Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

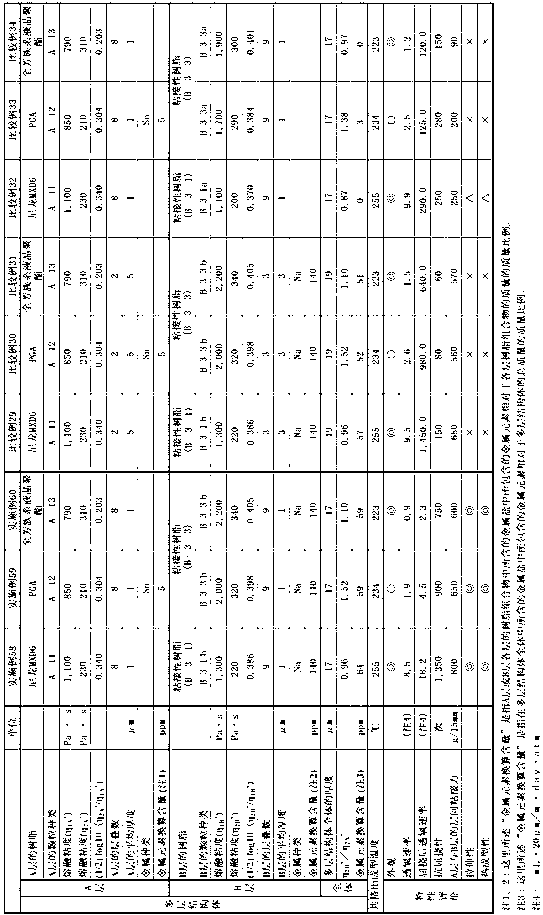

31results about How to "Excellent interlayer adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multilayer structure and method for producing same

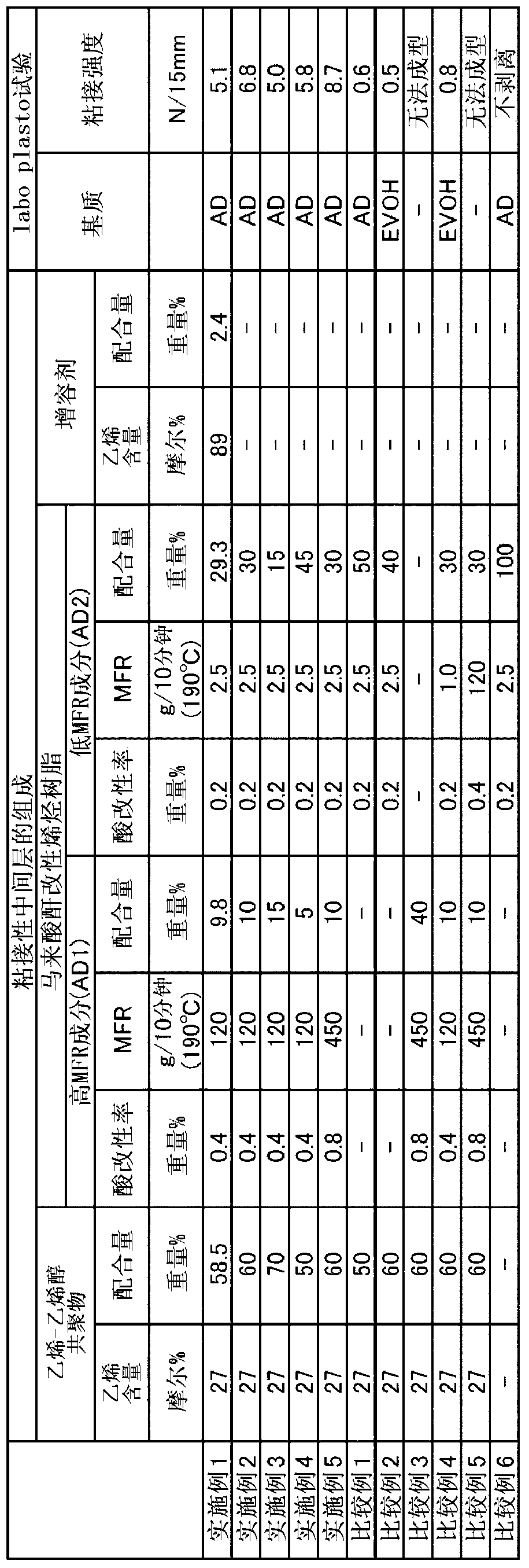

ActiveCN102712182AExcellent interlayer adhesionSuppression of manufacturing cost increaseSynthetic resin layered productsThin material handlingPolymer sciencePolymer chemistry

The disclosed multilayer structure provided with at least eight resin layers is characterized by: having, as resin layers, A layers comprising a resin composition containing a gas-barrier resin, and B layers comprising a resin composition containing a thermoplastic resin; containing a metal salt within at least one of the resin compositions of the adjacent A layers and B layers; the quantity of contained metal salt being at least 1 ppm and no more than 10,000 ppm in terms of the metallic element; and the interlayer adhesive force between the A layers and the B layers being at least 450 g / 15 mm. It is preferable that the A layers and B layers are layered in alternation. Furthermore, it is preferable for the average thickness of one layer of the A layers and / or the B layers to be at least 0.01 [mu]m and no more than 10 [mu]m.

Owner:KURARAY CO LTD

Passivation solution for soft roll lithium battery and packaging material of soft roll lithium battery

InactiveCN108179407AHigh bonding strengthAvoid destructionMetallic material coating processesCell component detailsOrganic acidAluminum foil

The invention relates to a passivation solution for a soft roll lithium battery and a packaging material of the soft roll lithium battery. The passivation solution comprises, by weight part, 0.3 to 1part of a metallic compound, 0.5 to 2 parts of organic acid, 0.5 to 2 parts of film forming polymer, 0.1 to 1 part of bonding resin and 100 to 200 parts of water. The invention further relates to a packaging material for the soft roll lithium battery. The packaging material is composed of a heat resisting layer, a first adhesive layer, an aluminum foil surface passivation treatment layer, an aluminum foil layer, an aluminum foil surface passivation treatment layer, a second adhesive layer and a heat seal layer. The aluminum foil surface passivation treatment layer is formed by coating of the passivation solution on the surface of the aluminum foil. The problem that in the long-term electrolyte resistance operation, bonding performance between the aluminum foil layer and the heat seal layeris seriously reduced or layered is solved, and the service life of the soft roll lithium battery is prolonged.

Owner:乐凯胶片股份有限公司

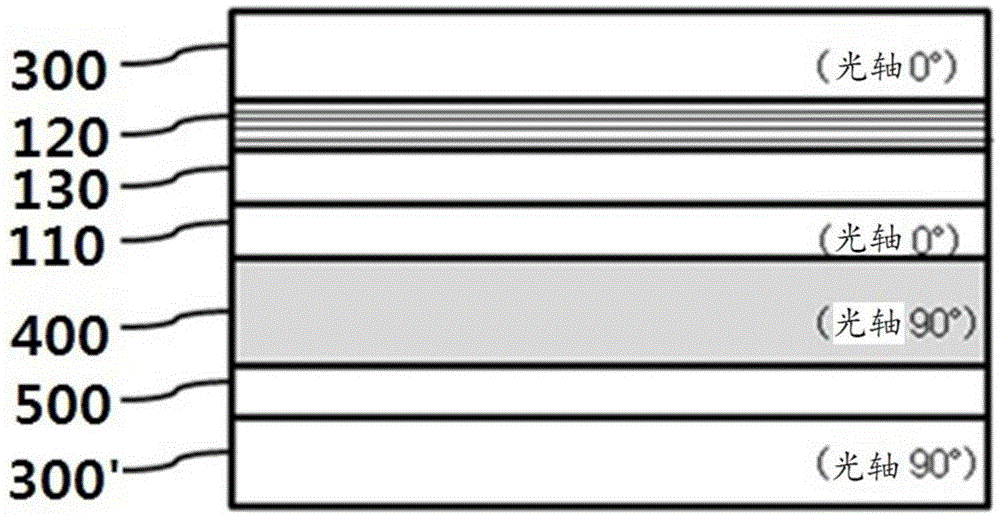

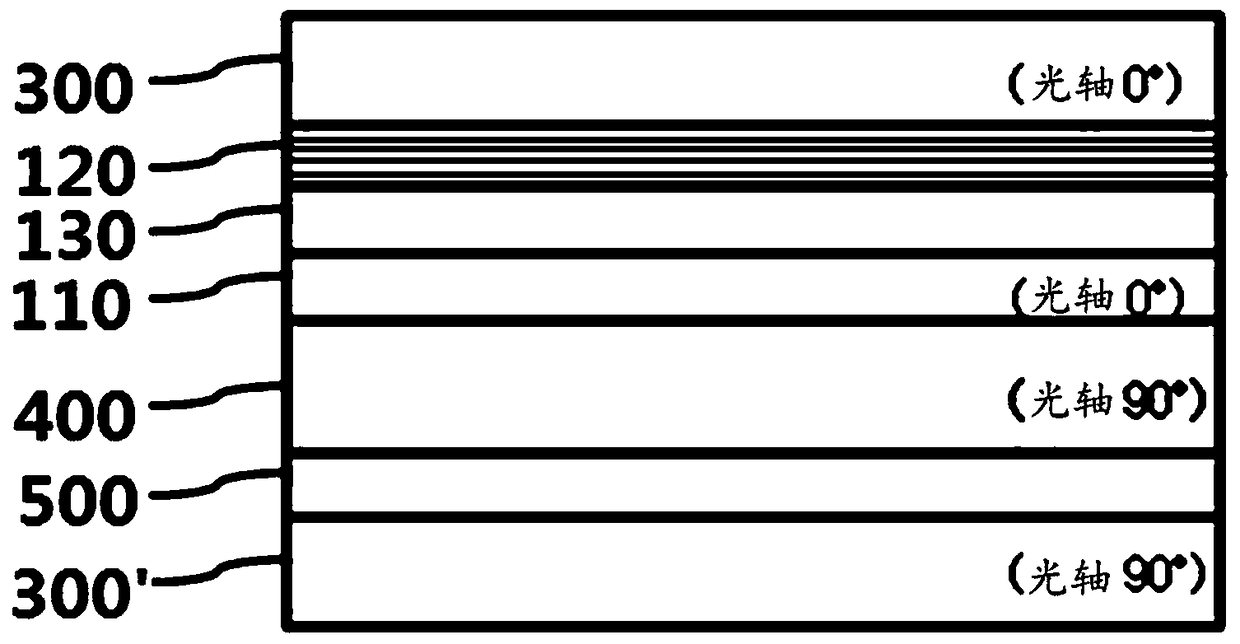

Retardation film and image display device having same

ActiveCN105431752AOrientation inductionExcellent interlayer adhesionPolarising elementsNon-linear opticsDisplay deviceCompound (substance)

The present invention relates to a retardation film and an image display device having the same and, more specifically, to a retardation film comprising a liquid crystal layer and a primer layer which are bonded by chemical bonding, wherein the chemical bonding is formed by a hydroxyl group and / or a carboxyl group on the surface of the primer layer and an isocyanate group and a (meth) acrylate group at the end of an adhesion-reinforcing agent included in the liquid crystal layer, such that the retardation film has a very high adhesive strength between the respective layers thereof.

Owner:DONGWOO FINE CHEM CO LTD

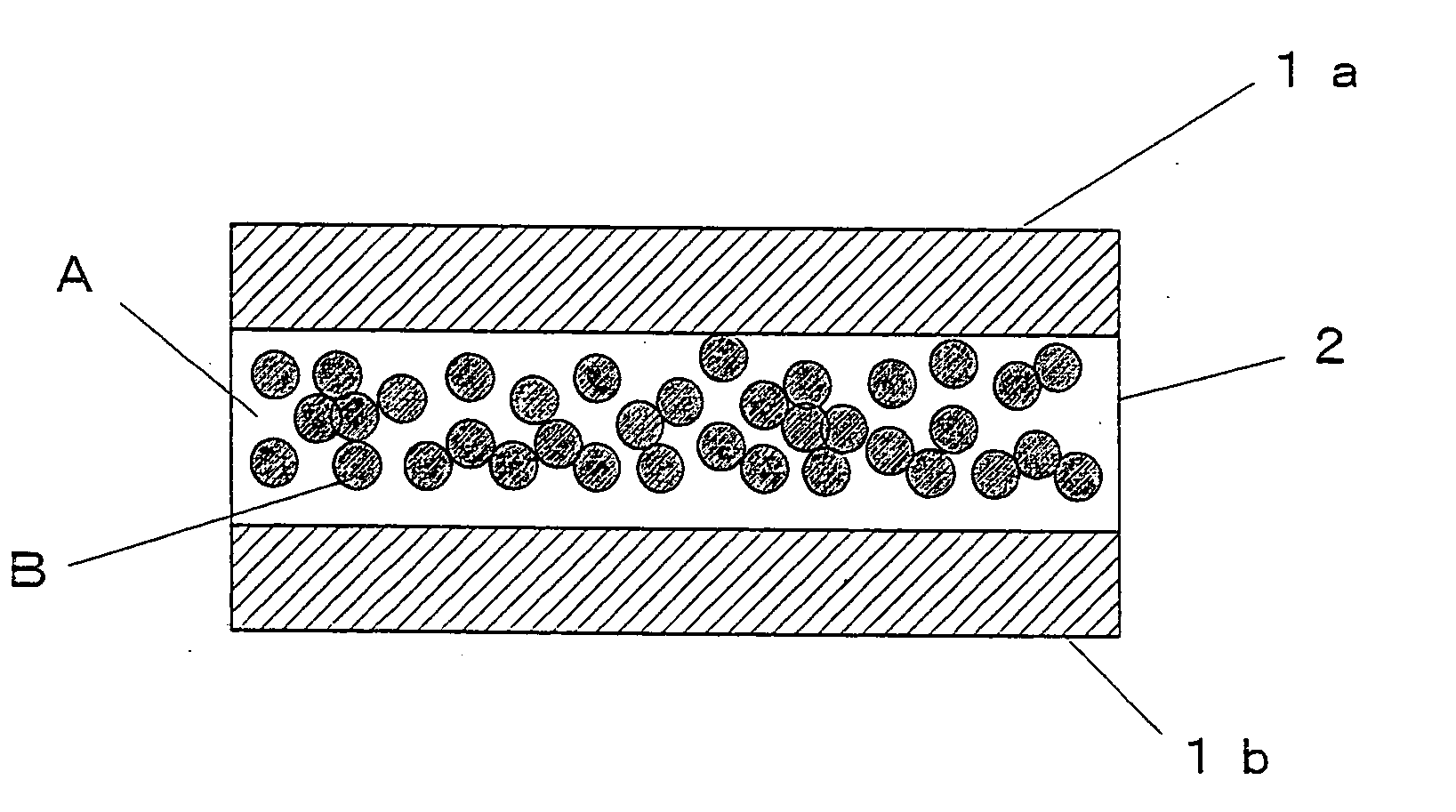

Multi-layer structure for packaging

ActiveUS20060286366A1Excellent interlayer adhesionExhibited propertySynthetic resin layered productsDomestic containersChemistryGas barrier

A multi-layer structure for packaging formed by at least an inner layer, an outer layer and an intermediate layer, the intermediate layer having an islands-in-a-sea structure comprising a resin A constituting sea portions and a functional resin B constituting island portions, the sea portions occupying not more than 80% of the area of the intermediate layer in cross section, and the inner layer and the outer layer being resins having adhesiveness to said resin A. The adhesion among the layers is improved without providing any particular adhesive layers among the intermediate layer having a function such as gas barrier property and the inner and outer layers, and, besides, transparency is improved.

