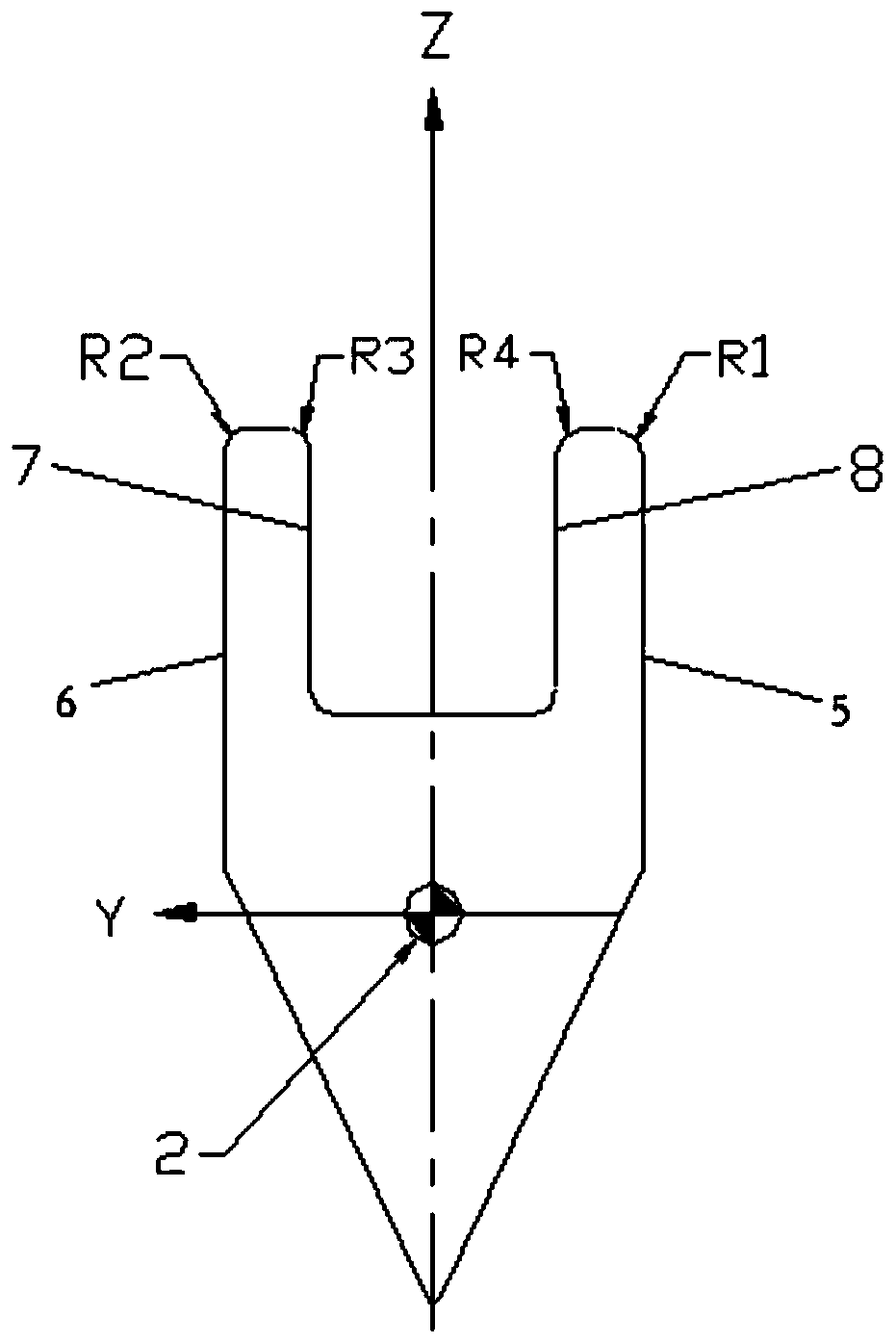

The invention relates to a tree-shaped structure pipe welding anti-deformation device and a positioning method thereof. In a discharging device, when a tree-shaped structure pipe is welded, the deformation problem is difficult to solve, especially when four spraying pipes need to be welded on a barrel body by a 60-degree included angle and the shape, size and tolerance requirements of the spraying pipes can not be controlled if without an auxiliary device. The device comprises two transition plates (6), wherein a cylinder body (13) is arranged between the two transition plates, and the lower transition plate is embedded into a limiting groove of the plane of a bottom plate (11) and is welded and fixed with the bottom plate; a pull rod (9) penetrates through the cylinder body and the upper and lower transition plates, wherein the lower portion of the pull rod is in threaded connection with the bottom plate, and the upper portion of the pull rod is provided with a gasket A (8) and a nut A (7); the plane of the bottom plate is connected with four positioning blocks (5) through bolts, wherein V-shaped grooves above the positioning blocks are attached to the bottoms of spraying pipes (14), and the upper parts of the spraying pipes are connected with the V-shaped grooves below a pressure plate (1). The tree-shaped structure pipe welding anti-deformation device and the positioning method thereof is used for preventing deformation during the welding of a tree-shaped structure pipe.

Owner:HARBIN BOILER

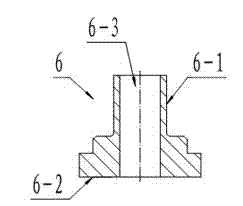

Reassembly method of high precision porous component

ActiveCN103111823AGuaranteed production cycleMeet assembly requirementsWorking environmentDislocation

The invention discloses a reassembly method of a high precision porous component. The high precision porous component is provided with a plurality of high-lock bolt holes, each high-lock bolt hole and an assemble place substrate are operated in an accurate counterpoint mode when the high precision porous component is assembled. The high precision porous component is characterized in that the method includes the following steps: a, dislocation processing of prefabricated holes; b, locating fastening of a novel high precision porous component; c, precision reaming of the prefabricated holes; and d, installation of high-lock bolts. According to the reassembly method of the high precision porous component, the prefabricated holes are required to be only renovated and processed on line, original hole manufacturing work which needs to be done in a narrow space and is difficult to operate is mostly transferred to a working environment which is spacious and easy for operation, the repair cycle is greatly shortened under the premise that assembly requirements are met, and assembly operation difficulty is reduced.

