Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Exceptional strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

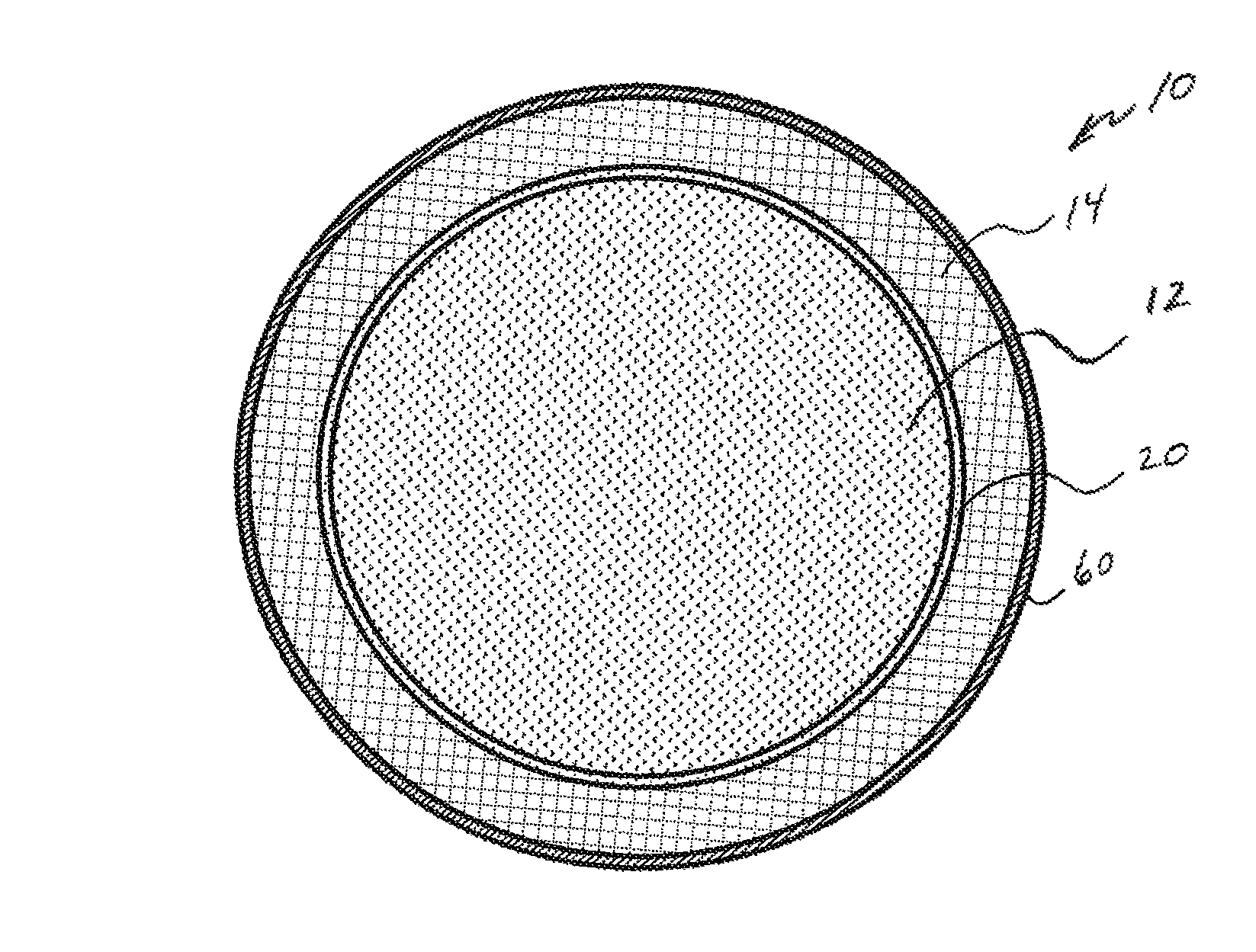

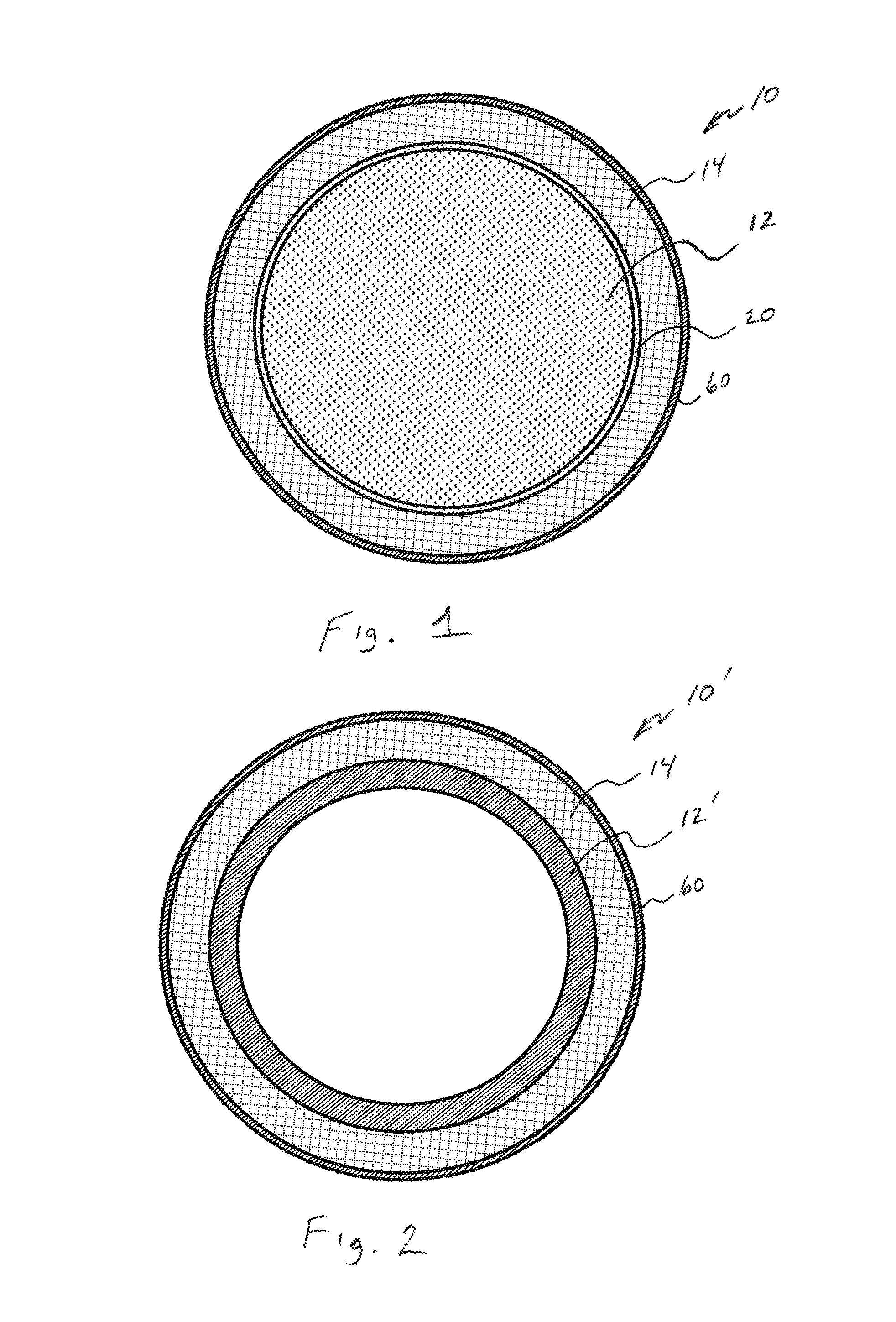

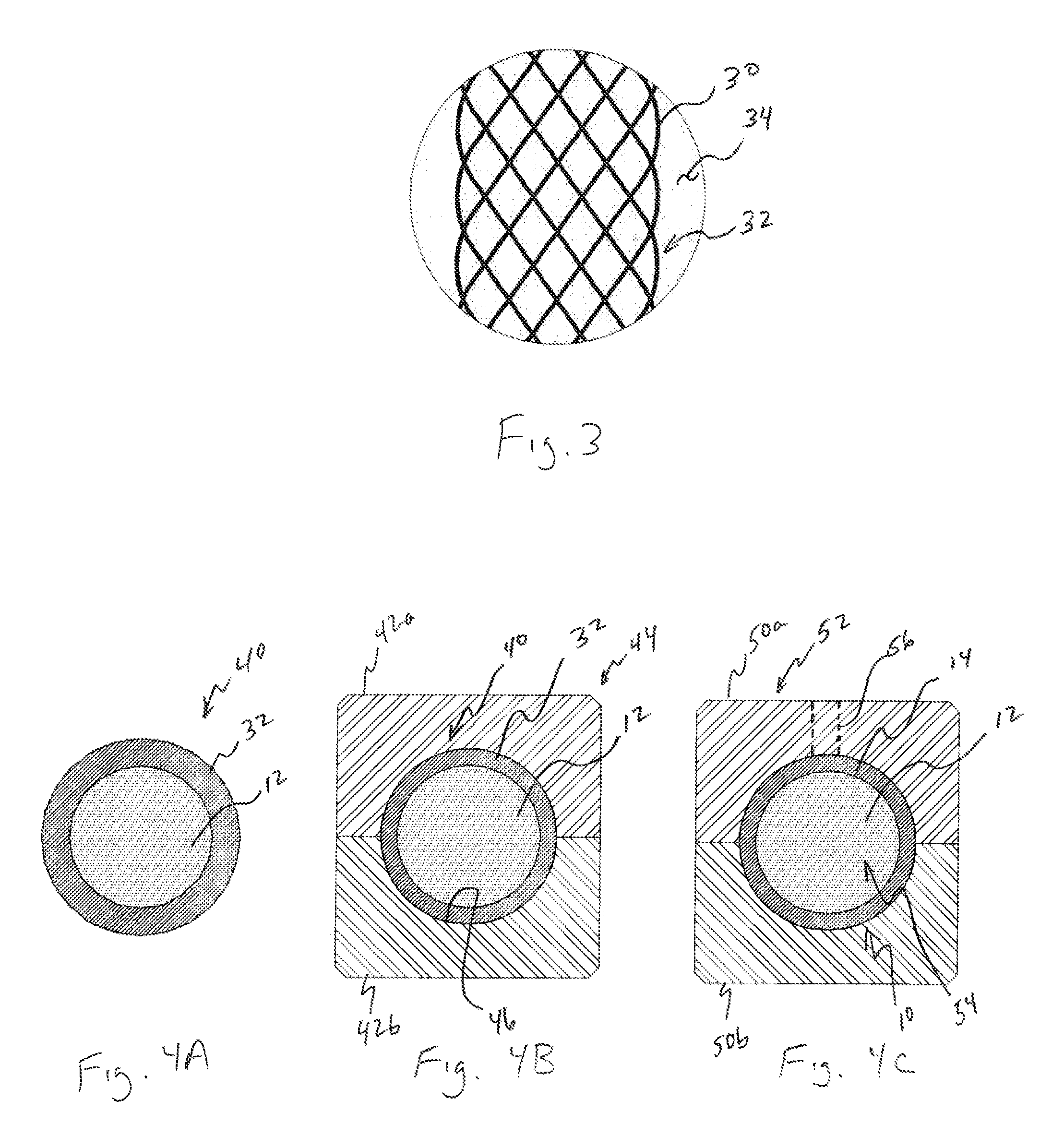

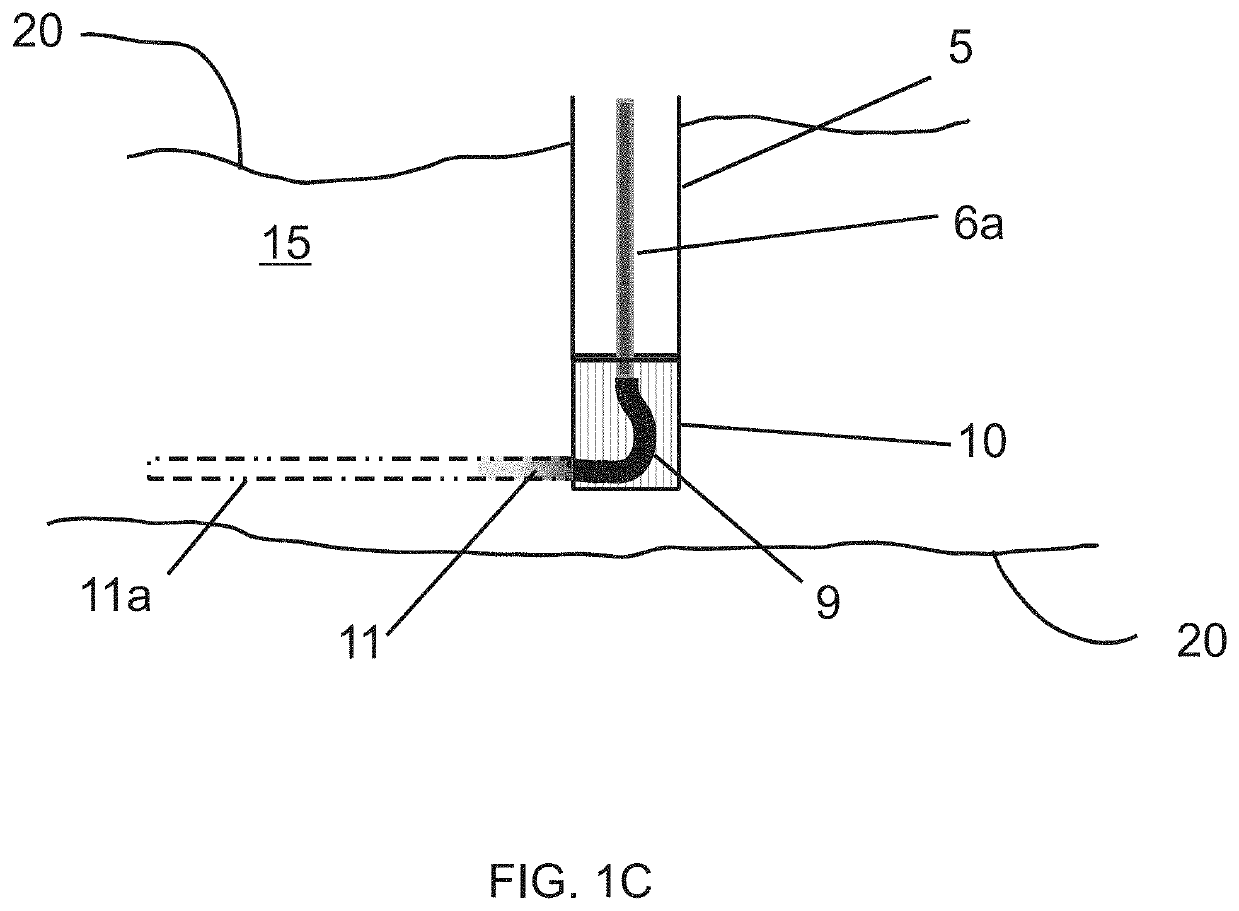

High strength, low density metal matrix composite ball sealer

High strength, low density ball sealer for sealing openings in oil or gas wells, such as perforations formed through the well casing or openings formed through slidable packers or sleeves received within a tubing string in the well, from the flow of a fluid injected into the well. The ball sealer is formed as having an inner core, and a metal matrix composite layer surrounding the core.

Owner:PARKER INTANGIBLES LLC

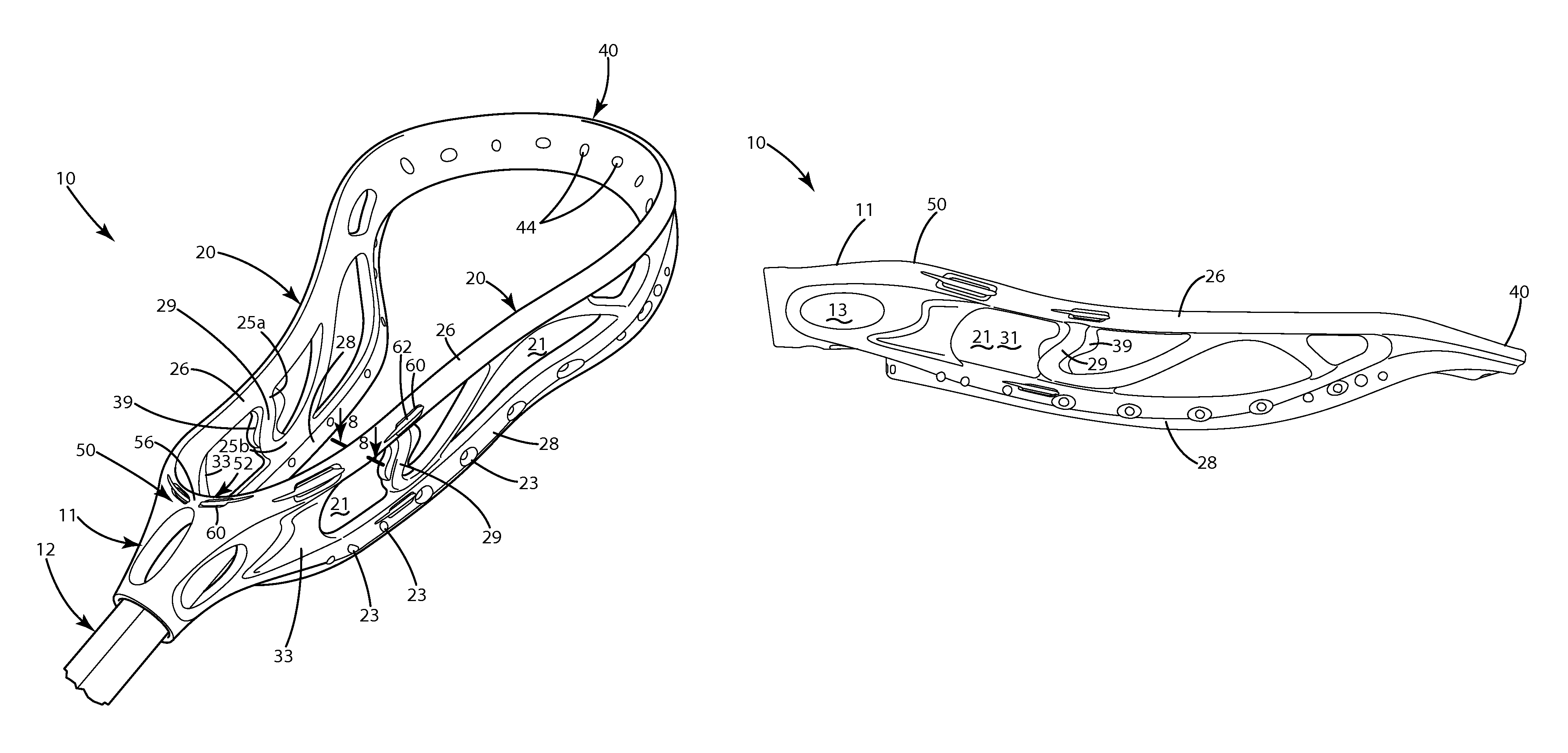

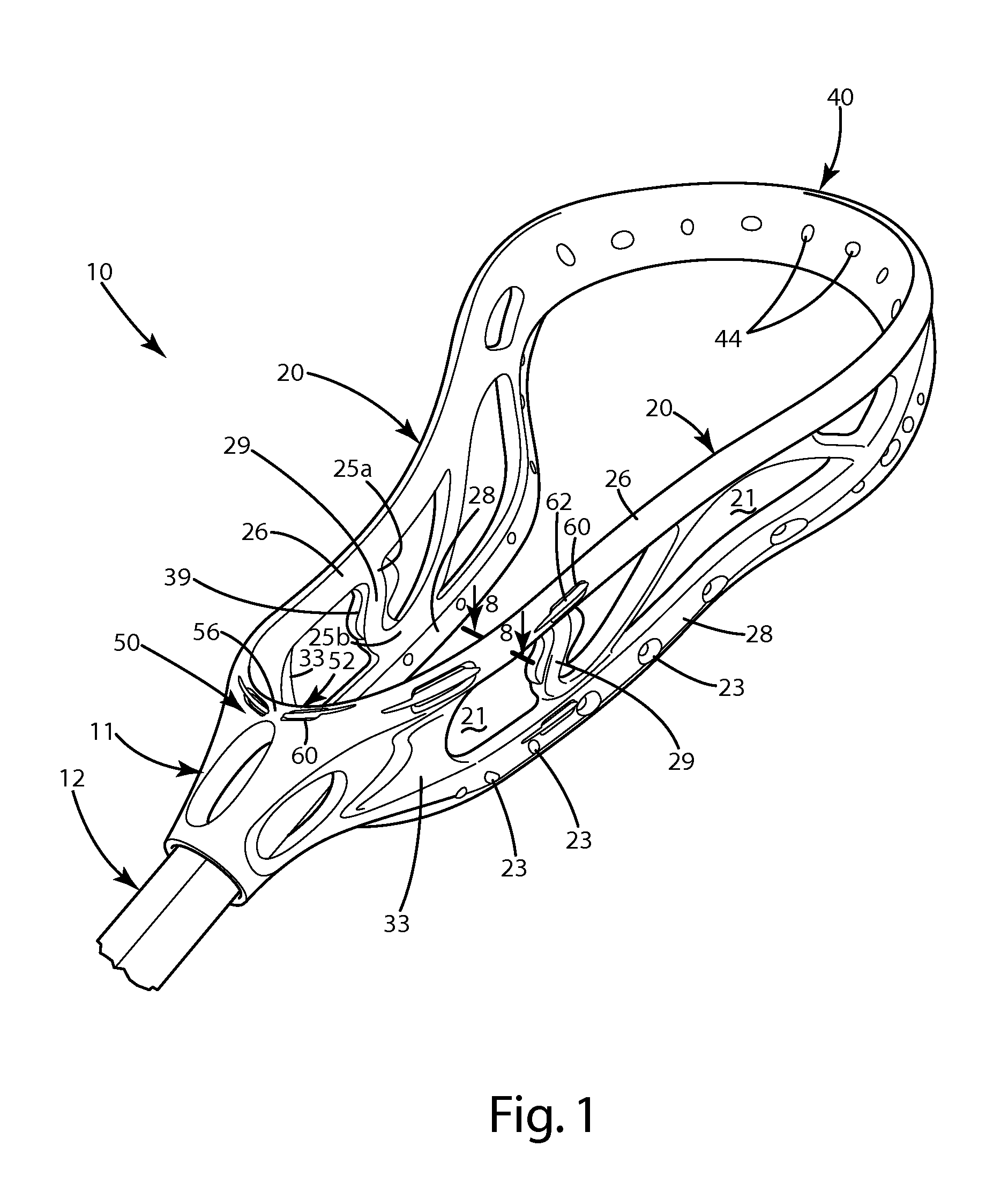

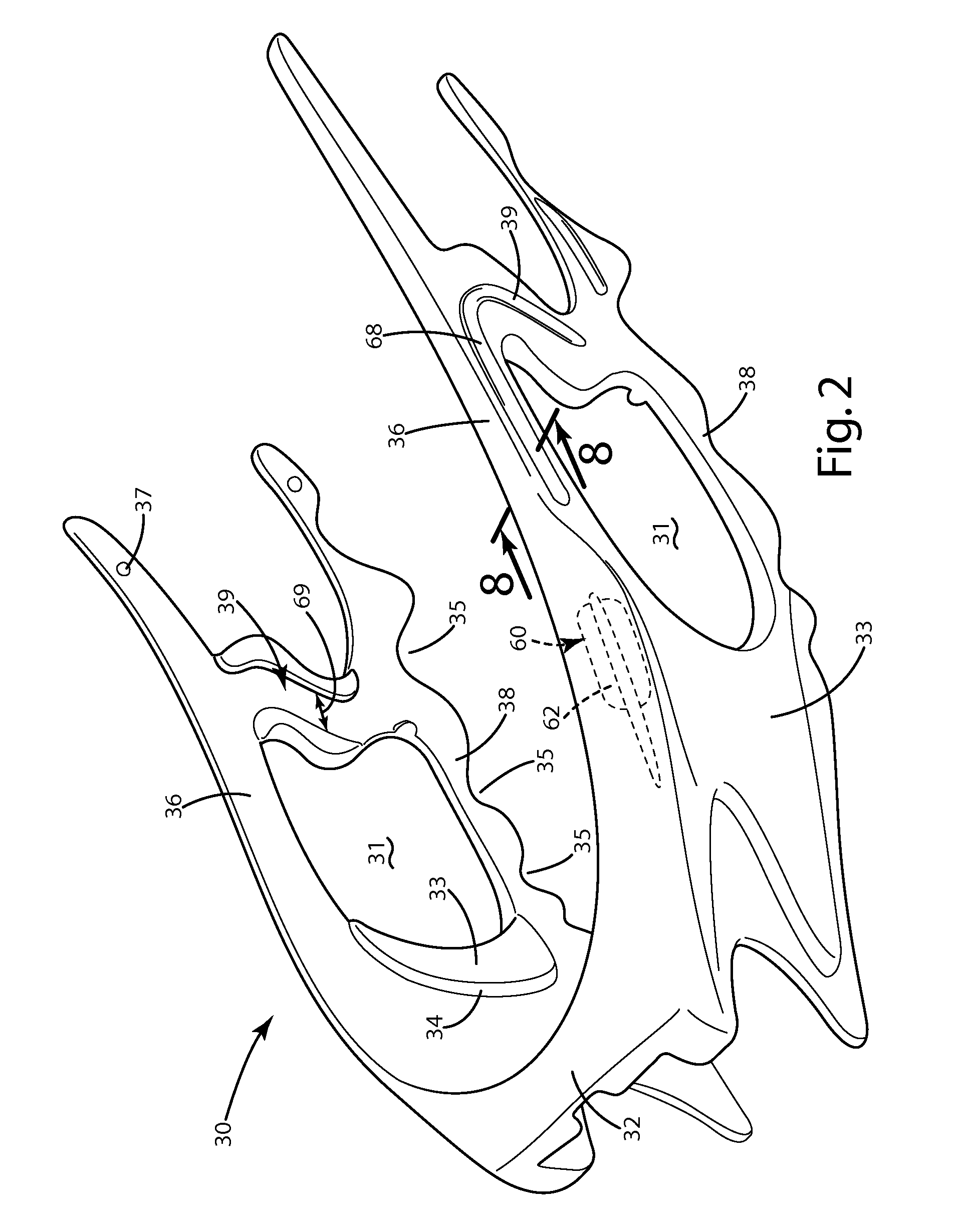

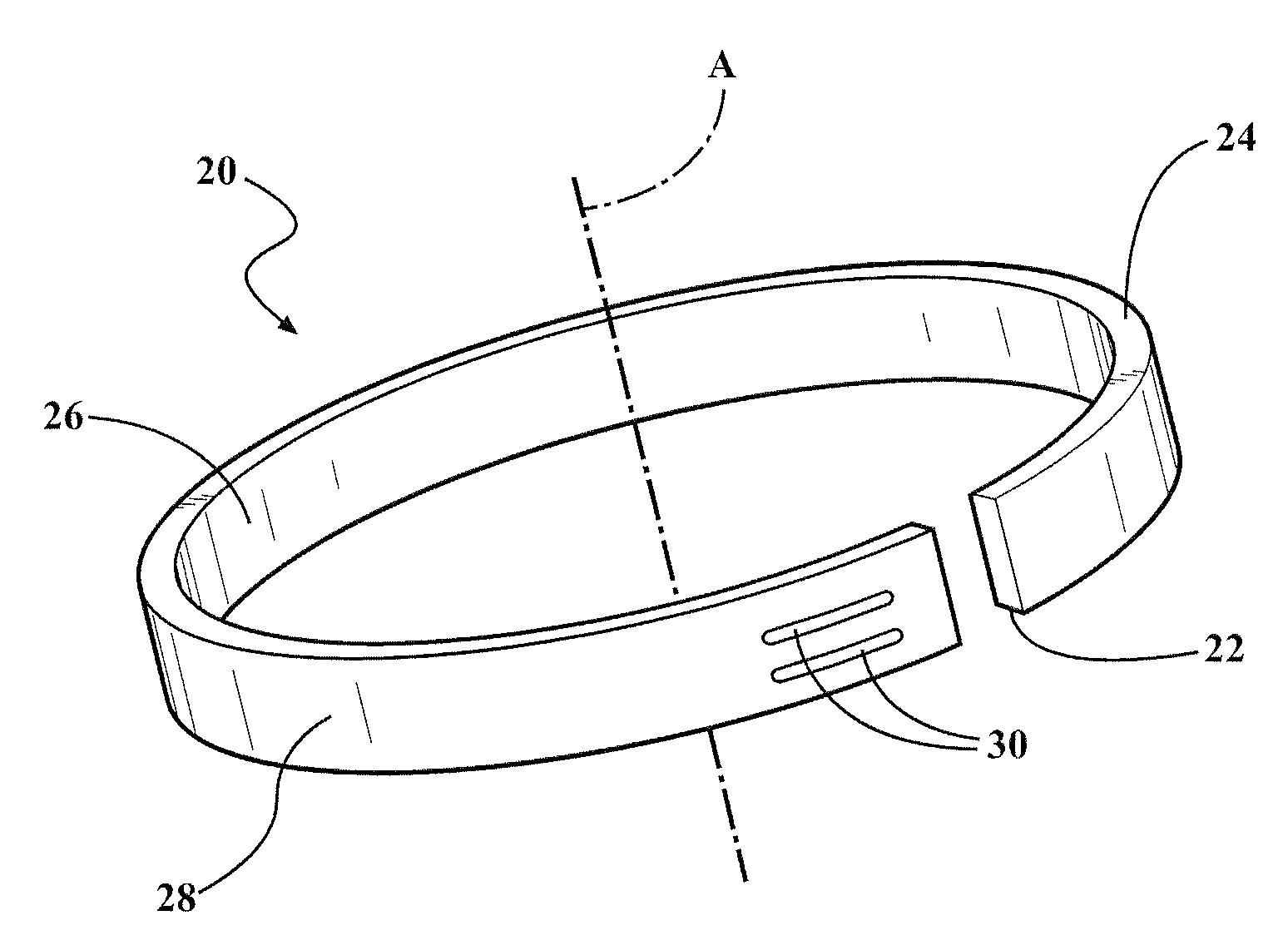

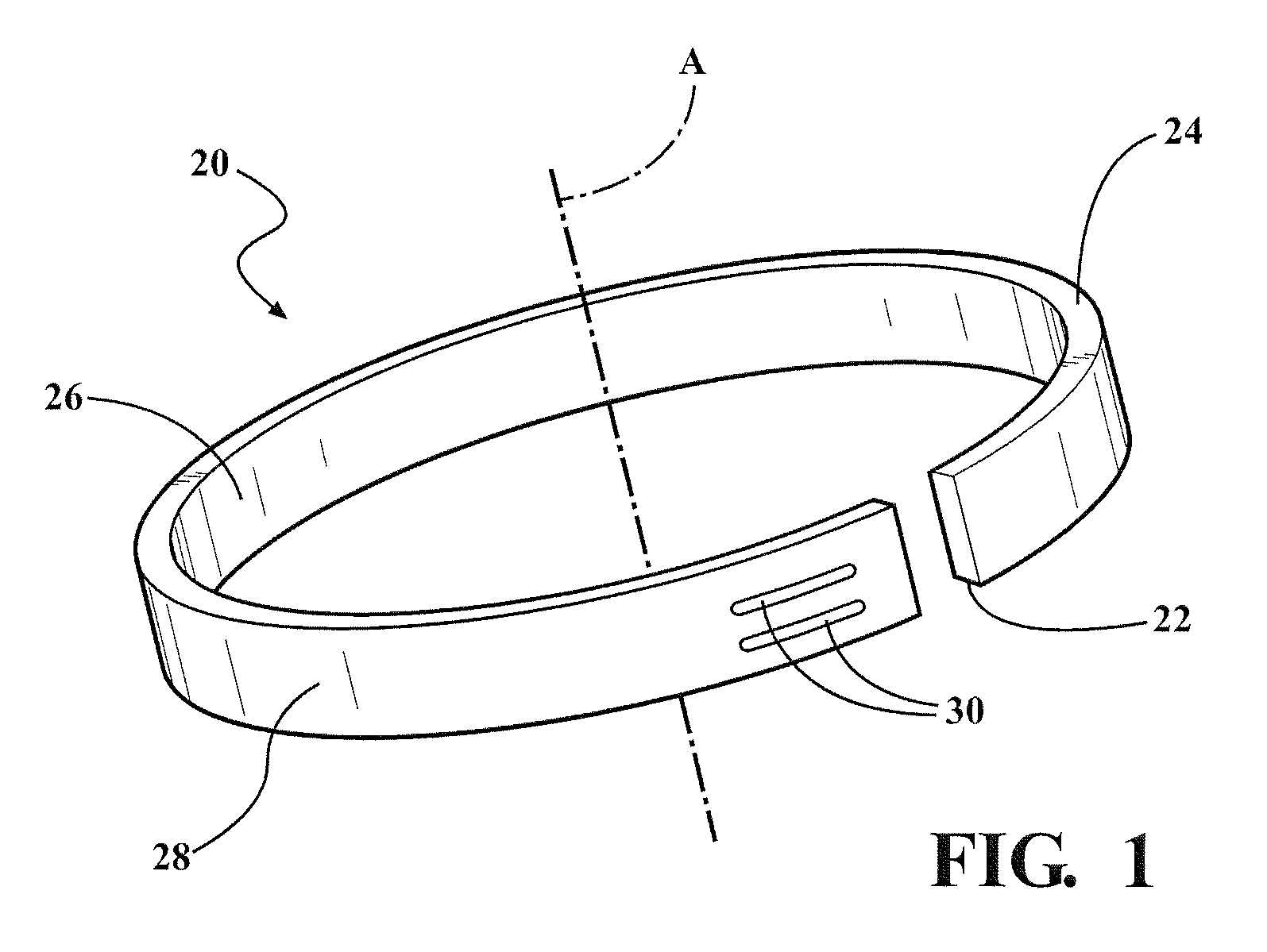

Lacrosse head

ActiveUS8282512B1Exceptional structural supportExceptional strengthThrow gamesRacket sportsBiomedical engineeringBuilding construction

