Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Guaranteed beneficial effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

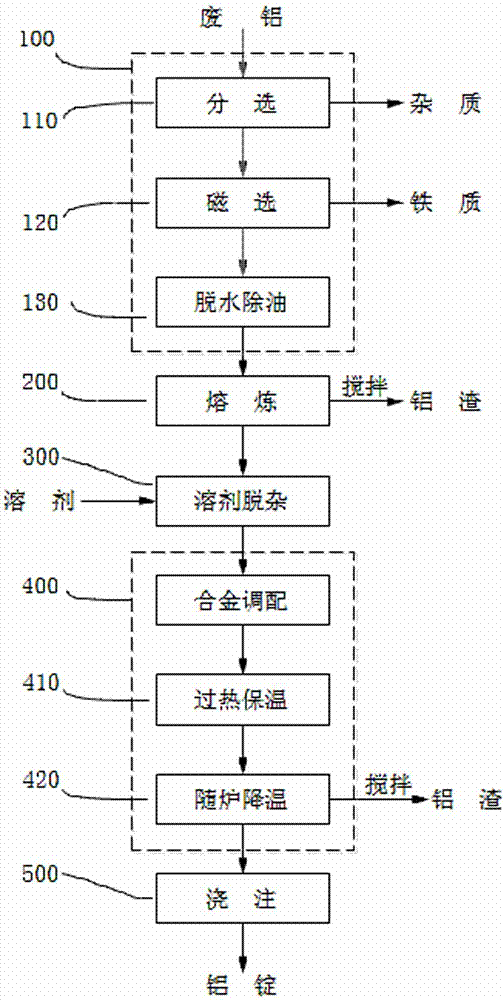

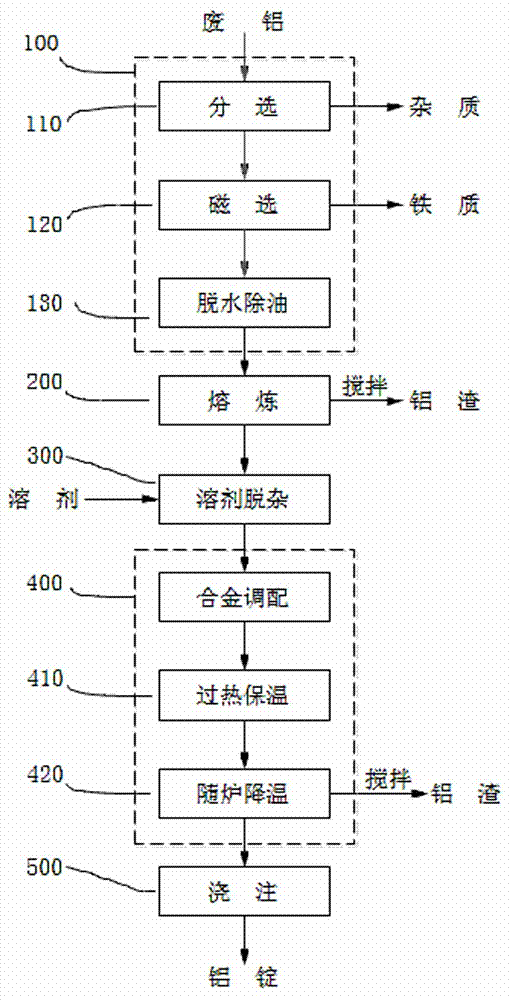

Method for efficiently regenerating cast aluminum alloy by aluminum scraps

The invention discloses a method for efficiently regenerating cast aluminum alloy by aluminum scraps. The method for efficiently regenerating cast aluminum alloy by aluminum scraps comprises the following processes of: screening, smelting, alloy-mixing and pouring, wherein the screening process specifically comprises the following step of: removing impurities and moisture in the aluminum scraps; the smelting process specifically comprises the step of melting and stirring the aluminum scraps after the screened aluminum scraps are charged, so that the slag is removed; the alloy-mixing process specifically comprises the following steps of: adding 9%-11% (in percentage by weight) of Si and 0.8%-1.1% of Fe when the temperature of the impurity-removed aluminum scrap solution reaches 680 DEG C to 740 DEG C, keeping the temperature after the components are uniformly stirred and removing the slag; and the casting process specifically comprises the following step of: pouring the slag-removed molten aluminum to the mould to obtain the cast aluminum alloy ingot or the aluminum alloy casting piece. According to the method for efficiently regenerating cast aluminum alloy by aluminum scraps, the aluminum scraps are enabled to reach the technical requirements of the cast aluminum alloy by aluminum scrap screening and alloy mixing, and therefore, the method has the advantages of being simple in process, strong in aluminum scrap adaptability, stable in aluminum alloy stability, low in cost, and high in aluminum recycling rate.

Owner:YUNNAN AOKAI TECH DEV

Image processing method, image processing system, image pickup device, image processing device and computer program

ActiveUS20070291140A1Guaranteed beneficial effectEnhance the imageImage enhancementTelevision system detailsImaging processingDriver/operator

A system using an in-vehicle camera mounted on a vehicle for an image pickup object of the face of the driver, for: continuously taking an image of the image pickup object; performing manipulation, such as enlargement of an area including the image pickup object with a reference point being the center, for a second image based on image pickup after a first image, on the basis of the range of the image pickup object detected from the first image, the width of the facial contour of the driver, for example, and also a reference point such as the center of the face to be decided based on the location of the eyes and nose of the driver; and performing image processing, such as detection of the range of the image pickup object and decision of the reference point, for the manipulated second image.

Owner:FUJITSU LTD

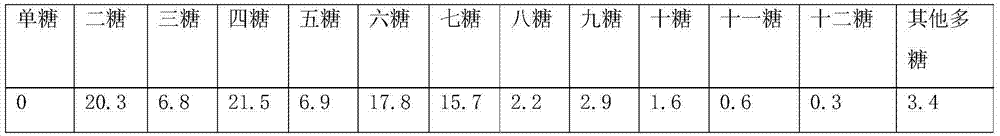

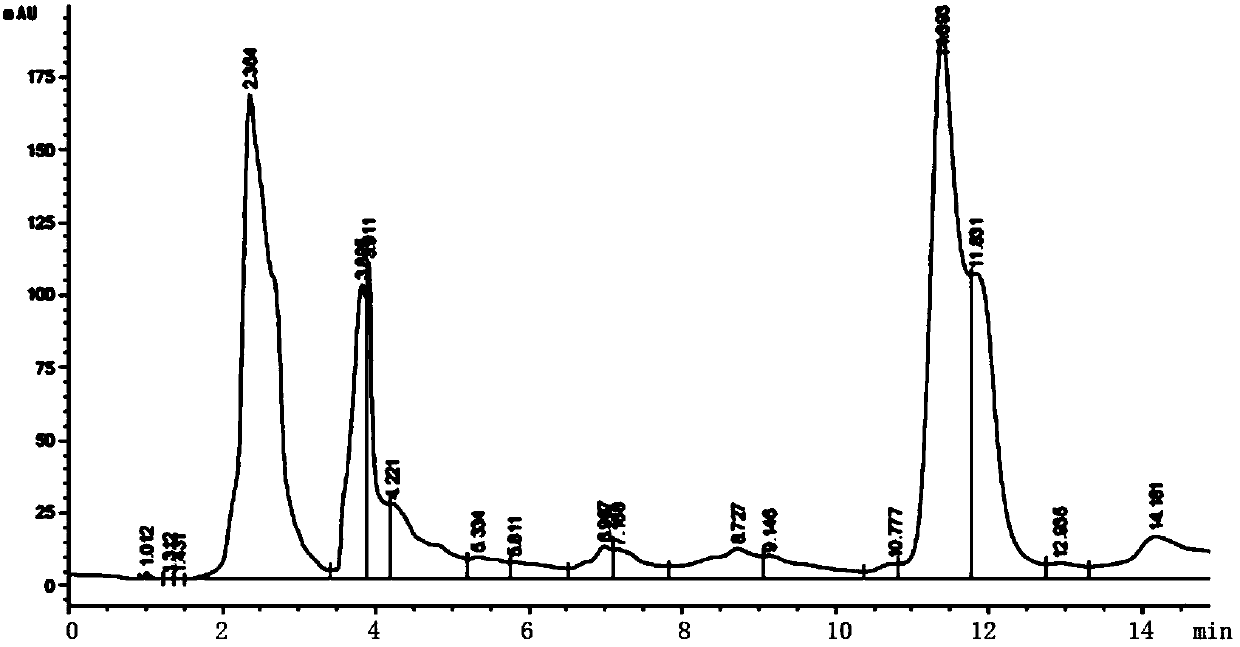

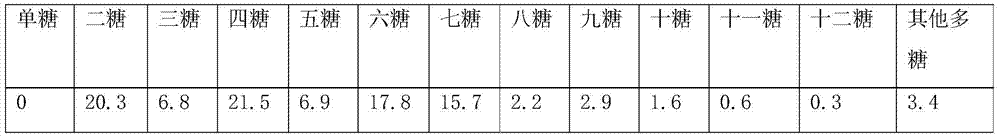

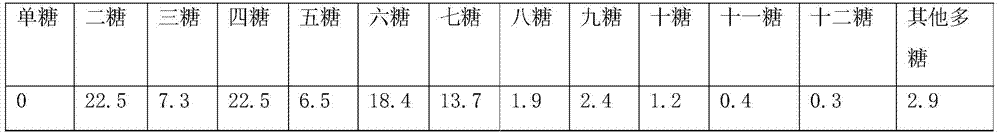

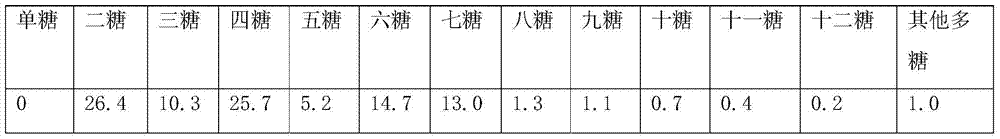

Method for preparing guar gum oligogalactomannan enzymolysis solution by composite enzyme process

