Method for ensuring coaxiality of bearing and stator core of circulating pump motor

A stator core and circulation pump technology, which is applied to parts, pumps, pump components, etc. of the pumping device used for elastic fluid, can solve the problems such as the lack of dimensional accuracy and roughness of the inner circle of the bearing sleeve, and achieve The production cycle is guaranteed, the quality is stable, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

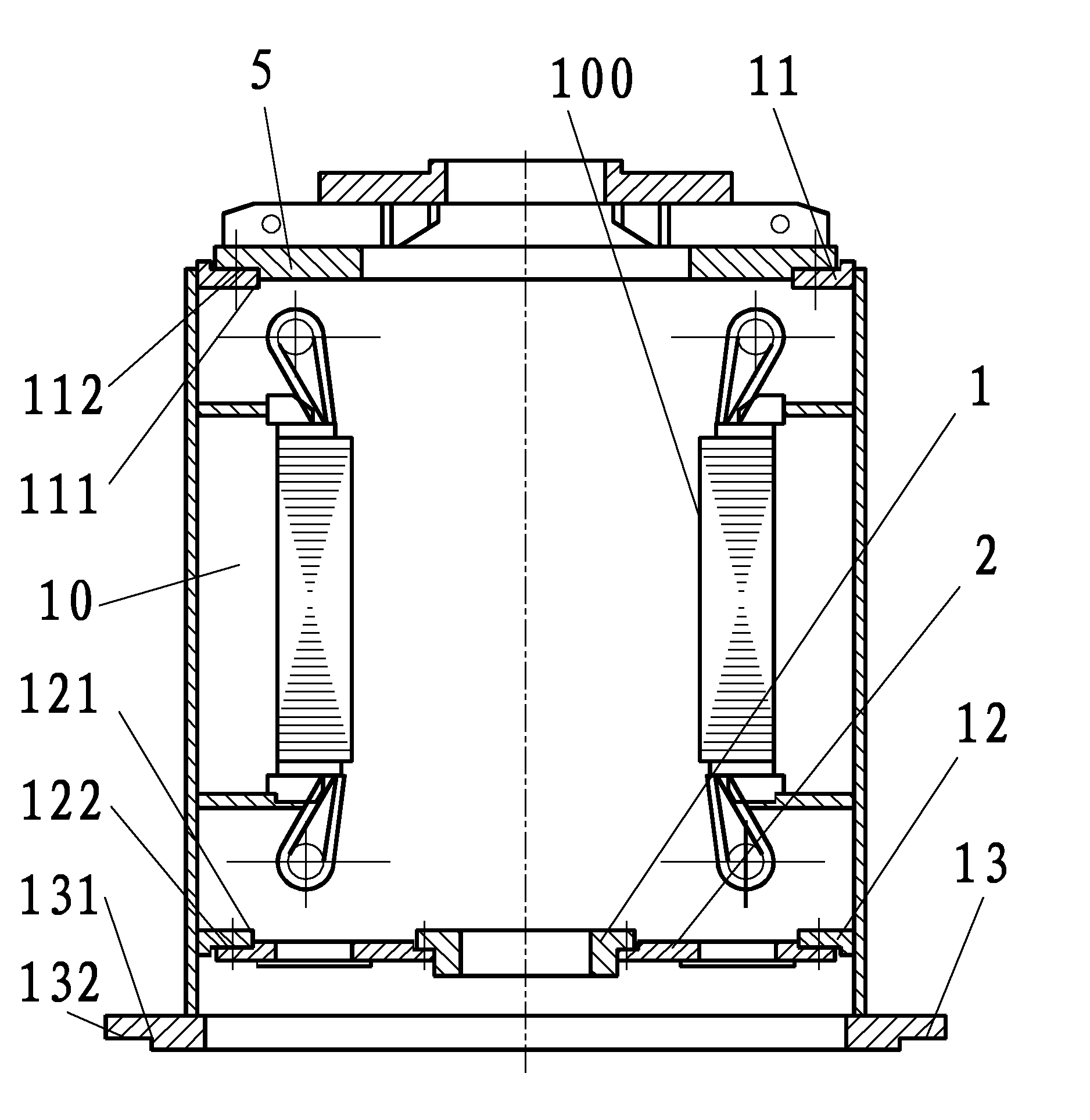

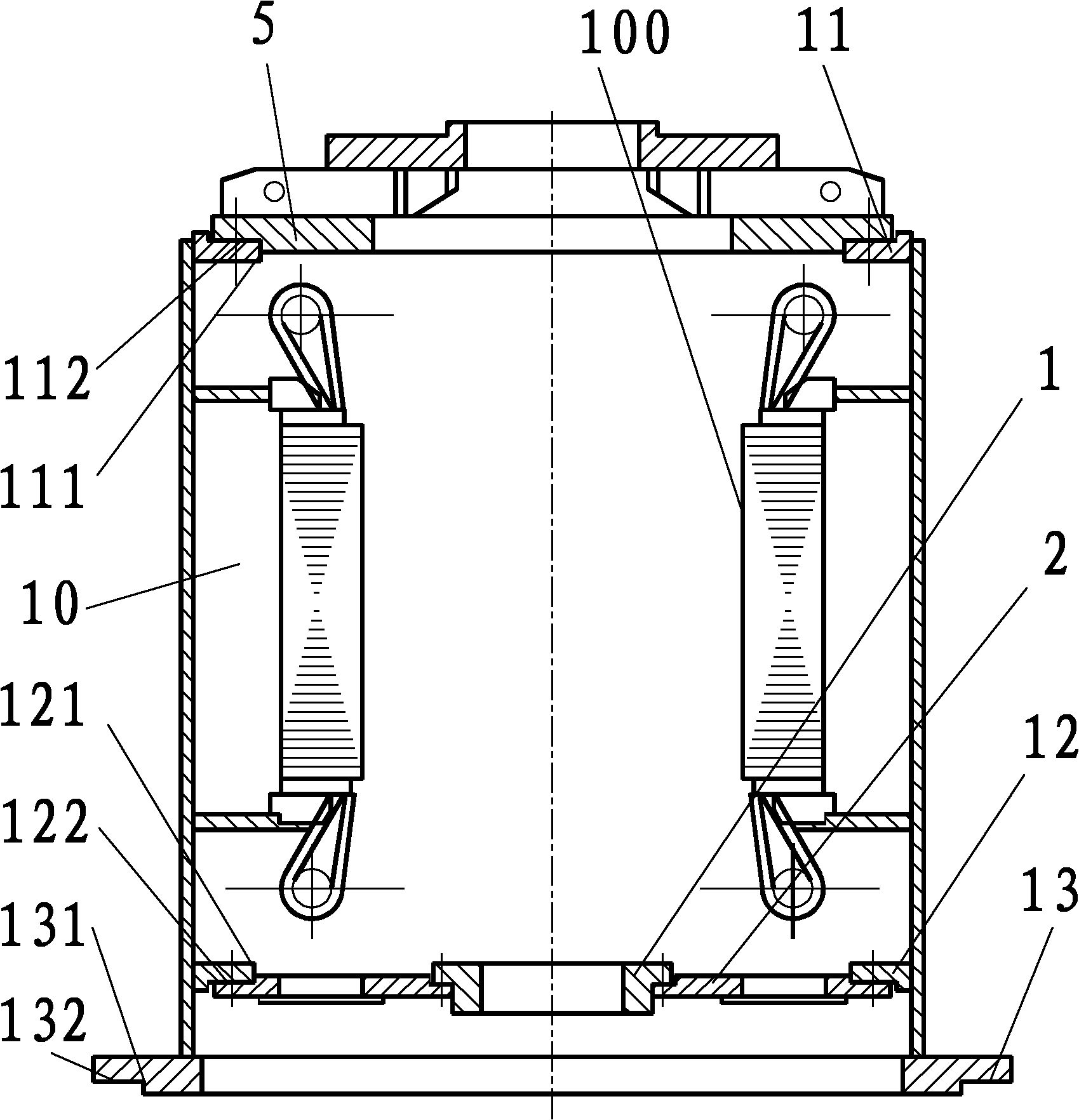

[0020] In order to better understand the technical solution of the present invention, a detailed description will be given below through specific embodiments and in conjunction with the accompanying drawings.

