High-manganese steel liquid purification method, high-manganese steel and application of high-manganese steel

A high-manganese steel and molten steel technology, applied in the field of high-manganese steel, can solve the problems of rare earth waste, incomplete melting, uneven distribution of additives, etc., and achieve the effect of reducing the content of impurity elements and the number of inclusions, and improving fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

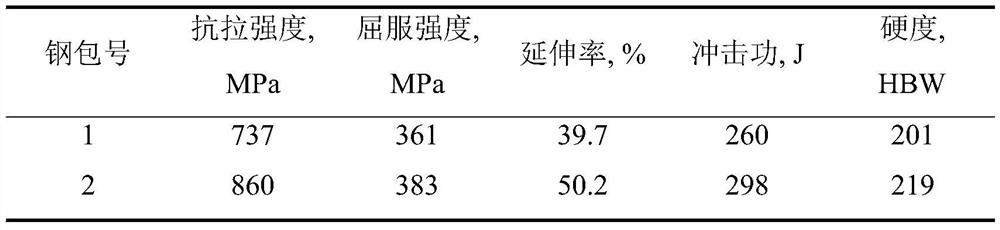

Embodiment 1

[0028] The high manganese steel is smelted in an electric arc furnace, and the high manganese steel molten steel is poured into two 10-ton ladles of the same capacity when the steel is tapped at 1500°C, which are respectively recorded as No. 1 ladle and No. 2 ladle. Ladle No. 1 is used to produce high manganese steel frogs according to the conventional deoxidation and casting process (using aluminum wire for deoxidation operation, and the casting process is common casting). After the No. 2 ladle is poured into molten steel, high-purity nitrogen gas is introduced into the bottom of the ladle immediately, and the nitrogen pressure is kept at 0.4MPa. First, feed silicon-aluminum-barium-calcium alloy wire with a diameter of 13mm into the molten steel, the amount added is 10m per ton of steel, and the wire feeding speed is 10m / s to complete the deoxidation treatment of the high manganese steel molten steel. Then feed the special heavy rare earth alloy wire with a diameter of 13mm i...

Embodiment 2

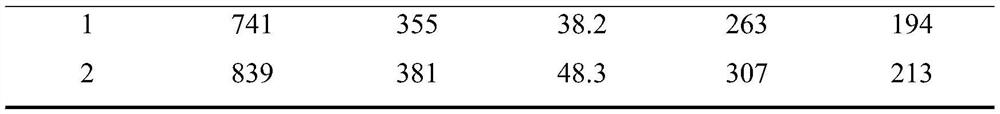

[0035] The high-manganese steel is smelted in an electric arc furnace, and the molten steel is poured into two ladles of the same capacity when the steel is tapped at 1495°C, which are respectively recorded as No. 1 ladle and No. 2 ladle. Ladle No. 1 is used to produce high manganese steel frogs according to the conventional deoxidation and casting process (using aluminum wire for deoxidation operation, and the casting process is common casting). After the No. 2 ladle is poured into molten steel, high-purity nitrogen gas is introduced into the bottom of the ladle immediately, and the nitrogen pressure is kept at 0.5MPa. Firstly, feed silicon-aluminum-barium-calcium alloy wire with a diameter of 13mm into the molten steel, the amount added is 11m per ton of steel, and the wire feeding speed is 9m / s to complete the deoxidation treatment of the high manganese steel molten steel. Then feed the special heavy rare earth alloy wire with a diameter of 13mm into the molten steel. The c...

Embodiment 3

[0042] The high manganese steel is smelted in an electric arc furnace, and the high manganese steel molten steel is tapped at 1500°C. The deoxidation operation is to insert pure aluminum to remove oxygen. The insertion amount is 1.2kg / ton of steel. During the deoxidation process, nitrogen is not blown into the ladle. Then feed the special heavy rare earth alloy wire with a diameter of 13mm into the molten steel. The chemical composition (wt.%) of the heavy rare earth alloy is RE: 42% (wherein Y accounts for 60% of the total rare earth, La accounts for 15%, Ce 25%), Si: 6%, Al: 13%, Ba: 10%, Ca: 11%, and the balance is Fe. The addition amount of heavy rare earth alloy wire is 11m per ton of steel, and the addition speed is 6m / s. When the molten steel cools down to 1450°C, start casting high manganese steel frogs. Manufacture high manganese steel frog casting cavity by fat hardening molding process. After testing, the chemical composition (wt.%) of the cast high manganese stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com