The invention discloses a method for preparing a guar gum oligogalactomannan enzymolysis solution by a composite enzyme process, which comprises the following steps: thoroughly mixing guar gum powder with beta-mannase, endoglucanase and cellobiase; adding a citric acid-sodium citrate buffer solution to prepare a mixed solution of the guar gum and three enzymes; and after the guar gum swells, controlling the enzymolysis temperature and time to perform enzymolysis. The method implements simultaneous enzymolysis of the three composite enzymes, omits the purification step after sequential degradation of single enzymes, saves the production time and cost and enhances the efficiency. The method implements enzymolysis of the guar gum under high-concentration conditions, obtains the oligogalactomannan enzymolysis solution, and saves the dehydration and drying cost of the subsequent oligogalactomannan production process.

Owner:QINGZHOU RONMER BIOLOGY TECH CO LTD

Gingko Pu'er raw tea and preparation method thereof

The invention discloses a ginkgo Pu'er raw tea and a preparation method thereof. The ginkgo Pu'er raw tea is composed of 45-65% of ginkgo leaves and 35-55% of Pu'er raw tea. Through the processing process carried out on the ginkgo leaves, active ingredients of the ginkgo leaves are activated and differentiated, and the active ingredients of the ginkgo leaves can be rapidly leached when the ginkgoPu'er raw tea is brewed, thus effects of beneficial ingredients of the ginkgo leaves are improved and guaranteed. The ginkgo Pu'er raw tea disclosed by the invention has good taste and strong fragrance, undesirable bitter and acerbic senses of common ginkgo Pu'er raw tea are changed, people can obtain health care effect while enjoying the tea, beneficial effects of the prepared ginkgo Pu'er raw tea, tea bags and block tea can be guaranteed, and the preparation method is simple, is easy to operate and can be accepted by the masses easily. The ginkgo Pu'er raw tea disclosed by the invention is a novel health care tea used for preventing and treating cerebral vascular and cardiovascular arteriosclerosis, hypertension and senile dementia and has the effects of diuresis, digestion aid, dispelling the effects of alcohol, losing weight, enhancing appetite, dispelling wind and relieving exterior syndrome as well as clearing head and eyes.

Owner:徐州绿之野生物食品有限公司

Ginkgo black tea and preparation method thereof

The invention discloses ginkgo black tea and a preparation method thereof. The ginkgo black tea comprises the following components: 45-65 percent of ginkgo leaves and 35-55 percent of black tea. According to the invention, in the process of processing the ginkgo leaves, activation and differentiation of effective components of the ginkgo leaves are solved, the effective components can be leached rapidly when the gingko black tea is brewed, and thus the efficacies of the beneficial components of the gingko black tea are improved and ensured. The gingko black tea is good in mouthfeel and strongin flavor, changes bitter and astringent mouthfeel of common gingko tea and can achieve a health care effect while people enjoy the tea; and all of the prepared gingko astringent, tea bags and blockytea can ensure the beneficial effects of the gingko black tea products, and are simple in the preparation method, convenient to use and easy to be accepted by the public. The black tea in the ginkgo black tea is warm in nature and good at warming the middle Jiao and expelling cold as well as warming the stomach. The ginkgo black tea disclosed by the invention is particularly suitable for people who suffer from stomach cold and spleen deficiency.

Owner:徐州绿之野生物食品有限公司

Gingko white tea and preparation method thereof

ActiveCN102578320ASimple methodEasy to usePre-extraction tea treatmentAnimal scienceCardiovascular arteriosclerosis

The invention discloses gingko white tea and a preparation method thereof. The gingko white tea comprises the following components: 45-65 percent of ginkgo leaves and 35-55 percent of white tea. According to the invention, in the process of processing the ginkgo leaves, activation and differentiation of effective components of the ginkgo leaves are solved, the effective components can be leached rapidly when the gingko white tea is brewed, and thus the efficacies of the beneficial components of the gingko white tea are improved and ensured. The gingko white tea is good in mouthfeel and strongin flavor, changes bitter and astringent mouthfeel of common gingko tea and can achieve a health care effect while people enjoy the tea; and all of the prepared gingko astringent, tea bags and blockytea can ensure the beneficial effects of the gingko white tea products, and are simple in the preparation method, convenient to use and easy to be accepted by the public. The gingko white tea disclosed by the invention is novel health tea which has the functions of preventing and treating cerebrovascular and cardiovascular arteriosclerosis, hypertension and senile dementia and simultaneously has the efficacies of detoxifying, bringing down a fever and lowering fire and is the health care tea particularly suitable for drinking in summer.