Owner:FACTORY 5721 OF PLA

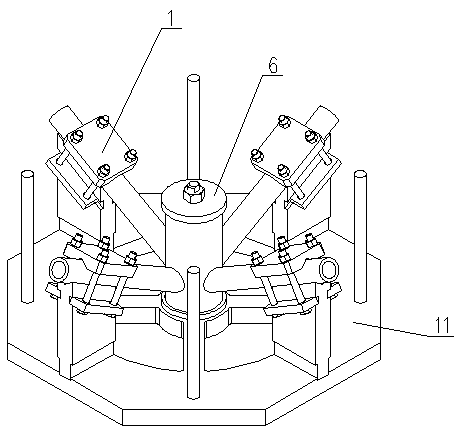

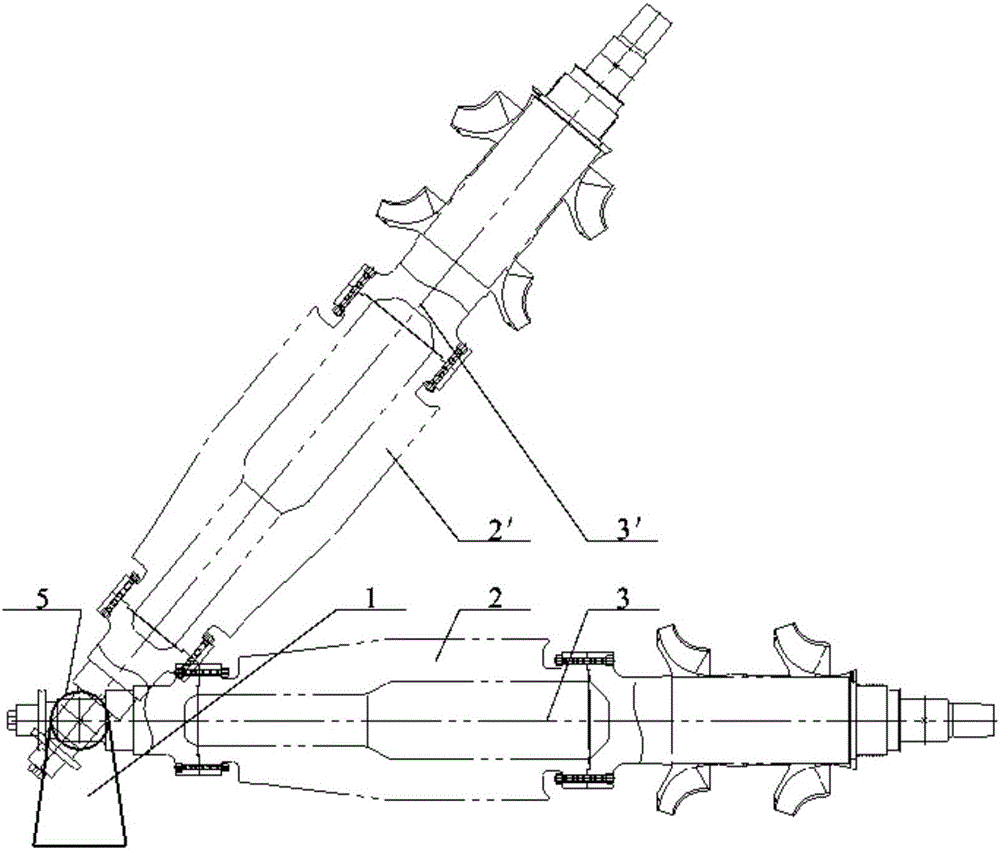

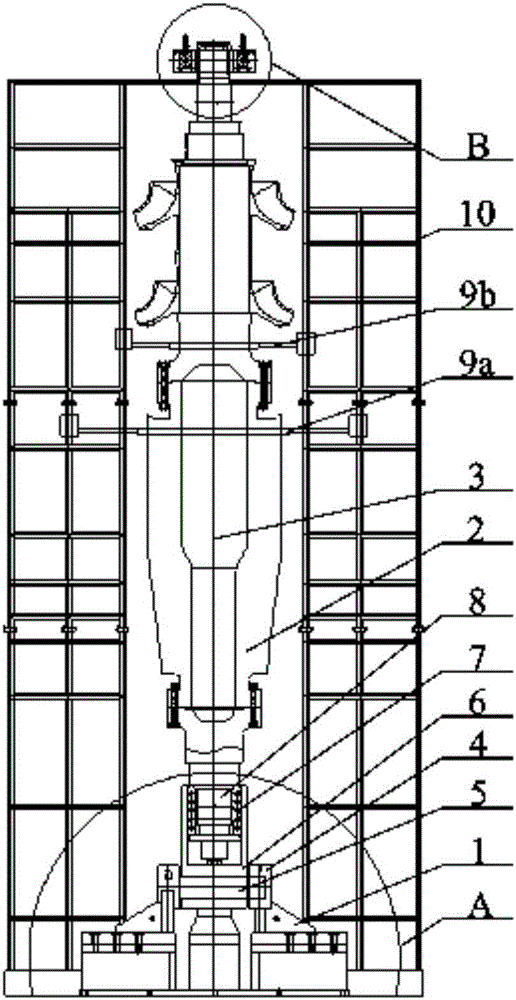

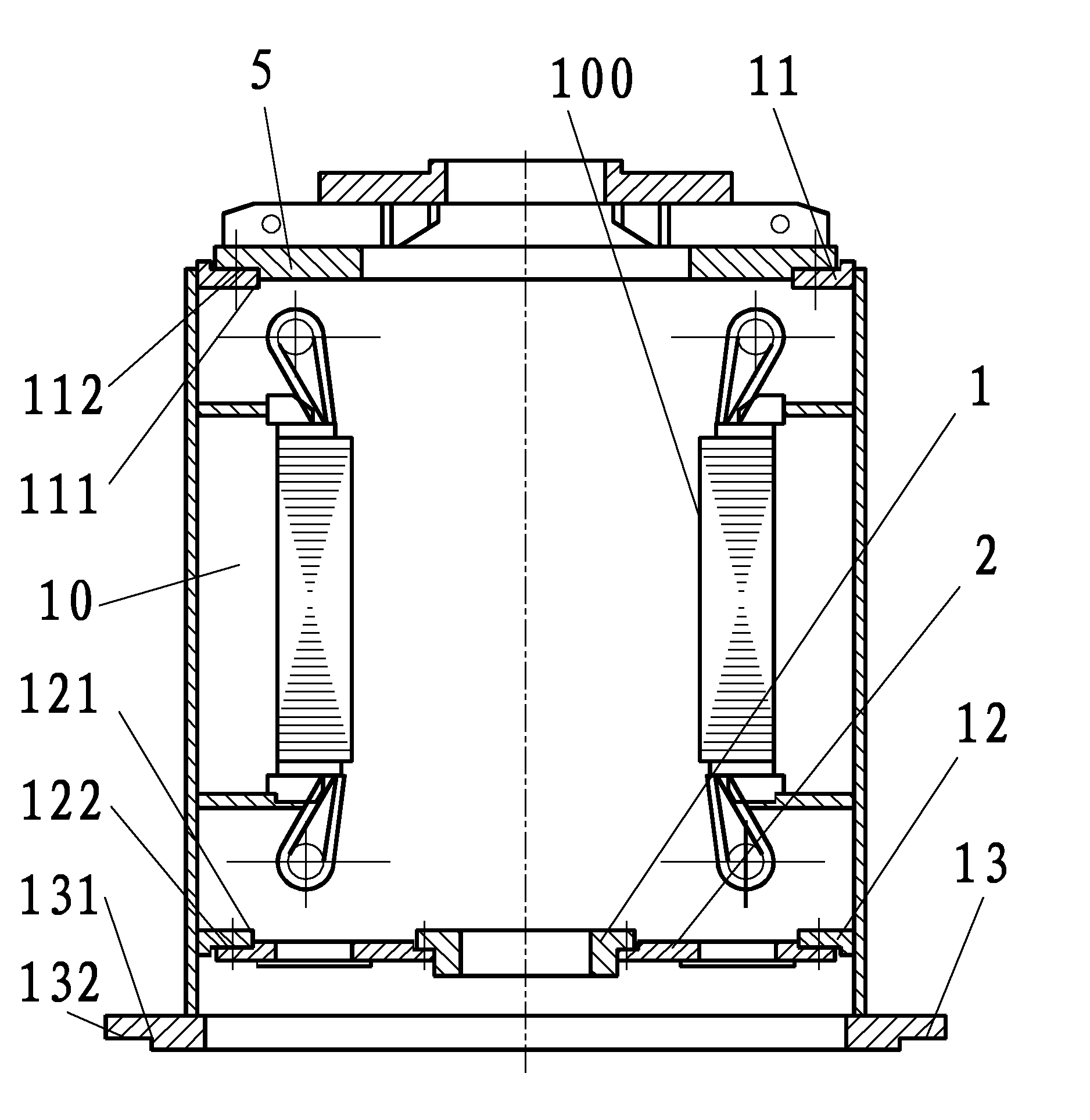

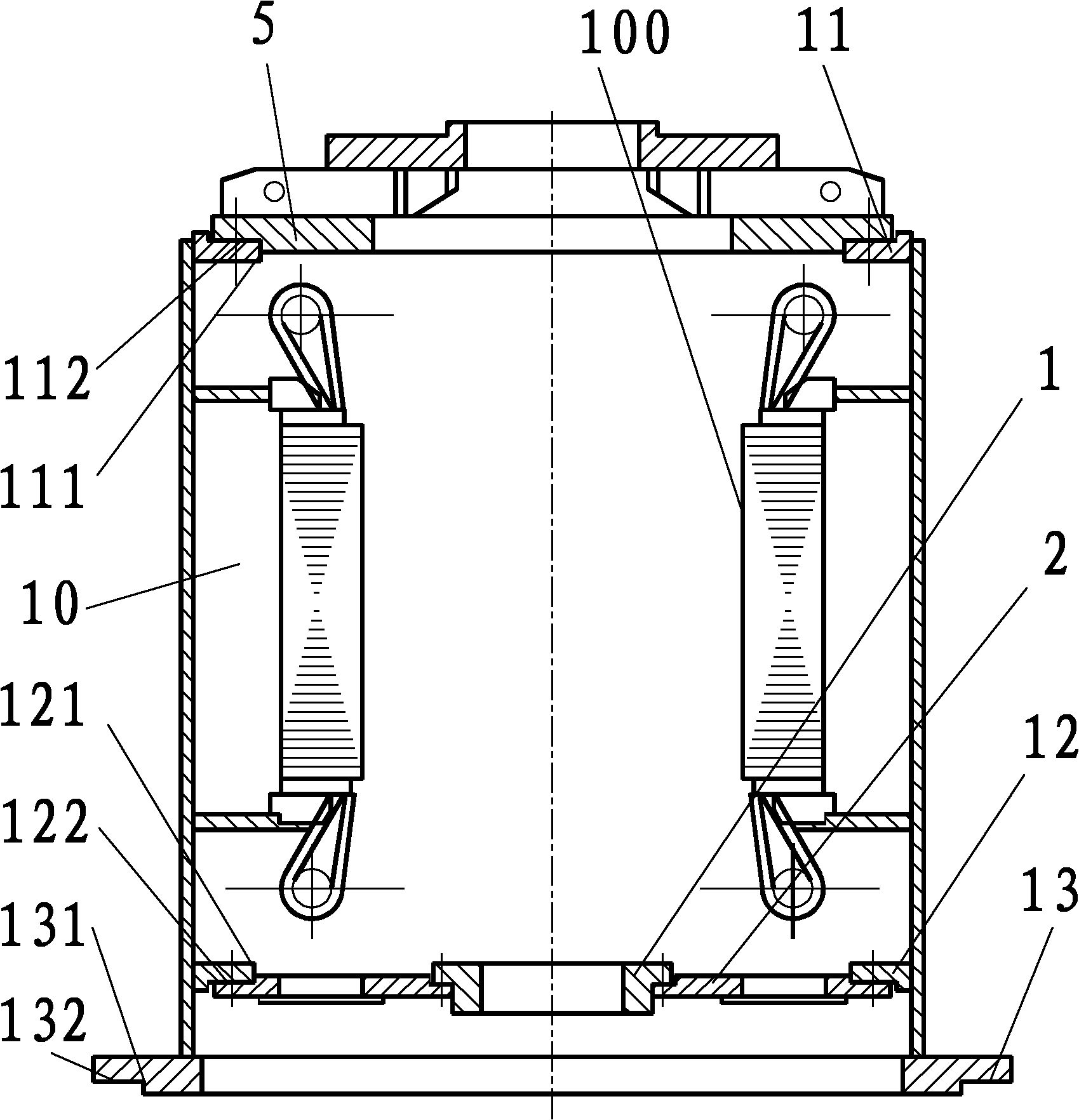

Vertical assembly device for single-side-fixed convolute ultra-large centrifugal compressor impeller

ActiveCN105927593ASolve the problem of vertical assemblyImprove assembly accuracyPump componentsPumpsDynamic balanceEngineering

The invention discloses a vertical assembly device for a single-side-fixed convolute ultra-large centrifugal compressor impeller, and belongs to the technical field of fixation or location for workpieces. The vertical assembly device comprises a stator and a rotary shaft, wherein the rotary shaft is connected to the stator; a main shaft of a rotor of the large centrifugal impeller is capable of rotating by taking the rotary shaft as a rotary centre, so that the main shaft of the rotor of the large centrifugal impeller is capable of gradually changing an included angle of 0 degree between the axis of the main shaft of the rotor and a horizontal plane to an included angle of 90 degrees between the axis of the main shaft of the rotor and the horizontal plane; the main shaft of the rotor of the large centrifugal impeller is kept at a position with the included angle of 90 degrees between the axis of the main shaft of the rotor and the horizontal plane after the rotor and the horizontal plane is in a vertical state; and a second-stage impeller is hoisted and installed in the main shaft after being heated. The main shaft is laid flatly by using a crown block after the impeller is completely cooled. A first-stage impeller is installed after dynamic balance of the rotor, and the assembly process thereof is the same as above. According to the assembly device, the purpose of vertical assembly for the large centrifugal impeller is achieved, the assembly accuracy is improved, and the product production cycle is guaranteed. A feasible scheme is provided for vertical assembly for impellers of large rotor compressors.

Owner:SHENYANG TURBO MASCH CORP

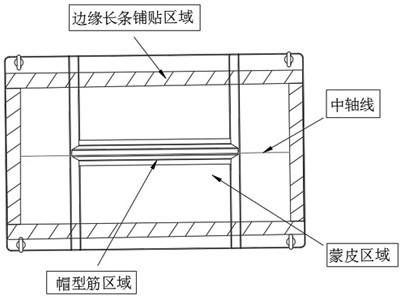

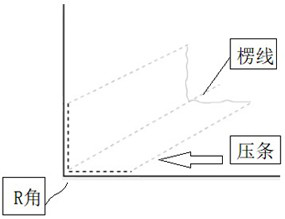

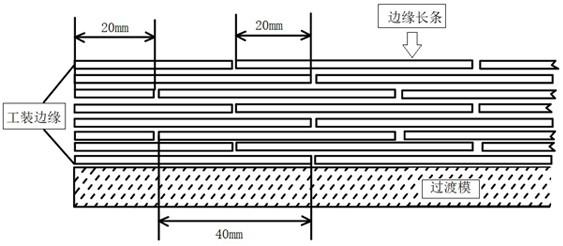

Tool manufacturing method for preventing air leakage of composite material forming tool

ActiveCN112873904AGuarantee internal qualityGuaranteed high temperature airtightnessEngineeringManufacturing engineering

The invention discloses a tool manufacturing method for preventing air leakage of a composite material forming tool. The composite material forming tool is used for forming a composite material part. The composite material forming tool is formed by assembling a composite material paving die and a supporting frame. The composite material paving die is formed by paving and hot-pressing tool prepreg with different thicknesses on the basis of a transition die. In the paving process, pressing strips are paved in the R area and the corner area of the transition die, the tool prepreg is paved in the edge allowance area of the tool in a photo frame mode, and a seam filling long strip is paved in the butt joint area. The photo frame type paving avoids expansion of the edge defect caused by cutting to the interior and cracking during collision or demolding in the carrying process; and the high-temperature air tightness of the tool is further ensured by the pressing strips and the seam filling long strip. The tool manufactured by the method is good in air tightness, the maintenance cost is effectively reduced, the forming quality and the manufacturing period of the composite material part are guaranteed, and good practical and economic values are achieved.

Owner:航天海鹰(镇江)特种材料有限公司

High-power variable frequency motor insulation bearing sleeve

ActiveCN103023190BReduce manufacturing costSimple structureSupports/enclosures/casingsGlass fiberInsulation layer

A high-power variable frequency motor insulation bearing sleeve comprises a motor shaft, a bearing, a bearing inner cap, a bearing outer cap, an oil baffle ring and a baffle ring, wherein an insulation sleeve is arranged out of the bearing. The high-power variable frequency motor insulation bearing sleeve is characterized in that the insulation sleeve comprises an inner insulation spacer arranged between the bearing and the bearing inner cap, an outer insulation spacer arranged between the bearing and the bearing outer cap, a rear end cap arranged out of the bearing, and a gap insulation strip and a glass fiber insulation layer arranged between the rear end cover and a bearing seat. Three insulation strips are respectively arranged on the left side, the right side and the outer circle of the bearing, can effectively cut off a loop of a motor shaft current, and prevent the motor shaft current from forming a current loop through a motor bearing end cap and a motor base to destroy bearing balls, raceway surface roughness and oil film, and furthermore the bearing is protected. In addition, the insulation strips are simple in structure, convenient to manufacture, low in cost, and convenient to replace, and therefore manufacturing cost of a motor is reduced, and production cycles of motor forming products are guaranteed.

Owner:ZHEJIANG JINLONG ELECTRICAL MASCH CO LTD

Method for ensuring coaxiality of bearing and stator core of circulating pump motor

ActiveCN101813102AGuaranteed coaxialityGuaranteed production cyclePump componentsPumpsManufacturing cost reductionElectric machinery

The invention discloses a method for ensuring the coaxiality of a bearing and a stator core of a circulating pump motor, which can greatly improve the production efficiency and reduce the manufacturing cost, and comprises the following steps: respectively fine finishing the whole specifications of a lower bearing bush and a lower end cover; assembling the lower bearing bush into the lower end cover; secondary machining a stator by being placed on a vertical lathe; placing the lower end cover well assembled with the lower bearing bush into a machined lower bearing guard, and simultaneously adjusting the inner circle of the lower bearing bush to meet the technical requirements; correspondingly drilling a plurality of pinholes between the lower bearing guard of the stator and the lower end cover and assembling pins, and simultaneously well marking positioning marks; turning over the stator after being removed from the vertical lathe; placing the stator on the vertical lathe again, and lathing the inner circle and the plane of the upper bearing guard of the stator by taking the inner circle of the lower bearing bush as the adjusting standard; firstly assembling a thrust bearing seat of an upper bearing into the machined upper bearing guard, and then correspondingly lathing the seam allowance and the plane of the thrust bearing seat; and correspondingly drilling a plurality of pinholes between the thrust bearing seat and the upper bearing guard of the stator and assembling pins.

Owner:上海电气集团上海电机厂有限公司

Delayed demolding device for stretching die part

InactiveCN107755510ASolve the problems of narrow application range, high manufacturing cost, and difficult debuggingGuaranteed production cycleShaping toolsEjection devicesManufacturing cost reductionPush pull

The invention provides a delayed demolding device for a stretching die part. The delayed demolding device for the stretching die part comprises an upper die body and a female die body; the female diebody is fixed below the upper die body through a bolt; an upper nitrogen cylinder is fixed above the upper die body; the driving end of the upper nitrogen cylinder is vertically and downwardly connected with an upper material pressing core; a lower edge pressing ring is arranged below the female die body; a lower nitrogen cylinder is arranged below the lower edge pressing ring; a demolding mechanism is arranged above the lower edge pressing ring, and comprises a push-pull cylinder fixed to the lower edge pressing ring; and the output end of the push-pull cylinder is connected with an embeddingblock which is embedded between the upper material pressing core and the lower edge pressing ring through a lower guiding plate and a cover plate fixed to the lower edge pressing ring. The delayed demolding device for the stretching die part has the beneficial effect that the problems that a traditional manner is narrow in application range, high in manufacturing cost, and large in debugging difficulty. The structure is simple, installing and debugging are convenient, cost is low, reliability is high, the production period and quality of the die are effectively guaranteed, and the manufacturing cost is reduced.

