Flame retardant polycarbonate resin composition

A technology of polycarbonate resin and composition, applied in the field of flame retardant polycarbonate resin composition, can solve the problems of poor flame retardancy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

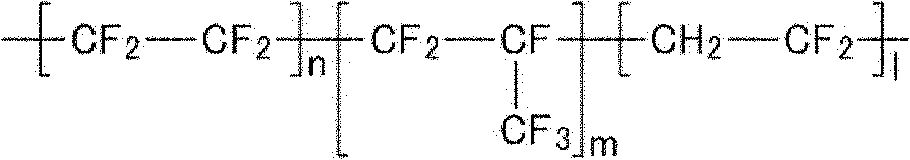

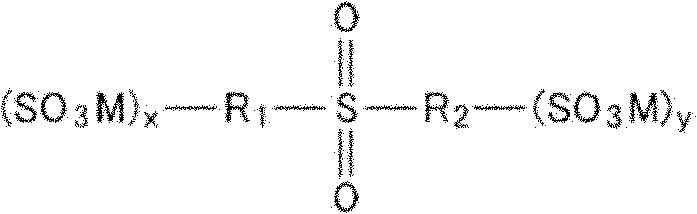

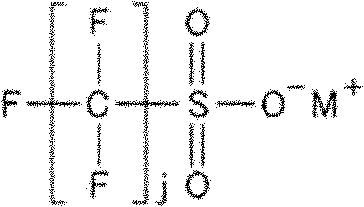

Method used

Image

Examples

Embodiment 1 and 2 and comparative example 1 to 6

[0112] The components were mixed in a typical mixer according to the compositions shown in Table 1 below. The mixture was extruded using a twin-screw extruder with L / D = 35 and Φ = 45 mm, and the extrudate was made into a pellet shape.

[0113] A 10-ounce injection molding apparatus and the prepared pellets were used to manufacture test specimens for measuring mechanical properties and evaluating flame retardancy at injection temperatures of 280°C to 300°C.

[0114] (Table 1)

[0115] (Unit: parts by weight)

[0116]

[0117] The samples manufactured as above were individually preserved for 48 hours at 23° C. and a relative humidity of 50%, and their mechanical properties were evaluated. The results are given in Table 2 below.

[0118] (1) Flame retardancy: Evaluation was performed using a sample with a thickness of 1.5 mm in accordance with the regulations of UL-94.

[0119] (2) Notched Izod Impact Strength: Measured using 1 / 8" specimens according to ASTM D256 specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com