Owner:徐州绿之野生物食品有限公司

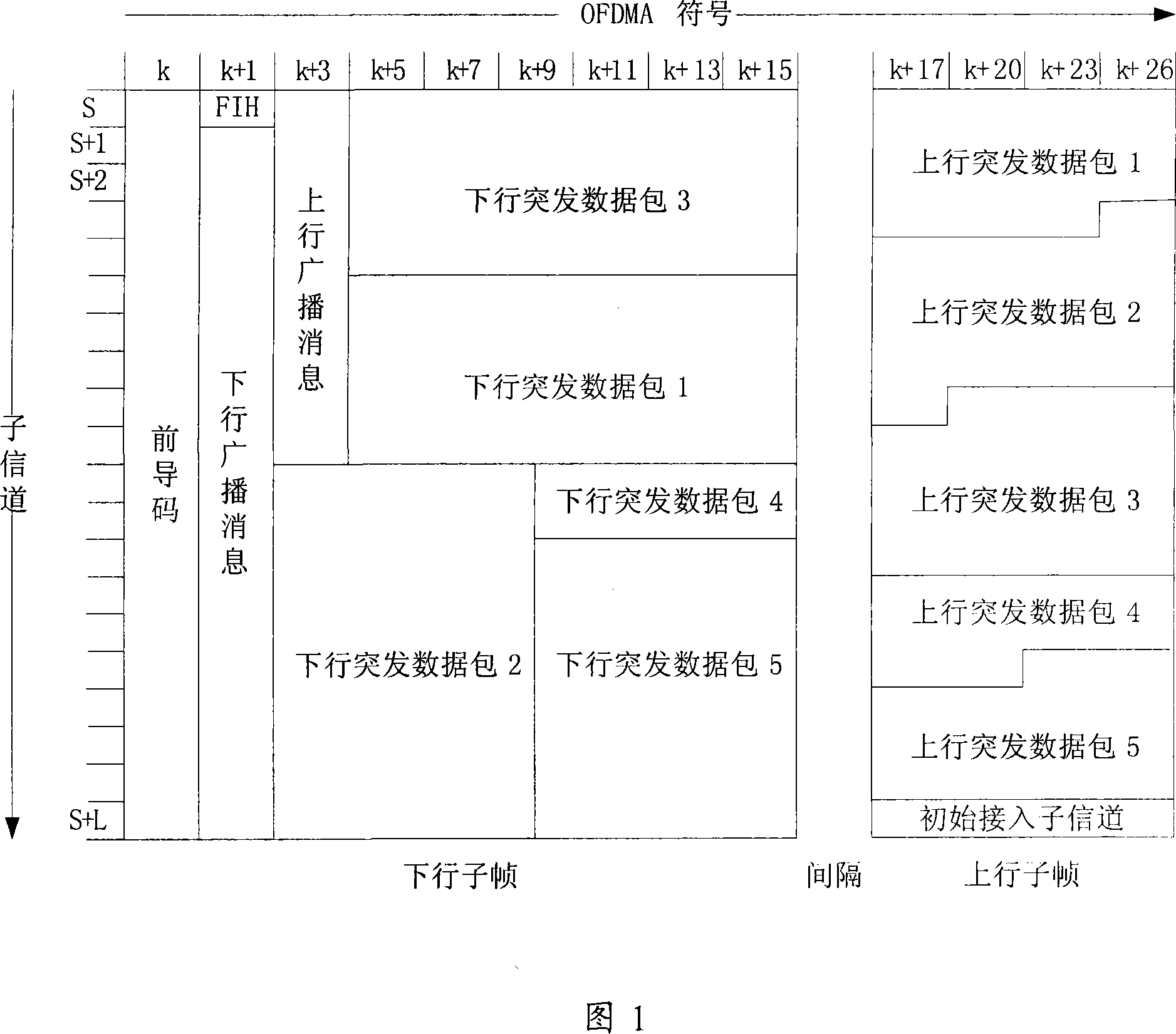

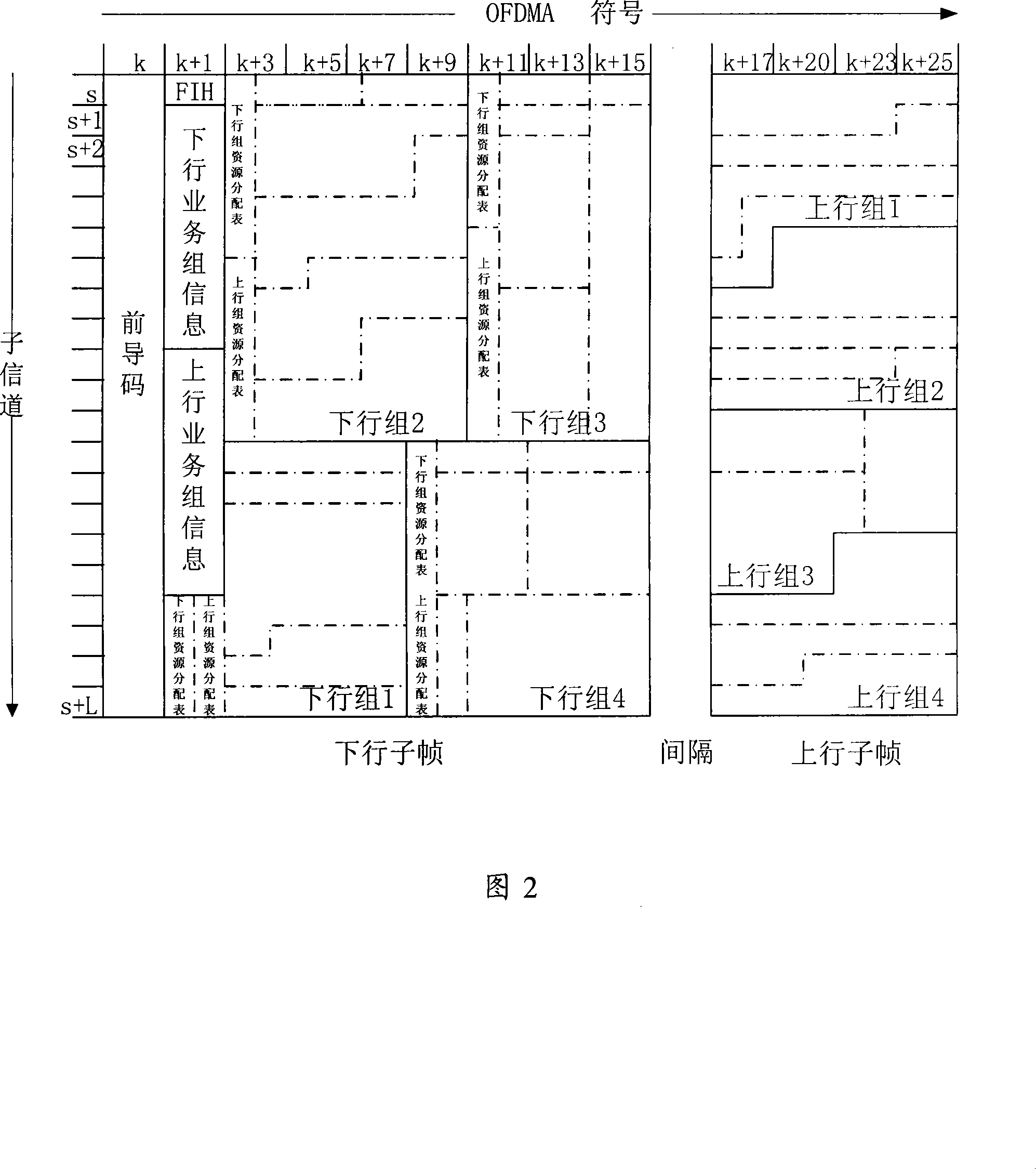

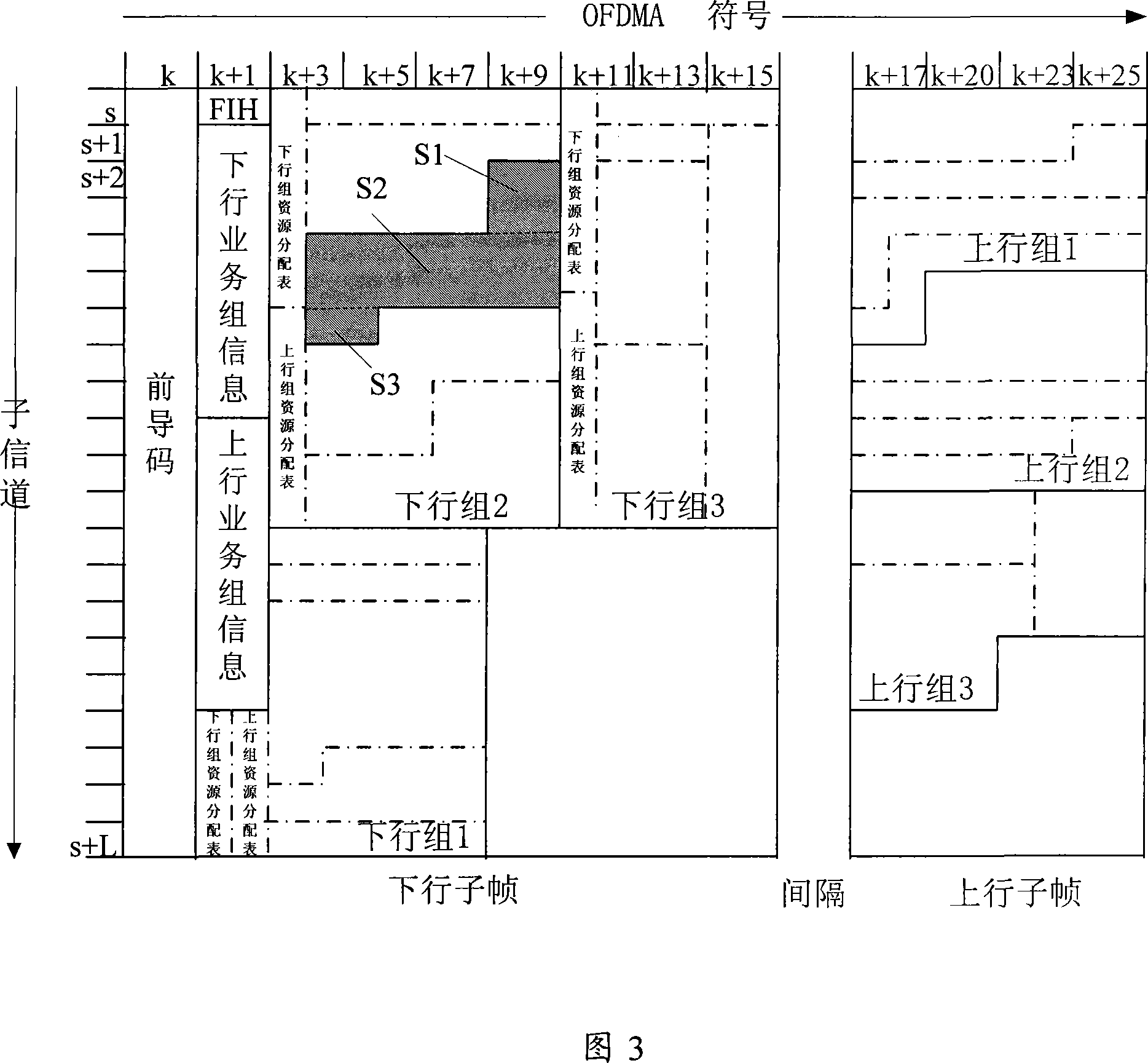

Method and apparatus for packet processing, information interactive method and frame constitution apparatus

InactiveCN101207469AAvoid movingTo overcome the increase of air interface resourcesRadio/inductive link selection arrangementsRadio transmission for post communicationPacket processingFrequency domain

The invention discloses a subgroup processing method and a device, an information alternating method and a frame constructing device. The information alternating method includes the steps that a base station alternates information with a terminal by a frame, the frame includes uplink operation group information, downlink operation group information, an uplink group resource allocation table, a downlink group resource allocation table, and a plurality of gap resource subgroups which are allocated according to the preset attribute and are distributed along the whole frequency domain. Using the embodiment of the invention can avoid the movements of the sub-channels caused by link adaptation among the gap resource subgroups, can overcome the defects that the broadcast information amount increases, the gap resource occupied by the resource allocation indication information increases, and the throughput of the effective data decreases due to the movements of sub-channels among the gap resource subgroups, and can fully ensure the advantageous effect that the two-class broadcast can produce.

