Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "No restrictions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

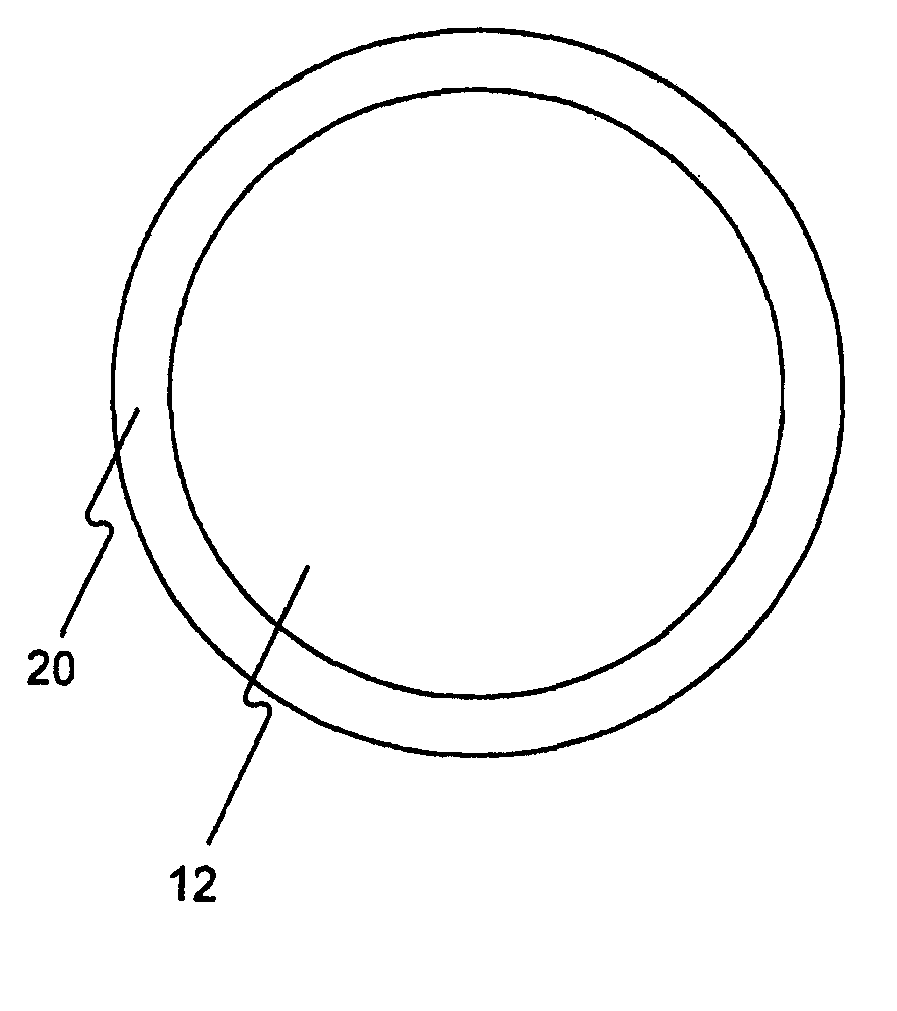

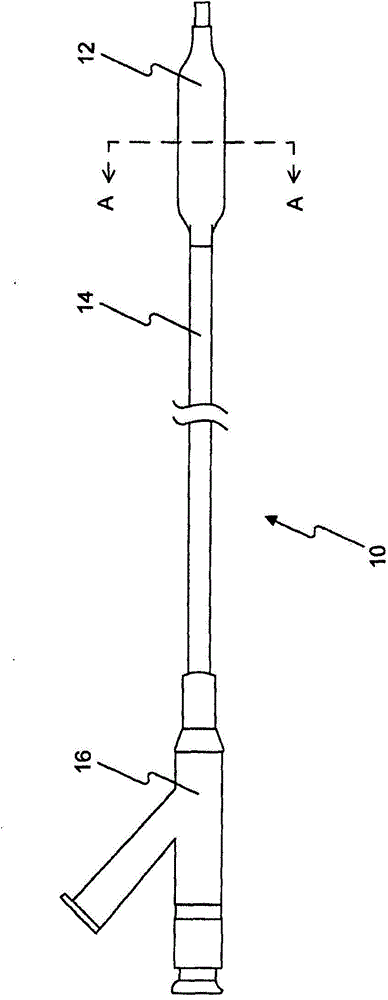

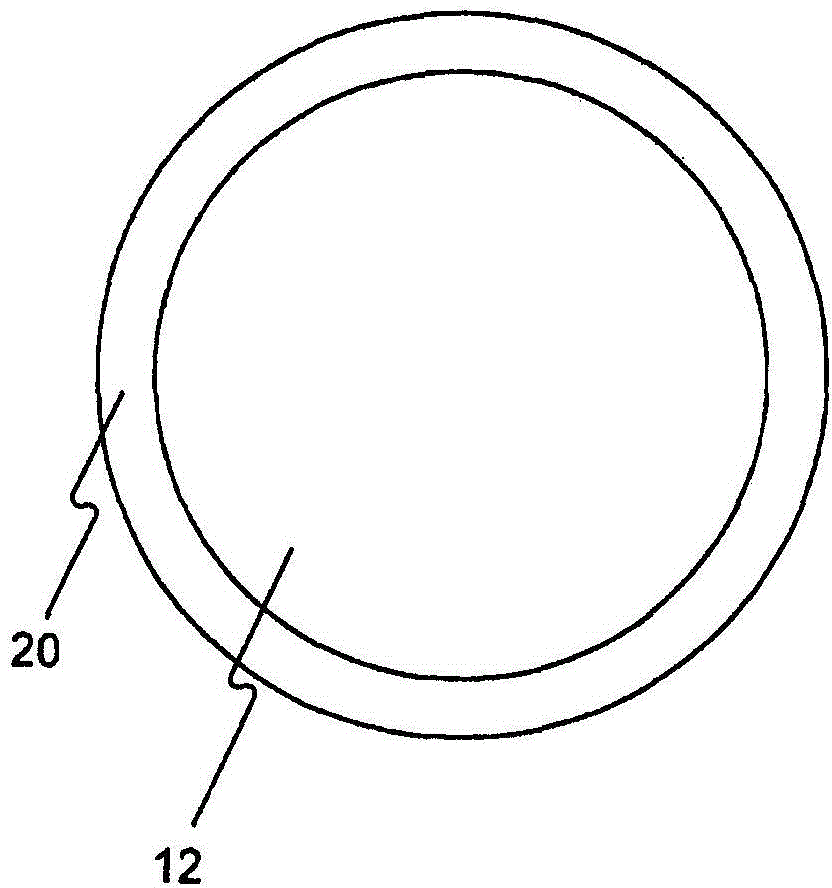

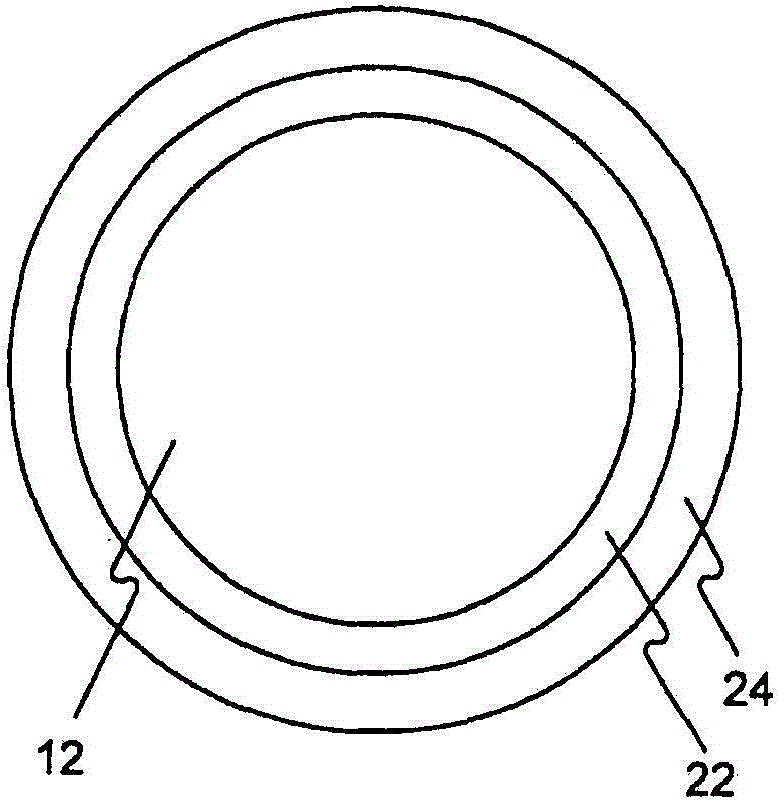

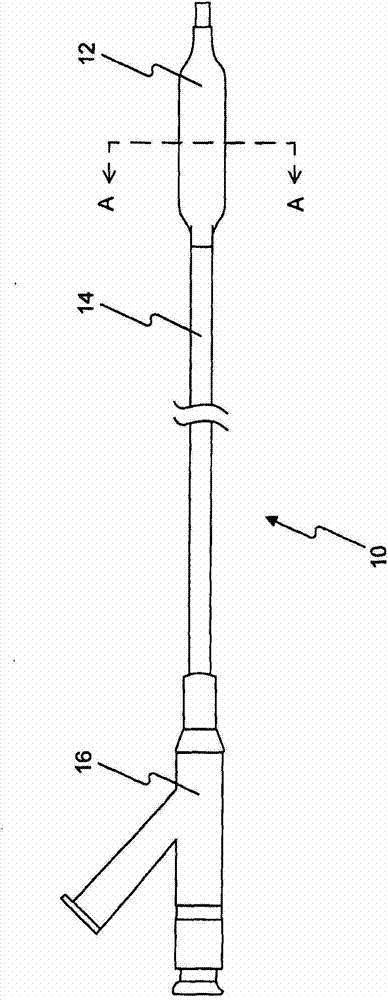

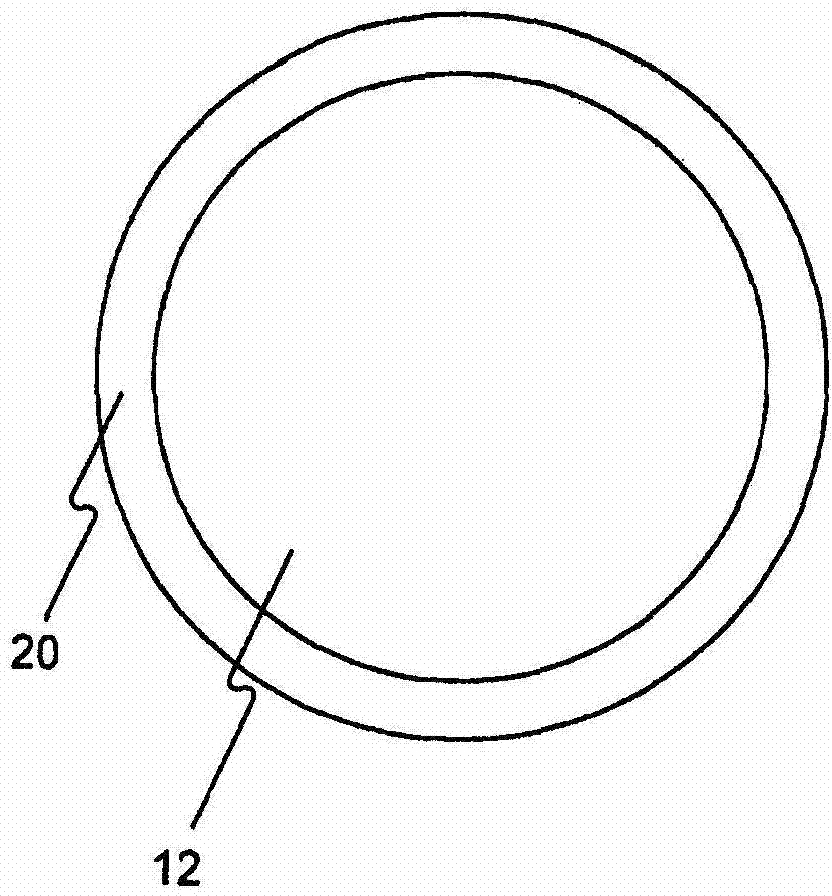

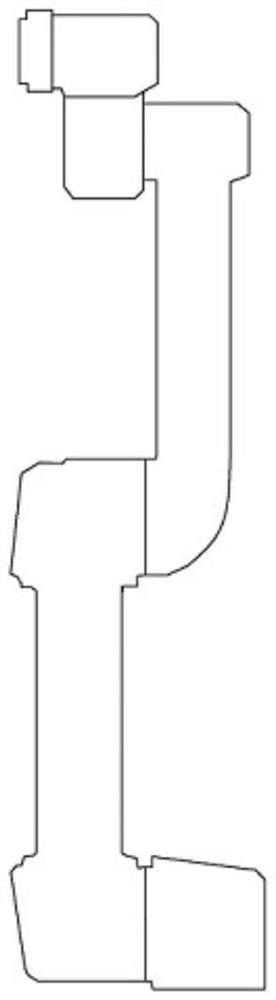

Drug releasing coatings for medical devices

The invention relates to a medical device for delivering a therapeutic agent to a tissue. The medical device has a layer overlying the exterior surface of the medical device. The layer contains a therapeutic agent, an antioxidant, and an additive. In certain embodiments, the additive has a hydrophilic part and a drug affinity part, wherein the drug affinity part is at least one of a hydrophobic part, a part that has an affinity to the therapeutic agent by hydrogen bonding, and a part that has an affinity to the therapeutic agent by van der Waals interactions. In some embodiments, the additive is a liquid. In other embodiments, the additive is at least one of a surfactant and a chemical compound, and the chemical compound has one or more hydroxyl, amino, carbonyl, carboxyl, acid, amide or ester groups.