Owner:天津星原汽车零部件有限公司

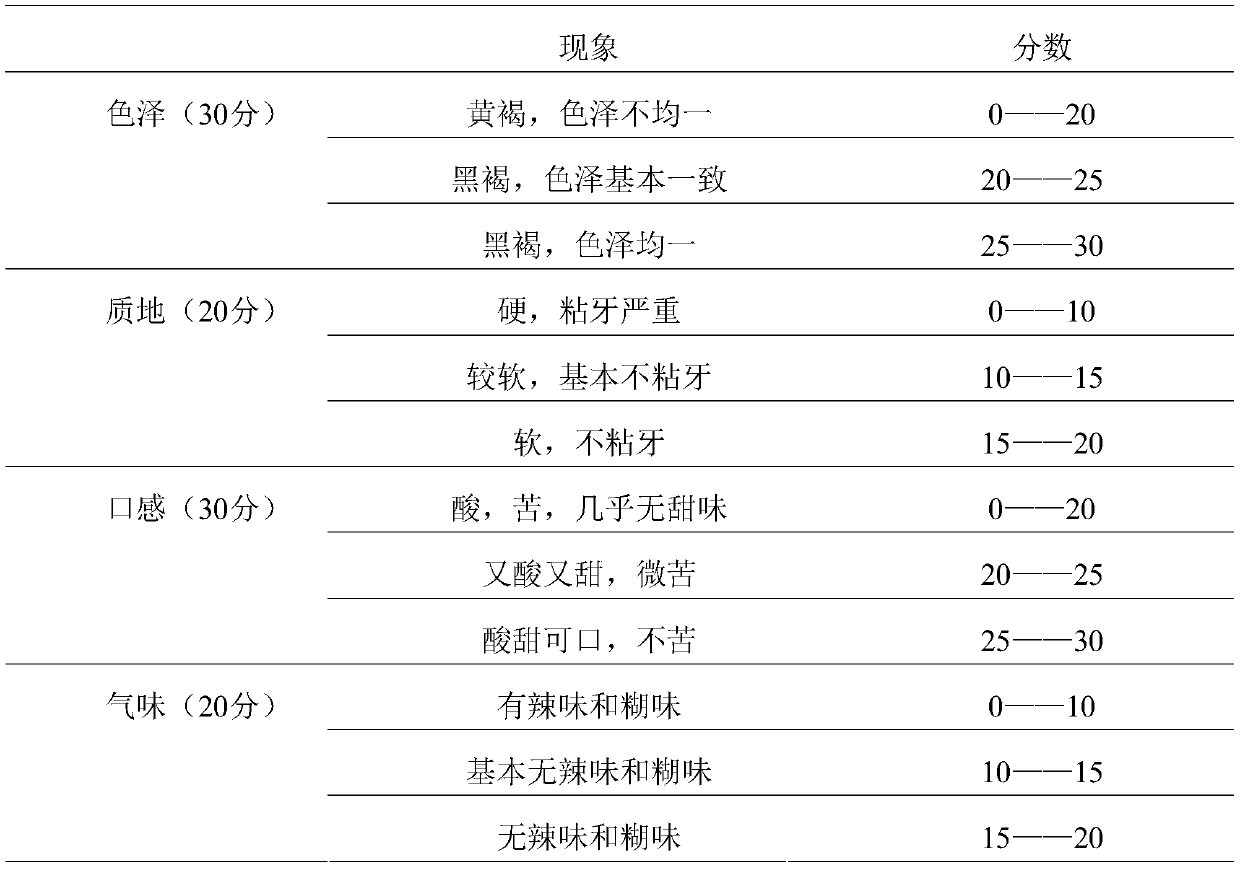

Preparation process of black garlic and preparation method of concentrated juice of black garlic

InactiveCN110074370AShorten the production cycleGuaranteed production cycleFood scienceRotary evaporatorFermentation

The invention belongs to the technical field of food, and particularly relates to a preparation process of black garlic. Specifically, the black garlic is obtained by performing constant-temperature fermentation or variable-temperature fermentation on unpeeled fresh garlic. A preparation method of black garlic concentrated juice comprises the steps of pulverizing the black garlic prepared to obtain mashed black garlic; placing the mashed black garlic into drinking water for extraction by a one-time extraction method to obtain black garlic coarse extraction juice; filtering and centrifuging theblack garlic coarse extraction juice to obtain black garlic extraction juice; concentrating the black garlic extraction juice in a rotary evaporator to obtain black concentrated juice with a solublesolid content of 20 to 50%. The black garlic production cycle is shortened and the production costs are reduced. In order to obtain high-quality black garlic, the conventional black garlic processinggenerally requires 30 to 60 days, although the production process recorded in the literature is shortened, but the quality of the black garlic is reduced, the black garlic processing process of the invention shortens the processing cycle of the black garlic, and also ensures the quality of the black garlic.

Owner:LIAONING UNIVERSITY

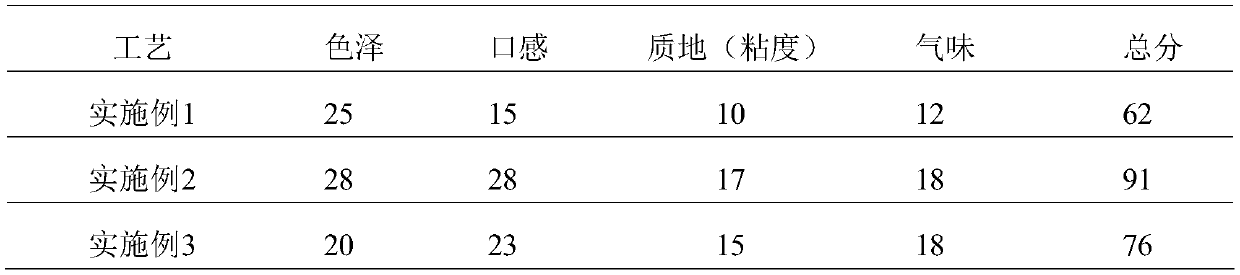

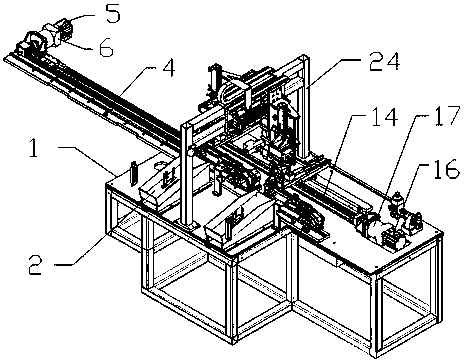

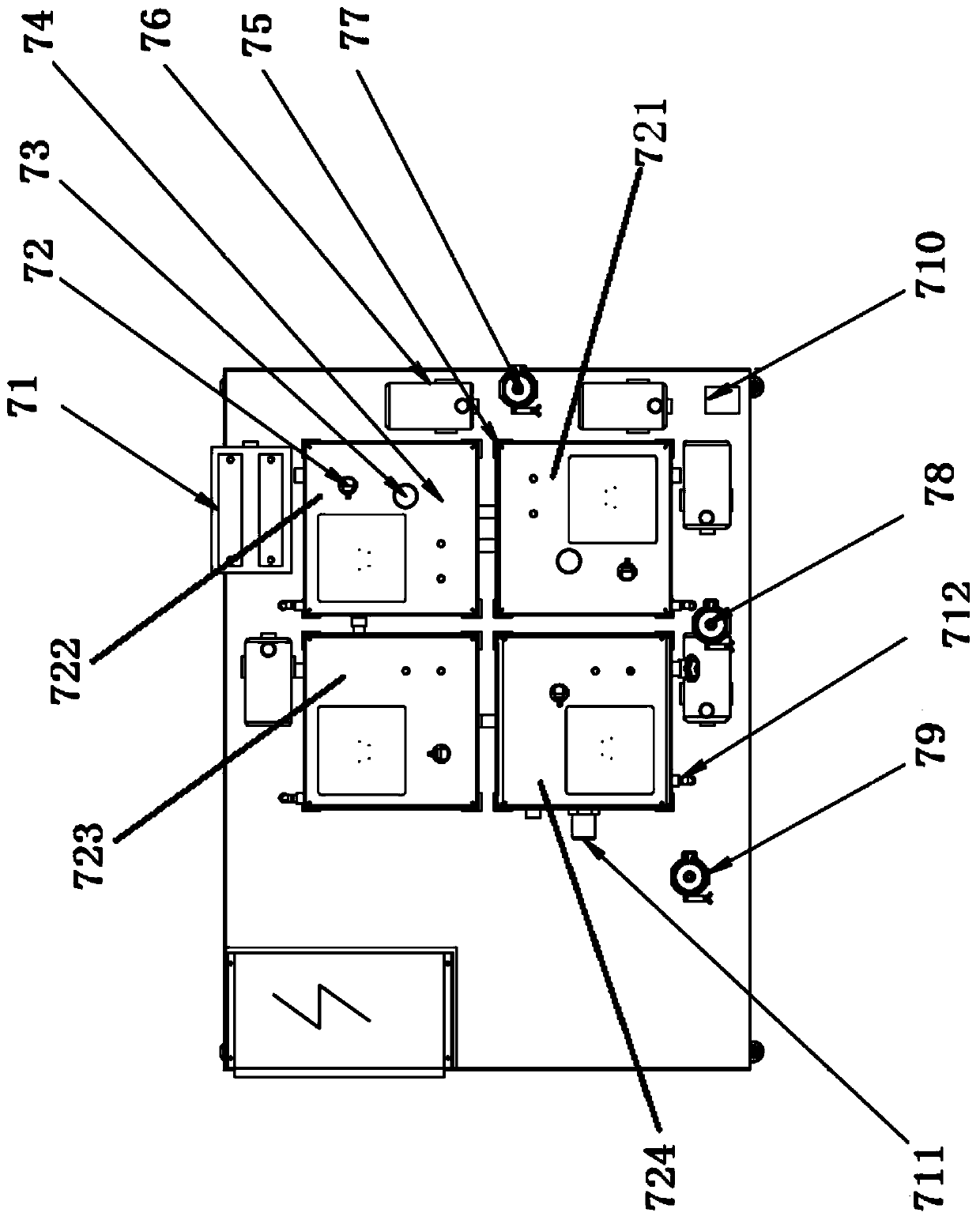

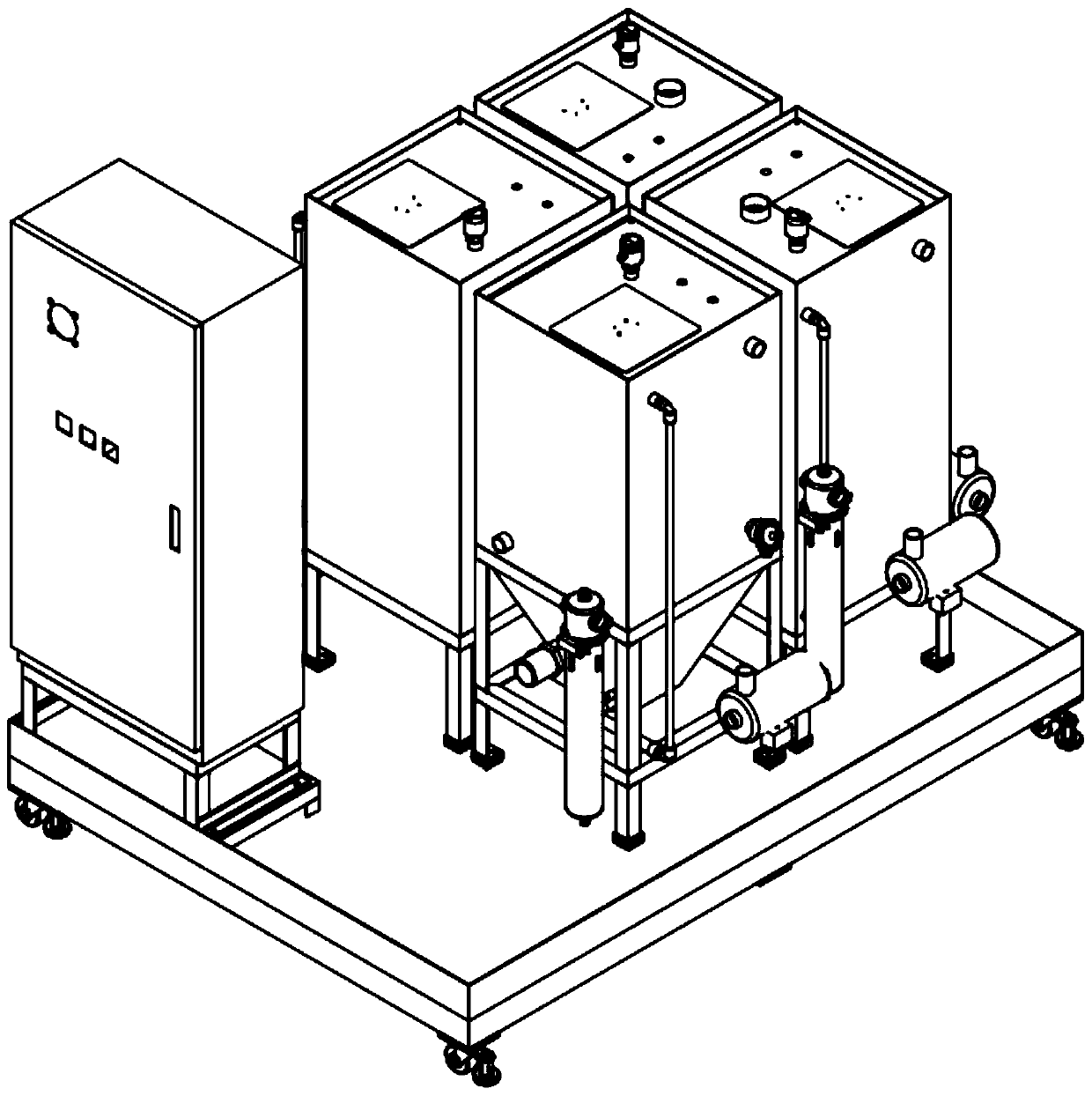

Automatic oiling device for slide rail and its operation method

ActiveCN105396752BSave human resourcesHuman resources improvementLiquid surface applicatorsCoatingsEngineeringTransfer mechanism

The invention discloses an automatic oiling device for slide rails and an operation method thereof, which includes an equipment support, a feeding chute fixedly arranged on the equipment support, and a loading and transferring mechanism for loading slide rail processed parts , an oil injection processing mechanism for injecting oil into the slide rail processed parts, and a blanking and grabbing mechanism for blanking the slide rail processed parts, the loading and loading mechanism, the oil injection processing mechanism and the blanking and grabbing mechanism are all fixed It is arranged on the equipment support; the loading and transferring mechanism cooperates with the oiling processing mechanism to complete the oiling operation on the slide rail processed parts; the unloading grabbing mechanism matches the unloading chute. The invention has the advantages of simple structure, easy assembly, stable and reliable oil injection effect, high degree of automation, high popularization value and wide application range.