Owner:HUAWEI TECH CO LTD

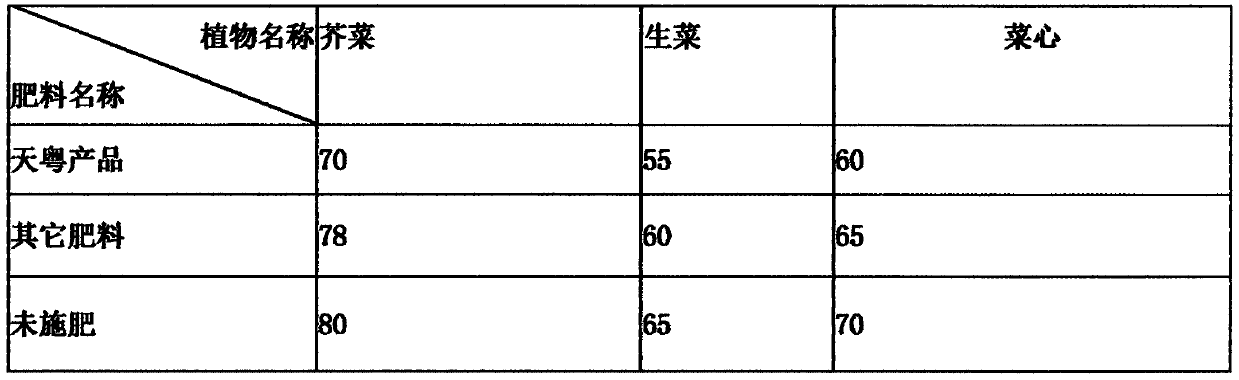

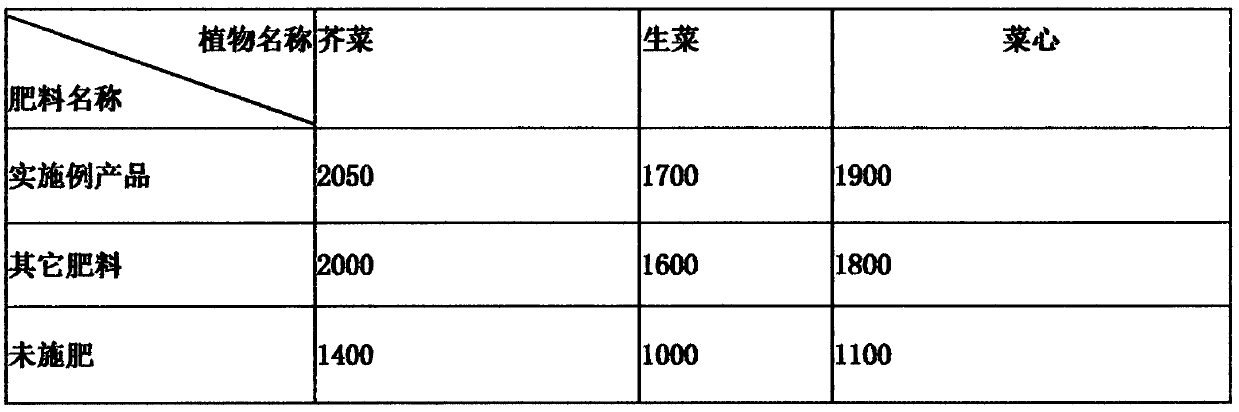

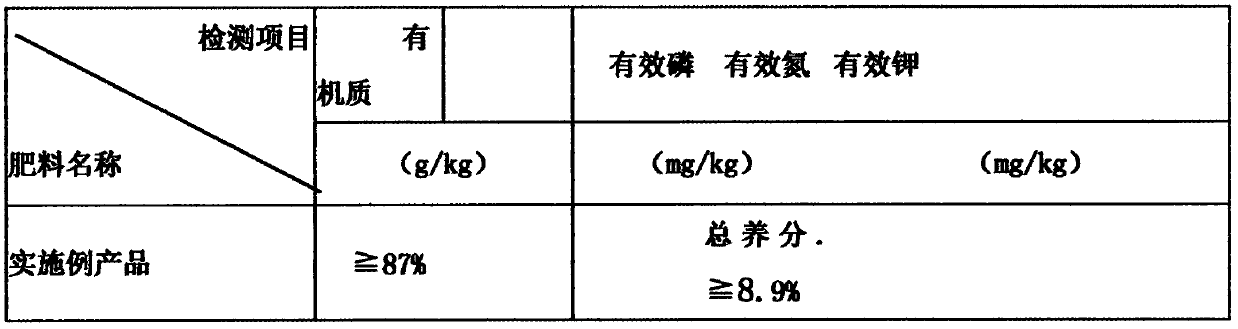

Microbial organic fertilizer and preparation method thereof

InactiveCN109928786AGuaranteed beneficial effectOrganic fertilisersFertilizer mixturesBiotechnologyBacillus licheniformis

The invention relates to a microbial organic fertilizer and a preparation method thereof, and belongs to the field of fertilizers. The microbial organic fertilizer is prepared as follows: seven kindsof bacteria including thermophilic bacillus, bacillus licheniformis, bacillus subtilis, aspergillus oryzae, thermophilic actinomycete, thermophilic fungus and saccharomyces cerevisiae are sealed and fermented according to a certain proportion to form a fermentation liquid, straw is crushed and mixed with rice bran, pig manure urine and trace elements according to a certain proportion to obtain a raw material mixture, the mixed fermentation liquid of the seven kinds of bacteria and the raw material mixture are fully stirred and dried in air according to a certain proportion to obtain the microbial organic fertilizer. The microbial organic fertilizer has the advantages of scientific proportioning, high organic matter content, full fermentation of various strains, environment-friendly raw materials, high fertilizer efficiency and capability of fully protecting ecology and improving soil.

Owner:广州天粤农业科技有限公司

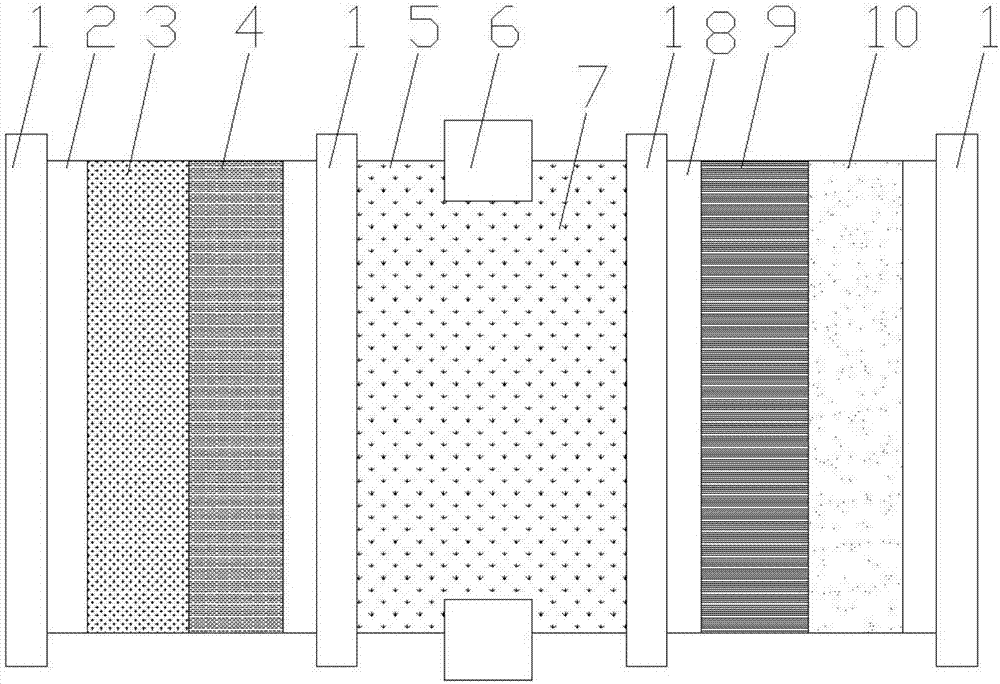

Air purification component for removing chemical pollutants in air

InactiveCN106964207AEasy to makeGuaranteed beneficial effectGas treatmentDispersed particle filtrationAir filterIon exchange

The invention discloses an air purification component for removing chemical pollutants in air. The air purification component comprises a primary filtering device, an atomized air humidification device and a chemical pollutant purification device. The atomized air humidification device is positioned between the primary filtering device and the chemical pollutant purification device. The primary filtering device comprises a primary-efficiency air filtering layer and a medium-efficiency air filtering layer, the atomized air humidification device comprises an atomized air humidifier cavity and an atomizing humidifier generation device, and the chemical pollutant purification device comprises an ion exchange fiber layer and an activated carbon layer. A filter layer of the primary filtering device is formed by PP cotton or nonwoven fabrics, and simplicity in preparation, cheapness and easiness in acquisition of materials and easiness in implementation are realized; by application of ion exchange fibers which are large in specific surface area and exchange capacity and counter ions which are short in mass transfer distance in fiber skeleton carriers and quick in response to the air purification component, the pollutants in air can be removed effectively; by additional arrangement of the atomized air humidification device, effects of the ion exchange fibers are guaranteed.

Owner:MAANSHAN ZHONGCHUANG ENVIRONMENTAL PROTECTION TECH CO LTD

Health-care product containing resveratrol and luteolin as well as preparation method and application of health-care product

InactiveCN107692230AActivate anti-aging genesRejuvenateOrganic chemistryOrganic compound preparationLuteolinSorbitol

The invention discloses a health-care product containing resveratrol and luteolin as well as a preparation method and application of the health-care product. The health-care product comprises a mixture of a resveratrol extract and a luteolin extract, particularly a mixture consisting of the resveratrol extract and the luteolin extract in the mass ratio of the resveratrol extract to the luteolin extract being 1 to 1, and further, white mulberry juice, citric acid, sorbitol and / or edible glycerine mutually cooperate to obtain the health-care product good in mouth feel. The health-care product not only has comprehensive health-care functions and fragrant taste, but also is delicious in taste and convenient to drink, and meets taste requirements of consumers.