Owner:路通医疗股份有限公司

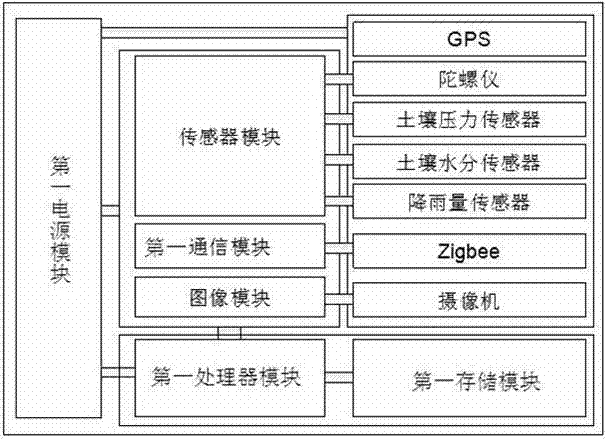

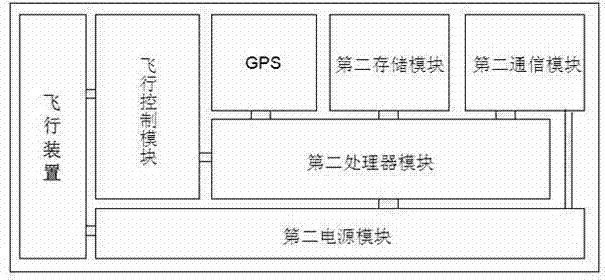

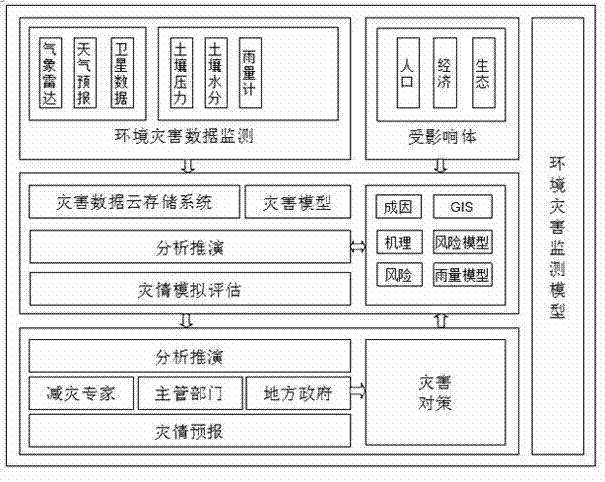

Monitoring system based on unmanned aerial vehicle and wireless sensor network

InactiveCN104517432ALower deployment costsLow costMeasurement devicesTransmission systemsWireless mesh networkWireless sensor networking

The invention discloses a monitoring system based on an unmanned aerial vehicle and a wireless sensor network. The monitoring system comprises an unmanned aerial vehicle device and an environment hazard detection device, wherein a first storage module, a first communication module, an image module and a sensor module of the environment hazard detection device are all in communication connection with a first processor module; a first power supply module is used for supplying direct-current power supply to the detection device; a fly control module, a GPS module, a second storage module and a second communication module of the unmanned aerial vehicle device are all in communication connection with a second processer module; a second power supply module is used for supplying power to an unmanned aerial vehicle; when the unmanned aerial vehicle device flies into the communication range of the environment hazard detection device, the first communication module and the second communication module are connected in a wireless communication mode. The purposes that the cost is lowered and limit of networks such as the 3G network, the 4G network and the satellite communication is avoided are achieved.

Owner:LANZHOU UNIVERSITY +2

Pesticide composition containing amino-oligosaccharide and kresoxim-methyl and use method and application thereof

The invention belongs to the field of pesticides, and relates to a sterilization composition taking amino-oligosaccharide and kresoxim-methyl as main active ingredients, and a use method and application thereof. The composition comprises at least two active ingredient components with dosage producing synergistic activity, and appropriate excipients, and is characterized in that the component I is the amino-oligosaccharide, and the component II is the kresoxim-methyl. The ratio of weight parts of the amino-oligosaccharide and the kresoxim-methyl is 30:1-1:50 in the invention. The preferred scheme is that the ratio of weight parts of the amino-oligosaccharide and the kresoxim-methyl is 1:1-1:50. The composition and appropriate excipients are made into any agriculturally available formulation. The preferred formulation is a suspending agent, water dispersible granules and wettable powder. The use method of the invention is that the component I and the component II can be used for treating positions which produce diseases or disease danger in any order or simultaneously. The sterilization composition is used for controlling diseases of fruit, cereal, fruits, vegetables, beans, oil crops and ornamental crops and other crops.

Owner:SHENZHEN LANGTAI BIOTECH

Drug releasing coating for medical device

The invention relates to a medical device for delivering a therapeutic agent to tissue. The medical device is provided with a coating that covers outer surface of the medical device. The coating contains the therapeutic agent, an antioxygen agent and an additive. In certain specific embodiments, the additive has a hydrophilic portion and a drug affinity portion, and at least one portion among a hydrophobic portion, a portion with the affinity to the therapeutic agent through a hydrogen bond and a portion with the affinity to the therapeutic agent through a van der waals interaction can serve as the drug affinity portion. In certain specific embodiments, the additive is a liquid. In other specific embodiments, at least one substance among surface active agents and compounds can serve as the additive, and the compounds have one or more hydroxyls, amino groups, carbonyls, carboxyls, acids, amides or ester groups.

Owner:路通医疗股份有限公司

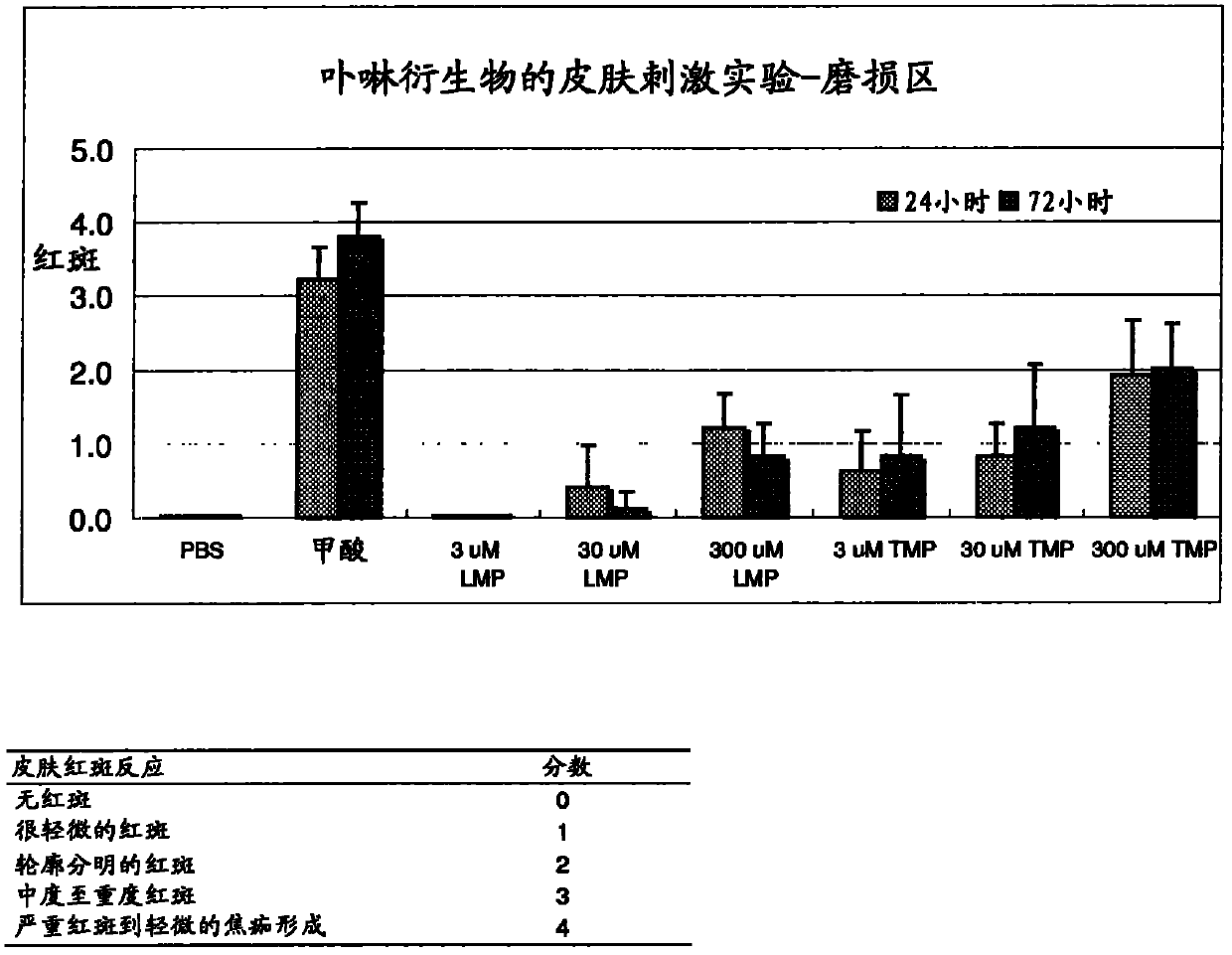

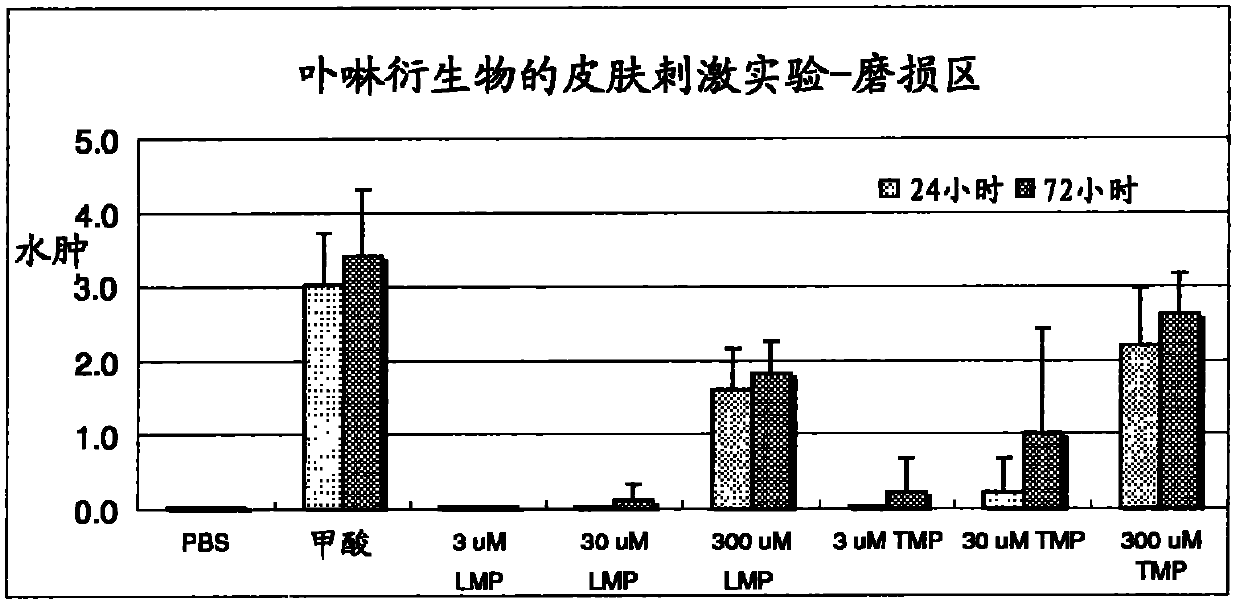

Use of tetrakis (n-alkylpyridinium) -porphyrin derivatives for killing microbes or preventing growth

InactiveCN102245027AInhibit growthNo restrictionsAntibacterial agentsOrganic active ingredientsMicroorganismPorphyrin

Owner:尖端科学公司

Pesticide composition containing amino-oligosaccharide and kresoxim-methyl and use method and application thereof

The invention belongs to the field of pesticides, and relates to a sterilization composition taking amino-oligosaccharide and kresoxim-methyl as main active ingredients, and a use method and application thereof. The composition comprises at least two active ingredient components with dosage producing synergistic activity, and appropriate excipients, and is characterized in that the component I is the amino-oligosaccharide, and the component II is the kresoxim-methyl. The ratio of weight parts of the amino-oligosaccharide and the kresoxim-methyl is 20:1-1:50 in the invention. The preferred scheme is that the ratio of weight parts of the amino-oligosaccharide and the kresoxim-methyl is 1:1-1:50. The composition and appropriate excipients are made into any agriculturally available formulation. The preferred formulation is a suspending agent, water dispersible granules and wettable powder. The use method of the invention is that the component I and the component II can be used for treating positions which produce diseases or disease danger in any order or simultaneously. The sterilization composition is used for controlling diseases of fruit, cereal, fruits, vegetables, beans, oil crops and ornamental crops and other crops.