Owner:TOYO SEIKAN KAISHA LTD

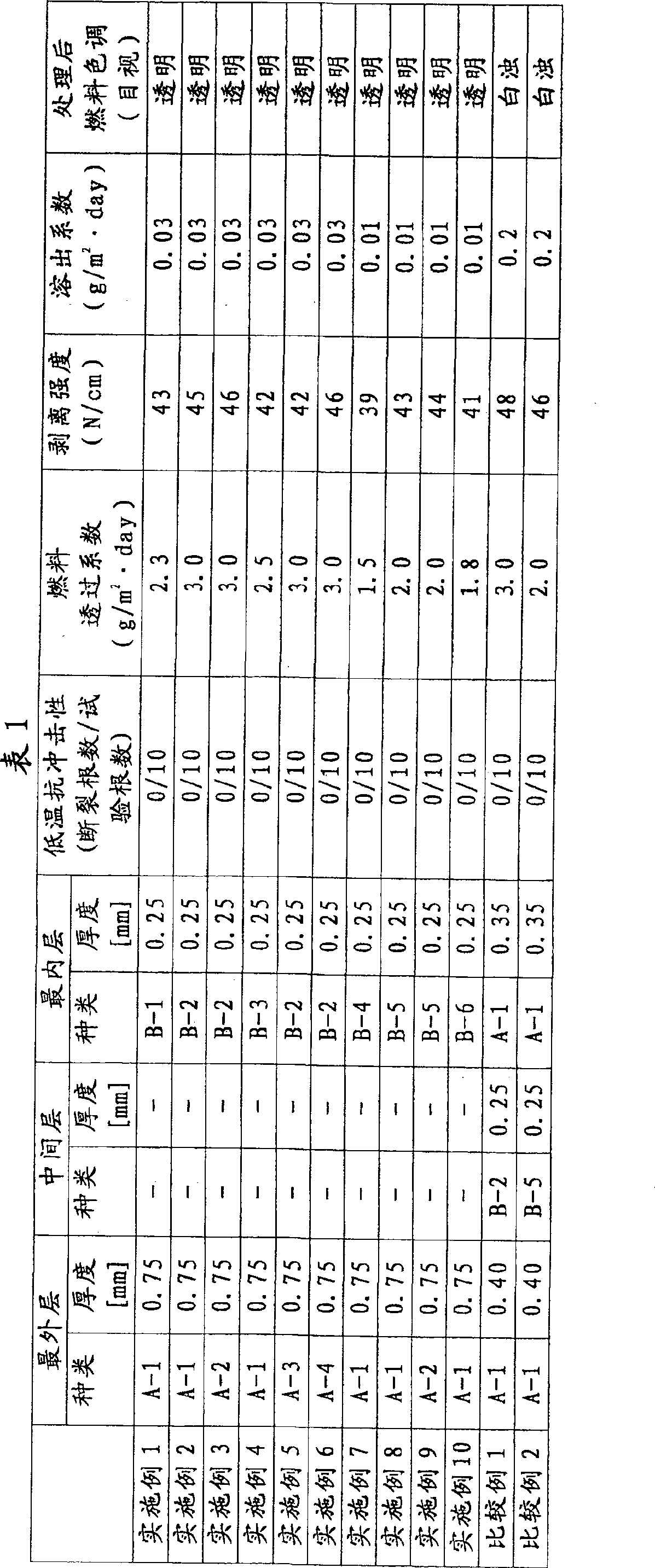

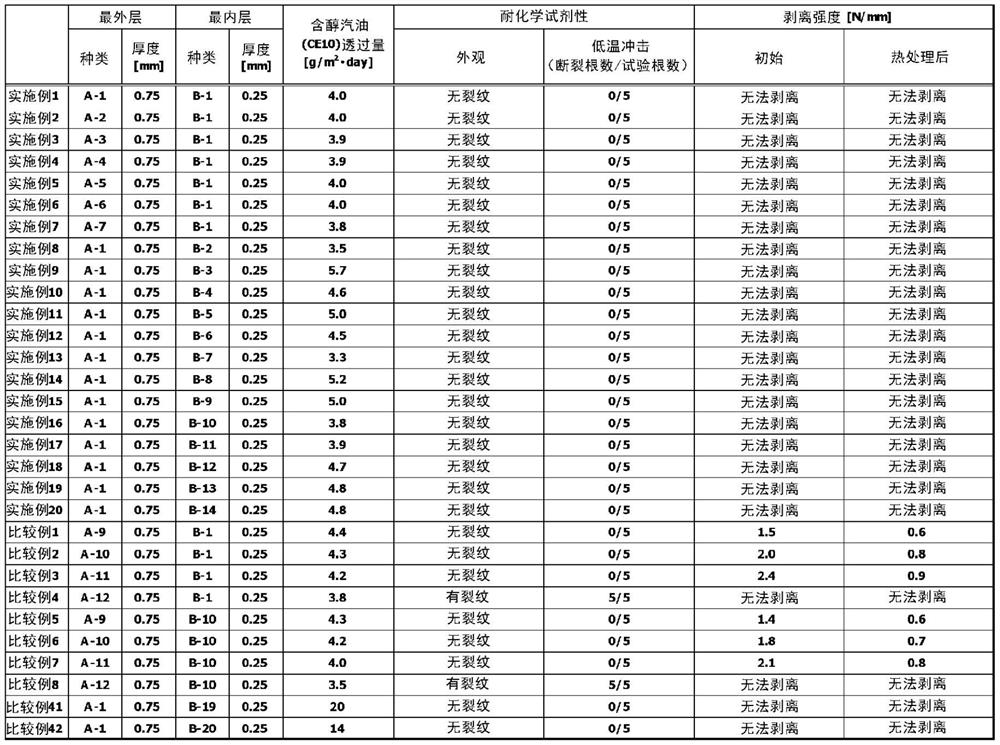

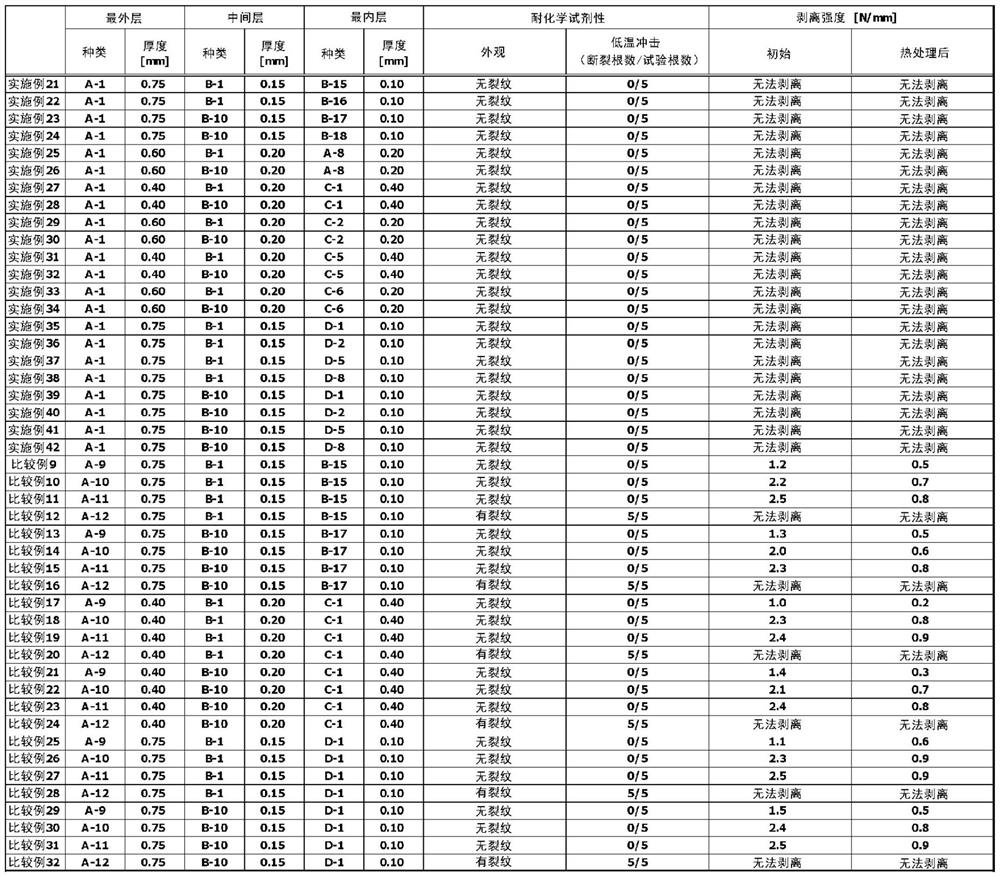

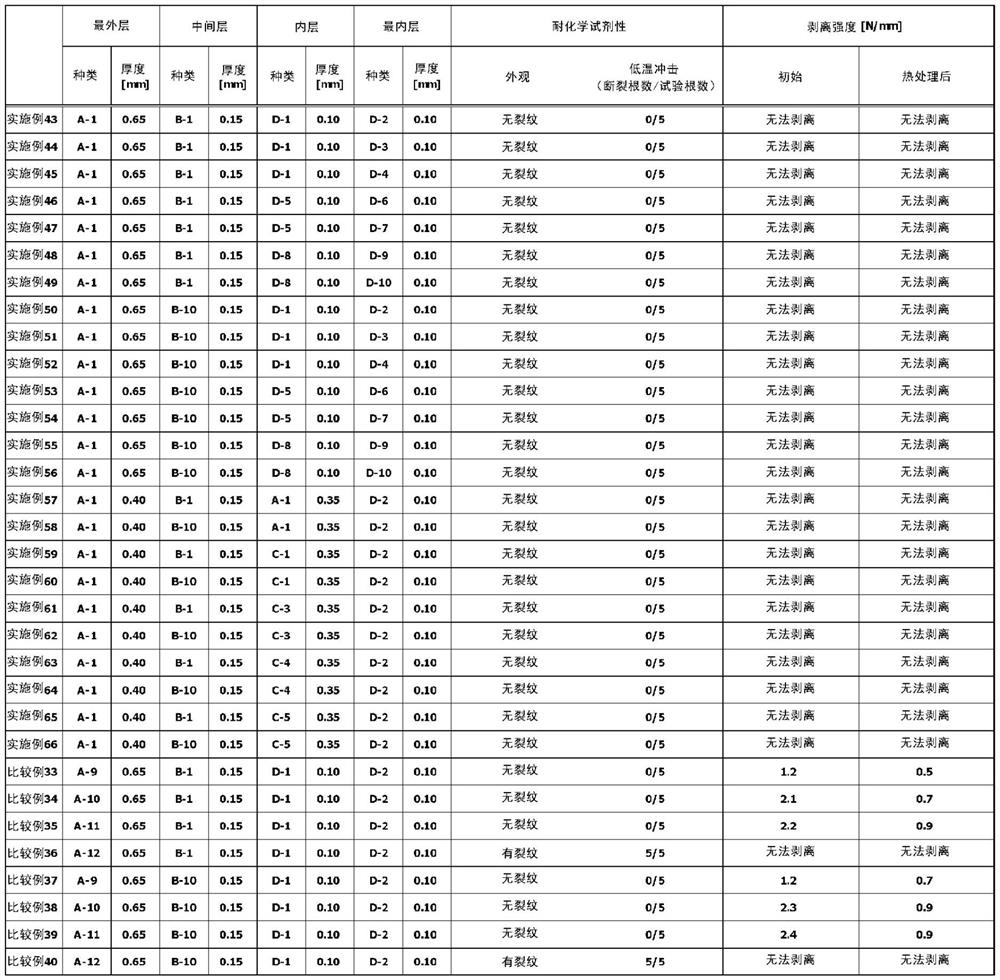

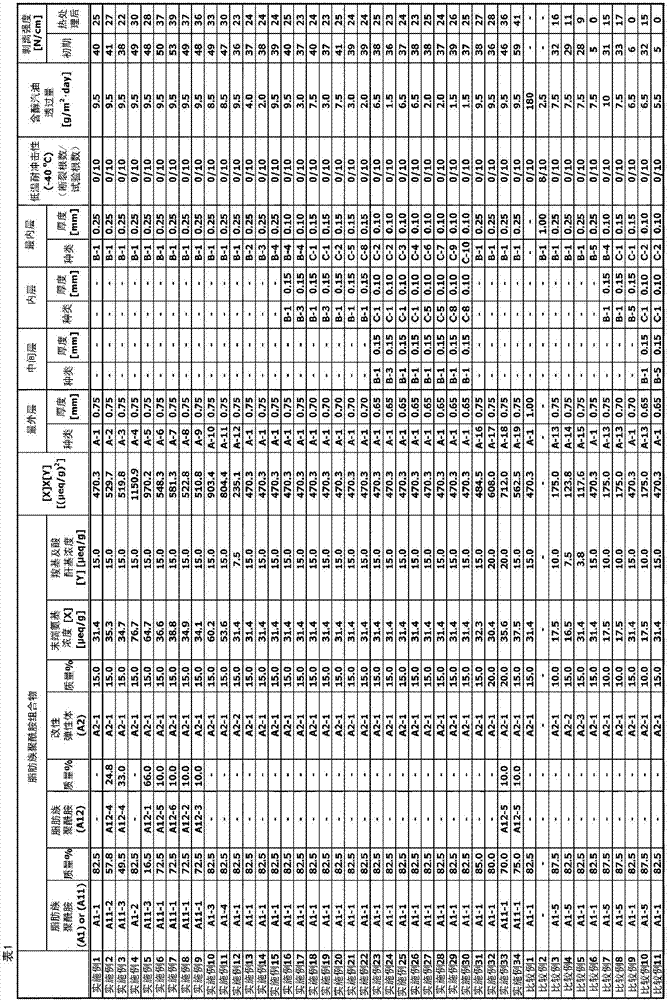

Laminated tube

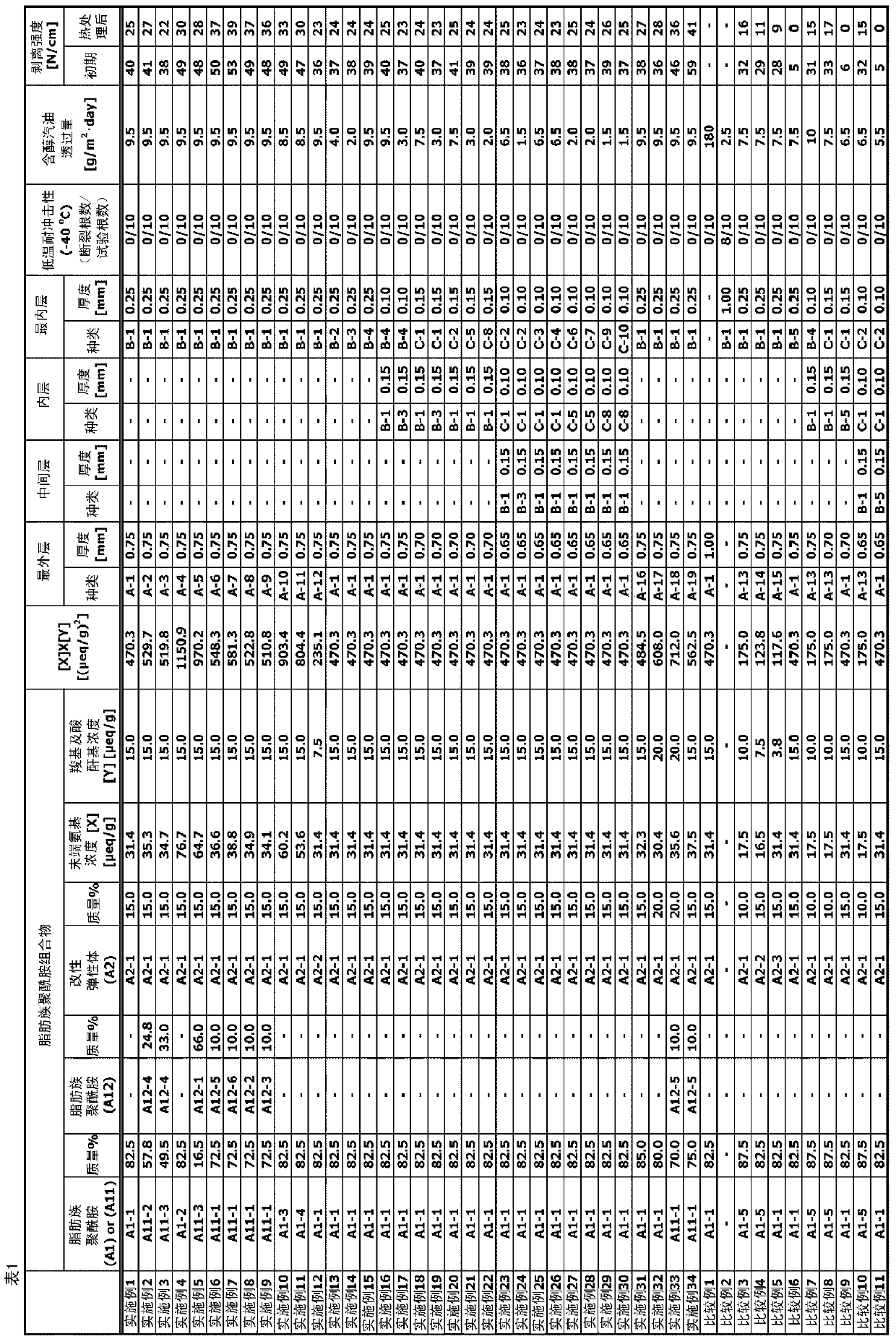

ActiveCN105517789AGood durabilityImproved durabilitySynthetic resin layered productsVehicle componentsPolyamideCarboxyl radical

A laminated tube comprising at least two layers and having an (a) layer including an aliphatic polyamide composition (A), and a (b) layer including a semi-aromatic polyamide composition (B) including a specific semi-aromatic polyamide (B1), wherein the aliphatic polyamide composition (A) includes a specific amount of an aliphatic polyamide (A1) and a specific amount of an elastomer polymer (A2) containing an unsaturated compound having a carboxyl group and / or an acid anhydride group, and the product, per 1g of the aliphatic polyamide composition (A), of the concentration [X] of the terminal amino group of the aliphatic polyamide (A1) and the total concentration [Y] of the carboxyl group and acid anhydride group of the elastomer polymer (A2) is a specific amount.

