Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Ensure spray uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

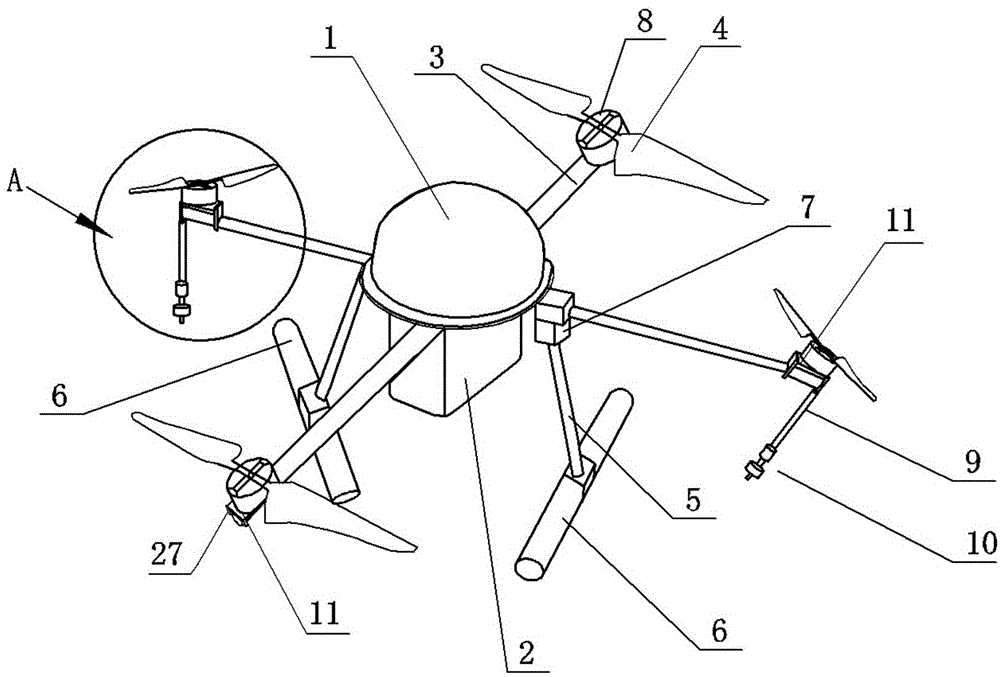