Owner:WARRIOR SPORTS INC

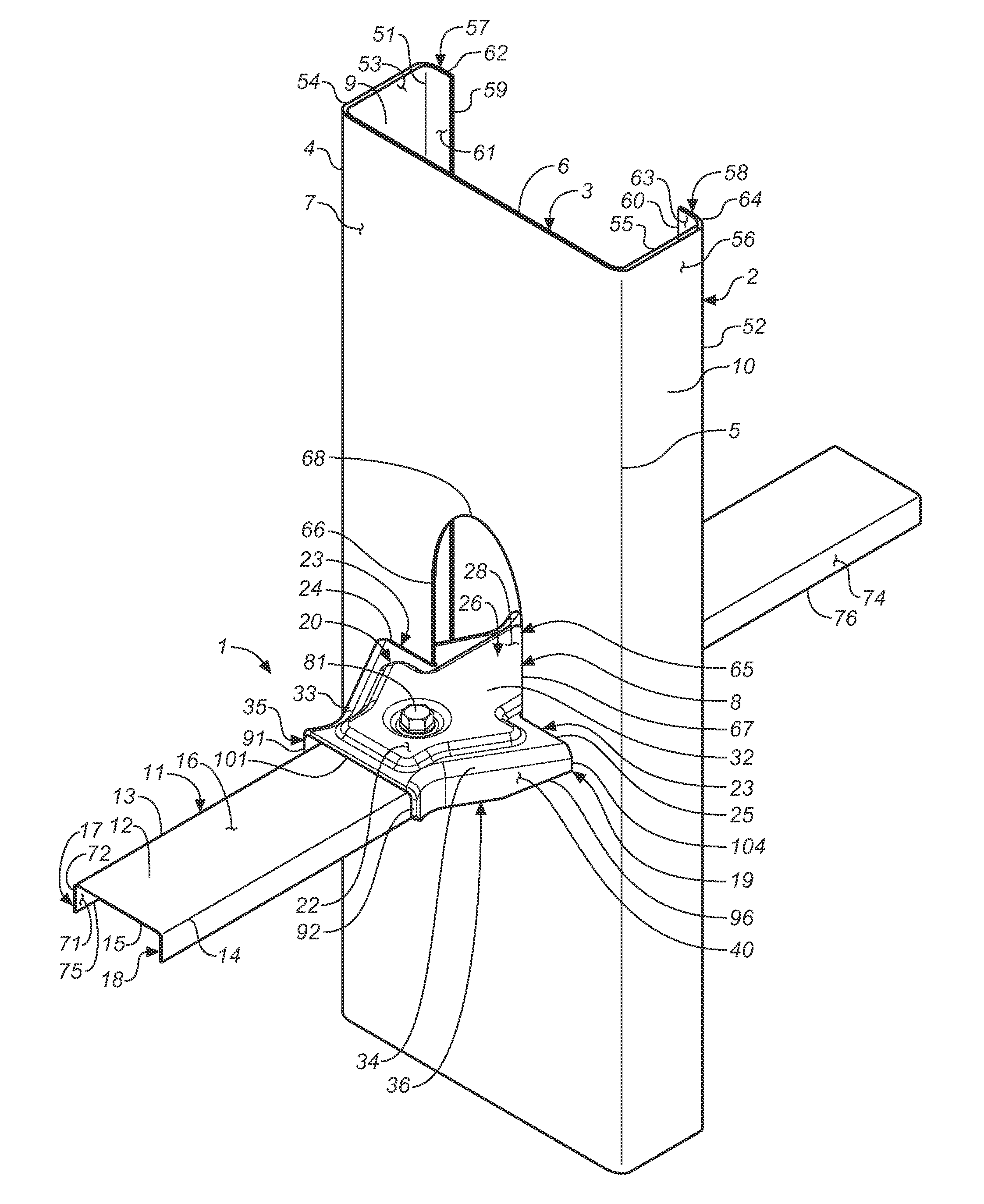

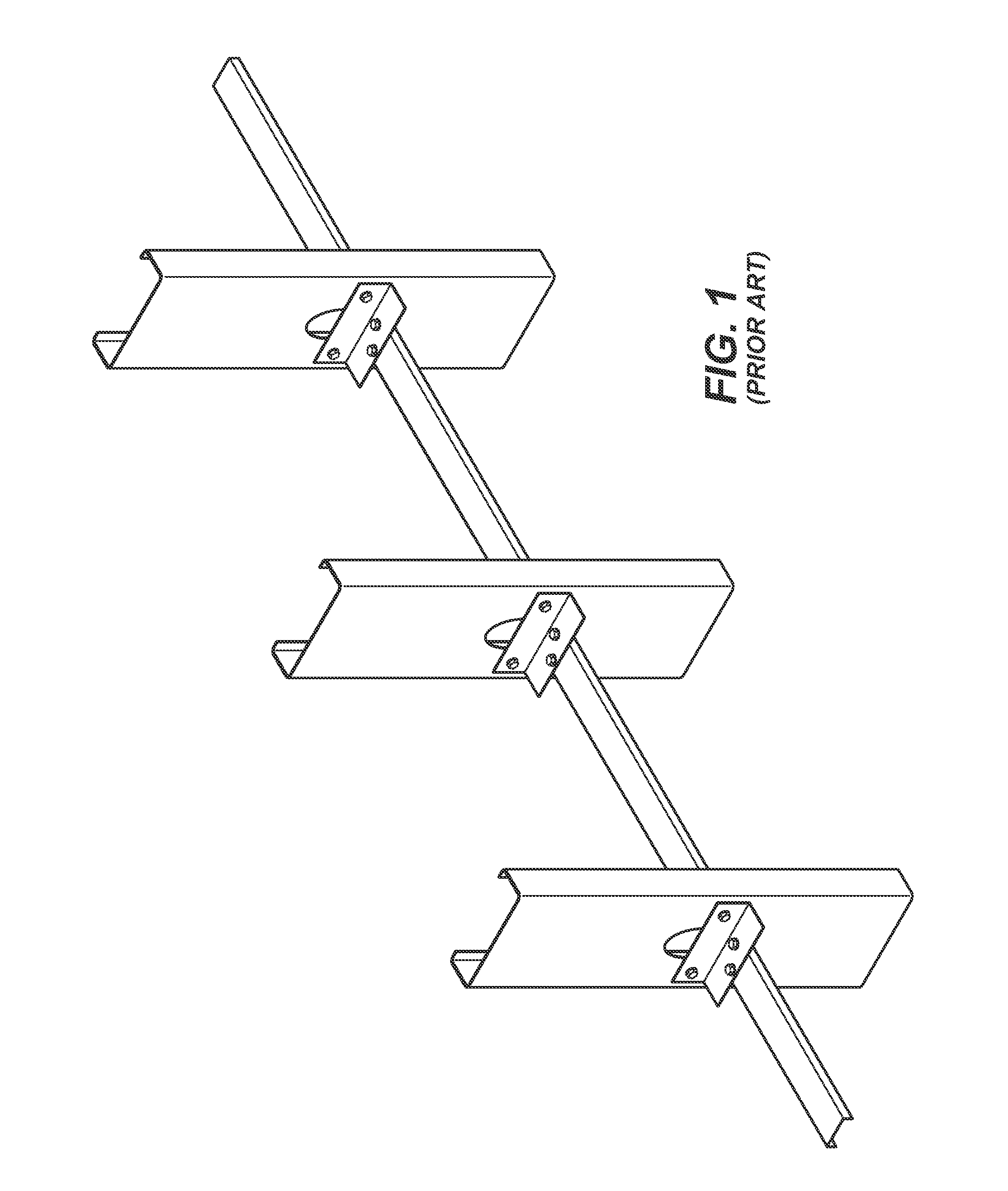

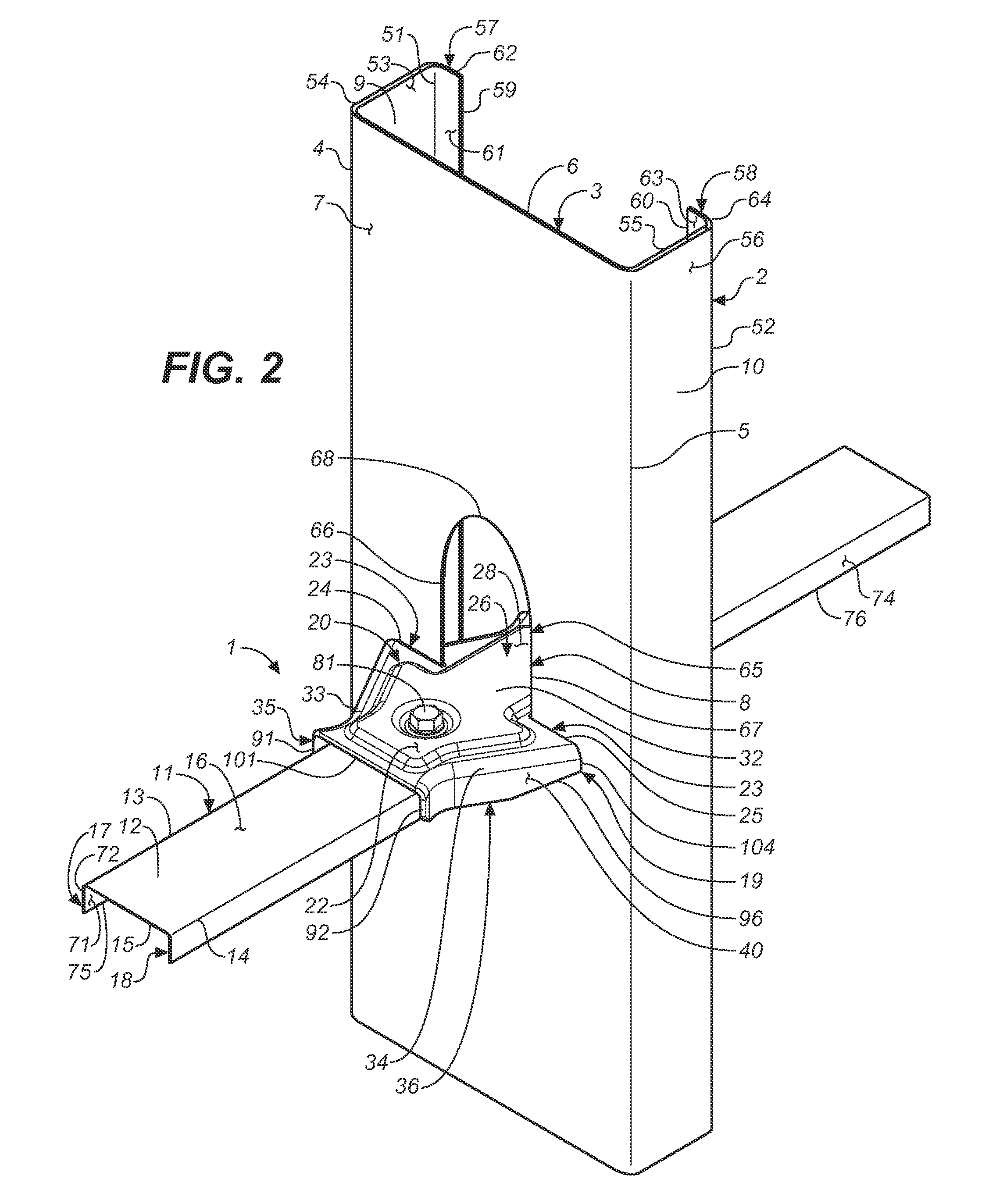

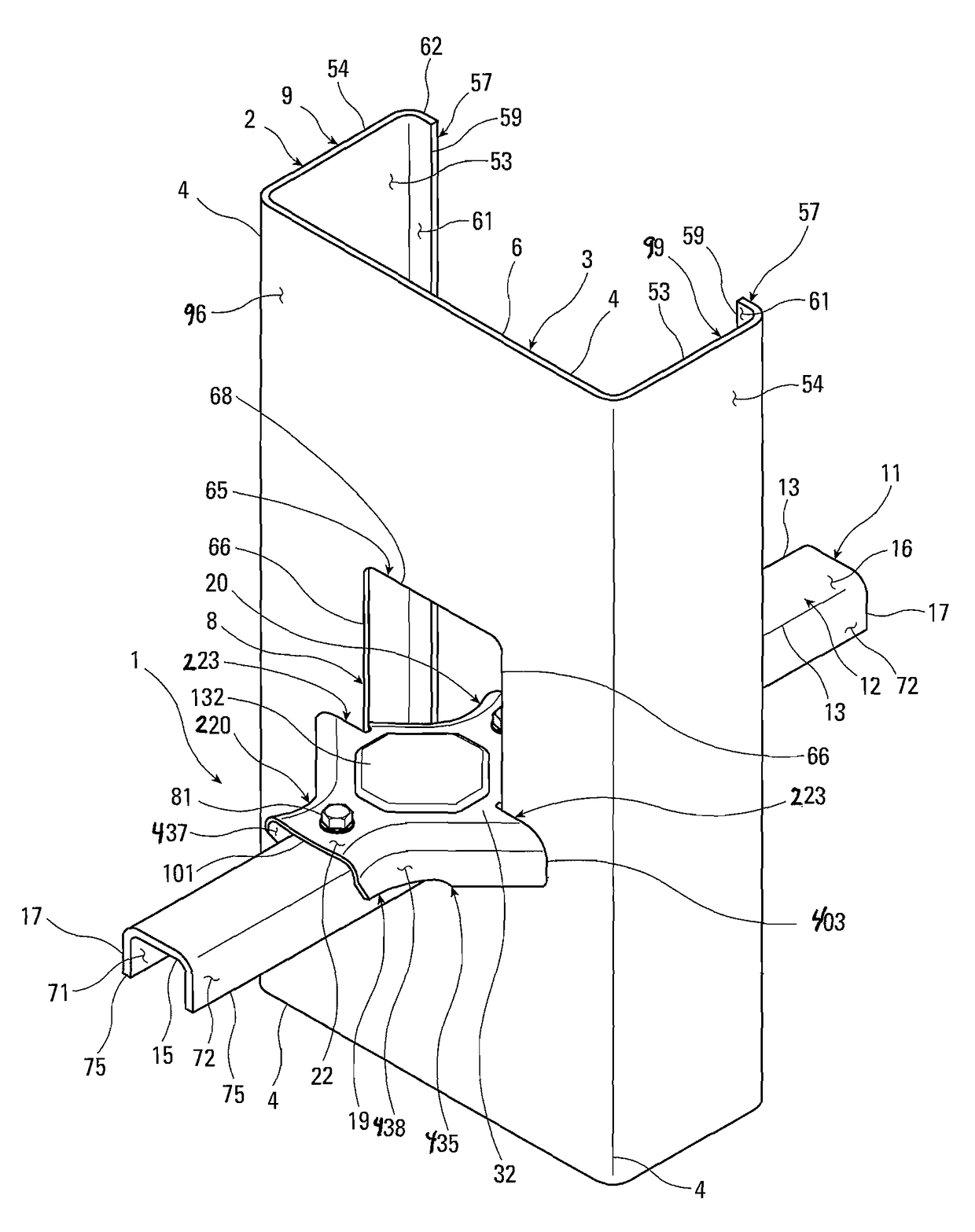

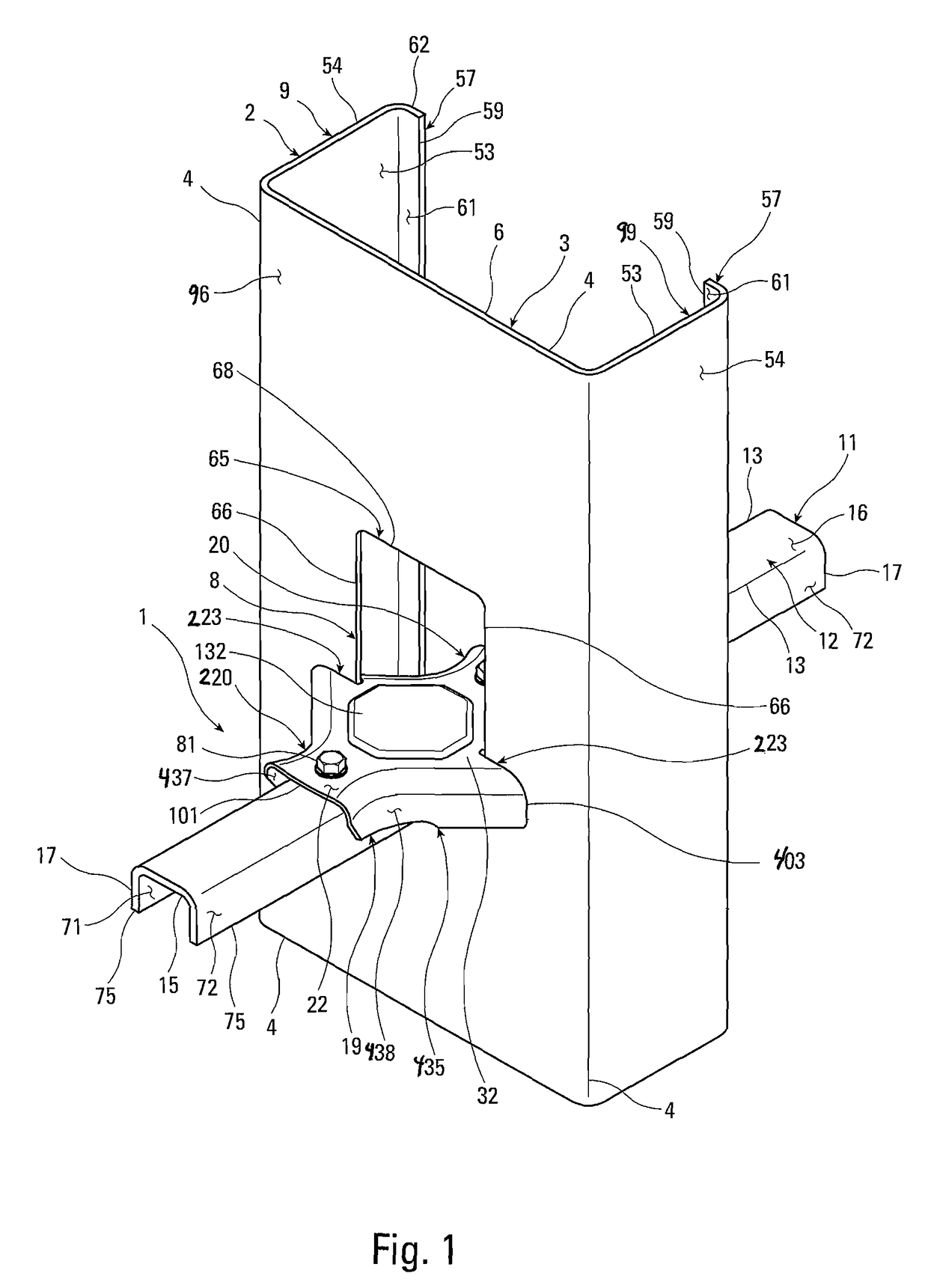

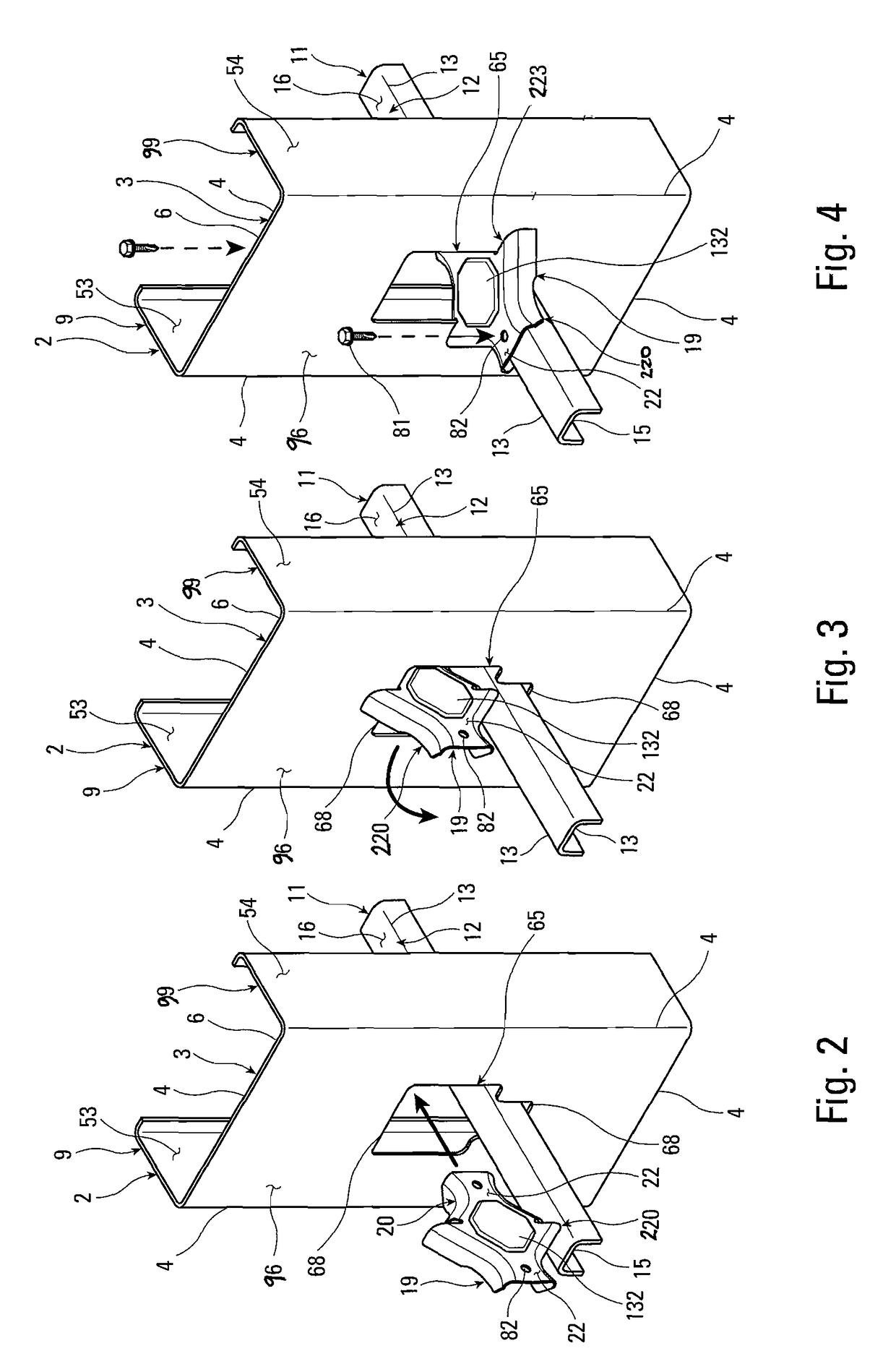

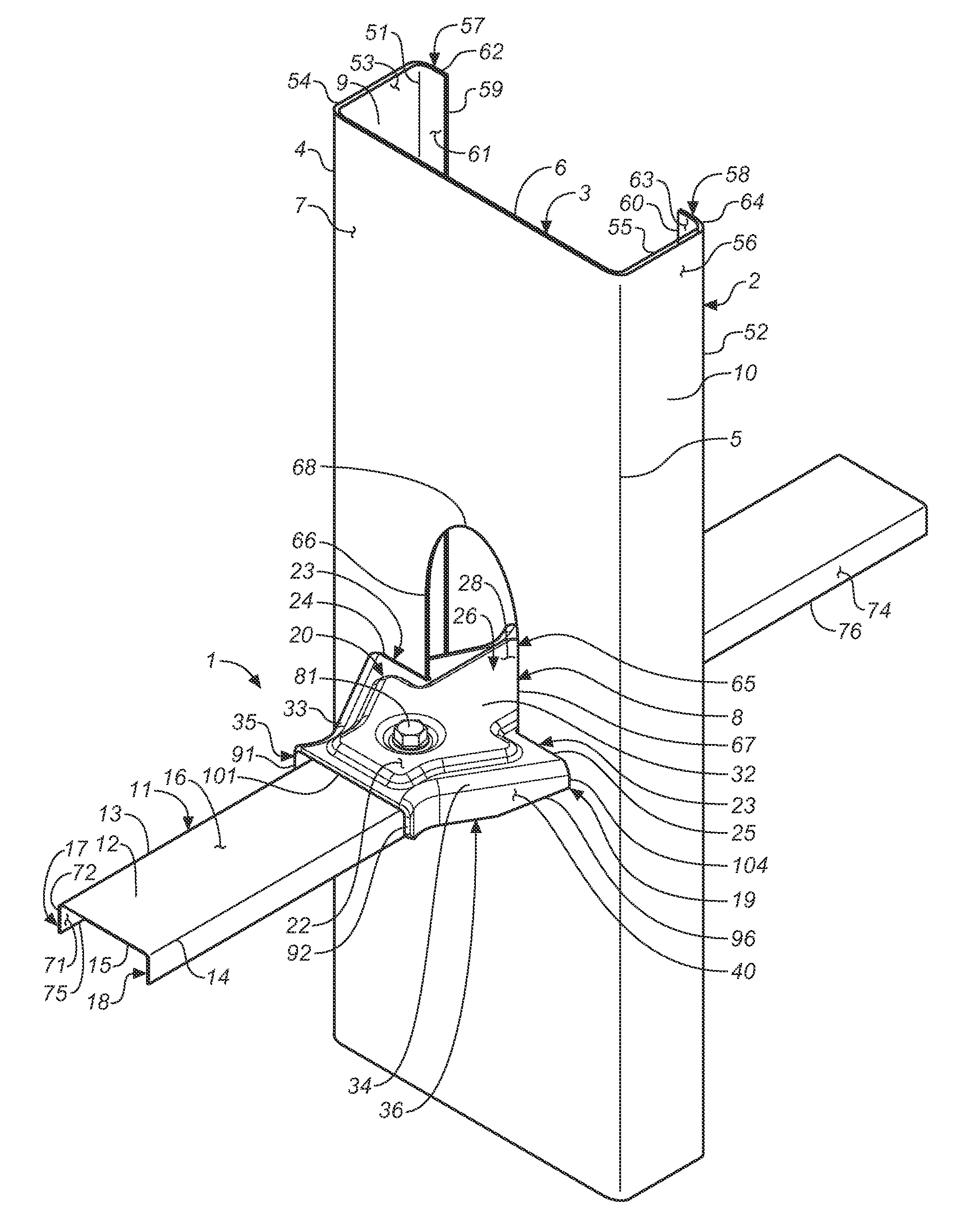

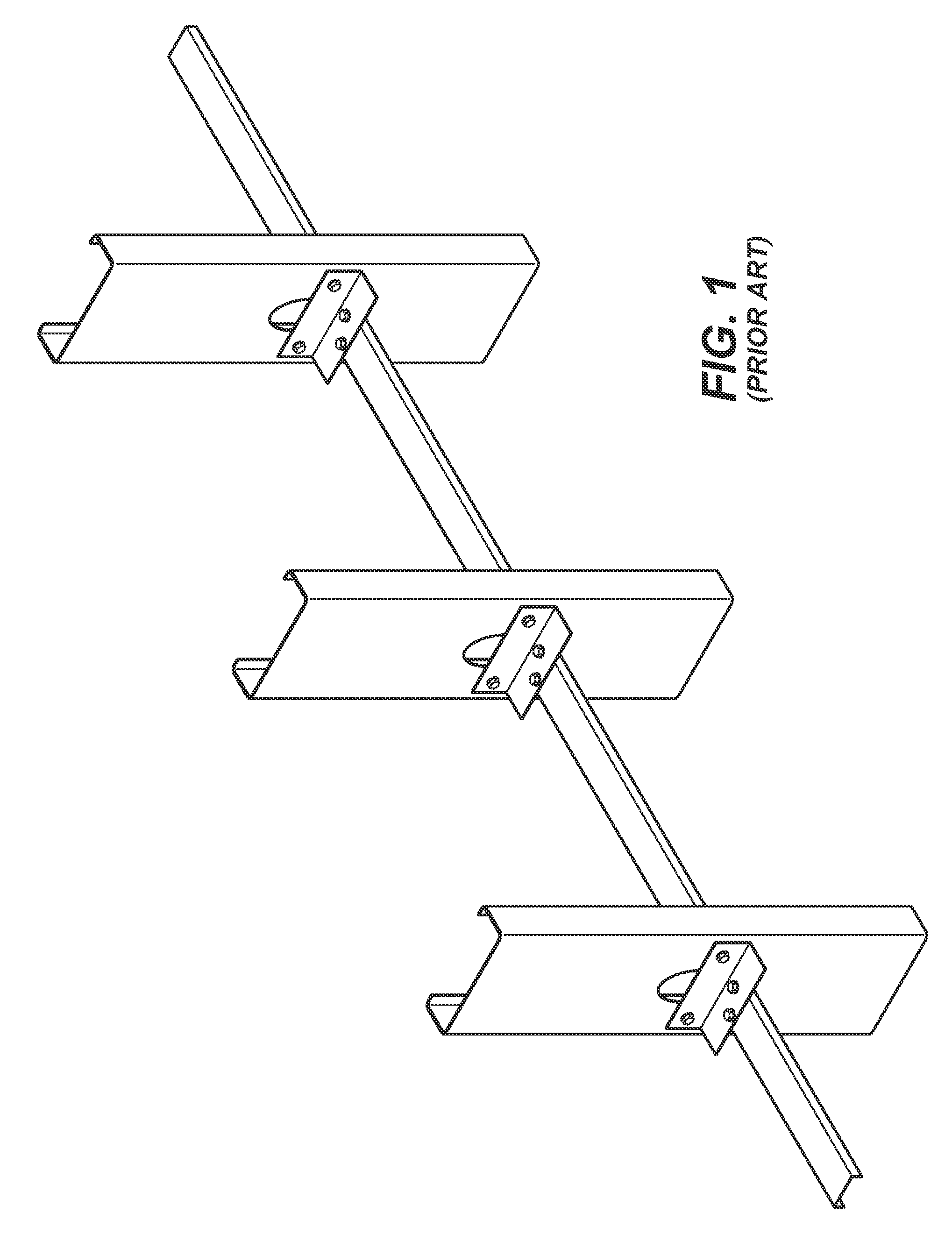

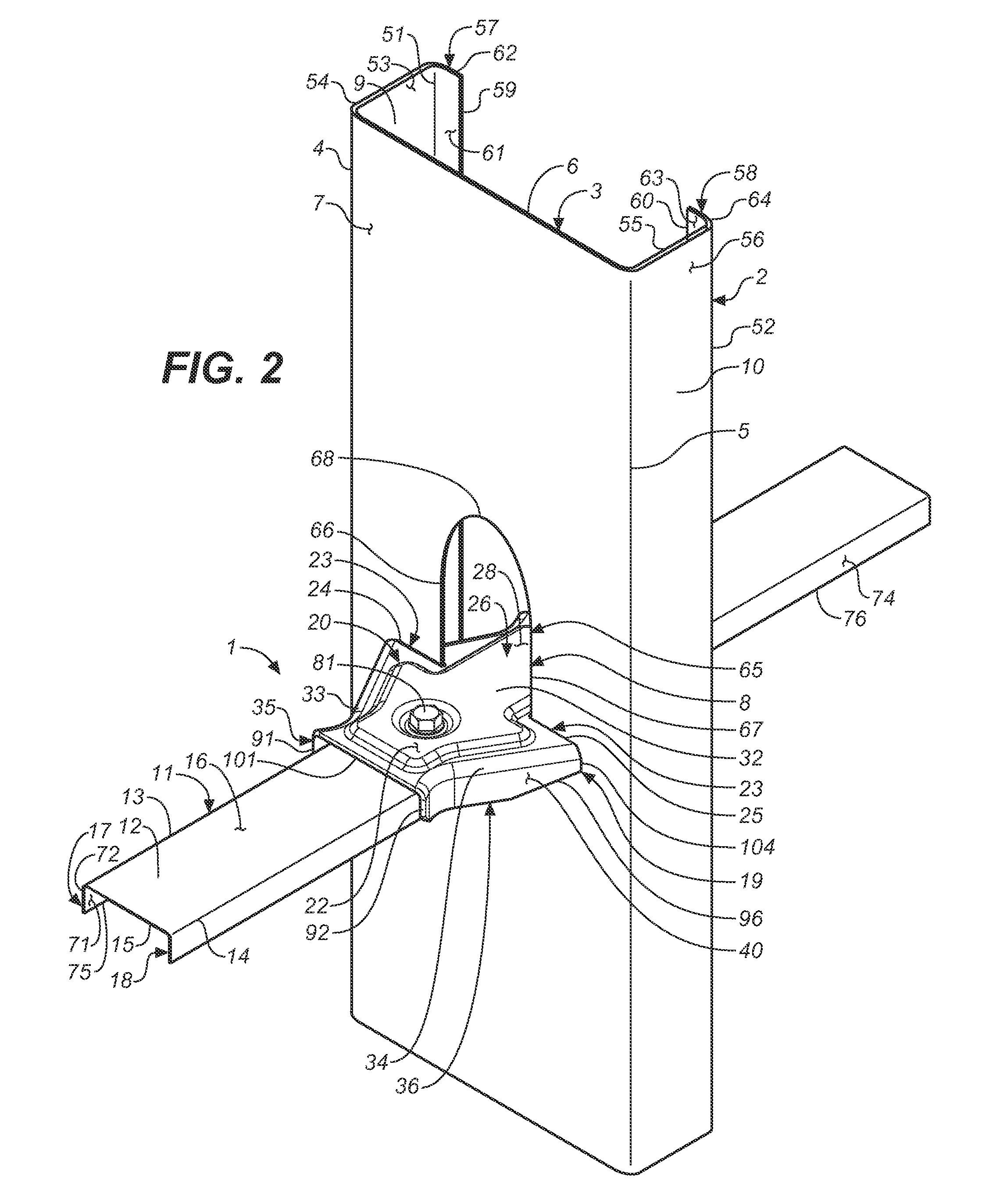

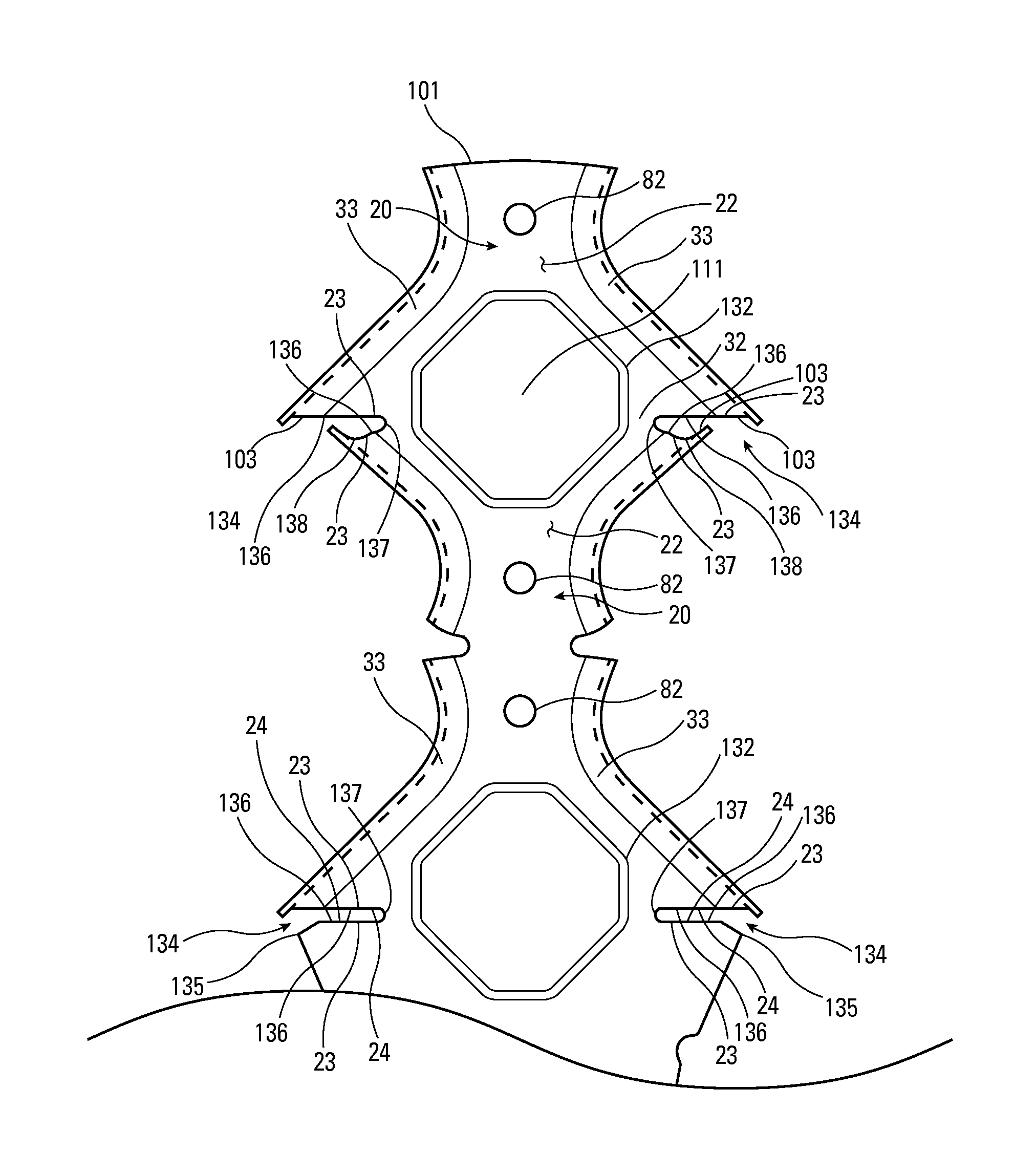

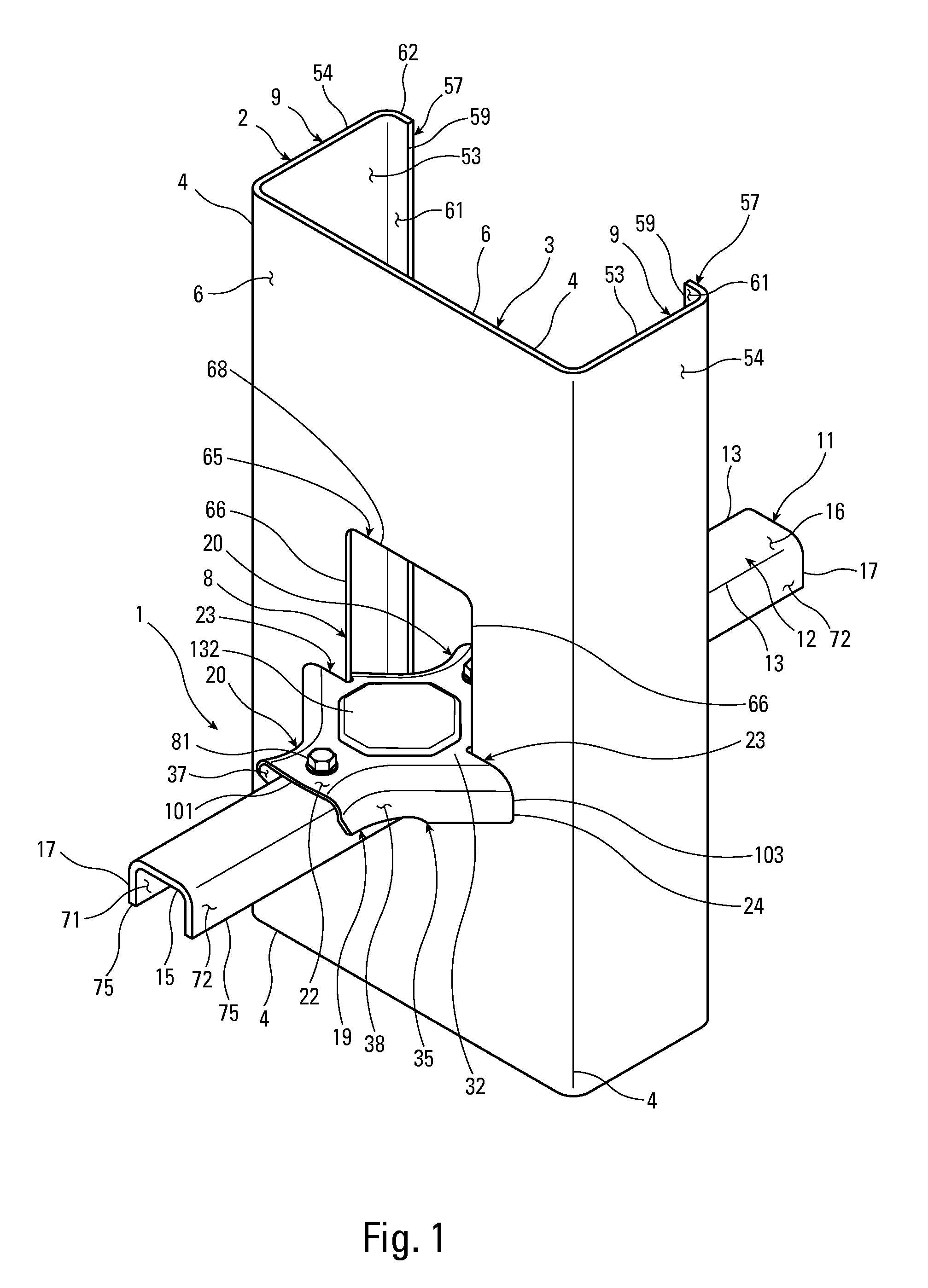

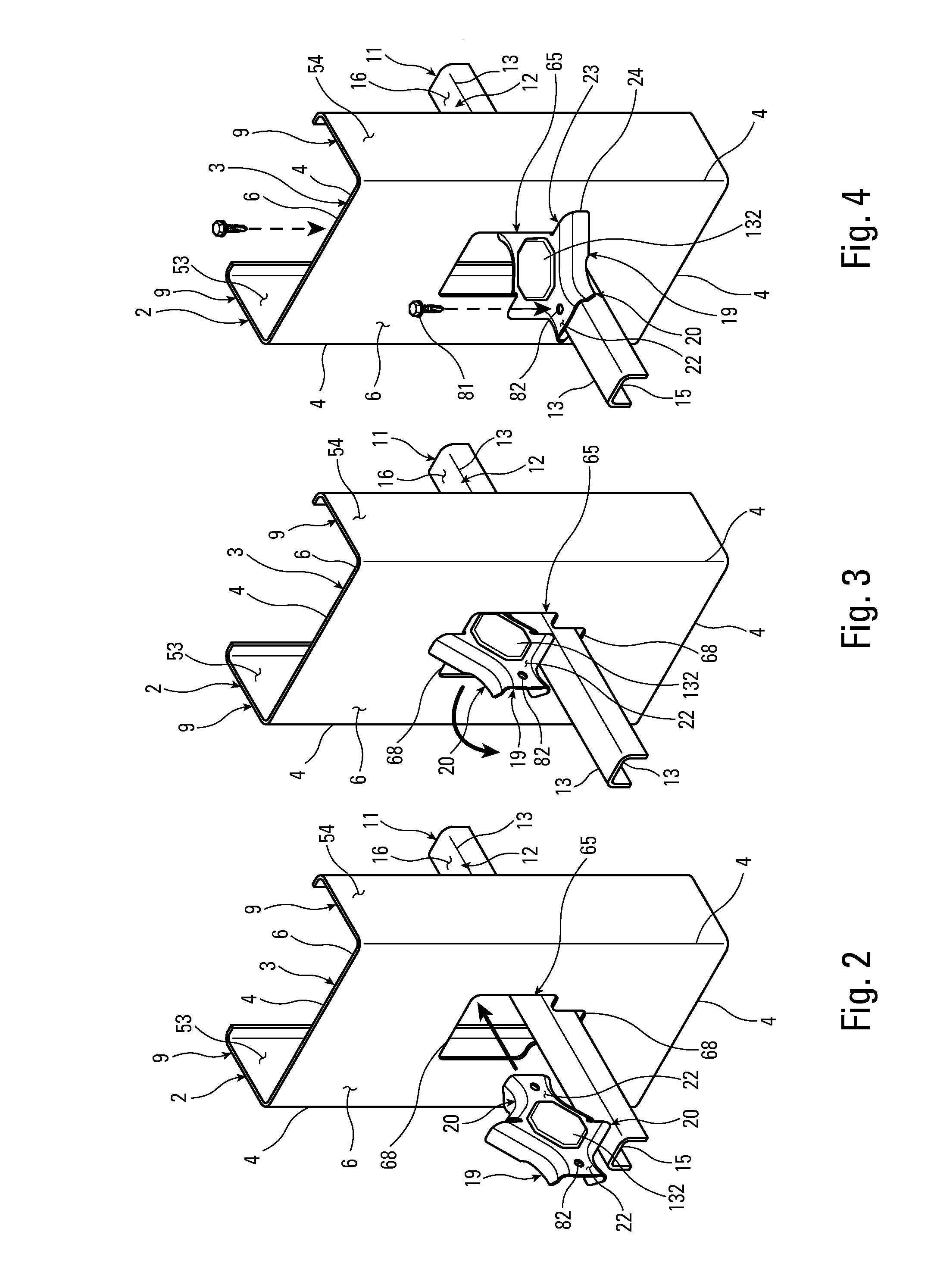

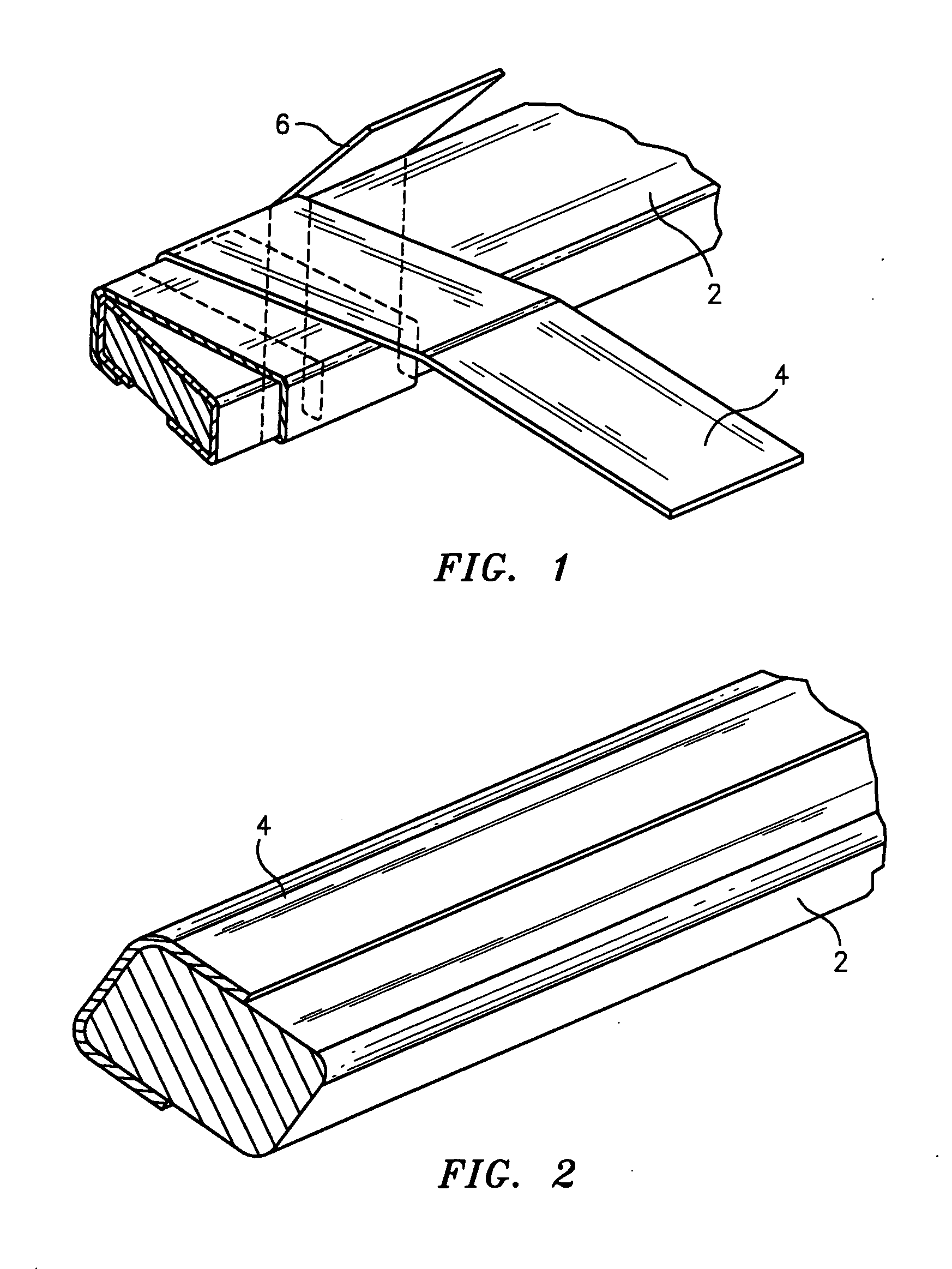

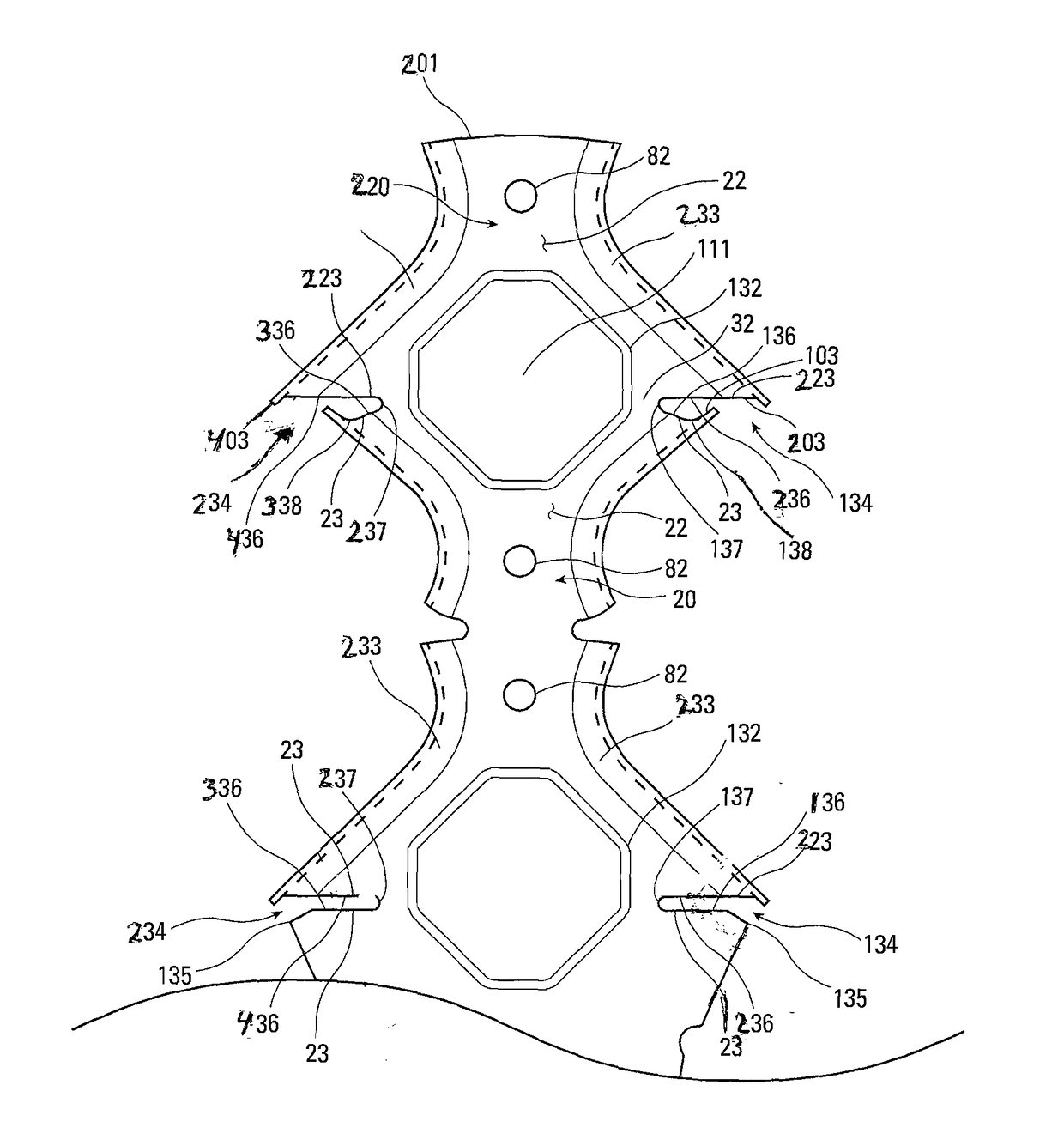

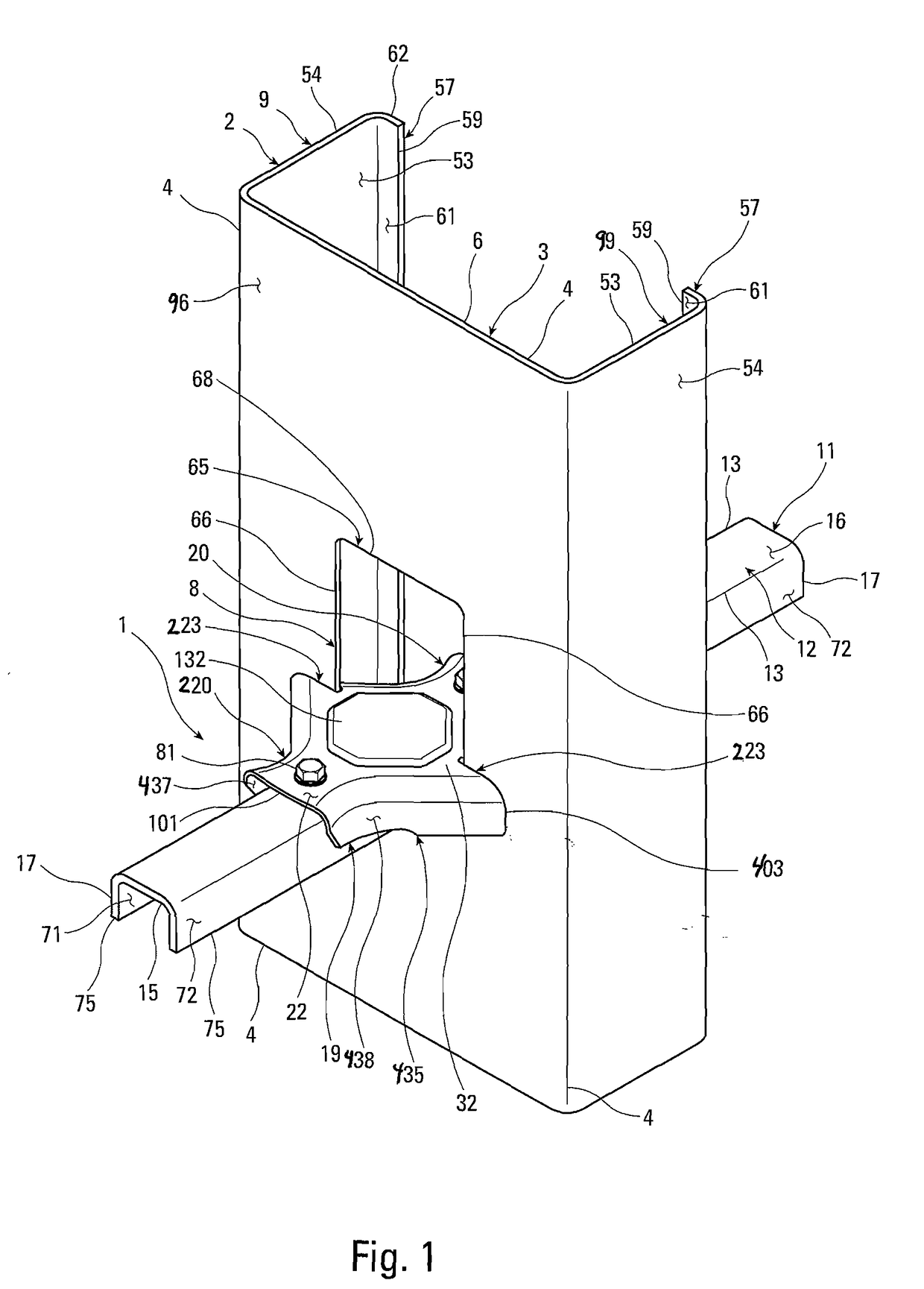

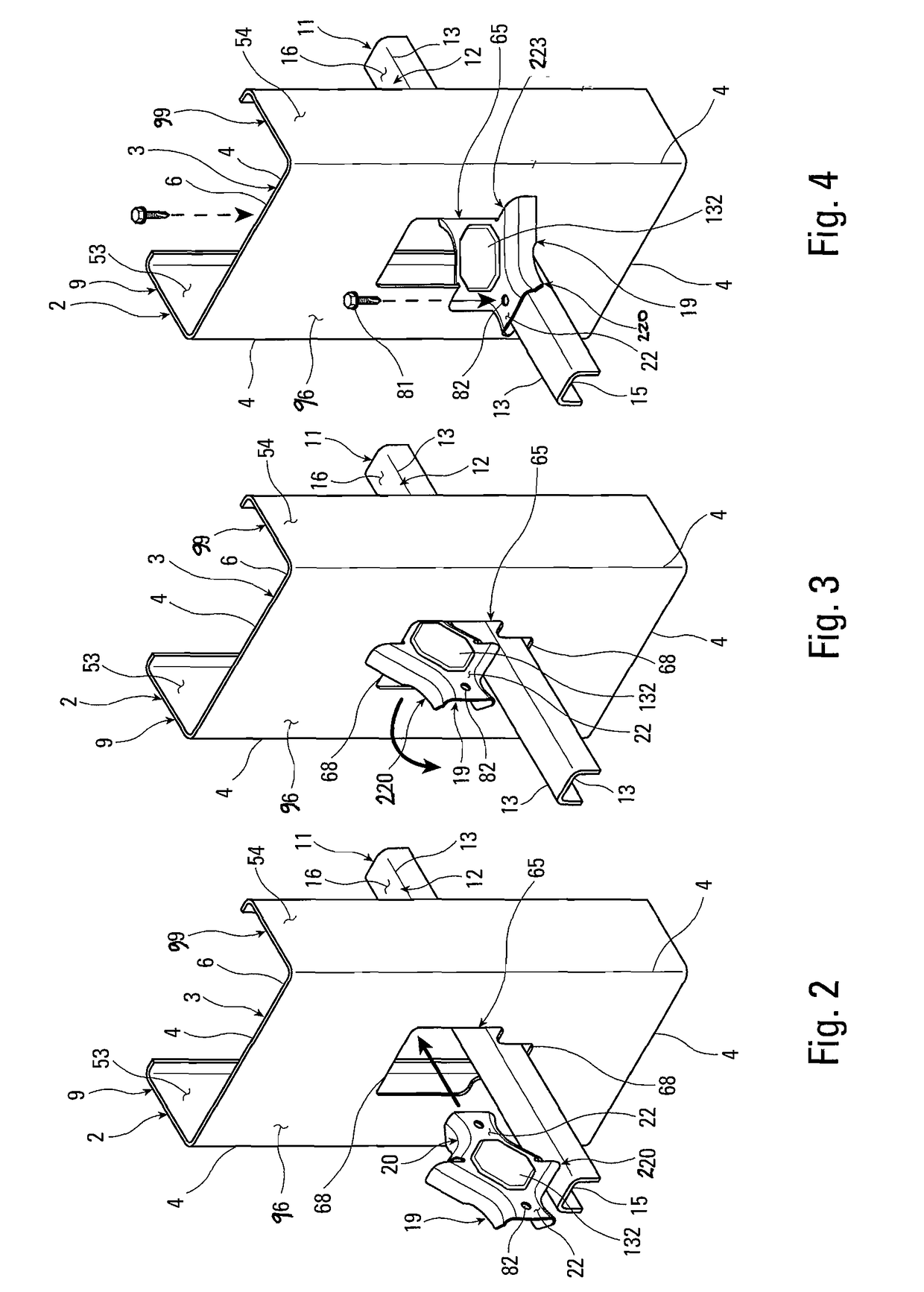

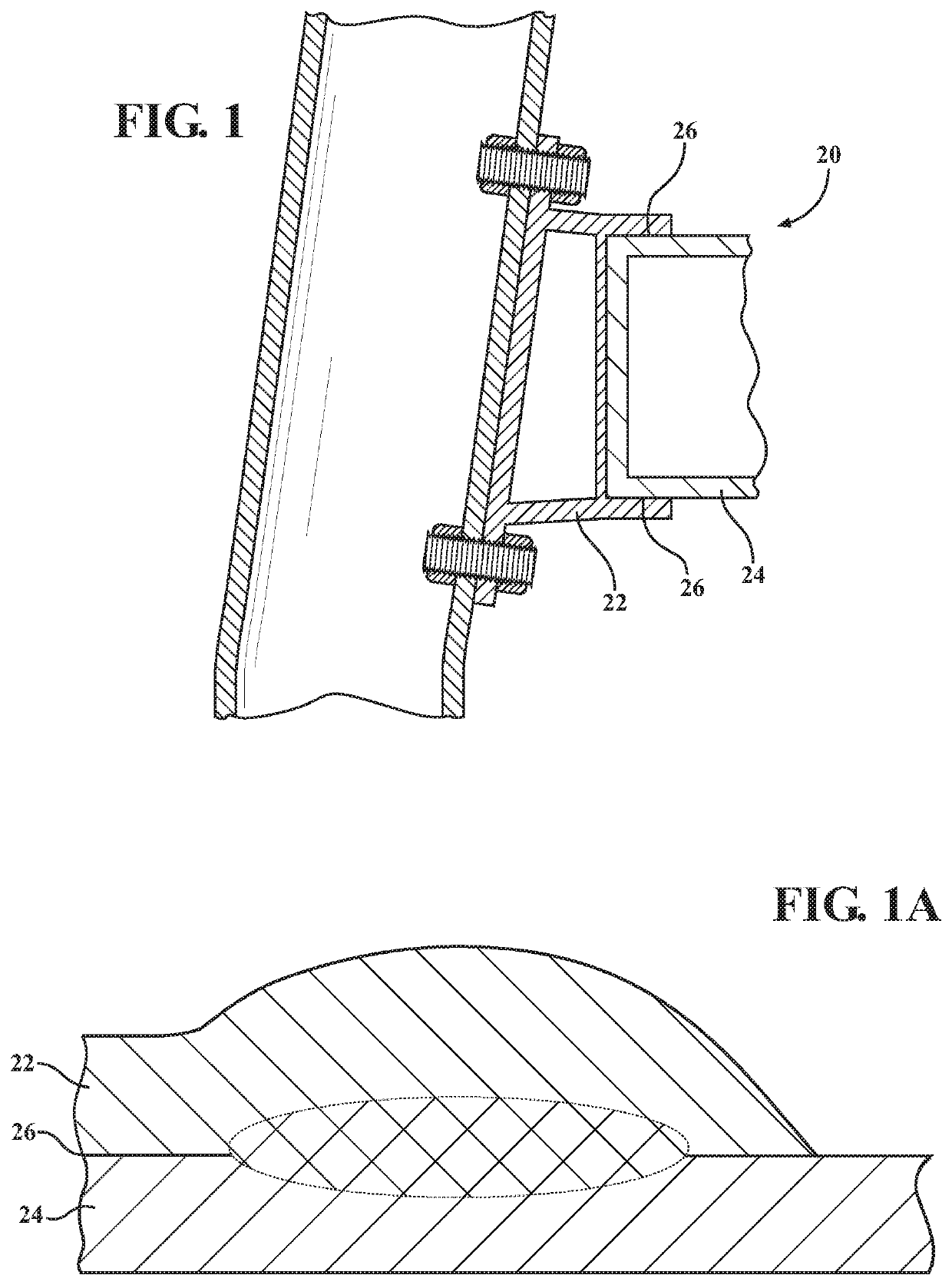

Bridging connector

ActiveUS20130104490A1Torsional rigidityExceptional strengthCeilingsCovering/liningsWall studPilaster

A building connection between a substantially vertical wall stud and a substantially horizontal bridging member, using a separate and distinct bridging connector that attaches the wall stud to the bridging member. The wall stud is typically one of several sequentially-arranged, cold-formed steel studs in the frame of a building wall. The bridging member is typically a separate cold-formed steel member that interfaces with and spans a plurality of wall studs.

Owner:SIMPSON STRONG TIE

Teardrop and offset notch bridging connector

ActiveUS9849497B2Simple interfaceFirmly connectedWallsRod connectionsEngineeringElectrical and Electronics engineering

