Delayed demolding device for stretching die part

A drawing die and part technology, applied in the field of delayed demoulding equipment for drawing die parts, can solve the problems of high machine tool cost, poor stability, complicated debugging, etc., to ensure production cycle and quality, high reliability, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

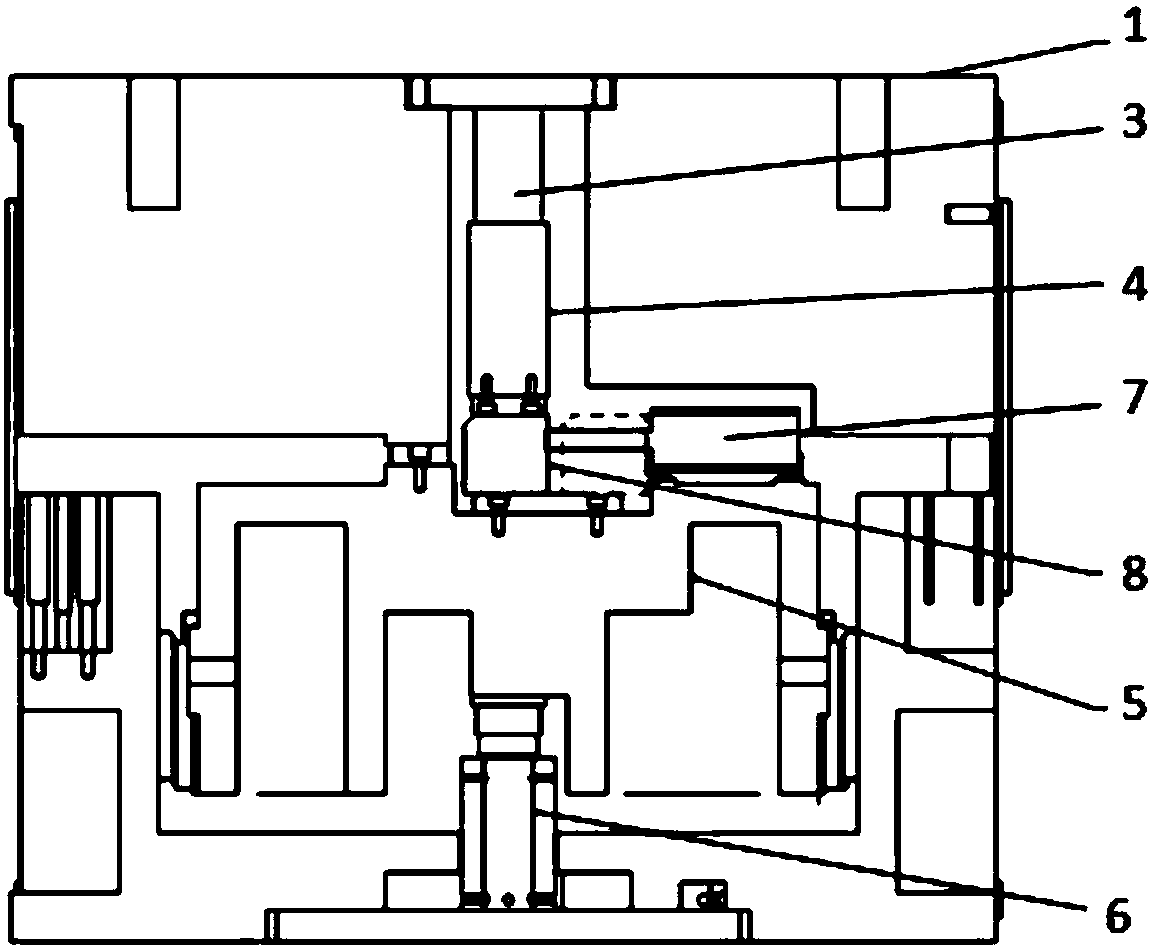

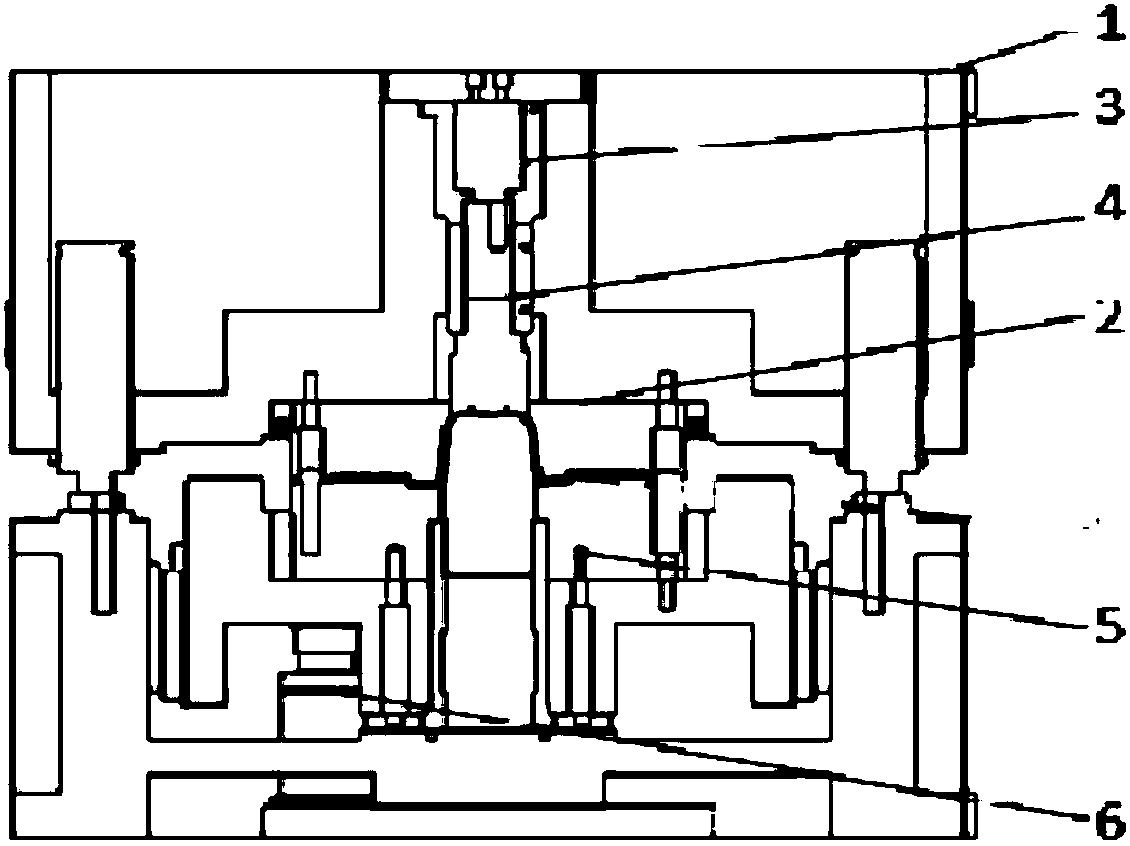

[0021] The problem solved by the present invention is that when the upper die 1 and the die 2 move upwards driven by the upper slider of the machine tool, the lower blank holder 5 moves upwards under the push of the lower nitrogen cylinder 6. At this time, due