Production process for Brasenia schreberi tea and Brasenia schreberi tea

A production process and technology of water shield, applied in tea substitutes, detergent compositions, detergent compounding agents, etc., can solve problems such as injury, large pesticide residues, and tea without health care effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

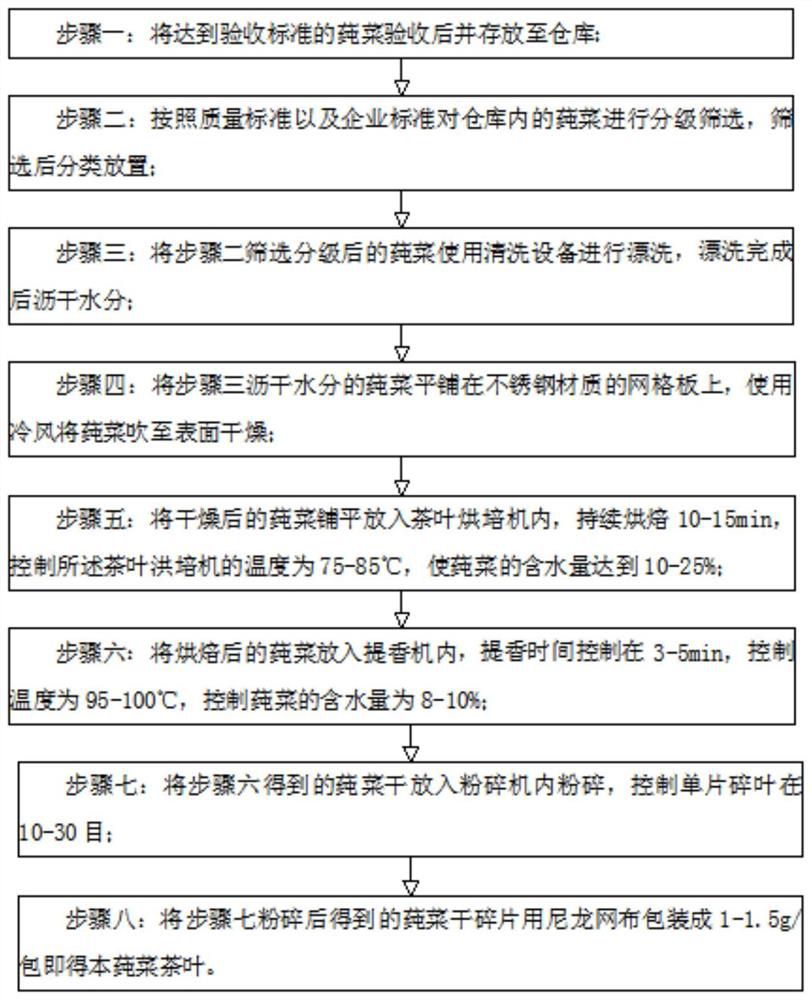

[0038] A kind of manufacture craft of water shield tealeaves and water shield tealeaves, a kind of manufacture craft of water shield tealeaves, comprises the following steps:

[0039] Step 1: Accept the water shield that meets the acceptance criteria and store it in the warehouse;

[0040] Step 2: Grading and screening the water shield in the warehouse according to the quality standards and enterprise standards, and sorting and placing them after screening;