Owner:SHENZHEN LANGTAI BIOTECH

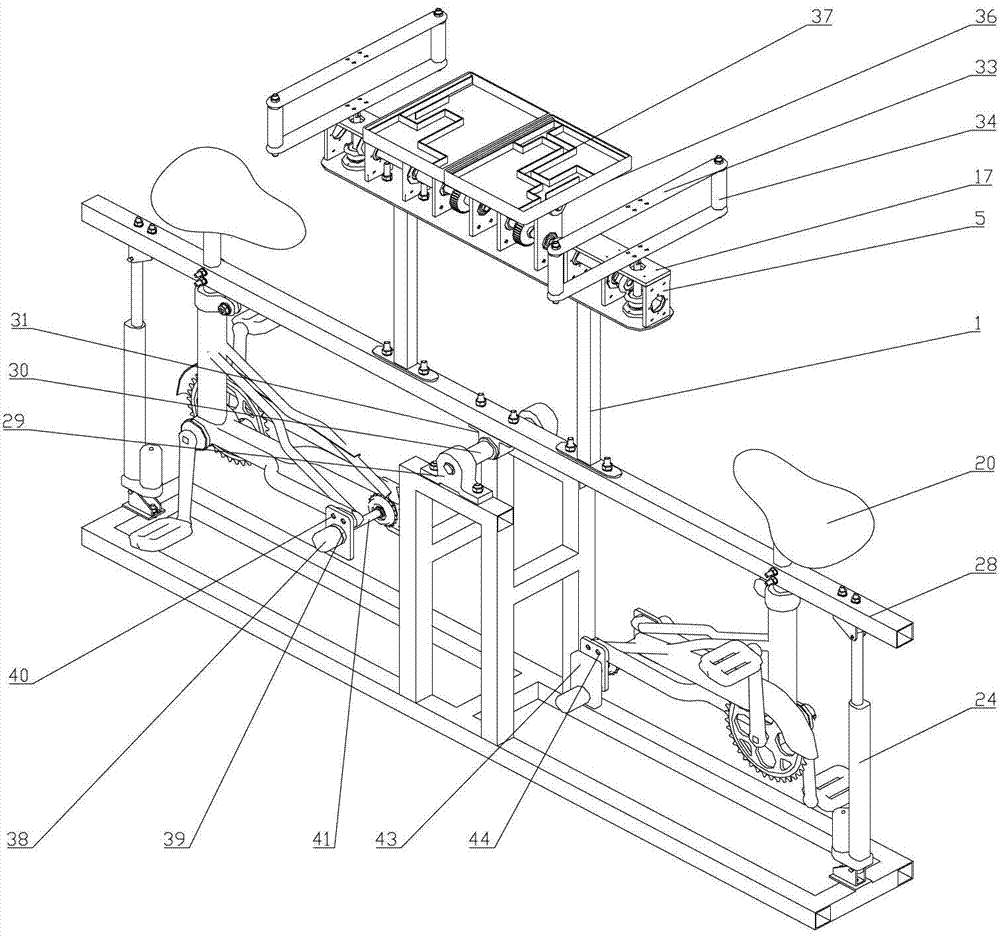

Fitness, entertainment and intelligence-promotion seesaw

InactiveCN102772897ANo restrictionsSports funFrom muscle energyMachines/enginesAutomatic controlControl system

The invention discloses a fitness, entertainment and intelligence-promotion seesaw, which comprises a push rod motor seesaw component, two fitness device components of the same structure, gameboards of the same structure, and a transmission component, wherein a controllable rod long hinge three-rod mechanism is adopted in the push rod motor seesaw, and is fixed on the ground as a frame; the fitness device components are arranged on two symmetrical sides of the seesaw, and are in chain transmission; an adjustable damping generator and a photoelectric encoder for acquiring speed signals are arranged; the gameboards and the transmission component are fixed above the seesaw through brackets; a maze box is controlled to rotate leftwards and rightwards by using a handle; and a control system is fixed inside the frame, and is used for automatically controlling an entire appliance. The controllable rod long hinge three-rod mechanism provided by the invention is simple; and under the condition of avoiding sliding friction of a crank slide block mechanism, linear push rod movement is transformed into circumferential swinging skillfully, so that high reliability and stable running are realized. Due to the adoption of the adjustable damping generator of the fitness device, energy collection can be realized, loading can be performed, and the fitness requirements of different consumers are met.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing culture medium with Chinese herbal medicine dregs

ActiveCN104072219AReduce saltLower EC valueBio-organic fraction processingOrganic fertiliser preparationCation-exchange capacityFermentation

The invention discloses a method for preparing a culture medium with Chinese herbal medicine dregs. The method comprises the steps as follows: after the Chinese herbal medicine dregs are accumulated for anaerobic fermentation, compound bacteria of bacillus subtilis and aspergillus niger as per the bacterial content are added and mixed uniformly to enable the bacterial content concentration to be higher than 500 thousands bacteria per gram, then syrup is sprayed and mixed uniformly, after accumulation, the accumulated materials are covered with a black plastic film until the highest temperature in the accumulated materials reaches 55 DEG C, the black plastic film is removed for aerobic fermentation until the moisture content of the accumulated materials is lower than 45%, and the culture medium can be obtained through accumulation and ageing. The culture medium prepared with the method is low in salinity, low in EC value, large in cation exchange capacity and high in acid-base buffering capacity and saline-alkaline buffering capacity; meanwhile, by the aid of the culture medium, the soil looseness degree, the fertilizer keeping and water holding capacity and the heat insulation and ventilation capacity can also be improved; the culture medium is suitable for most of crops, even flowers, plants and the like with very strict cultivation requirements, the culture medium is suitable for mixing with any materials to be prepared into required media without limitations, and salinization conditions caused by excessive use can be avoided.

Owner:广东巴斯德环境科技有限公司

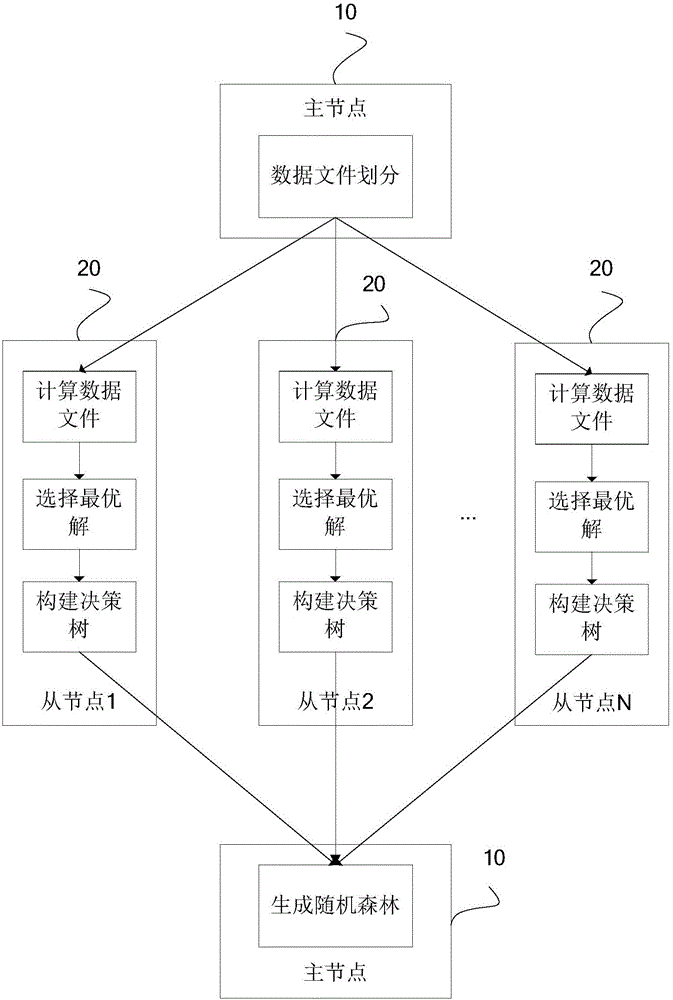

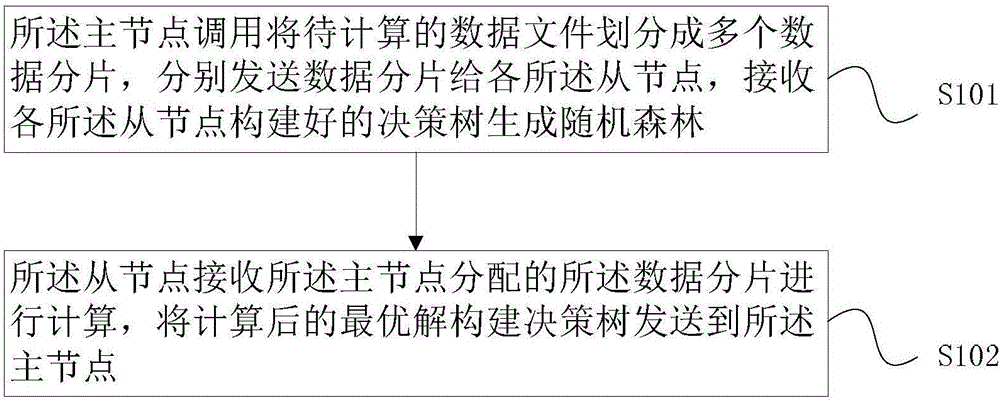

Heterogeneous system parallel random forest optimization method and system

The invention discloses a heterogeneous system parallel random forest optimization system and method. The heterogeneous system parallel random forest optimization system is applied to a central processing unit and a coprocessor mixed heterogeneous cluster and comprises one master node and multiple slave nodes, wherein the main master node is used for dividing a data file to be calculated into multiple data fragments and transmitting the data fragments to all the slave nodes respectively; all the slave nodes are used for receiving the data fragments distributed by the master node to calculate the data fragments and transmitting a calculated optimal solution building decision-making tree to the master node to generate a random forest. As the data fragments are calculated by the slave nodes in parallel, the time for searching for the optimal solution is shortened, efficiency of the whole system is substantially improved, the system is unnecessarily limited by network bandwidth deficiency, small memory capacity and other conditions, and the requirement for processing large-scale data of high-performance application is met.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

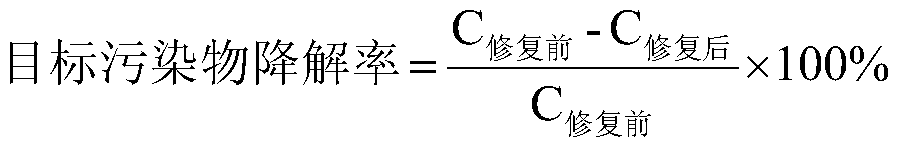

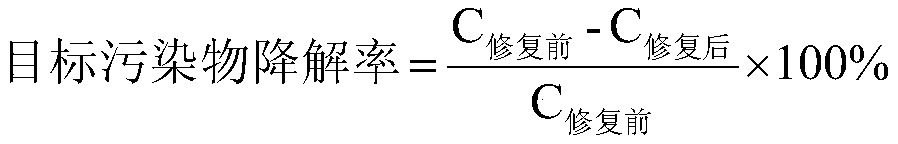

Method for in-situ microbial remediation of petroleum-contaminated soil under the assistance of heat strengthening

PendingCN110842020ASolve environmental problemsResolution cycleContaminated soil reclamationMicroorganismSoil science

The invention relates to a method for in-situ microbial remediation of petroleum-contaminated soil under the assistance of heat strengthening, and the method comprises the following steps: preparing afree-state bacteria solution from microorganisms suitable for remediation of the petroleum-contaminated soil; preparing a bacterial liquid preparation by matching the free-state bacteria solution with a nutrient solution; according to a triangular point distribution method, using a GPS position indicator, arranging injection wells to allow point distribution parameters to ensure that the preparedbacterial liquid preparation completely covers the repair area within the diffusion radius range; injecting the bacterial liquid preparation into distributed points by adopting a high-pressure jet grouting injection device; and installing a heating device in an injection hole, and filling a gap between the injection hole and the heating device with gravel. The heating device heats the contaminated soil to a set value and keeps the temperature until the target pollutant concentration is lower than a remediation target value, and the remediation target is achieved.