A connection between metal studs and bridging members using a separate light gauge bridging connector with teardrop-shaped interface notches and longitudinally-offset interface notches.

Owner:SIMPSON STRONG TIE

Bridging connector

A building connection between a substantially vertical wall stud and a substantially horizontal bridging member, using a separate and distinct bridging connector that attaches the wall stud to the bridging member. The wall stud is typically one of several sequentially-arranged, cold-formed steel studs in the frame of a building wall. The bridging member is typically a separate cold-formed steel member that interfaces with and spans a plurality of wall studs.

Owner:SIMPSON STRONG TIE

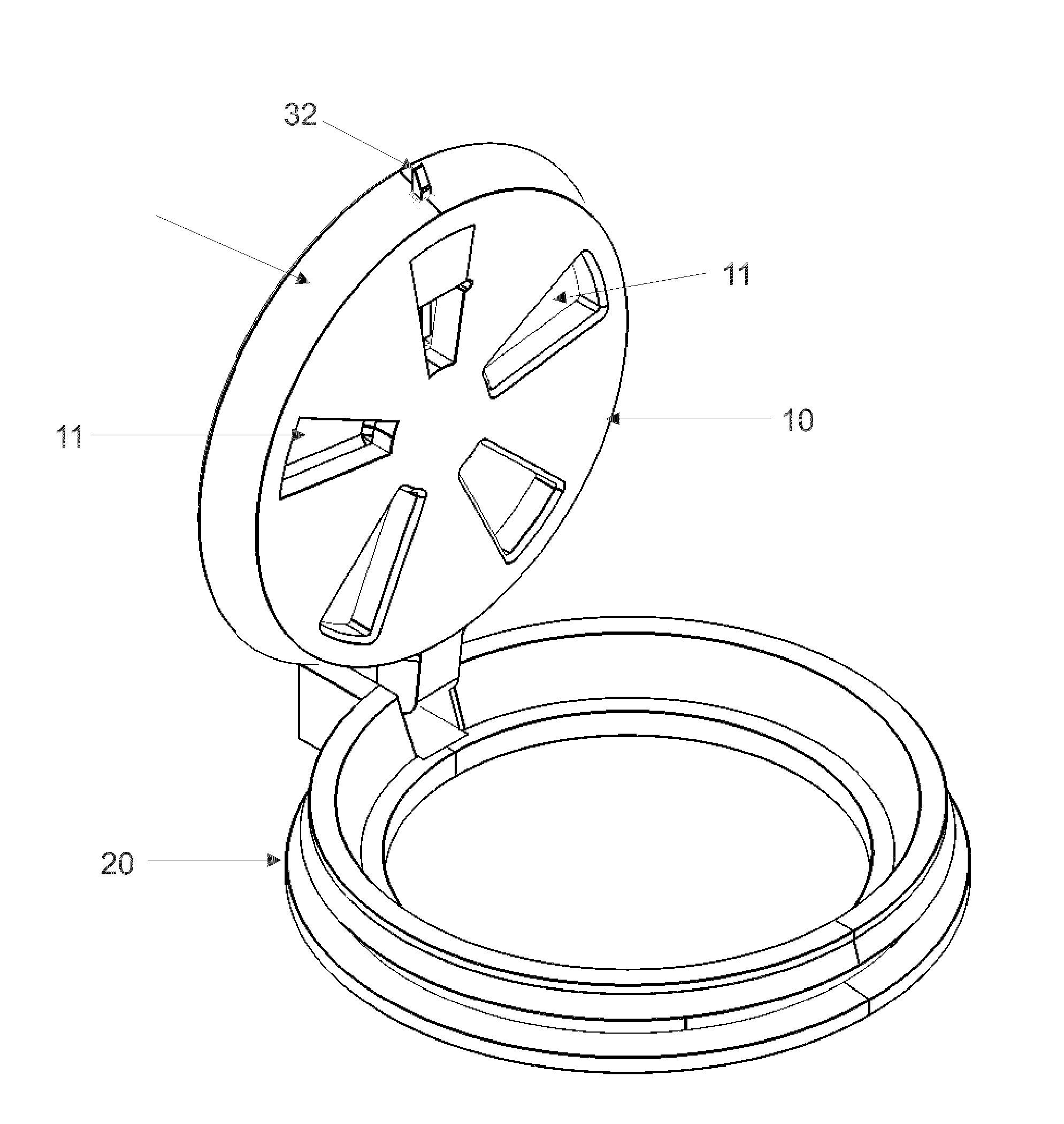

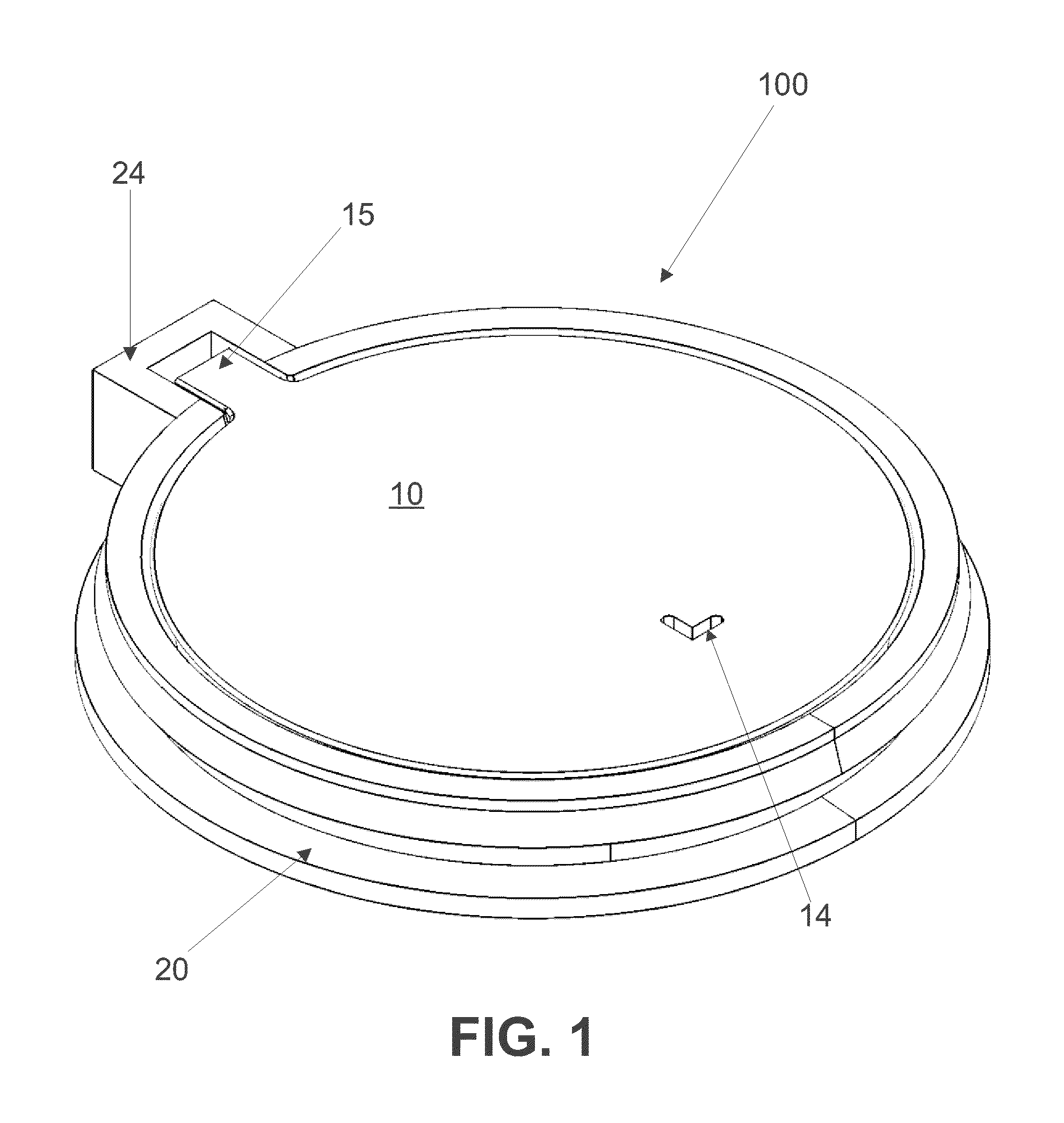

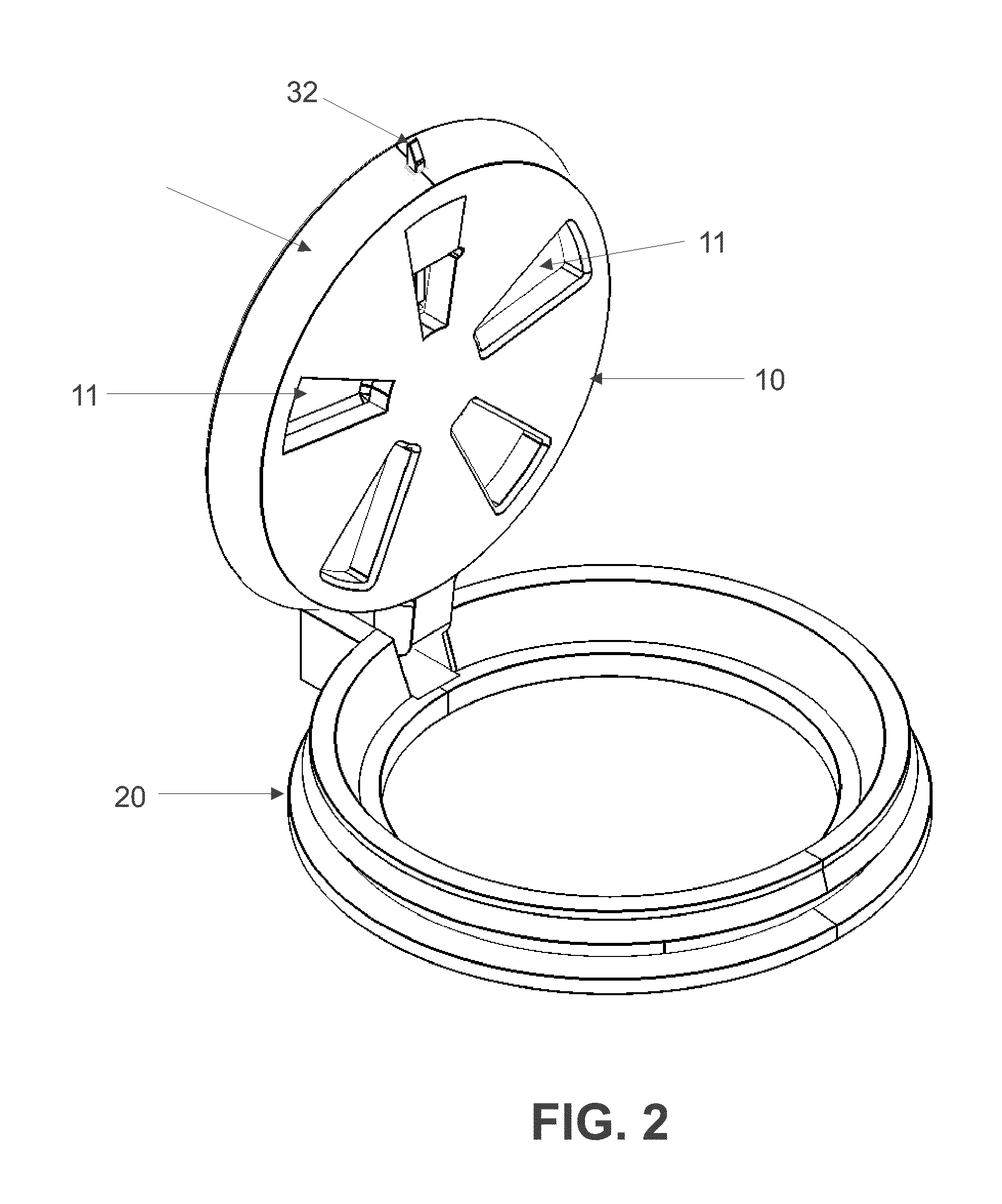

Cap and rim assembly for sewer

InactiveUS20100281778A1Discourage traditional theftEasy to openBuilding locksWing fastenersEngineeringSewerage

The invention comprising a cap and rim assembly for sewer or inspection wells, which is characterized by a hermetic closing system due to the configuration of complementary angled flanges provided between the periphery of the cap and the inner seat flange of said rim and a novel safety locking system which prevents the cap from being opened accidentally or intentionally unless a specially designed opening element is used.