Owner:UBE IND LTD

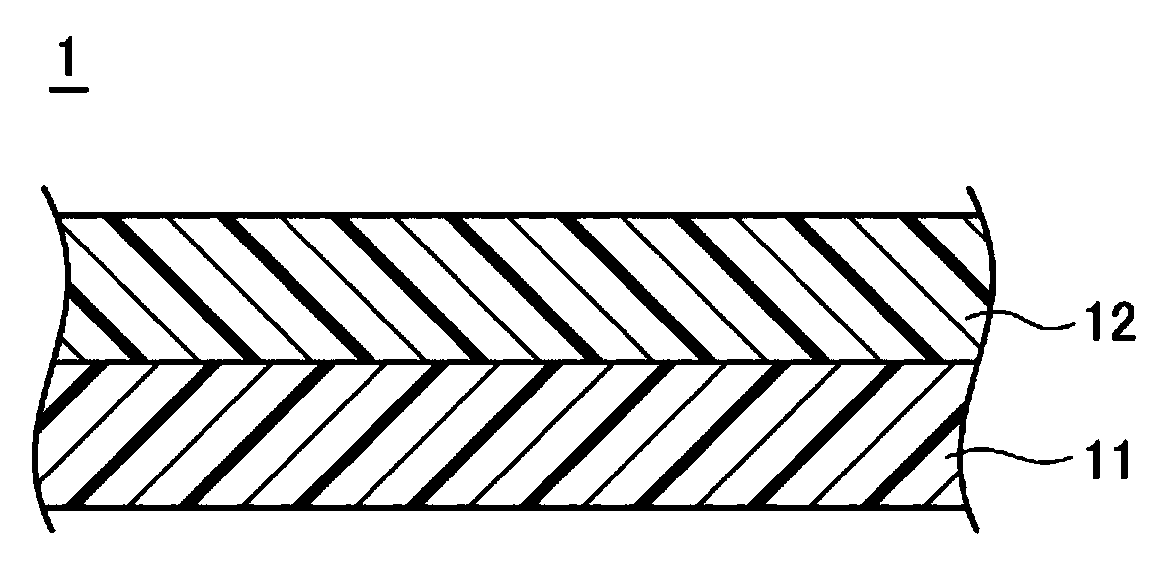

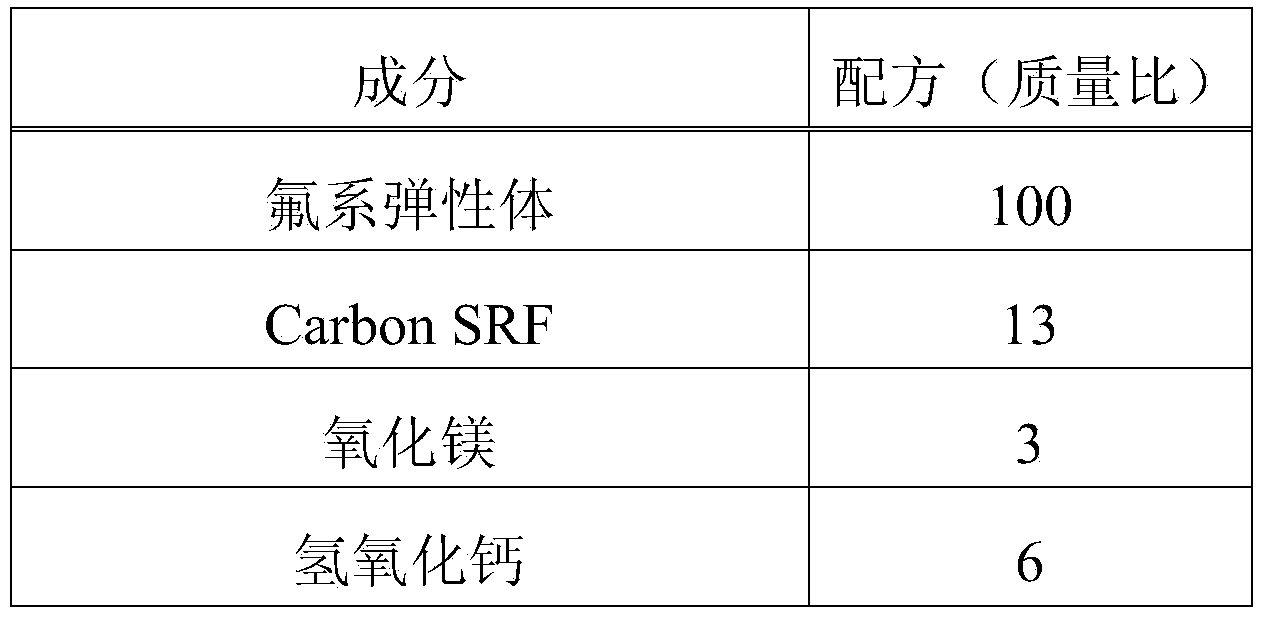

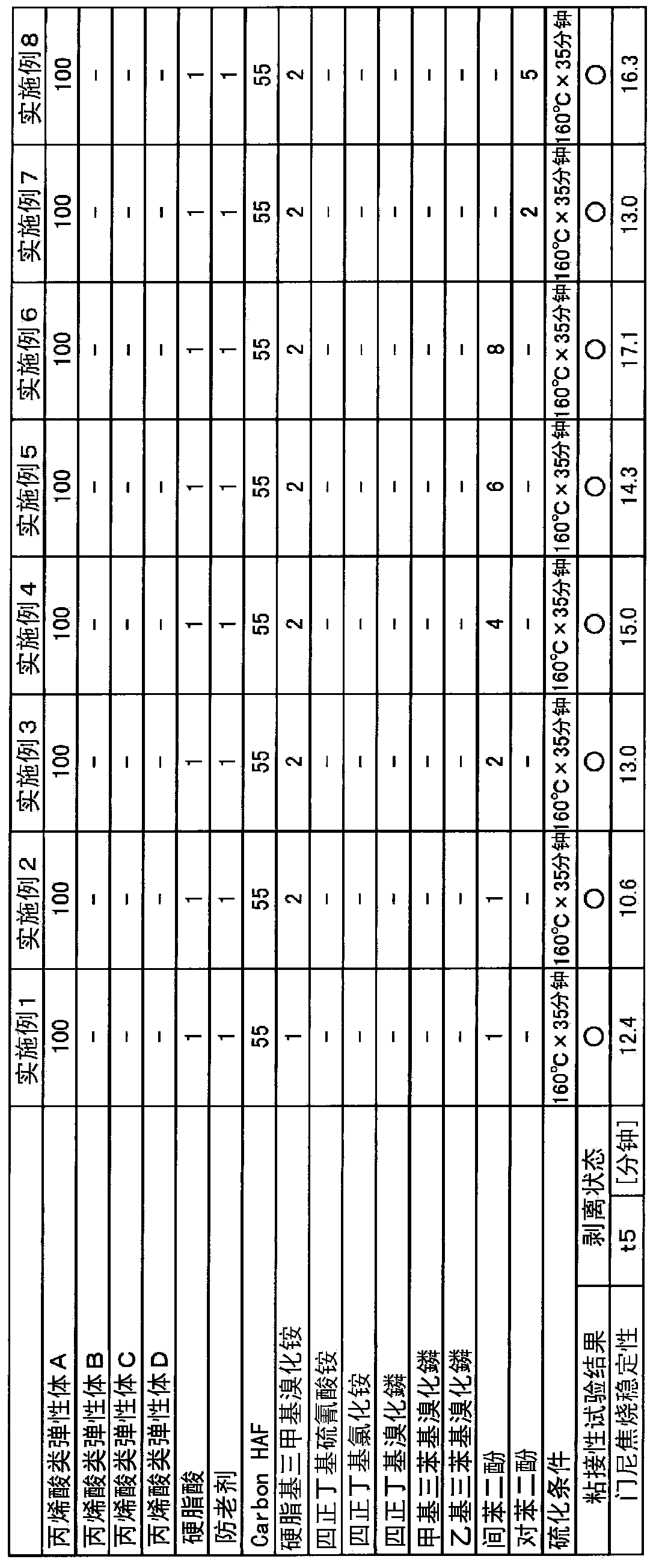

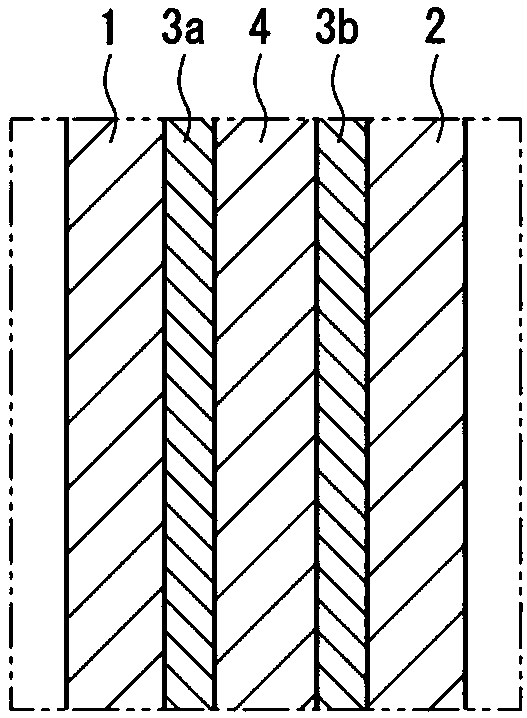

Laminate body, cross-linked product, and molded member

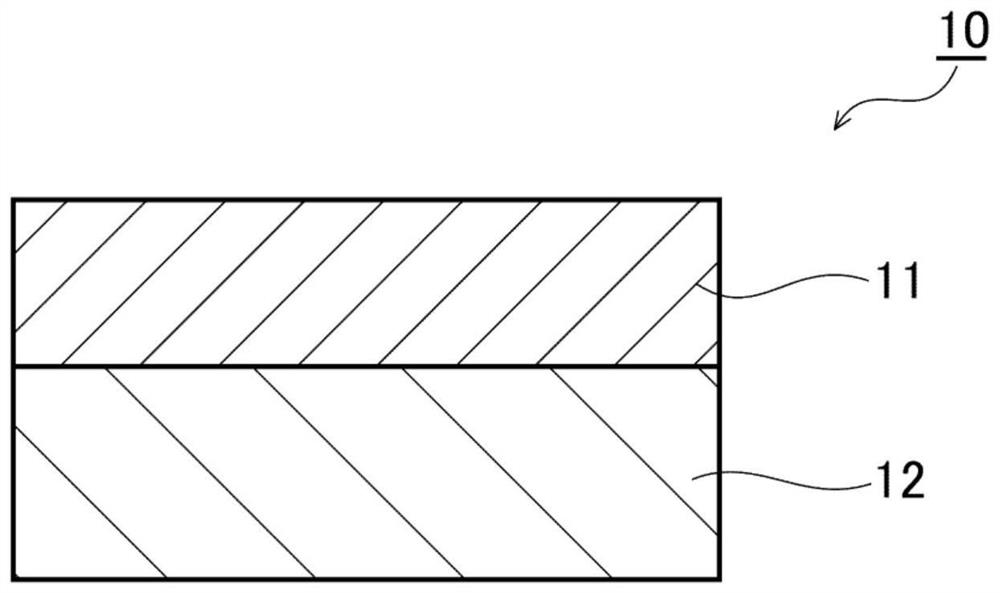

Provided are a laminate body having excellent interlayer adhesion, a cross-linked product, and a molded member. An acrylic-based elastomer layer (11) is formed by an acrylic-based elastomer composition containing 1-5 parts by mass of an onium salt and 1-8 parts by mass of a polyol compound with respect to 100 parts by mass of the acrylic-based elastomer, and a fluorine-based elastomer layer (12) is formed by a fluorine-based elastomer composition containing a polyol cross-linking agent. The acrylic-based elastomer layer (11) and the fluorine-based elastomer layer (12) are laminated to obtain a laminate body (1). The laminate body (1) is cross-linked to obtain a cross-linked product and a molded member.

Owner:DENKA CO LTD

Splicing manufacturing process of dual-density composite fiber felt

InactiveCN103643405AIncrease productivityExcellent interlayer adhesionNon-woven fabricsProduction lineFiber

The invention relates to a splicing manufacturing process of dual-density composite fiber felt. The splicing manufacturing process comprises the steps as follows: (1) production of an upper-layer material, (2) placement of the upper-layer material, (3) production of a lower-layer material and double-layer splicing composition and (4) cooling and cutting. The dual-density composite fiber felt produced with the process is directly heated and spliced through a production line, so that the production efficiency is high; the interlayer adhesion is good, and the dual-density composite fiber felt is particularly suitable for follow-up heating molding; glue is not needed, so that the cost is saved, and the felt is odorless; and the material and leftover materials can be recycled, so that the process is environment-friendly.

Owner:镇江立达纤维工业有限责任公司

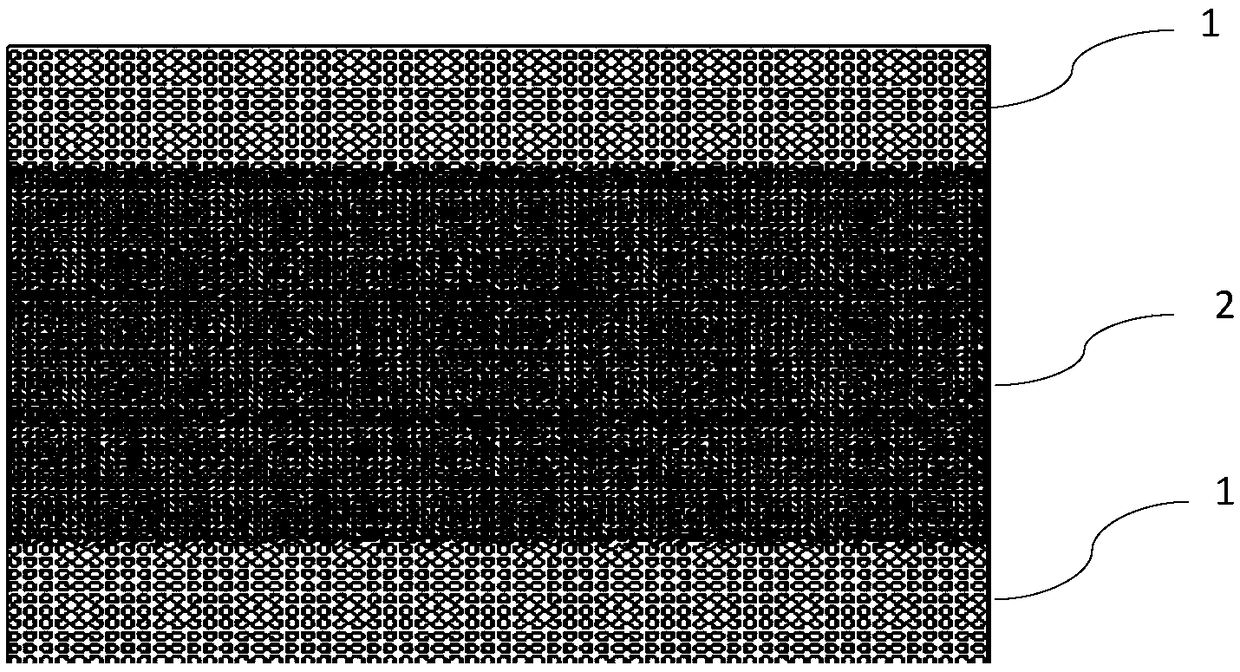

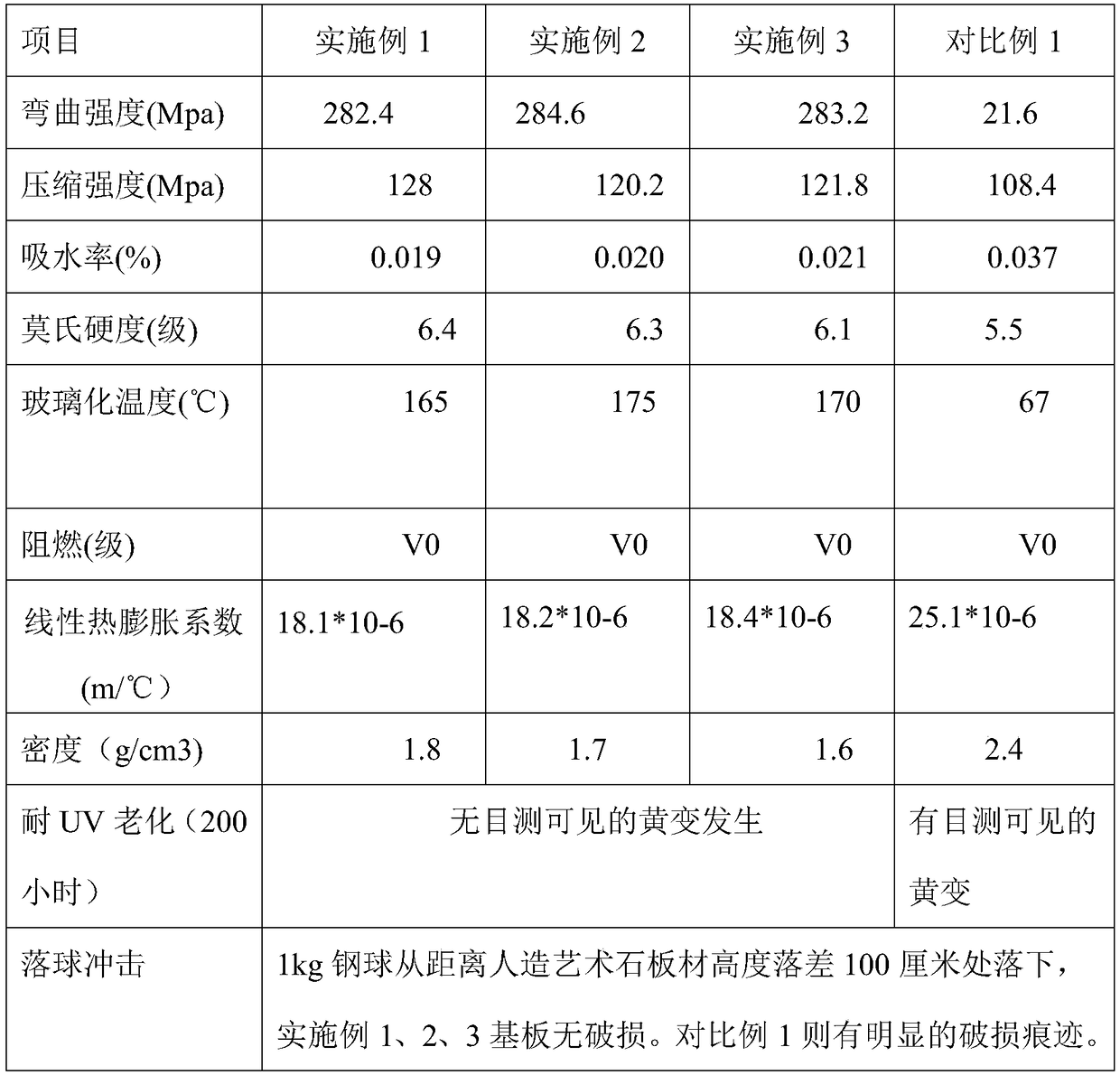

Ultra-thin high-strength compound man-made art slabstone and preparation method thereof

The invention relates to an ultra-thin high-strength compound man-made art slabstone and a preparation method thereof. The man-made art slabstone comprises a surface layer and a base material layer; the surface layer contains the following components: surface-layer quartz sand grains, surface-layer quartz sand powder, talcum powder, a curing agent, an accelerant, multifunctional epoxy resin, isocyanate modified epoxy resin, phosphorus-containing epoxy resin, phenoxy resin, a coupling agent, pigment and aramid fiber gridding cloth; the base material layer contains the following components: aluminum hydroxide, base material layer quartz sand powder, a curing agent, an accelerator, multifunctional epoxy resin, isocyanate modified epoxy resin, phenoxy resin, a coupling agent and carbon fiber plain cloth. The ultra-thin high-strength compound man-made art slabstone is ultra-thin and light in mass, and high in strength, has the performances of torsion resistance, compression resistance, bending resistance, deformation resistance and the like, can be directly laid without a bottom pad for supporting in use, and is simple and convenient in operation.

Owner:深圳市绿志新型建材研究院有限公司

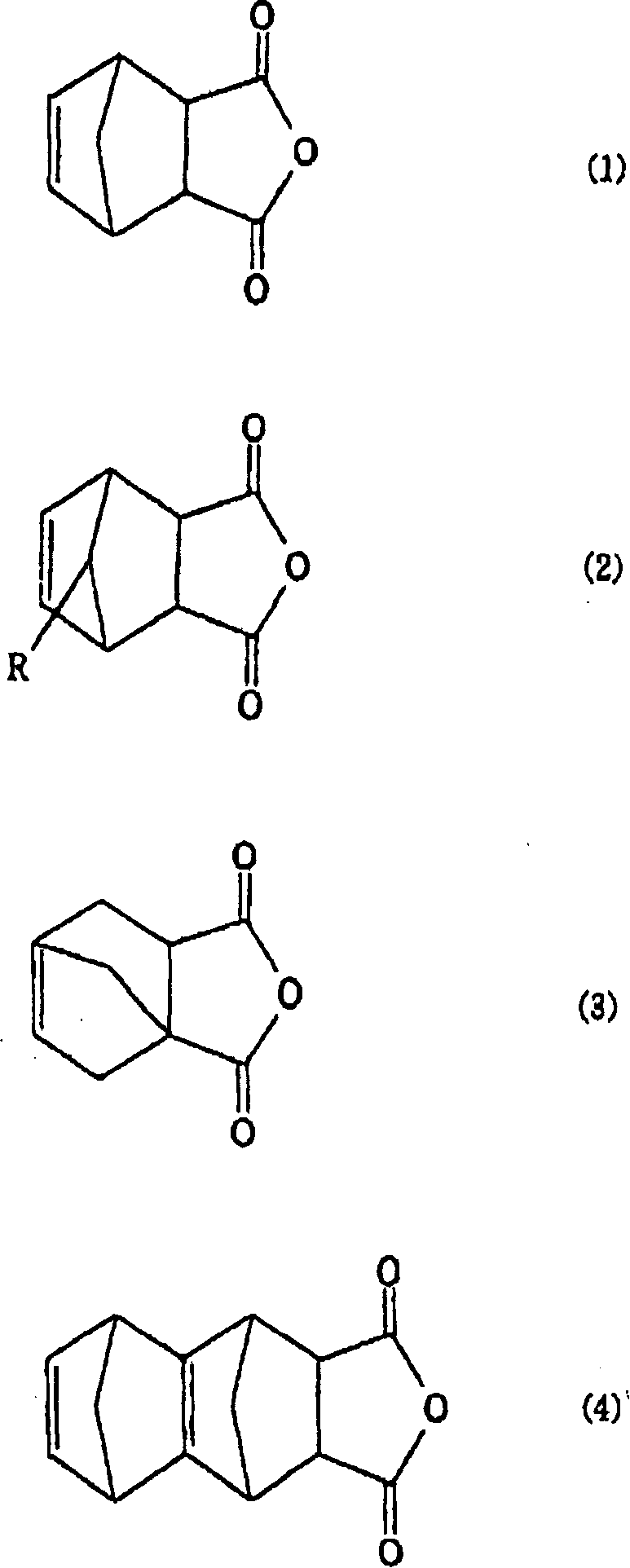

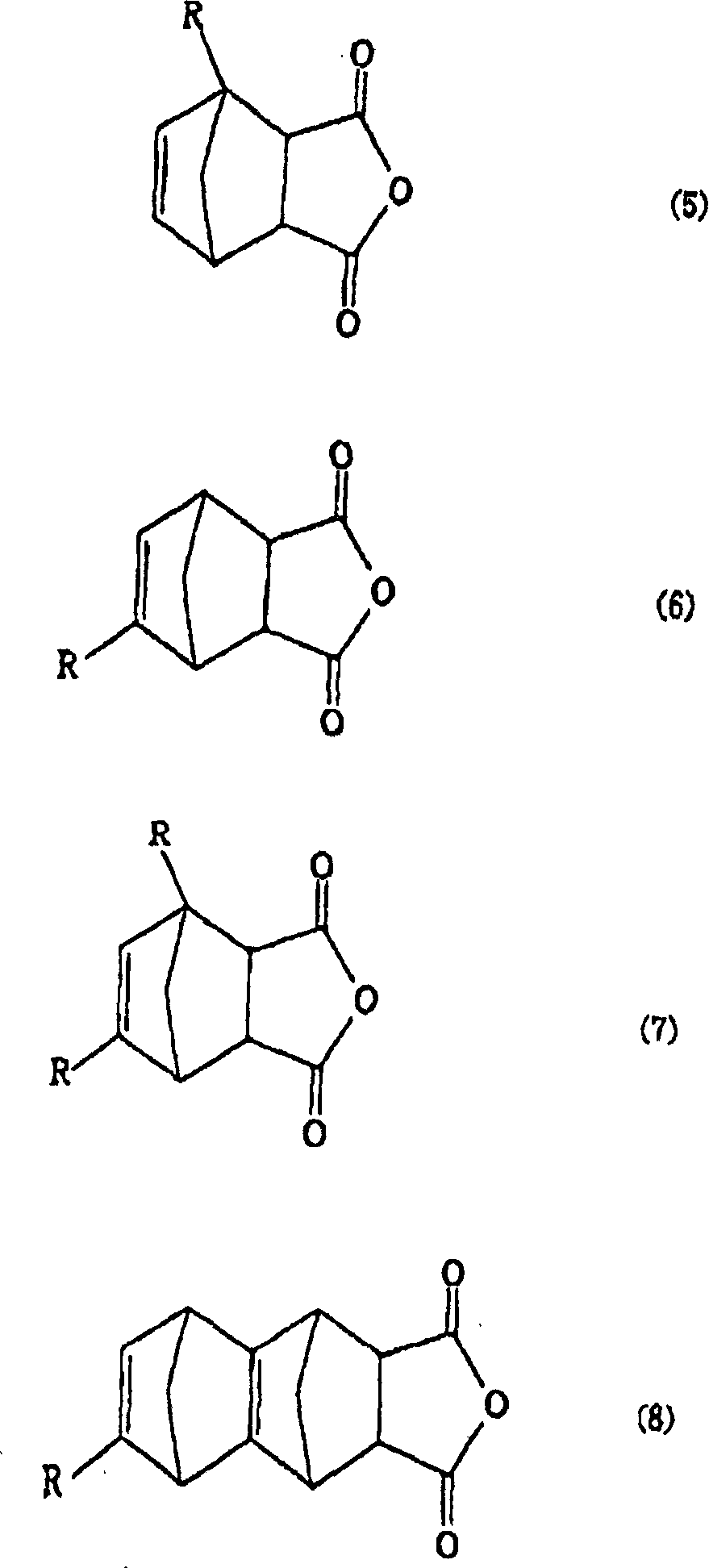

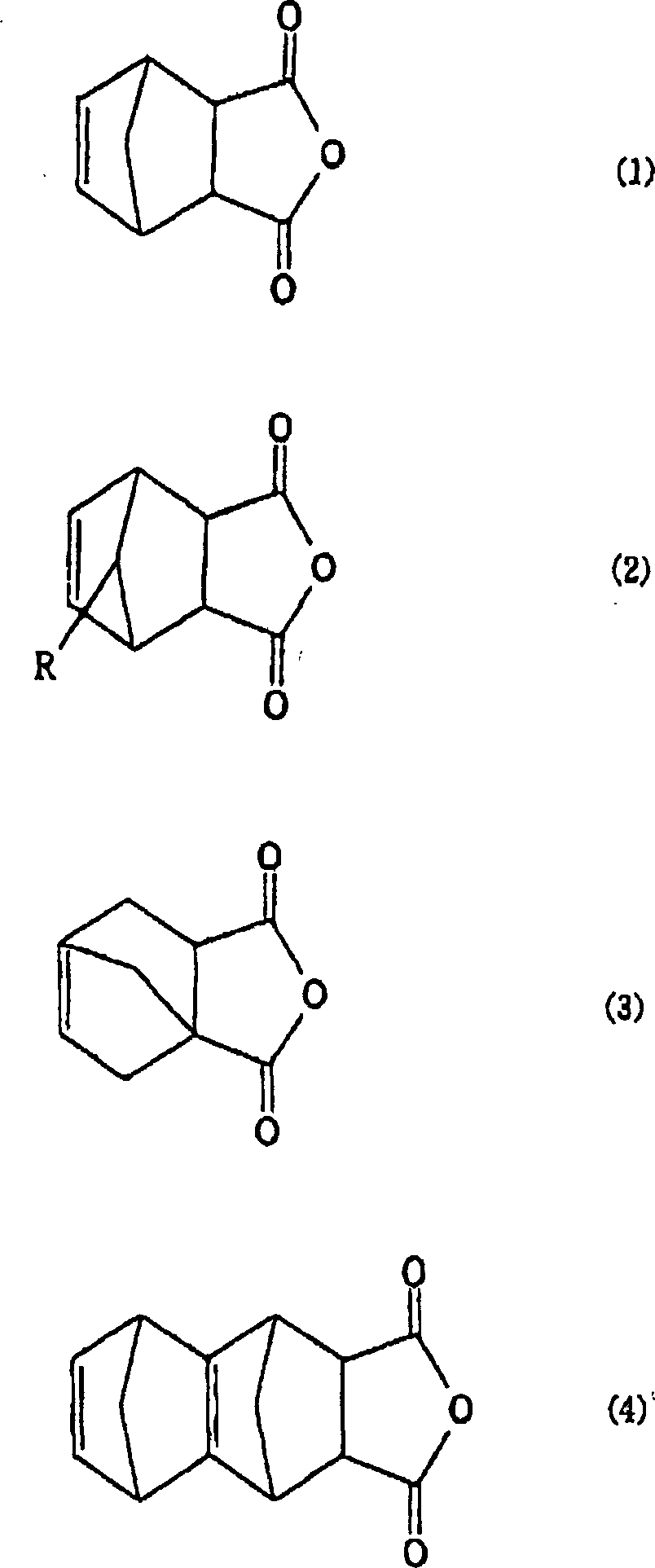

Laminate hose made of fluorocopolymer

ActiveCN1854181AGood heat resistanceExcellent interlayer adhesionSynthetic resin layered productsLaminationPolyamideChemistry

