Electronic expansion valve

An electronic expansion valve and valve needle technology, which is used in lift valves, valve devices, lighting and heating equipment, etc., can solve the problem that electric valves have high requirements on the neutrality of valve needle components and nuts, and it is difficult to ensure the nut and valve needle wire. Rod assembly coaxiality, reducing the service life of the electronic expansion valve, etc., to avoid the valve port sealing is not tight, the coaxiality is high, and the installation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

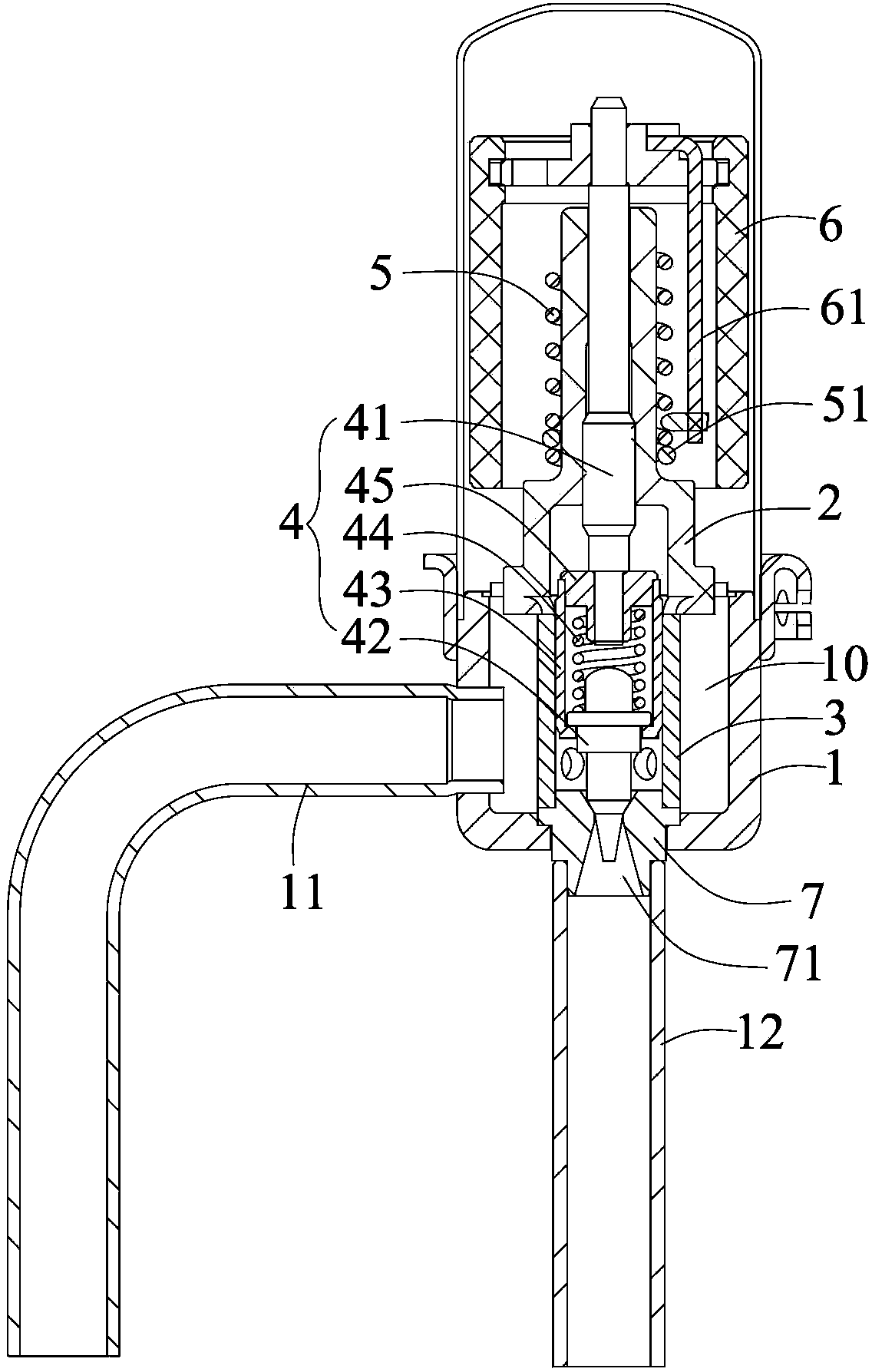

[0029] refer to figure 1 , 2 , the electronic expansion valve of this embodiment includes a valve body 1, a nut 2, a valve needle assembly 4, and a guide sleeve 3. The inside of the valve body 1 is a valve chamber 10, and the valve body 1 is connected with an inlet connecting pipe 11 and an outlet connecting pipe 12. The lower end of the valve body 1 is provided with a valve port seat 7, the valve port seat 7 is provided with a valve port 71, the valve port 71 corresponds to the outlet connecting pipe 12, the lower end of the guide sleeve 3 is socketed with the valve port seat 7; the valve needle assembly 4 includes a valve needle 42, The screw rod 41 and the positioning sleeve 43, the lower end of the screw rod 41 and the upper end of the positioning sleeve 43 are fixedly connected through the valve needle sleeve 45, the valve needle 42 is movably installed at the lower end of the positioning sleeve 43, and a valve needle is arranged between the valve needle 42 and the screw ...