Owner:上海康恒环境修复有限公司

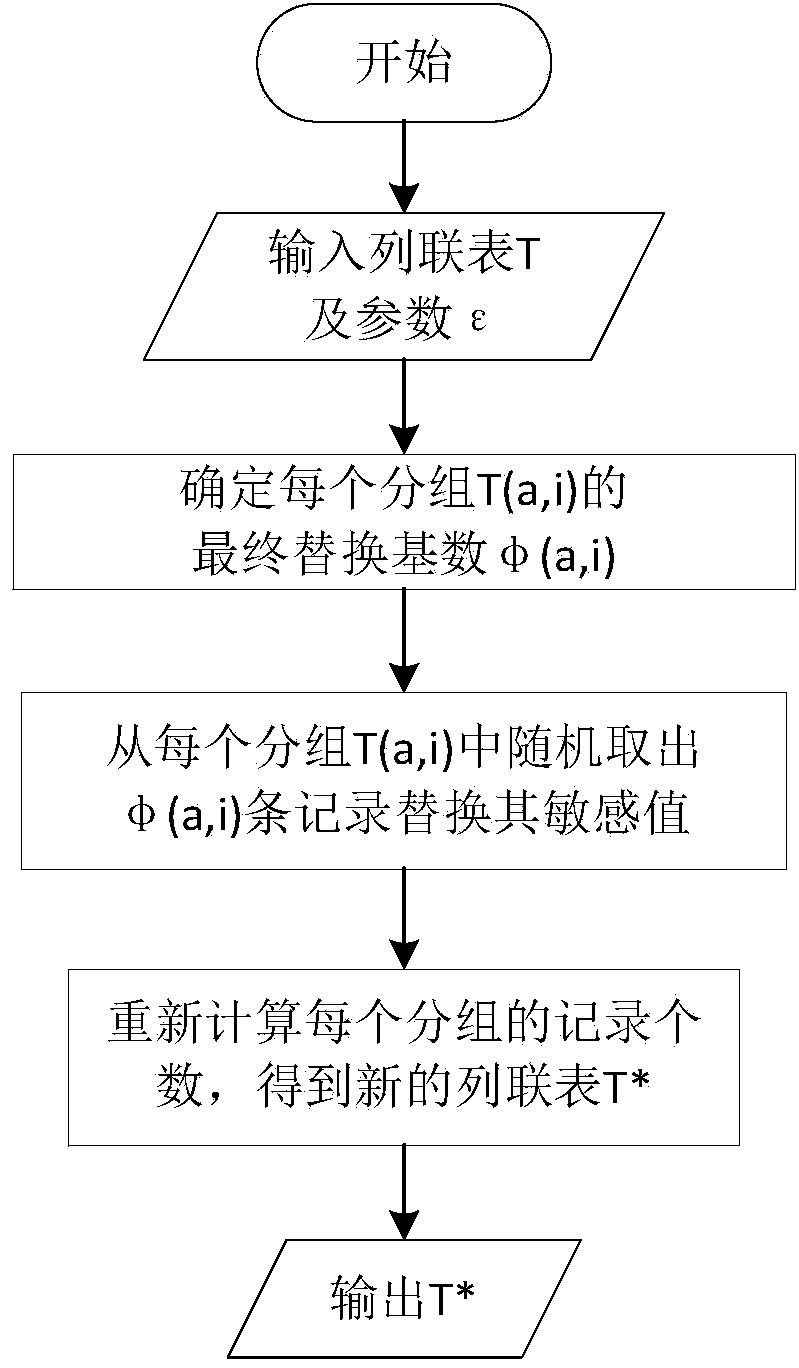

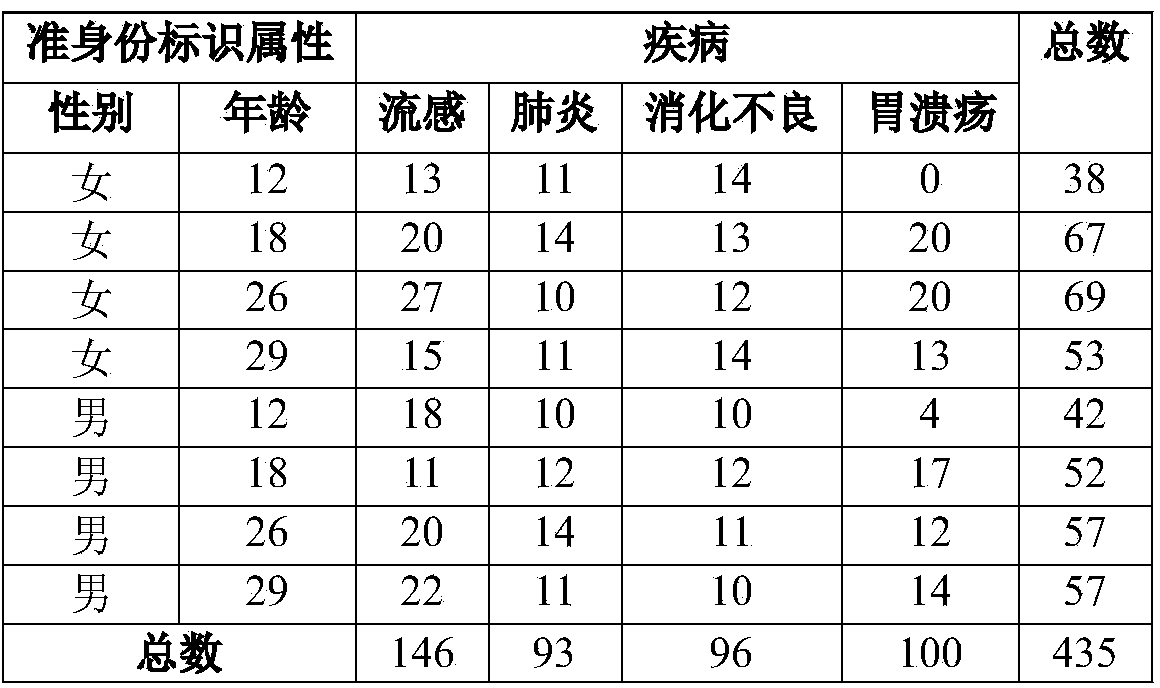

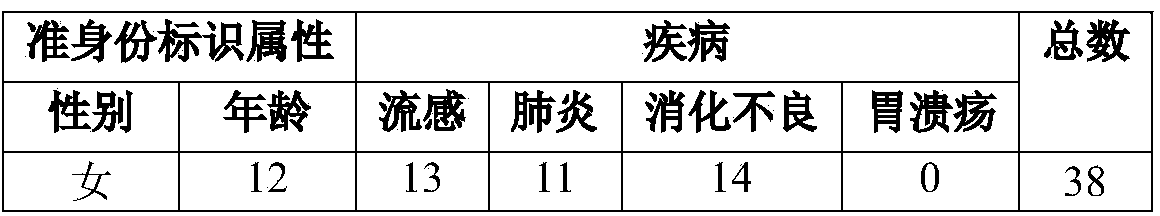

Privacy protection method for contingency table data dissemination

ActiveCN104216994AMeet security needsHigh precisionDigital data protectionSpecial data processing applicationsData privacy protectionRandom replacement

The invention discloses a privacy protection method for contingency table data dissemination and belongs to the field of privacy protection of computer data. The privacy protection method comprises the following steps: determining an initial replacement base number and a final replacement base number of each group in a contingency table; recording random replacement of a sensitive value based on an index mechanism; repeatedly calculating each replaced group and outputting a new contingency table. According to the privacy protection method, the processed contingency table meets safety requirements of epsilon-difference privacy; meanwhile, inquires supported by any meta-data are supported; processed data errors are small and the accuracy is high so that the data availability is stronger.

Owner:HUAZHONG UNIV OF SCI & TECH

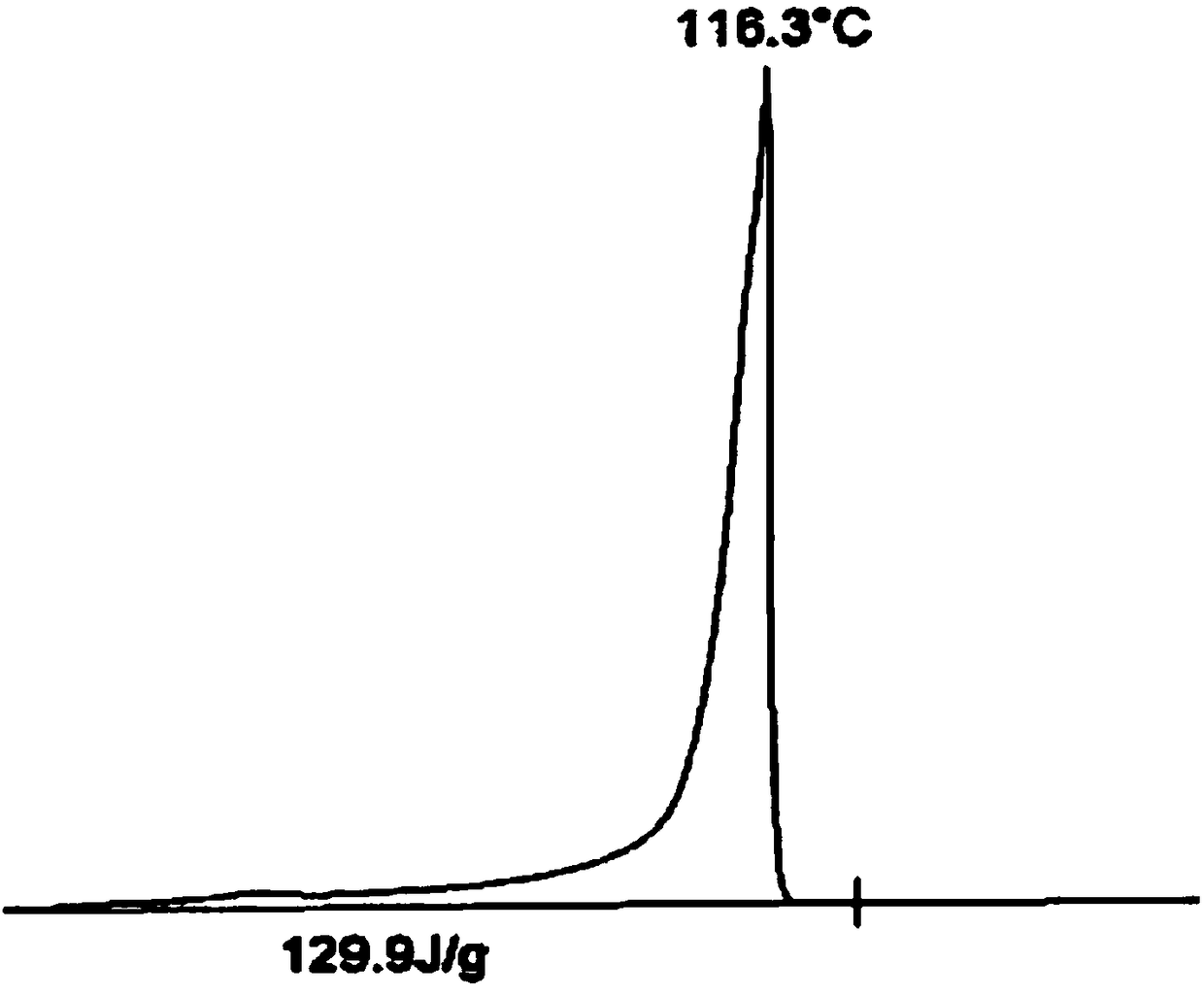

Electrothermal cooker

InactiveCN102450944AHigh sensitivityImprove linearityWater-boiling vesselsBeverage vesselsScreen printingTemperature control

The invention discloses an electrothermal cooker, which comprises a body, a temperature change detection element and a temperature control circuit, wherein the body is provided with a cooking cavity; the temperature change detection element is a positive temperature coefficient (PTC) thermal resistor; and the PTC thermal resistor is printed on the surface of a substrate in a printing way. Compared with an electrothermal cooker in the prior art, the electrothermal cooker has the advantages that: temperature is controlled by using the PTC thermal resistor, and the resistance value of the PTC thermal resistor increases along the rise of the temperature and changes linearly, so that high linearity, high reaction speed, high sensitivity and accurate pressure control are realized, the reaction speed is still within two seconds after an insulating layer is printed, and real accurate temperature control can be realized; a printing mode is adopted, so that the overall cost of the PTC thermal resistor can be reduced greatly, the process is simplified, and manufacturing is available by adopting a simple screen printing process; and meanwhile, insulation can be realized without influencing the temperature measuring accuracy by printing a very thin insulating layer, so that large-scale production is facilitated.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

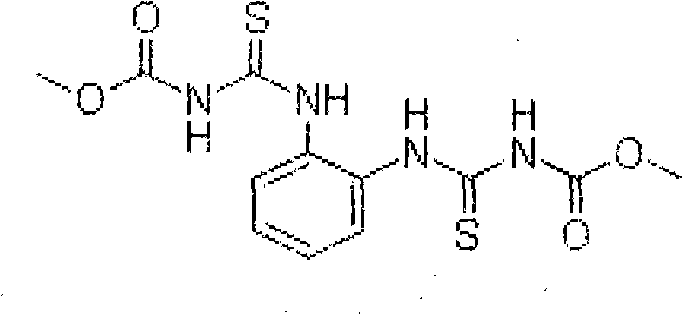

Pesticide composition containing amino-oligosaccharide and thiophanate methyl and use method and application thereof

The invention belongs to the field of pesticides, and relates to a sterilization composition taking amino-oligosaccharide and thiophanate methyl as main active ingredient components, and a use method and application thereof. The composition comprises at least two active ingredients with dosage producing synergistic activity, and appropriate excipients, and is characterized in that the component I is the amino-oligosaccharide, and the component II is the thiophanate methyl. The ratio of weight parts of the amino-oligosaccharide and the thiophanate methyl is 20:1-1:50 in the invention. The preferred scheme is that the ratio of weight parts of the amino-oligosaccharide and the thiophanate methyl is 20:1-1:50. The composition and appropriate excipients are made into any agriculturally available formulation. The preferred formulation is a suspending agent, water dispersible granules and wettable powder. The use method of the invention is that the component I and the component II can be used for treating positions which produce diseases or disease danger in any order or simultaneously. The sterilization composition is used for controlling diseases of fruit, cereal, fruits, vegetables, beans, oil crops and ornamental crops and other crops.

Owner:SHENZHEN LANGTAI BIOTECH

Method for preparing roller brush fabric from thermoplastic fiber

InactiveCN109868542AHas the effect of hot melt adhesionNot fusion strongBristlePile-fabric loomsFiberEnvironmental resistance

The invention provides a method for preparing a roller brush fabric from thermoplastic fiber. A certain proportion of thermoplastic fiber serves as main fiber materials of upper-layer base cloth and lower-layer base layer, conventional fiber is used for connection of the upper-layer base cloth and the lower-layer base cloth, blank cloth is prepared through a machine knitting method, the upper-layer base cloth and the lower-layer base cloth have hot melting adhesion effects through pile cutting, heating and solidification, and the solidification and non-nap-off effects are achieved without gluing. The fabric can be used for a roller brush and a scrubbing brush, the environmental protection purpose is achieved by omitting the coating process, compared with the similar products, the fabric has fuller suede, a thick and solid hand feeling and non-silk-off and non-nap-off effects, and the solidification effect and the bottom stiffness are good.

Owner:沂水恒泰纺园有限公司

Preparation method of sequence and length customized circular single-stranded DNA (Deoxyribonucleic Acid) and application of sequence and length customized circular single-stranded DNA to DNA origami

The invention discloses a preparation method of sequence and length customized circular single-stranded DNA (Deoxyribonucleic Acid) and application of the sequence and length customized circular single-stranded DNA (ssDNA) to DNA origami. The preparation method of the sequence and length customized circular single-stranded DNA, disclosed by the invention, comprises the following steps: (1) designing and synthesizing circular double-stranded recombinant phagemid; (2) transforming escherichia coli through the recombinant phagemid and infecting through helper phage to prepare the circular single-stranded DNA with a corresponding form; (3) assembling different origami structures by taking prepared the ssDNA as a framework chain respectively, and carrying out characterization through atomic force microscope imaging. According to the method disclosed by the invention, aiming at the certain specific DNA, various types of single-stranded DNAs with different base sequences and lengths can be designed according to application requirements, so that customization is realized.

