Preparation process of black garlic and preparation method of concentrated juice of black garlic

A technology of black garlic concentrated juice and preparation technology, which is applied in the field of food processing, can solve the problems of limited storage time for deep-processed products, few black garlic processing enterprises, and long fermentation cycle, so as to shorten the production cycle, ensure the quality of black garlic, and save time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

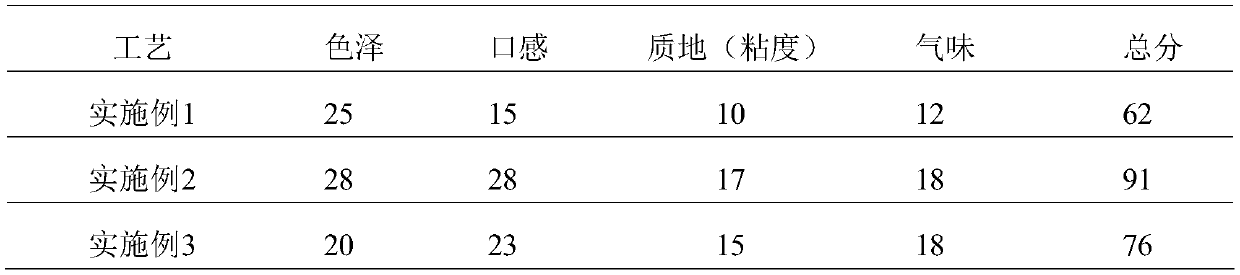

Embodiment 1

[0028] (1) Fermentation of black garlic

[0029] 1) Select fresh and plump garlic and wash;

[0030] 2) Put it in a drying oven, set the temperature at 90°C, and let it be colored. When the coloring time reaches 24 hours, open the lid of the drying oven, dry at 90°C for 9 hours, and then cover the drying box to seal it. Continue heating and coloring at 90°C for 22 hours; keep the humidity in the drying oven at 70-90%;

[0031] 3) After the coloring is completed, adjust the temperature of the drying box to 70°C and heat for 29 hours to preliminarily ripen the black garlic with skin;

[0032] 4) After the preliminary ripening of the black garlic, the temperature is adjusted to 60° C., and post-ripening is carried out for 48 hours;

[0033] 5) Dry the fermented black garlic at 45° C. for 24 hours to obtain the finished black garlic.

[0034] (2) Preparation of concentrated juice

[0035] 1) Peel the black garlic prepared above to obtain rice garlic and single clove garlic;

...

Embodiment 2

[0041] (1) Fermentation preparation of black garlic

[0042] 1) Select fresh and plump garlic and wash;

[0043] 2) Put it into a drying box, set the temperature at 75°C, and ferment for 15 days.

[0044] 3) The fermented black garlic was dried in a drying oven at 45° C. for 24 hours to obtain a finished black garlic product.

[0045] (2) Preparation of concentrated juice

[0046] 1) Peel the black garlic prepared above to obtain rice garlic and single clove garlic;

[0047] 2) Crushing the single clove of garlic or garlic with a crusher to obtain black garlic and garlic paste;

[0048] 3) Using one-time extraction method, according to the ratio of material to liquid, black garlic and garlic: drinking water = 1:6, put the black garlic and garlic into drinking water for extraction, the extraction temperature is 50 ° C, and the extraction time is 20 minutes Under the condition of black garlic rough infusion extract;

[0049] 4) Filter the crude black garlic extract juice th...

Embodiment 3

[0052] (1) Fermentation preparation of black garlic

[0053] 1) Select fresh and plump garlic and wash;

[0054] 2) Put it into a drying oven, set the temperature at 65°C, and ferment for 15 days.

[0055] 3) The fermented black garlic was dried in a drying oven at 45° C. for 24 hours to obtain a finished black garlic product.

[0056] (2) Preparation of concentrated juice

[0057] 1) Peel the black garlic prepared above to obtain rice garlic and single clove garlic;

[0058] 2) Crushing the single clove of garlic or garlic with a crusher to obtain black garlic and garlic paste;

[0059] 3) Using one-time extraction method, according to the ratio of material to liquid, black garlic and garlic: drinking water = 1:6, put the black garlic and garlic into drinking water for extraction, the extraction temperature is 50 ° C, and the extraction time is 20 minutes Under the condition of black garlic rough infusion extract;

[0060] 4) Filter the crude black garlic extract juice t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com