Owner:ZHONGKAI UNIV OF AGRI & ENG

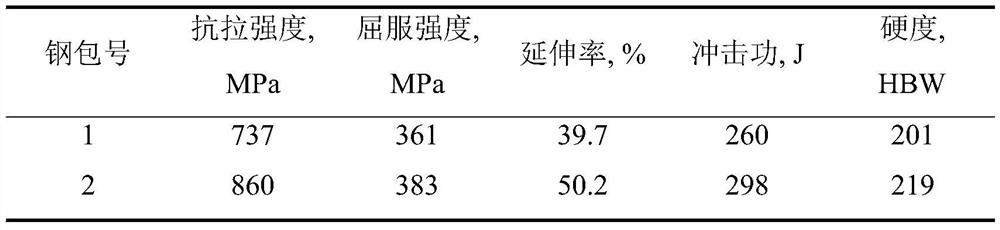

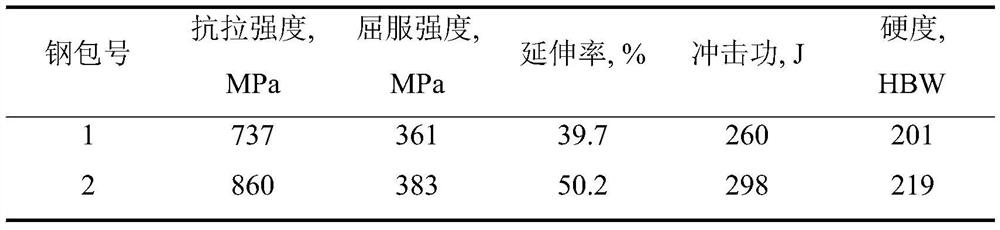

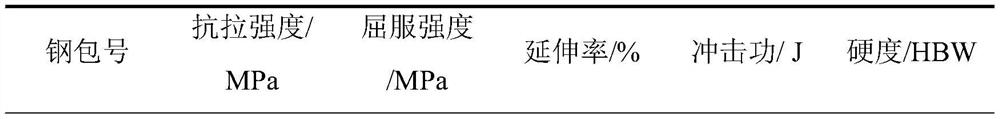

High-manganese steel liquid purification method, high-manganese steel and application of high-manganese steel

The invention provides a high-manganese steel liquid purification method, high-manganese steel and application of the high-manganese steel. High-manganese steel liquid is subjected to deoxidation operation by using a silicon-aluminum-barium-calcium alloy, and after completion, a heavy rare earth alloy is added into the steel liquid so as to achieve the purpose of purifying and microalloying the steel liquid. According to the high-manganese steel liquid purification method, the product and application thereof, a silicon-aluminum-barium-calcium alloy wire is used for deoxidation treatment in advance, so that the beneficial effect of heavy rare earth treatment is guaranteed, the rare earth loss is reduced, and the rare earth yield is improved; blowing nitrogen and feeding heavy rare earth alloy wires are carried out at the same time, and nitrogen and yttrium act synergistically to achieve the purpose of fixing nitrogen and increasing yttrium, so that microalloying treatment of nitrogen and yttrium of high manganese steel is promoted, and purifying and microalloying of the high manganese steel are simultaneously achieved; and after treating by a process technology, the strong plastic toughness, wear resistance and fatigue performance of the high manganese steel are remarkably improved.