Owner:NANJING UNIV

Lithium-oxygen codoping method of ternary lithium ion anode material

InactiveCN108190973ANo restrictionsDoping amount is controllableSecondary cellsPositive electrodesHigh energyPhysical chemistry

The invention discloses a lithium-oxygen codoping method of a ternary lithium ion anode material. The method comprises the steps of mixing a solid substance containing target cations and anions into the ternary lithium ion anode material, performing high energy ball milling to achieve completely uniform mixing, and performing low temperature sintering to form the lithium-oxygen codoped ternary lithium ion anode material. Due to lithium doping, a lithium layer channel can be enlarged; the disembedding resistance of lithium ions is reduced; the rate capability of the material is improved; fluorine doping of oxygen can improve cycling stability of the material; compared with the conventional liquid phase coprecipitation method, the method is short in flow, simple in technology, low in cost and applicable to large-scale plant production and can massively modify the anode material when the method is used for doping modification of the ternary anode material.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

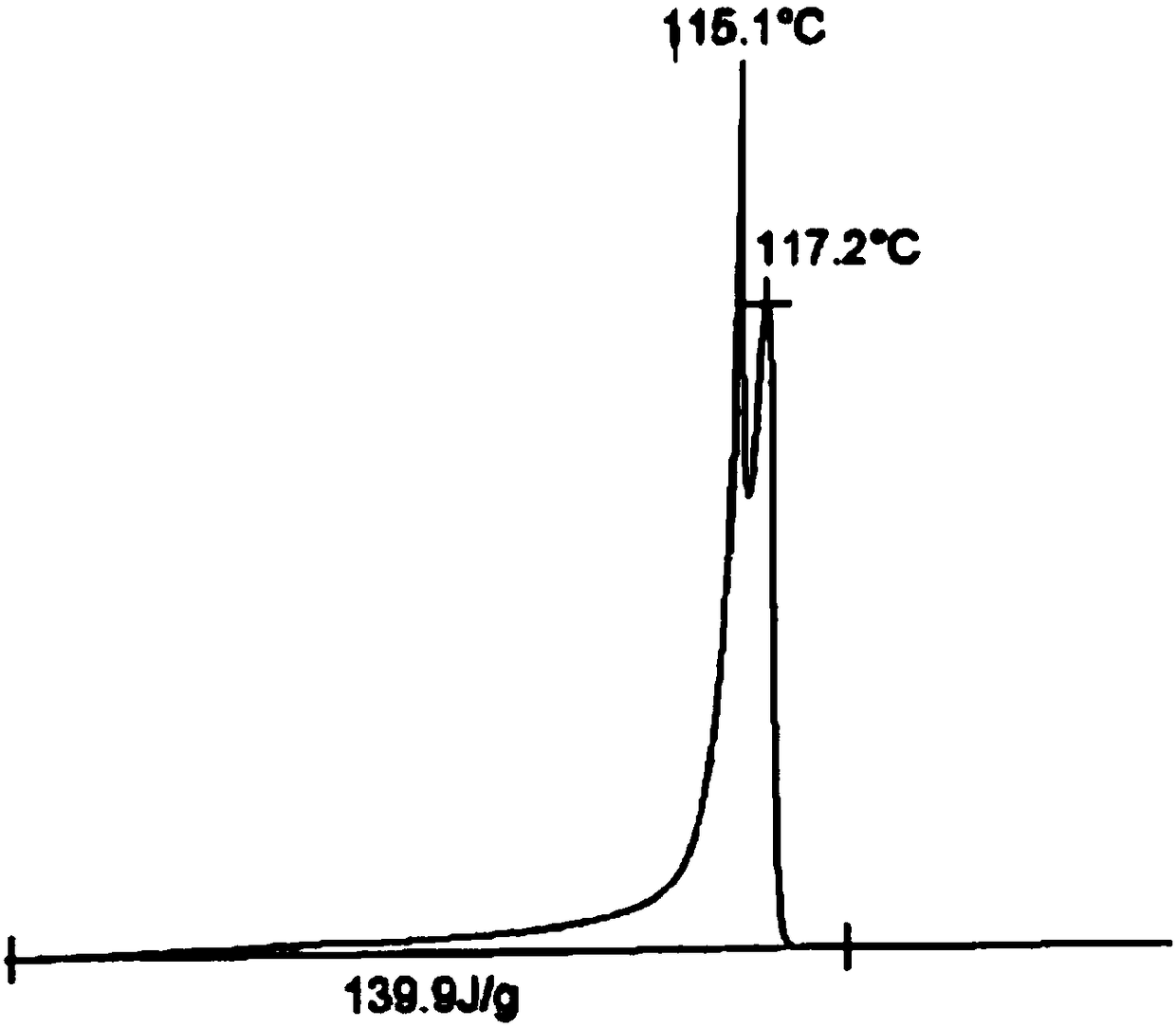

Pore-forming method for diaphragms of lithium ion batteries

ActiveCN102655229BNo restrictionsSimple and flexible adjustment methodCell electrodesPhysical chemistryPorous membrane

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a pore-forming method for diaphragms of lithium ion batteries. The method comprises the following steps: fully dissolving a pore-forming agent into a solvent so as to prepare a pore-forming agent solution; uniformly coating the pore-forming agent solution on the surface of a to-be-cold-pressed diaphragm, and carrying out baking on the diaphragm at a temperature lower than the sublimation or decomposition temperature of the pore-forming agent, so that a solvent of the pore-forming agent solution is volatilized, and the pore-forming agent is recrystallized in the diaphragm; and carrying out cold pressing on the diaphragm, and then carrying out baking on the diaphragm at a temperature higher than the sublimation or decomposition temperature of the pore-forming agent, so that the pore-forming agent recrystallized in the diaphragm is sublimated or decomposed, thereby obtaining a porous diaphragm. According to the invention, through regulating the viscosity of the pore-forming agent solution, a diaphragm with adjustably-distributed pores can be obtained, and the regulating method is simple and flexible, and wide in applicable range; and particularly, according to the invention, an efficient gradient pore distribution structure that more pores are distributed on the surface layer of the diaphragm and less pores are distributed on the inner layer of the diaphragm can be realized just through selecting an appropriate viscosity of the pore-forming agent solution..

Owner:NINGDE AMPEREX TECH +1

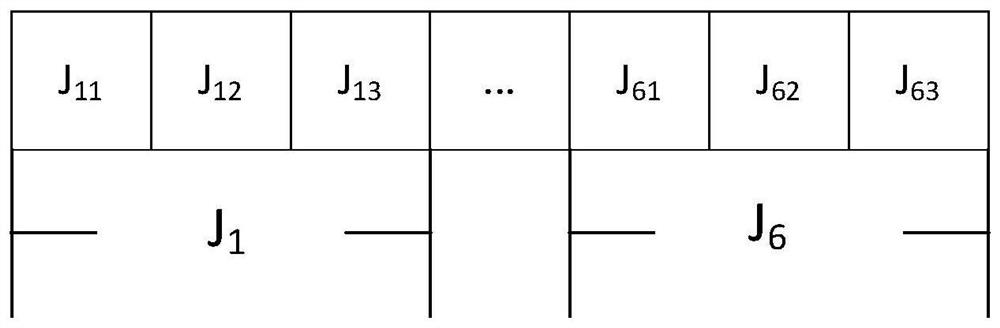

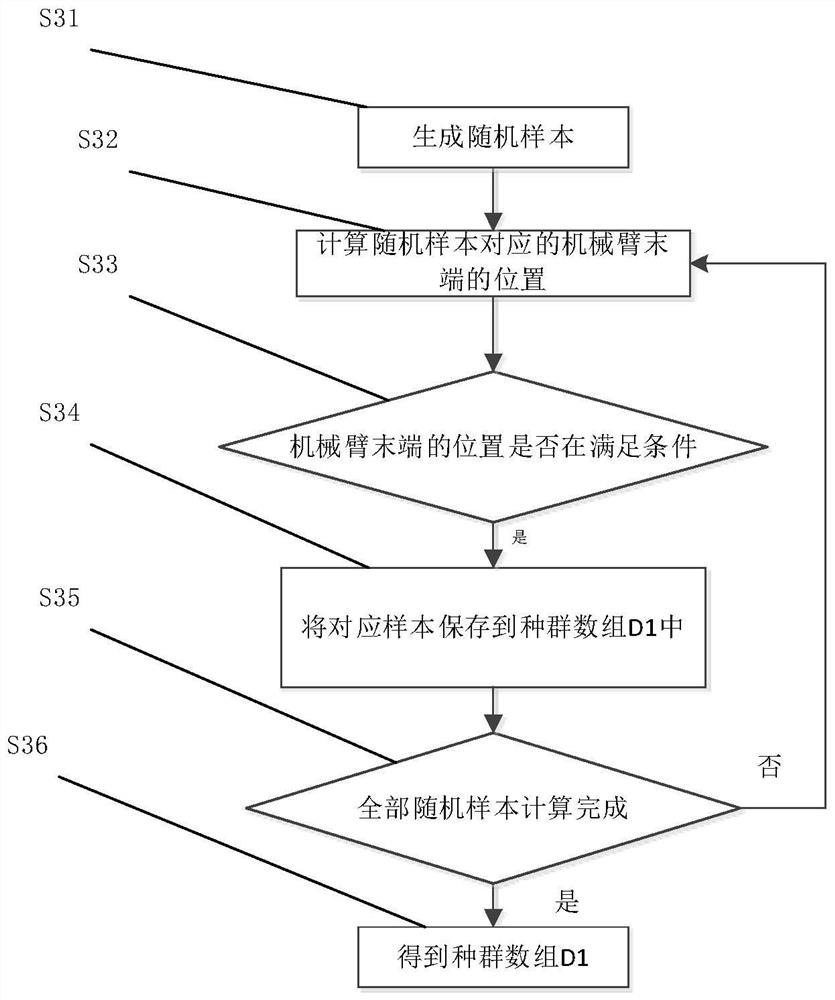

A method for inverse kinematics solution of 6-DOF manipulator

ActiveCN109344477AAvoid inverse and inverse trigonometric functionsReduce computationGeometric CADSpecial data processing applicationsGenetic populationAlgorithm

The invention discloses a 6-DOF manipulator inverse kinematics solution method in the field of industrial robots. The method firstly uses Monte Carlo method to assign a certain number of random samples to the joint space of the manipulator, and then calculates the end position of each sample, and selects the sample satisfying the target position condition as a part of the initial population of thegenetic algorithm; The other part of the initial population of the genetic algorithm is composed of random individuals, and then the inverse kinematics of the manipulator is solved by genetic algorithm. On the one hand, the invention optimizes the initial population of the genetic algorithm through the Monte Carlo method, thereby effectively improving the searching speed and the searching successrate of the genetic algorithm; On the other hand, the diversity of genetic population is ensured by the addition of random individuals, and the global searching ability of genetic algorithm is improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

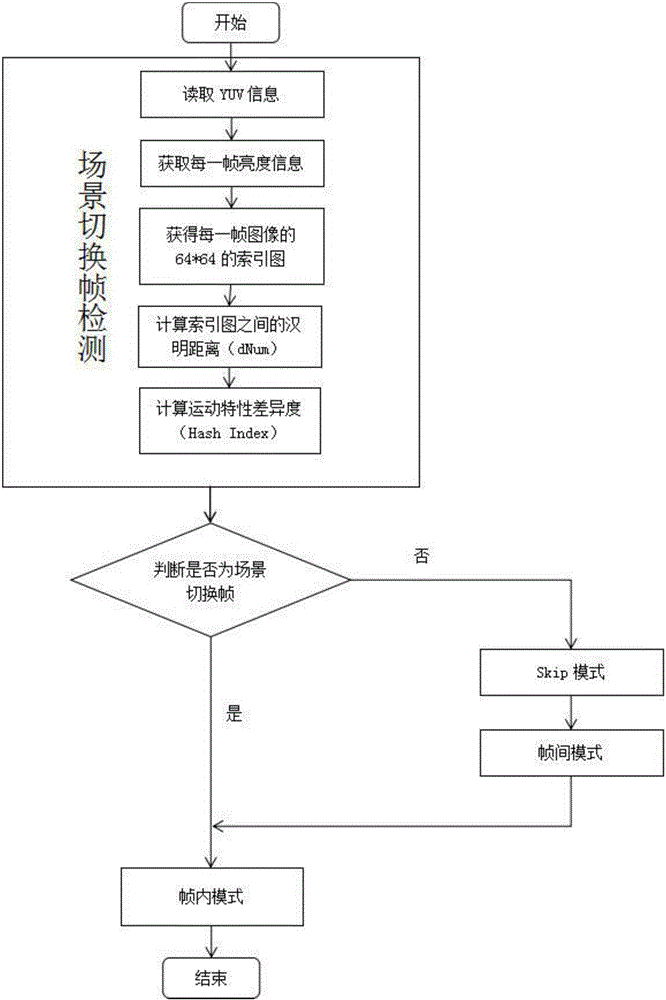

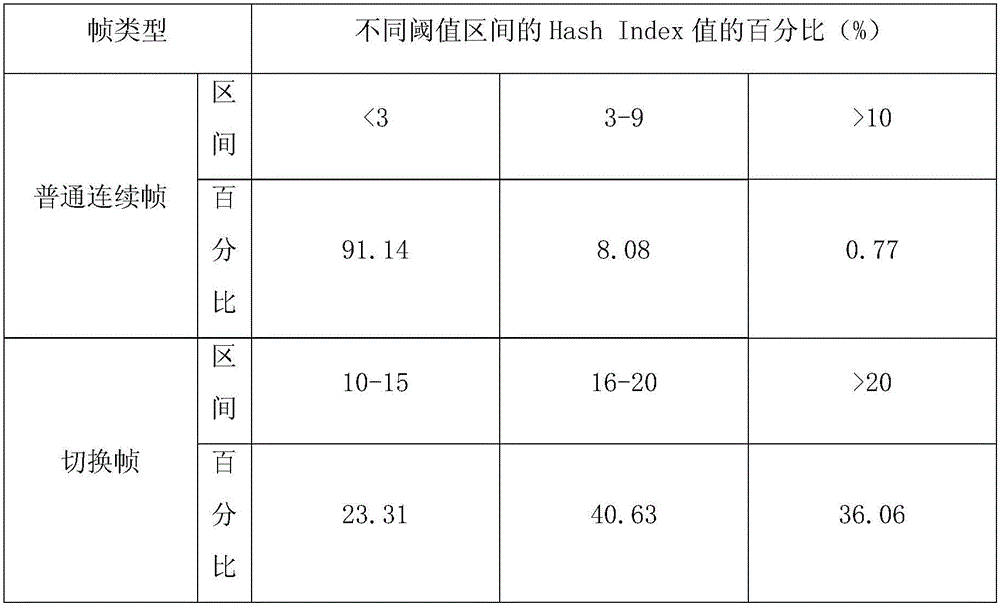

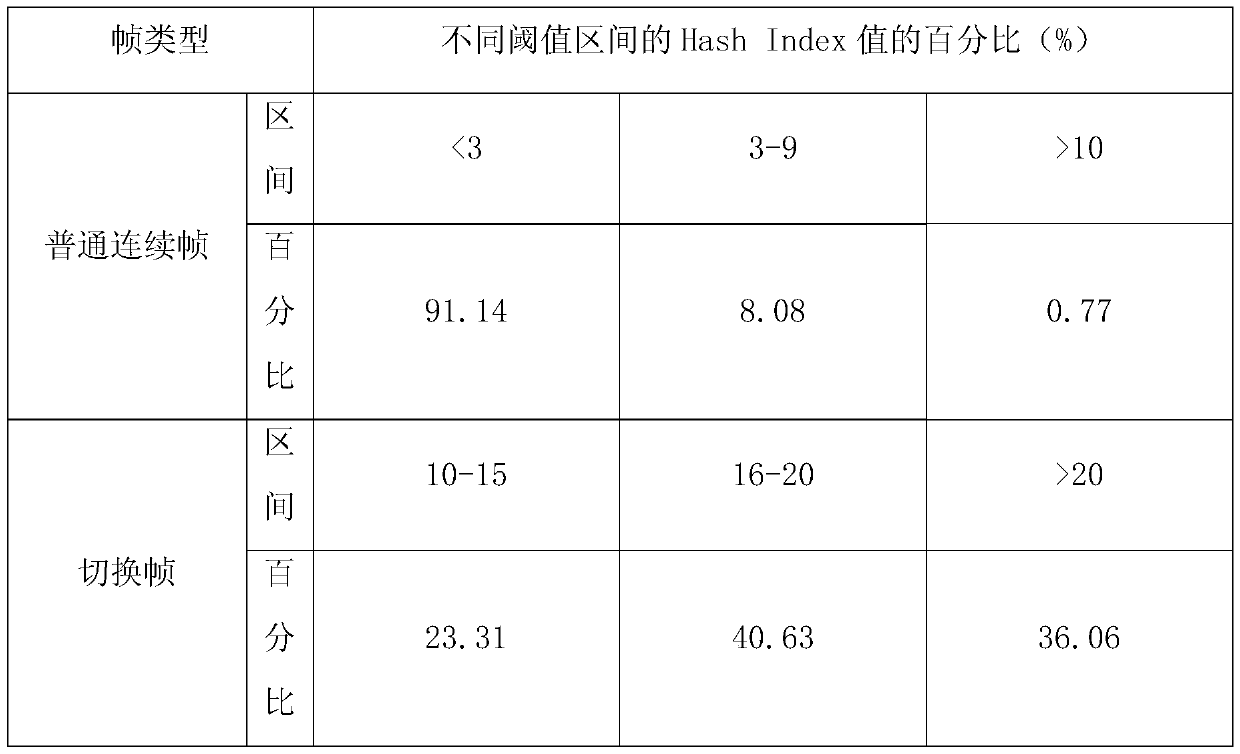

Method for rapidly selecting HEVC prediction mode based on scene switching

ActiveCN106454341ATotal encoding time does not increaseImprove applicabilityDigital video signal modificationPrediction algorithmsComputer vision