to the upper pressing core 4 is also pressed on the part, and the lower blankholder 5 will cause upward shape damage to the part that has been stretched.

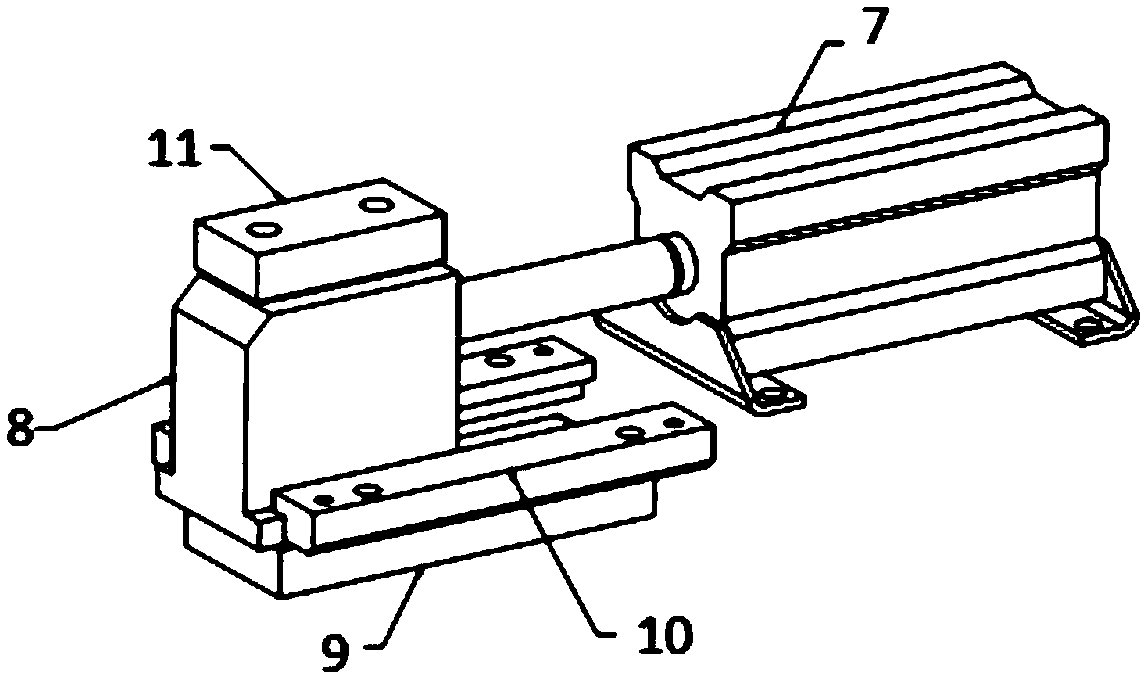

[0022] like Figure 1-Figure 3 As shown in the schematic diagram of the structure of the present invention, the present invention provides a delayed demoulding device for stretching die parts, comprising an upper die 1 and a die 2, the die 2 is fixed below the upper die 1 by bolts, and the upper die 1 is fixed with an upper nitrogen cylinder 3, the driving end of the upper nitrogen cylinder 3 is connected vertically downward with an upper binder core 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com