Owner:YANSHAN UNIV

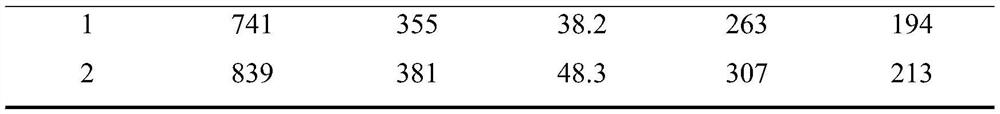

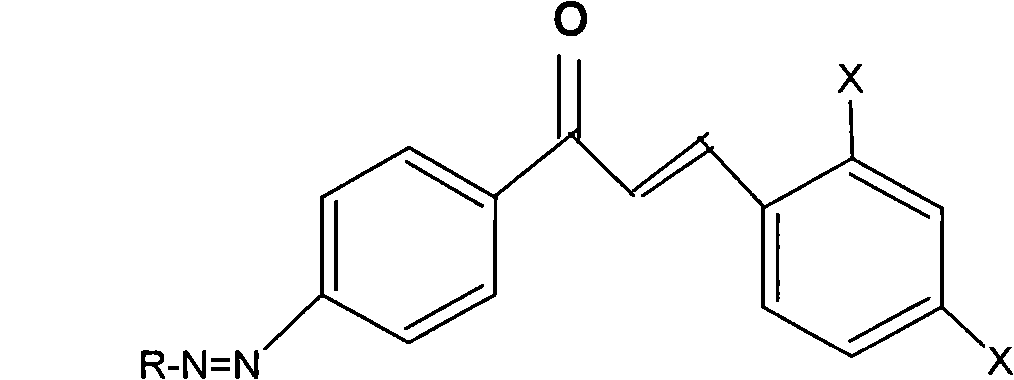

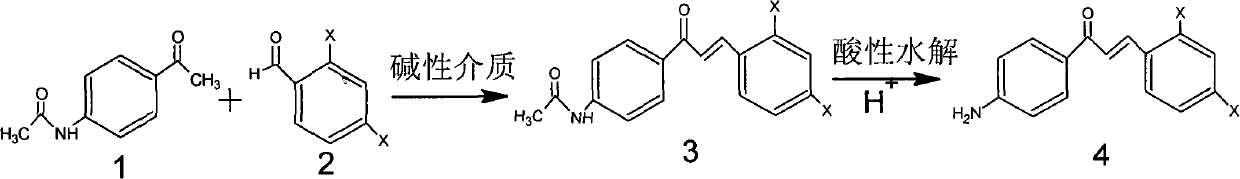

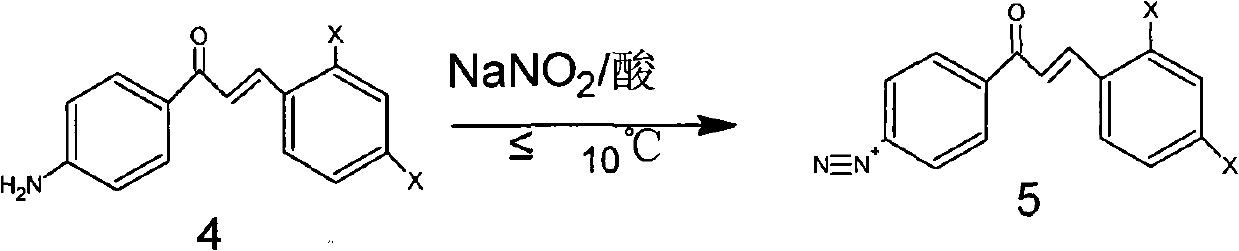

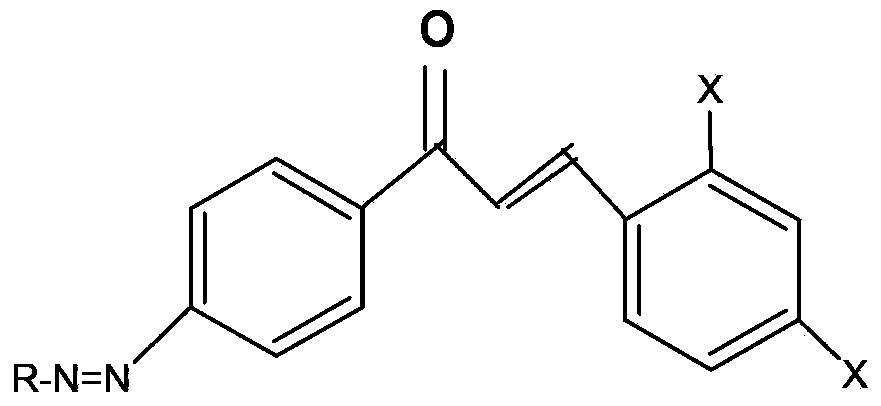

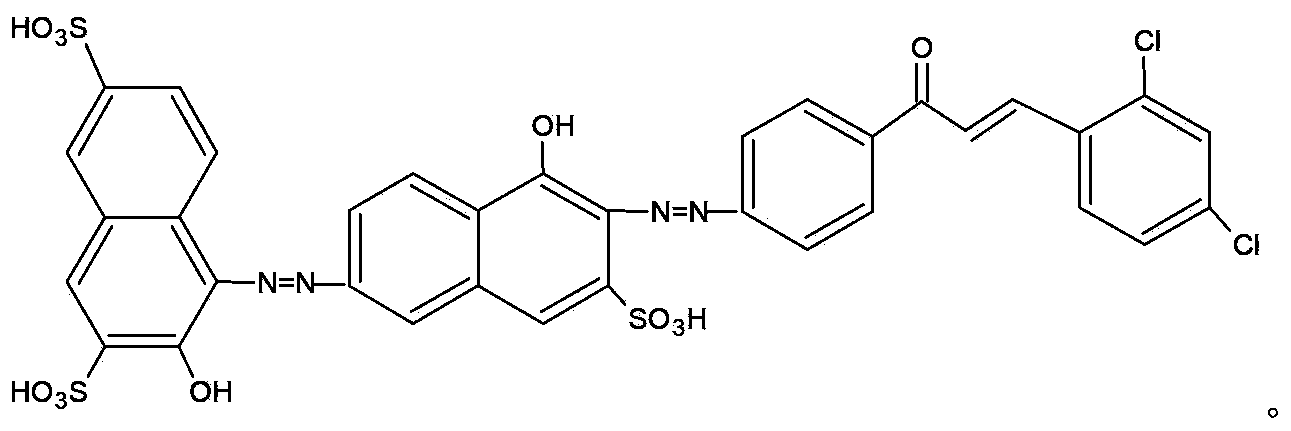

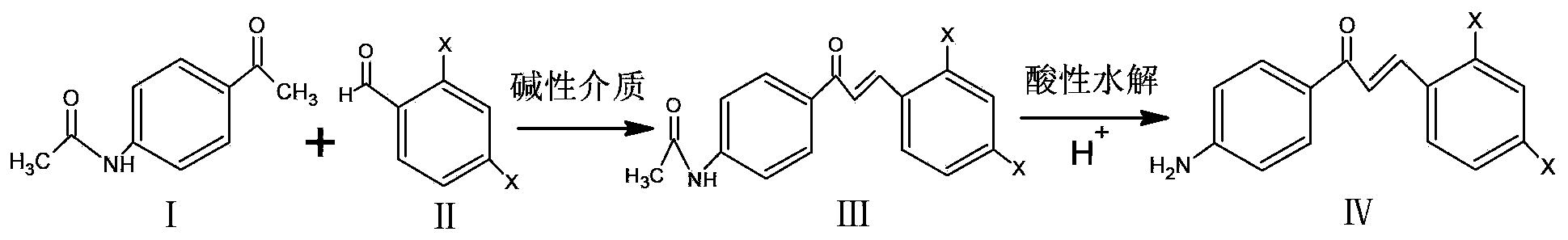

Monoazo and polyazo dyes favorable for health and synthesis method thereof

InactiveCN102146216AGuaranteed beneficial effectImprove living qualityMonoazo dyesSynthesis methodsStructural formula

The invention discloses monoazo and polyazo dyes favorable for health, which have the general formula shown as the description. The monoazo and polyazo dyes are characterized by having the structural formula shown as the description; and the synthesis method comprises the following steps of: (1) synthesizing an amino-containing chalcone dye intermediate; (2) preparing a 4'-amino chalcone derivative dye intermediate into diazonium salt; and (3) coupling the diazonium salt with phenols, aromatic amines, letter acid containing aromatic amino and phenolic hydroxyl, or heterocyclic compounds containing hydroxyl or amino to form heath dyes. By utilizing the health care effect of the chalcone compound and under the condition of keeping the structure of the chalcone compound unchanged, the chalcone derivative containing the aromatic amino is synthesized to serve as the intermediate of the health dyes, and the amino is prepared into diazonium salt, so that the diazonium salt is coupled with a series of aromatic amines and phenols into a series of monoazo and polyazo health dyes; therefore, health and bright clothes are provided for people, the new living standard is improved and the dyes are favorable for human bodies.

Owner:ZHENGZHOU UNIV

A method of mechanized prevention and control of grassland rodents

InactiveCN105594528BIntegrity guaranteedGuaranteed uptimeAnimal repellantsPlant protectionZokorScarification

The invention provides a method for mechanically preventing and controlling rodent damage in grassland. When the rodent damage is mainly caused by superficial layer activity rodent animals such as ochotona alpina, a disc harrow is used in a corresponding region for scarification at the depth being 15cm to 25cm; meanwhile, 45-90-degree repeated operation is performed; when the rodent damage is mainly caused by deep layer activity rodent animals such as zokors, the disc harrow is used for scarification at the depth being 10cm to 15cm; repeated operation is respectively performed after 10 days and 20 days; the operation in each time has 60-degree differences from the former time. The prevention and control method has the advantages that the utilization is simple; an instrument capable of realizing large-scale operation performs proper interference on the grassland; principles of bioinformatics and ecological niche and the like are used for controlling the rodent population density in a proper range so as to achieve the goals of reducing the rodent damage and protecting the grassland.

Owner:LANZHOU UNIVERSITY

Method for preparing guar galactomannose enzymatic hydrolysis solution by compound enzyme method

InactiveCN104711306BEvenly mixedOmit the purification stepFermentationHigh concentrationEnzymatic hydrolysis

The invention discloses a method for preparing guar gum oligogalactomannose enzymolysis solution by using a compound enzyme method, which comprises the following steps: guar gum powder is first mixed with β-mannanase, endoglucanase, The cellobiase is fully mixed; then a citric acid-sodium citrate buffer solution is added to prepare a mixture of guar gum and the three enzymes; after the guar gum is swollen, the enzymolysis temperature and time are controlled for enzymolysis. The invention realizes the simultaneous enzymolysis of three compound enzymes, omits the purification step after sequential degradation of a single enzyme, saves production time and cost, and improves efficiency. The enzymatic hydrolysis of guar gum at a high concentration is realized, and the enzymatic hydrolyzate of galactomannose is obtained, which saves the cost of dehydration and drying in the subsequent production of galactomannose.

Owner:QINGZHOU RONMER BIOLOGY TECH CO LTD

Gingko yellow tea and preparation method thereof

ActiveCN102578324BEfficacy Enhancement and GuaranteeEasy to acceptPre-extraction tea treatmentAdditive ingredientDecomposition

The invention discloses a gingko yellow tea and a preparation method thereof. The gingko yellow tea is composed of 45-65% of gingko leaf and 35-55% of yellow tea. According to the machining and processing process of the gingko leaf, the effective ingredients of the gingko leaf are activated and differentiated, the effective ingredients can be quickly leached when the gingko yellow tea is made, and the efficacy of the beneficial ingredients is improved and guaranteed. The gingko yellow tea disclosed by the invention has good taste and strong fragrance, adverse bitter taste of common gingko teais improved, and people can enjoy the tea tasting process while the health care effect is obtained. The obtained gingko yellow tea, the obtained tea bag and the obtained block tea all can guarantee the beneficial effect of the product of the gingko yellow tea. The preparation method is simple, is convenient to use and is easy to accept by the public. The gingko yellow tea has good efficacy on maldigestion, inappetence and fat decomposition and can satisfy the selection requirements of people with bad gastrointestinal function and obese people.

Owner:徐州绿之野生物食品有限公司

Gingko snow tea and preparation method thereof

ActiveCN102578323BEfficacy Enhancement and GuaranteeEasy to acceptPre-extraction tea treatmentAdditive ingredientBlack tea

The invention discloses a ginkgo snow tea and a preparation method thereof. The ginkgo snow tea is composed of 65-85% of ginkgo leaves and 15-35% of snow tea. Through the processing process carried out on the ginkgo leaves, active ingredients of the ginkgo leaves are activated and differentiated, and the active ingredients of the ginkgo leaves can be rapidly leached when the ginkgo snow tea is brewed, thus effects of beneficial ingredients of the ginkgo leaves are improved and guaranteed. The ginkgo snow tea disclosed by the invention has good taste and strong fragrance, undesirable bitter and acerbic senses of common ginkgo tea are changed, people can obtain health care effect while enjoying the tea, beneficial effects of the prepared ginkgo snow tea, tea bags and block tea can be guaranteed, and the preparation method is simple, is easy to operate and can be accepted easily by the masses. The gingko snow tea disclosed by the invention is a novel health care tea used for preventing and treating cerebral vascular and cardiovascular arteriosclerosis, hypertension and senile dementia, has the effects of clearing heat and removing toxicity, removing fire and reducing phlegm, promoting the secretion of saliva or body fluid and relieving a cough, clearing liver and improving eyesight as well as restoring consciousness and calming the nerves and has the health care effect for a patient.

Owner:徐州绿之野生物食品有限公司

Gingko/broadleaf holly tea and preparation method thereof

ActiveCN102550763BEfficacy Enhancement and GuaranteeEasy to acceptTea substituesCEREBROVASCULAR ARTERIOSCLEROSISAdditive ingredient

The invention discloses gingko / broadleaf holly tea and a preparation method thereof. The gingko / broadleaf holly tea contains 65% to 85% of ginkgo leaves and 15% to 35% of broadleaf holly leaves. The ginkgo leaves are processed and treated to activate and differentiate effective components of ginkgo leaves, and the effective components can be rapidly released during tea infusion, so that the efficacy of effective components is improved and guaranteed. The gingko / broadleaf holly tea has a good taste and mellow fragrance, is free of bitter and astringent taste of the common gingko tea, and can improve the health of people who enjoy the tea. The prepared gingko / broadleaf holly tea, bagged gingko / broadleaf holly tea and blocky gingko / broadleaf holly tea has good benefits, are easy to prepare and convenient to use, and are well accepted by people. The gingko / broadleaf holly tea helps prevent and treat cardiovascular arteriosclerosis, cerebrovascular arteriosclerosis, hypertension and seniledementia. Particularly, broadleaf holly tea has a better therapeutic effect on hypertension and hyperlipoidemia, and the combination of broadleaf holly leaf and gingko leaf is good for health improvement.