The invention discloses a method for rapidly selecting a HEVC prediction mode based on scene switching. The method comprises the following steps of: firstly, when an input YUV file is read, recording the brightness component of each frame of image to form a gray-level image; compressing each frame of gray-level image into an index image in the M*M format by utilizing an interpolation method; calculating the average value V<average> of the M*M gray values, and comparing each gray value with the V<average> to obtain a M*M-bit binary fingerprint sequence of each frame of image; for two sequential images, comparing fingerprint sequences thereof, counting the number dNum of different binary values at corresponding positions, and generating a hash index; and, for a current frame of image, the hash index of which is greater than a threshold value T, judging that the current frame is a scene switching frame, setting the current frame to the I frame when the frame type is set, performing predication coding according to the I frame, and otherwise, not performing any operation. By means of the method disclosed by the invention, for the scene switching frame in a video, rapid detection can be carried out; furthermore, other related optimal acceleration algorithms cannot be influenced; and the coding quality cannot be changed. The method disclosed by the invention can be used together with the existing HEVC rapid prediction algorithm.

Owner:NANJING UNIV OF POSTS & TELECOMM

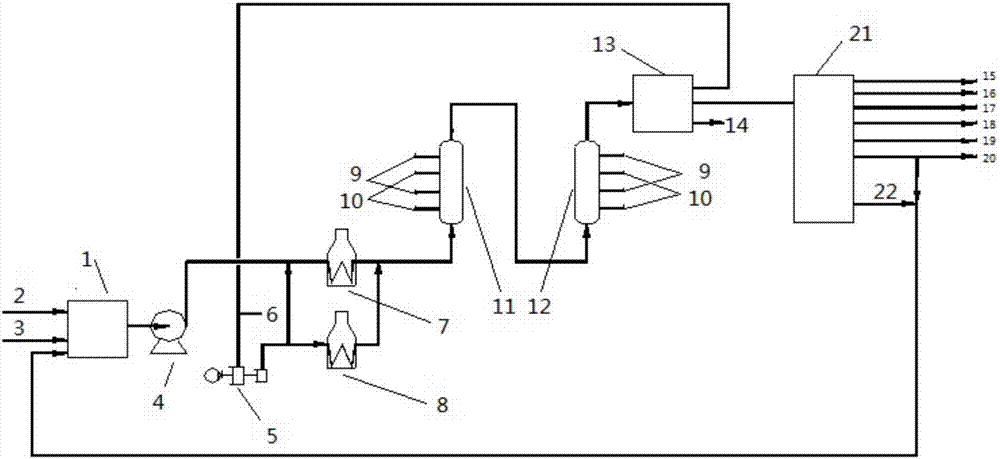

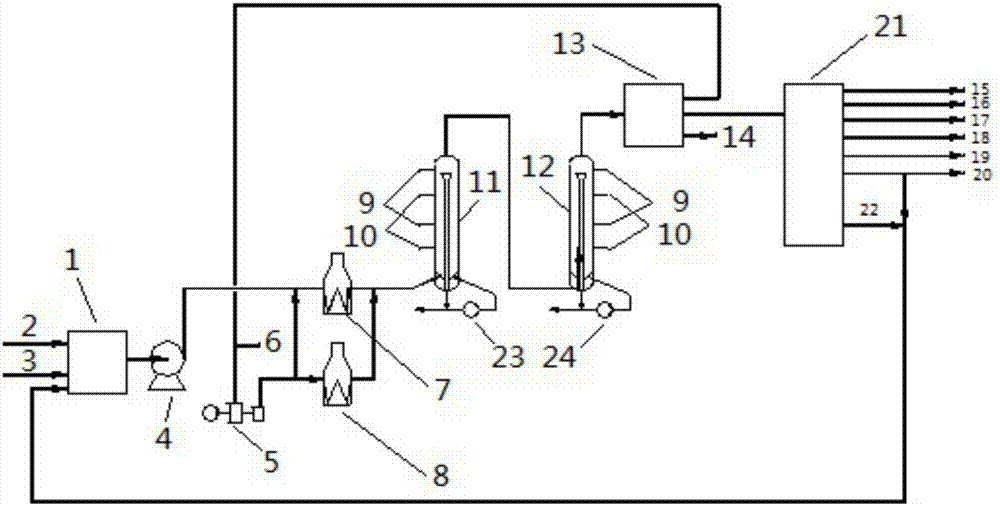

Omnipotent bed hydrogenation technology

InactiveCN107057756AReduce maintenance workloadShort processHydrocarbon oil crackingTreatment with hydrotreatment processesVulcanizationAtmospheric air

The invention provides an omnipotent bed hydrogenation technology. Raw materials comprise atmospheric pressure residual oil, vacuum residual oil, catalytic slurry oil, deoiled asphalt, coal tar or distillate oil, and can further comprise coal dust, firstly, the raw material oil and an oil soluble catalyst are mixed in a raw material / catalyst mixing system, the mixing temperature is 60-350 DEG C, and the mixing time is 20-200 minutes; the vulcanization process is completed in a reactor; the omnipotent bed is a cylindrical reactor excluding a fixed bed layer; the oil soluble catalyst is the combination of one or more of active components of Mo, Ni, Co, W, Fe. According to the omnipotent bed hydrogenation technology, firstly, the oil soluble catalyst and the raw material oil are mutually mixed (after an oil-coal joint hydrogenation technology, coal dust is added to prepare coal-oil slurry, and swelling is conducted), hydrogen is added, the temperature is raised, the pressure is raised, a reaction is conducted, separation is conducted, and fractional distillation is conducted. The omnipotent bed hydrogenation technology has the advantages of being high in raw material adaptability, high in light oil yield, less in atmospheric and solid waste and low in temperature and pressure.

Owner:CATECH TECH

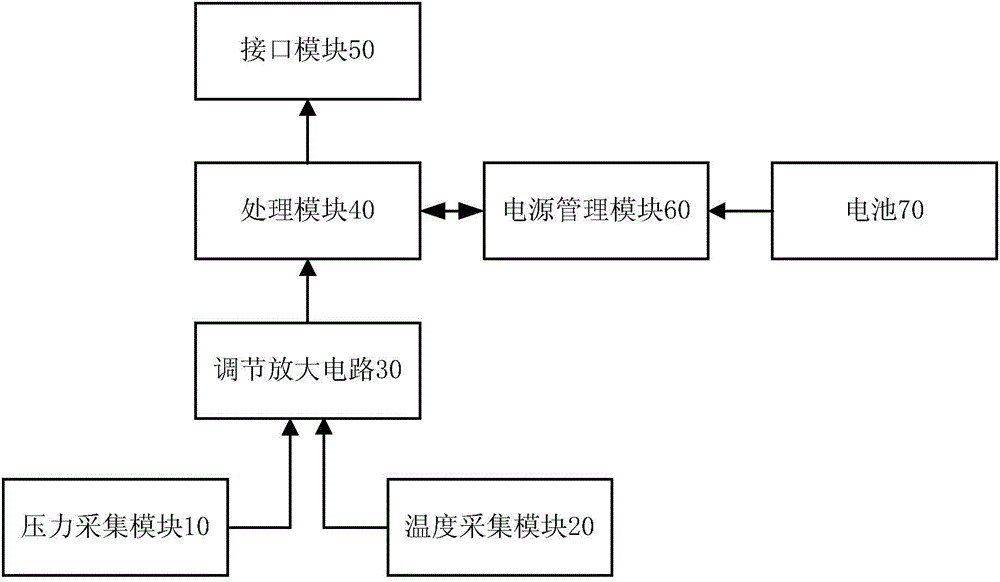

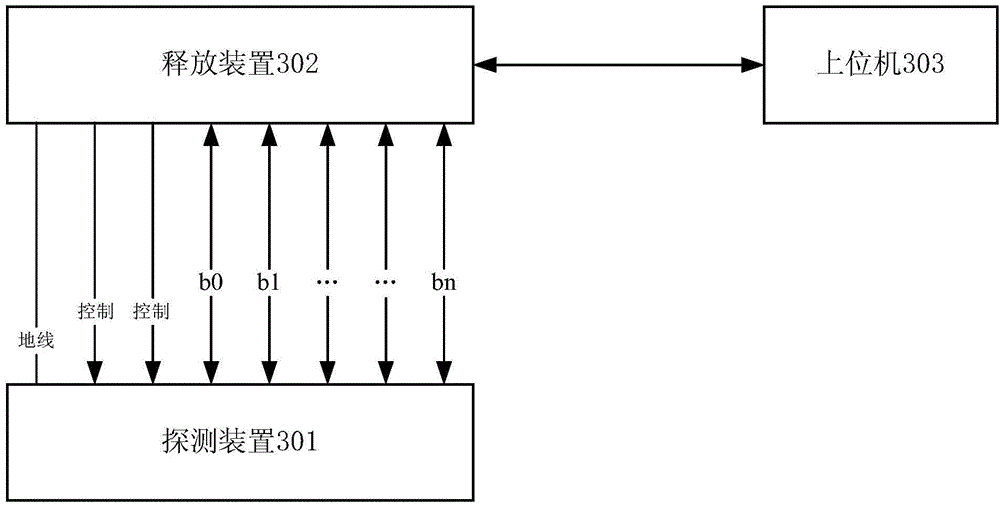

Data acquisition device, a detection device and a system

InactiveCN104913858AThere is no limit to the speed of descentNo restrictionsThermometers using electric/magnetic elementsUsing electrical meansData acquisitionSea temperature

The invention discloses a data acquisition device, a detection device and a system. The system comprises a detection device, a releasing device and an upper computer. Parallel communication sampling data is adopted between the releasing device and the detection device; the releasing device is used for connecting to the detection device and the upper computer; the detection device is used for obtaining pressure signals and temperature signals and converting the pressure signals and the temperature signals to first digital signals and second digital signals to transmit signals to the upper computer after signal amplification; the upper computer is used for receiving the first digital signals and the second digital signals which are transmitted by the detection device; and the sea temperature profile graph is drawn according to the first digital signals and the second digital signals. In the invention, the multi-core cable is utilized in order to transmit the data collected by the temperature detection device to the upper computer in a manner of parallel communication so as to solve the problem that the sea depth is needed to be measured through estimating the falling time of the probe, and the falling speed and the throwing mode of the probe are not limited.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