Owner:SUZHOU IND PARK GAGB MANDE CO LTD

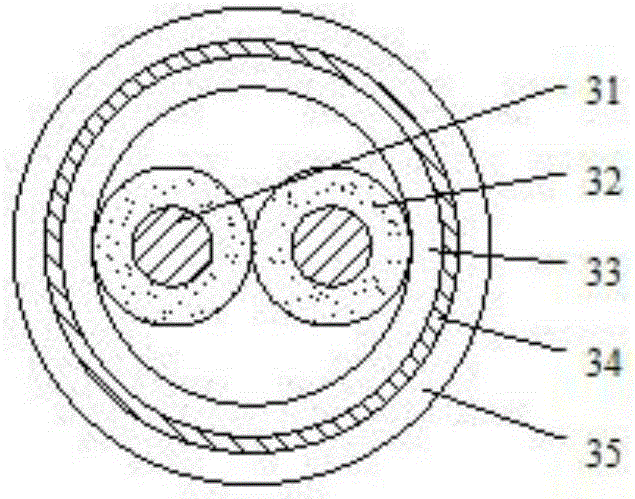

Low-voltage power cable capable of temperature self-testing and fabrication method thereof

ActiveCN105225755AImprove performanceAvoid failureThermometers using electric/magnetic elementsPower cables with screens/conductive layersPolyesterPower cable

A low-voltage power cable capable of temperature self-testing comprises a plurality of insulation wire cores arranged in an outer sheath, wherein each insulation wire core comprises a conductor and a wire core insulation sleeve wrapping the conductor, a temperature detection module is arranged in the outer sheath and comprises a temperature detection line, a polyester lining layer, a shielding layer and a plastic wrapping belt are sequentially arranged outside the temperature detection line, the temperature detection line is formed by pair twisting of two copper cores provided with copper core insulation sleeves, and the temperature detection module is arranged outside the wire core insulation sleeve, and is consistent to the wire core insulation sleeve in a length direction. The invention also provides a corresponding fabrication method of the low-voltage power cable capable of temperature self-testing. By the low-voltage power cable capable of temperature self-testing, the temperature self-testing ability of the cable can be improved, and the cable is prevented from excessively heating to cause a circuit fault.

Owner:SHAANXI WANTONG WIRE & CABLE CO LTD

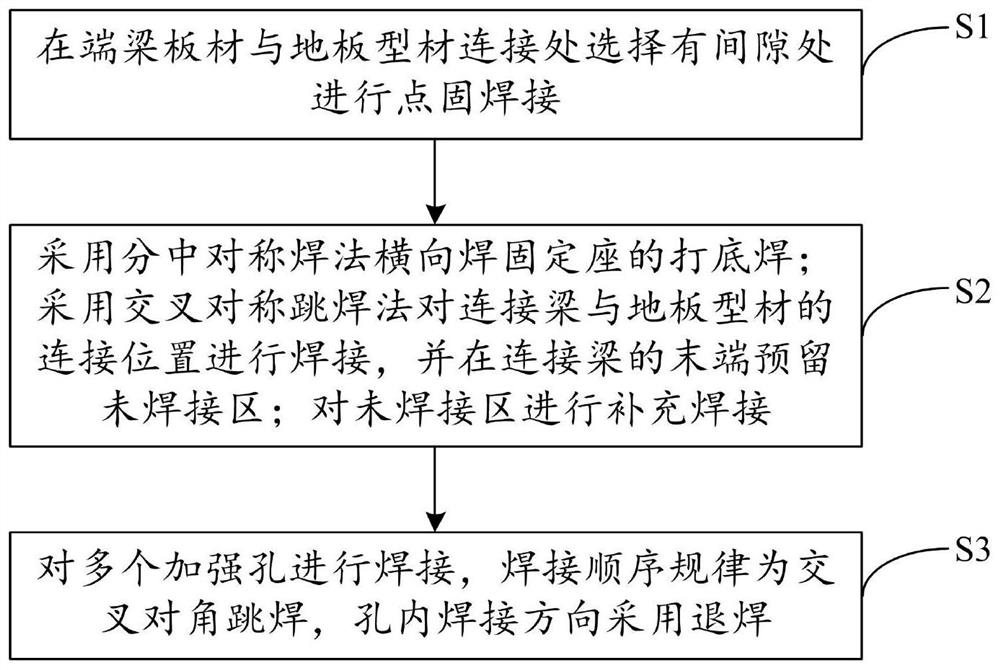

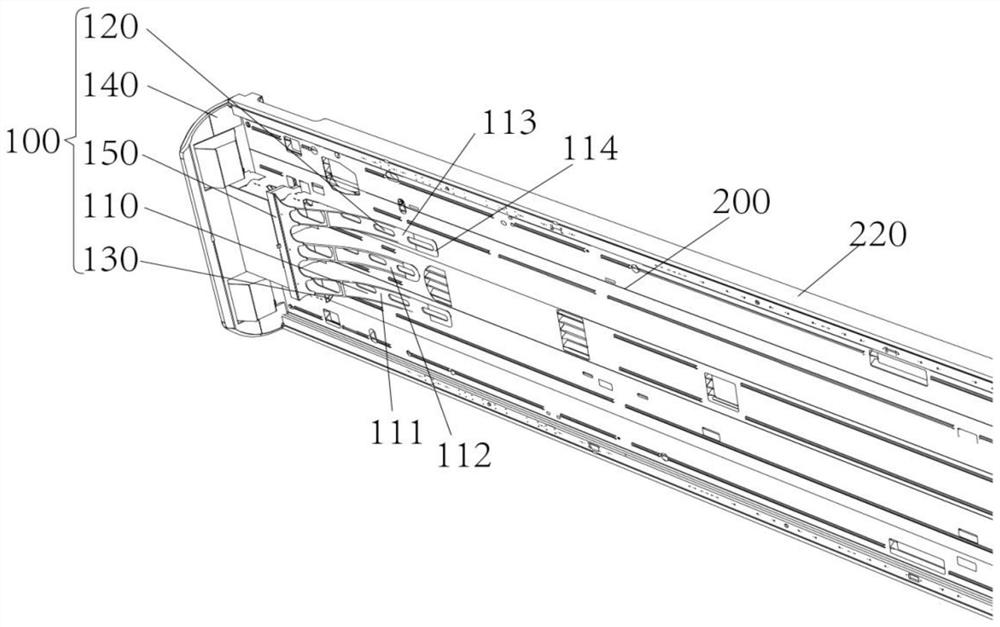

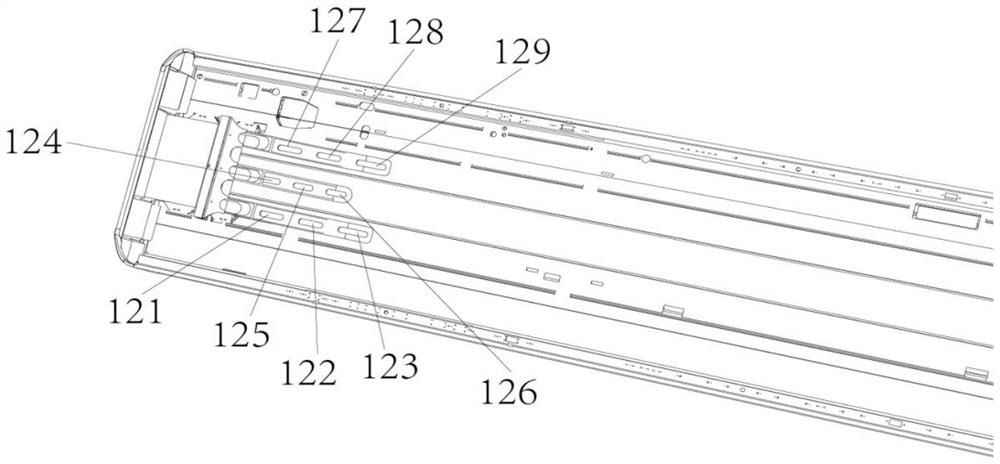

A control welding method for the shape and position deformation of the underframe floor of the EMU

ActiveCN112171095BShape deformation controlMake sure it is flat and not deformedWelding apparatusClassical mechanicsStructural engineering

The invention relates to a welding method for shape and position deformation control of the underframe floor of an EMU, comprising the following steps: selecting a place with a gap between the end beam plate and the floor profile to perform spot welding, and the end beam plate includes a fixing seat and several connecting beams , each connecting beam is provided with a plurality of reinforcement holes; the bottom welding of the fixed seat is welded horizontally by the split symmetrical welding method, and the connecting position of the connecting beam and the floor profile is welded by the cross symmetrical jump welding method, and the connecting beam is welded on the connecting beam. Reserve the unwelded area at the end of the hole, and then perform supplementary welding on the unwelded area; weld multiple reinforced holes, the welding sequence is cross-diagonal jump welding, and the welding direction in the hole is reversed. The invention improves product quality, ensures that the floor of the underframe of the EMU is flat and not deformed after welding; improves production efficiency, prevents size adjustment after welding, and effectively guarantees the production cycle; reduces labor intensity, and prevents repeated cutting after welding , so that the entire welding procedure becomes simplified and easy to operate.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

