Tree-shaped structure pipe welding anti-deformation device and positioning method thereof

A tree structure, anti-deformation technology, applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of deformation, uncontrollable shape, size and tolerance requirements, etc., to reduce manufacturing costs, improve welding speed and welding quality , The effect of quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

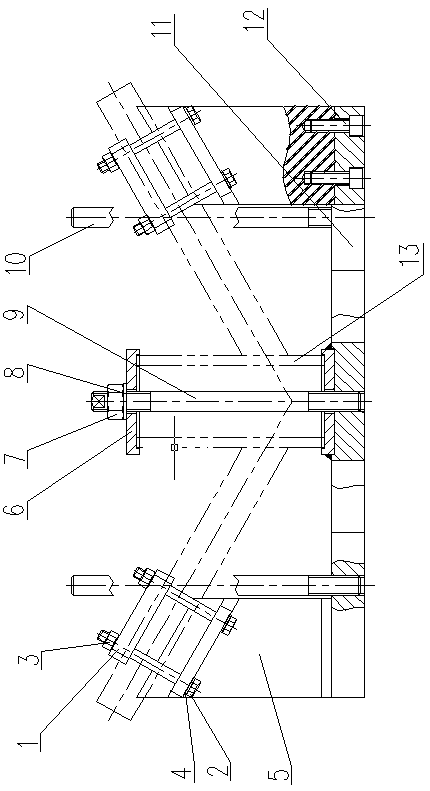

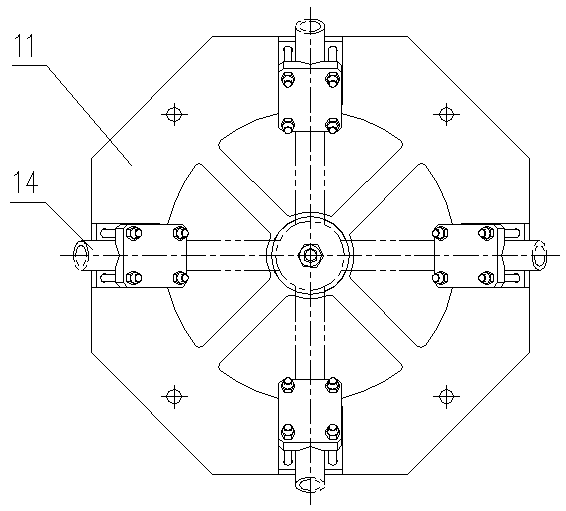

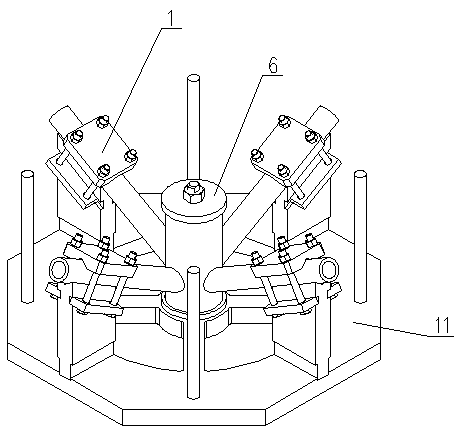

[0025] A tree structure pipe welding anti-deformation device, which consists of: 2 transition plates 6, and a cylinder 13 is installed between the 2 transition plates, wherein the lower transition plate is embedded in the seam of the upper plane of the bottom plate 11 , and welded and fixed with the base plate, the pull rod 9 passes through the cylinder and the upper and lower transition plates, the bottom of which is threadedly connected with the base plate, and the top is respectively equipped with a washer A8 and a nut A7, and the plane on the base plate is connected with 4 bolts respectively. The positioning block 5 is connected, the V-shaped groove above the positioning block is attached to the bottom of the spray pipe 14, the upper part of the spray pipe is attached to the V-shaped groove below the pressure plate 1, and passed through a set of backing plates and bolts 2 , Washer B4 and nut B3 are fixed.

Embodiment 2

[0027] According to the tree structure pipe welding anti-deformation device described in Embodiment 1, the positioning blocks are evenly and symmetrically arranged, and four legs 10 are respectively installed between the two positioning blocks, and the legs are threaded. It is connected with the bottom plate and arranged evenly and symmetrically. The middle of the bottom plate is a hollow structure. The cylinder is at an angle of 60 degrees to the spray pipe. The spray pipe has a set of holes. The holes are arranged axially in n groups.

Embodiment 3

[0029] A positioning method for welding an anti-deformation device using the tree structure pipe described in Embodiment 1-2, the method includes the following steps:

[0030] First, process the middle position of the plane on the bottom plate into a spigot with the same diameter as the transition plate, so that the bottom surface of the spigot is parallel to the lower plane of the bottom plate, and at the same time process a threaded hole at the center of the spigot so that it is perpendicular to the bottom surface of the spigot, and then The transition plate is put into the seam and fixed by welding, and the cylinder is placed in the seam between the two transition plates, and fixed by the tie rod, washer A and nut A;

[0031] Then fix the four spray pipes on the positioning block in turn, clamp them respectively through a set of backing plates, bolts, washers B, and nuts B, and fit one end of the four spray pipes to the outer circle of the cylinder, Make the axis of the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com