A laminate hose comprising a laminate of a fluorocopolymer and a polyamide, wherein the fluorocopolymer comprises repeating units (a) based on tetrafluoroethylene and / or chlorotrifluoroethylene, repeating units (b) based on a cyclic hydrocarbon monomer having a dicarboxylic anhydride group and having a polymerizable unsaturated group in the ring, and repeating units (c) based on another fluoromonomer (excluding tetrfluoroethylene and chlorofluoroethylene) with contents of the repeating units (a) of from 50 to 99.89 mol%, the repeating units (b) of from 0.01 to 5 mol% and the repeating units (c) of from 0.1 to 49.99 mol% based on the total number of mols of the repeating units (a), (b) and (c), and has a flow coefficient of from 0.1 to 1,000 mm 3 / sec.

Owner:ASAHI GLASS CO LTD

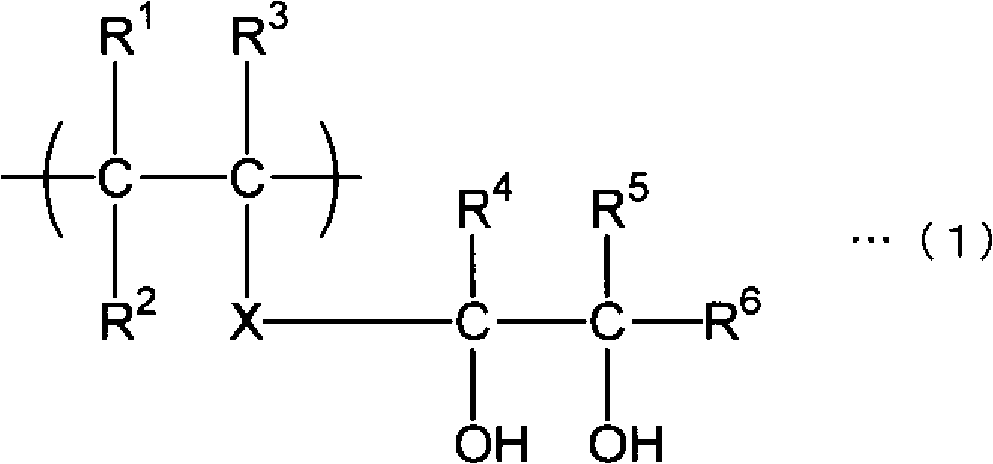

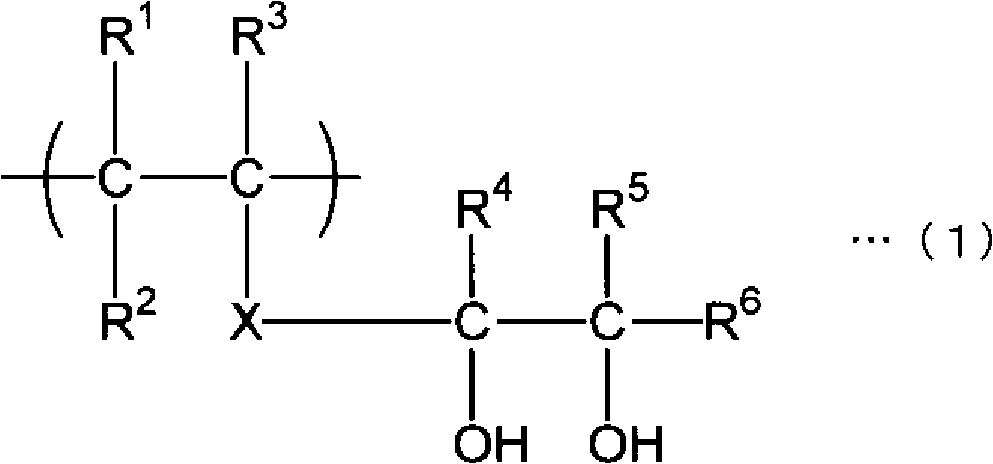

Multi-layer structure

ActiveCN102596570AEnhanced resistance to peelingExcellent interlayer adhesionSynthetic resin layered productsDomestic containersPolyethylene terephthalate glycolPolyvinyl alcohol

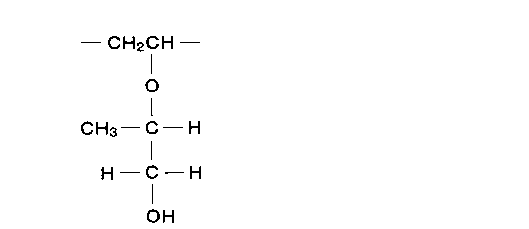

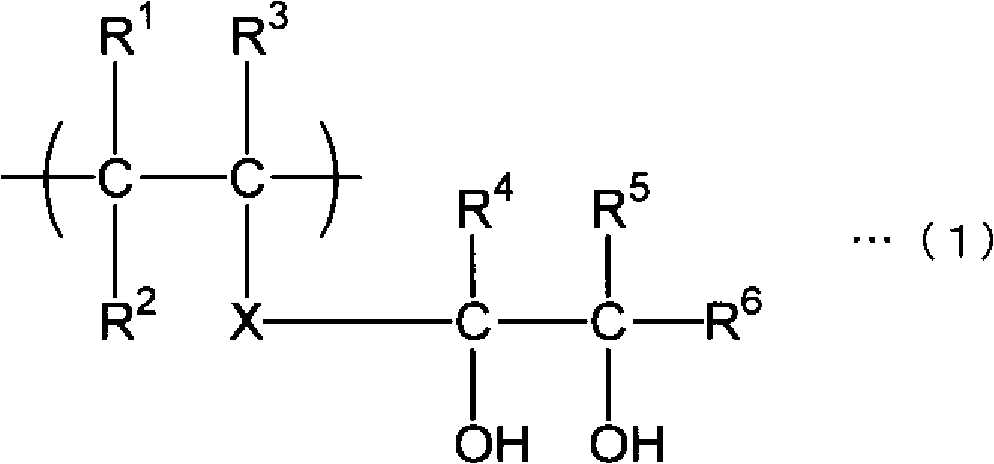

Provided is a multi-layer structure comprising the following layers: a layer (A) consisting primarily of a polyethylene terephthalate resin, which comprises a dicarboxylic acid component that contains terephthalic acid and a diol component that consists primarily of ethylene glycol, wherein the copolymer fraction of non-terephthalic-acid dicarboxylic acids in the dicarboxylic acid component is 15-40 mol% of the entire dicarboxylic acid component; and a layer (B) that is adjacent to the abovementioned layer (A) and consists primarily of a polyvinyl alcohol resin having the structural unit represented by general formula (1). This results in increased interlayer adhesion between the layers (A and B), yielding a multi-layer structure that is highly resistant to separation of the layers thereof. (1) (In formula (1), R1, R2, and R3 each independently represent a hydrogen atom or an organic group, and X represents a single bond or a bond chain. R4, R5, and R6 each independently represent a hydrogen atom or an organic group.)

Owner:MITSUBISHI CHEM CORP

High-performance odorless balcony paint and preparation method thereof

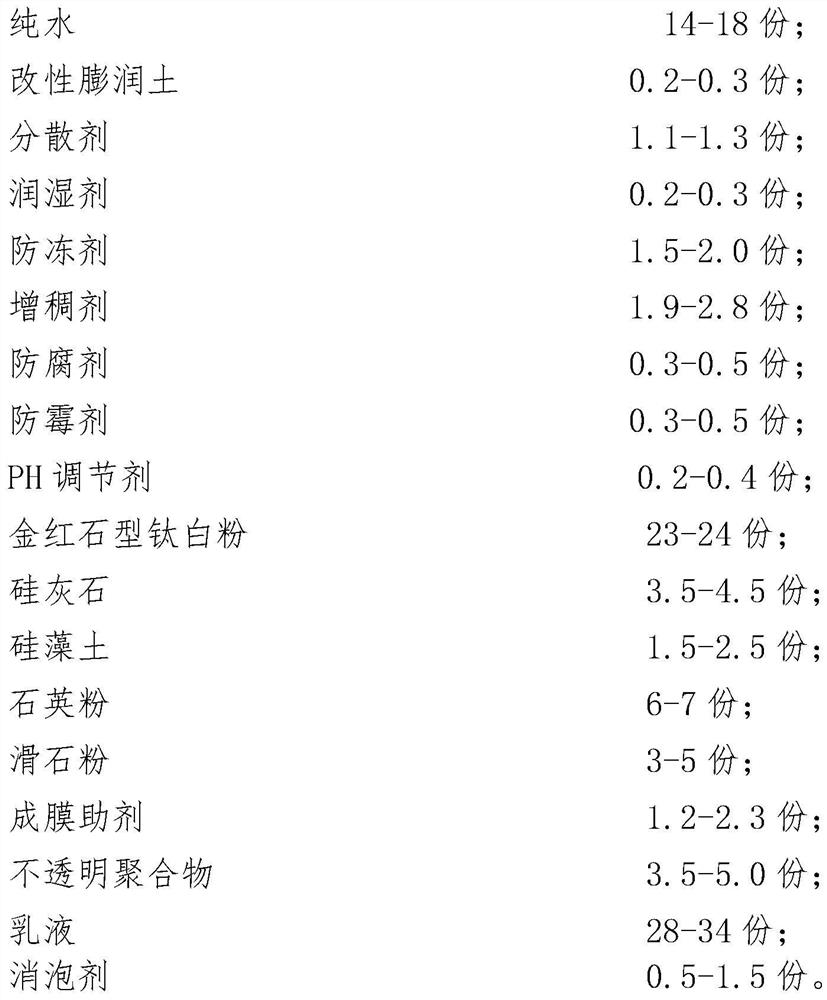

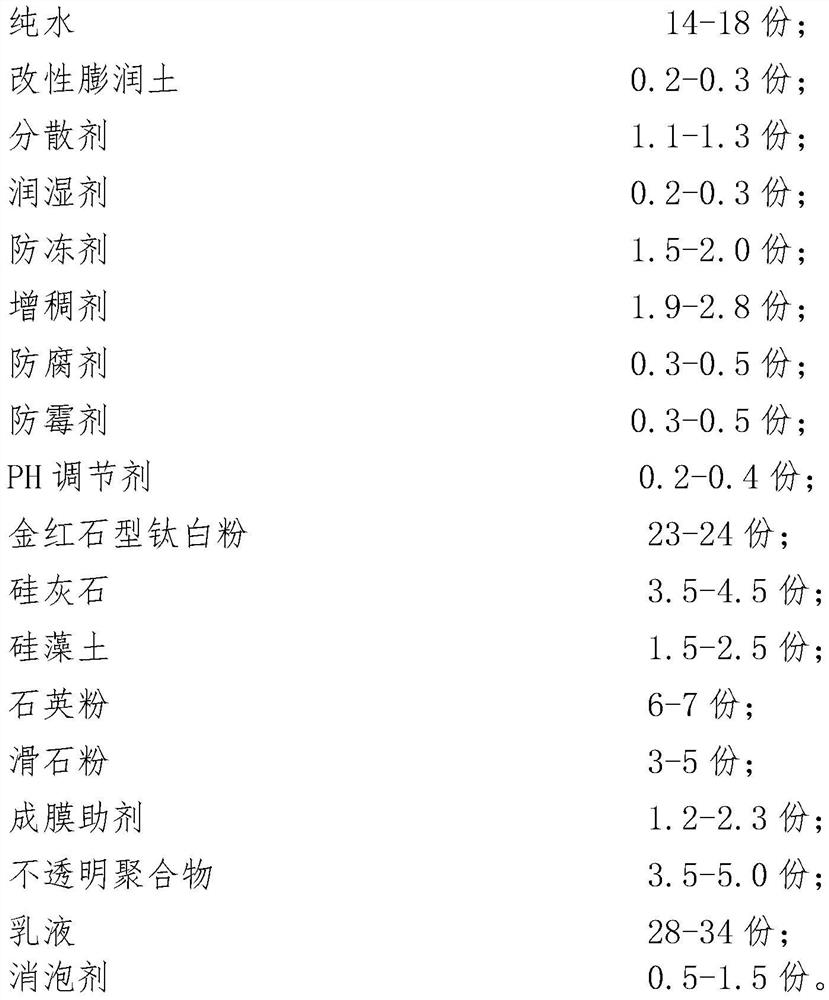

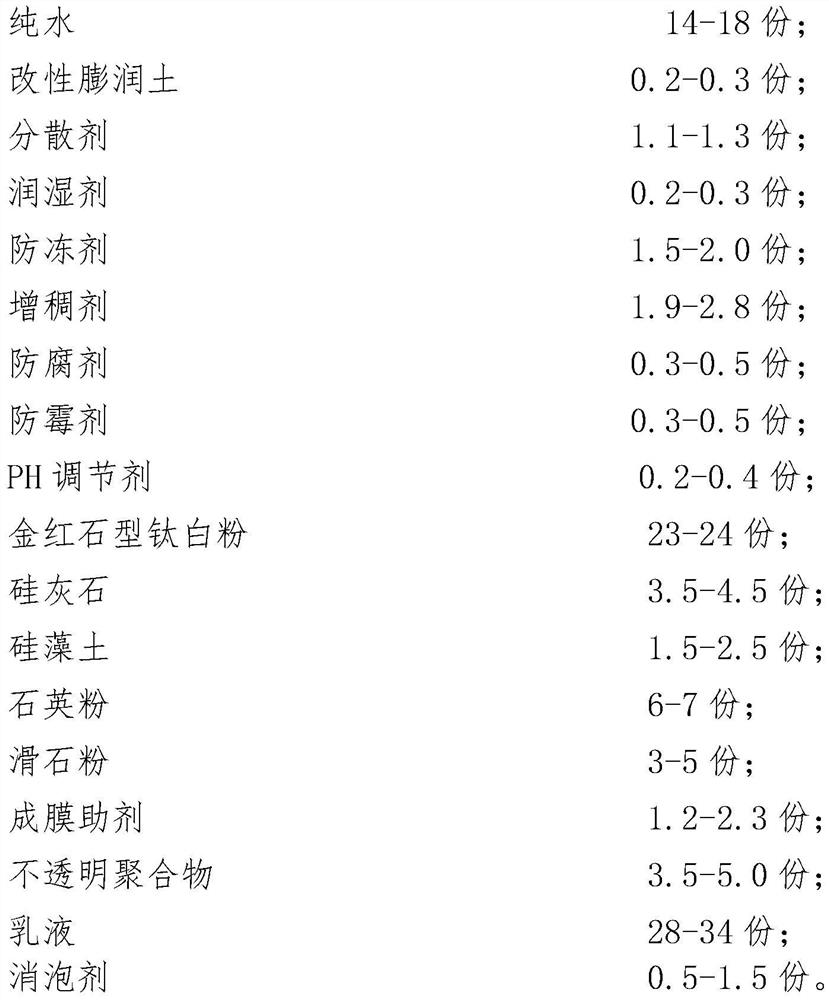

InactiveCN113088137AExcellent interlayer adhesionGood construction performanceCoatingsEmulsionDefoaming Agents

The invention relates to high-performance odorless balcony paint which is prepared from the following raw materials: pure water, modified bentonite, a dispersing agent, a wetting agent, an anti-freezing agent, a thickening agent, a preservative, a mildew preventive, a pH regulator, rutile titanium dioxide, wollastonite, diatomite, quartz powder, talcum powder, a coalescing agent, an opaque polymer, an emulsion and a defoaming agent. The high-performance odorless balcony paint and the preparation method thereof are developed on the basis of emulsion and assistant type screening and dosage ratio research, so that the product not only has healthy, odorless and stain-resistant indoor paint performance, meets the requirements of high-weather-resistant and water-resistant exterior wall paint, but also has construction performance of interlayer adhesive force.

