Automatic oiling device for slide rail and its operation method

An automatic oiling and sliding rail technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of prolonging the production cycle of sliding rails, low degree of automation, and affecting the oiling effect, so as to achieve stable, reliable and automatic oiling effect High degree, the effect of improving the quality of oil injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention discloses an automatic oiling device for slide rails and an operating method thereof, which are suitable for automatic conveying and oiling of processed parts of slide rails.

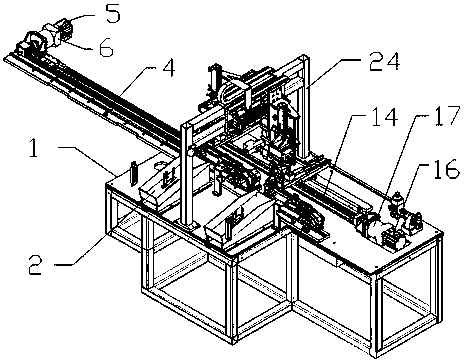

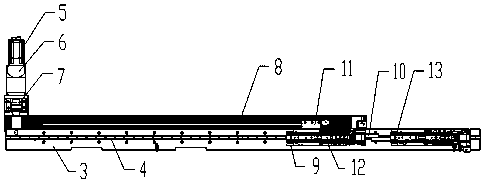

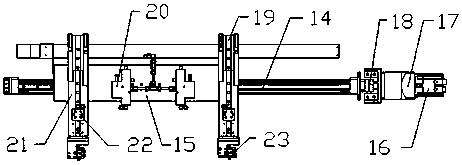

[0035] Such as Figure 1 ~ Figure 4 As shown, a slide rail automatic oiling device includes an equipment support 1, and an unloading trough 2 fixedly arranged on the equipment support 1, and also includes a loading and transferring mechanism for loading slide rail processed parts, For the oil injection processing mechanism for injecting oil into the slide rail processed parts, and the blanking and grabbing mechanism for blanking the slide rail processed parts, the loading and loading mechanism, the oil injection processing mechanism and the blanking and grabbing mechanism are all fixedly arranged on the On the equipment support 1; the loading and transferring mechanism cooperates with the oil injection processing mechanism to complete the oil injection operation on the slide rail pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com