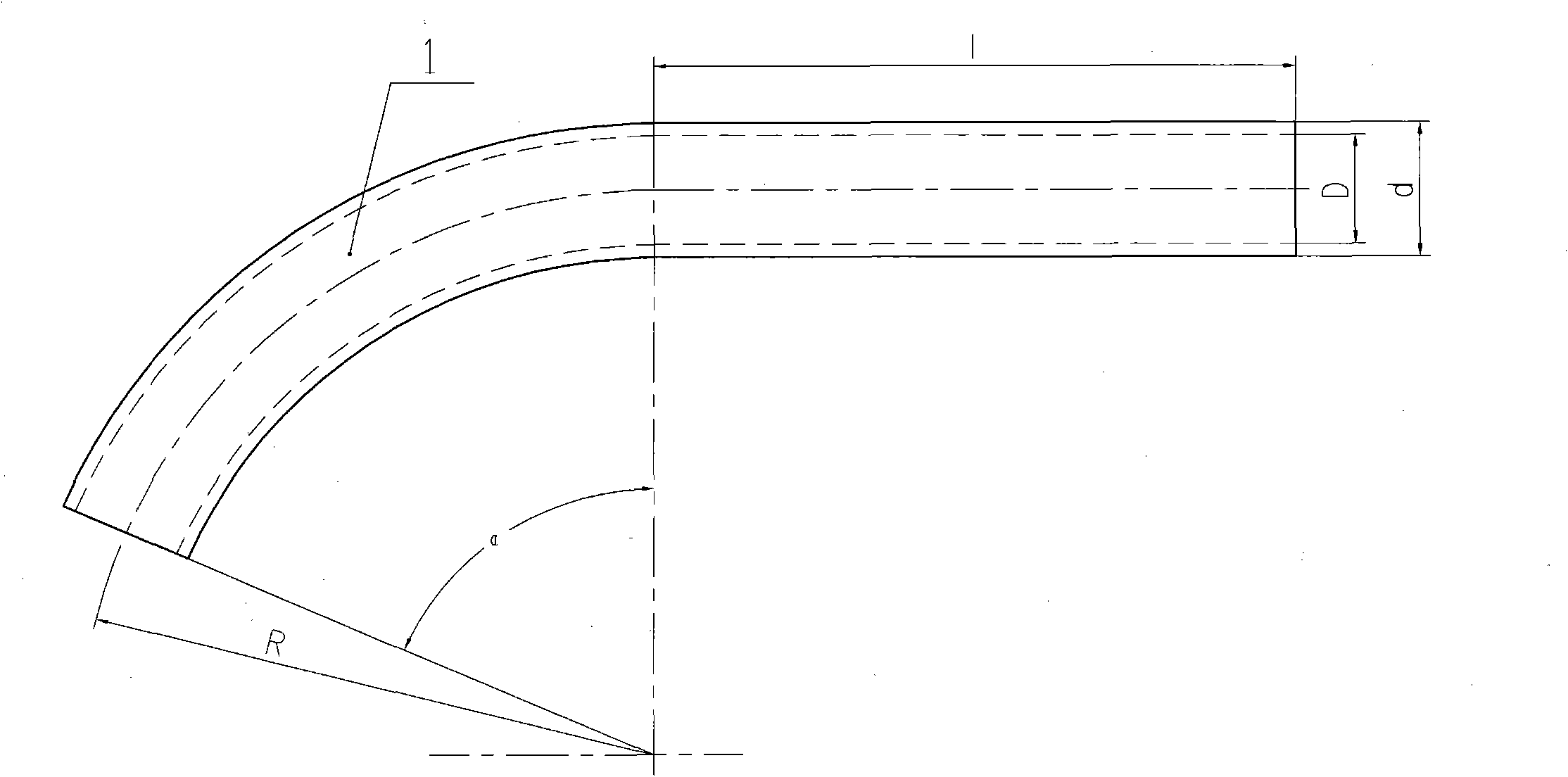

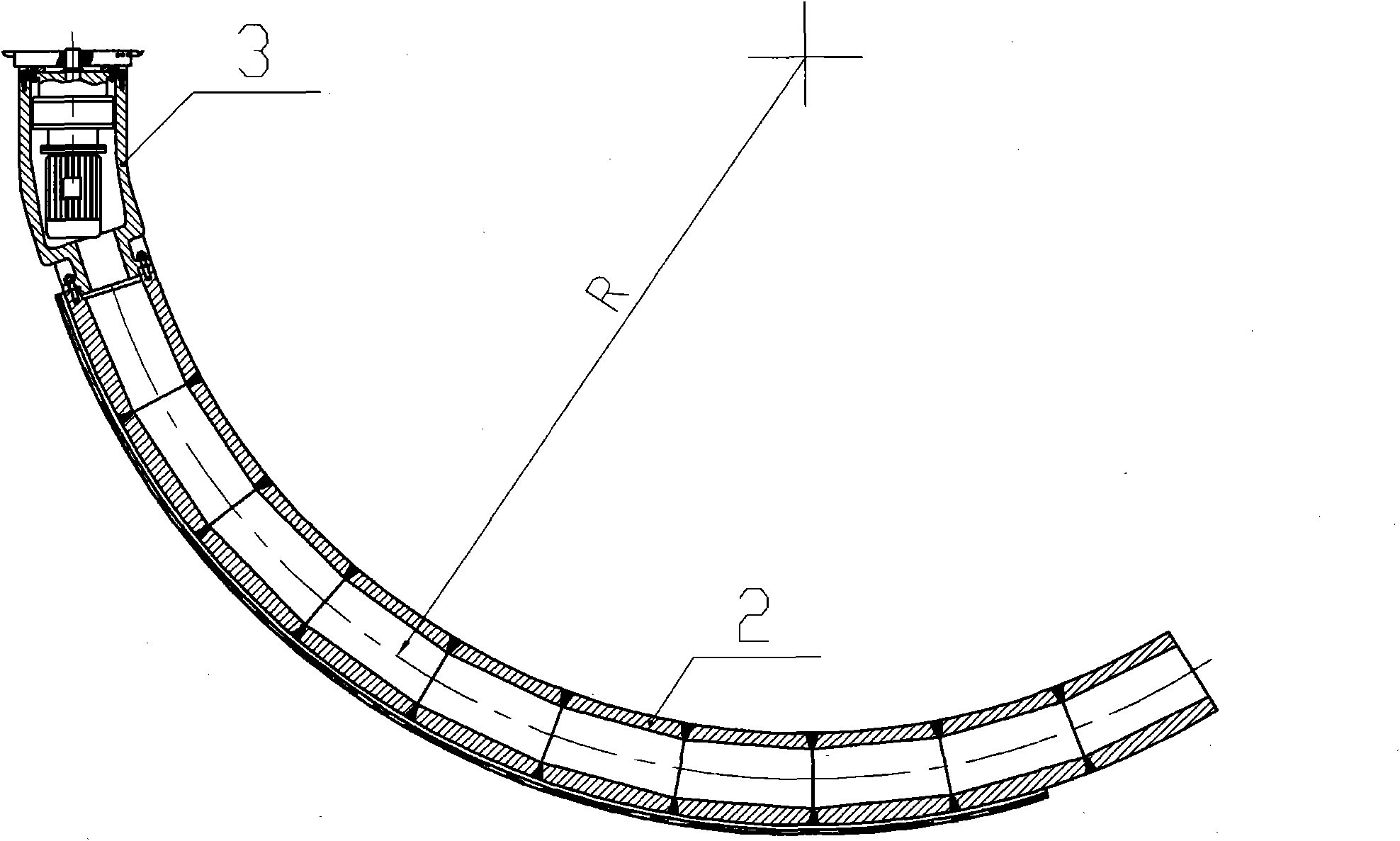

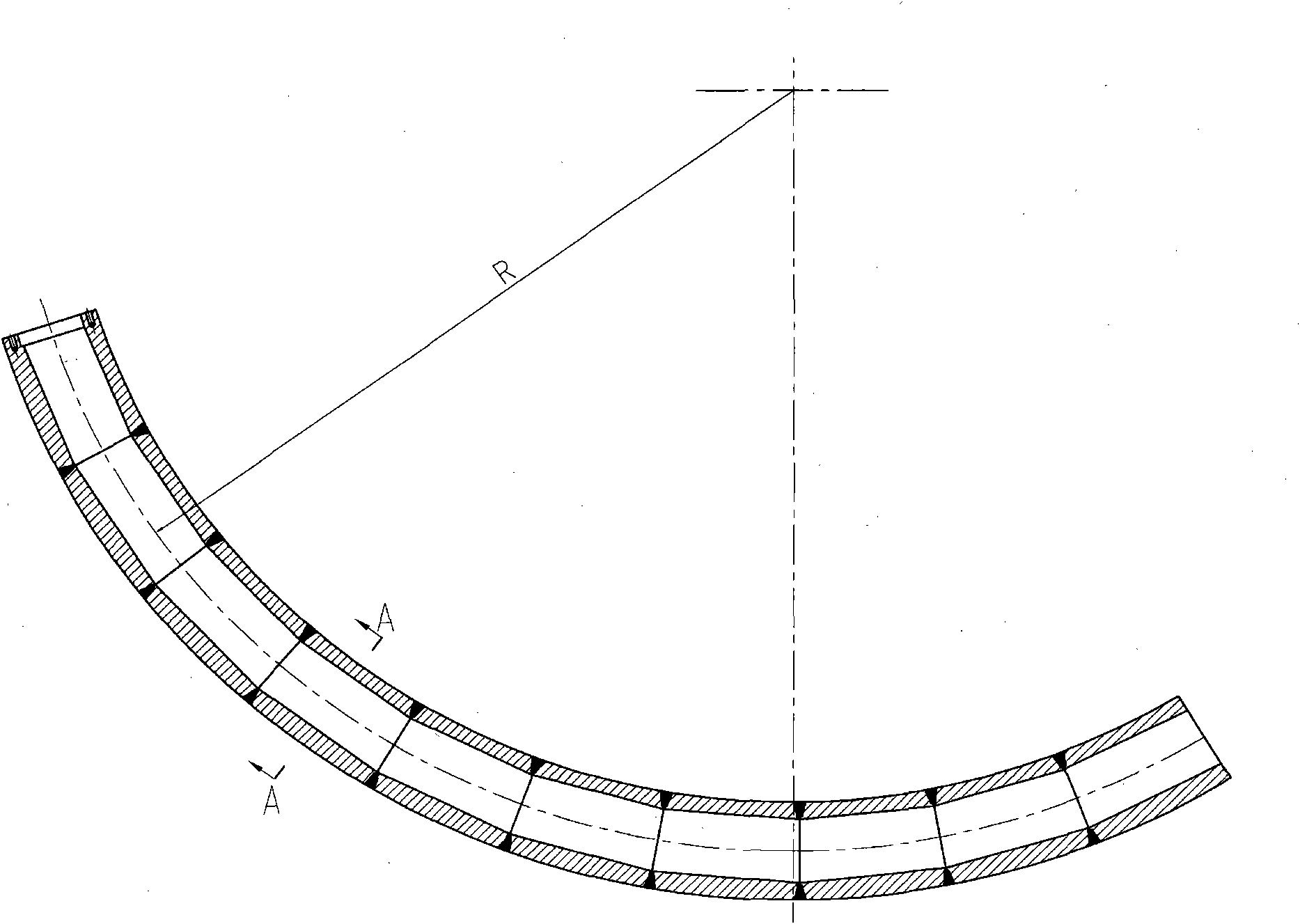

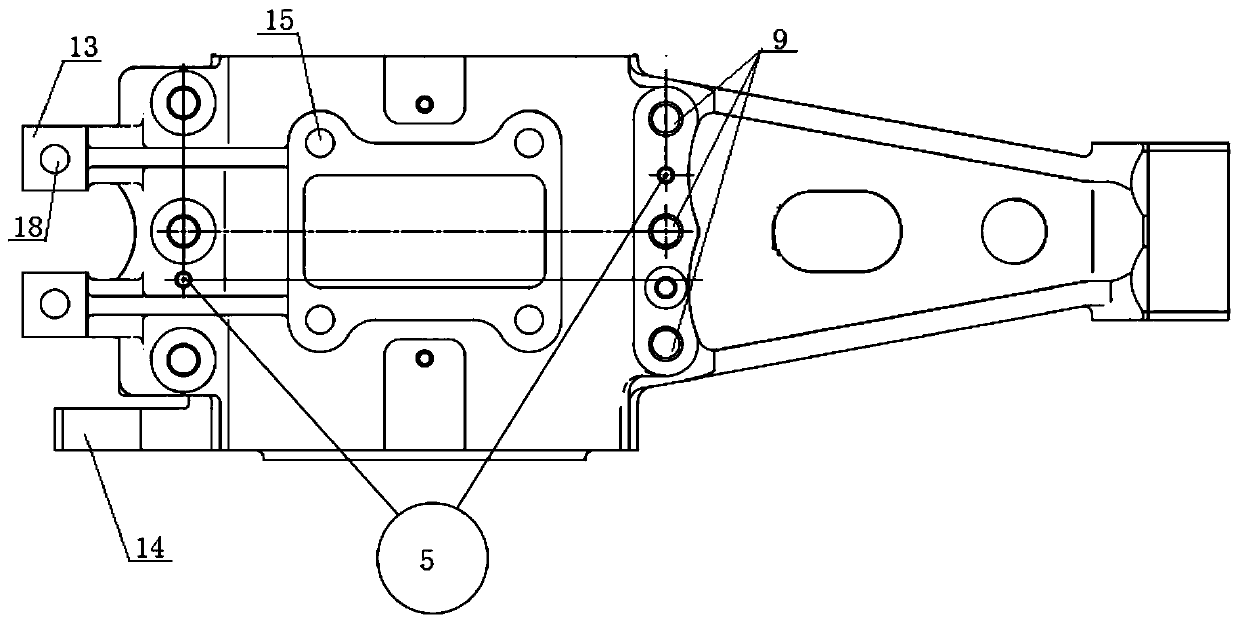

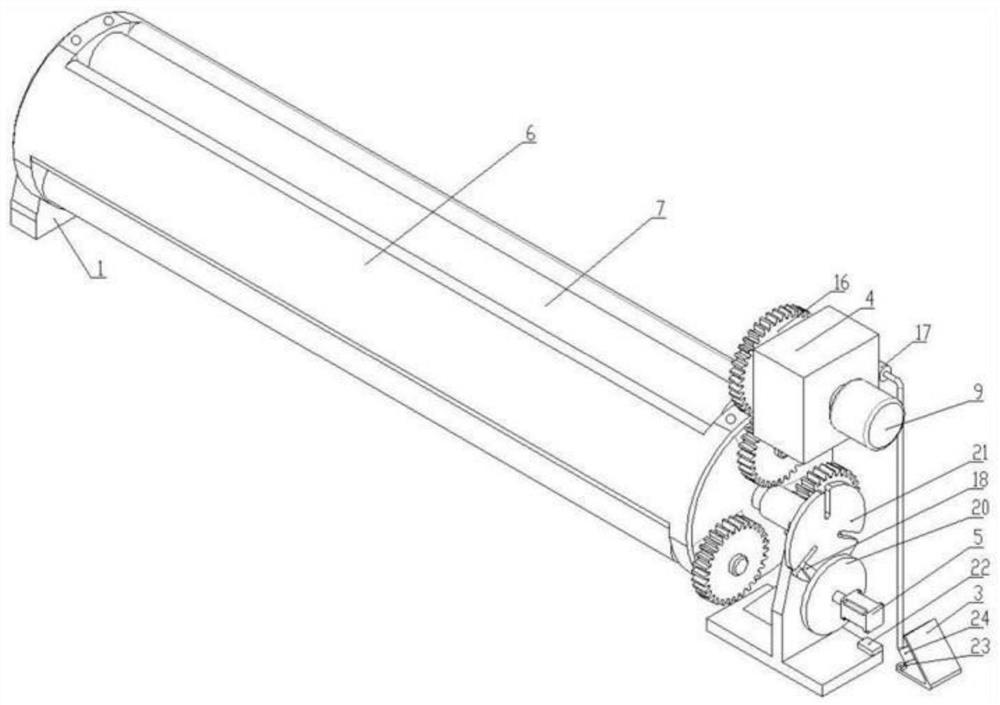

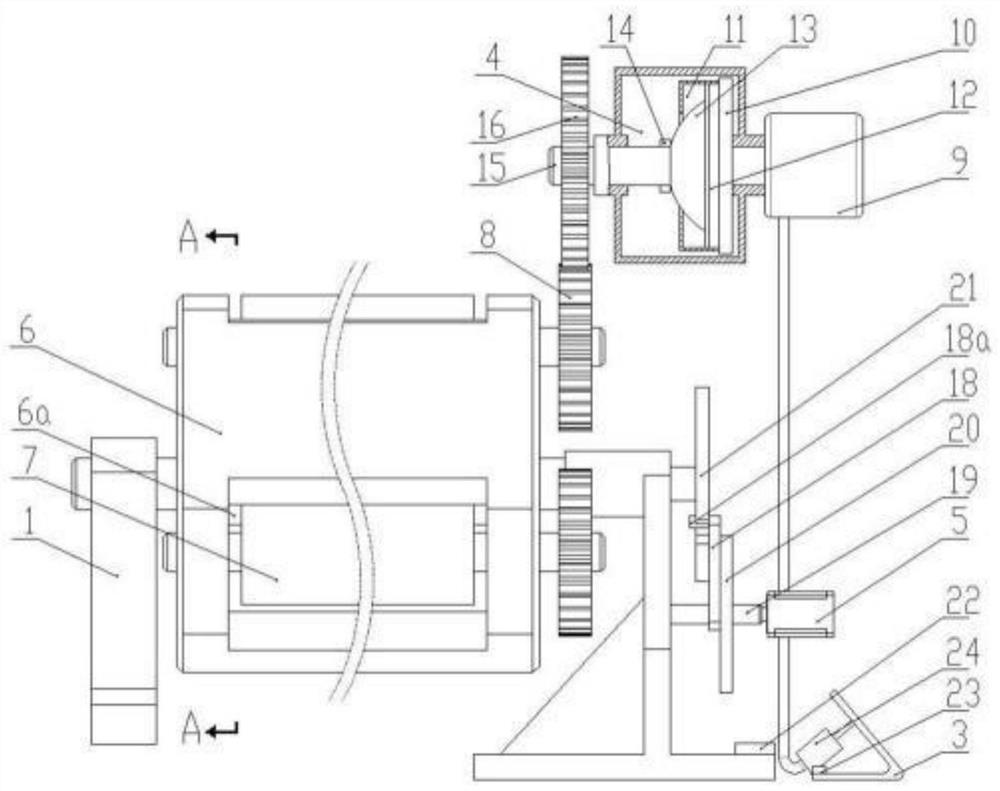

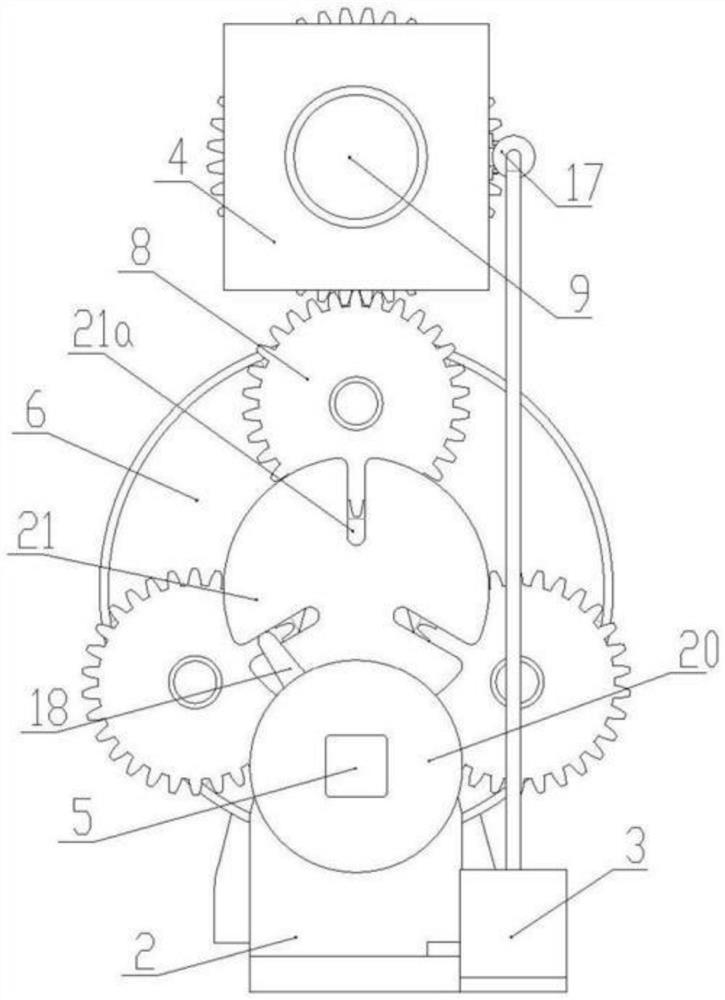

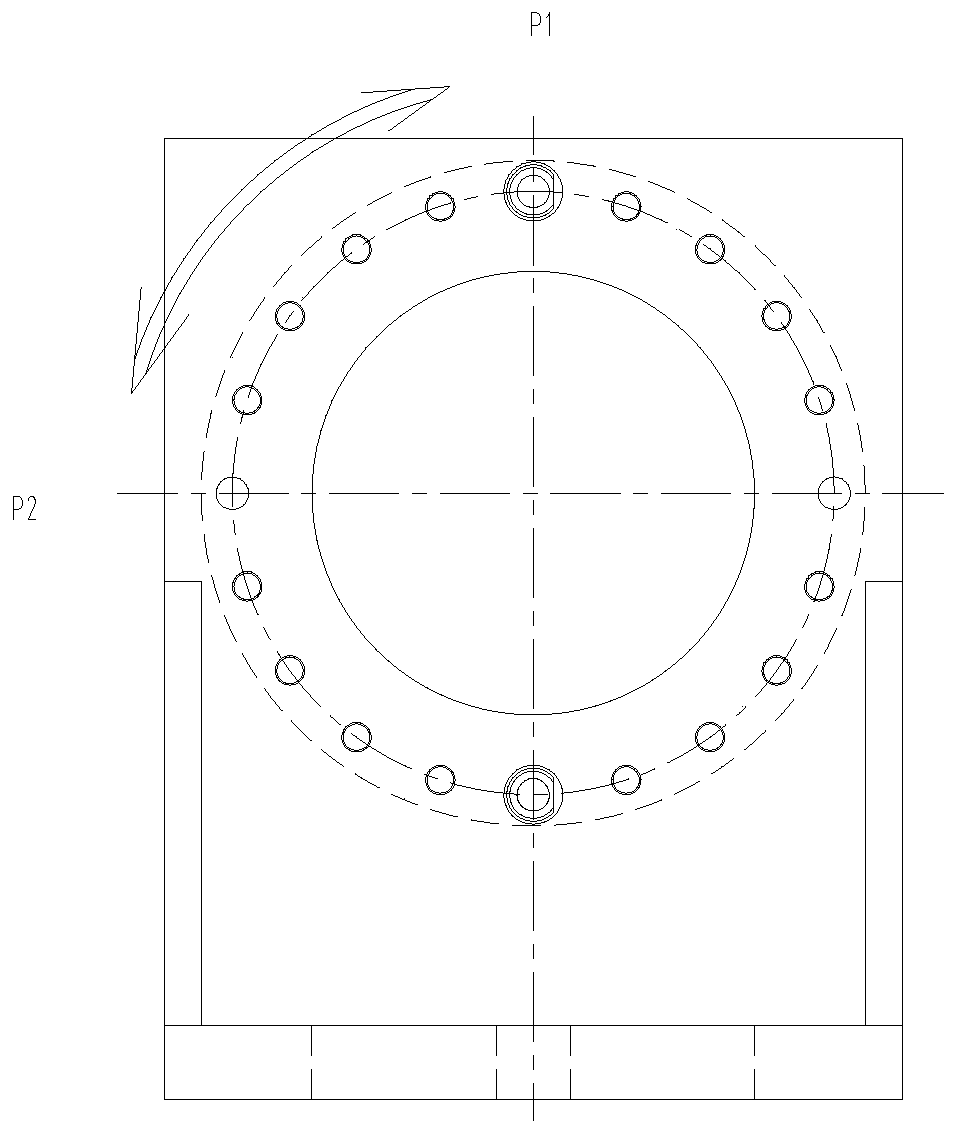

Device and method for machining inner hole of bent pipe of nuclear power main pipeline

InactiveCN102266960BRealize the main cutting movementSolve processing problemsBoring barsBoring/drilling componentsNuclear powerEngineering

The invention discloses a device for machining an inner hole of a bent pipe of a nuclear power main pipeline. The device comprises a cambered boring rod, a cutter rotating power source, a large gear ring strip and a small gear, wherein the cutter rotating power source is connected with a flange port formed at one end of the cambered boring rod; the large gear ring strip is fixedly arranged on theouter side of the cambered boring rod; the small gear is engaged with the large gear ring strip so as to drive feeding of the boring rod; and the radius of the central axis of the cambered boring rodis equal to the radius of the central axis of the inner hole of the bent pipe of the main pipeline. During machining, the cambered boring rod and the bent pipe of the main pipeline are positioned on the same horizontal plane, and moving centers of the cambered boring rod and the bent pipe are positioned on the same circle center, so that the cambered boring rod and the bent pipe can move along the same trace to realize main cutting motion similar to the trace; therefore, the desired inner hole of the bent pipe of the main pipeline can be machined. The invention also discloses a method for machining the inner hole of the bent pipe of the nuclear power main pipeline.

Owner:SHANGHAI HEAVY MACHINERY PLANT

A Micro-deformation Control Technology of Split Type Axle Box

ActiveCN107900608BAvoid micro deformationMicro-deformation prevention and controlSand blastingSingle element

The invention relates to a micro-deformation control process for a split axle box body. The micro-deformation control process specifically comprises the following steps: carrying out blank casting onan upper box body and a lower box body separately; carrying out rough machining on single elements; carrying out heat treatment on the single elements; carrying out finish machining on the single elements; carrying out box combination, machining a bearing hole, a node hole and the two end surfaces of the axle box body and a node, machining a labyrinth groove in the inner surface of the bearing hole as well as a shock absorber seat, a cowcatcher installation seat, a top surface, a