Owner:河北三棵树涂料有限公司

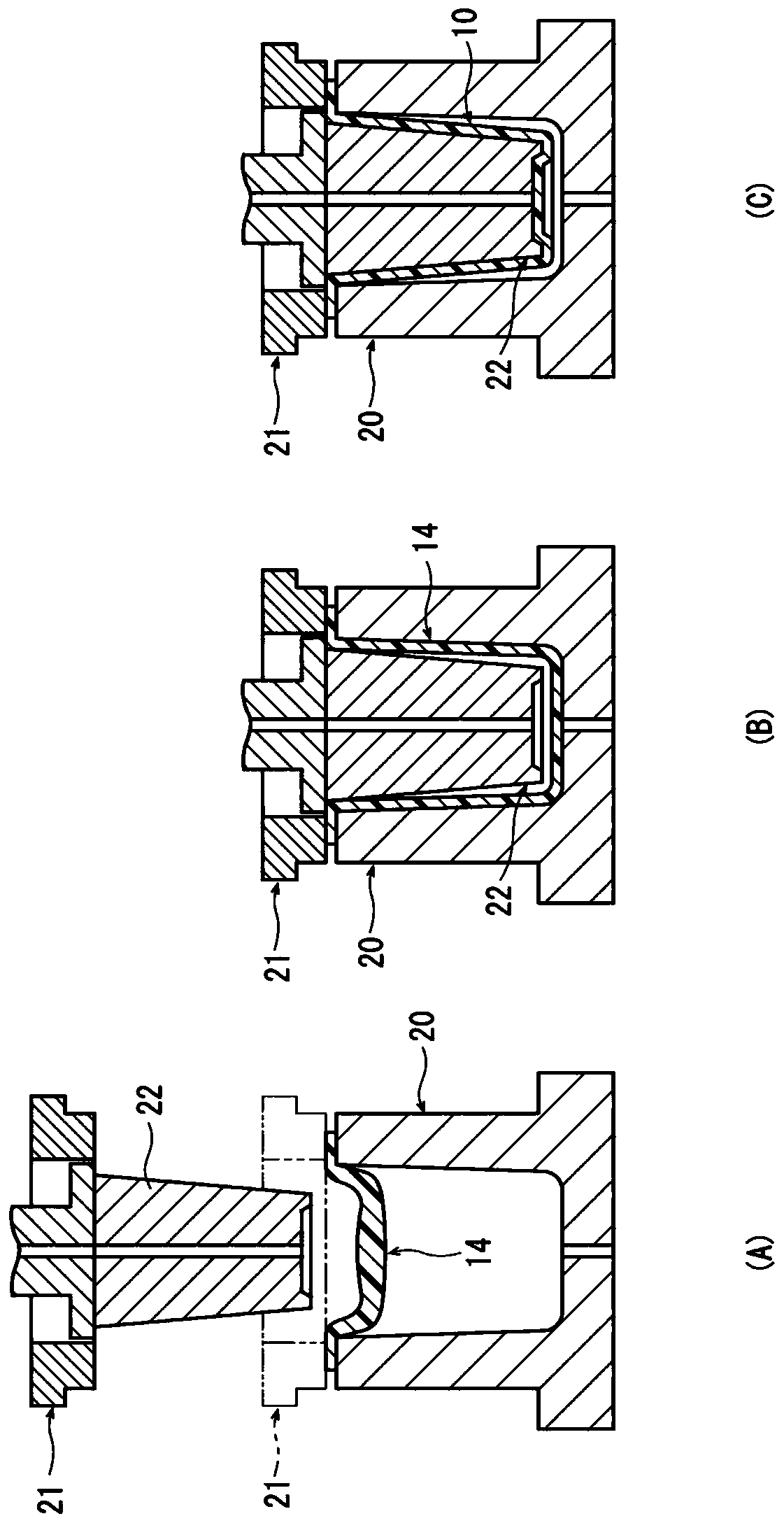

Multilayer plastic container

ActiveCN103282199AExcellent interlayer adhesionImprove practicalitySynthetic resin layered productsDomestic containersPolyolefinOxygen barrier

Owner:TOYO SEIKAN KAISHA LTD

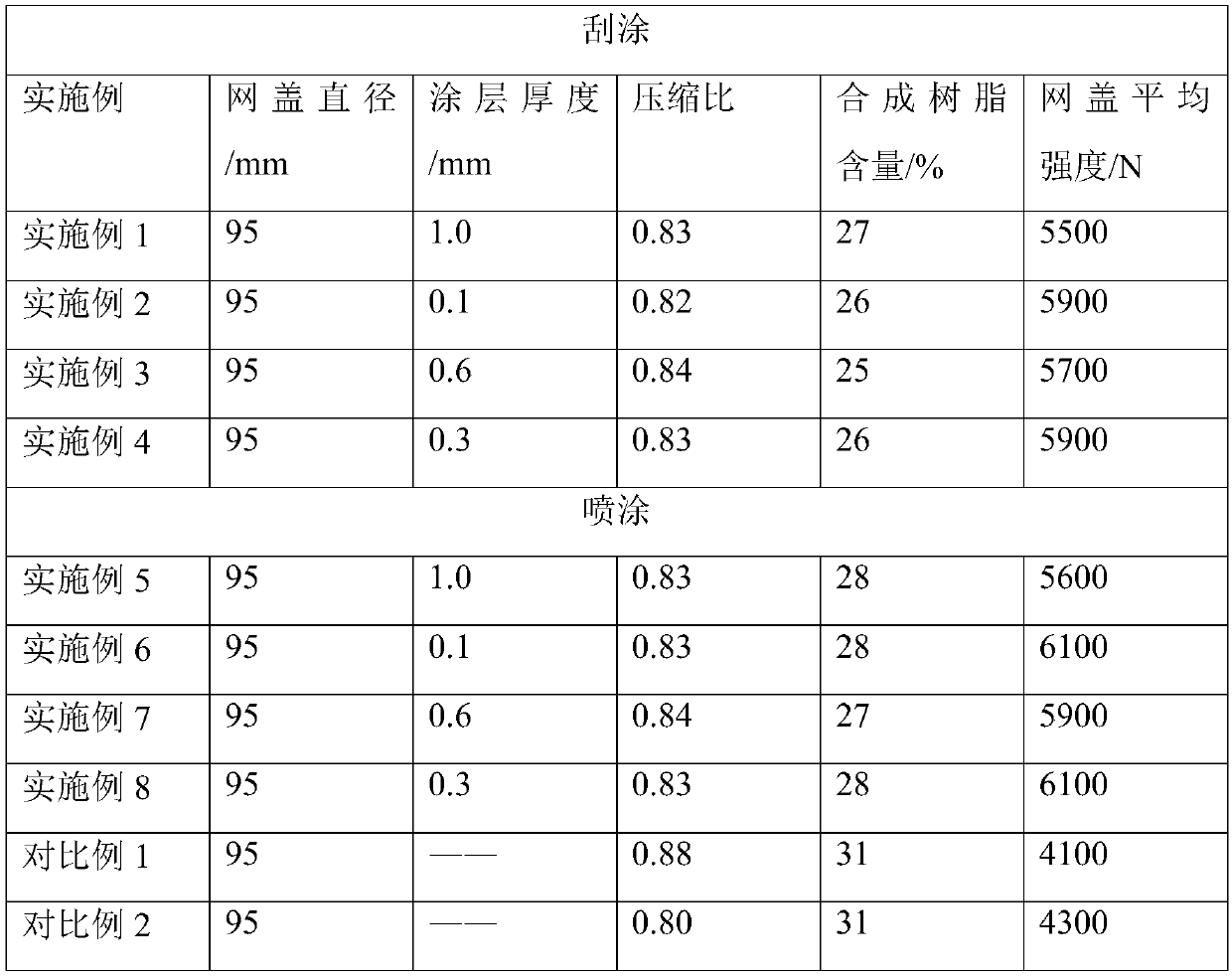

Production method of glass fiber mesh cover

InactiveCN111331876ADifficult to disperseReduce gyration strengthPlastic recyclingFiberglass meshGlass fiber

The invention provides a production method of a glass fiber mesh cover. Glass fiber cloth which is impregnated in synthetic resin and pre-baked is coated with a mixed solution to form a coating, the mixed solution is prepared from synthetic resin and crushed leftover materials after solidifying and crushing treatment, and the leftover materials are leftover materials recycled and produced during the production process of the glass fiber mesh cover. The glass fiber mesh cover produced by the production method has higher strength and does not affect the impregnation with an adhesive; the glass fiber mesh cover is economic, the leftover materials can be fully used in manufacturing process, and compared with a glass fiber cloth layer used in a normal glass fiber mesh cover, the usage amount ofthe glass fiber cloth can be reduced by 1-3 layers according to different specifications; and the production cost of the glass fiber mesh cover is reduced, and the utilization rate of the glass fibercloth and synthetic resin is improved.

Owner:绵阳中研磨具有限责任公司

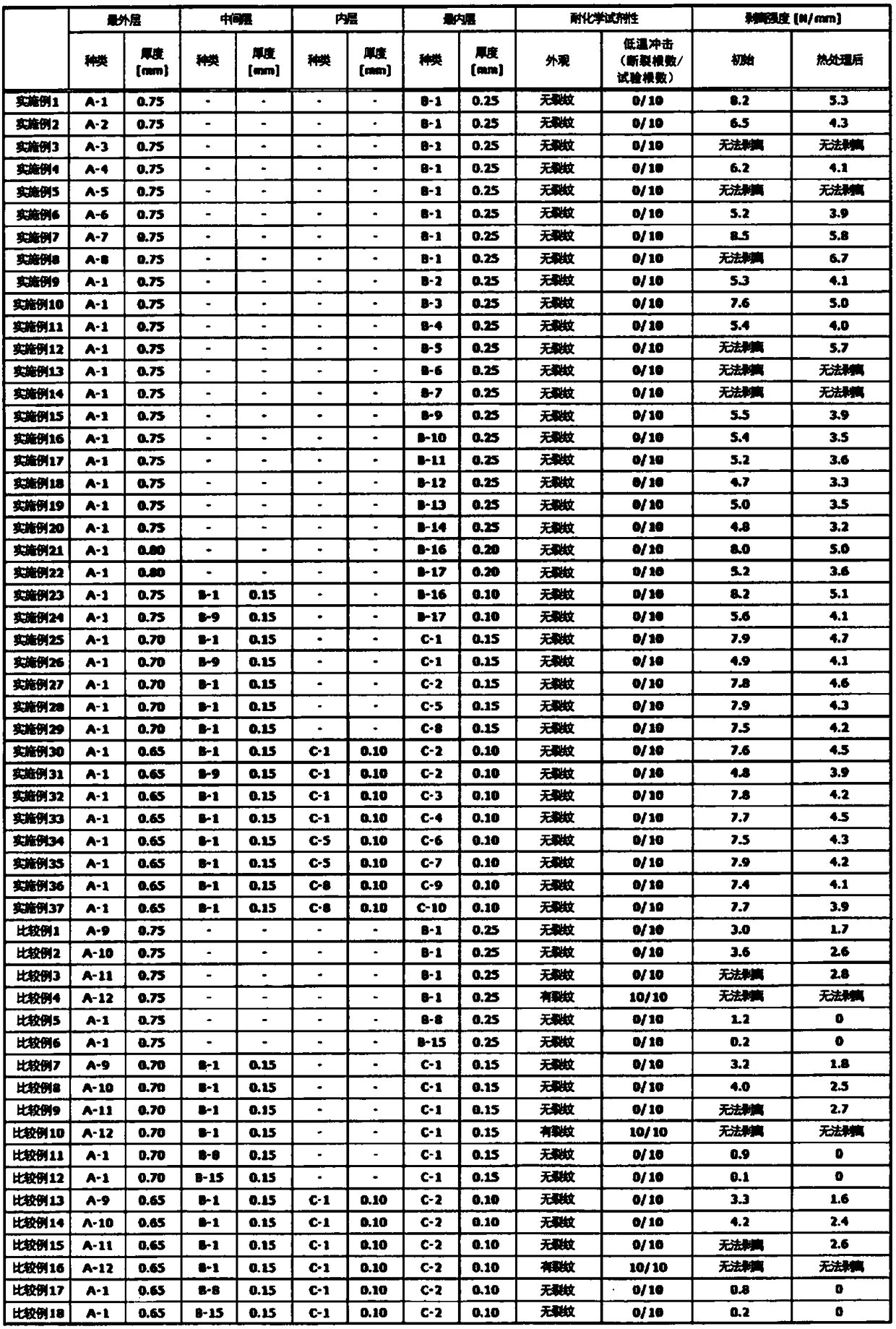

Multilayer structure

ActiveCN100537228CImprove heat resistanceExcellent interlayer adhesionSynthetic resin layered productsAmpoulesCarbon numberPolyamide

A laminated structure is a laminated structure composed of two or more layers, and includes at least a layer (a) containing (A) aliphatic polyamide and a layer (b) containing (B) semi-aromatic polyamide ) layer, wherein the semi-aromatic polyamide contains 60 mol % or more of diamine units containing aliphatic diamine units having 9 to 13 carbon atoms with respect to all diamine units and 50 mol % with respect to all dicarboxylic acid units The dicarboxylic acid unit of the above terephthalic acid and / or naphthalenedicarboxylic acid unit, and the above-mentioned (b) layer is arranged in the innermost layer. The laminated structure of the present invention has excellent heat resistance, chemical resistance, chemical resistance and / or gas permeability resistance, elution resistance of monomers and oligomers, interlayer adhesion, and durability.

Owner:UBE IND LTD +1

Multilayer tube

ActiveCN109311259AGuaranteed barrier propertiesMaintain dissolution resistanceSynthetic resin layered productsLaminationElastomerPolymer science

Provided is a multilayer tube which comprises a layer containing a specific aliphatic polyamide composition and a layer containing a semiaromatic polyamide composition that contains a semiaromatic polyamide having a specific structure, and wherein the layers are arranged adjacent to each other. The aliphatic polyamide composition contains: an aliphatic polyamide wherein the ratio of the number ofmethylene groups to the number of amide groups is a specific value or higher; a polyamide wherein the absolute value of the difference of the solubility parameter SP value between itself and the above-described aliphatic polyamide is within a specific range; and an elastomer polymer which contains a constituent unit derived from an unsaturated compound having a carboxyl group and / or an acid anhydride group.

Owner:UBE IND LTD

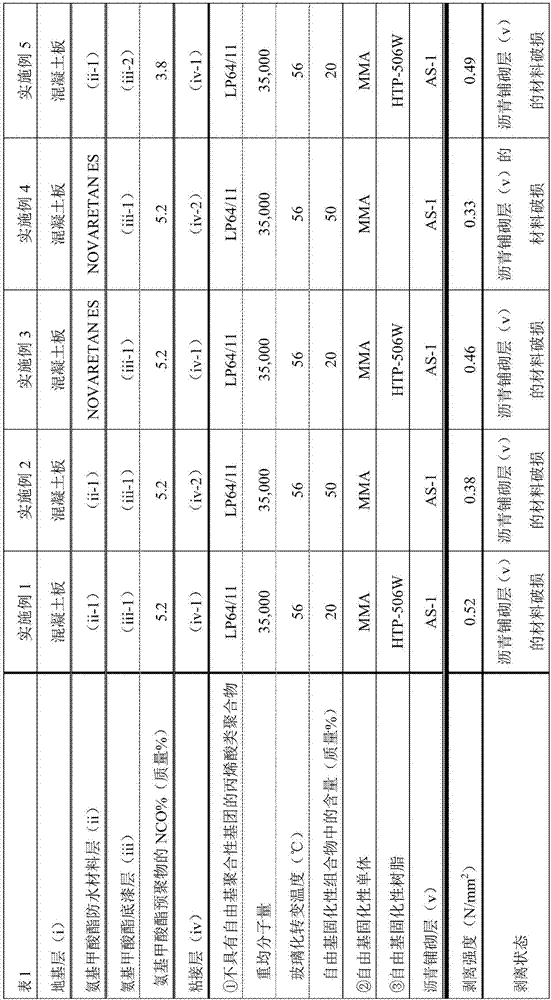

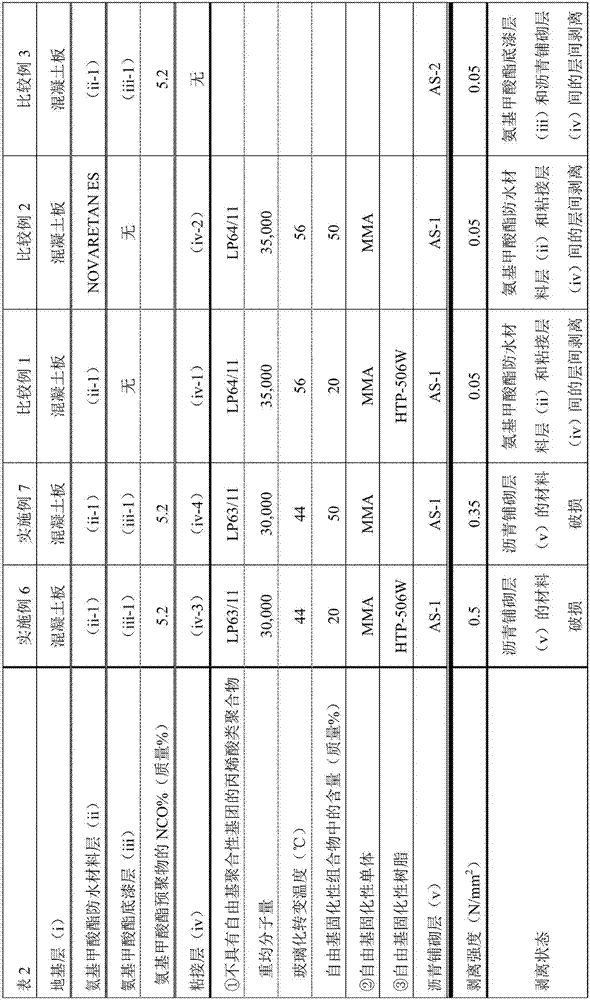

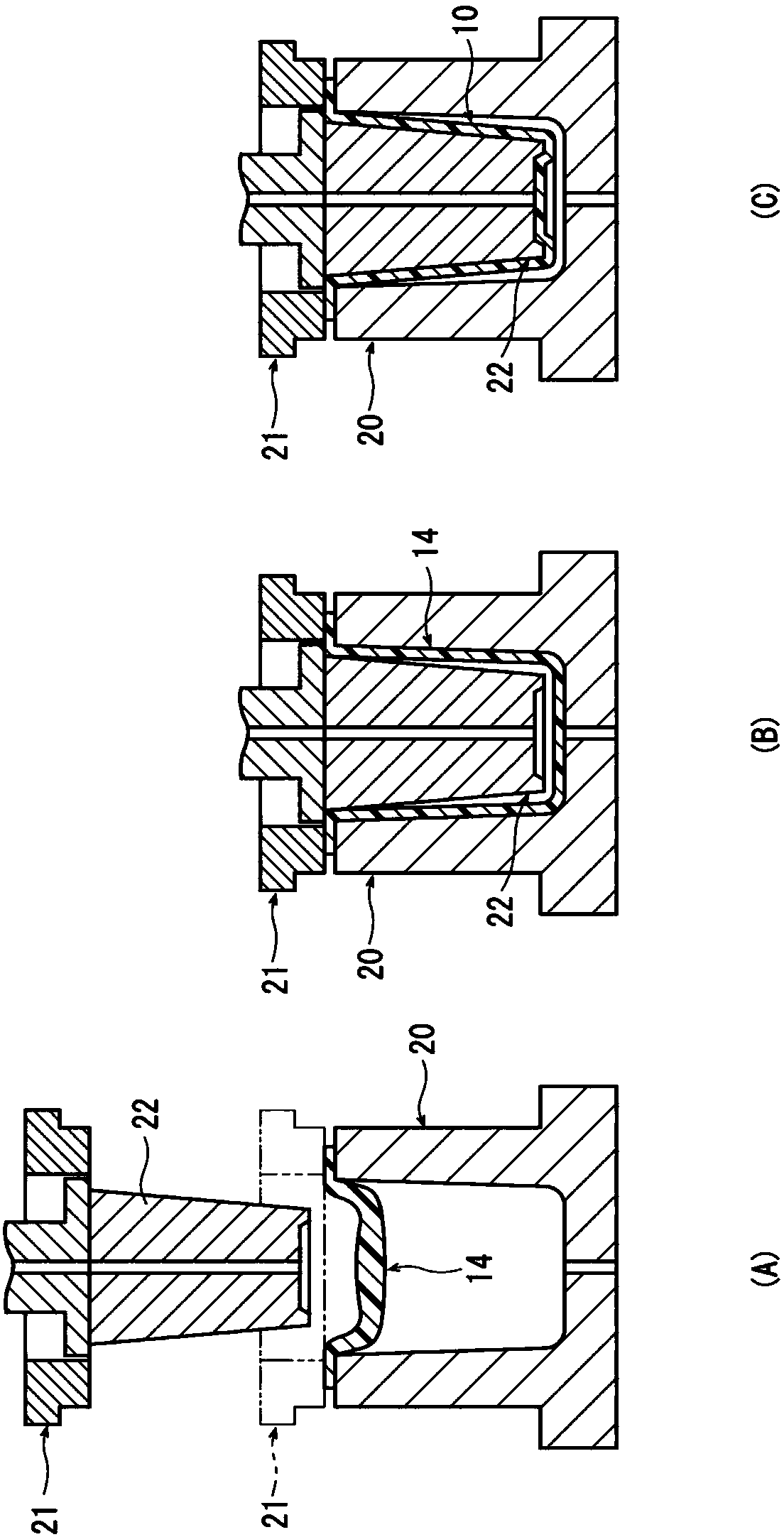

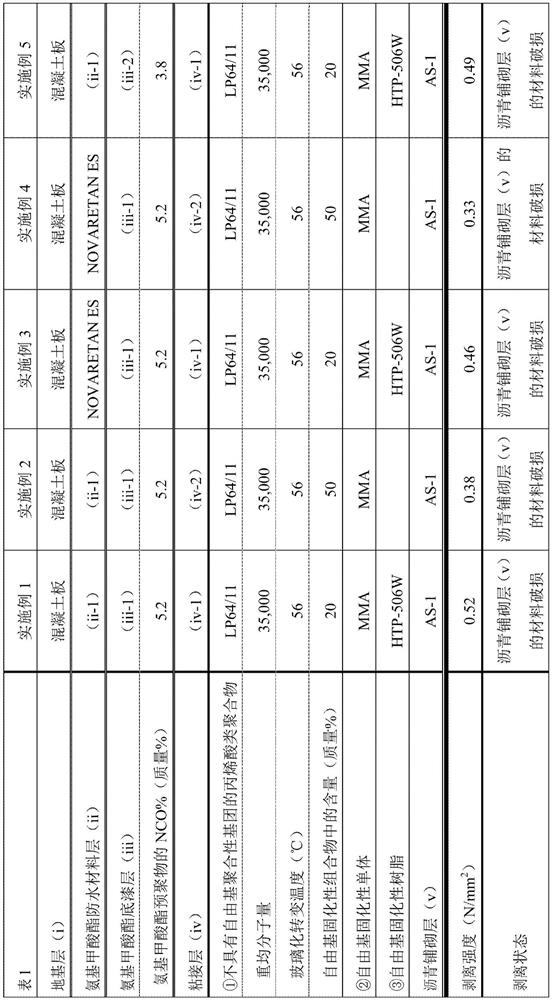

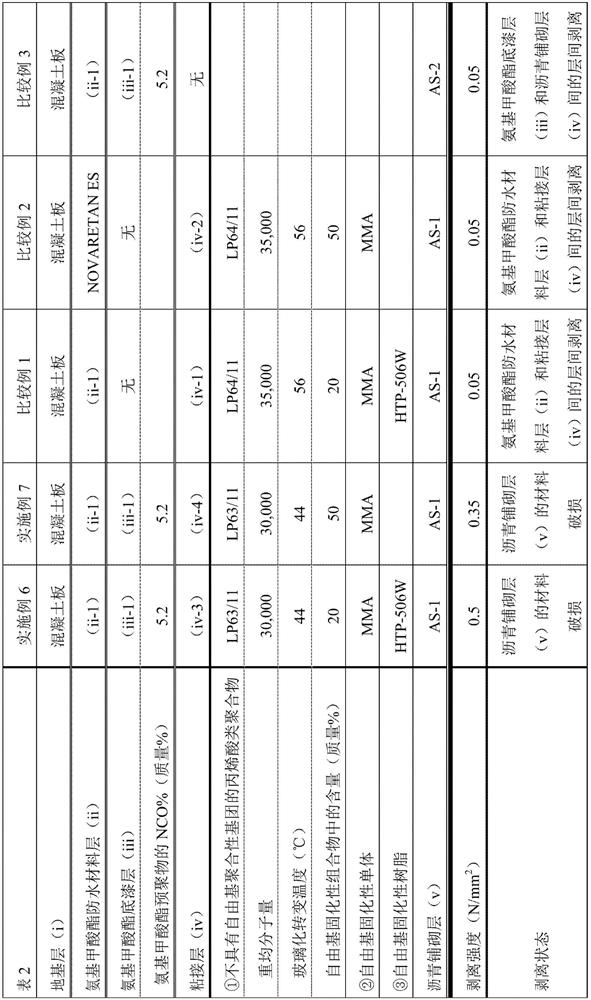

Floor slab waterproof structure

ActiveCN107208387AShorten construction timeExcellent interlayer adhesionIn situ pavingsSynthetic resin layered productsFloor slabRoom temperature

