Electrothermal cooker

A technology of electric cooking utensils and thermistors, which can be used in household utensils, kitchen utensils, and water-boiling utensils, etc. It can solve the problems of lagging reaction speed, influence of consumers' use, and many processes, etc., and achieve good scratch resistance and wear resistance on the surface , Facilitate large-scale mass production, good process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Figure 3-Figure 5 The shown electric cooker is an electric pressure cooker, including a pot body and a pot cover mainly composed of an outer pot 5 and an inner pot 4, and an electric pressure cooker control circuit board 8 arranged between the pot body and the inner pot, and the pot cover includes There is a pot inner cover 6 and a middle seat 7 for fixing each part,

[0045] A barrel-shaped connection seat 8 is arranged on the middle seat 7, and the connection seat 8 is vertically inserted into the through hole of the pot cover and extends into the pot. The positive temperature coefficient thermistor 1 is printed on the base material 2 to form a temperature change detection element. An insulating layer is printed on the outer layer of the positive temperature coefficient thermistor 1, and the positive temperature coefficient thermistor is also composed of an electrode sheet 9, which is electrically connected to the temperature signal line, and the temperature signal l...

Embodiment 2

[0065] Figure 6 The electric cooker shown is different from Embodiment 1 in that the positive temperature coefficient thermistor 1 is installed in the hollow cavity of the connecting seat 8 near the end of the inner cover of the pot, and there is an upward shoulder under the connecting seat 8, and the positive temperature coefficient thermistor The sensitive resistor 1 is installed on the shoulder, the contact surface between the positive temperature coefficient thermistor 1 and the shoulder is provided with a sealing ring 11, and the positive temperature coefficient thermistor 1 is arranged at the end close to the inner cover of the pot, the steam path is short and the detection is faster more acurrate.