bottom surface and a cylinder which surround the axle box body by taking the machined bearing hole, node hole and end surfaces as location reference; carrying out semi-finish milling and boring for the bearing hole; carrying out box splitting, and then placing the box bodies under a room-temperature condition andcarrying out aging treatment separately; carrying out fine trimming on a box splitting surface; carrying out box combination and carrying out semi-finish milling and boring for the bearing hole; carrying out box splitting, and then carrying out polishing; and carrying out box combination again, detecting the axle box body subjected to the box combination, and then carrying out sand blasting and painting. According to the micro-deformation control process disclosed by the invention, the micro-deformation of the axle box body is prevented and controlled simultaneously in many aspects through reasonable optimization for a process flow and optimization for process parameters, so that the product pass percent is increased, the production period is ensured, and the production cost is lowered.

Owner:CRRC QINGDAO SIFANG CO LTD

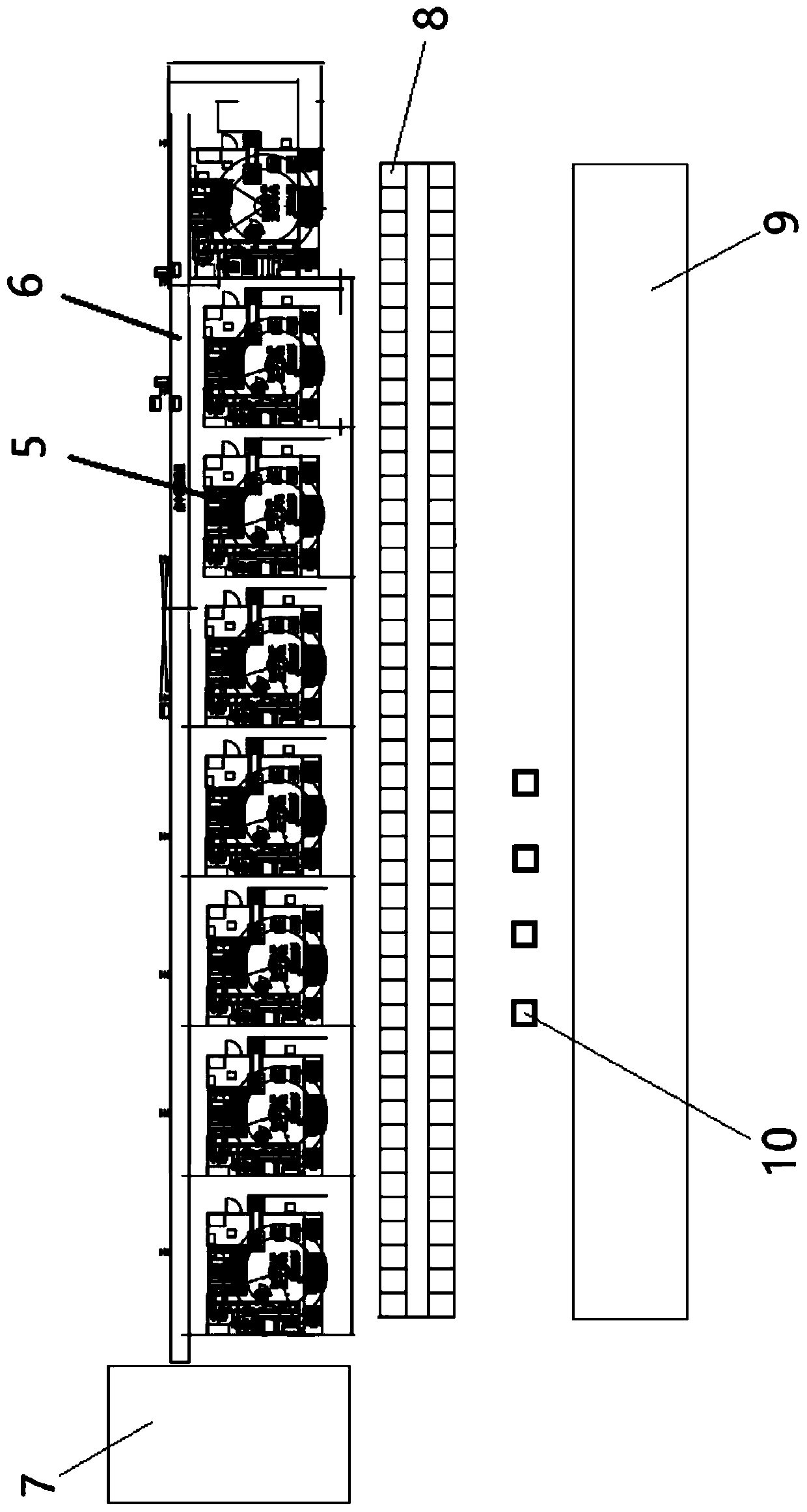

Motor rotor machining center

ActiveCN110932495AGuaranteed production cycleHigh degree of intelligenceManufacturing stator/rotor bodiesControl systemElectric machinery

The invention discloses a motor rotor machining center, which is characterized in that a plurality of rotor machining units are used for machining motor rotors of different models; a plurality of rotor storage racks are used for placing rotors to be machined in a transition manner, and an intelligent three-dimensional warehouse orderly and controllably places finished products, semi-finished products and turnover racks of various specifications in the intelligent three-dimensional warehouse through a control system and safely and orderly enters and exits the intelligent three-dimensional warehouse; and the control system controls the rotor storage racks of different types to be conveyed to the corresponding rotor machining units through the AGVs to complete the machining procedures of turning, milling, polishing, drying, paint rolling and the like. And meanwhile, the rotor storage rack is carried by the AGV under the control of the control system, so that the processed rotor which is loaded into the rotor storage rack after being processed on the rotor processing unit is transported to the intelligent three-dimensional warehouse to be stored. The motor rotor machining center is intelligent and automatic, can efficiently complete motor machining and transporting in an environment-friendly mode, and can improve the motor production efficiency.