[0021] Please refer to Fig. 1 to Fig. 5, the method for ensuring the coaxiality of the bearing and the stator core of the circulating pump motor of the present invention comprises the following steps:

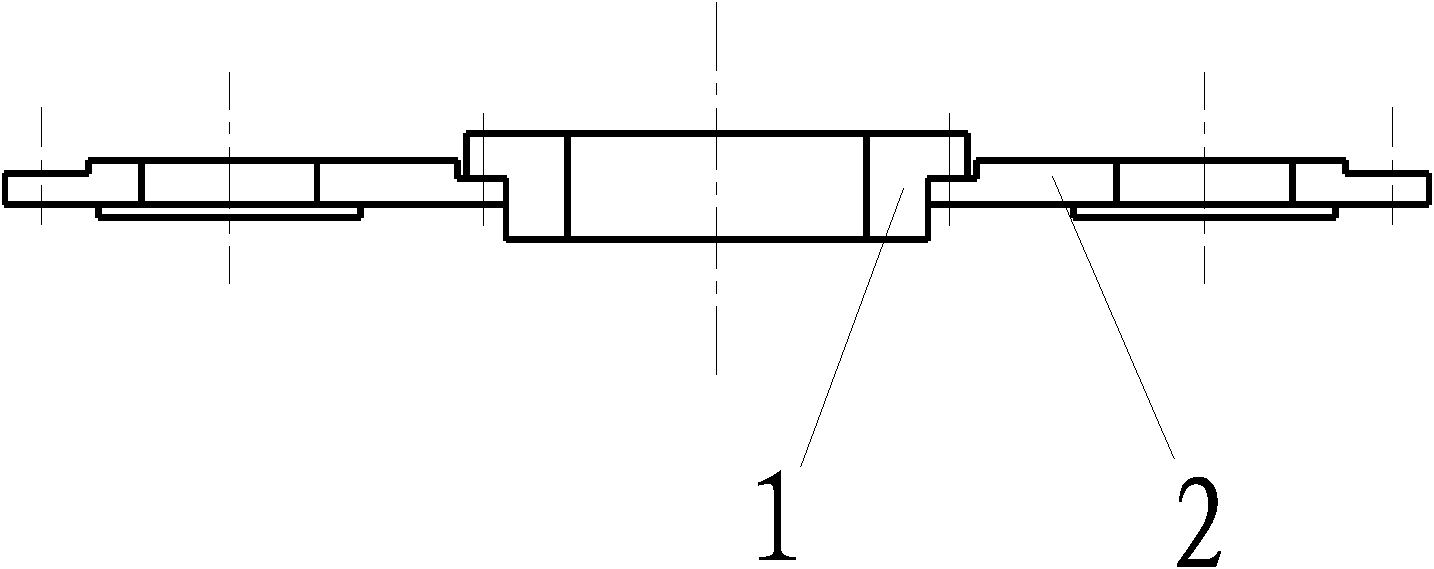

[0022] Step 1, respectively finishing all the dimensions of the lower bearing sleeve 1 and the lower end cover 2 to meet the design requirements;

[0023] Step 2, put the lower bearing sleeve 1 into the lower end cover 2, drill a number of pin holes 3 between the lower bearing sleeve 1 and the lower end cover 2 and install the pins, and make positioning marks at the same time;

[0024] Step 3, the secondary machining of the upper vertical lathe of the stator 10, the inner circle 121 and the plane 122 of the lower bearing rack 12 of the stator 10 are firstly machined with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com