Resin composition, its production method and multilayer structure

A technology of resin composition and manufacturing method, applied in synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of reduced appearance characteristics, prone to coloring, thermal degradation, etc. Adhesion, good appearance, excellent long-term processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0149] Hereinafter, the present invention will be further described in detail through examples. In Examples and Comparative Examples described below, analysis and evaluation were performed by the methods shown below.

[0150] (1) Determination of moisture content of water-containing EVOH pellets

[0151] Using a halogen moisture analysis device, under the conditions of a drying temperature of 180° C., a drying time of 20 minutes, and a sample weight of 10 g, the moisture content of the water-containing EVOH pellets was measured by a heating and dry weight measurement method. The water content of hydrous EVOH shown below is mass % on the basis of dry EVOH.

[0152] (2) Ethylene unit content and saponification degree of EVOH (A)

[0153] Dried EVOH pellets were dissolved in dimethyl sulfoxide (DMSO)-d containing tetramethylsilane as an internal standard and trifluoroacetic acid (TFA) as an additive 6 , use a 500MHz 1 H-NMR was measured at 80° C., and the ethylene unit conten...

Synthetic example 1

[0223] In synthetic example 1, the feed intake of vinyl acetate and methyl alcohol during the polymerization of EVAc is changed to 85.2kg, 32.3kg respectively, and reaction tank pressure is changed to 2.9MPa, and initiator solution (2.5g / L concentration of AMV (methanol solution) was changed to 310 mL at the start of polymerization, and the continuous addition amount of the initiator solution was changed to 950 mL / hr, except that, by the same operation as Synthesis Example 1, a methanol solution of EVAc was obtained. The reaction time during the polymerization reaction was 5 hours, and the polymerization rate was 40%.

[0224] Next, saponification and washing were performed in the same manner as in Synthesis Example 1, except that the addition amount of the alkali solution was changed to 31.1 L and the addition amount of acetic acid at the time of neutralization was changed to 3.7 kg, to obtain a roughly dried EVOH product.

Embodiment 2~16 and comparative example 1~8

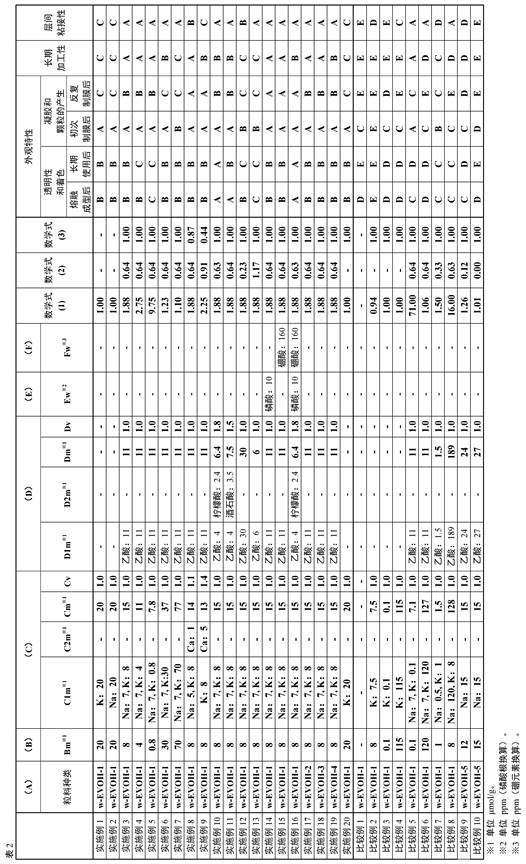

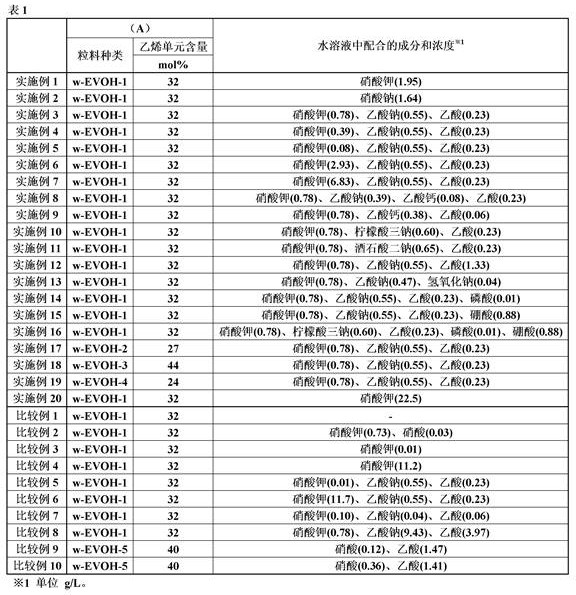

[0243]Dry EVOH pellets were obtained in the same manner as in Example 1 except that the components and concentrations blended in the aqueous solution were changed as shown in Table 1. Table 2 shows the results of the analysis and evaluation described above for each of the obtained pellets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com