Owner:GRUPO BARGO DE MEXICO DE C V

Teardrop and offset notch bridging connector

ActiveUS20140270923A1Exceptional strengthSimple interfaceDrilling rodsWallsEngineeringElectrical and Electronics engineering

Owner:SIMPSON STRONG TIE

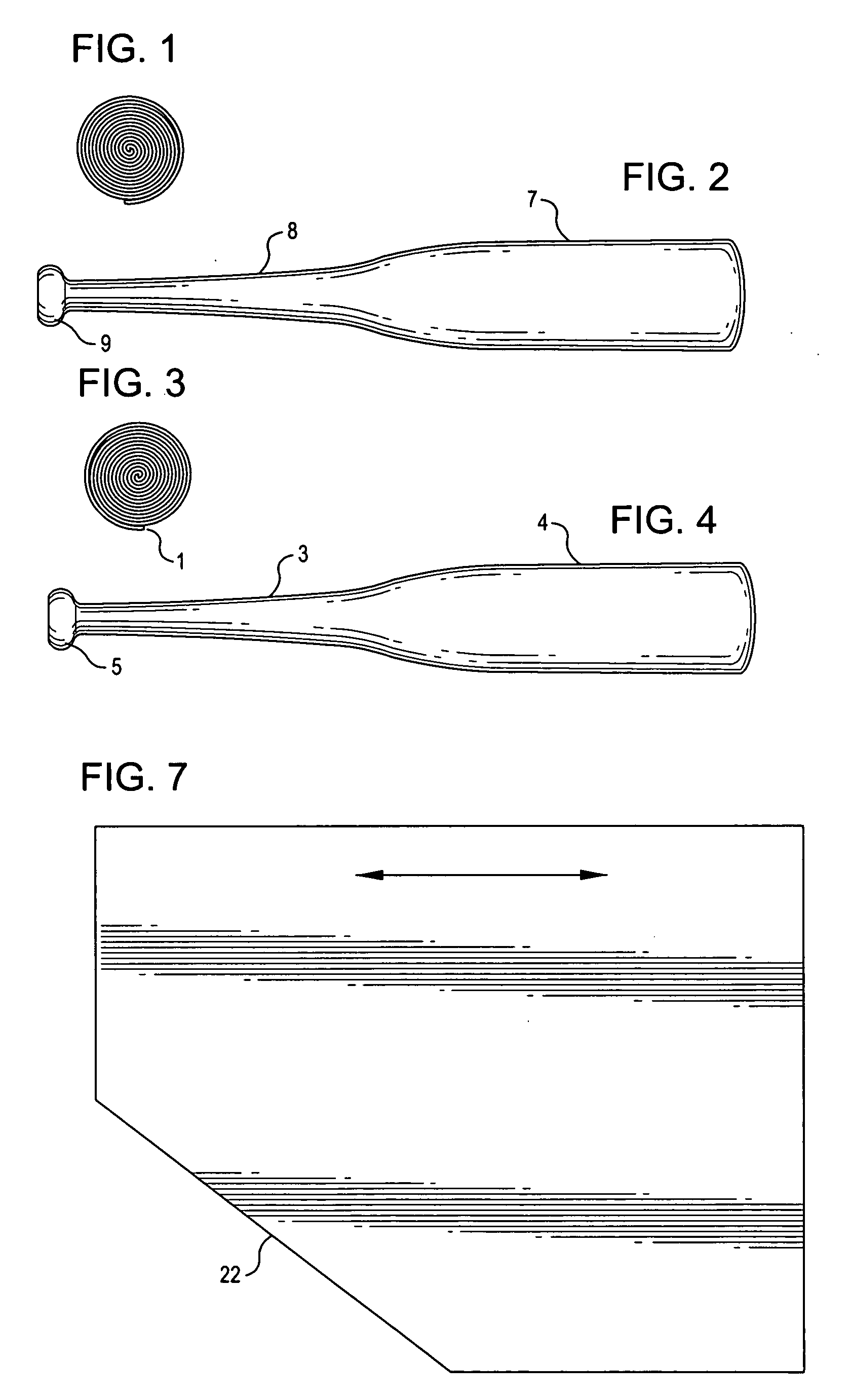

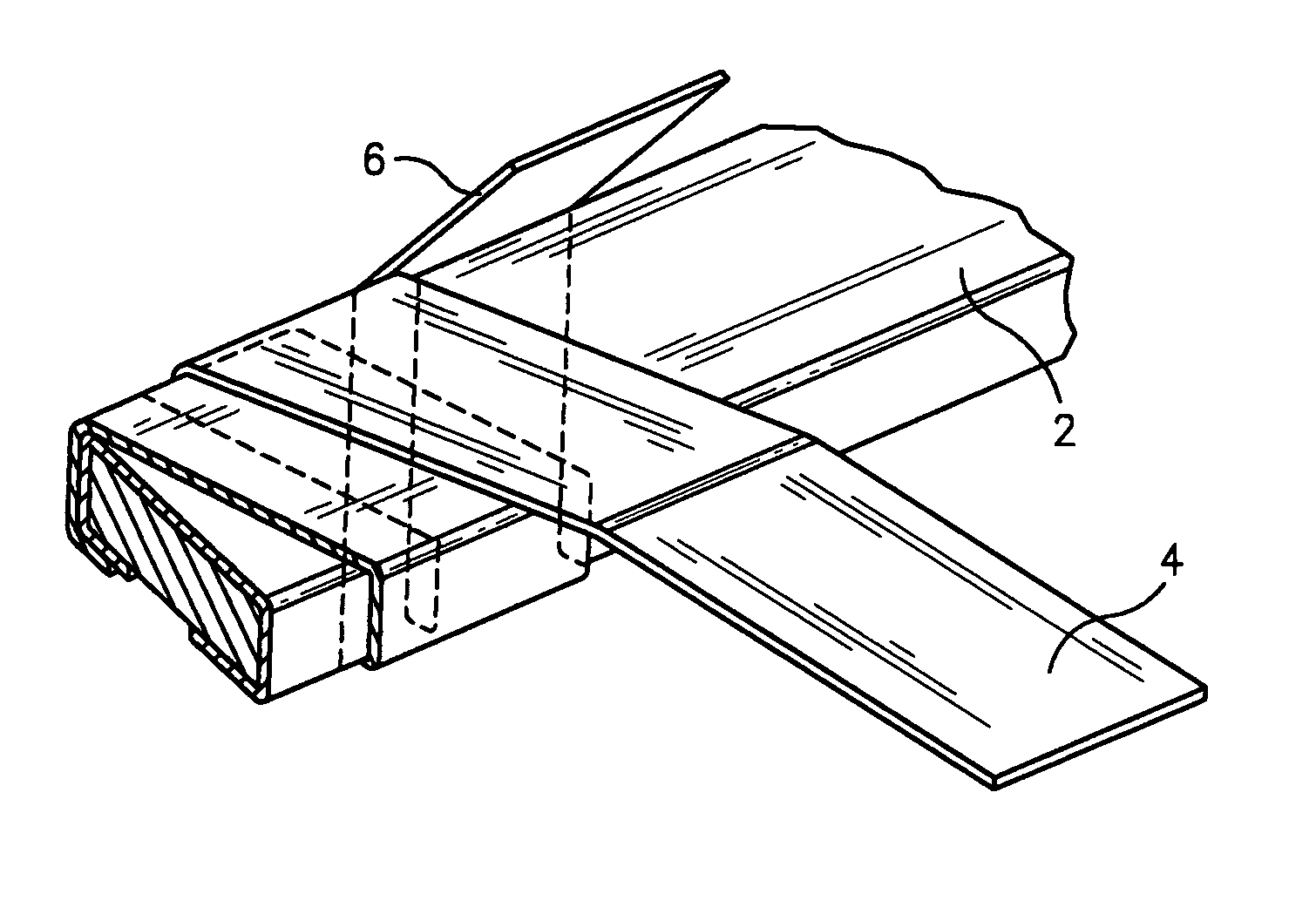

Spiral wound laminate wood and method for construction

InactiveUS20050124441A1Eliminate the air voidsThickness minimizationWood veneer joiningRacket sportsCelluloseEpoxy

A baseball bat or the like comprised of one or more continuous spiral wound layers of wood, cellulose, or other like material rolled in a spiral fashion from the center to the outermost surface. The cellulose or other material is bound to each subsequent layer with a thin layer of resin, glue, epoxy, or other binding material of adequate strength to hold the layers together for multiple impacts by a baseball or other object. This spiral wound composite roll, in its final configuration, is of comparable density, weight and balance to ash, maple or oak material commonly used in baseball bat construction. The composite roll can be machined to a shape consistent with the shape and balance of traditional baseball bats.

Owner:WOUND WOOD TECH

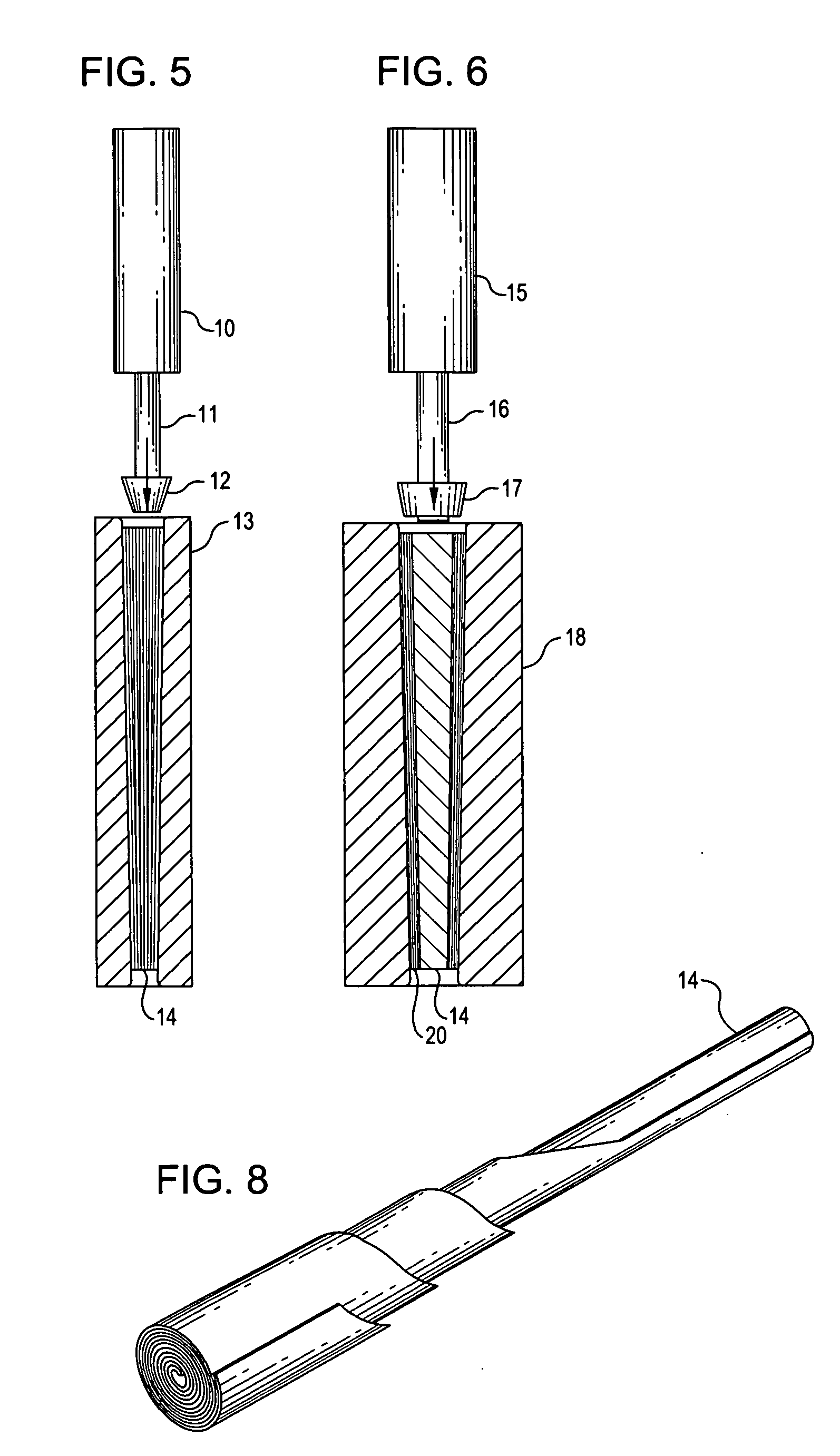

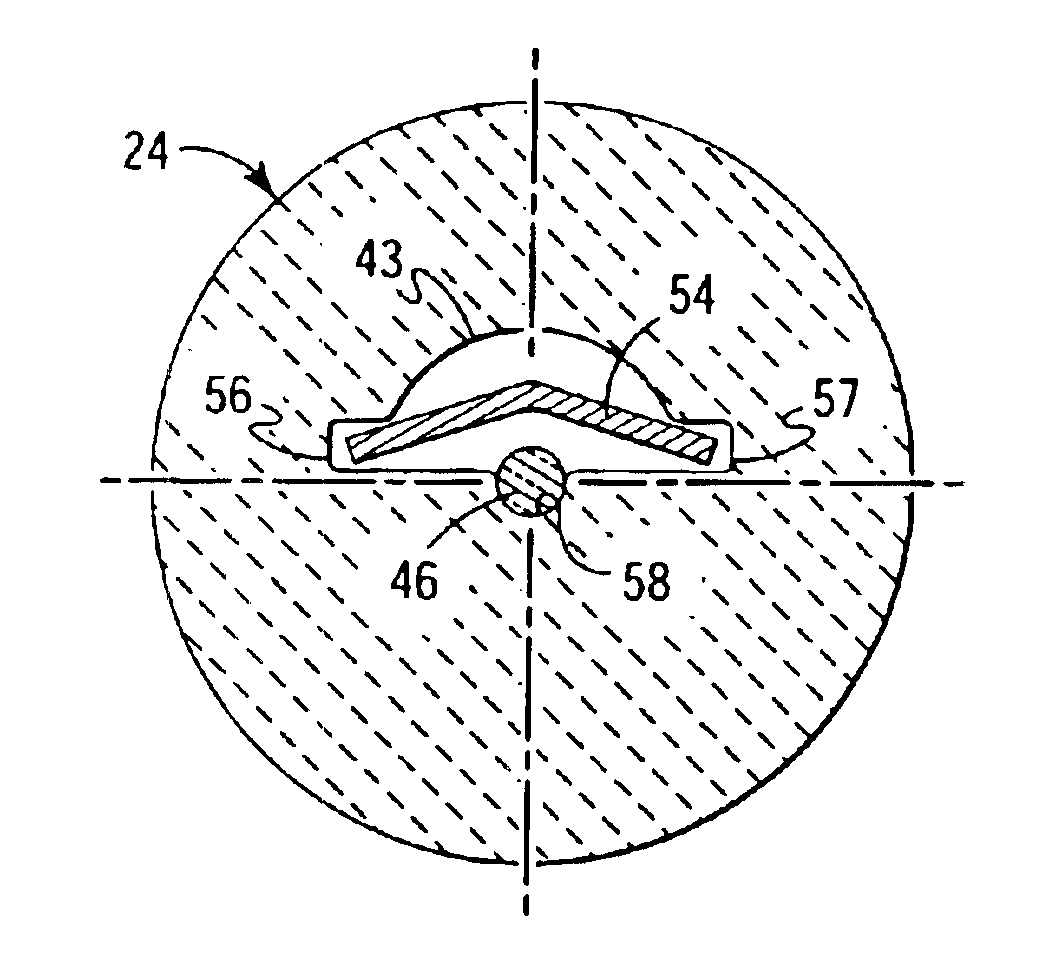

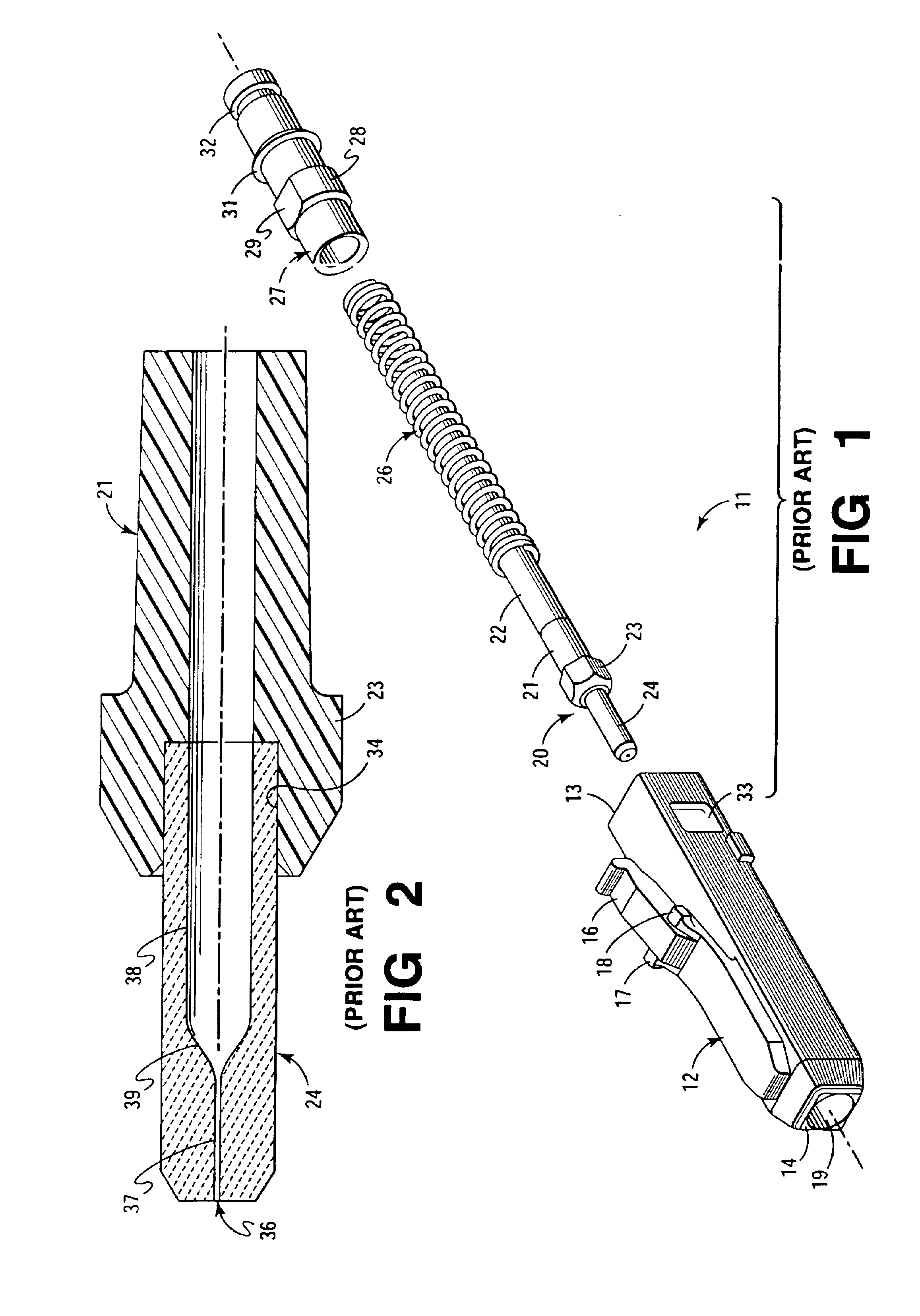

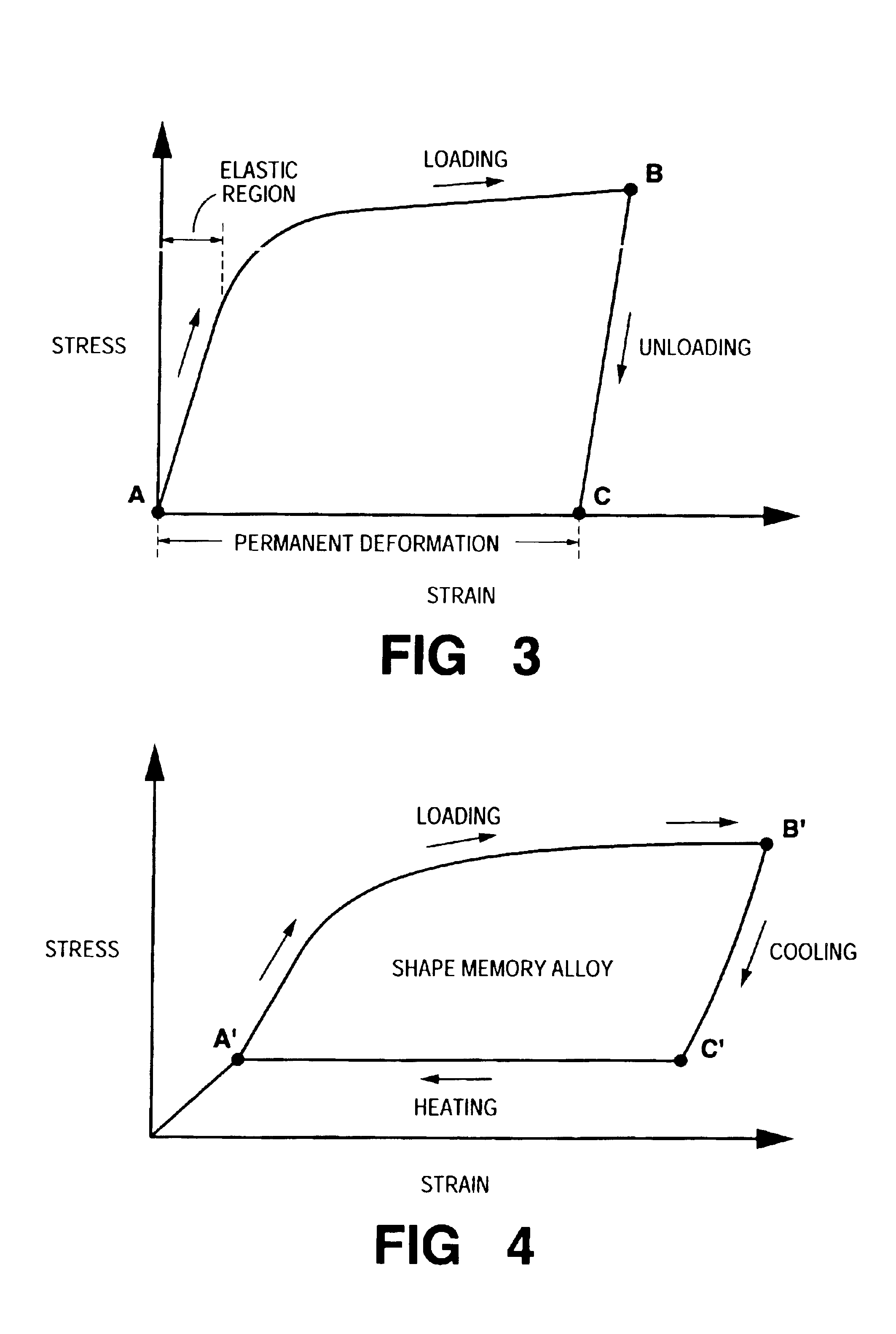

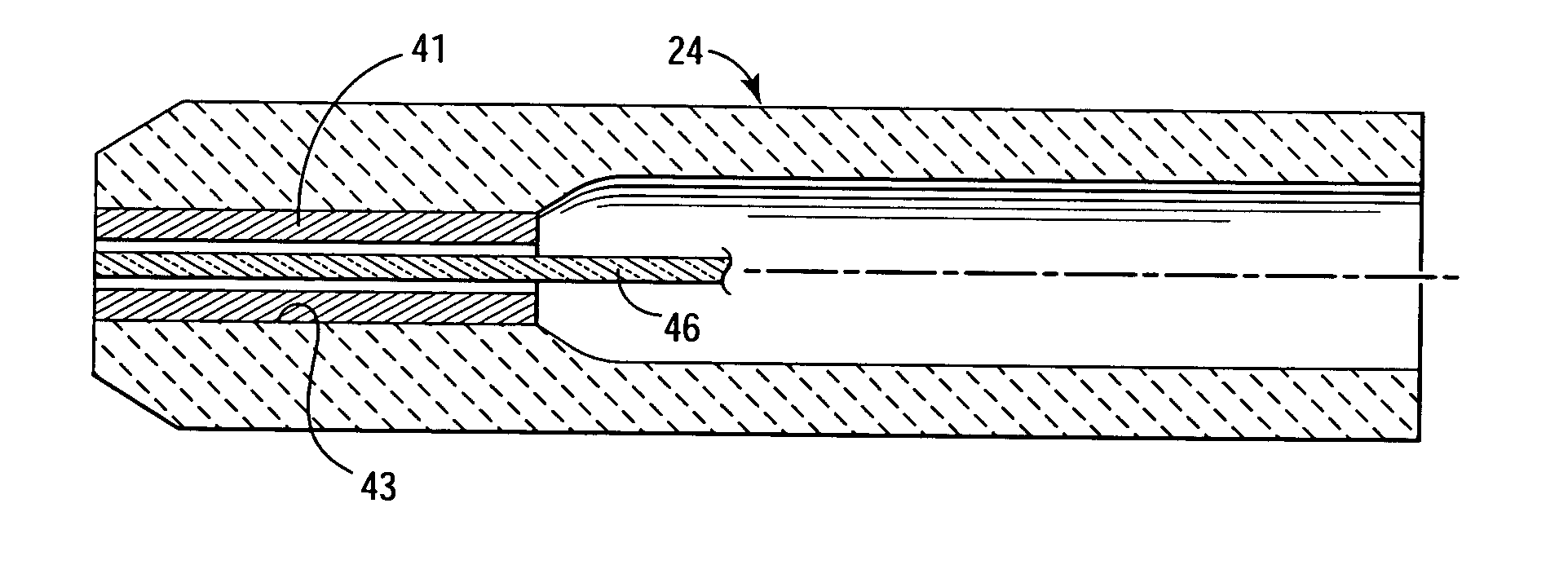

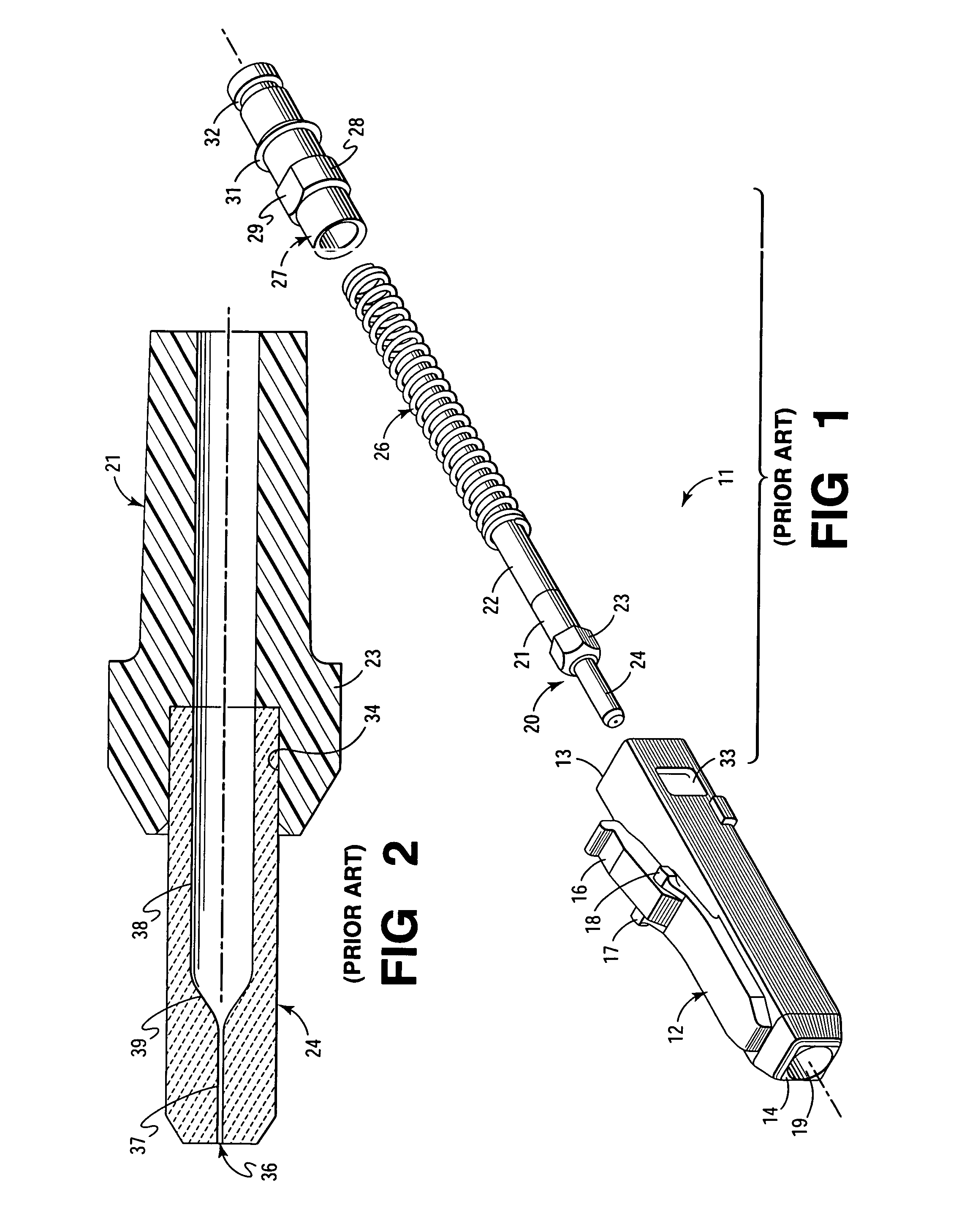

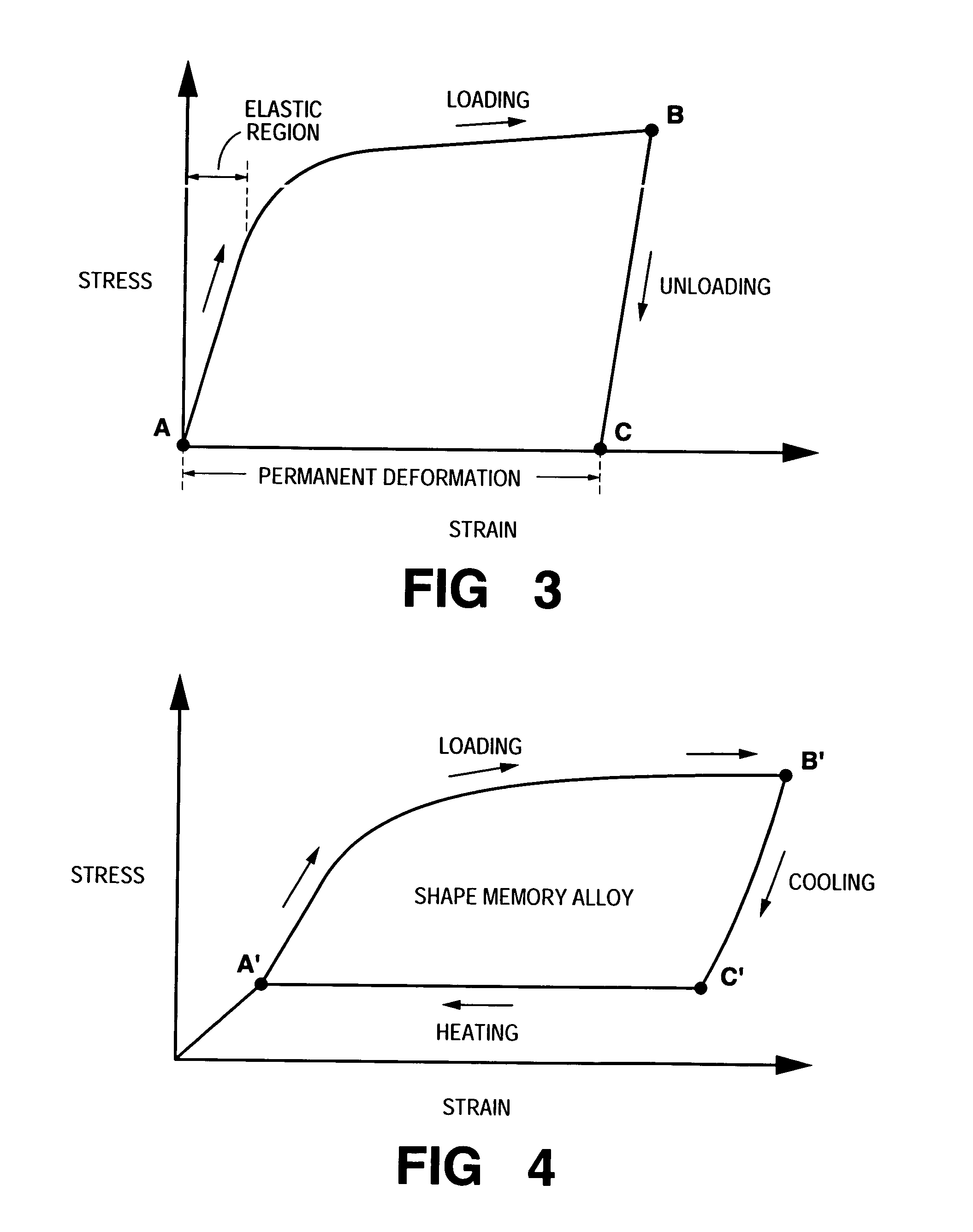

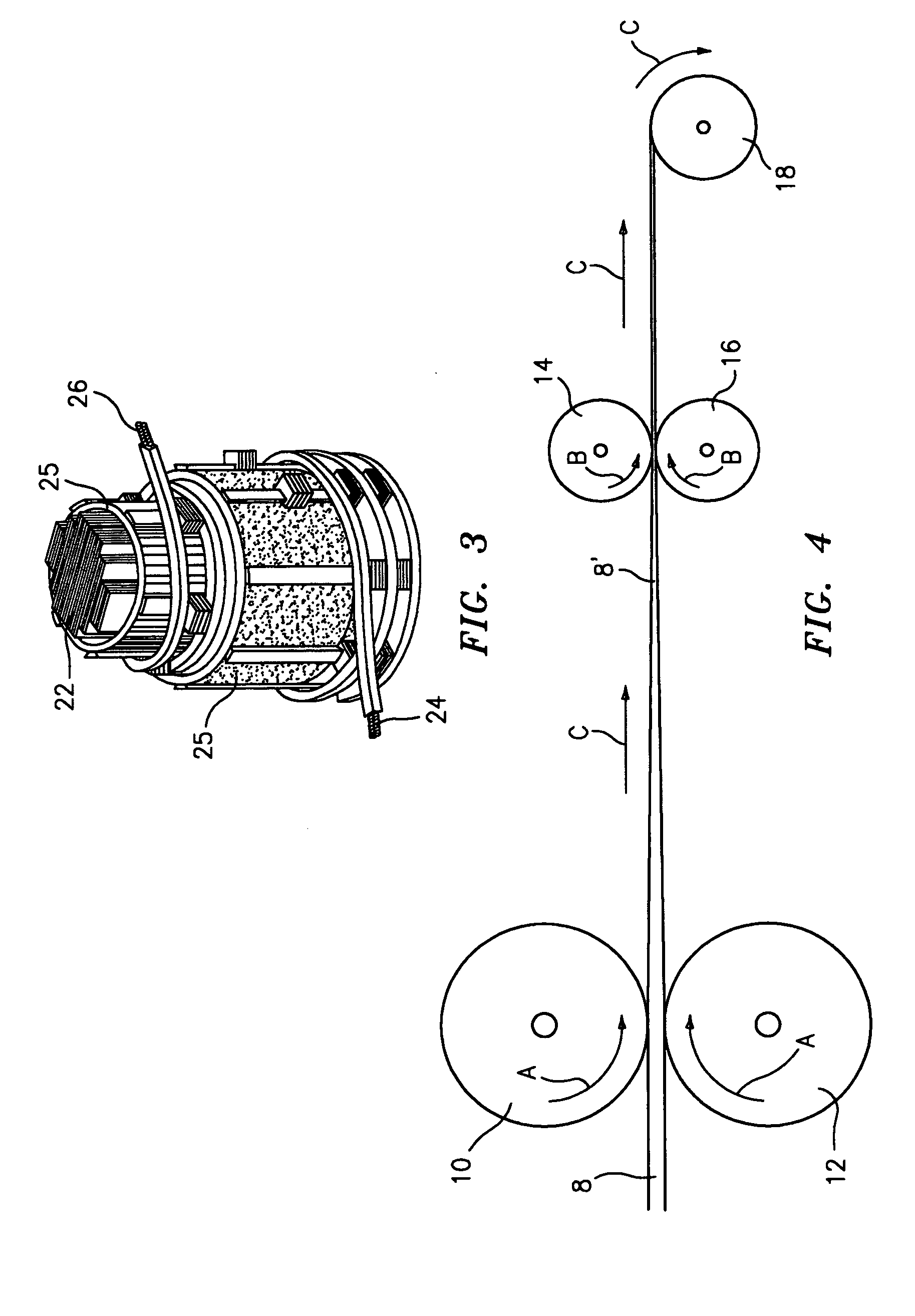

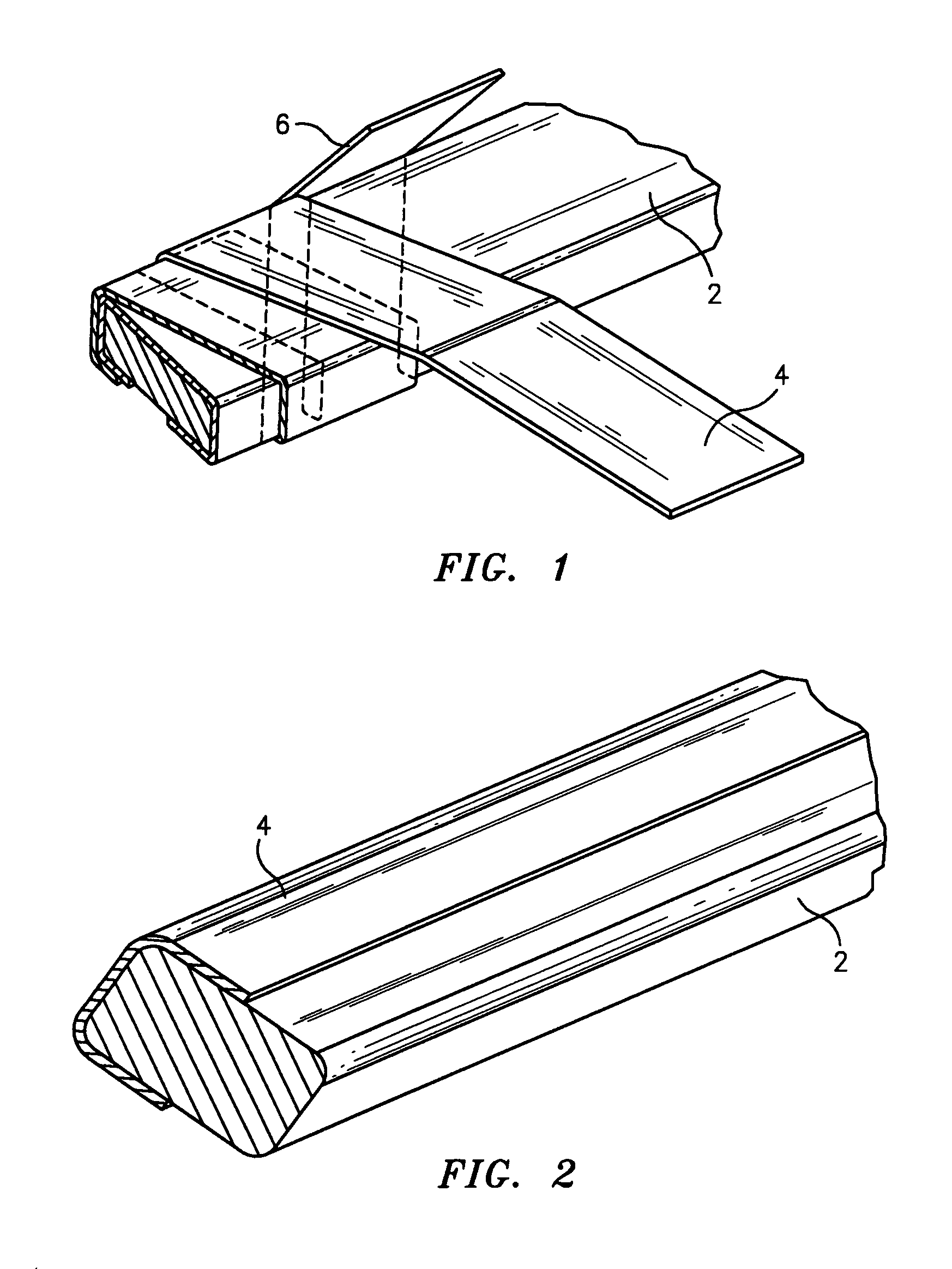

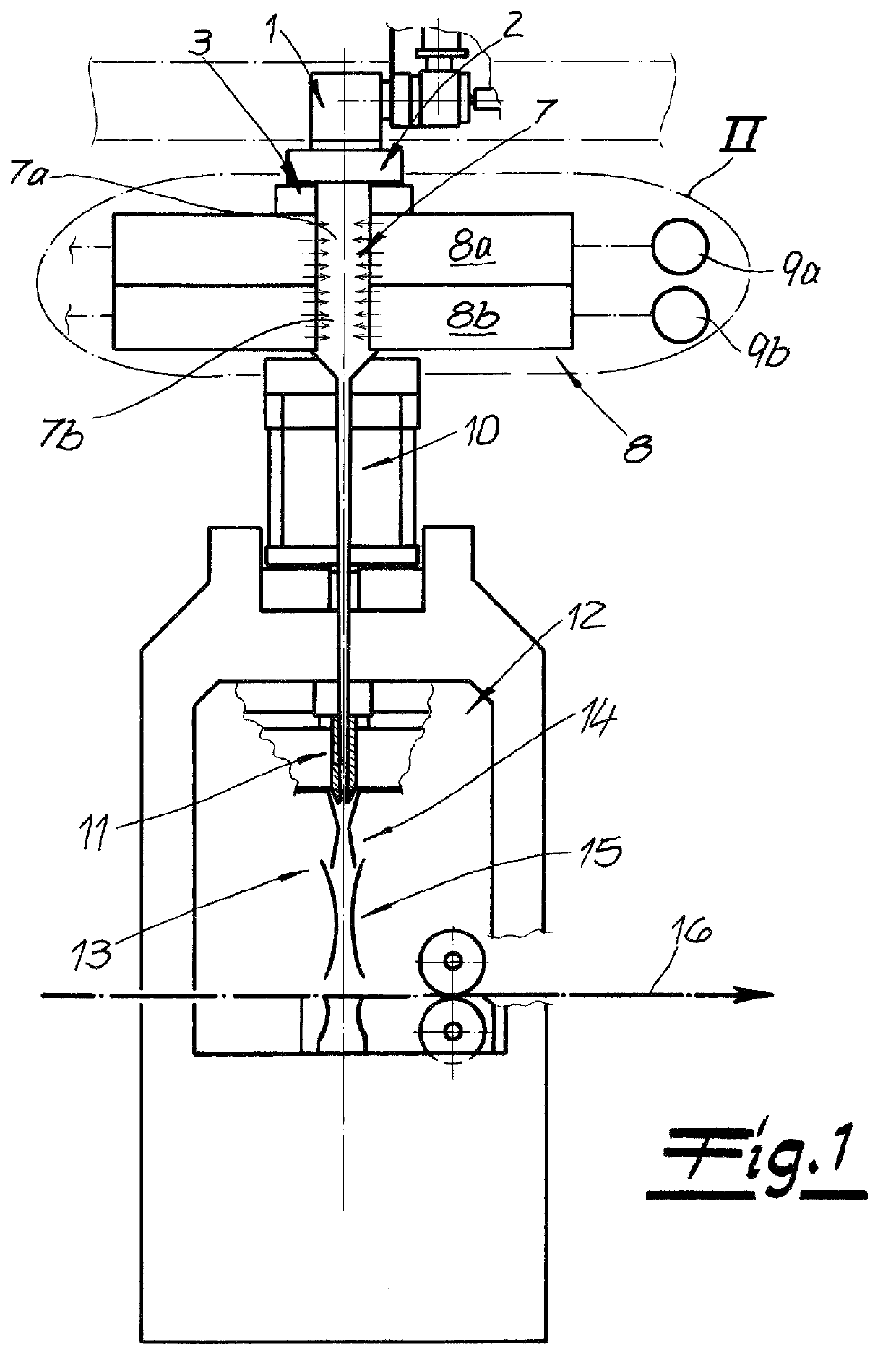

Optical fiber connection utilizing fiber containing ferrules

A ferrule for use in optical fiber connections has an optical fiber containing a bore extending therethrough. Within the bore is a member of shaped memory alloy (SMA) which clamps and affixes the fiber firmly in place within the ferrule without the necessity of cementing the fiber in place. The shaped memory alloy has two states: the initial or primary state and the secondary or deformed state. In the embodiments of the invention, the member is deformed from the initial state to the secondary state and the fiber is inserted in the ferrule. The member is then returned to the primary state in which it firmly clamps the fiber within the ferrule.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