The present invention addresses the problem of providing a floor slab waterproof structure which exhibits excellent interlayer adhesion between a urethane waterproof material layer and an asphalt pavement layer. The present invention provides a floor slab waterproof structure which is characterized by being obtained by sequentially laminating a floor slab layer (i), a urethane waterproof material layer (ii), a urethane primer layer (iii), a bonding layer (iv) which is obtained by curing a radically curable composition, and an asphalt pavement layer (v). This floor slab waterproof structure has excellent interlayer adhesion between the urethane waterproof material layer and the asphalt pavement layer. Since this floor slab waterproof structure uses a radically curable composition which has excellent drying properties at room temperature for the bonding layer, installation time of this floor slab waterproof structure is able to be reduced.

Owner:DIC CORP

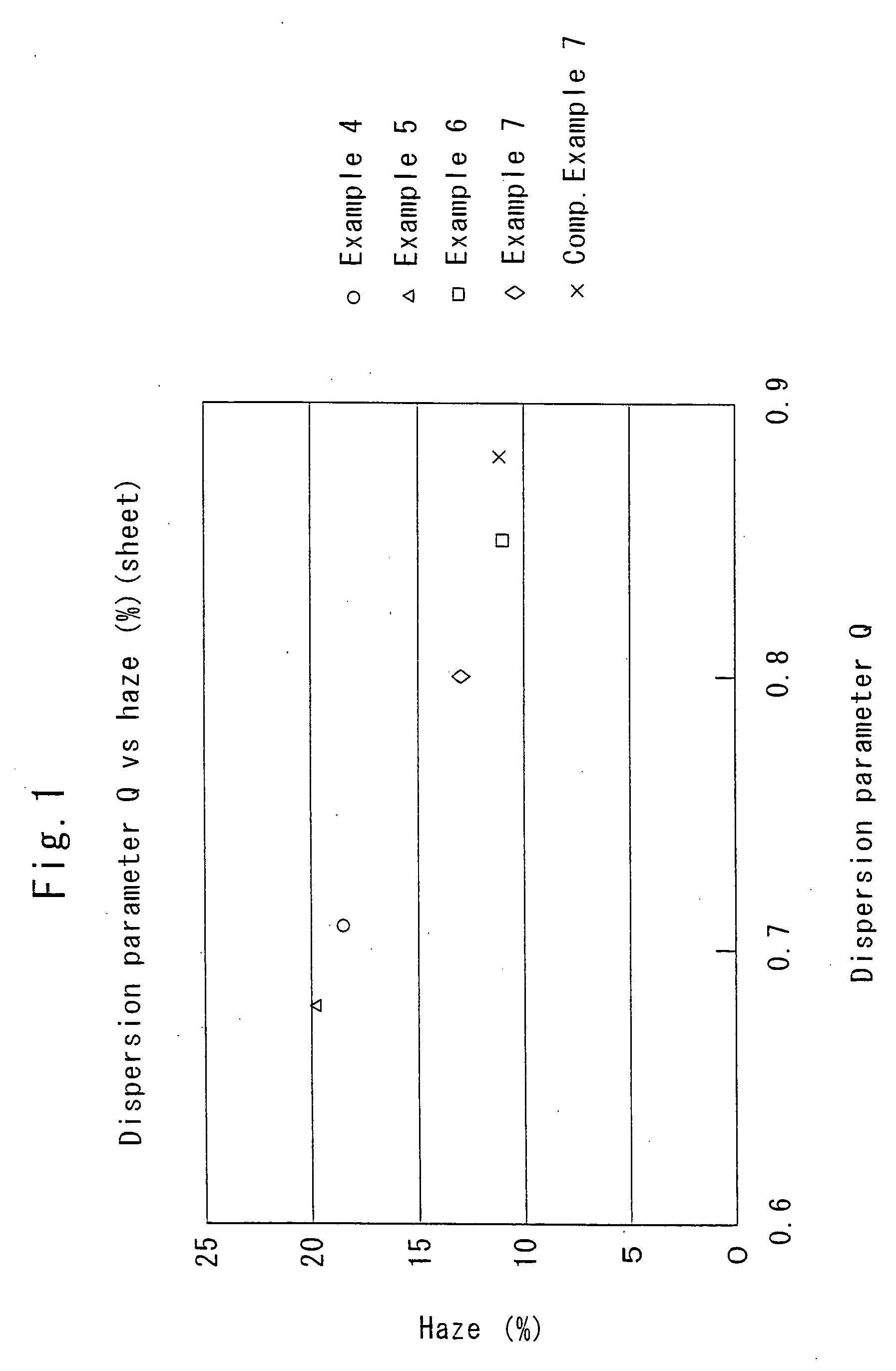

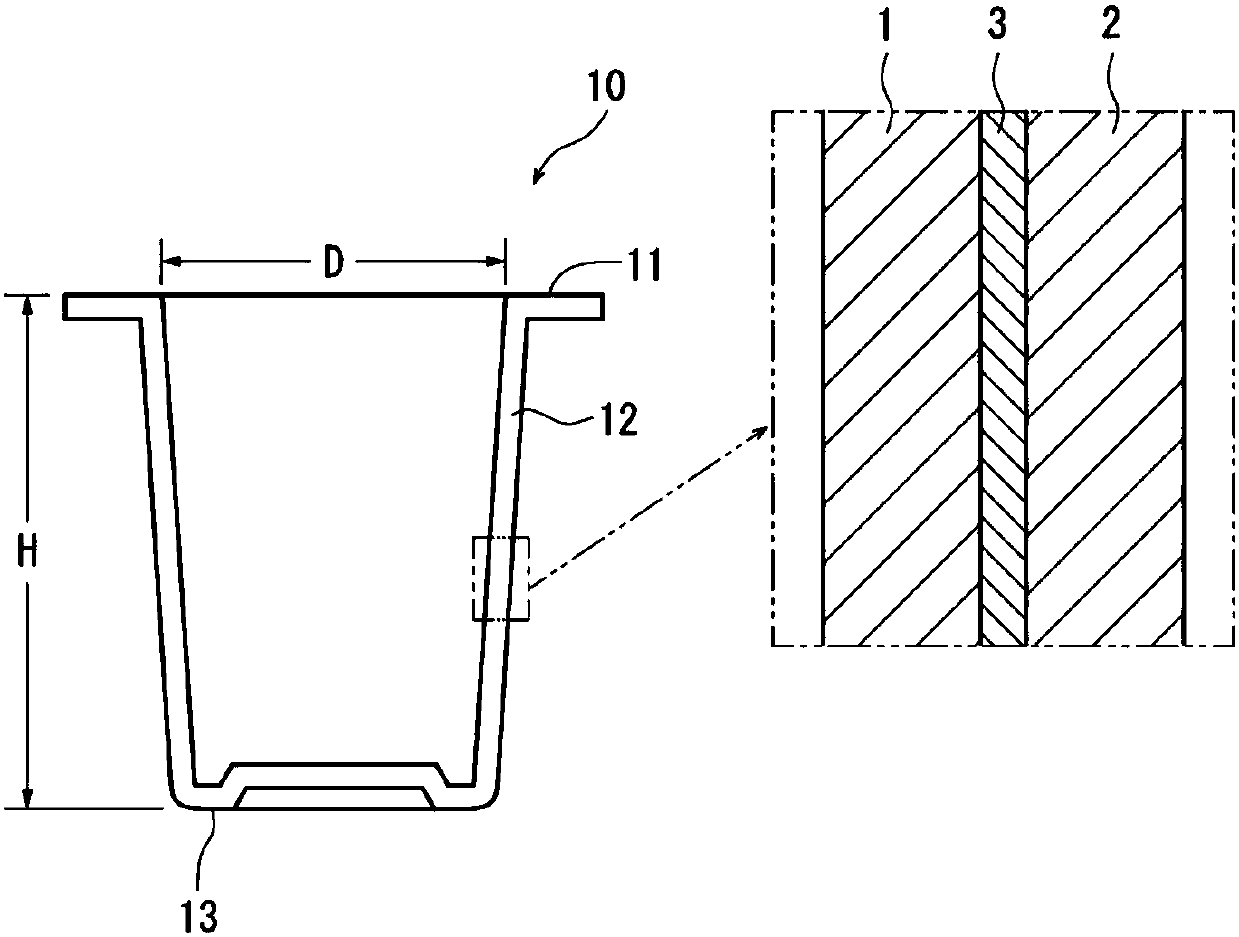

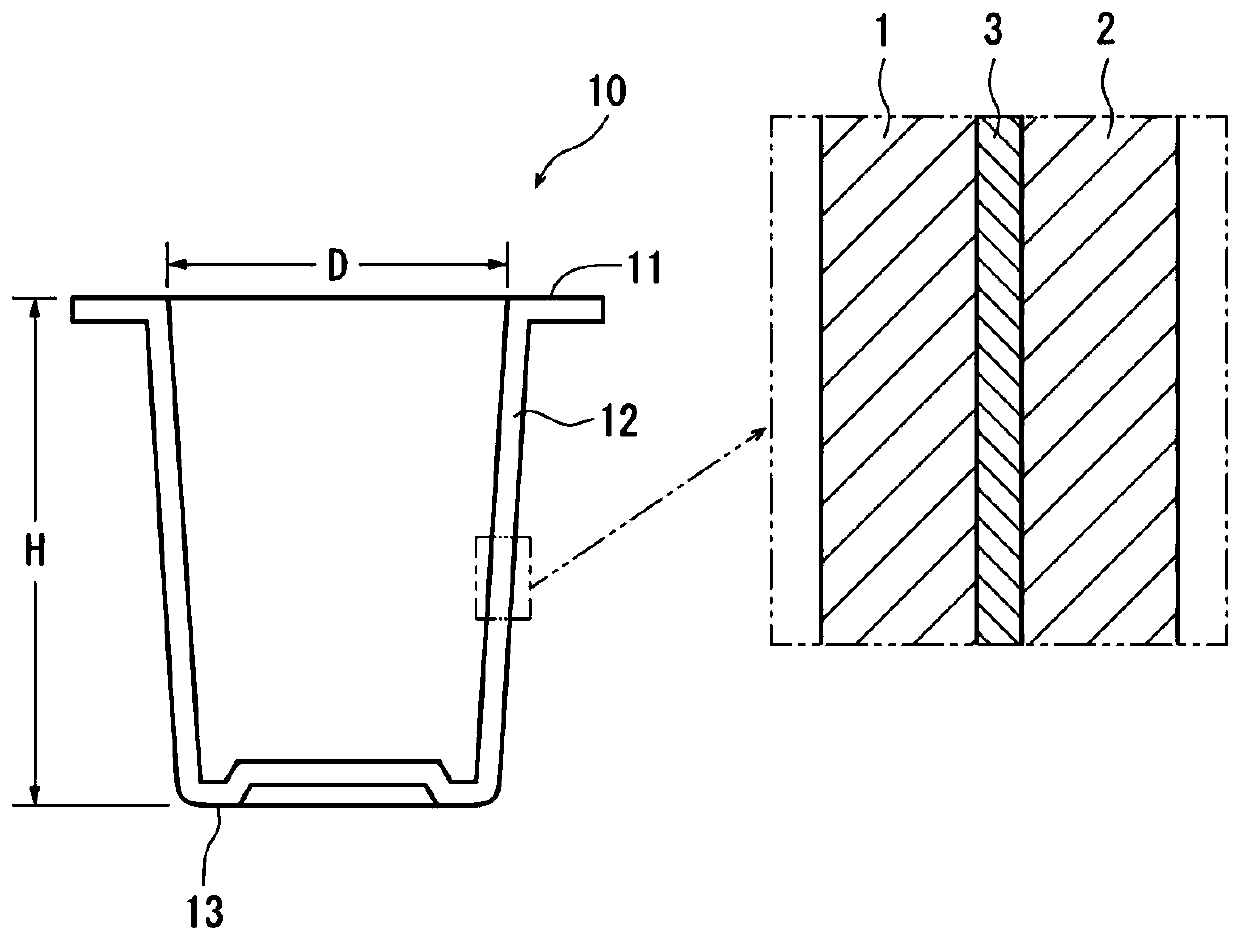

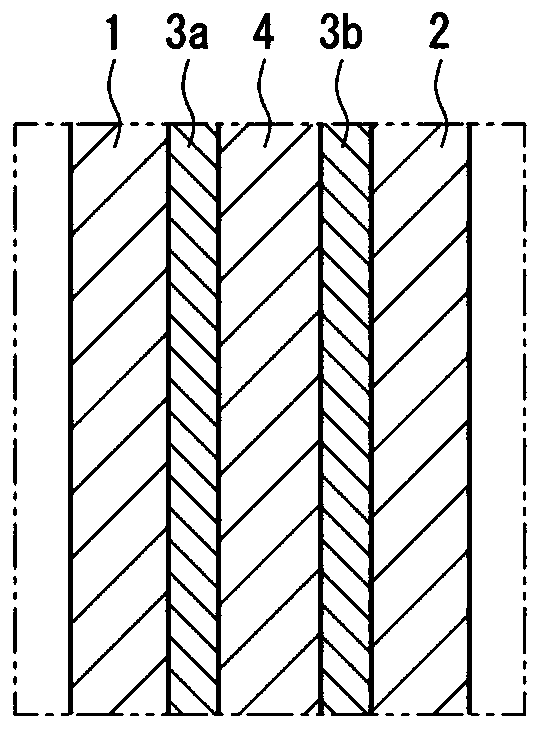

Cup-type multilayered container

Owner:TOYO SEIKAN GRP HLDG LTD

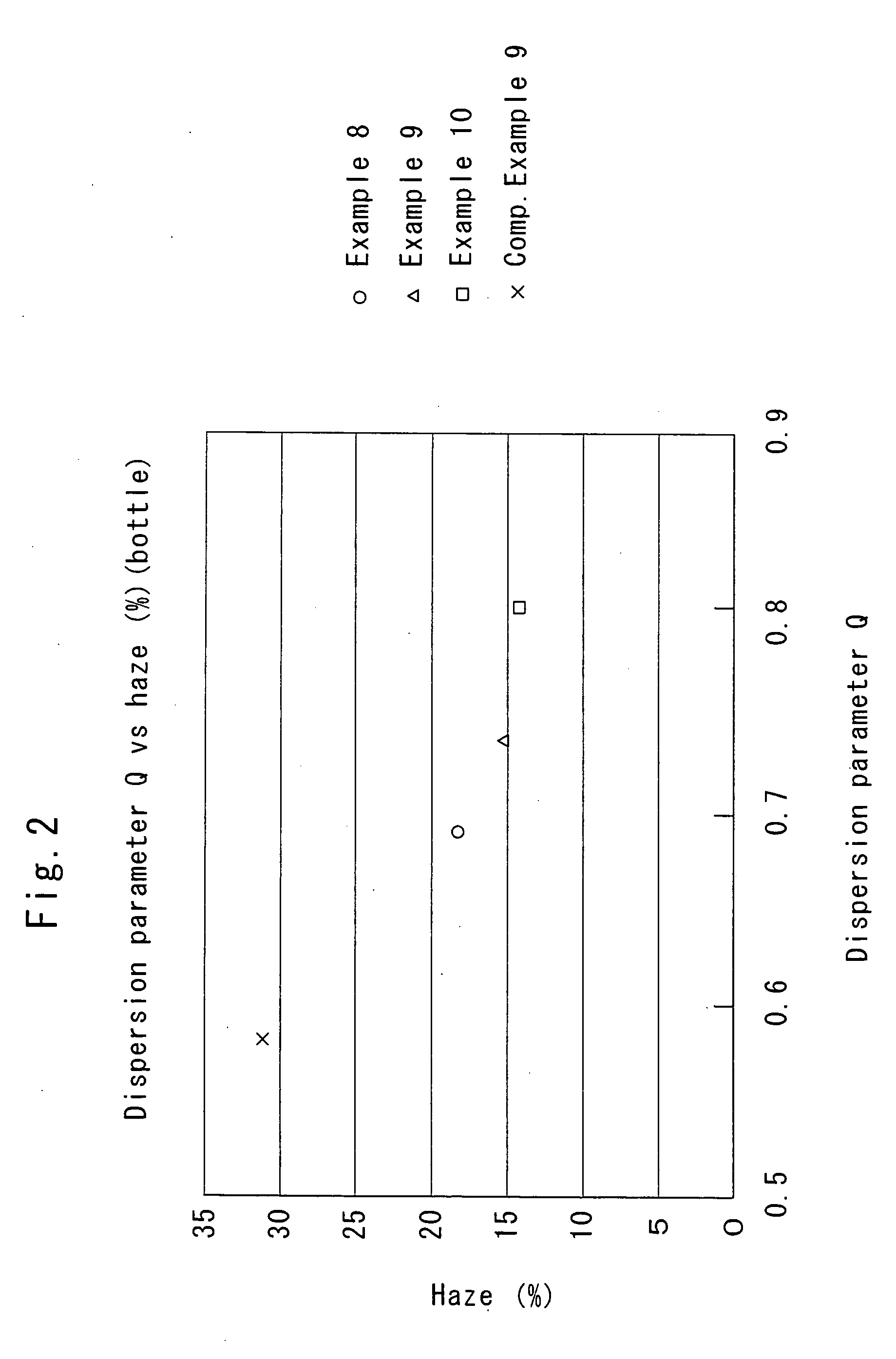

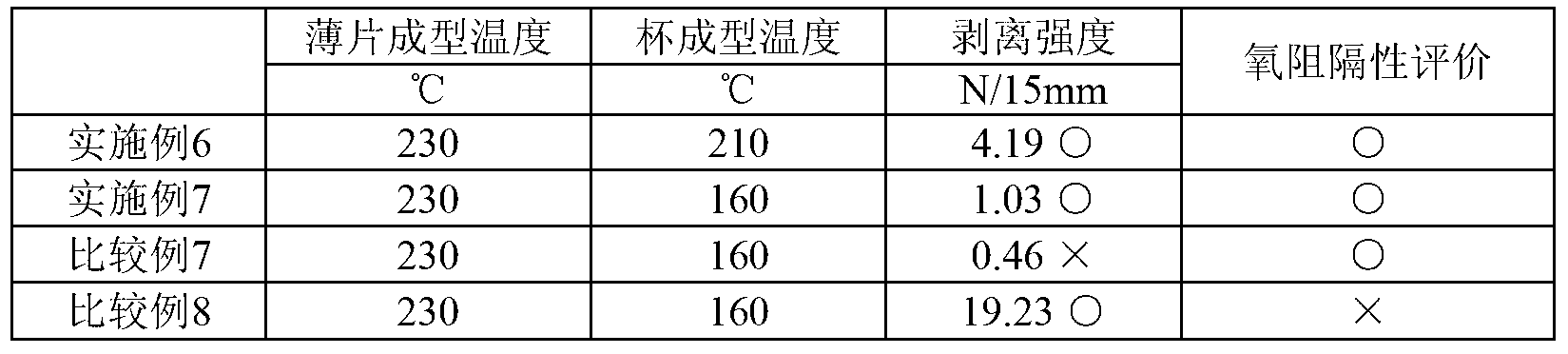

Cup Multilayer Container

The present invention relates to a multilayer container obtained by thermoforming a multilayer precursor comprising: an inner layer and an outer layer obtained from an ethylene terephthalate-based polyester resin; At least one intermediate layer obtained from a crystalline ethylene terephthalate-based polyester resin and a gas-barrier aromatic polyamide resin. The difference in refractive index (ΔRI) represented by the formula (1) between the low-crystalline ethylene terephthalate-based polyester resin and the gas-barrier aromatic polyamide resin is 0.03 or less, ΔRI=∣RI E –RI A ∣(1), where RI E and RI A Represents the refractive index after uniaxial stretching of an injection molded plate obtained from a low-crystalline ethylene terephthalate-based polyester resin and a gas-barrier aromatic polyamide resin, respectively, after 3 times, and the haze on the side of the container is 5% or less. As a result, the container has a multilayer structure obtained from inner and outer layers made of polyester resin and an intermediate layer made of a blend of polyester resin and aromatic polyamide resin, and satisfies excellent transparency , gas barrier and interlayer adhesion requirements.