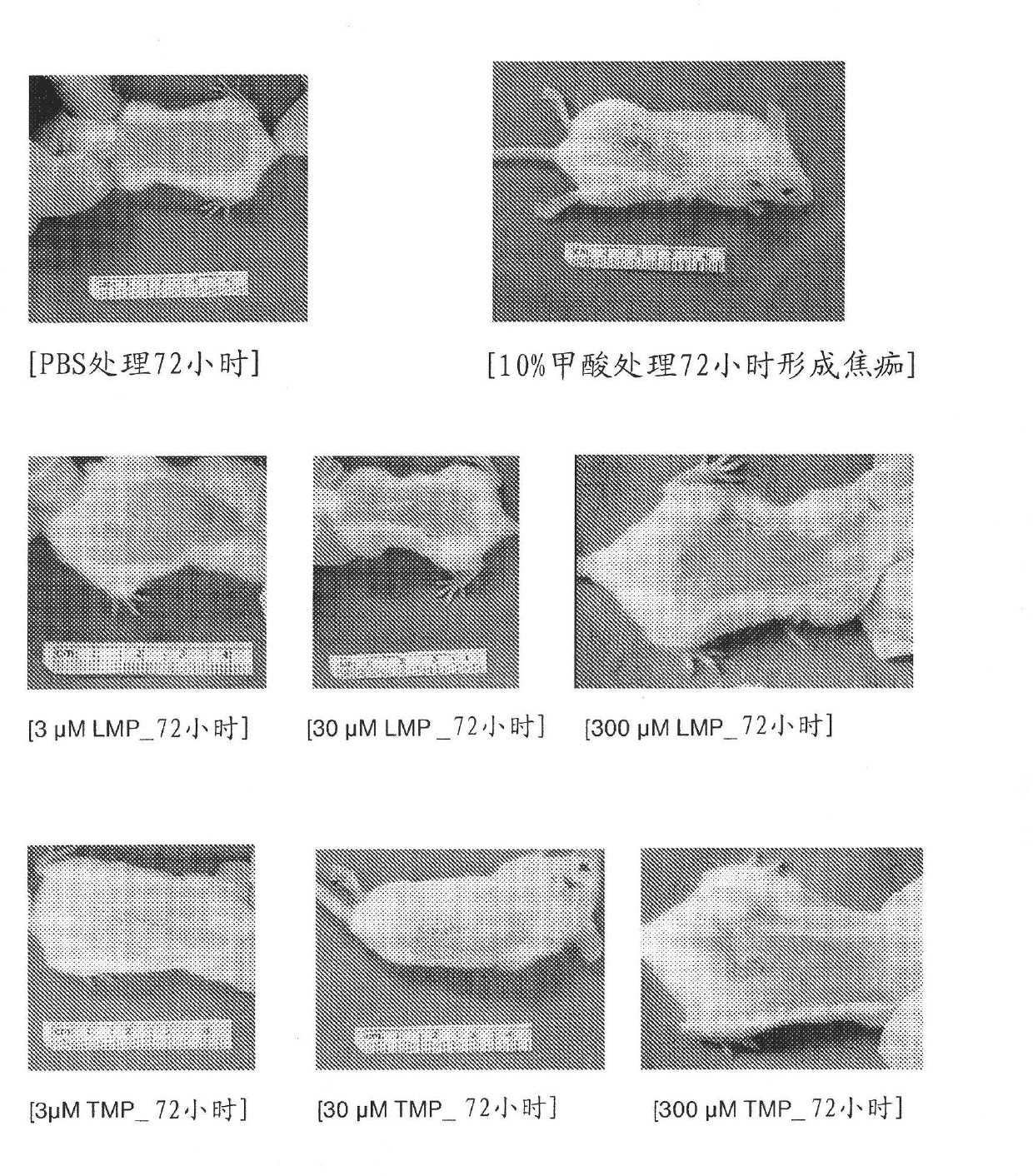

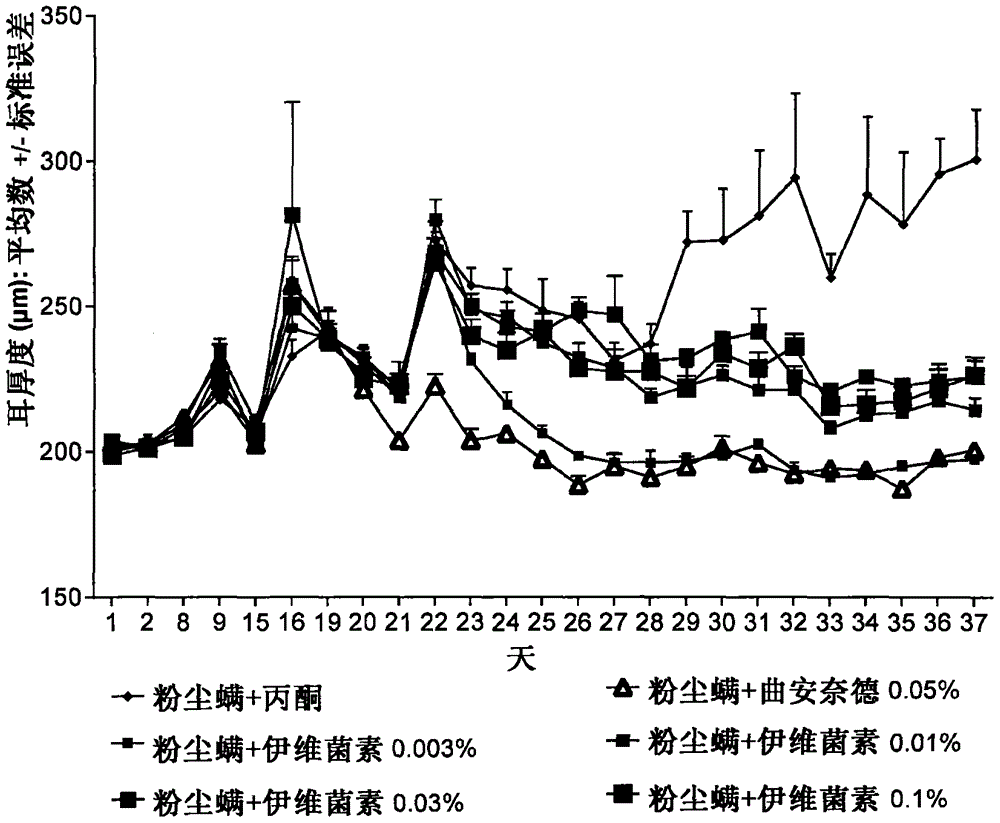

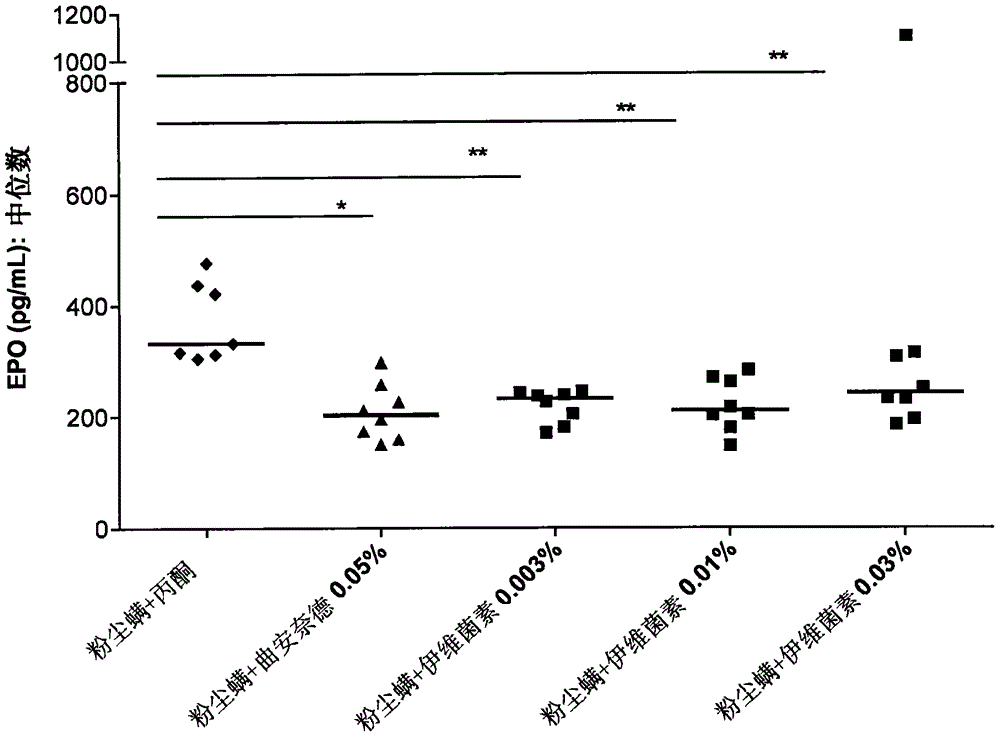

Compound of the avermectin family or of the milbemycin family for the treatment and/or prevention of atopic dermatitis

InactiveCN105916511ANo restrictionsOrganic active ingredientsAerosol deliveryAtopic dermatitisMilbemycin

The present invention relates to a pharmaceutical composition comprising a compound of the avermectin family, preferably ivermectin, or a compound of the milbemycin family in a pharmaceutically acceptable carrier, for use in the treatment and / or prevention of atopic dermatitis.

Owner:GALDERMA SA

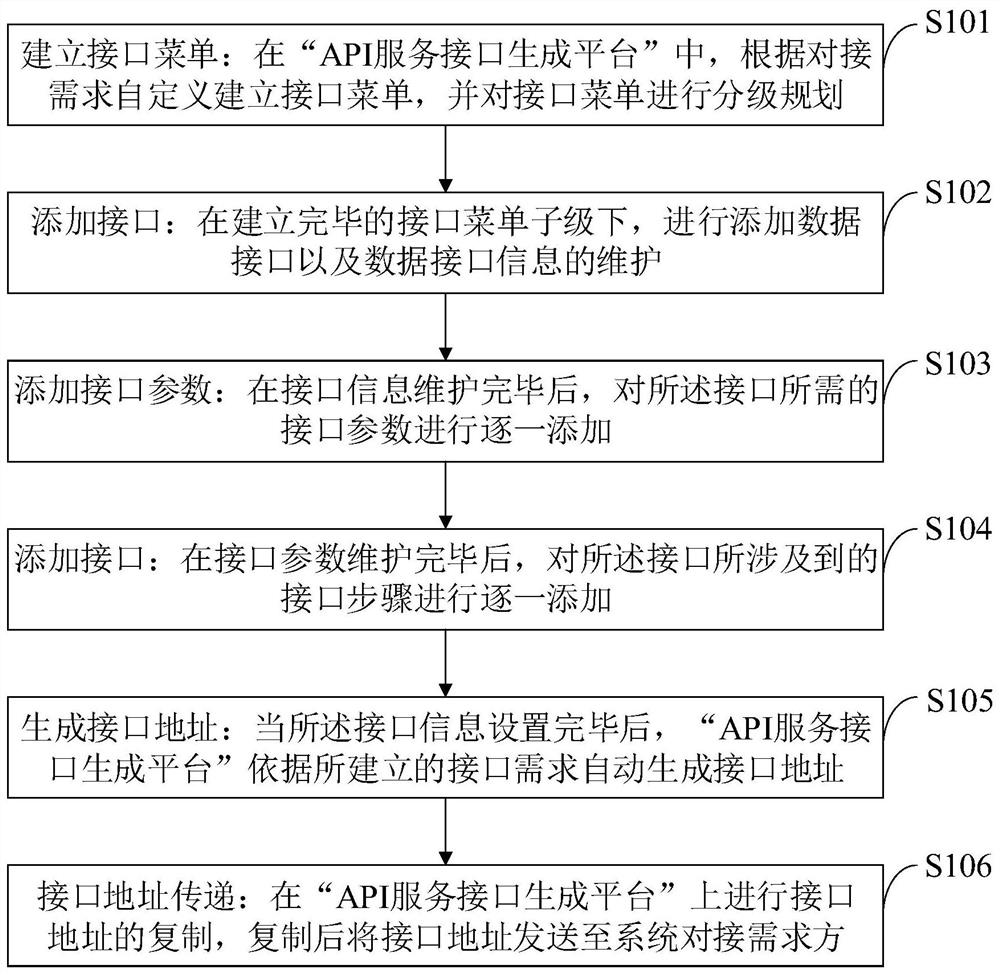

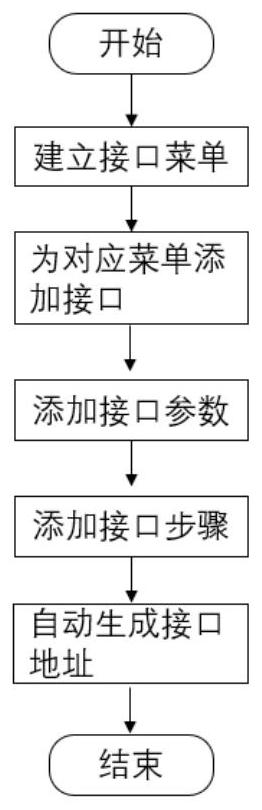

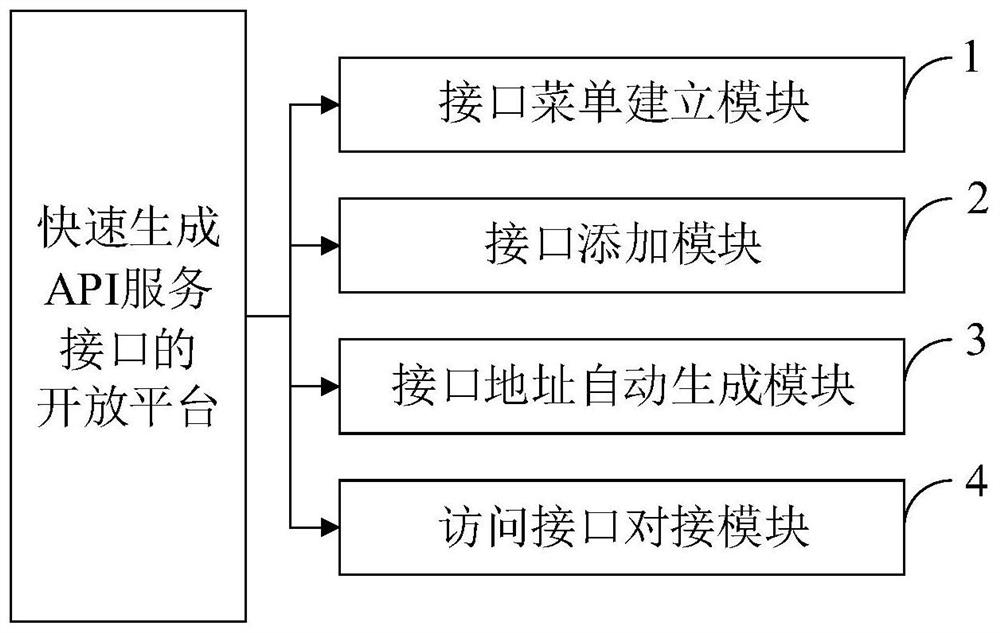

Method for quickly generating API service interface, open platform, terminal and medium

InactiveCN112835561AFlexible callRealize developmentDatabase management systemsInterprogram communicationData connectionStreaming data

The invention belongs to the technical field of open service interface generation, and discloses a method for quickly generating an API service interface, an open platform, a terminal and a medium, and the method for quickly generating the API service interface comprises the steps of establishing an interface menu, adding an interface, adding interface parameters, adding an interface step, generating an interface address and transmitting the interface address. The open platform for quickly generating the API service interface comprises an interface menu establishing module, an interface adding module, an interface address automatic generating module and an access interface docking module. The method is not limited by calling of a front-end framework, and flexible calling of a market mainstream front-end framework is supported; data interface generation is flexible and diversified, and interface data generation of mainstream databases can be met; infinite expansion and addition can be realized; code development is avoided, operation can be carried out without technicians, and rapidness, safety and accuracy of data docking are improved; the time cost of workers is reduced, the working efficiency is improved, and meanwhile the replicability of data connection can be achieved.

Owner:吉林省裕林信息科技有限公司

Drug releasing coatings for medical devices

The invention relates to a medical device for delivering a therapeutic agent to a tissue. The medical device has a layer overlying the exterior surface of the medical device. The layer contains a therapeutic agent, an antioxidant, and an additive. In certain embodiments, the additive has a hydrophilic part and a drug affinity part, wherein the drug affinity part is at least one of a hydrophobic part, a part that has an affinity to the therapeutic agent by hydrogen bonding, and a part that has an affinity to the therapeutic agent by van der Waals interactions. In some embodiments, the additive is a liquid. In other embodiments, the additive is at least one of a surfactant and a chemical compound, and the chemical compound has one or more hydroxyl, amino, carbonyl, carboxyl, acid, amide or ester groups.