Optical fiber connection utilizing fiber containing ferrules

A ferrule for use in optical fiber connections has an optical fiber containing a bore extending therethrough. Within the bore is a member of shaped memory alloy (SMA) which clamps and affixes the fiber firmly in place within the ferrule without the necessity of cementing the fiber in place. The shaped memory alloy has two states: the initial or primary state and the secondary or deformed state. In the embodiments of the invention, the member is deformed from the initial state to the secondary state and the fiber is inserted in the ferrule. The member is then returned to the primary state in which it firmly clamps the fiber within the ferrule.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

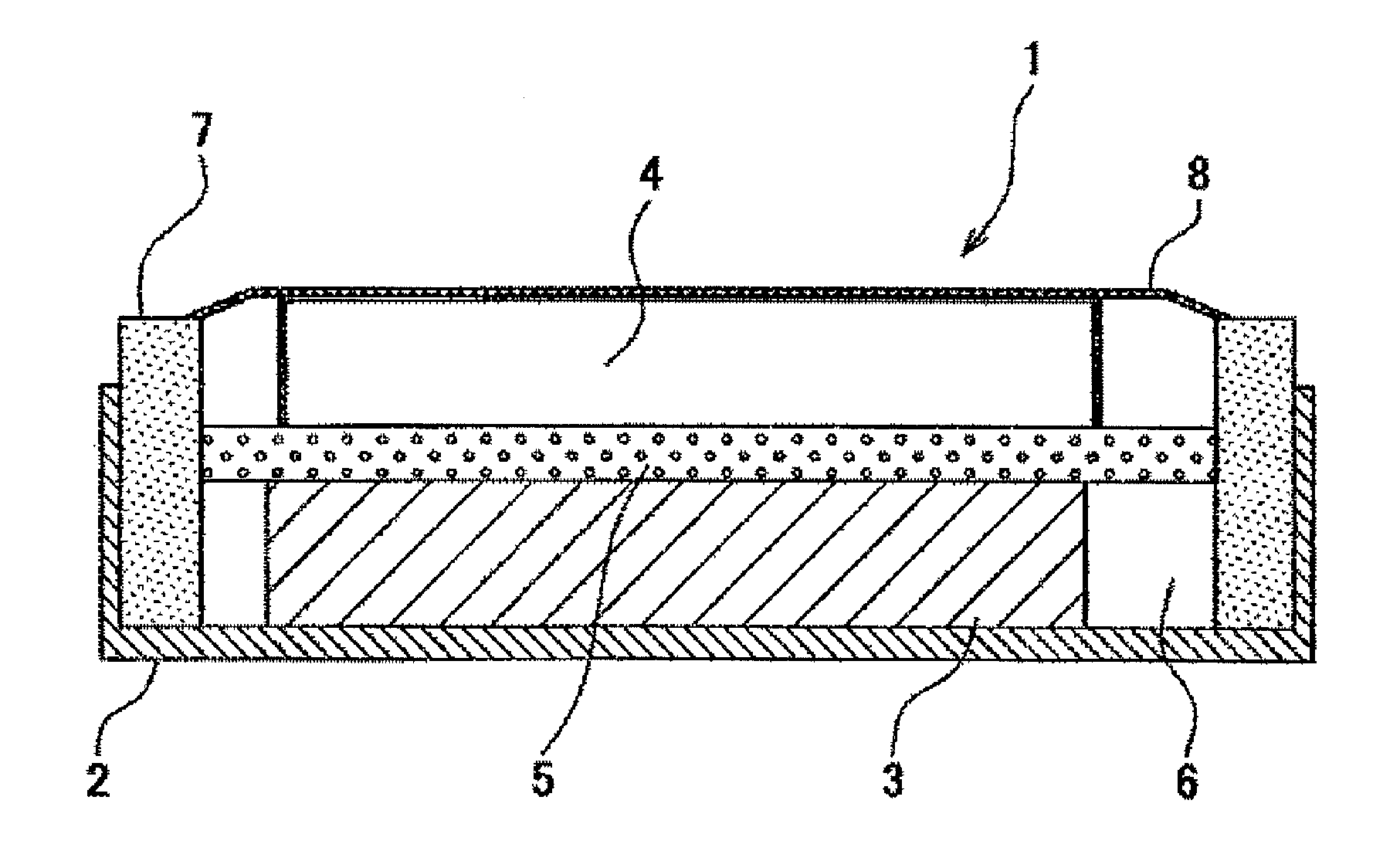

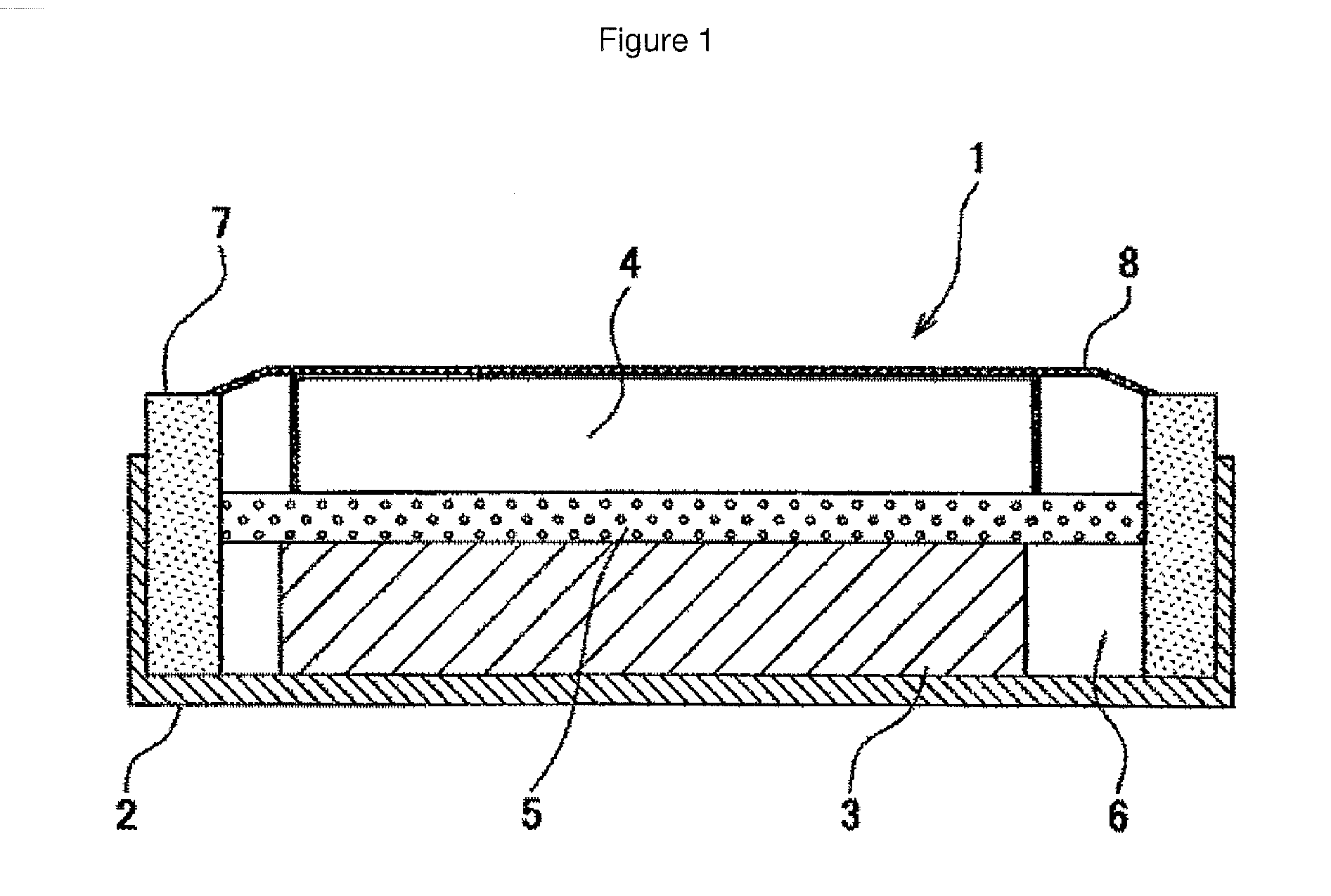

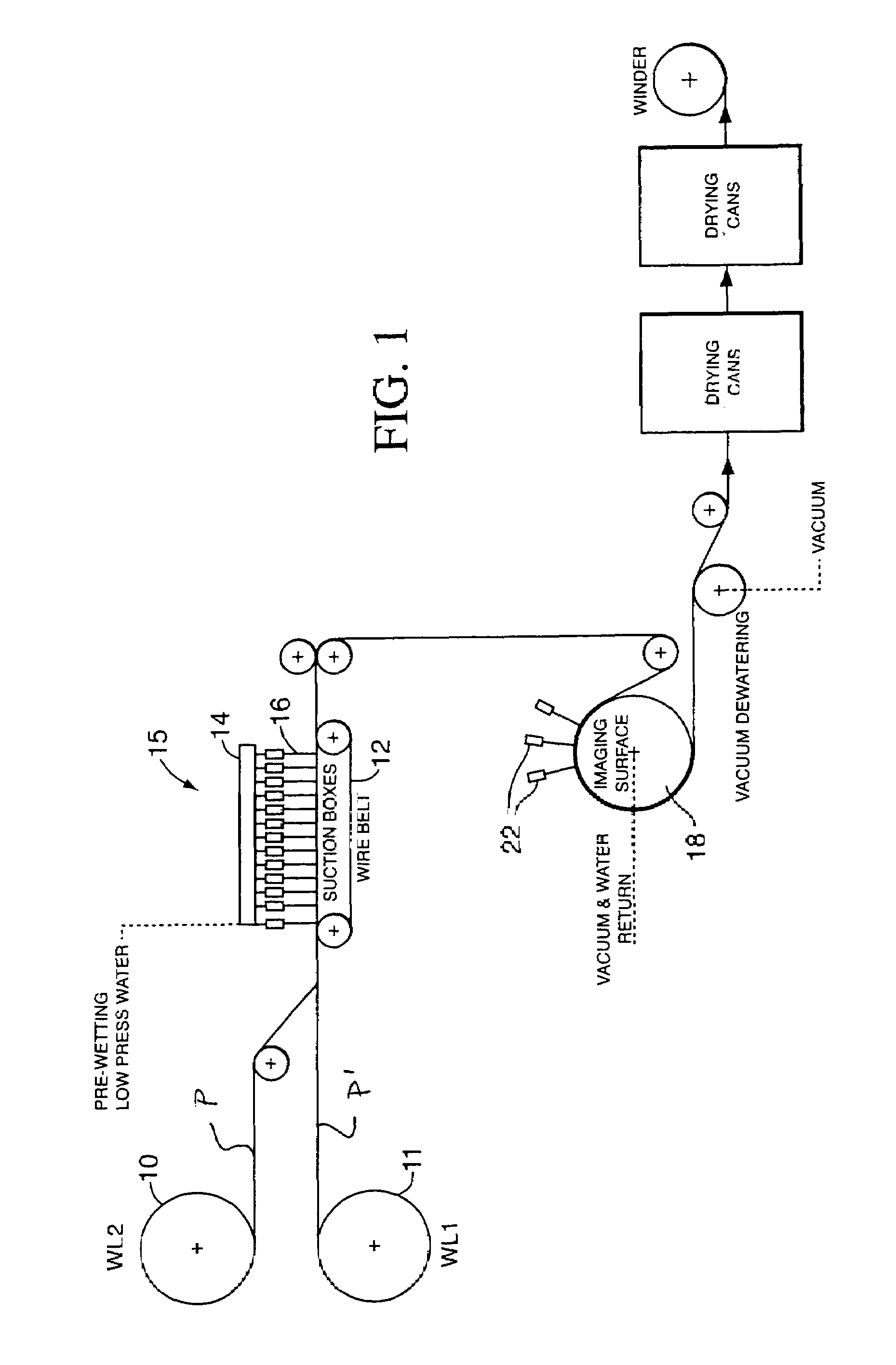

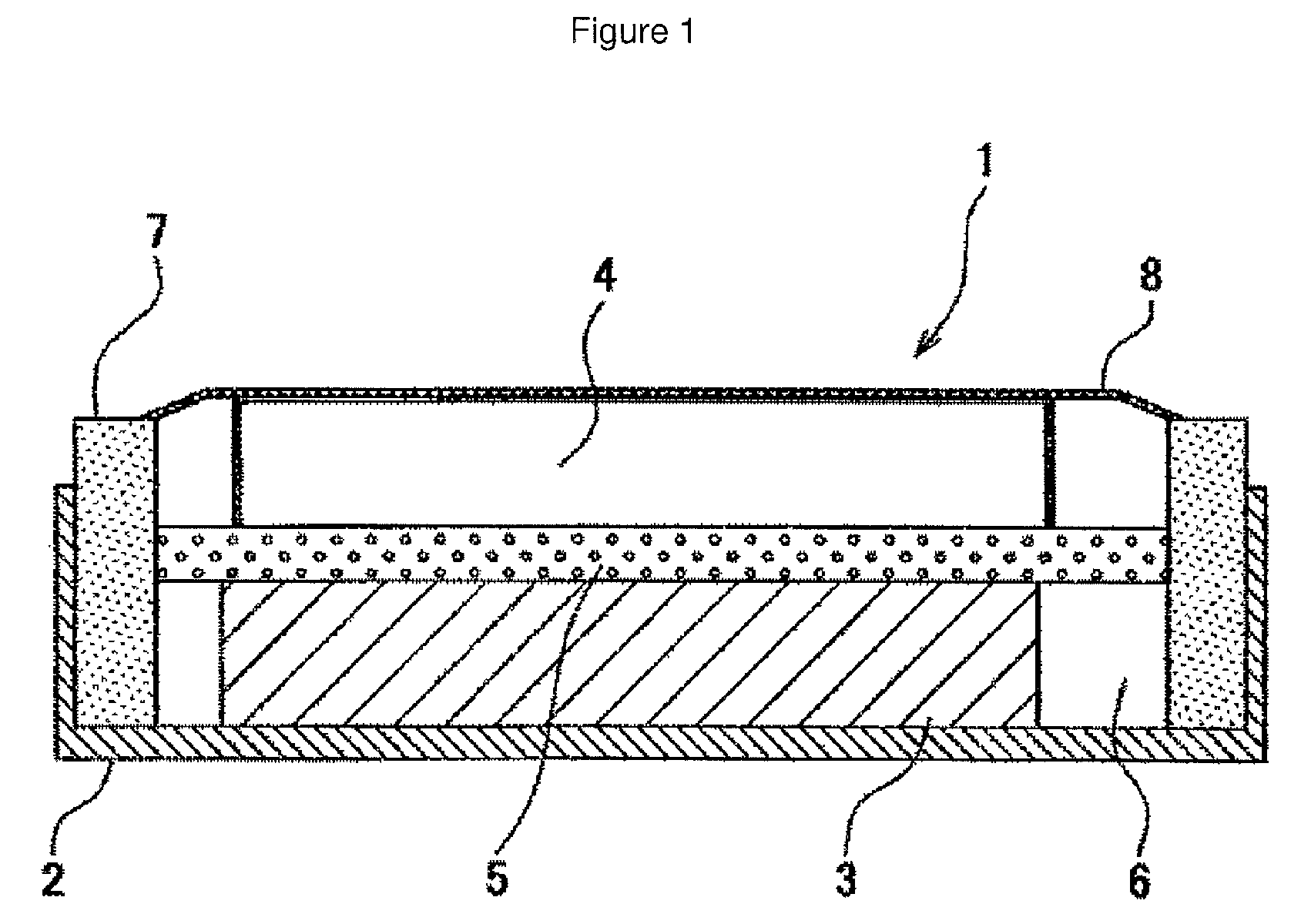

Battery separator comprising a polyolefin nanofilament porous sheet

ActiveUS20130065133A1High porosityLower internal resistancePrimary cellsElectrode carriers/collectorsProduction rateElectricity

Disclosed is a highly safe battery separator, in particular a separator for a lithium ion secondary battery, which reduces internal resistance, achieves good ionic conductivity, prevents passing of electrode active materials, and also prevents electrical short circuit by controlling deposition of lithium metal (dendrite). Also disclosed is a means for stably producing the battery separator with high productivity. Specifically disclosed are: a battery separator which is composed of a porous polyolefin sheet that is formed from a group of polyolefin nanofilaments that have an average filament diameter of less than 1 μm and a filament size distribution of 0.2 or less; and a means for producing the battery separator.

Owner:UNIVERSITY OF YAMANASHI

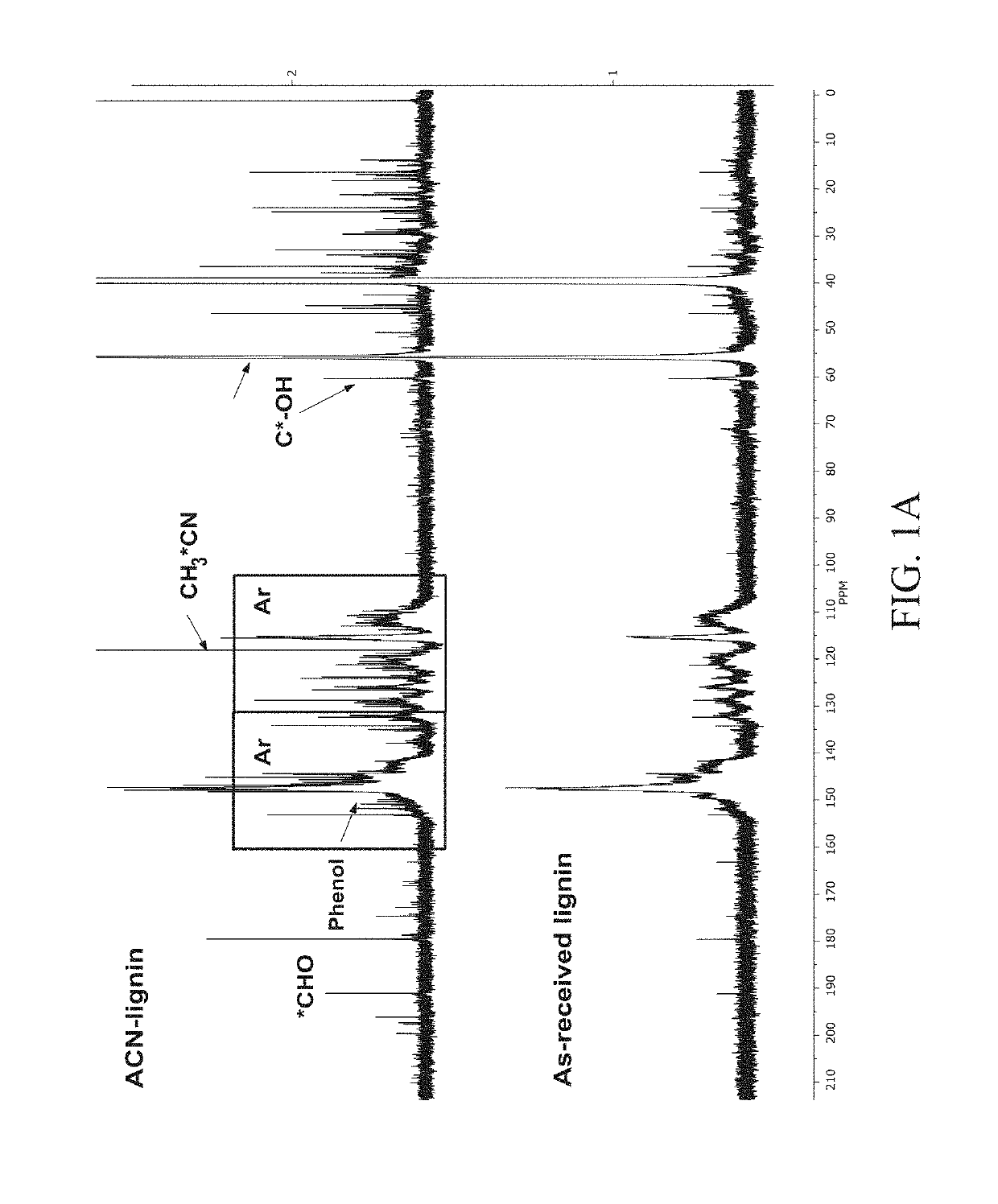

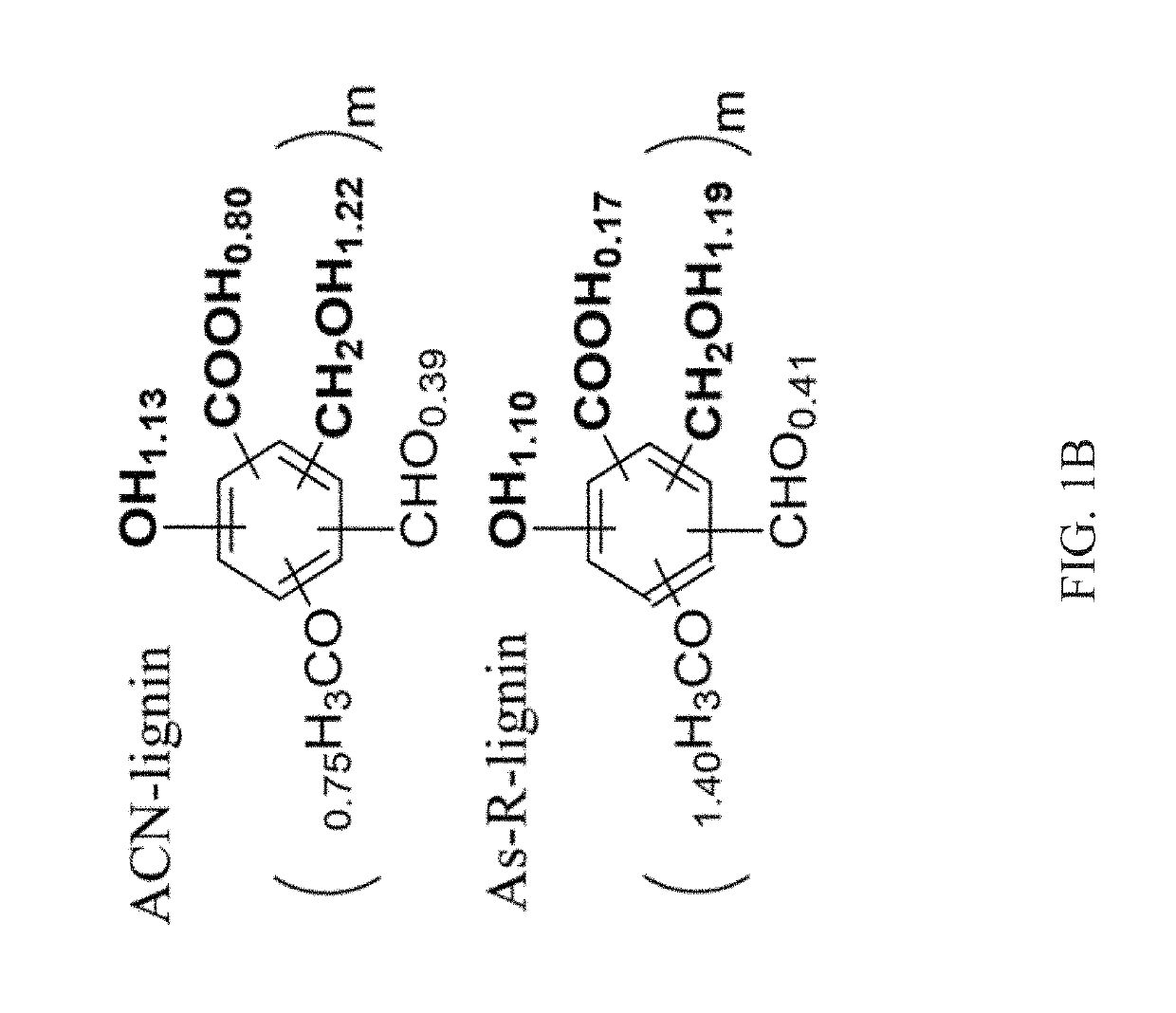

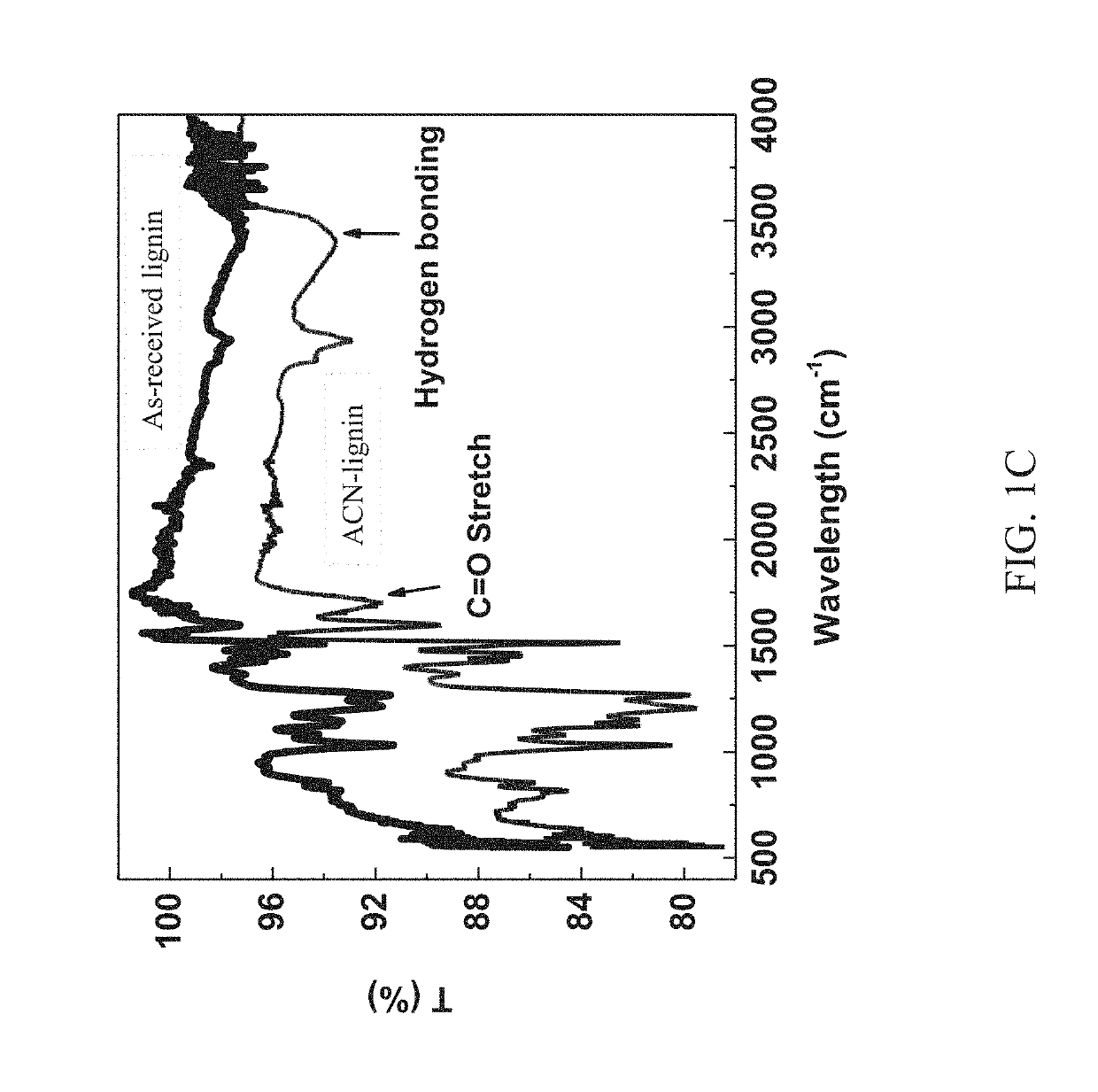

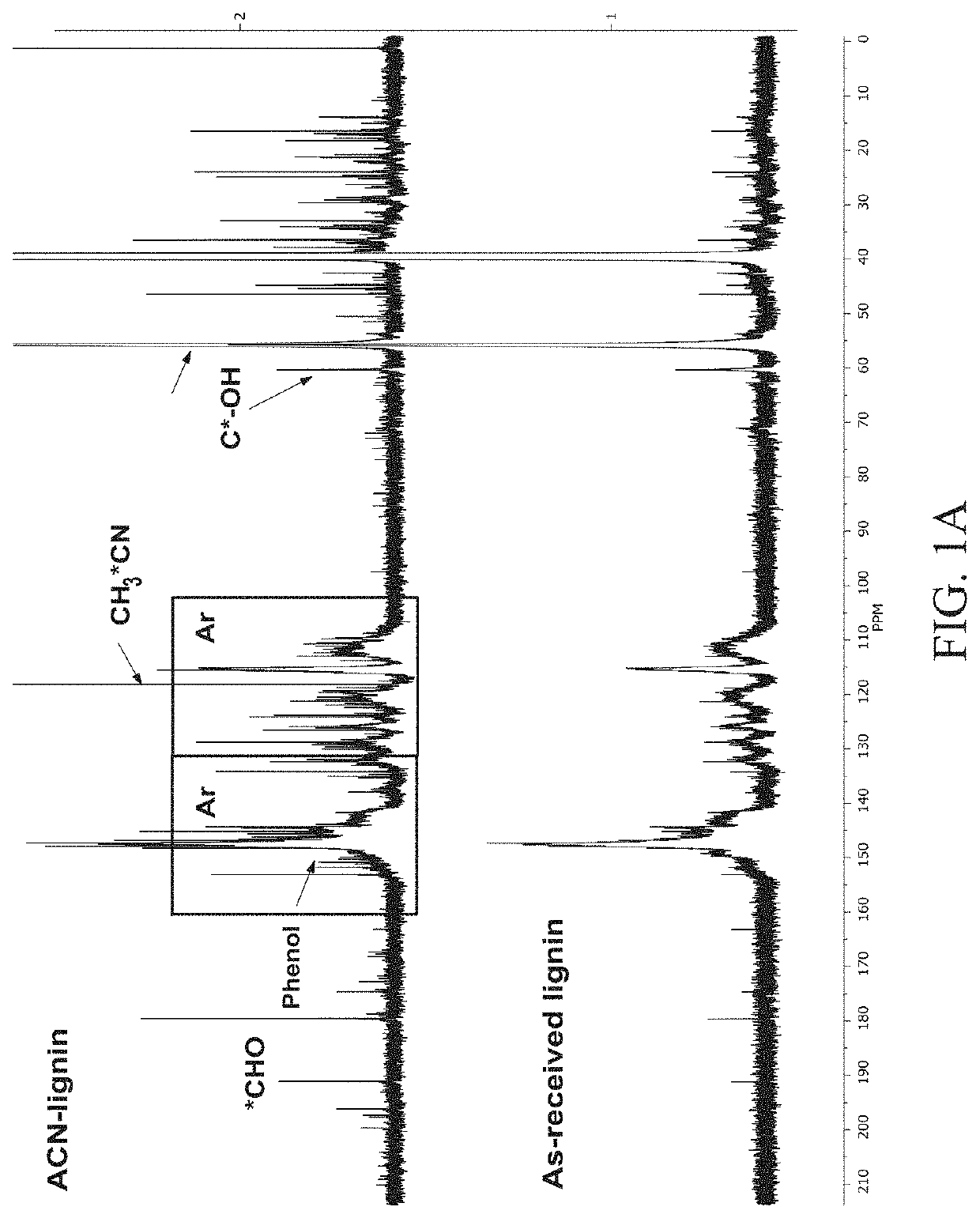

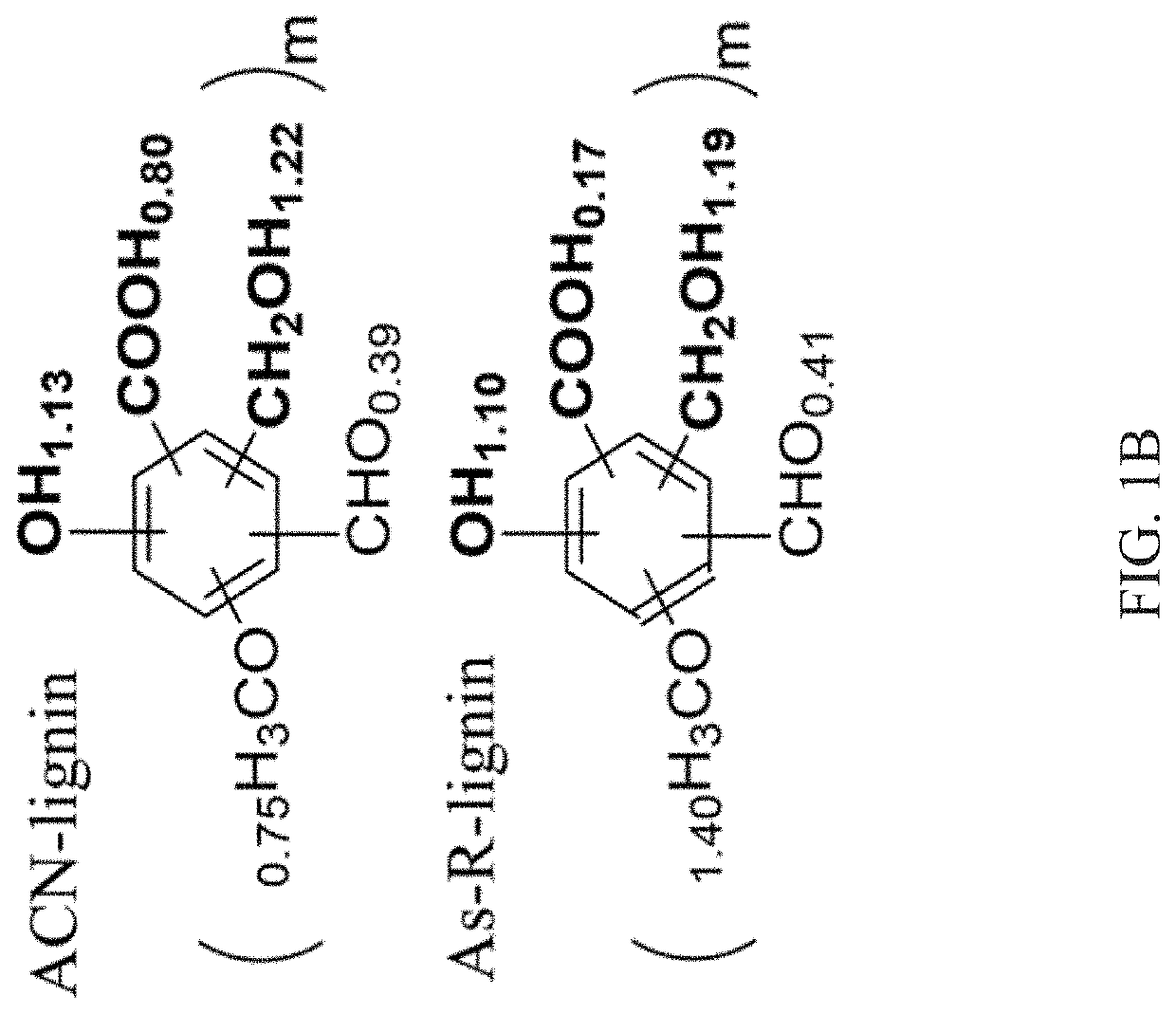

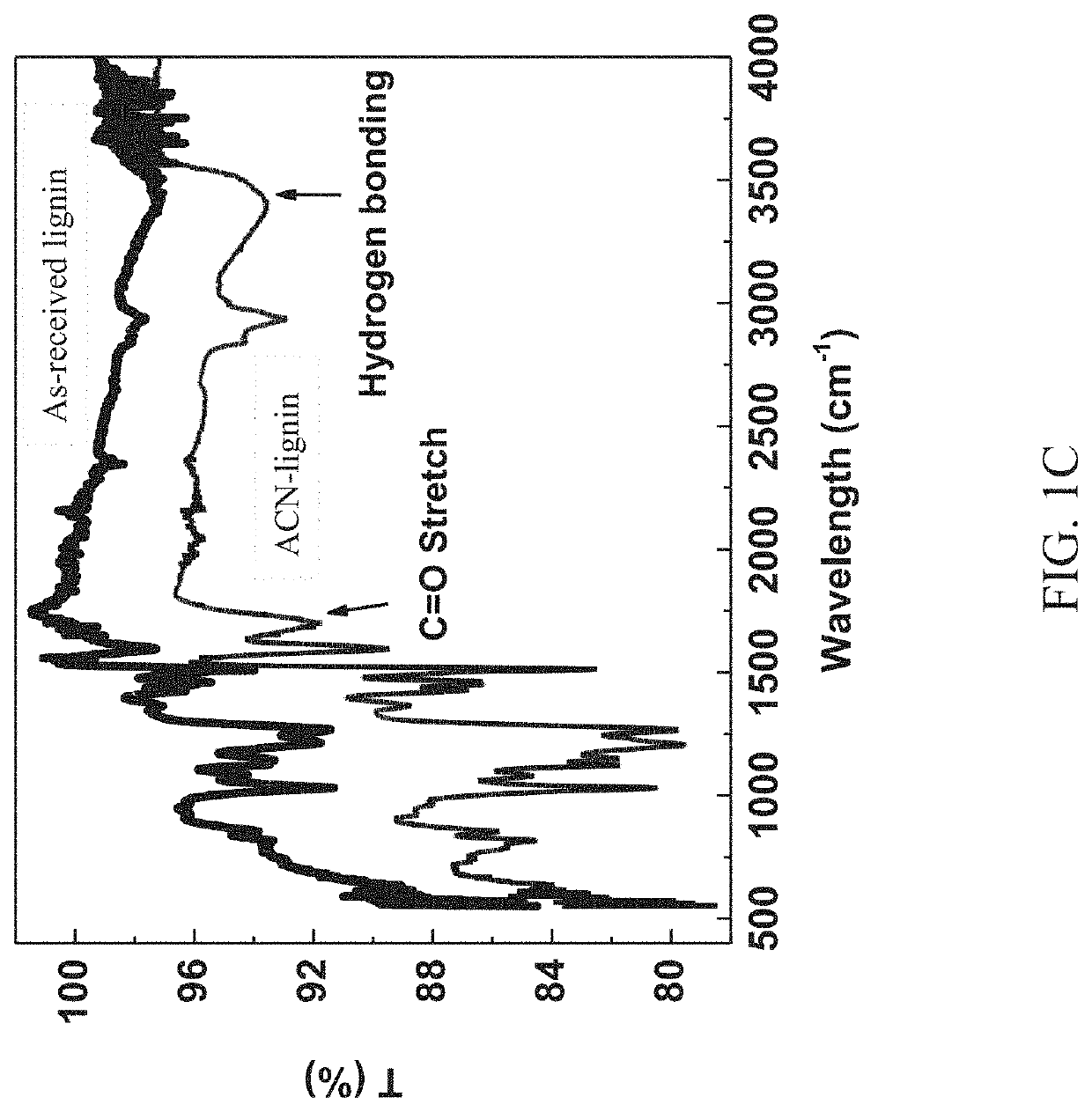

Functional lignin, and its use in producing blends, copolymers, and self-healing elastomers

A composition comprising lignin compounds possessing 8-30 (or 5-15 or 8-12) phenyl rings interconnected by ether and alkylene linkages and containing hydroxy and / or methoxy groups attached to said phenyl rings, wherein said composition possesses a glass transition temperature of 80-100° C. (or 95-98° C.) and a degree of substitution (DS) of carboxylic acid groups per phenyl ring of at least 0.5 and a DS of methoxy groups per phenyl ring of no more than 1.2, 1.1, or 1.0, wherein at least 90 wt % of said lignin compounds has a molecular weight within a range of 500-5000 g / mol, 1500-3000 g / mol, or 2000-2500 g / mol and / or wherein the molecular weight distribution of the lignin compounds is characterized by a polydispersity index of 1.0-1.5, 1.0-1.4, or 1.0-1.3, and wherein other lignin compounds not possessing the above characteristics are not present. Methods for producing the lignin extract and lignin copolymers and blends produced therefrom are also described.