Owner:TOYO SEIKAN GRP HLDG LTD

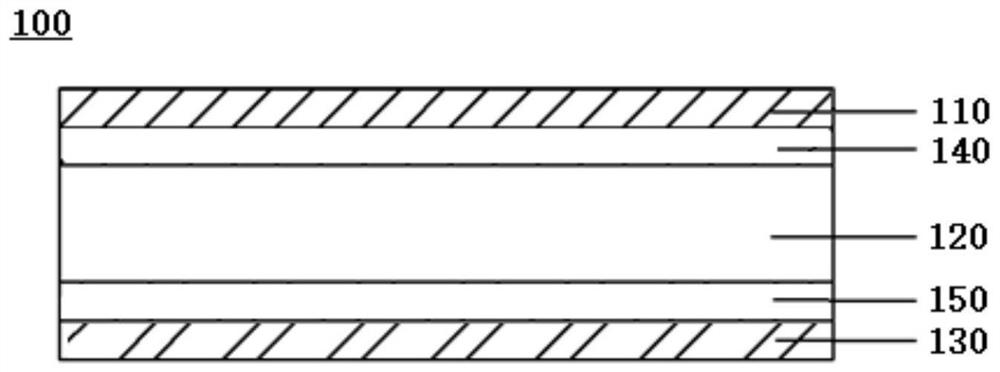

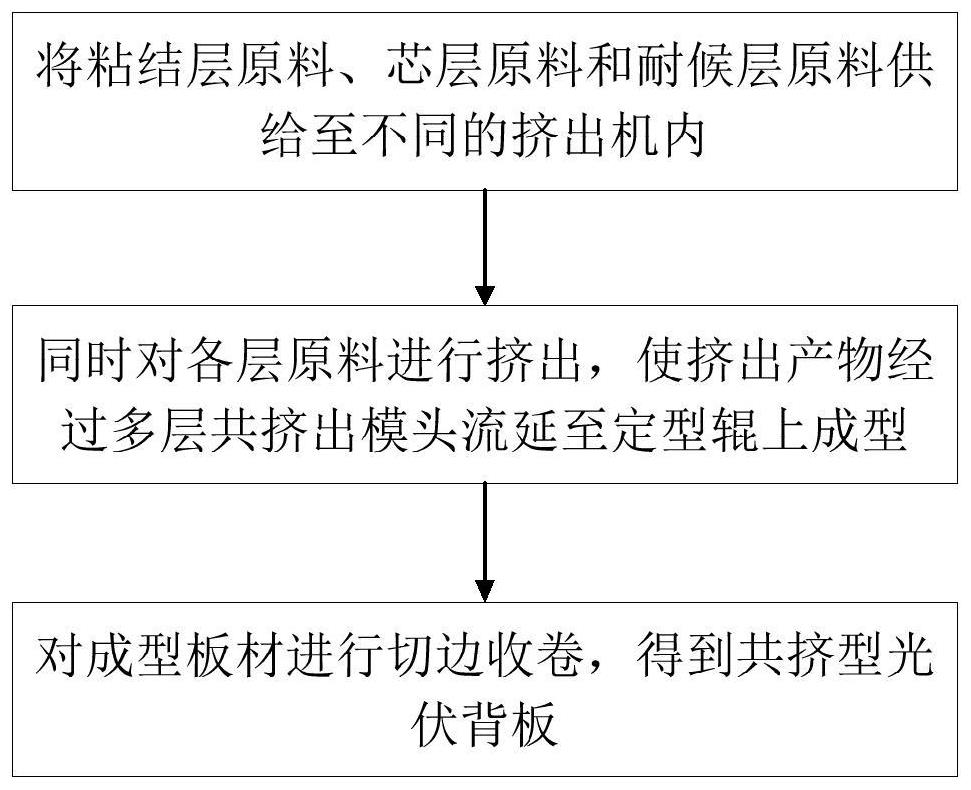

Photovoltaic backboard and preparation method and application thereof

PendingCN114497252AImprove heat resistanceImprove adhesionPhotovoltaic energy generationSemiconductor devicesWeather resistancePhysical chemistry

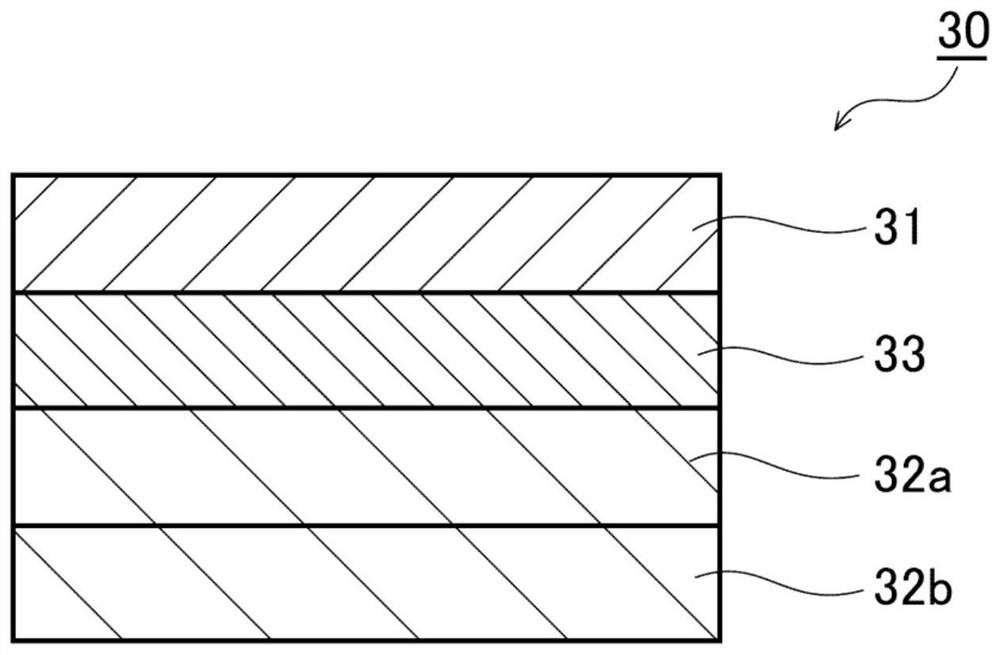

The invention discloses a photovoltaic backboard and a preparation method and application thereof. The photovoltaic backboard at least comprises a bonding layer, a core layer and a weather-resistant layer which are sequentially arranged from inside to outside, and the bonding layer comprises, by mass, 50-80 parts of heat-resistant polyamide, 5-20 parts of tackifying resin, 1-10 parts of ionic polymer, 1-30 parts of first filler and 0.1-5 parts of first anti-aging agent; the core layer comprises 50-80 parts by mass of first polypropylene, 5-20 parts by mass of a first modified material, 1-30 parts by mass of a second filler and 0.1-5 parts by mass of a second anti-aging agent; and the weather-resistant layer comprises 50-80 parts by mass of second polypropylene, 5-20 parts by mass of a second modified material, 1-30 parts by mass of a third filler, 0-25 parts by mass of polyamide and 0.1-5 parts by mass of a third anti-aging agent. The photovoltaic backboard has good heat resistance, weather resistance, cohesiveness and interlayer cohesive force, and the heat resistance of the photovoltaic backboard can be greatly improved.

Owner:乐凯胶片股份有限公司

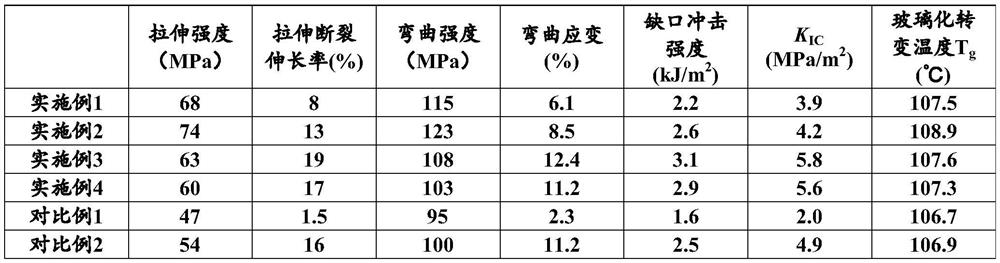

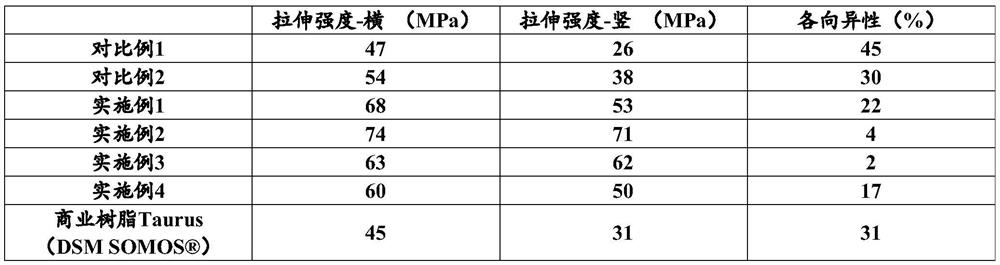

A kind of 3D printing photosensitive resin and its preparation method and application

ActiveCN112280241BExcellent interlayer adhesionImprove mechanical propertiesAdditive manufacturing apparatus3d printPolymer science

The invention provides a 3D printing photosensitive resin and a preparation method thereof. The photosensitive resin composition comprises the following components in parts by mass: 20-80 parts of a prepolymer, 20-50 parts of a reactive diluent, and 1 photoinitiator -20 parts, 1-20 parts of modified styrene-butadiene rubber nanoparticles; wherein, the modified styrene-butadiene rubber nanoparticles have a core-shell structure, wherein the core is styrene-butadiene rubber, and the shell is group of styrene and methyl methacrylate copolymers. The interlayer adhesion of the workpiece prepared by the photosensitive resin is higher, and the uniformity of mechanical properties in the isotropic direction can be improved. When used in 3D printing, the mechanical properties and surface step effect of the workpiece can be improved, and the printing effect is greatly improved. And the forming effect of the part can meet the needs of multi-degree-of-freedom 3D printing.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

laminated tube

ActiveCN111183023BLow dissolution resistanceImprove barrier propertiesSynthetic resin layered productsMachines/enginesElastomerPolymer science

Provided is a laminated tube having: a layer comprising a specific aliphatic polyamide composition; and a layer comprising a semi-aromatic polyamide composition containing a semi-aromatic polyamide having a specific structure. A polyamide or a mixture thereof, wherein the two layers are adjacent, wherein the aliphatic polyamide composition comprises: an aliphatic polyamide having a melting point of not more than a specific value and a ratio of the number of methylene groups to the number of amide groups not less than a specific value; and The aliphatic polyamide in which the absolute value of the difference in solubility parameter SP value falls within a specific range, and an elastomer polymer containing a structural unit derived from an unsaturated compound having a carboxyl group and / or an acid anhydride group.

Owner:UBE IND LTD

A kind of anti-potential induced decay multilayer composite photovoltaic encapsulation film and preparation method and application

ActiveCN109337599BImprove anti-PID performanceDurable and stable anti-PID performanceNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveEngineering

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

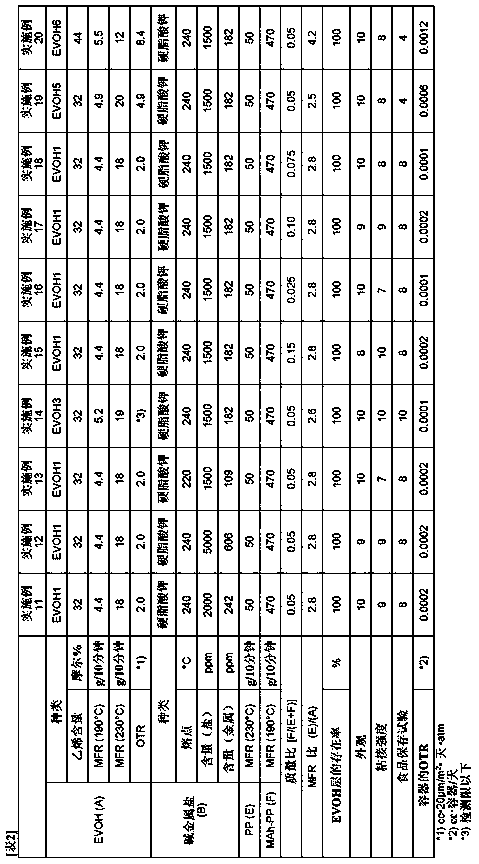

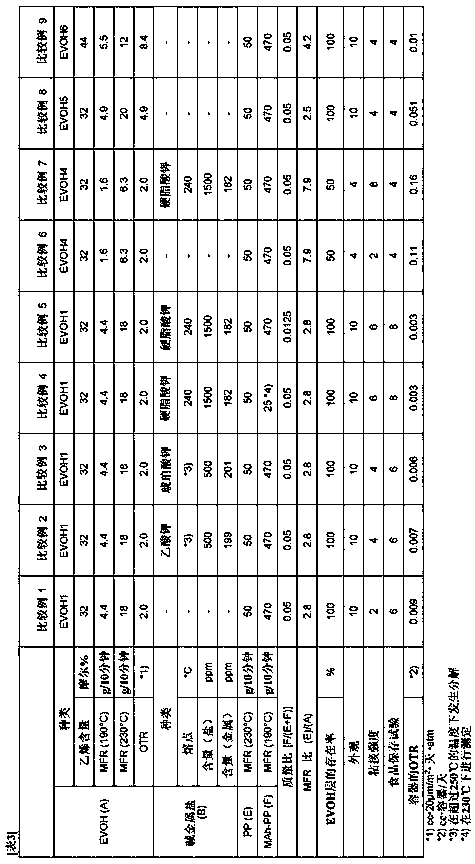

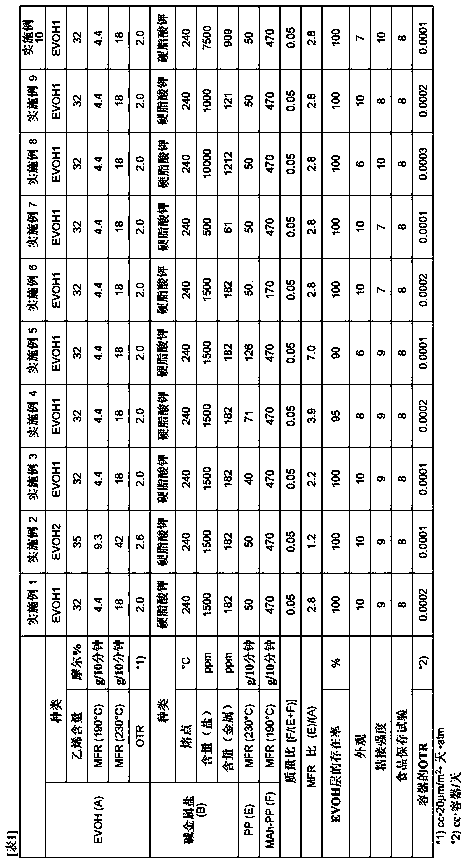

Co-injection-molded multilayer structure

ActiveCN110062698AExcellent interlayer adhesionGood adhesionFlexible coversWrappersPolymer sciencePolypropylene

Provided is a co-injection-molded multilayer structure having a barrier layer and outer layers layered in contact therewith on both sides thereof, wherein the barrier layer comprises a resin composition including an ethylene-vinyl alcohol copolymer (A) and an alkali metal salt (B) of a higher fatty acid having a melting point of 250 DEG C or lower, the content of the alkali metal salt (B) in the barrier layer is 50-1500 ppm, and the outer layers comprise a resin composition including an unmodified polypropylene (E) and an anhydrous maleic-acid-modified polypropylene (F) having a lower melt viscosity than the unmodified polypropylene (E). The co-injection-molded multilayer structure has excellent adhesion of the barrier layer comprising an EVOH resin composition and the outer layers comprising a polypropylene resin composition, despite not having an adhesive layer.