Owner:徐州绿之野生物食品有限公司

A kind of processing method of ginkgo leaf tea

Owner:徐州绿之野生物食品有限公司

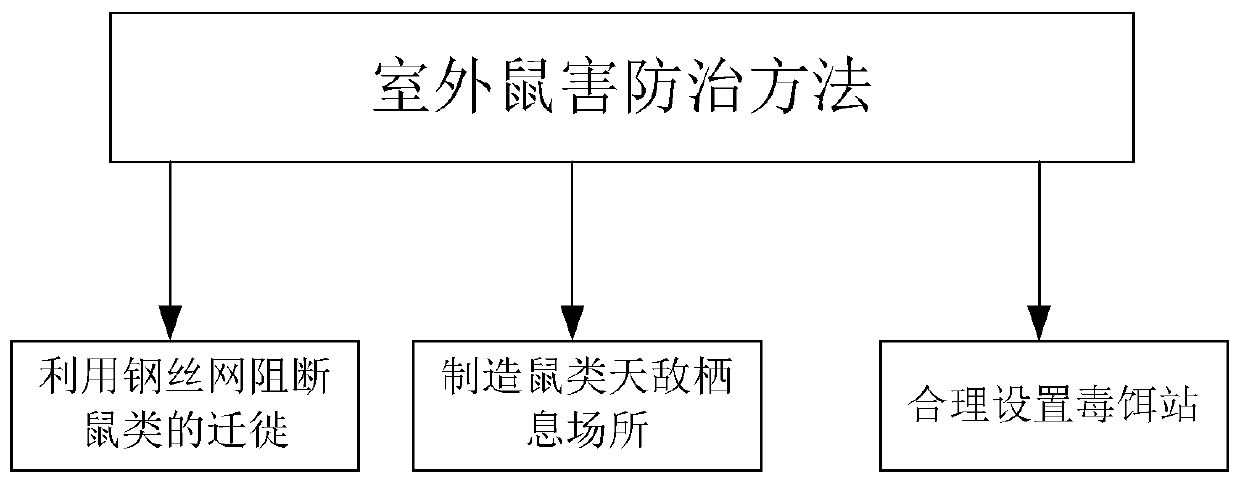

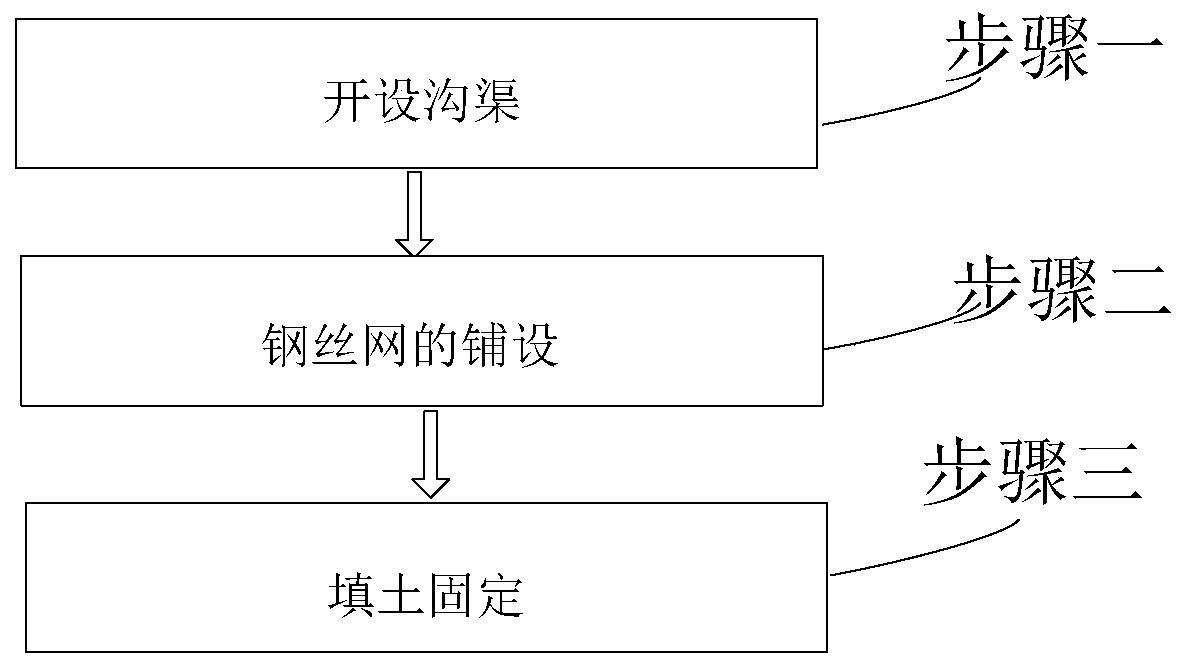

Outdoor rodent pest control method

InactiveCN110973107AEffective destructionReduce churnAnimal repellantsPoisonAgricultural scienceEnvironmental engineering

The invention provides an outdoor rodent pest control method. The method comprises cutting off migration paths of rodents by utilizing steel wire gauzes, establishing rodent enemy habitats and reasonably setting poison bait stations; according to the way of cutting off the migration paths of rodents by utilizing the steel wire gauzes, migration and spreading paths of subterranean rodents are cut off by zones, and the steel wire gauzes hinder and disturb probing of the subterranean rodents on vibration waves, and limit mating and normal activities of the subterranean rodents. According to the outdoor rodent pest control method, by combining physical control with medical prevention, the control effect is improved; the migration paths of the rodents are cut off by utilizing the steel wire gauzes, and thus, the function of protecting a local biologic chain is exerted; and environmental pollution can be avoided, so that an ecological system has a positive cycle, and biological diversity iskept.

Owner:上海蒂锦特环境科技发展有限公司

A method for high-efficiency recycling of waste aluminum to cast aluminum alloy

The invention discloses a method for efficiently regenerating cast aluminum alloy by aluminum scraps. The method for efficiently regenerating cast aluminum alloy by aluminum scraps comprises the following processes of: screening, smelting, alloy-mixing and pouring, wherein the screening process specifically comprises the following step of: removing impurities and moisture in the aluminum scraps; the smelting process specifically comprises the step of melting and stirring the aluminum scraps after the screened aluminum scraps are charged, so that the slag is removed; the alloy-mixing process specifically comprises the following steps of: adding 9%-11% (in percentage by weight) of Si and 0.8%-1.1% of Fe when the temperature of the impurity-removed aluminum scrap solution reaches 680 DEG C to 740 DEG C, keeping the temperature after the components are uniformly stirred and removing the slag; and the casting process specifically comprises the following step of: pouring the slag-removed molten aluminum to the mould to obtain the cast aluminum alloy ingot or the aluminum alloy casting piece. According to the method for efficiently regenerating cast aluminum alloy by aluminum scraps, the aluminum scraps are enabled to reach the technical requirements of the cast aluminum alloy by aluminum scrap screening and alloy mixing, and therefore, the method has the advantages of being simple in process, strong in aluminum scrap adaptability, stable in aluminum alloy stability, low in cost, and high in aluminum recycling rate.

Owner:YUNNAN AOKAI TECH DEV

Ginkgo black tea and preparation method thereof

ActiveCN102578325BEfficacy Enhancement and GuaranteeEasy to acceptPre-extraction tea treatmentFlavorAdditive ingredient

The invention discloses ginkgo black tea and a preparation method thereof. The ginkgo black tea comprises the following components: 45-65 percent of ginkgo leaves and 35-55 percent of black tea. According to the invention, in the process of processing the ginkgo leaves, activation and differentiation of effective components of the ginkgo leaves are solved, the effective components can be leached rapidly when the gingko black tea is brewed, and thus the efficacies of the beneficial components of the gingko black tea are improved and ensured. The gingko black tea is good in mouthfeel and strongin flavor, changes bitter and astringent mouthfeel of common gingko tea and can achieve a health care effect while people enjoy the tea; and all of the prepared gingko astringent, tea bags and blockytea can ensure the beneficial effects of the gingko black tea products, and are simple in the preparation method, convenient to use and easy to be accepted by the public. The black tea in the ginkgo black tea is warm in nature and good at warming the middle Jiao and expelling cold as well as warming the stomach. The ginkgo black tea disclosed by the invention is particularly suitable for people who suffer from stomach cold and spleen deficiency.

Owner:徐州绿之野生物食品有限公司

A kind of high manganese steel molten steel purification method, product and application

The invention provides a high manganese steel molten steel purification method, product and application. The high manganese steel molten steel uses a silicon aluminum barium calcium alloy for deoxidation operation, and after completion, a heavy rare earth alloy is added to the molten steel to achieve purification and microalloying The purpose of molten steel. In the present invention, the beneficial effect of heavy rare earth treatment is ensured by using silicon aluminum barium calcium alloy wire in advance for deoxidation treatment, the loss of rare earth is reduced, and the yield of rare earth is improved; nitrogen blowing and heavy rare earth alloy wire feeding are carried out at the same time, and nitrogen and yttrium are synergistic function, play the role of nitrogen fixation and increase yttrium, promote the microalloying treatment of nitrogen and yttrium in high manganese steel, and realize the purification and microalloying of high manganese steel; , wear resistance and fatigue performance are significantly improved.