Owner:UT BATTELLE LLC

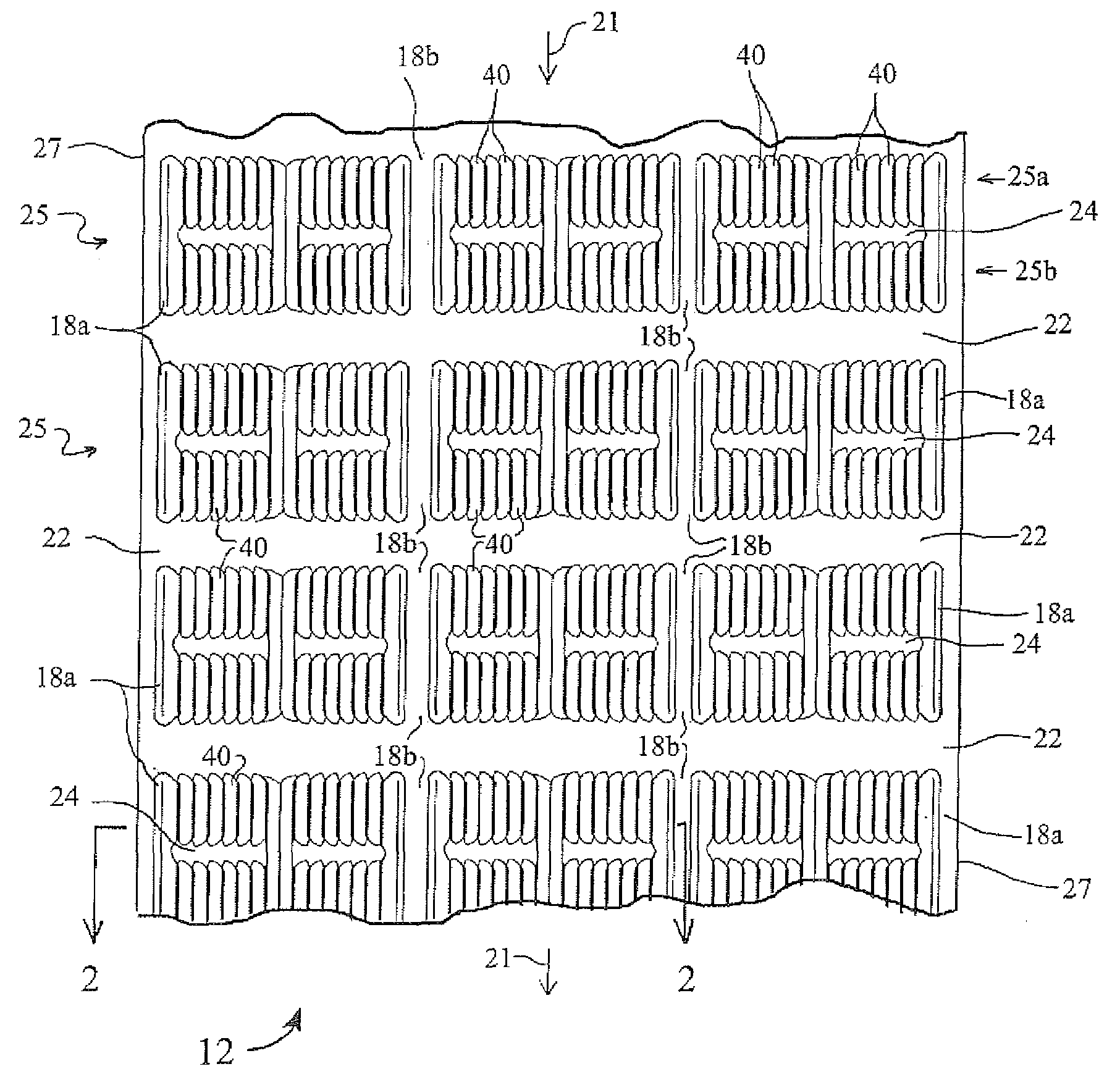

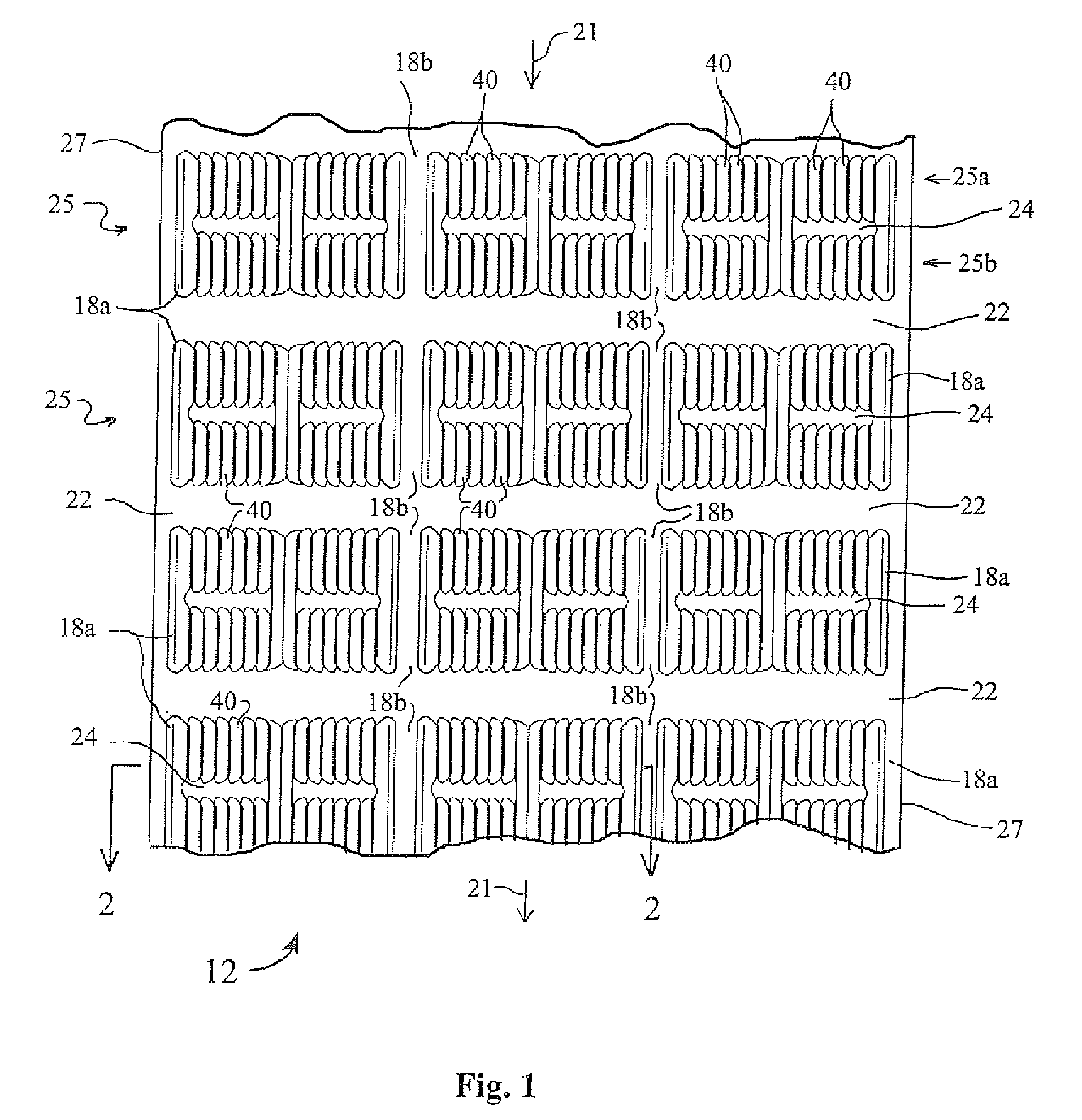

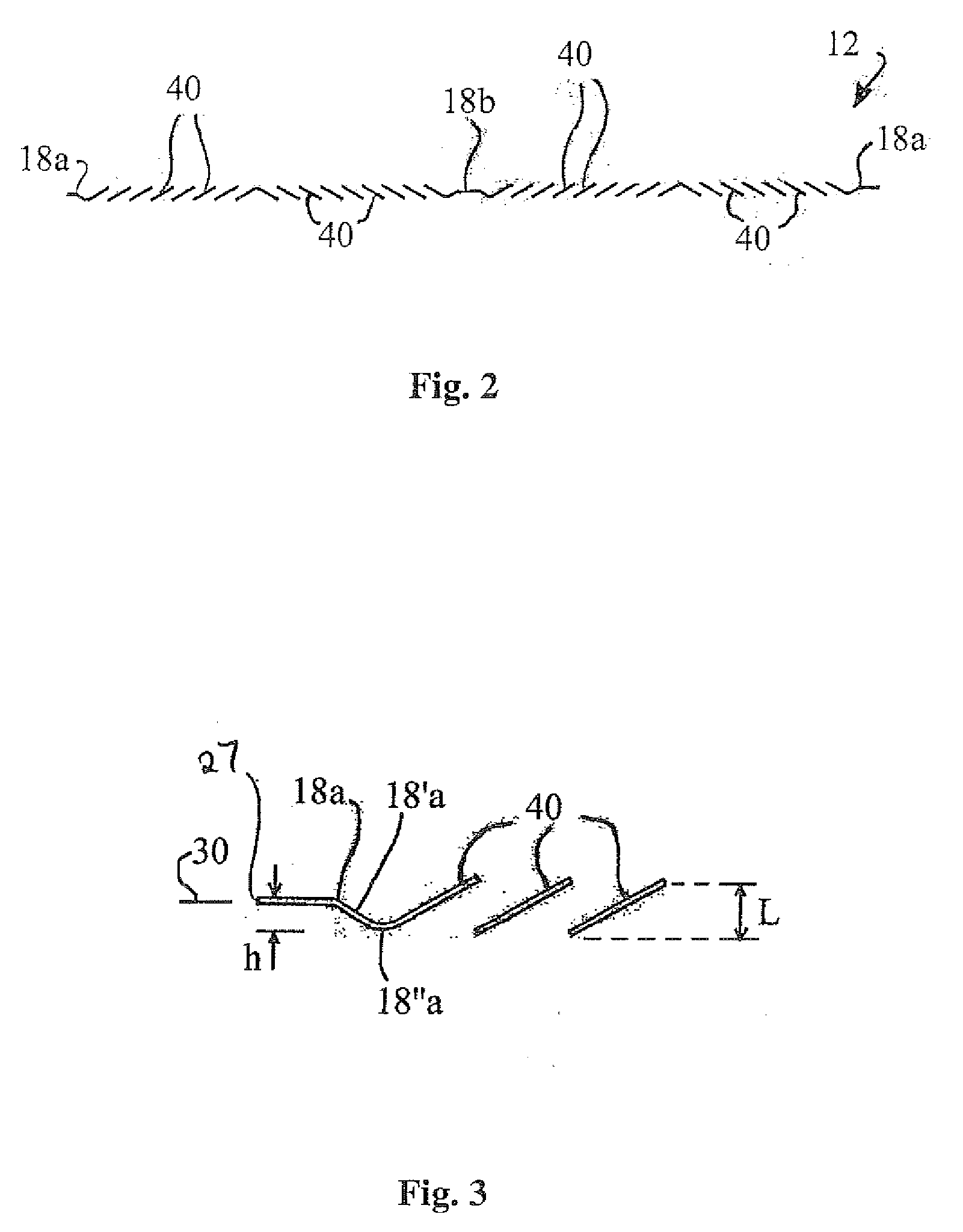

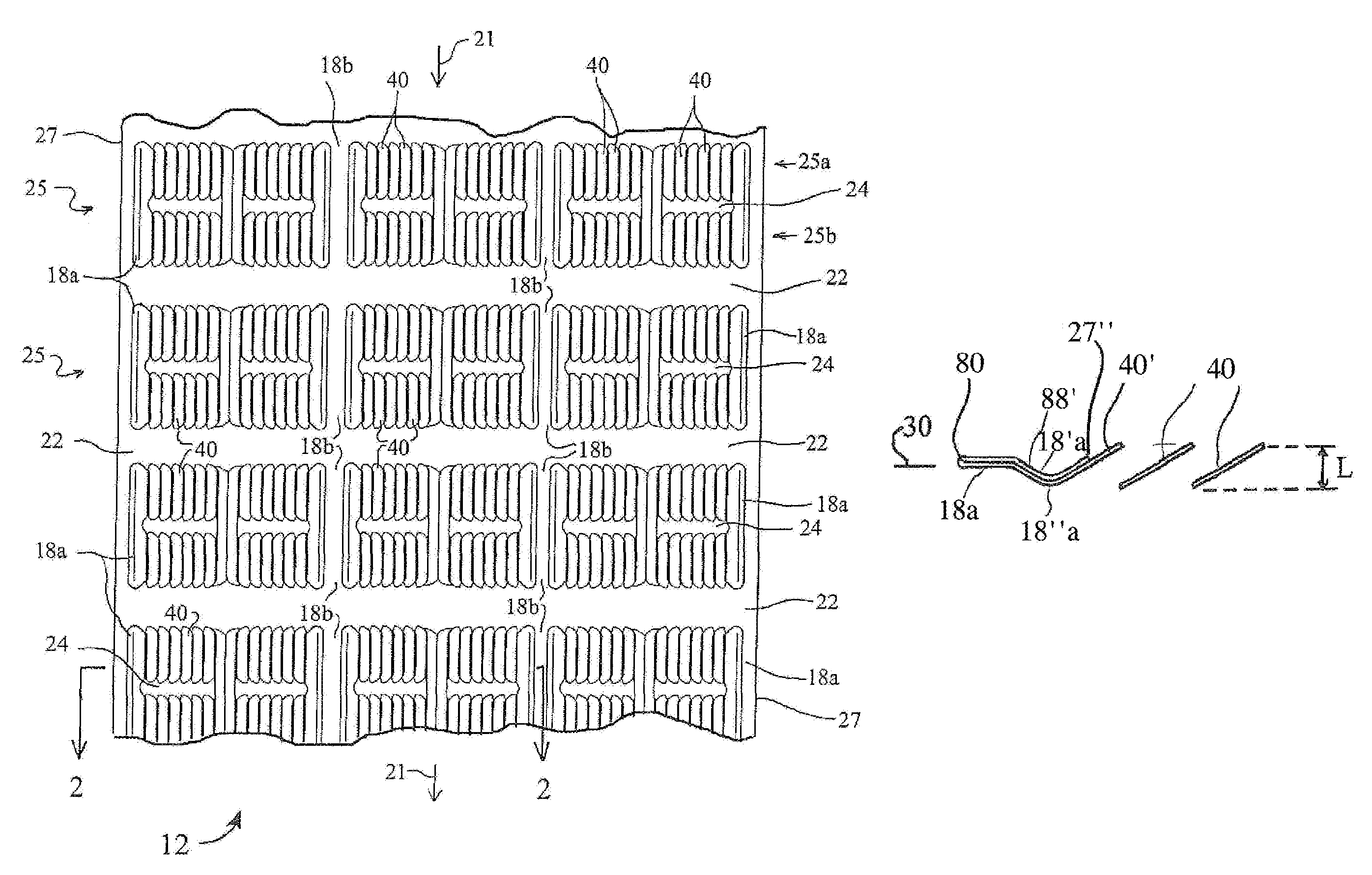

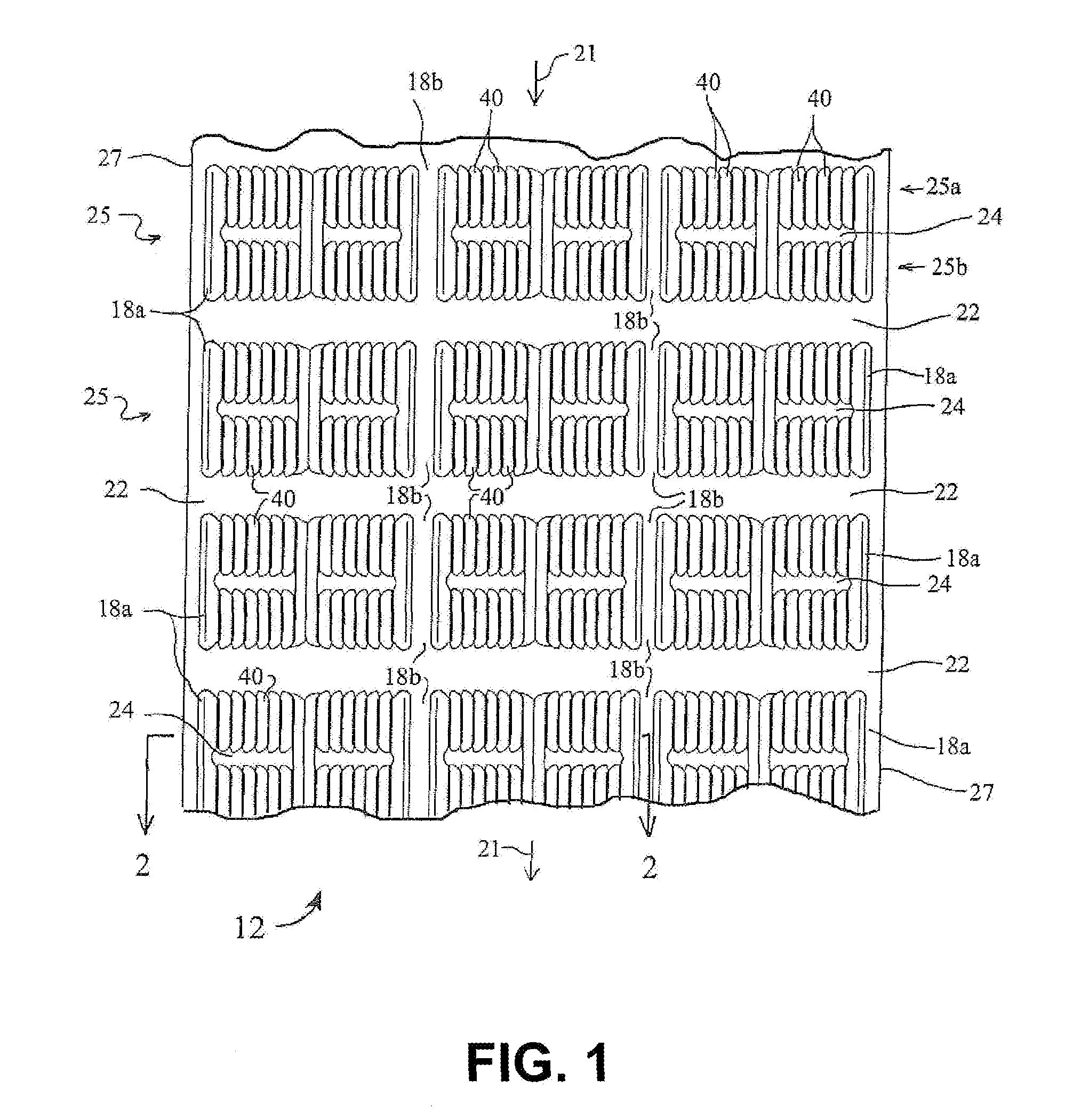

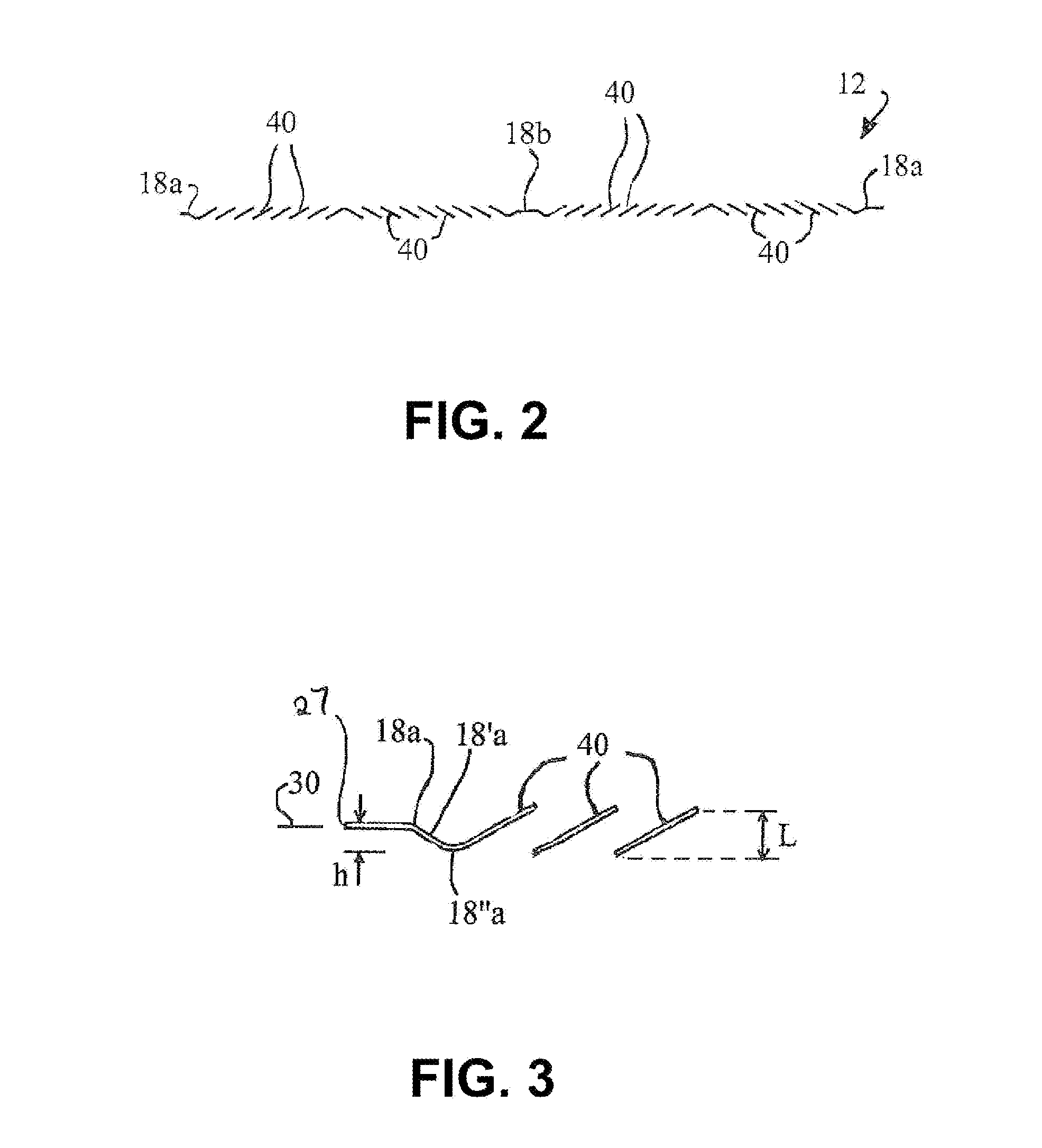

Heat exchanger fin with ribbed hem

InactiveUS20090000776A1Cost-effectiveCost-effective manufacturingStationary conduit assembliesTubular elementsLouverHeat exchanger

A serpentine fin for assembly between tubes in a heat exchanger core, and a method of making same from a metal strip. The strip edges have a hem comprising a double thickness of the strip material extending inward from the edge. The metal strip has folds extending across the strip width such that the strip forms a serpentine shape, with the folds being adapted to contact the tubes in the heat exchanger core. Multiple rows of split louvers are disposed between adjacent folds. Each row of split louvers comprises louvers having openings extending in the direction of the strip length and formed in a pair of adjacent, spaced louver banks. Ribs are disposed parallel to the louver openings adjacent the strip edges and in at least one center portion of the strip between the strip edges, and extend across the pair of louver banks.

Owner:VISTA PRO AUTOMOTIVE

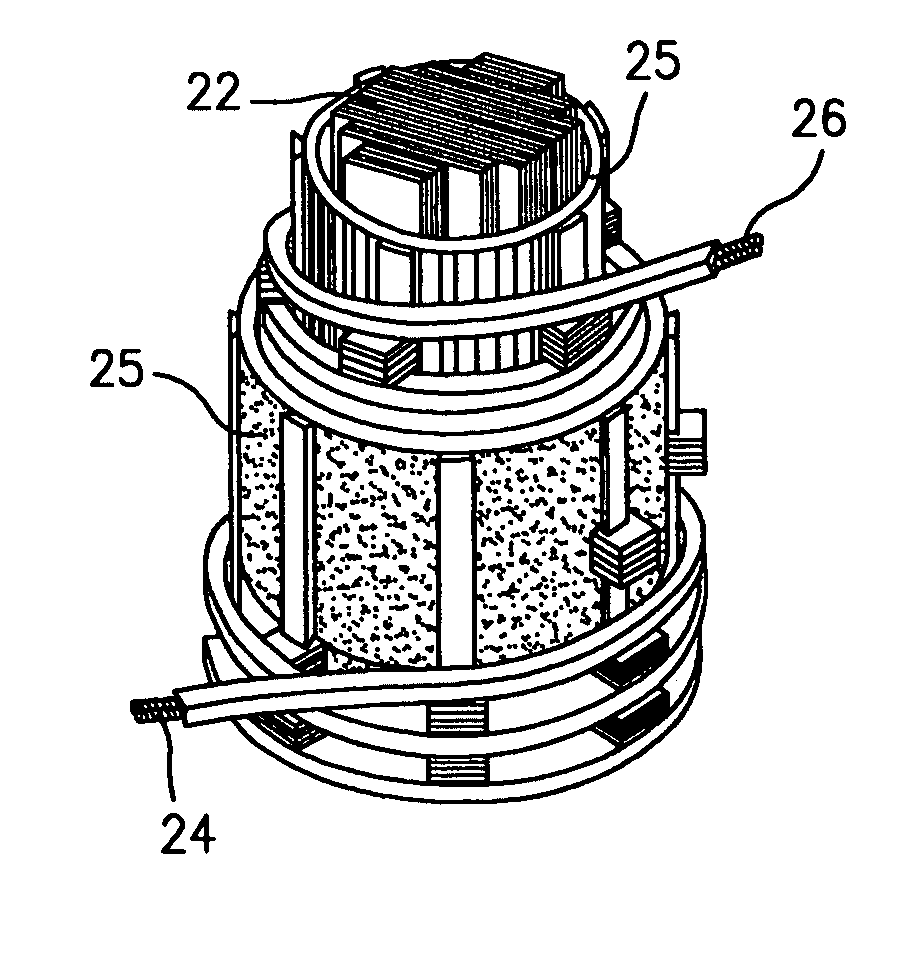

Polyamide electrical insulation for use in liquid filled transformers

ActiveUS20100039199A1Improve barrier propertiesExceptional strengthTransformers/inductances coolingTransformers/inductances casingsPolyamideThermal conductivity

An aliphatic polyamide film or fibrous material is employed for electrical insulation in individual conductors, groups of conductors, magnet wire, magnet wire coils, and layers in liquid filled electrical transformers. The material is stabilized with additives that produce improved moisture resistance, moisture stability, thermal stability, thermal conductivity, reduced insulation thickness, reduced shrinkage, and improved insulation elasticity for the insulation material thereby providing a longer useful life for the material.

Owner:WEINBERG MARTIN

Structurally stable flame retardant bedding articles

ActiveUS7326664B2Exceptional retardancyExceptional softnessWoven fabricsNon-woven fabricsEngineeringStructural integrity

A flame retardant bedding article comprises a hydroentangled flame retardant nonwoven component, and more specifically, a bedding article such as a mattress, pillow cover or mattress pad, comprising a structurally stable, flame retardant nonwoven component. The component comprises at least two layers that have a synergistic relationship so as to maintain the structural integrity of the bedding article upon burning.