Owner:路通医疗股份有限公司

A fast selection method for HEVC prediction mode based on scene switching

ActiveCN106454341BTotal encoding time does not increaseImprove applicabilityDigital video signal modificationPrediction algorithmsComputer vision

The invention discloses a method for rapidly selecting a HEVC prediction mode based on scene switching. The method comprises the following steps of: firstly, when an input YUV file is read, recording the brightness component of each frame of image to form a gray-level image; compressing each frame of gray-level image into an index image in the M*M format by utilizing an interpolation method; calculating the average value V<average> of the M*M gray values, and comparing each gray value with the V<average> to obtain a M*M-bit binary fingerprint sequence of each frame of image; for two sequential images, comparing fingerprint sequences thereof, counting the number dNum of different binary values at corresponding positions, and generating a hash index; and, for a current frame of image, the hash index of which is greater than a threshold value T, judging that the current frame is a scene switching frame, setting the current frame to the I frame when the frame type is set, performing predication coding according to the I frame, and otherwise, not performing any operation. By means of the method disclosed by the invention, for the scene switching frame in a video, rapid detection can be carried out; furthermore, other related optimal acceleration algorithms cannot be influenced; and the coding quality cannot be changed. The method disclosed by the invention can be used together with the existing HEVC rapid prediction algorithm.

Owner:NANJING UNIV OF POSTS & TELECOMM

A method for solving inverse kinematics of a 6-DOF manipulator

ActiveCN109344477BReduce computationNo restrictionsGeometric CADSpecial data processing applicationsAlgorithmClassical mechanics

Owner:GUILIN UNIV OF ELECTRONIC TECH

Polyolefin-based compositions, adhesives, and related multi-layered structures prepared therefrom

ActiveCN108463502ANo restrictionsSignboardsSynthetic resin layered productsPolymer sciencePolyolefin

The present invention provides for a polyolefin-based composition made from or comprising (A) a first polymer composition made from, or containing an ethylene polymer grafted with an unsaturated monomer, and (B) a second polymer composition comprising a propylene polymer, wherein the ethylene polymer grafted with an unsaturated monomer is covalently bonded to the propylene polymer. The polymeric composition may be used as a tie-layer adhesive composition.

Owner:EQUSR CHEM LP

A method of making cultivation substrate by using herb residues of traditional Chinese medicine

ActiveCN104072219BReduce saltNo restrictionsBio-organic fraction processingOrganic fertiliser preparationCation-exchange capacityMoisture

Owner:广东巴斯德环境科技有限公司

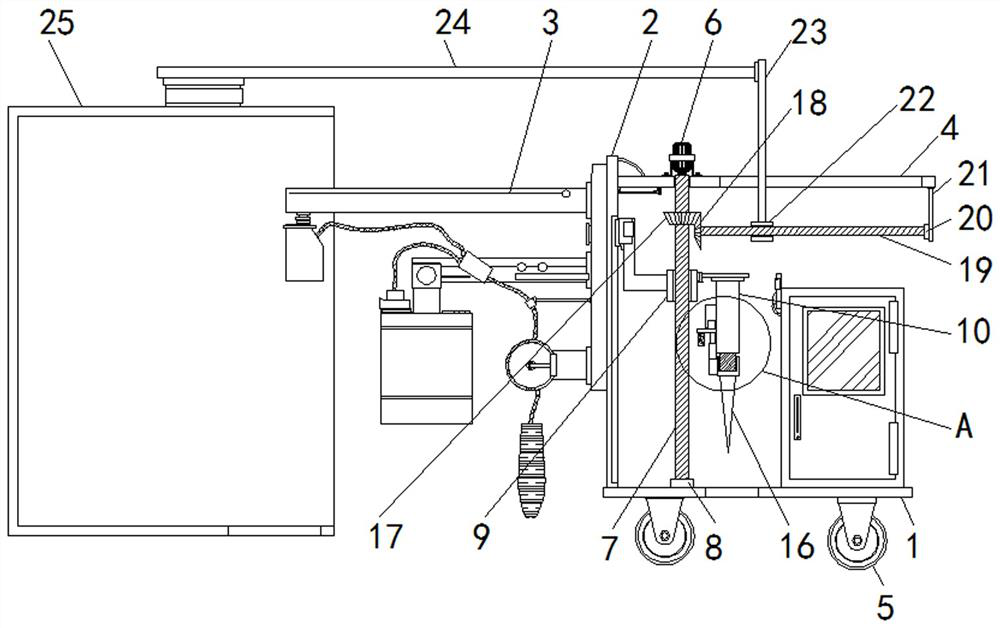

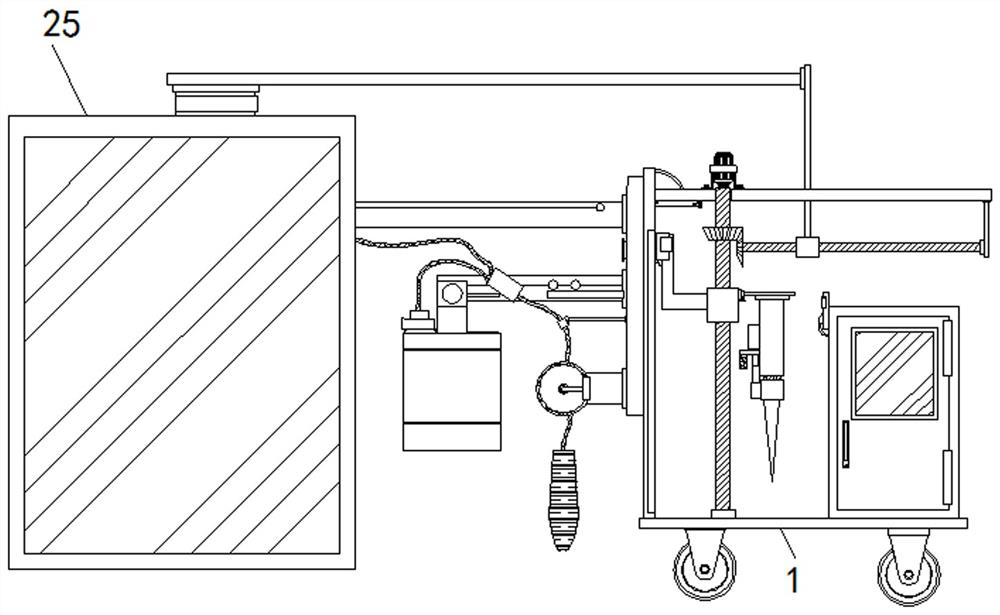

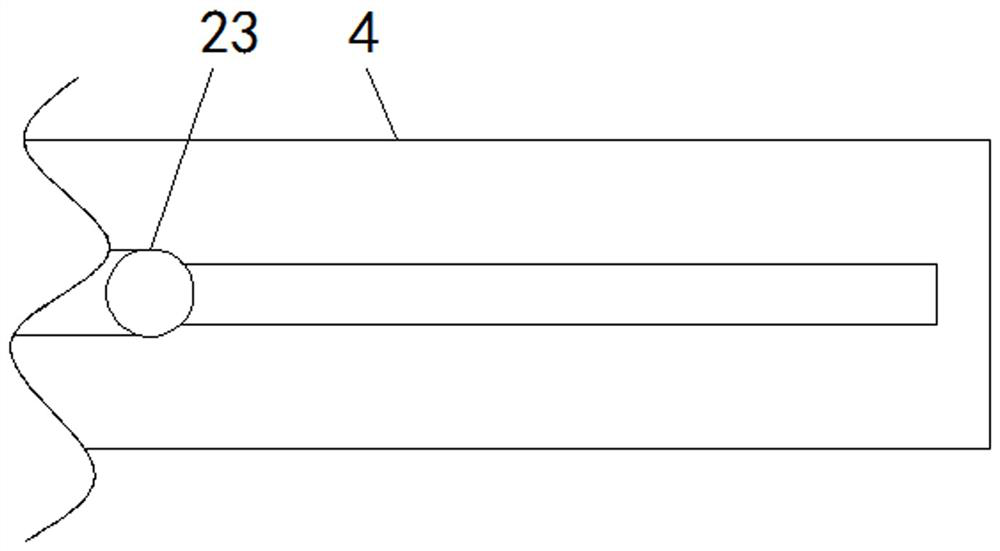

A Submersible Ultrasonic Flow Monitor Convenient for Field Use

ActiveCN113340364BEasy to use in the fieldNo restrictionsVolume/mass flow measurementVolume meteringWater flowThreaded rod

The invention relates to the technical field of water flow monitoring, and discloses an input-type ultrasonic flow monitor that is convenient for field use, including a moving seat, the top of the moving seat is fixedly connected with a side mounting frame, and the side mounting frame The left side is fixedly connected with the main body of the input type ultrasonic flow monitor, the right side of the side mounting frame is fixedly connected with a bearing plate, the bottom of the moving base is fixedly connected with four wheels, and the top of the bearing plate A servo motor is fixedly connected, the output shaft of the servo motor is fixedly connected with a first threaded rod with one end penetrating and extending to the bottom of the bearing plate, and the bottom of the first threaded rod is fixedly connected with a first threaded rod whose bottom is fixedly connected with the moving seat. Bearing, the outer side of the first threaded rod is threaded with a first threaded block. The input-type ultrasonic flow monitor which is convenient for field use has achieved the purpose of being convenient for field use as a whole.

Owner:WUHAN NEWFIBER OPTOELECTRONICS TECH

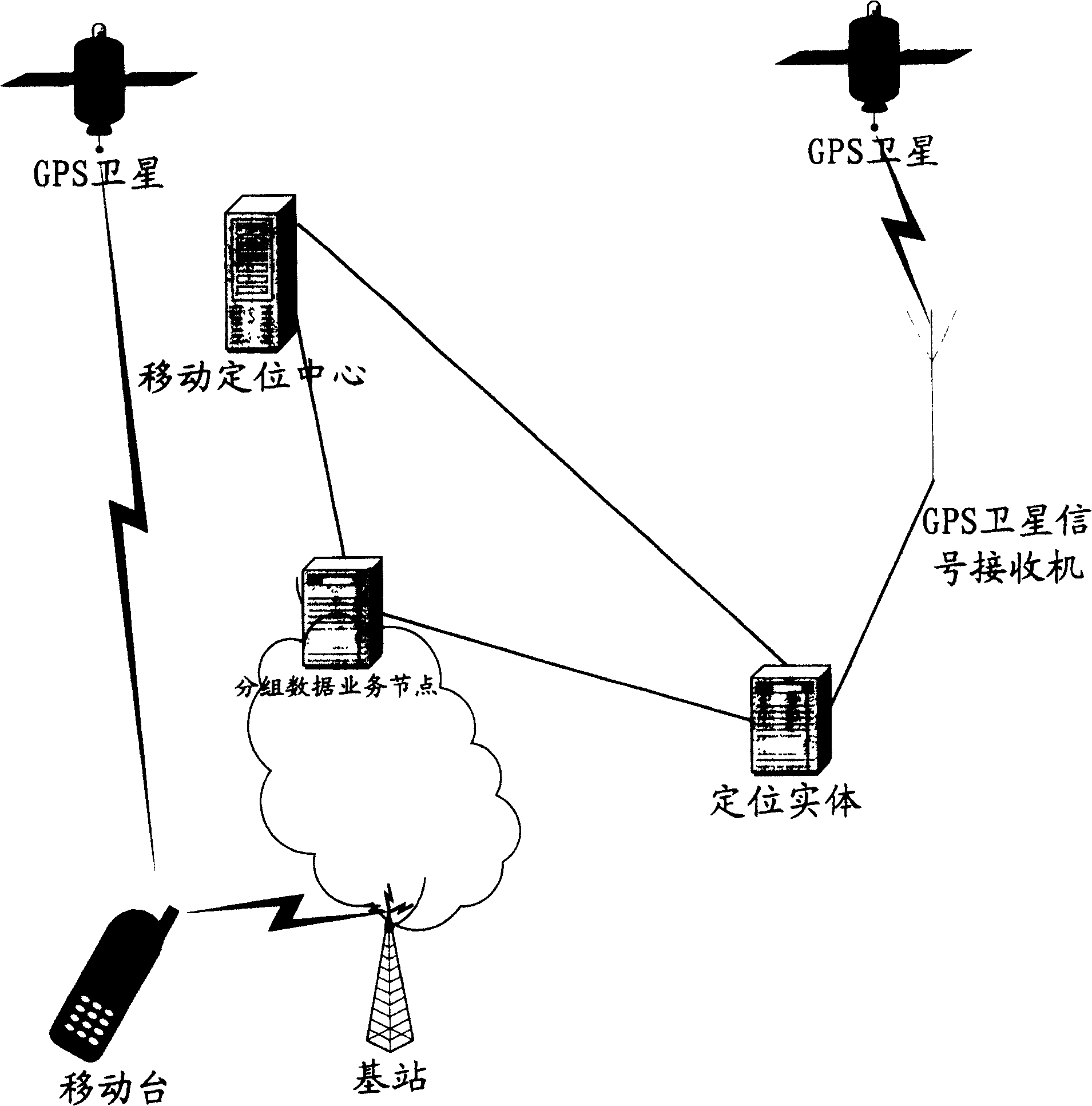

Analogue mobile station system, analogue mobile station positioning testing system and testing method

InactiveCN100431370CAvoid restrictionsNo restrictionsRadio/inductive link selection arrangementsTransmission monitoringSatellite dataCode module

An analog mobile station system includes a man-machine interaction module, a control module, a test data derivation module, a database management module and a code / de-code module. An analog mobile station location test system includes: an analog mobile station system, a mobile location center, a location entity and a satellite data receiver. The test method includes: finishing the designing of the test request by the man-machine interaction module and transmits it to the control module to set the time trigger of each test task and the control module sets up the connection with the location entity based on the TCP / IP, the test data derivation module finishes the calculation of pilot phase and satellite false distance, the control module finishes the signaling interaction with the location entity on the location flows by the calculated data to transmit the position result computed by the location entity to the man-machine interaction module.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com