Owner:KURARAY CO LTD

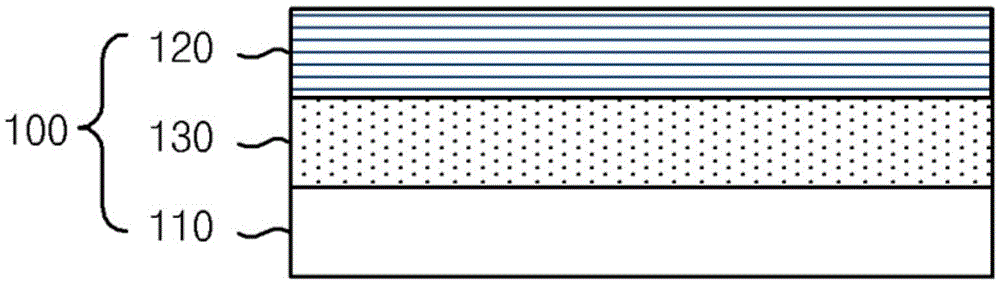

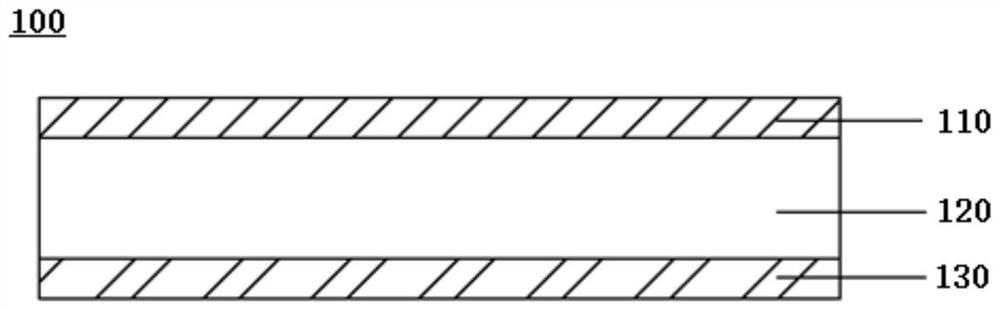

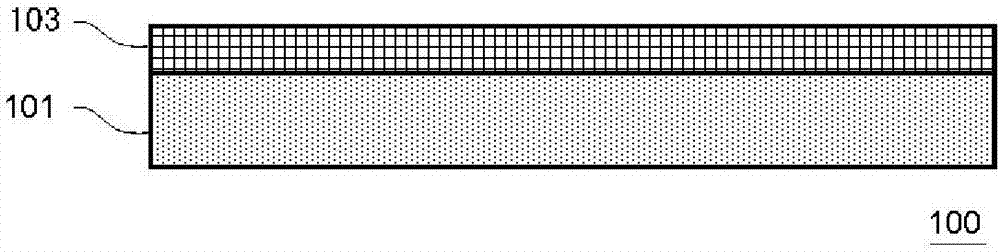

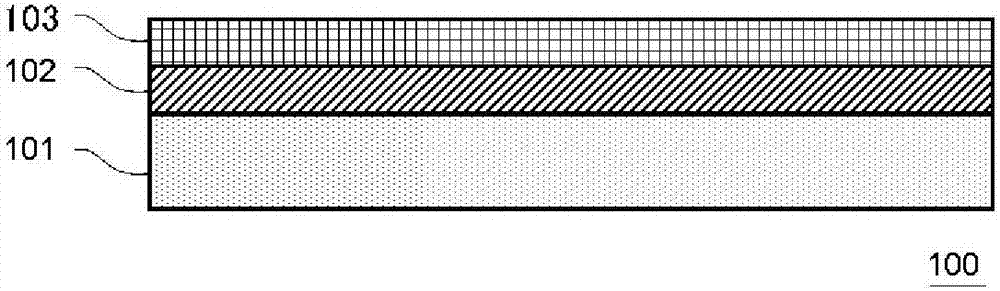

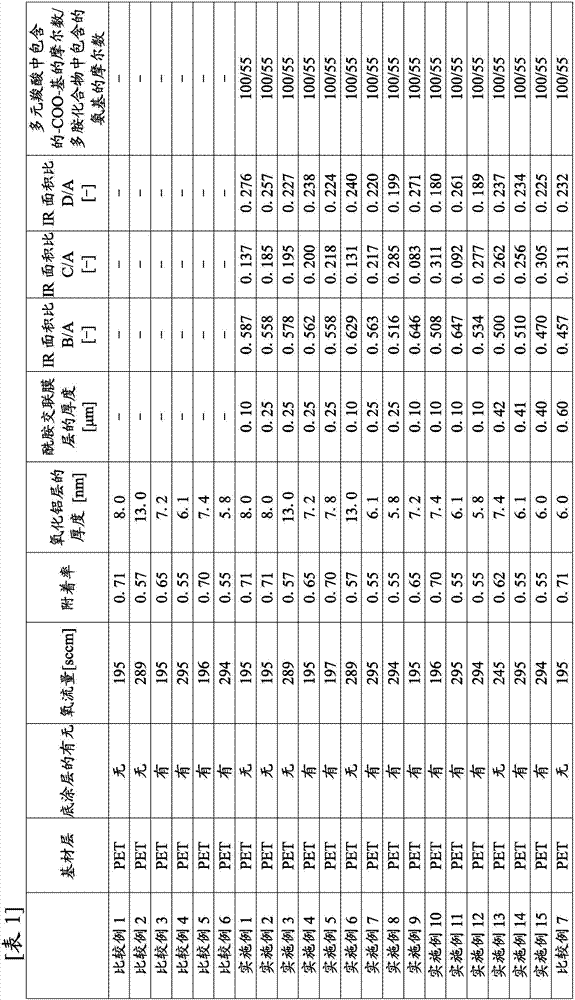

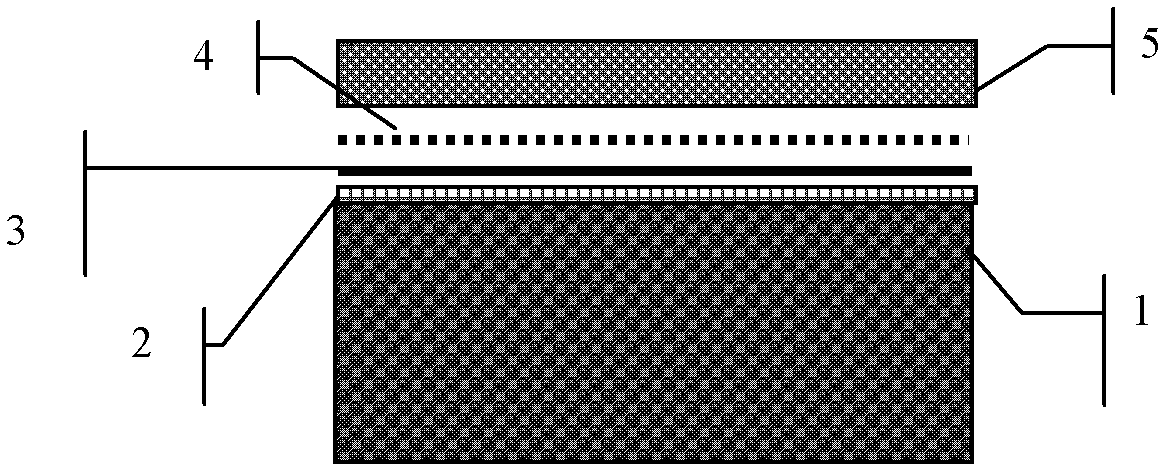

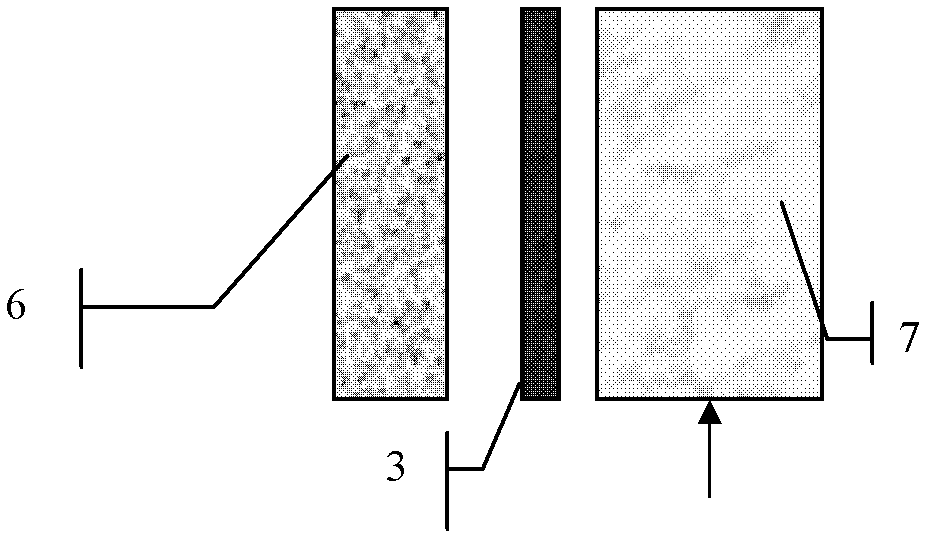

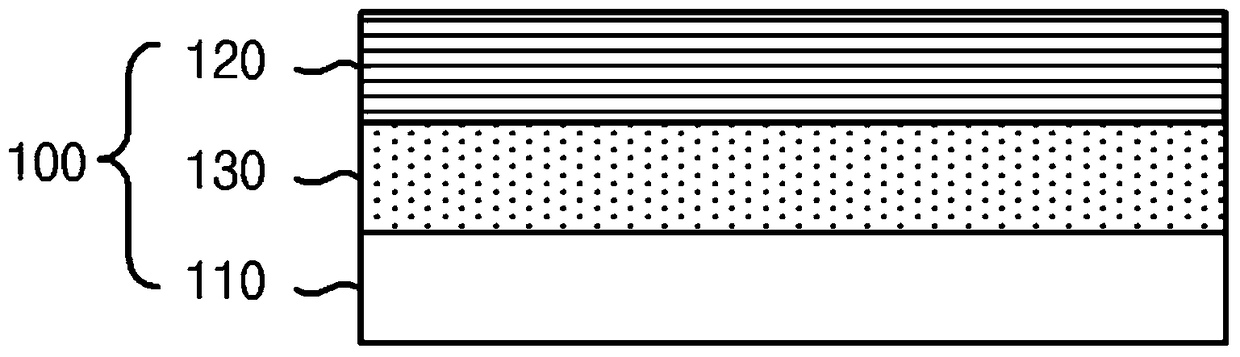

Gas barrier laminate

InactiveCN107531036AExcellent gas barrier propertiesExcellent interlayer adhesionSynthetic resin layered productsMaterial analysis by optical meansPolyamine CompoundMicrometer

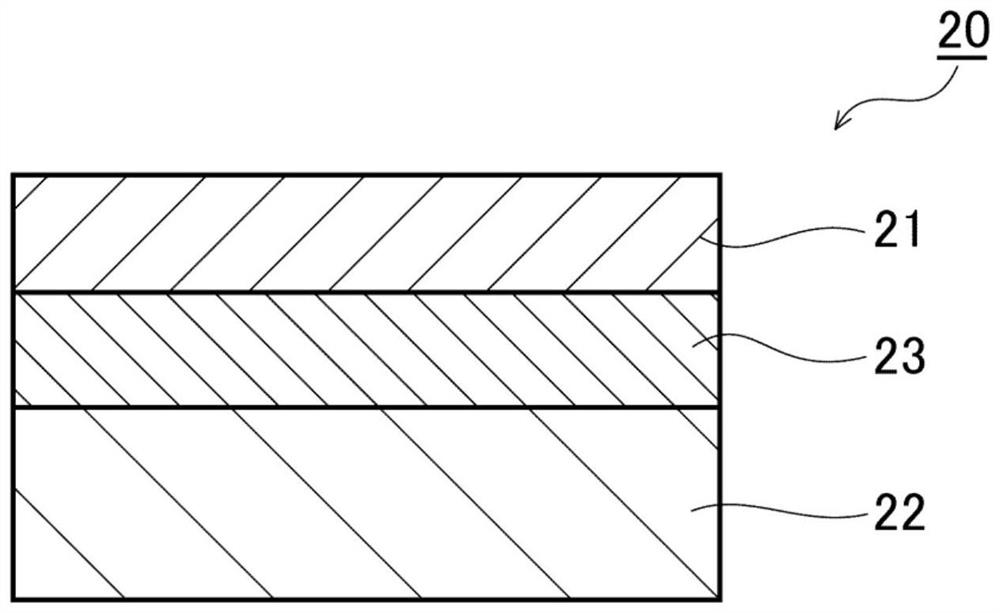

A gas barrier laminate (100) according to the present invention is provided with: a base layer (101); and a gas barrier polymer layer (103) which is provided on at least one of the surfaces of the base layer (101), is formed by heating a mixture containing a polycarboxylic acid and a polyamine compound, and has a thickness of 0.01-0.45 micrometers.

Owner:MITSUI CHEM TOHCELLO INC

Composite waterproof adhesive layer and preparation method thereof

ActiveCN102433817BImprove waterproof performanceImprove adhesionIn situ pavingsGlass fiberCrack resistance

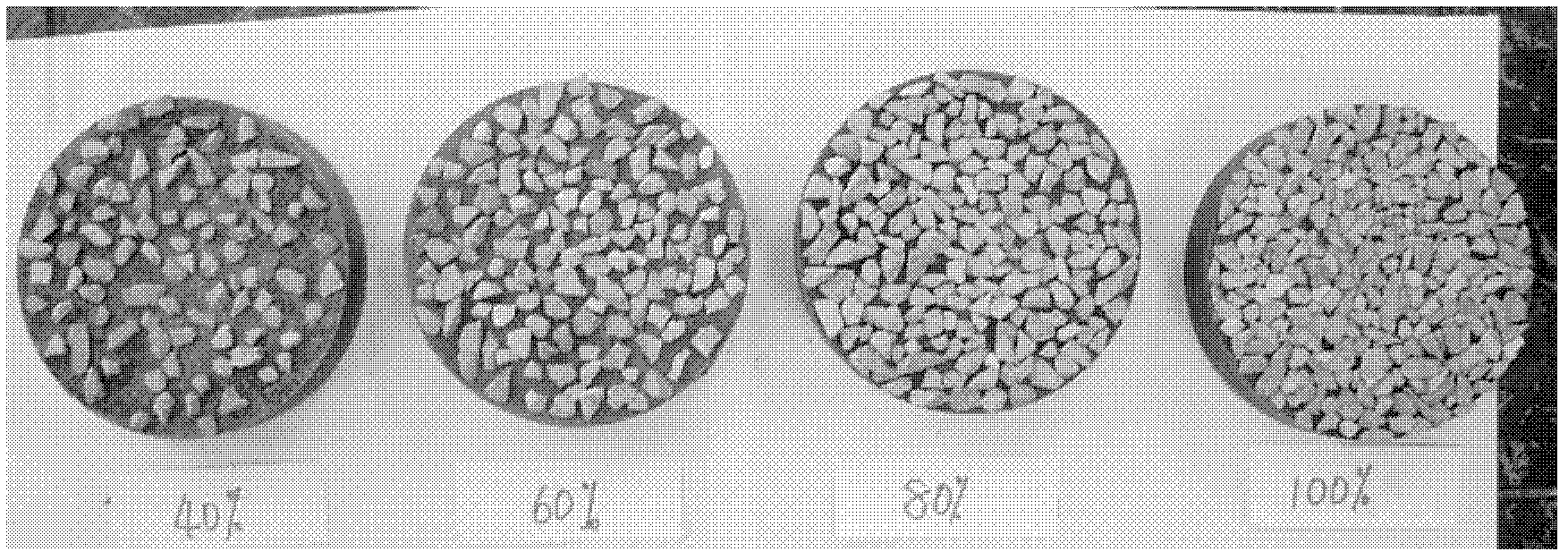

The invention relates to a ''composite waterproof adhesive layer and a preparation method thereof'', and belongs to the technical field of road construction. The composite waterproof adhesive layer comprises the following three structural layers from bottom to top: a glass fiber geogrid layer, a rubber asphalt layer and a single grain diameter gravel layer; the glass fiber geogrid is formed by bidirectional warp knitting, the longitudinal and transverse tensile strength at break in each linear meter is not less than 25kN / m, and the longitudinal and transverse elongation at break is not more than 4 percent; the rubber asphalt is high-viscosity asphalt, and the spray value is 2.0 to 2.6kg / m<2>; and the grain diameter range of the single grain diameter gravel is 13.2 to 19 millimeters, the single grain diameter gravel exceeding the grain diameter range is not more than 10 percent, and the spread area is 60 to 85 percent. The composite waterproof adhesive layer has strong bonding capacity with an upper bearing layer or a lower bearing layer, can integrally improve the adhesion and the waterproof performance among pavement structure layers, and obviously improves the integral cracking resistance of the pavement structure.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

Cover film and electronic component package using same

PendingCN114007862AExcellent interlayer adhesionFlexible coversWrappersPolymer scienceElectronic component

The present invention is a cover film having at least a substrate layer and a sealant resin layer. The sealant resin layer is formed such as to be in contact with one surface of the substrate layer, or is formed on an intermediate resin layer that is in contact with one surface of the substrate layer. The intermediate resin layer in contact with the substrate layer or the sealant resin layer in contact with the substrate layer contains an epoxidized fatty acid or a derivative thereof. The cover film has excellent interlayer adhesiveness without using an anchor coating agent.

Owner:DENKA CO LTD

foundation waterproof structure

ActiveCN107208387BShorten construction timeExcellent interlayer adhesionIn situ pavingsSynthetic resin layered productsCarbamateStructural engineering

The problem to be solved by the present invention is to provide a foundation waterproof structure having excellent interlayer adhesion between a urethane waterproof material layer and an asphalt pavement layer. The invention provides a foundation waterproof structure, which is characterized in that a foundation layer (i), a urethane waterproof material layer (ii), a urethane primer layer (iii), and a free radical layer are sequentially stacked from bottom to top. An adhesive layer (iv) obtained by curing the curable composition, and an asphalt pavement layer (v). The urethane waterproof material layer and the asphalt pavement layer in the foundation waterproof structure of the present invention have excellent interlayer adhesion. In addition, since the foundation waterproof structure of the present invention uses a radical curable composition excellent in normal temperature drying properties for the adhesive layer, the construction time of the foundation waterproof structure can be shortened.

Owner:DIC CORP

laminated tube

ActiveCN105517789BImprove reliabilityImprove use valueSynthetic resin layered productsVehicle componentsElastomerCarboxyl radical

Owner:UBE IND LTD

Retardation film and image display device provided with the retardation film

ActiveCN105431752BOrientation inductionExcellent interlayer adhesionPolarising elementsNon-linear opticsMethacrylatePolymer science

The present invention provides a retardation film with extremely high adhesion between layers and an image display device provided with the retardation film. The retardation film of the present invention is a retardation film having a liquid crystal layer and a primer layer joined by a chemical bond formed by at least one of hydroxyl groups and carboxyl groups on the surface of the primer layer and existing in the liquid crystal layer. It is formed by the isocyanate group and (meth)acrylate group at the end of the adhesion enhancer contained.

Owner:DONGWOO FINE CHEM CO LTD

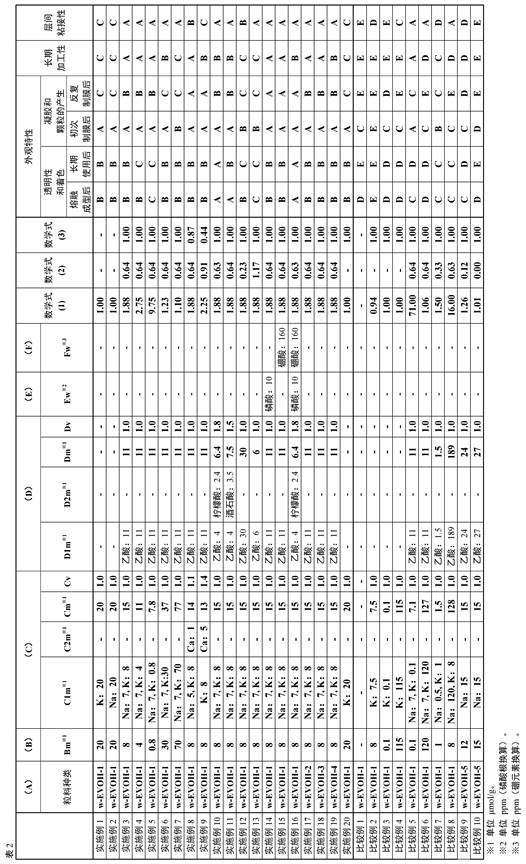

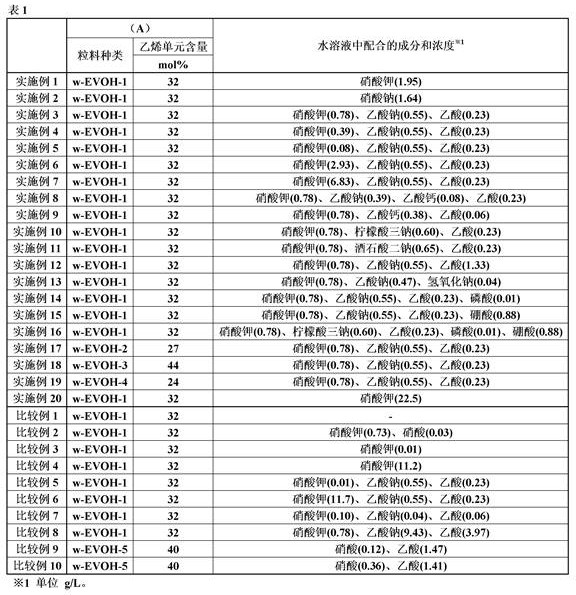

Resin composition, its production method and multilayer structure

ActiveCN108026347BExcellent appearance characteristicsExcellent long-term processabilitySynthetic resin layered productsPhysical chemistryCarboxylic acid

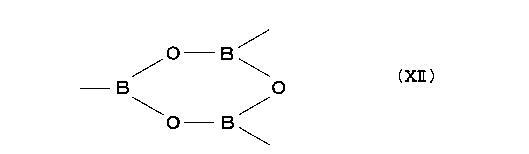

The present invention is a resin composition comprising: EVOH (A), component (B) containing at least any one of nitric acid and nitrate ions, and metal ions (C), wherein the content Bm of the component (B) is 0.5 μmol / g to 100 μmol / g, the content Cm of the metal ion (C) is 2 μmol / g to 120 μmol / g, and the content Bm of the component (B) is equal to the metal ion (C) )’s content Cm and its average valence Cv satisfy the following formula (1), and when the component (D) containing at least any one of carboxylic acid and carboxylate ion is contained, the aforementioned Bm, the aforementioned Cm, the aforementioned Cv, The content Dm of the aforementioned component (D) and the average valence Dv thereof satisfy the following formula (2). (Cv×Cm) / Bm≥1.0・・・(1) ((Cv×Cm)‑Bm) / (Dv×Dm)≥0.2・・・(2).

Owner:KURARAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com