Owner:AVINTIV SPECIALTY MATERIALS INC

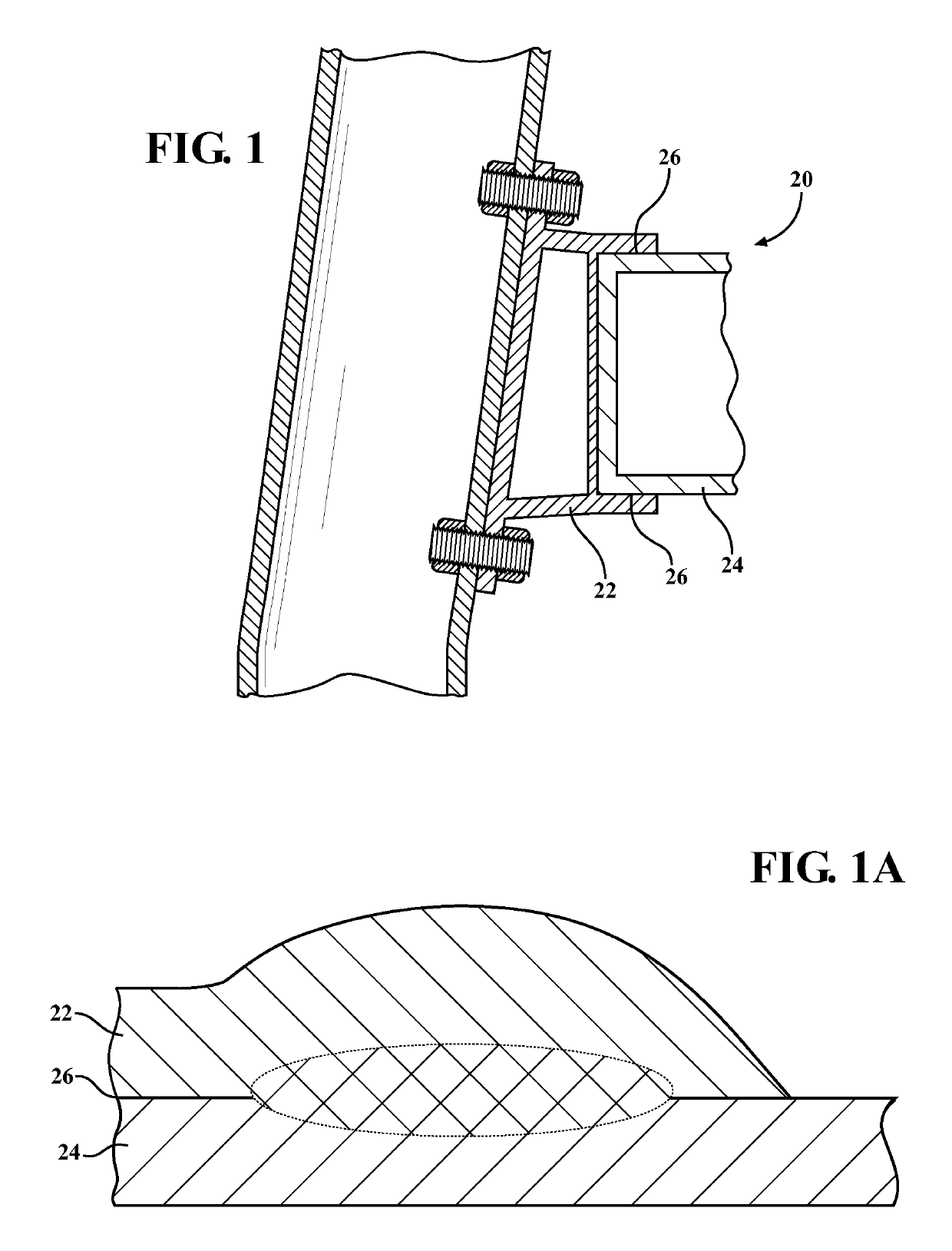

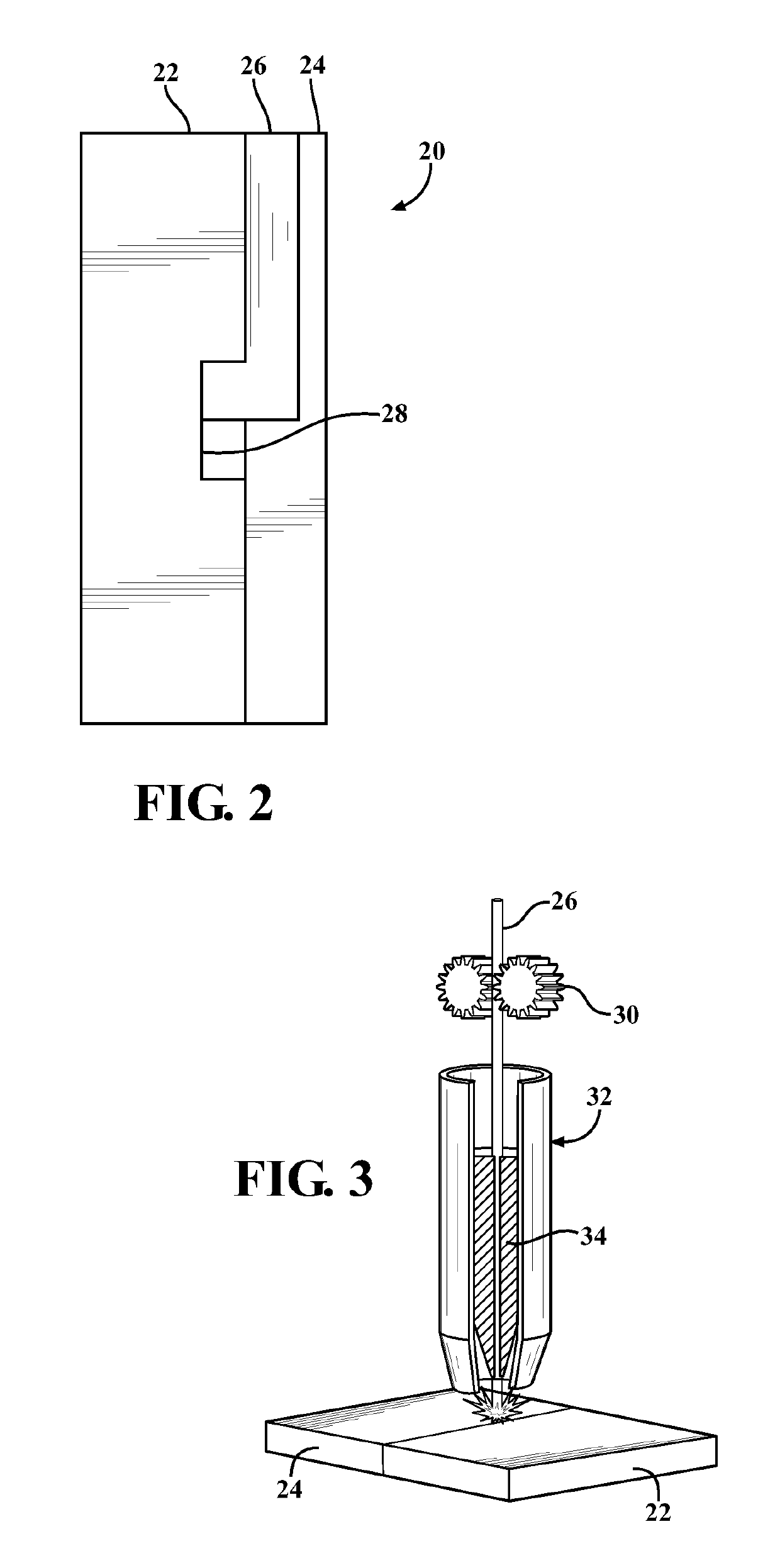

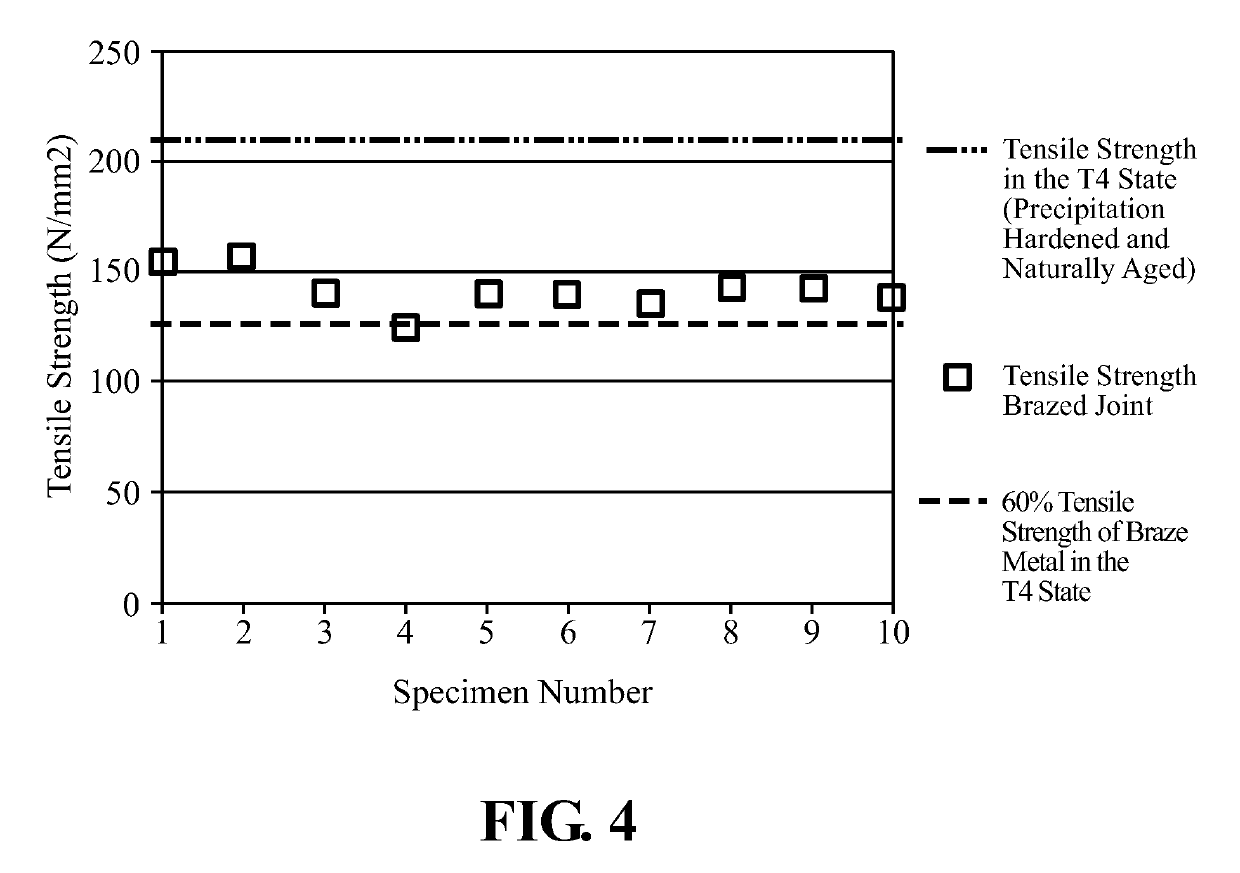

Joining of dissimilar materials

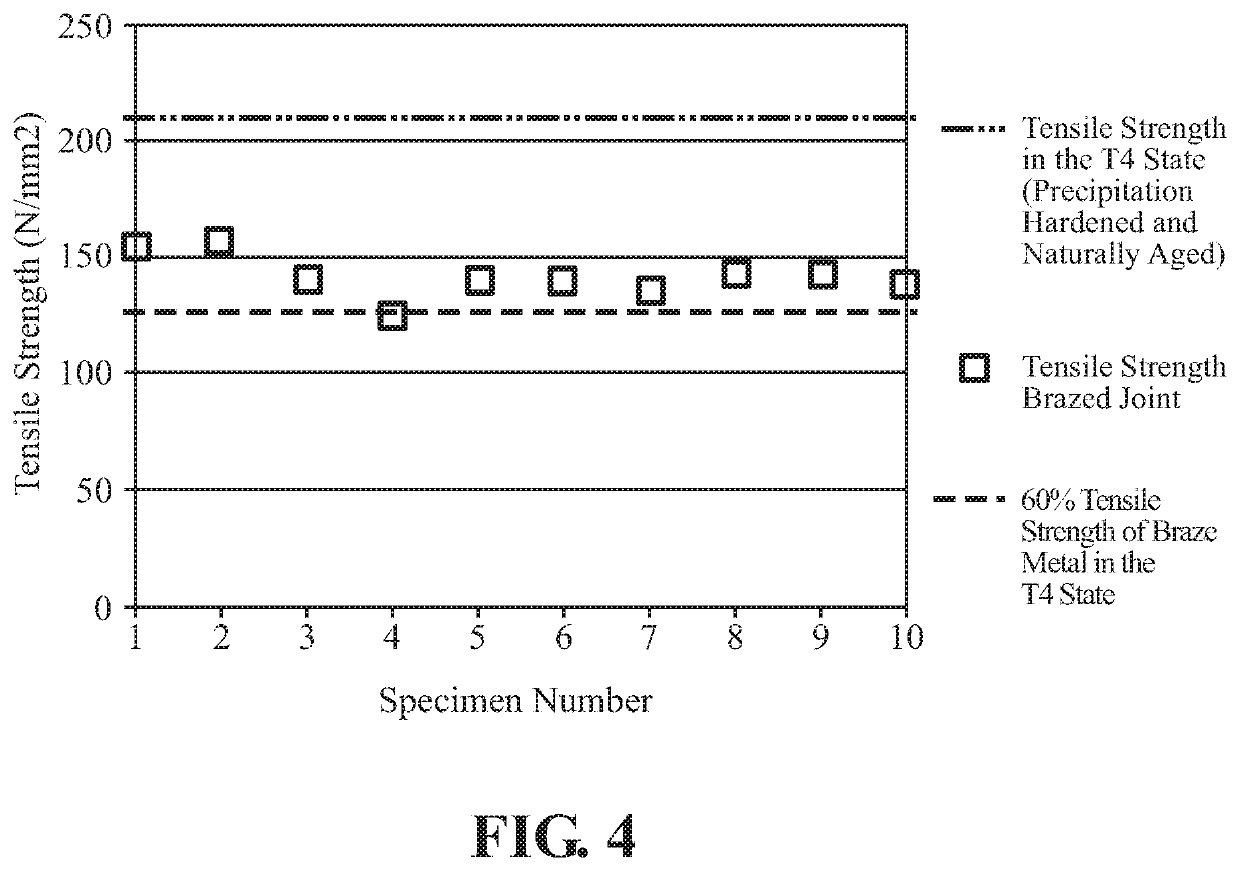

ActiveUS10456850B2Exceptional strengthHigh strengthArc welding apparatusPlasma welding apparatusMetalCHEEK DIMPLES

Owner:MAGNA INTERNATIONAL INC

Offset Notch Bridging Connector

ActiveUS20180154421A1Simple interfaceFirmly connectedWallsRod connectionsMechanical engineeringPhysics

A connection between metal studs and bridging members using a separate light gauge bridging connector with longitudinally-offset interface notches.

Owner:SIMPSON STRONG TIE

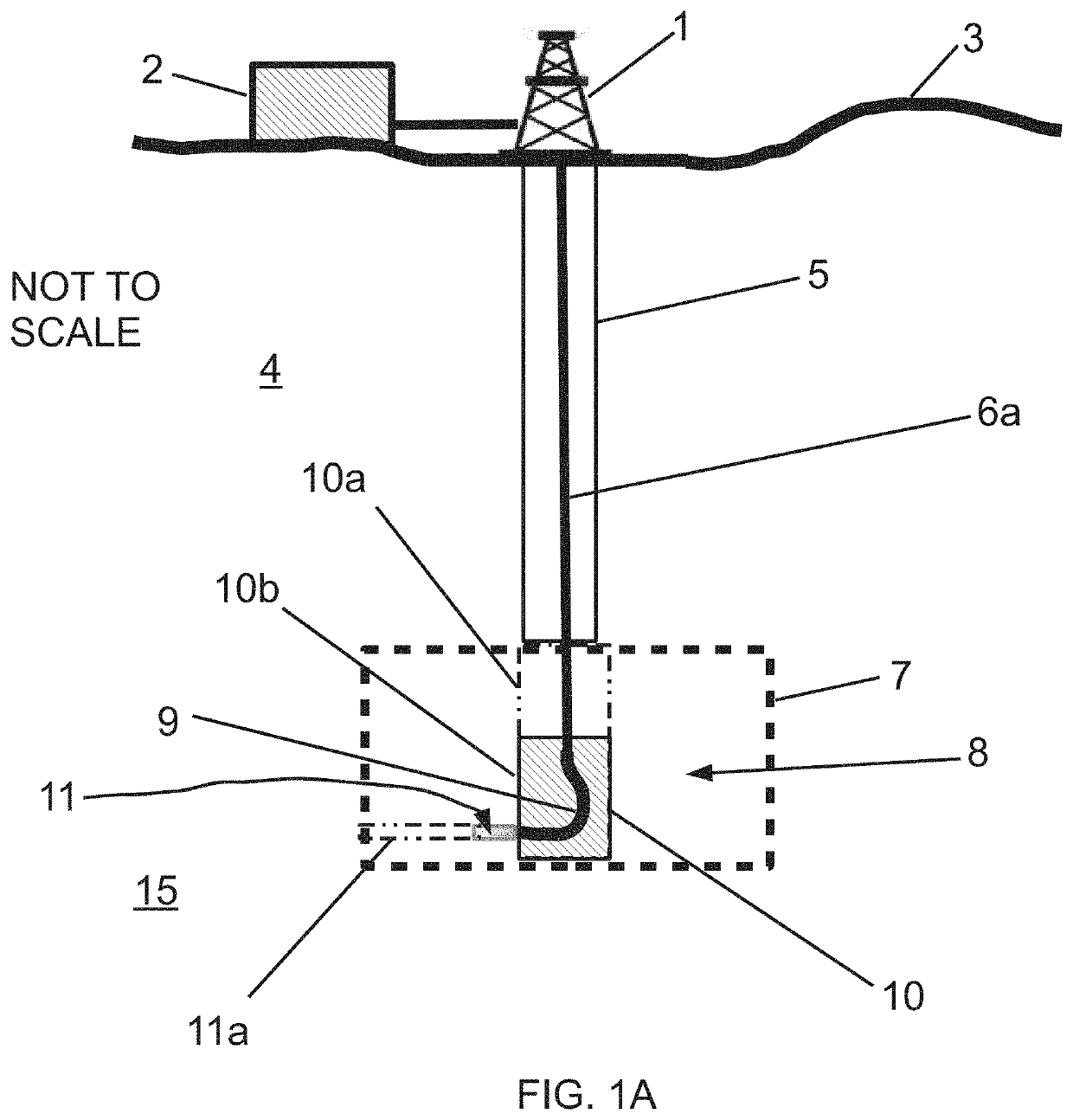

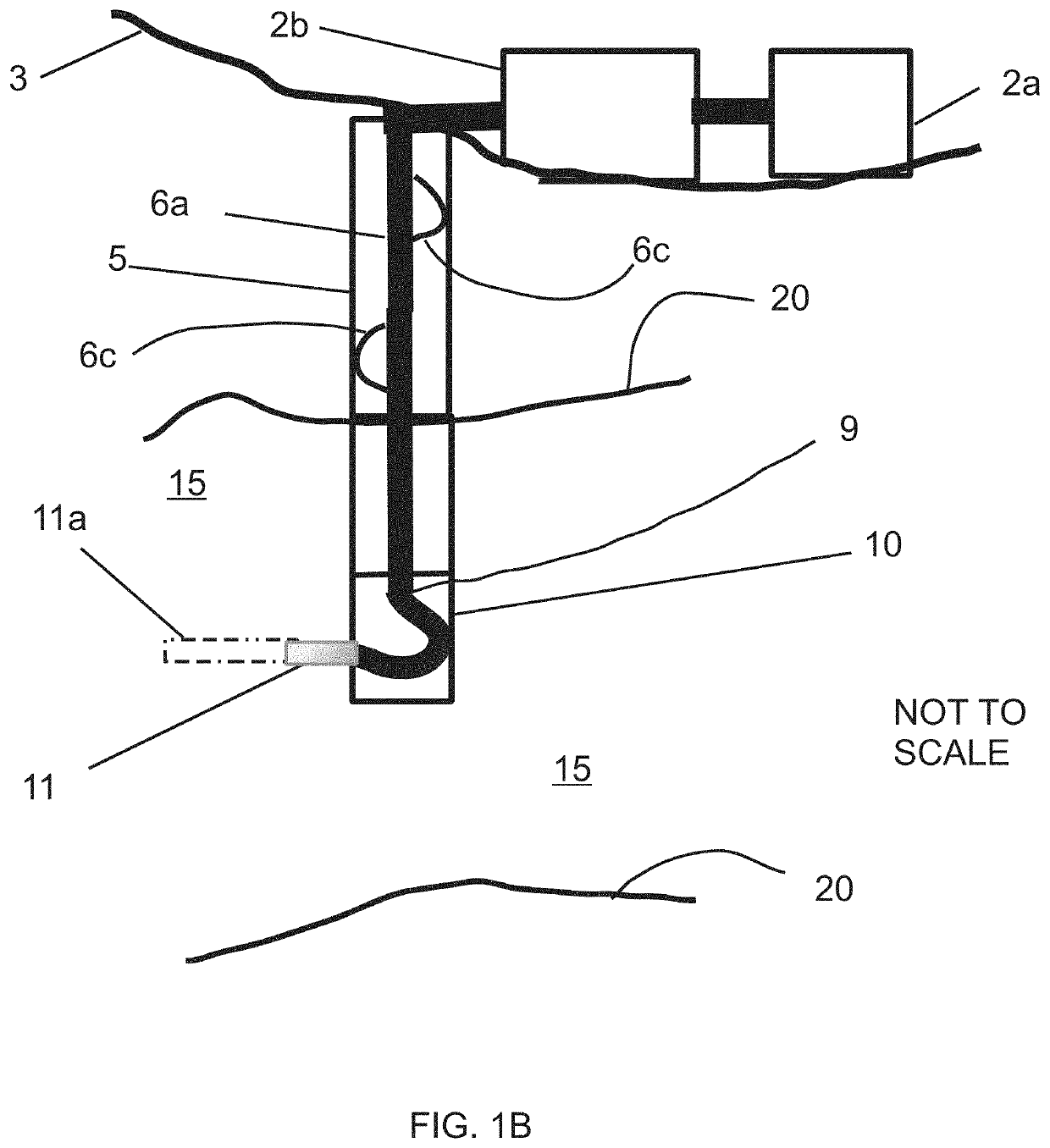

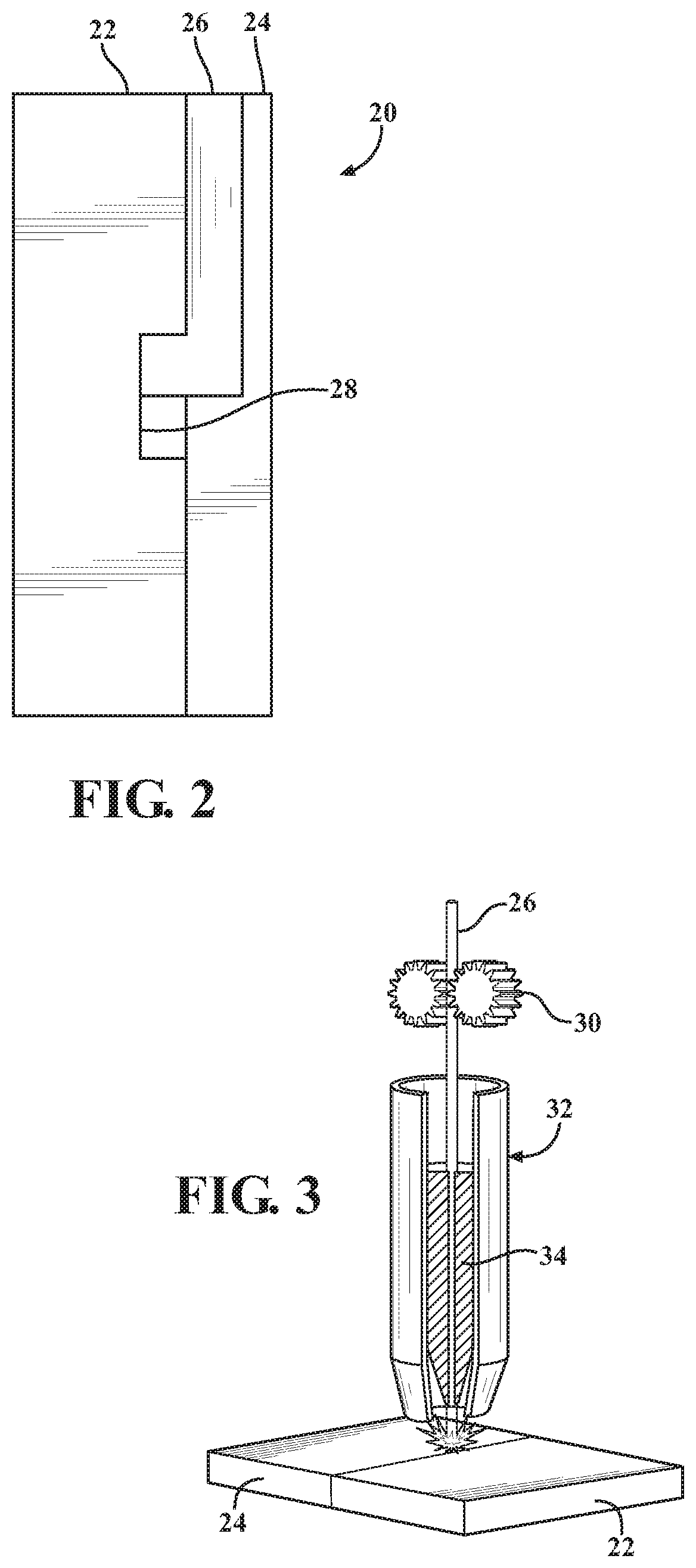

Deep human-made cavern construction

ActiveUS20210025241A1Cost efficientSafe and efficientDrill bitsDrilling rodsMechanical engineeringWaste disposal

Systems and / or methods of waste disposal use human-made caverns that are constructed within deep geological formations. A given human-made cavern may be constructed by first drilling out a vertical wellbore to a deep geological formation. Then a bottom portion of the vertical wellbore is jet drilled using an abrasive jetting fluid to form a launch chamber of void volume, that is sized to fit a reaming tool in its deployed open configuration. A reaming tool, in a closed configuration, is then inserted into the vertical wellbore for landing in the launch chamber. The reaming tool is then deployed into its open configuration while in the launch chamber. Reaming operations then occur from the launch chamber directed downwards within the deep geological formation, forming a given human-made cavern. The newly formed human-made cavern may be conditioned and / or configured for receiving amounts of the waste for long-term disposal and / or storage.

Owner:CRICHLOW HENRY

Polyamide electrical insulation for use in liquid filled transformers

ActiveUS8193896B2High melting pointExceptional stiffnessPlastic/resin/waxes insulatorsTransformers/inductances casingsElectricityFiber

An aliphatic polyamide film or fibrous material is employed for electrical insulation in individual conductors, groups of conductors, magnet wire, magnet wire coils, and layers in liquid filled electrical transformers. The material is stabilized with additives that produce improved moisture resistance, moisture stability, thermal stability, thermal conductivity, reduced insulation thickness, reduced shrinkage, and improved insulation elasticity for the insulation material thereby providing a longer useful life for the material.