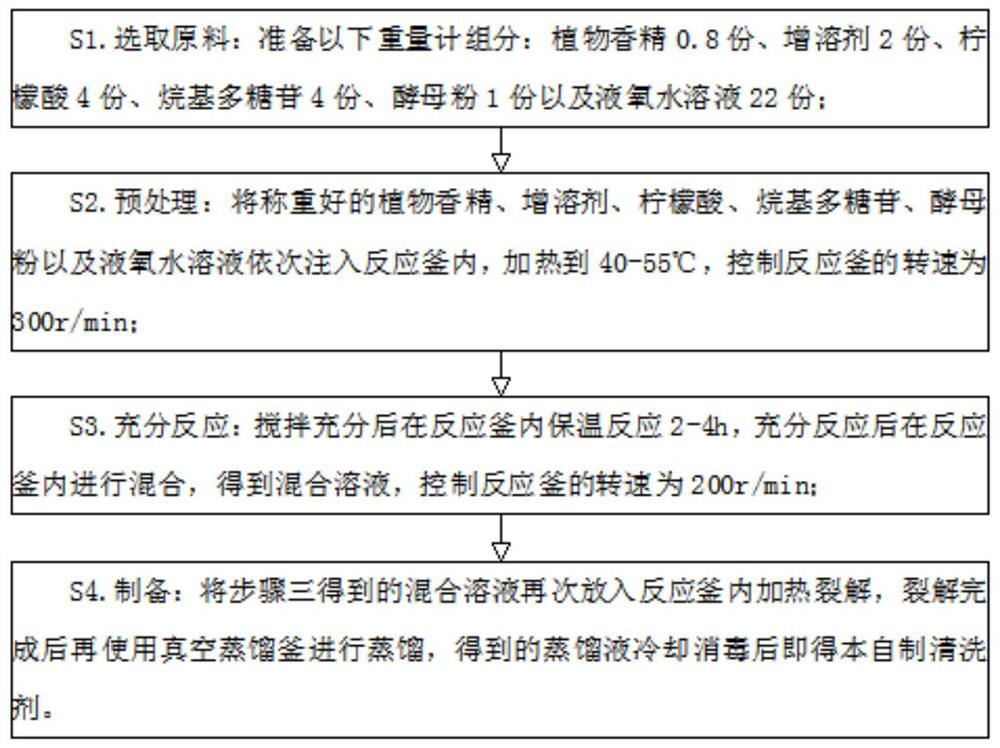

[0041] Step 3: Rinse the water shield after screening and grading in Step 2 with cleaning equipment, and drain the water after rinsing;

[0042] Step 4: Spread the water shield drained in step 3 on a stainless steel grid plate, and use cold wind to blow the water shield to the surface to dry;

[0043] Step 5: Put the dried water shield into the tea roasting machine, continue to bake for 10 minutes, control the temperature of the tea roasting machine at 85°C, and make the water content of water shield reach 25%;

[0044]...

Embodiment 2

[0066] A kind of manufacture craft of water shield tealeaves and water shield tealeaves, a kind of manufacture craft of water shield tealeaves, comprises the following steps:

[0067] Step 1: Accept the water shield that meets the acceptance criteria and store it in the warehouse;

[0068] Step 2: Grading and screening the water shield in the warehouse according to the quality standards and enterprise standards, and sorting and placing them after screening;

[0069] Step 3: Rinse the water shield after screening and grading in Step 2 with cleaning equipment, and drain the water after rinsing;

[0070] Step 4: Spread the water shield drained in step 3 on a stainless steel grid plate, and use cold wind to blow the water shield to the surface to dry;

[0071] Step 5: Put the dried water shield into the tea roasting machine and continue to bake for 15 minutes. Control the temperature of the tea roasting machine to 75°C so that the water content of water shield reaches 10%;

[00...

Embodiment 3

[0082] A kind of manufacture craft of water shield tealeaves and water shield tealeaves, a kind of manufacture craft of water shield tealeaves, comprises the following steps:

[0083] Step 1: Accept the water shield that meets the acceptance criteria and store it in the warehouse;

[0084] Step 2: Grading and screening the water shield in the warehouse according to the quality standards and enterprise standards, and sorting and placing them after screening;

[0085] Step 3: Rinse the water shield after screening and grading in Step 2 with cleaning equipment, and drain the water after rinsing;

[0086] Step 4: Spread the water shield drained in step 3 on a stainless steel grid plate, and use cold wind to blow the water shield to the surface to dry;

[0087] Step 5: Put the dried water shield into the tea roasting machine, continue to bake for 15 minutes, control the temperature of the tea roasting machine at 75°C, and make the water content of water shield reach 15%;

[0088]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com