Owner:YANSHAN UNIV

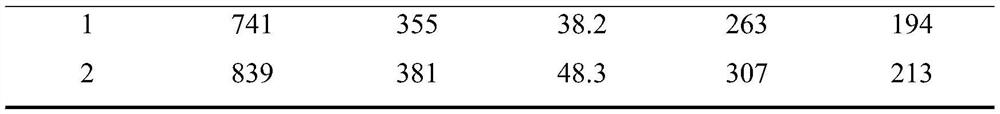

Production process for Brasenia schreberi tea and Brasenia schreberi tea

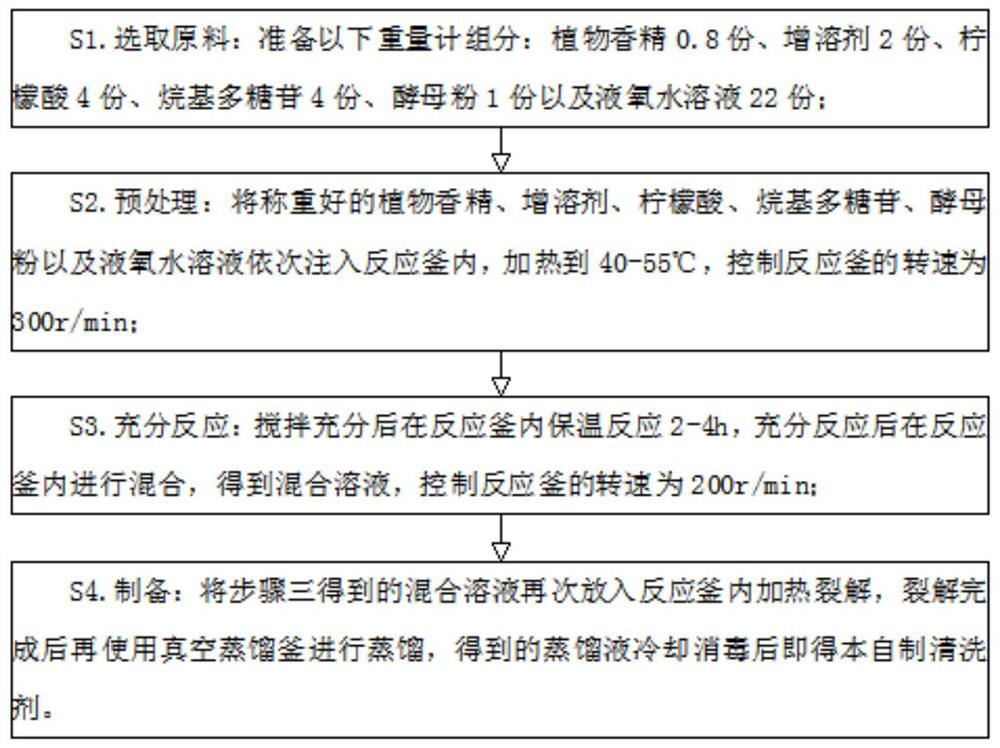

PendingCN113068753ARelaxReduce incidenceInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEngineeringToxic material

The invention discloses a production process for Brasenia schreberi tea and the Brasenia schreberi tea. A key of the technical scheme of the invention is as follows: the production process for the Brasenia schreberi tea comprises the following steps: S1: accepting Brasenia schreberi reaching acceptance check standards, and storing the Brasenia schreberi into a storehouse; S2: carrying out grading and screening on the Brasenia schreberi in the storehouse according to quality standards enterprise standard, and carrying out classified placement after screening; S3: rinsing the Brasenia schreberi screened and graded in the S2 with cleaning equipment, and carrying out moisture draining after the rinsing is completed; and S4: tiling the Brasenia schreberi drained in the S3 on meshed plates made from stainless steel, and blowing the Brasenia schreberi with cold air until the surface of the Brasenia schreberi is dry. Through drinking the Brasenia schreberi tea prepared by the production process for a long term, the effects of clearing away heat and toxic materials, protecting and strengthening the stomach, lowering probability of disease occurrence, treating insomnia and resting and restoring energy, and delighting mind and body can be achieved.

Owner:苏州东山东湖莼菜厂

Ginkgo dark tea and method for preparing same

ActiveCN102578321BEfficacy Enhancement and GuaranteeEasy to acceptPre-extraction tea treatmentAcute hyperglycaemiaUltraviolet irradiation

The invention discloses a ginkgo dark tea and a method for preparing the ginkgo dark tea. The ginkgo dark tea comprises 45-65% of ginkgo leaves and 35-55% of dark tea. The ginkgo leaves are processed to activate and differentiate the active components in the ginkgo leaves so that the active components can be extracted rapidly when the ginkgo dark tea is infused and the efficacy of the beneficial components can be guaranteed or improved. The ginkgo dark tea disclosed by the invention has good taste and strong aroma, has no bitter and astringent taste of the common ginkgo tea. People can enjoy drinking the ginkgo dark tea, and the health care effect can be achieved. The quality of the prepared ginkgo dark tea, bagged tea and bulk tea can be guaranteed. The ginkgo dark tea is easy to prepareand drink and can be easily accepted by people. The ginkgo dark tea has a high content of polysaccharide and strong activity, has good effects of resisting ultraviolet irradiation and treating senileosteoporosis and is more suitable for the patients with hyperlipemia and hyperglycemia, the elderly and people working in the sunshine to drink.

Owner:徐州绿之野生物食品有限公司

Gingko white tea and preparation method thereof

ActiveCN102578320BEfficacy Enhancement and GuaranteeEasy to acceptPre-extraction tea treatmentFlavorAnimal science

The invention discloses gingko white tea and a preparation method thereof. The gingko white tea comprises the following components: 45-65 percent of ginkgo leaves and 35-55 percent of white tea. According to the invention, in the process of processing the ginkgo leaves, activation and differentiation of effective components of the ginkgo leaves are solved, the effective components can be leached rapidly when the gingko white tea is brewed, and thus the efficacies of the beneficial components of the gingko white tea are improved and ensured. The gingko white tea is good in mouthfeel and strongin flavor, changes bitter and astringent mouthfeel of common gingko tea and can achieve a health care effect while people enjoy the tea; and all of the prepared gingko astringent, tea bags and blockytea can ensure the beneficial effects of the gingko white tea products, and are simple in the preparation method, convenient to use and easy to be accepted by the public. The gingko white tea disclosed by the invention is novel health tea which has the functions of preventing and treating cerebrovascular and cardiovascular arteriosclerosis, hypertension and senile dementia and simultaneously has the efficacies of detoxifying, bringing down a fever and lowering fire and is the health care tea particularly suitable for drinking in summer.

Owner:徐州绿之野生物食品有限公司

Gingko Pu-Er ripe tea and preparation method thereof

ActiveCN102578318BEfficacy Enhancement and GuaranteeEasy to acceptPre-extraction tea treatmentFlavorAlcohol

Owner:北京锡纯中医研究院

Ginkgo oolong tea and preparation method thereof

ActiveCN102578322BEfficacy Enhancement and GuaranteeEasy to acceptPre-extraction tea treatmentFlavorAdditive ingredient

The invention discloses ginkgo oolong tea and a preparation method thereof. The ginkgo oolong tea comprises the following components: 45-65 percent of ginkgo leaves and 35-55 percent of oolong tea. According to the invention, in the process of processing the ginkgo leaves, activation and differentiation of effective components of the ginkgo leaves are solved, the effective components can be leached rapidly when the gingko oolong tea is brewed, and thus the efficacies of the beneficial components of the gingko oolong tea are improved and ensured. The gingko oolong tea is good in mouthfeel and strong in flavor, changes bitter and astringent mouthfeel of common gingko tea and can achieve a health care effect while people enjoy the tea; and all of the prepared gingko astringent, tea bags and blocky tea can ensure the beneficial effects of the gingko oolong tea products, and are simple in the preparation method, convenient to use and easy to be accepted by the public.

Owner:徐州绿之野生物食品有限公司

Gingko Pu'er raw tea and preparation method thereof

ActiveCN102578319BEfficacy Enhancement and GuaranteeEasy to acceptPre-extraction tea treatmentAlcoholAdditive ingredient

The invention discloses a ginkgo Pu'er raw tea and a preparation method thereof. The ginkgo Pu'er raw tea is composed of 45-65% of ginkgo leaves and 35-55% of Pu'er raw tea. Through the processing process carried out on the ginkgo leaves, active ingredients of the ginkgo leaves are activated and differentiated, and the active ingredients of the ginkgo leaves can be rapidly leached when the ginkgoPu'er raw tea is brewed, thus effects of beneficial ingredients of the ginkgo leaves are improved and guaranteed. The ginkgo Pu'er raw tea disclosed by the invention has good taste and strong fragrance, undesirable bitter and acerbic senses of common ginkgo Pu'er raw tea are changed, people can obtain health care effect while enjoying the tea, beneficial effects of the prepared ginkgo Pu'er raw tea, tea bags and block tea can be guaranteed, and the preparation method is simple, is easy to operate and can be accepted by the masses easily. The ginkgo Pu'er raw tea disclosed by the invention is a novel health care tea used for preventing and treating cerebral vascular and cardiovascular arteriosclerosis, hypertension and senile dementia and has the effects of diuresis, digestion aid, dispelling the effects of alcohol, losing weight, enhancing appetite, dispelling wind and relieving exterior syndrome as well as clearing head and eyes.

Owner:徐州绿之野生物食品有限公司

Monoazo and polyazo dyes favorable for health and synthesis method thereof

InactiveCN102146216BGuaranteed beneficial effectImprove living qualityMonoazo dyesSynthesis methodsStructural formula

Owner:ZHENGZHOU UNIV

Gingko green tea and preparation method thereof

ActiveCN102550739BEfficacy Enhancement and GuaranteeEasy to acceptPre-extraction tea treatmentAdditive ingredientGinkgo biloba

Owner:徐州绿之野生物食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com