Owner:安徽朗轶工业自动化系统有限公司

Split type rubber roller capable of being replaced quickly

InactiveCN113883160AGuaranteed production cycleGuaranteed production efficiencyShaft and bearingsMechanical energy handlingHydraulic cylinderGear wheel

The invention provides a split type rubber roller capable of being replaced quickly, belongs to the technical field of textile equipment, and aims to solve the technical problems that a machine needs to be stopped when working rubber rollers are switched, the production cycle cannot be guaranteed, and the operation of replacing worn rubber rollers is inconvenient. The split type rubber roller comprises a bearing seat, an indexing support, a pedal, a clutch box and an indexing motor; an outer roller body is arranged between the bearing seat and the indexing support; a contact roller is arranged on the outer roller body; a driven gear is fixed to the contact roller; a controller is fixed to the indexing support; a grooved wheel indexing mechanism is arranged on the indexing support; a sensor and a second hydraulic cylinder are arranged on the pedal; an input motor, an output shaft and a first hydraulic cylinder are arranged on the clutch box; a driving gear is fixed to the output shaft; and a clutch mechanism is arranged in the clutch box. The small contact rollers replace an original large roller body to work, roller replacement without shutdown can be achieved, the production cycle and the production efficiency are guaranteed, the worn rubber roller can be rapidly detached and replaced by detaching mounting bases at the two ends of a roller groove, and disassembly and assembly are convenient.

Owner:六安微领时代工业智能科技有限公司

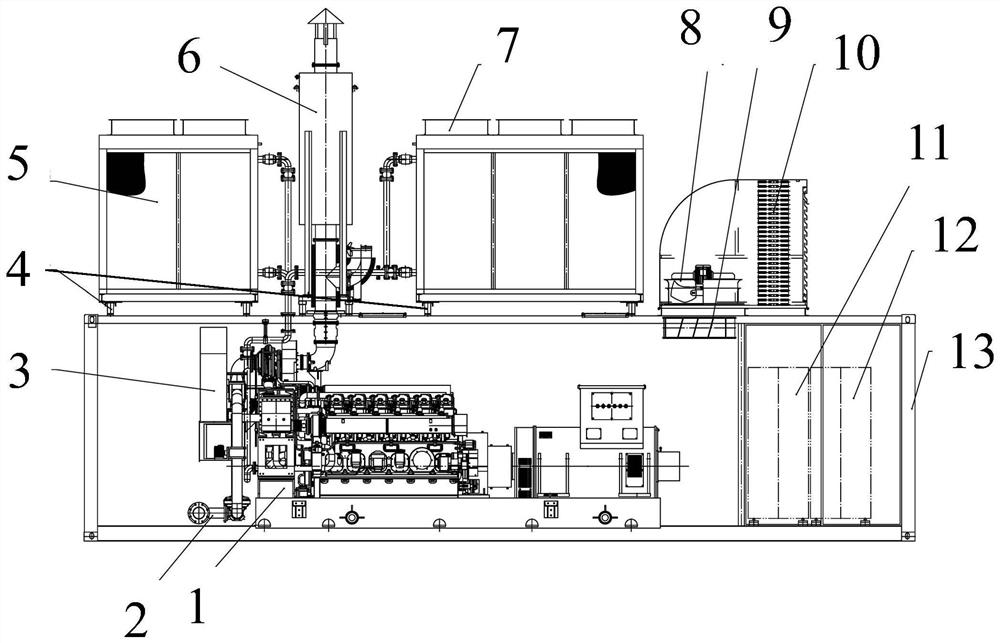

Integrated gas power generation device

InactiveCN111608798ALow costGuaranteed production cycleInternal combustion piston enginesEngine controllersPower stationMonitoring system

The invention discloses an integrated gas power generation device. The integrated gas power generation device includes a gas generator set and a movable generator house; the movable generator house includes an equipment room and a monitoring room; the equipment room is equipped with the gas generator set and a gas / air intake mechanism; the gas / air intake mechanism includes a gas intake mechanism and an air intake mechanism; the monitoring room is equipped with a main control cabinet and a circuit breaker cabinet; and the gas intake mechanism is connected to a gas source through an interface arranged on the side of the equipment room. The invention highly integrates the gas generator set, the monitoring system, the gas intake mechanism, a cooling system, an exhaust muffler system, a machineroom and the like, so as to form a micro-power station; and after the equipment is in place, power generation can be realized by connecting water, electricity, gas and the like with the outside world.

Owner:西安科美动力科技有限公司

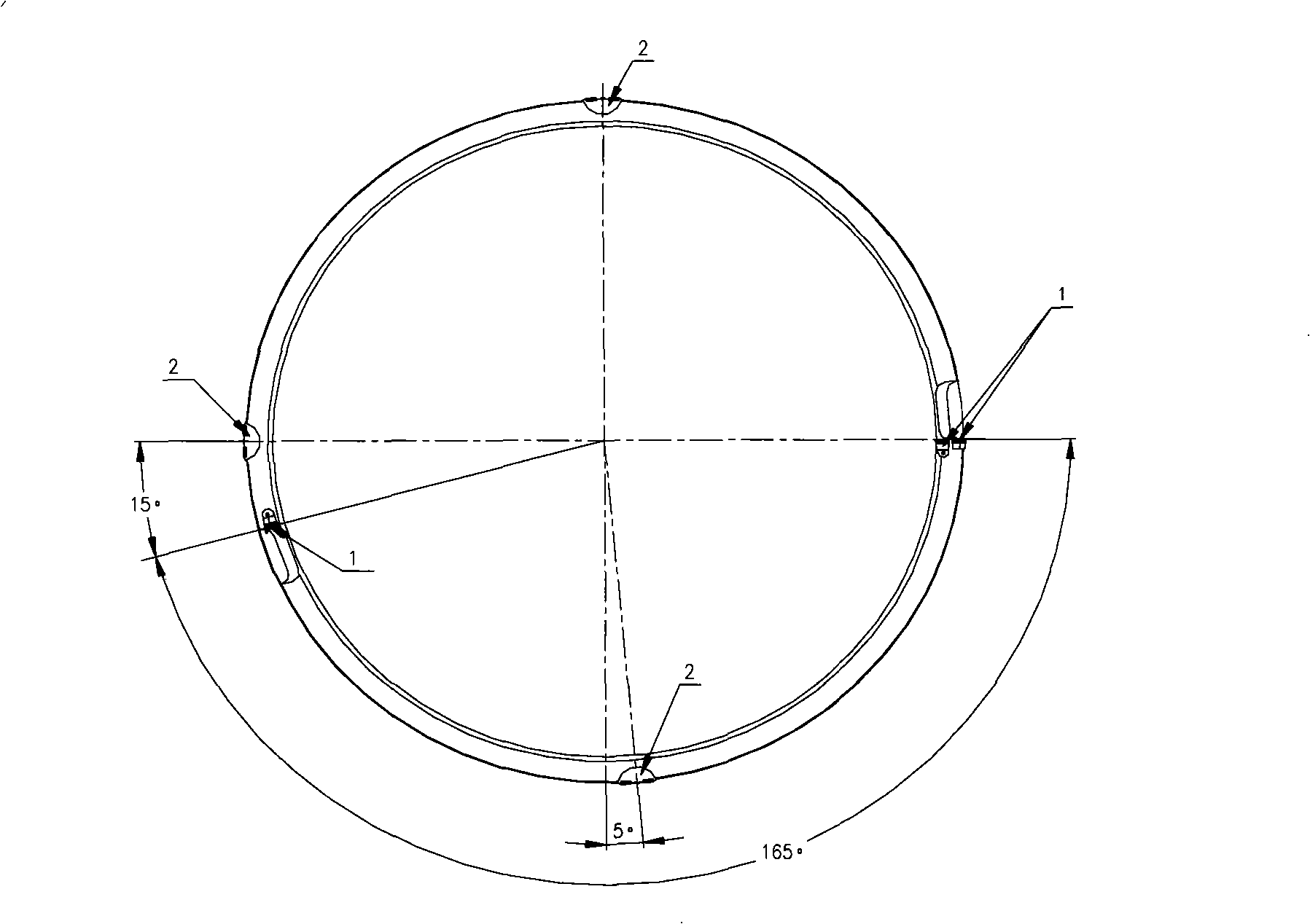

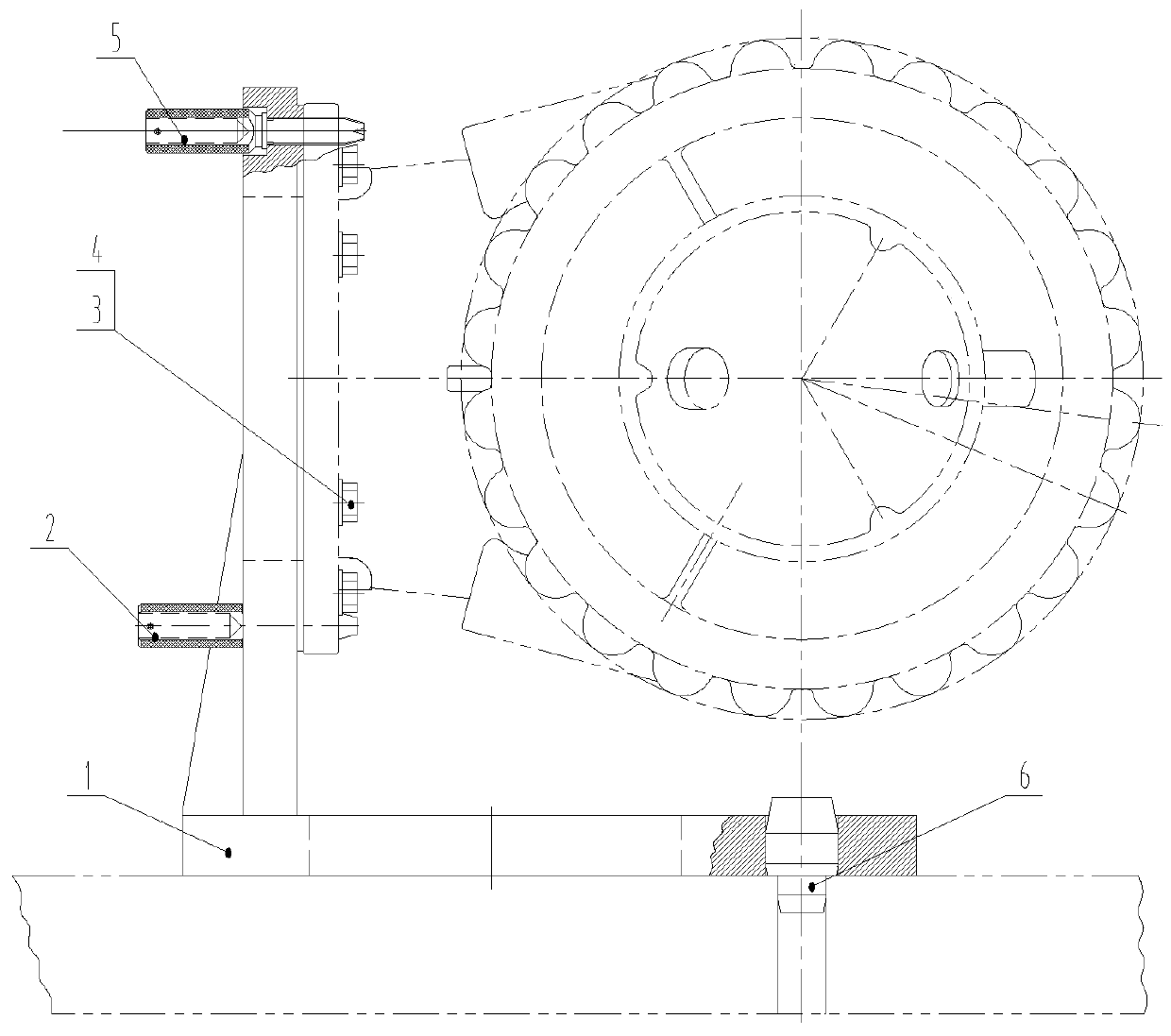

Method for processing trepanning of crankshaft crank red trepanning hole for large-scale ship and special trepanning drill

InactiveCN101745659BQuality assuranceSave energyTransportation and packagingBoring/drilling machinesLathe faceplateEngineering

The invention discloses a method for processing a trepanning of a crankshaft crank red trepanning hole for a large-scale ship, wherein the diameter of the red trepanning hole is more than 708mm, a trepanning drill is fixedly arranged on a chuck disc of a main shaft box of a machine tool, and the trepanning of the crank red trepanning hole is processed by means of machinery processing; and a corresponding angle between cutting edges of knife blades on the two end points of the trepanning drill is 165 degrees, the trepanning drill is guided and supported by using three supports, and cutting scraps are directly discharged by means of external scrap discharge. The invention also discloses the trepanning drill used in the method and a method for taking materials after the trepanning. The invention ensures the processing quality and the manufacture cycle of workpieces with energy-saving and environmental protection.