Owner:WEINBERG MARTIN

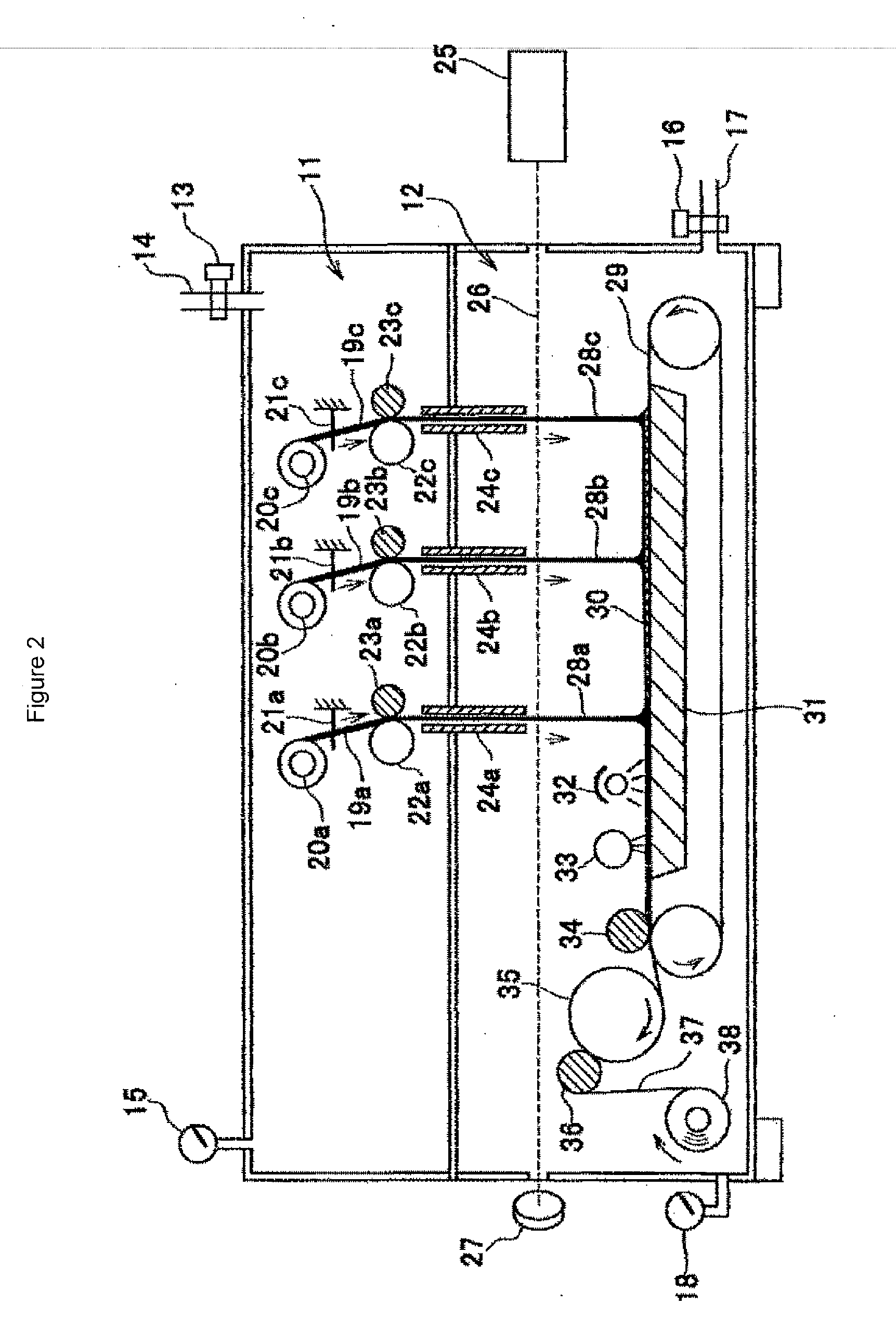

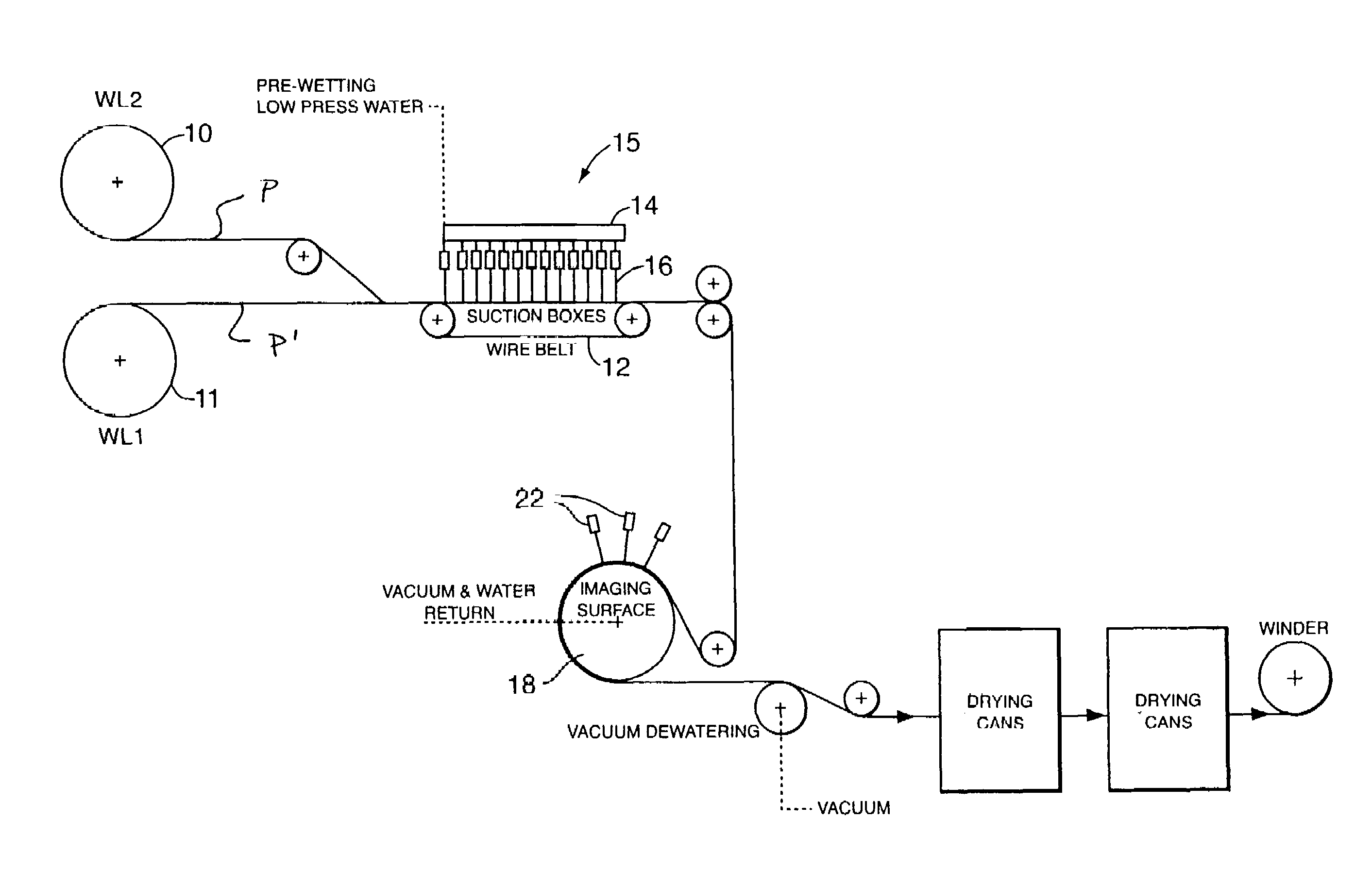

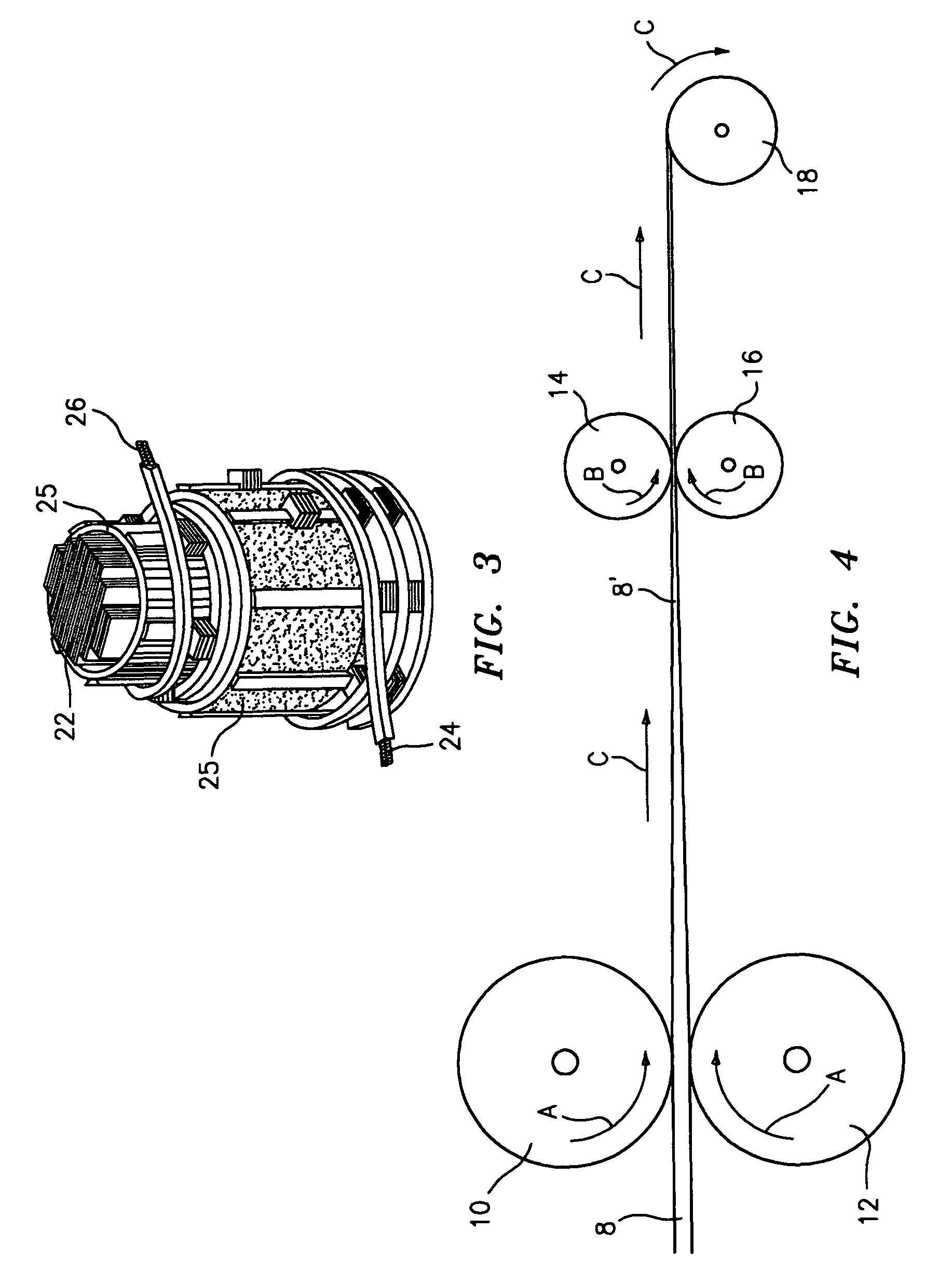

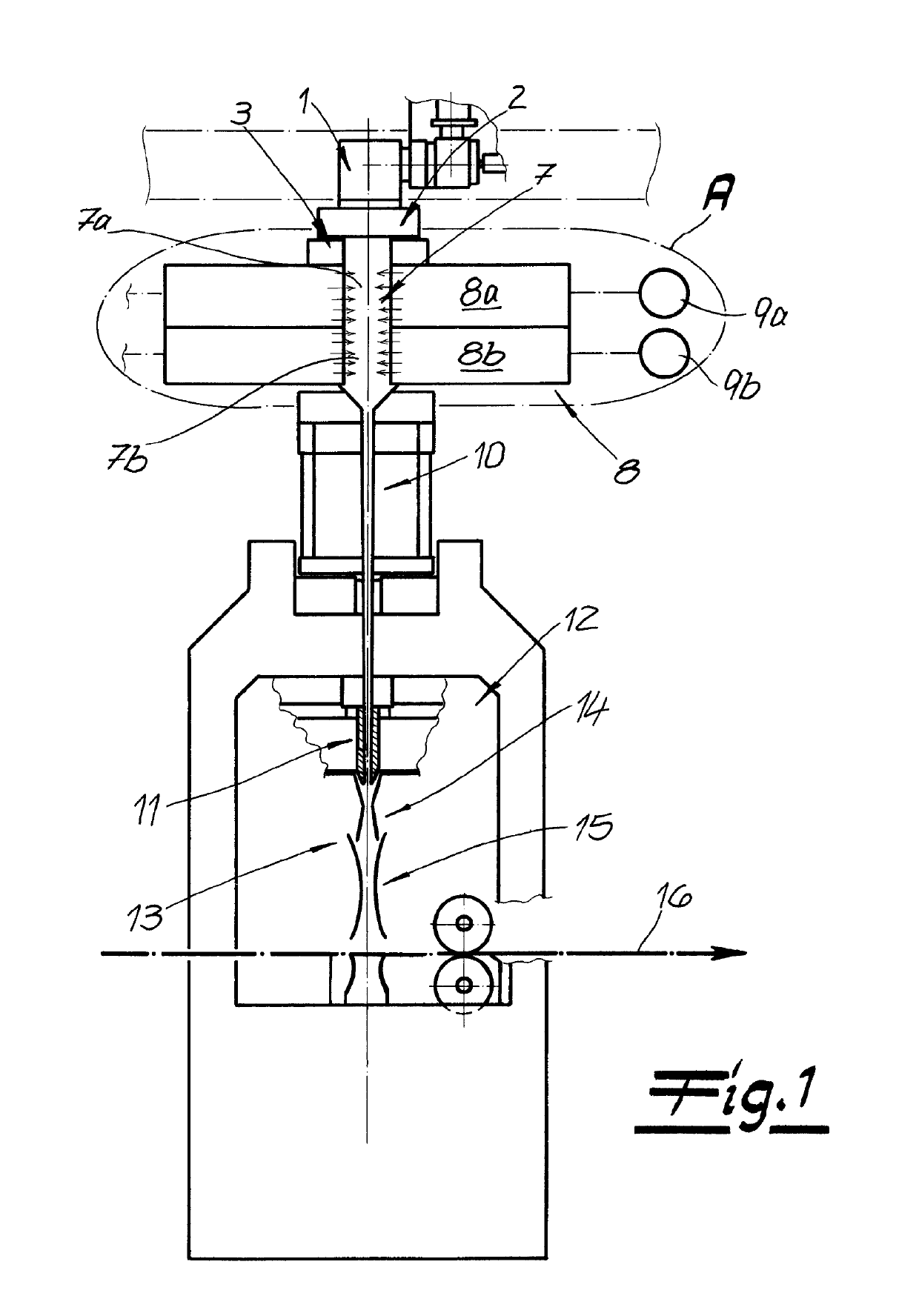

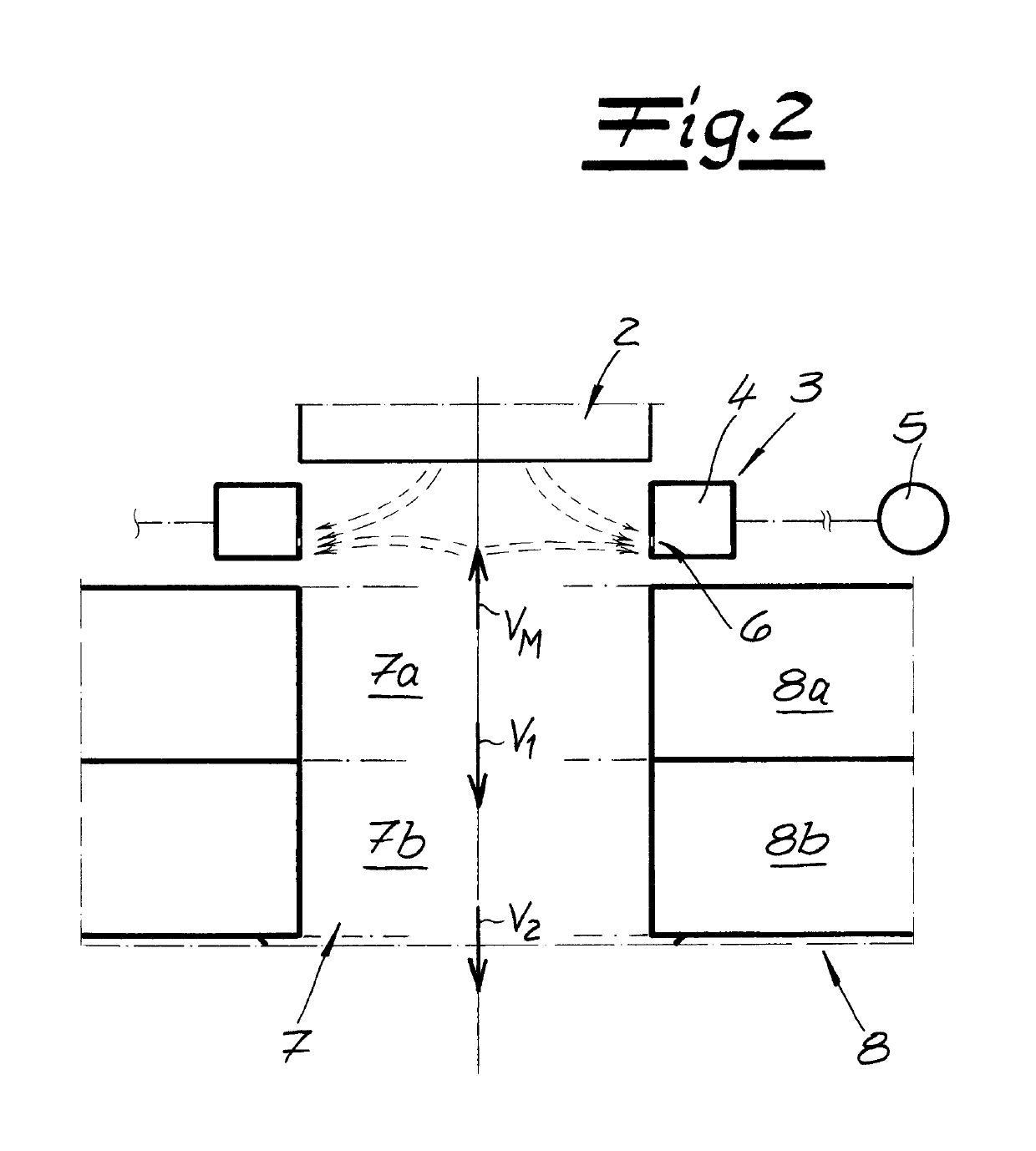

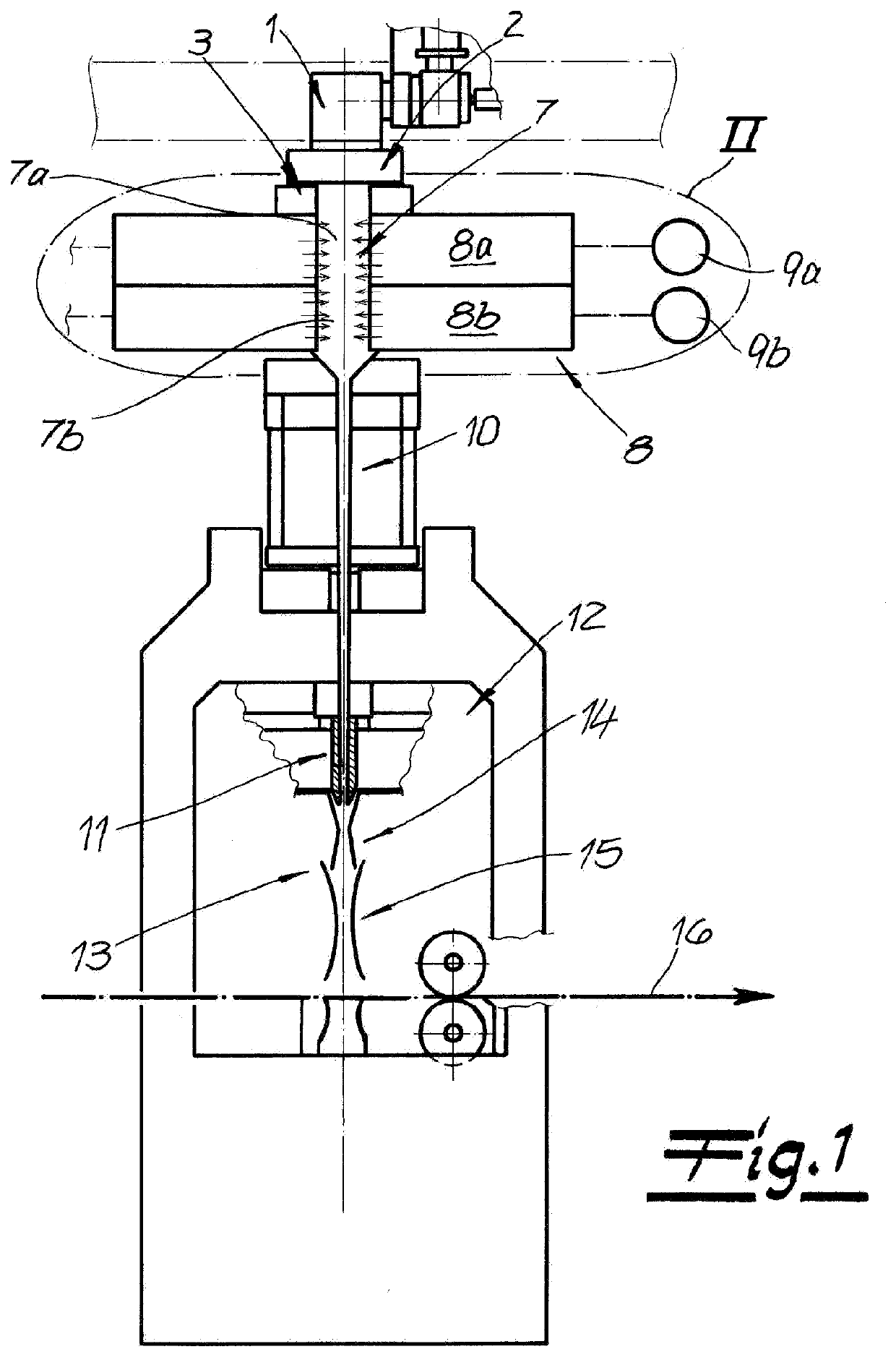

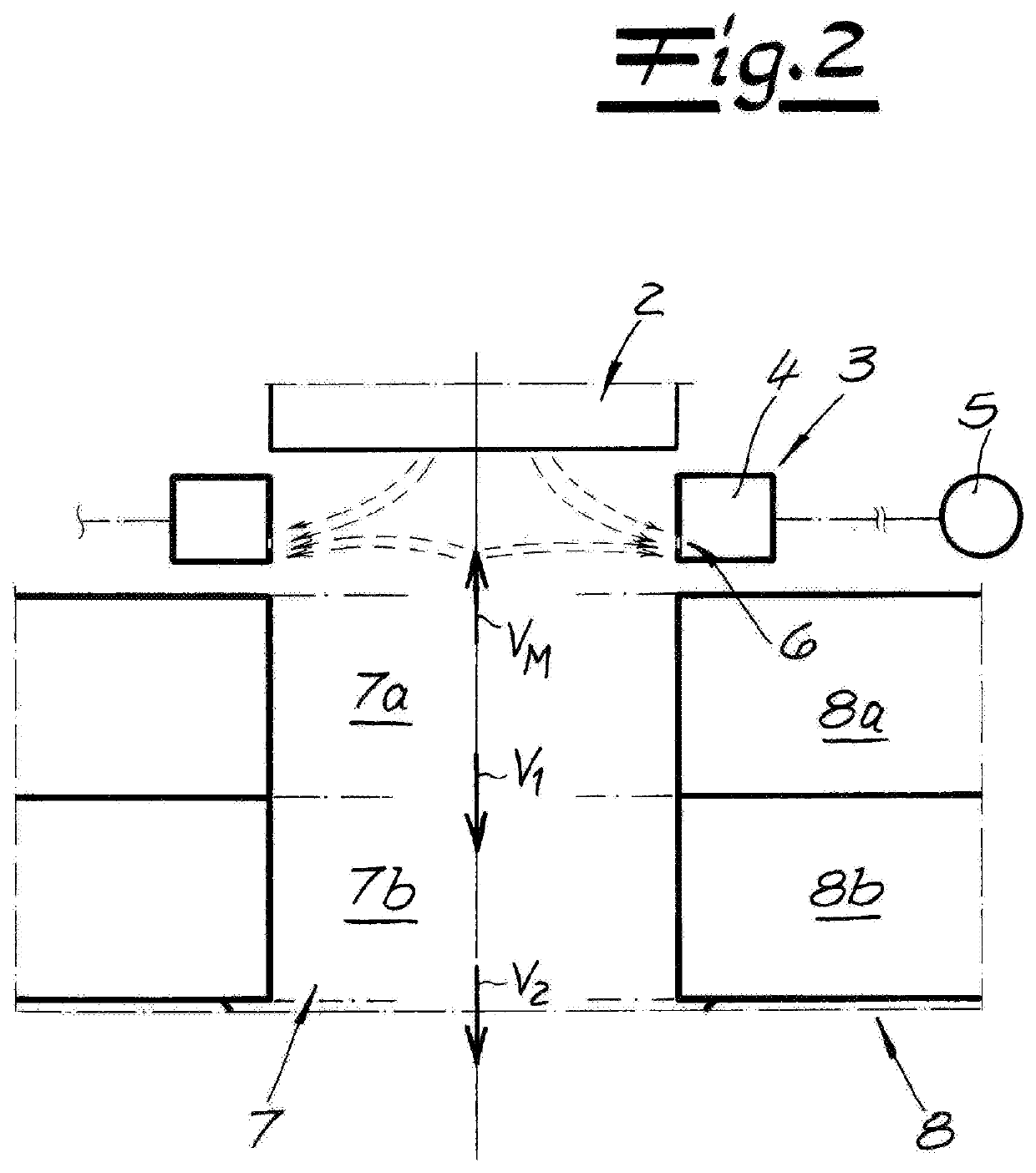

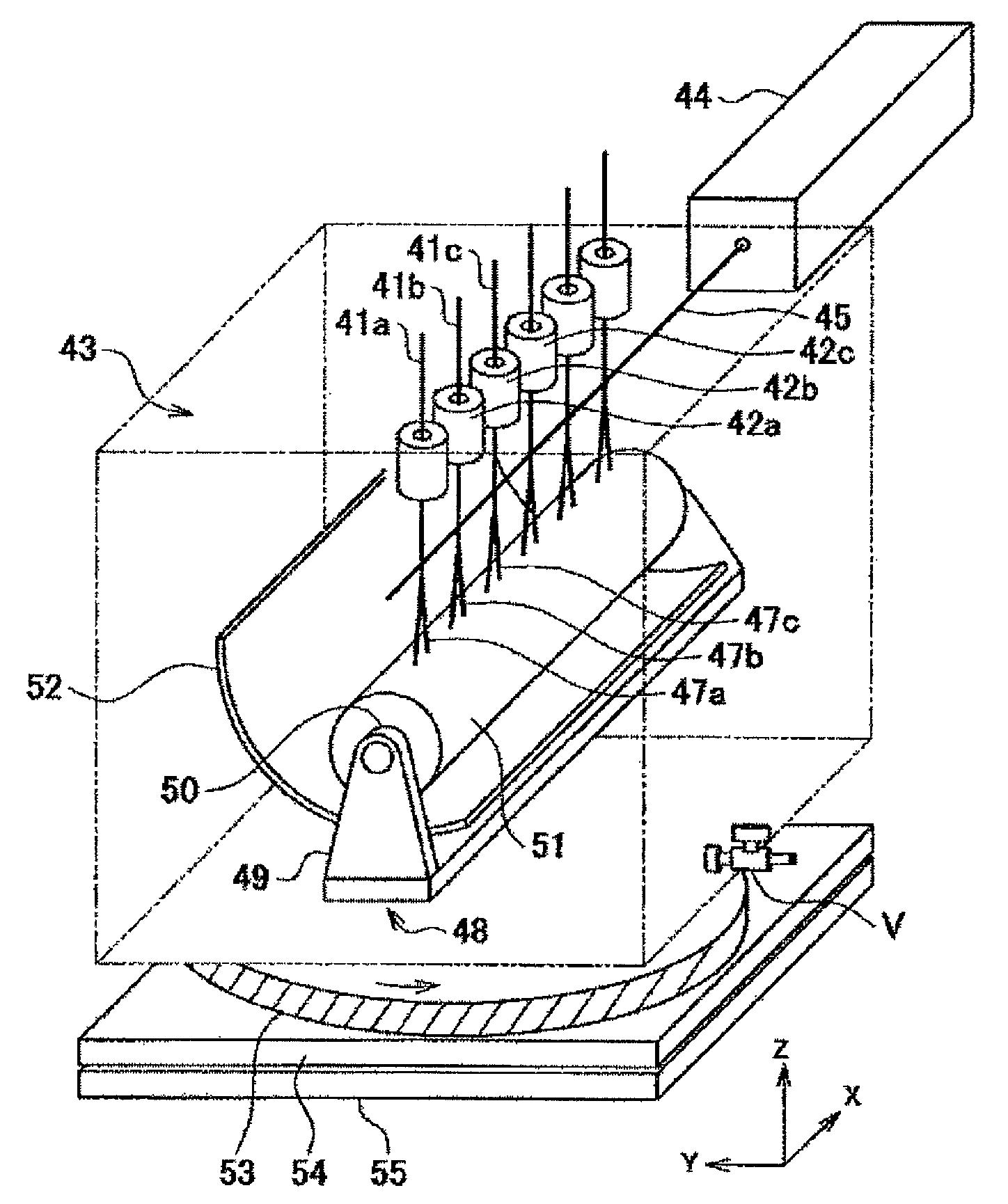

Method of making a spunbond from filaments

ActiveUS10428443B2Good homogeneityExceptional strengthNew-spun product collectionMonocomponent polypropylene artificial filamentEngineeringMechanical engineering

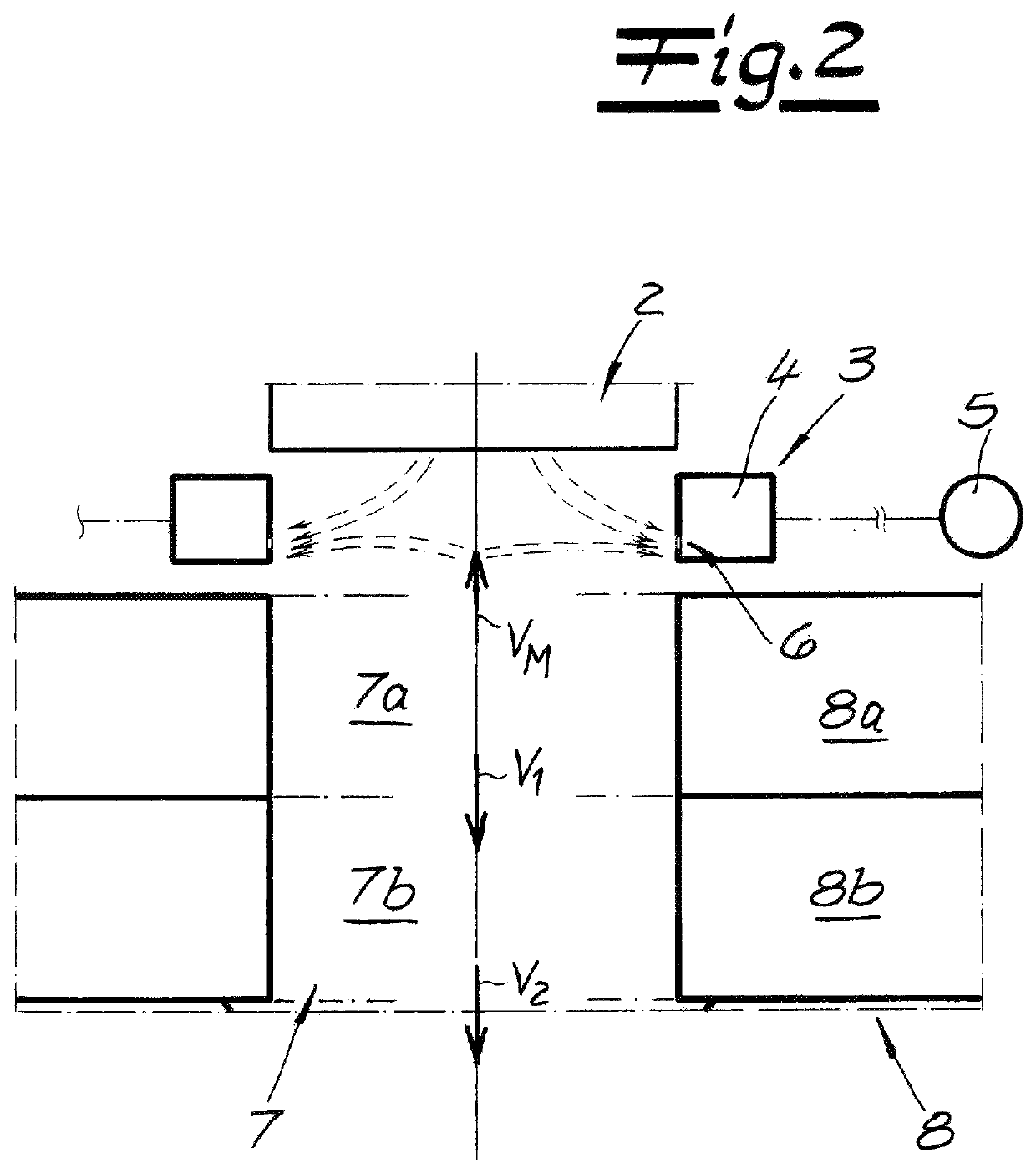

The invention relates to a device for producing a spun-bonded web from filaments, comprising spinnerets, a cooling chamber into which process air can be introduced in order to cool the filaments, a monomer suction device arranged between the spinnerets and the cooling chamber, a stretching unit, and a placing device for placing the filaments so as to form the spun-bonded web. The cooling chamber is divided into two cooling chamber portions. Process air can be suctioned out of a first upper cooling chamber portion to the monomer suction device with a volumetric flow rate Vm, and process air exits the first upper cooling chamber portion into a second lower cooling chamber portion with a volumetric flow rate V1. The volumetric flow rate ratio VM / V1 is 0.1 to 0.3.

Owner:REIFENHAUSER GMBH & CO

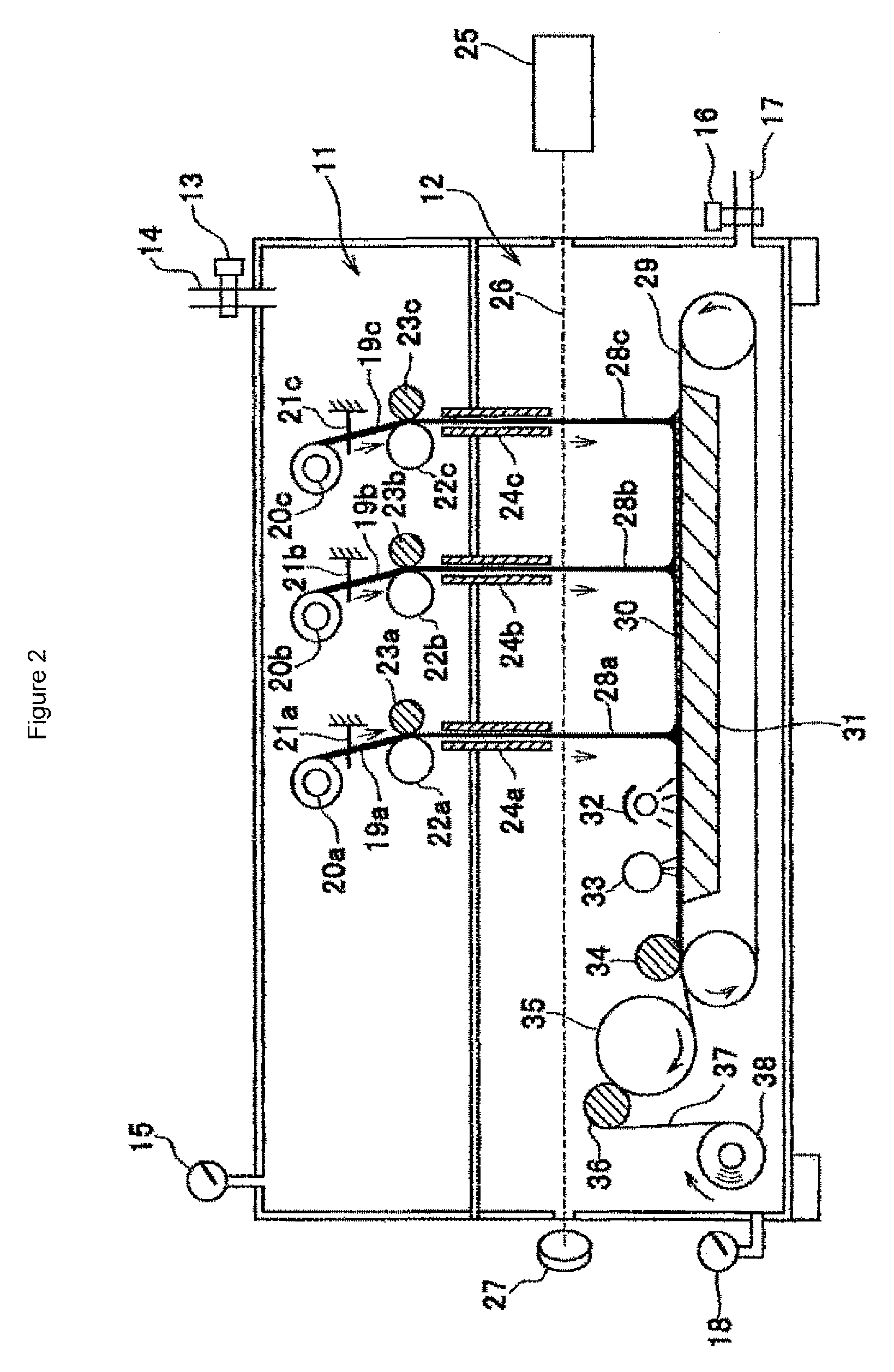

Apparatus for making a spunbond web from filaments

ActiveUS20190376208A1Effective and functionally safeAvoid disadvantagesNew-spun product collectionMonocomponent polypropylene artificial filamentCooling chamberEngineering

An apparatus for continuously making a spunbond web of filaments comprises a spinneret, a cooling chamber into which process air for can be introduced for the purpose of cooling the filaments, a monomer suction device between a spinneret and cooling chamber, a stretcher and a deposition device for depositing the filaments of the spunbond web. The cooling chamber is divided into two cooling compartments, and process air can be suctioned out from a first upper cooling compartment at a volumetric flow rate (VM) to a monomer suction device. Process air exits from the first upper cooling compartment at a volumetric flow rate (V1) into a second lower cooling compartment and from the first upper cooling compartment at a volumetric flow rate (V1) into a second lower cooling compartment. A ratio (VM / V1) is 0.1 to 0.35.

Owner:REFENHAEUSER GMBH & CO KG MASCHFAB

Heat exchanger fin with ribbed hem

InactiveUS8408283B2Cost-effectiveCost-effective manufacturingStationary conduit assembliesTubular elementsMetal stripsEngineering

A serpentine fin for assembly between tubes in a heat exchanger core, and a method of making same from a metal strip. The strip edges have a hem comprising a double thickness of the strip material extending inward from the edge. The metal strip has folds extending across the strip width such that the strip forms a serpentine shape, with the folds being adapted to contact the tubes in the heat exchanger core. Multiple rows of split louvers are disposed between adjacent folds. Each row of split louvers comprises louvers having openings extending in the direction of the strip length and formed in a pair of adjacent, spaced louver banks. Ribs are disposed parallel to the louver openings adjacent the strip edges and in at least one center portion of the strip between the strip edges, and extend across the pair of louver banks.

Owner:VISTA PRO AUTOMOTIVE

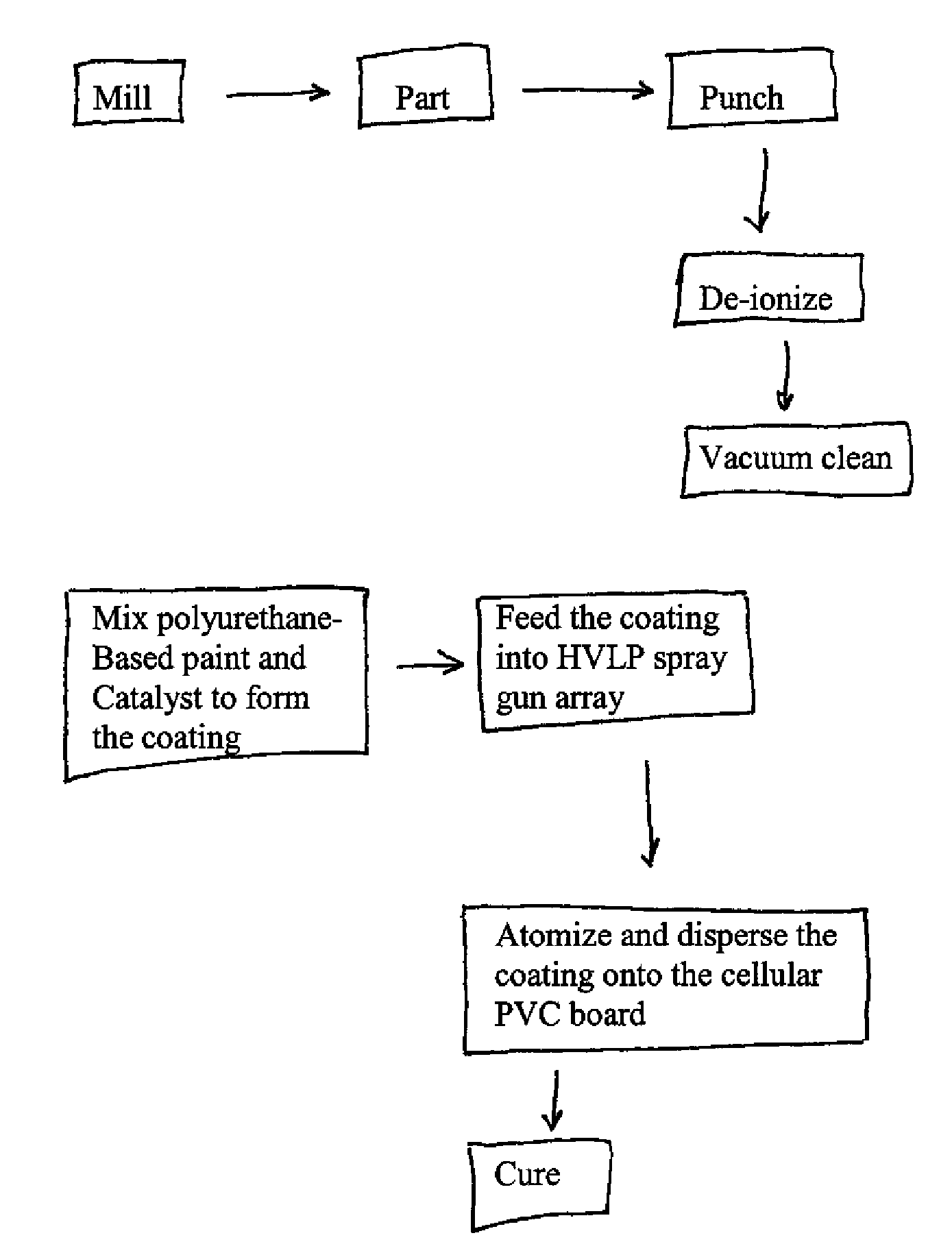

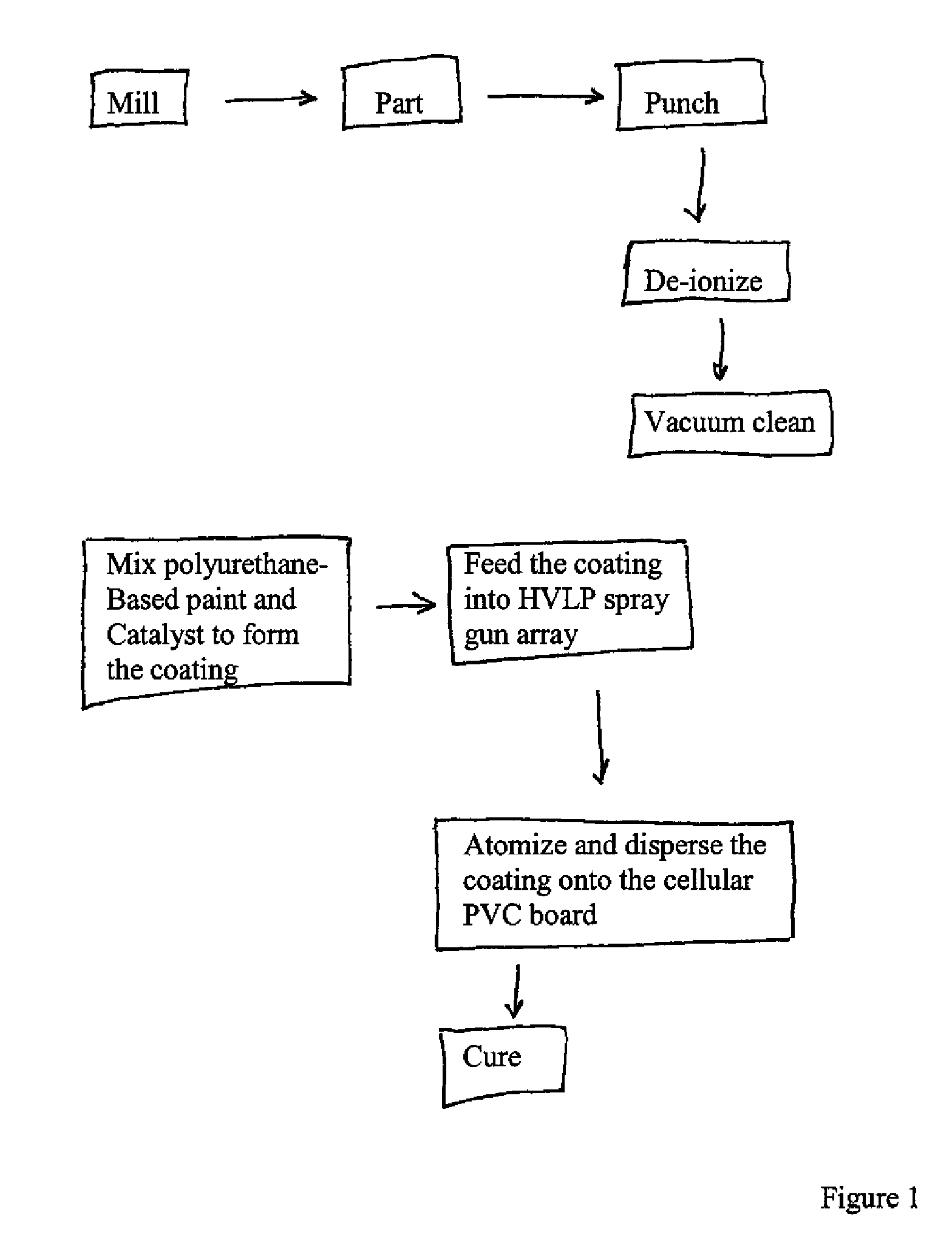

Method forming a polyurethane coated cellular polyvinylchloride board for use as siding

ActiveUS7776399B1Improve adhesionExceptional strength and flexibilityPretreated surfacesLiquid/solution decomposition chemical coatingEngineeringHoneycomb like

A method for forming a polyurethane coated cellular polyvinylchloride board, comprising: de-ionizing a cellular polyvinylchloride board; vacuuming the cellular polyvinylchloride board; coating the cellular polyvinylchloride board with a coating comprising a polyurethane-based paint and a catalyst to form a coated cellular polyvinylchloride board; and curing the coated cellular polyvinylchloride board. The method allows for the high speed application of a diverse number of colored coatings onto the cellular polyvinylchloride board.

Owner:JAIN AMERICA HLDG INC

High modulus wear resistant gray cast iron for piston ring applications

ActiveUS9091345B2Improve machinabilityExceptional hardnessPiston ringsBraking action transmissionWear resistantPiston ring

A piston ring formed of cast iron provides improved machinability and exceptional performance and minimum costs. The cast iron includes 2.2 to 2.9 wt. % carbon, 3.2 to 4.2 wt. % silicon, 0.75 to 1.25 wt. % copper, 1.0 to 1.5 wt. % manganese, 0.09 to 0.15 wt. % sulfur, not greater than 0.2 wt. % phosphorous, and an average carbon equivalent of 3.8. The cast iron preferably includes a matrix of martensite with MnS and carbides dispersed therein. The matrix is also preferably free of ferrite, austenite, and steadite. The cast iron is formed by casting, autenitizing, quenching, and tempering the alloy.

Owner:TENNECO INC

A process of manufacturing of segments for carbon thrust bearing

ActiveUS20200391275A1Reduce maintenanceImprove anti-friction performanceShaftsAbrasion apparatusTemperingThrust bearing

A process of manufacturing of segment for carbon thrust bearing uses stainless-steel (SS) round bars / sheets / logs of suitable grade as raw material. The SS round bars / sheets / logs undergo cutting operation to cut into SS billets. The billets successively undergo heating and hot forging processes to form segments of desired shapes. Thereafter, the segment is subjected to heat treatment process i.e. stress relieving, hardening and tempering process successively for obtaining consistent and uniform grain structure, mechanical properties and physical properties of segments which are cost-effective in terms of lower maintenance and lower handling efforts. After heat-treatment process, segment undergoes surface-finishing processes i.e. grinding, lapping and polishing successively for obtaining mirror like surface finishing that gives greater anti-friction property and lower co-efficient of friction. The manufacturing process according to present invention yields consistent grain structure, refine, dense and uniform microstructure of segments which imparts optimum strength, ductility, toughness and resistance to impact and fatigue.

Owner:SARADVA ATULKUMAR RAGHAVJIBHAI

Joining of dissimilar materials

ActiveUS20200061731A1Exceptional strengthHigh strengthArc welding apparatusPlasma welding apparatusMetalFastener

Owner:MAGNA INTERNATIONAL INC

Process of manufacturing of segments for carbon thrust bearing

ActiveUS11065672B2Exceptional strengthExceptional hardnessShaftsAbrasion apparatusTemperingThrust bearing

A process of manufacturing of segment for carbon thrust bearing uses stainless-steel (SS) round bars / sheets / logs of suitable grade as raw material. The SS round bars / sheets / logs undergo cutting operation to cut into SS billets. The billets successively undergo heating and hot forging processes to form segments of desired shapes. Thereafter, the segment is subjected to heat treatment process i.e. stress relieving, hardening and tempering process successively for obtaining consistent and uniform grain structure, mechanical properties and physical properties of segments which are cost-effective in terms of lower maintenance and lower handling efforts. After heat-treatment process, segment undergoes surface-finishing processes i.e. grinding, lapping and polishing successively for obtaining mirror like surface finishing that gives greater anti-friction property and lower co-efficient of friction. The manufacturing process according to present invention yields consistent grain structure, refine, dense and uniform microstructure of segments which imparts optimum strength, ductility, toughness and resistance to impact and fatigue.

Owner:SARADVA ATULKUMAR RAGHAVJIBHAI

Battery separator comprising a polyolefin nanofilament porous sheet

ActiveUS9074308B2High porosityLower internal resistanceSecondary cellsNanotechnologyProduction rateElectricity

Owner:UNIVERSITY OF YAMANASHI

Apparatus for making a spunbond web from filaments

ActiveUS10988861B2Effective and functionally safeAvoid disadvantagesNew-spun product collectionMonocomponent polypropylene artificial filamentThermodynamicsCooling chamber

An apparatus for continuously making a spunbond web of filaments comprises a spinneret, a cooling chamber into which process air for can be introduced for the purpose of cooling the filaments, a monomer suction device between a spinneret and cooling chamber, a stretcher and a deposition device for depositing the filaments of the spunbond web. The cooling chamber is divided into two cooling compartments, and process air can be suctioned out from a first upper cooling compartment at a volumetric flow rate (VM) to a monomer suction device. Process air exits from the first upper cooling compartment at a volumetric flow rate (V1) into a second lower cooling compartment and from the first upper cooling compartment at a volumetric flow rate (V1) into a second lower cooling compartment. A ratio (VM / V1) is 0.1 to 0.35.

Owner:REFENHAEUSER GMBH & CO KG MASCHFAB

Functional lignin, and its use in producing blends, copolymers, and self-healing elastomers

A composition comprising lignin compounds possessing 8-30 (or 5-15 or 8-12) phenyl rings interconnected by ether and alkylene linkages and containing hydroxy and / or methoxy groups attached to said phenyl rings, wherein said composition possesses a glass transition temperature of 80-100° C. (or 95-98° C.) and a degree of substitution (DS) of carboxylic acid groups per phenyl ring of at least 0.5 and a DS of methoxy groups per phenyl ring of no more than 1.2, 1.1, or 1.0, wherein at least 90 wt % of said lignin compounds has a molecular weight within a range of 500-5000 g / mol, 1500-3000 g / mol, or 2000-2500 g / mol and / or wherein the molecular weight distribution of the lignin compounds is characterized by a polydispersity index of 1.0-1.5, 1.0-1.4, or 1.0-1.3, and wherein other lignin compounds not possessing the above characteristics are not present. Methods for producing the lignin extract and lignin copolymers and blends produced therefrom are also described.

Owner:UT BATTELLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com