Embodiment 2

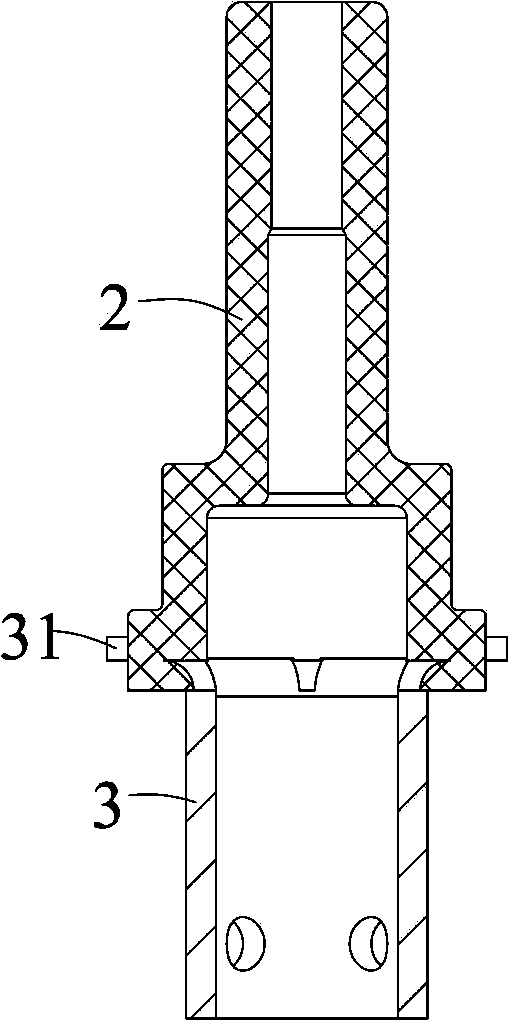

[0036] refer to Figure 4 , 5 , the structure of the electronic expansion valve in this embodiment is roughly the same as in Embodiment 1, the difference is that the connecting piece 31 and the guide sleeve 3 are separate structures, the connecting piece 31 is ring-shaped and fixed on the upper end of the guide sleeve 3, and the fixing method can be It is an interference fit or solder connection. The split structure of the connecting piece 31 can avoid the problem of deformation of the connecting piece 31 caused by the residual stress formed by the stamping and bending process, and the stability is better.

[0037] The connecting piece 31 is provided with an injection hole 33, which is convenient for the injection material to pass through during the injection molding process; the nut 2 or the connecting piece 31 is also provided with a spring guide rail positioning hole 34, so that the lower end of the spring guide rail is limited. For other structures of the electronic expa...

Embodiment 3

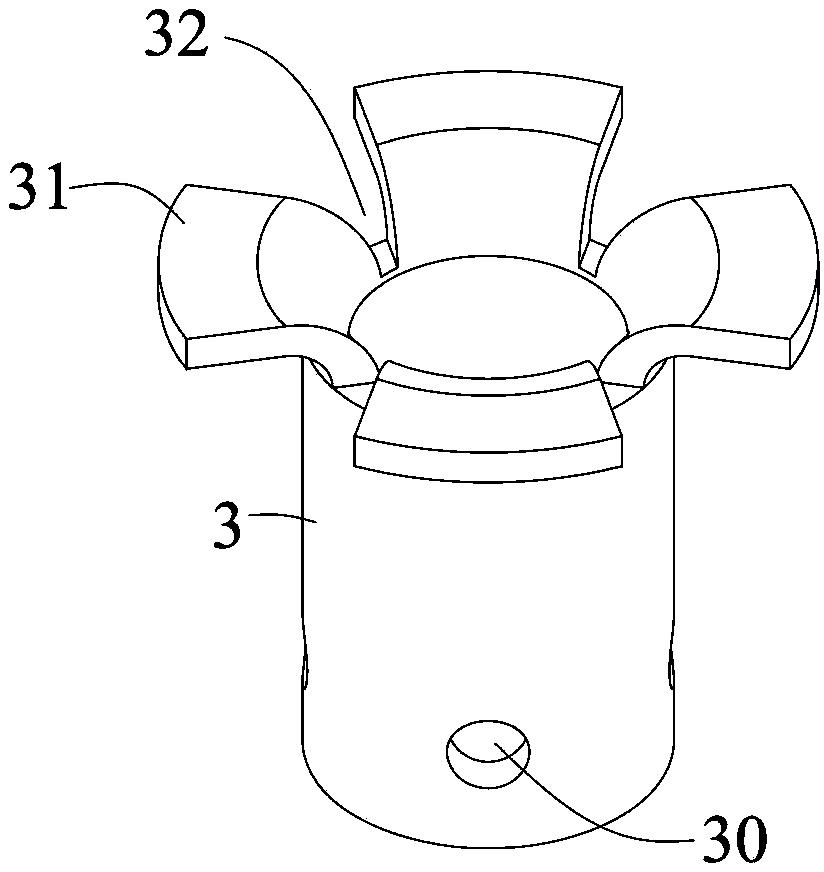

[0039] refer to Figure 6 , 7 , the structure of the electronic expansion valve in this embodiment is roughly the same as that in Embodiment 1, the difference is that the connecting piece 31 and the guide sleeve 3 are separate structures, and the connecting piece 31 is ring-shaped and can be axially slidably sleeved on the guide sleeve 3 upper end. During specific implementation, the upper end of the guide sleeve 3 forms a necking boss 35, and there is a clearance fit between the connecting piece 31 and the necking boss 35, and the connecting piece 31 can freely slide axially on the necking boss 35. During injection molding, The shrinkage boss 35 is inserted into the inner hole at the lower end of the nut 2, and the depth of the shrinkage boss 35 inserted into the nut 2 can be adjusted according to the installation requirements of the guide sleeve 3 in the inner cavity of the valve body 1, so as to better fix the guide sleeve 3 ; In addition to the above method, it is still ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com