Owner:SHANGHAI HEAVY MACHINERY PLANT

Machining Method and Boring and Milling Tool of Turbocharger Gas Intake Shell

ActiveCN107322027BGuaranteed service lifeGuaranteed accuracyBoring/drilling machinesTurbochargerEngineering

The invention discloses a machining method and a boring and milling tool for turbocharger gas inlet shells. According to the machining method and the boring and milling tool, by designing and using the special boring and milling tool, parts are machined through an ordinary boring machine instead of a five-axis machining center, the production cycle of the turbocharger gas inlet shells is shortened, and the machining cost of the turbocharger gas inlet shells is reduced. The method includes the following procedures, namely, the first procedure of line drawing, the second procedure of first flange plate boring and the third procedure of second flange plate boring. The boring and milling tool comprises a base. A positioning mandrel and an installation plate are arranged on the base in an erected manner. The upper end of the positioning mandrel is matched with a positioning hole formed in the base. The lower end of the positioning mandrel is used for being embedded in a machining tool work table. The installation plate is located on one side of the positioning mandrel. Positioning pins are installed on the installation plate and are used for positioning first flange plates of the turbocharger gas inlet shells.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

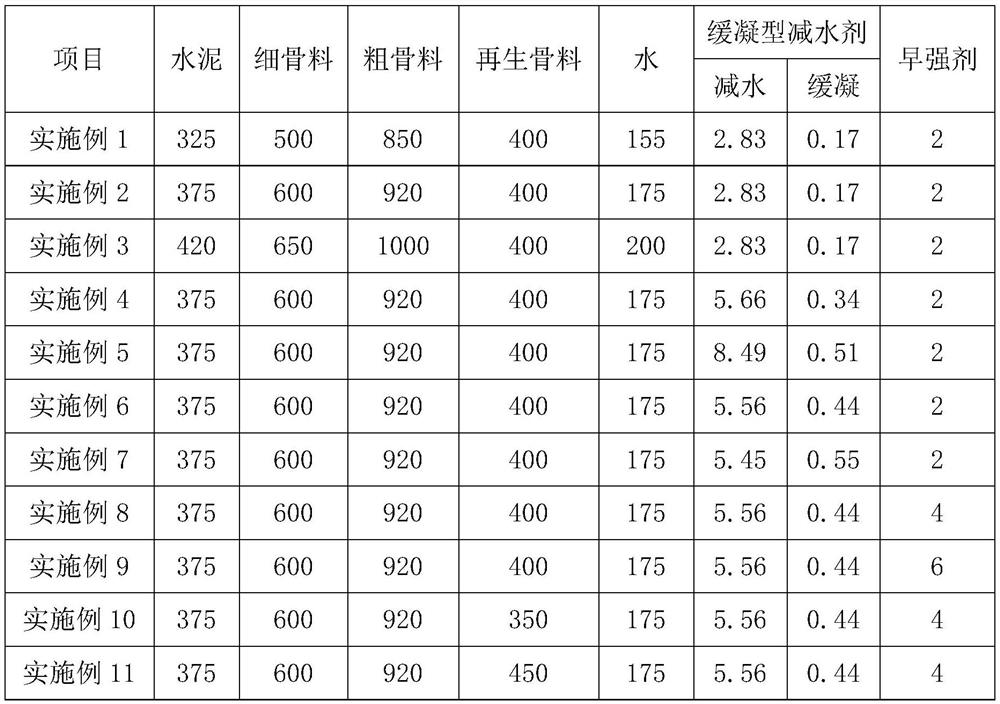

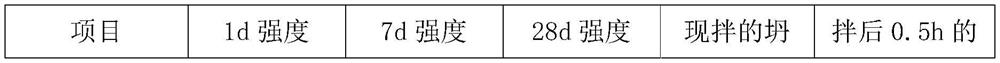

Recycled concrete, recycled concrete prefabricated part and preparation method thereof

PendingCN113354362AImprove liquidityImprove mechanical propertiesArchitectural engineeringStructural engineering

The invention relates to recycled concrete, a recycled concrete prefabricated part and a preparation method thereof. The recycled concrete is prepared from the following raw materials in parts by weight: 325 to 420 parts of cement, 500 to 650 parts of fine aggregate, 850 to 1000 parts of coarse aggregate, 350 to 450 parts of recycled aggregate, 155 to 200 parts of water, 3 to 9 parts of a retarding type water reducing agent and 2 to 6 parts of an early strength agent. The preparation method of the recycled concrete prefabricated part comprises the steps of recycled concrete slurry preparation, concrete pouring, prefabricated part maintenance and the like. The concrete prefabricated part is obtained by adopting the preparation method of the recycled concrete prefabricated part. The flowing property of the concrete containing the recycled aggregate is improved, and the problems that the slump loss of the recycled concrete is large and the vibrating operation is difficult are solved; meanwhile, the early strength and the later strength of the concrete are also improved, the problem that demolding is difficult to realize in one day after the delayed coagulation component is added is solved, and the production cycle and the product quality of the concrete member are ensured.

Owner:苏州建国建筑工业有限公司

A numerical control machining method for improving the fillet quality of overflow brick weir crest

ActiveCN108549318BGuaranteed qualityEliminate uncontrollable phenomenaTotal factory controlNumerical controlNumerical controlBrick

The measured size of a processing reference surface of the circular corners of the weir crest of an overflow brick is compared with a design size, so the polarization direction during processing of the four circular corners of the weir crest of the overflow brick can be ensured, uncontrollable phenomena in the processing of the circular corners of the weir crest are removed, production periods areensured and quality of the finished products of the overflow brick is ensured.

Owner:IRICO

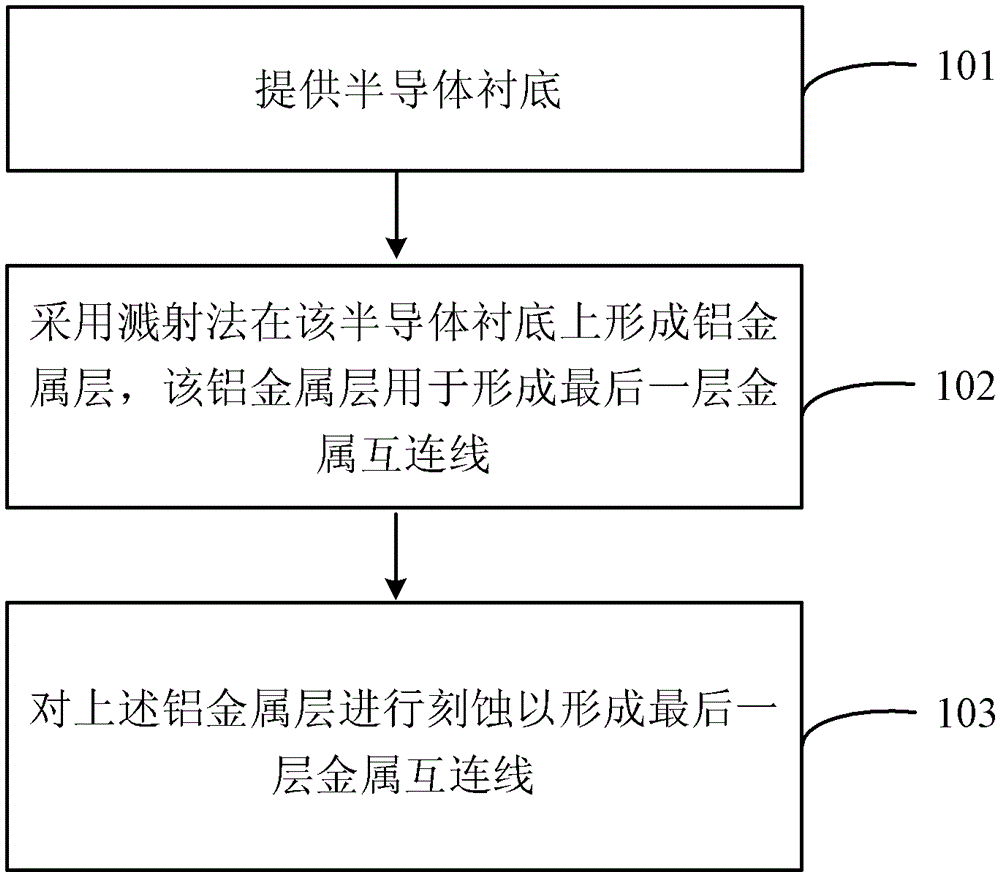

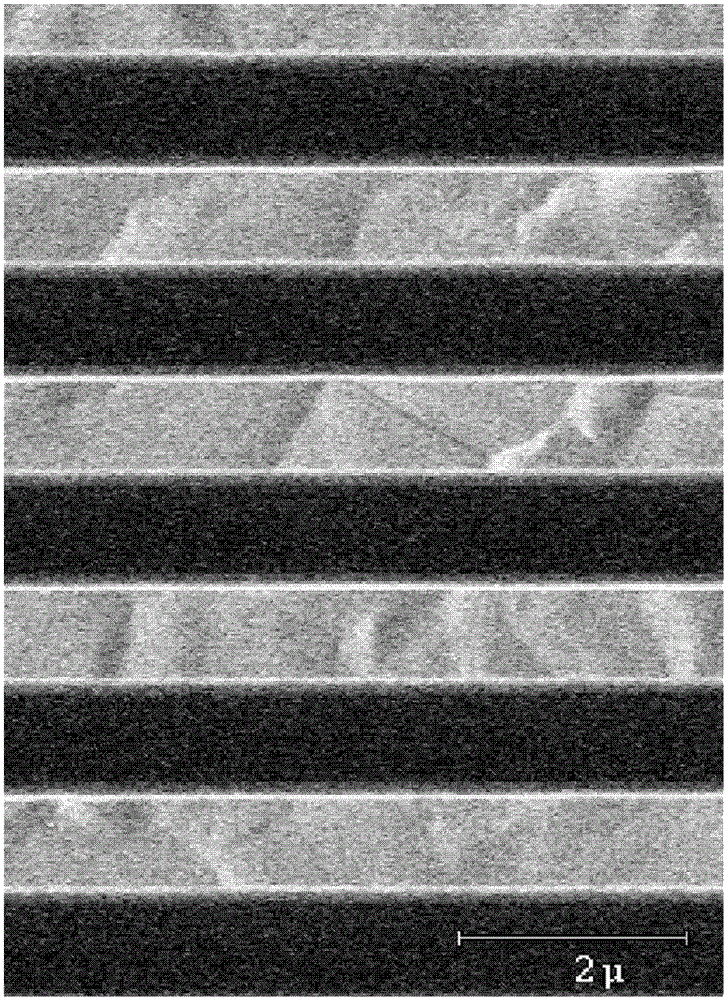

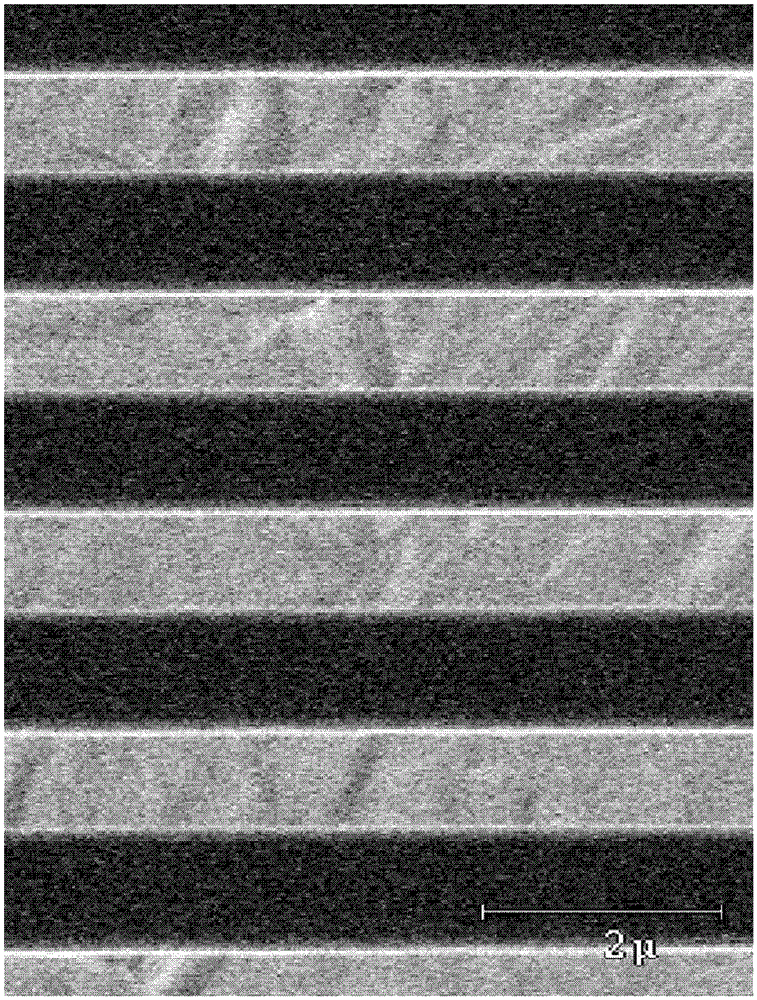

Method for preventing the formation of ring-like metal residues on metal interconnect lines

ActiveCN103187357BSolving metal residue problemsGuaranteed production cycleVacuum evaporation coatingSputtering coatingInterconnectionAluminum metal

The invention provides a method for preventing a hooped metal residue from being formed on a metal interconnection line. The method comprises the steps that a semiconductor substrate is provided, an aluminum metal layer is formed on the semiconductor substrate by a sputtering method and used for forming a final layer of the metal interconnection line, and the sputtering temperature when the aluminum metal layer is formed is lower than or equal to 250 DEG C. According to the method, since the sputtering temperature when the aluminum metal layer is formed is lowered, the hooped metal residue can be effectively avoided. Compared with the prior art, no processing step is added in the method, so that the original production cycle can be ensured, and the product quality is improved.

Owner:CSMC TECH FAB2 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com