Embodiment 3- Embodiment 10

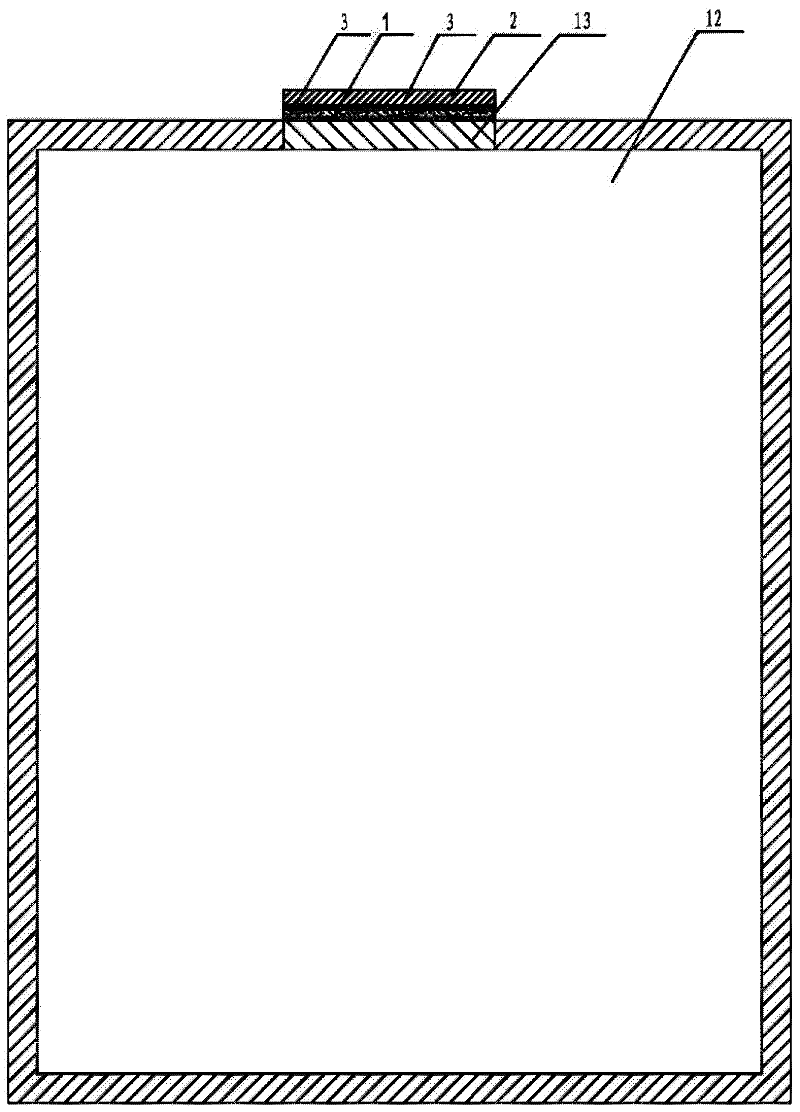

[0067] Figure 7 The positive temperature coefficient thermistor 1 (PTC thermistor) of the shown embodiment 3 is printed on the base material 2, and the base material 2 is metal, and the positive temperature coefficient thermistor 1 both sides are all printed insulating layers 3, and then installed on The surrounding wall of the cooking cavity of the electric cooker is preferably the upper position shown in the figure. The positive temperature coefficient thermistor 1 is on the side close to the cooking cavity of the electric cooker, and the temperature coefficient thermistor 1 is located below, which can directly detect the steam temperature in the cooking cavity 12. Carry out precise temperature control.

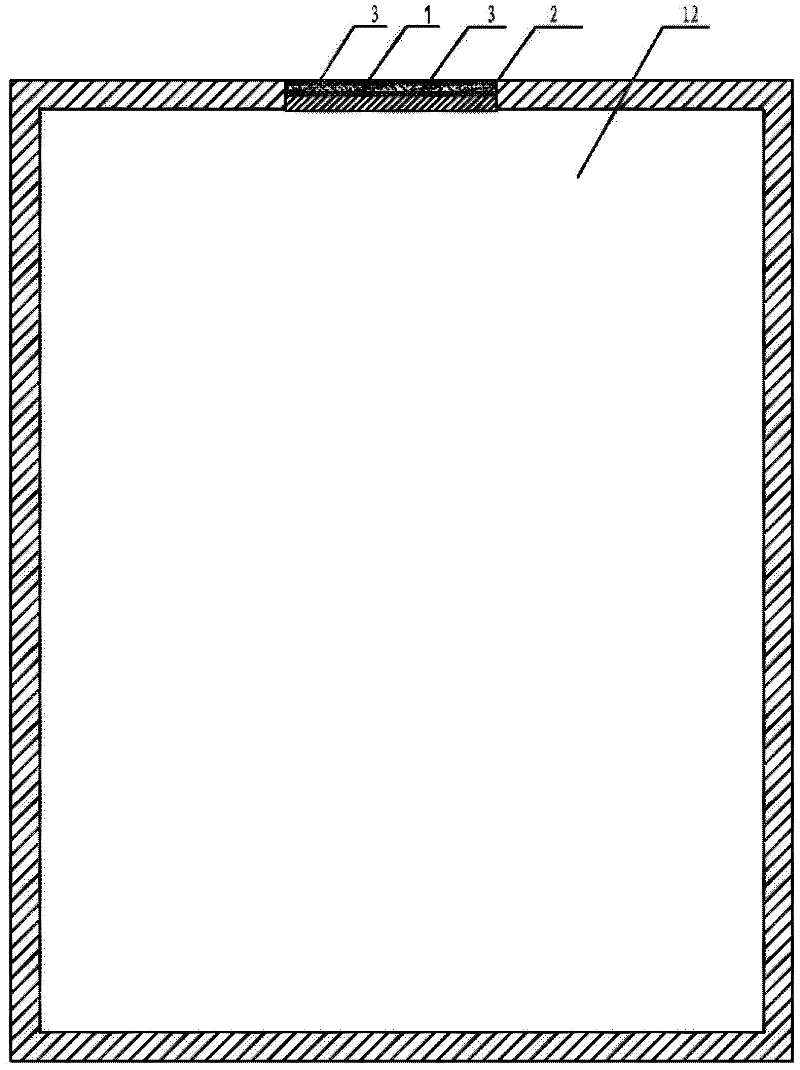

[0068] Figure 8 The shown embodiment 4 positive temperature coefficient thermistor 1 (PTC thermistor) is printed on the substrate 2, and the substrate 2 is metal, and the substrate is on the side close to the cooking cavity of the electric cooker. By detecting the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com