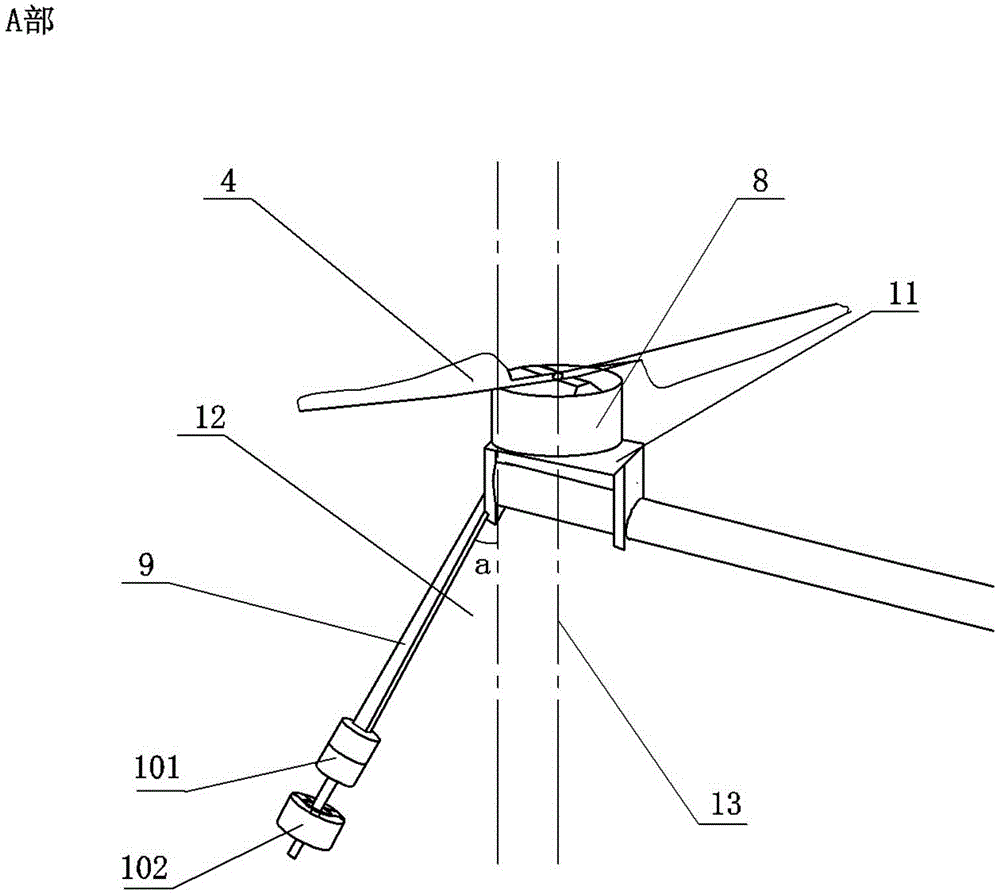

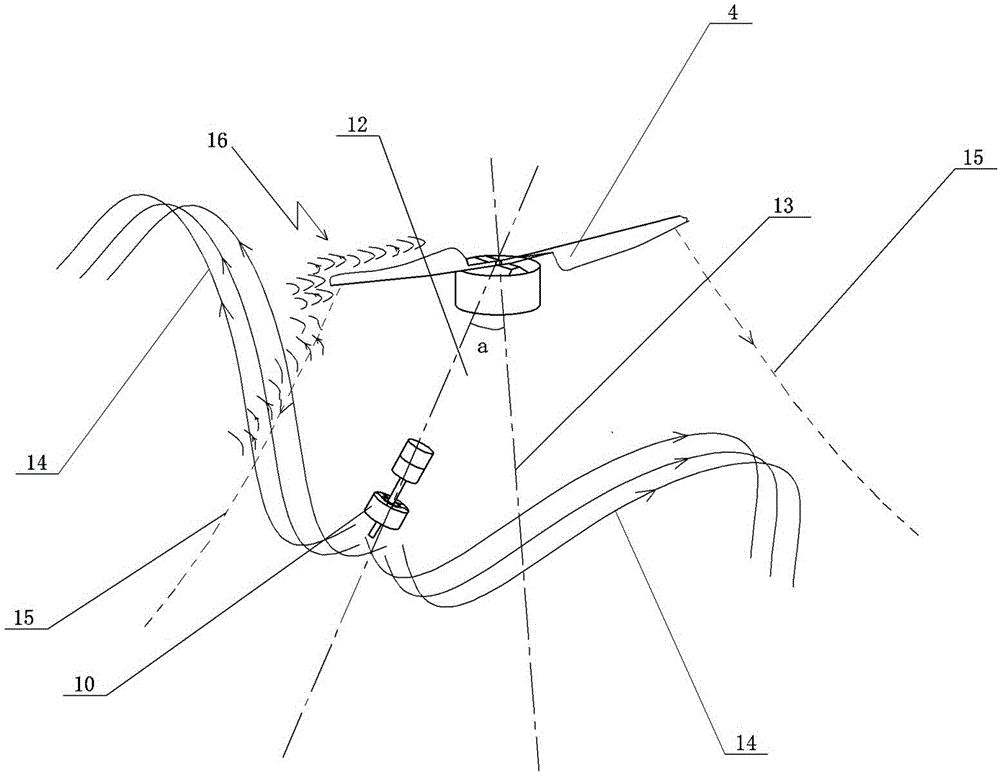

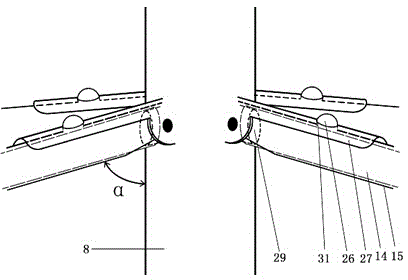

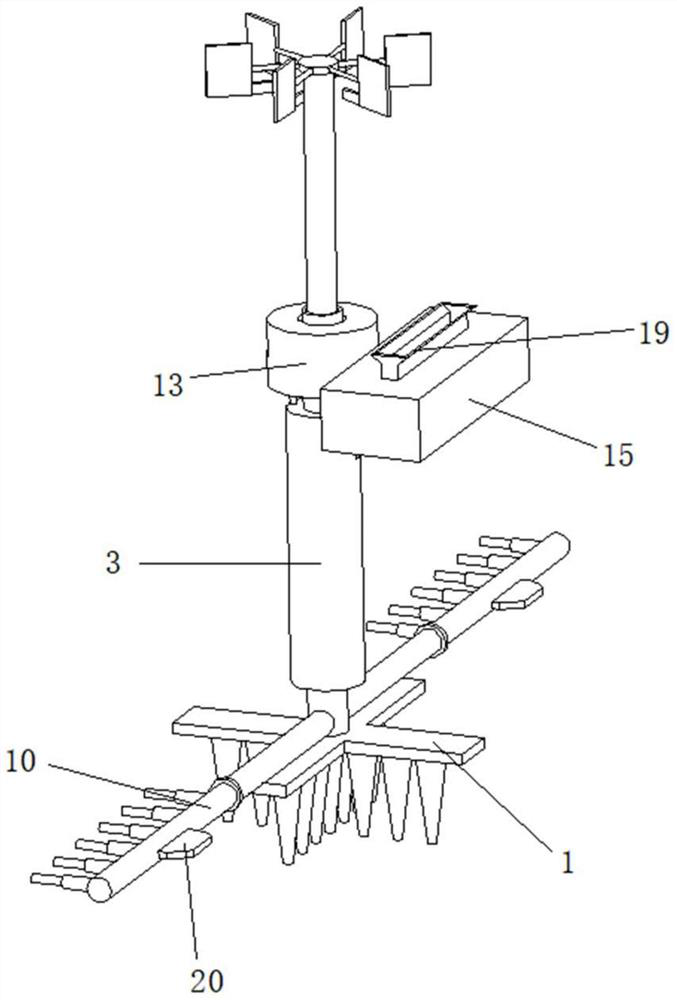

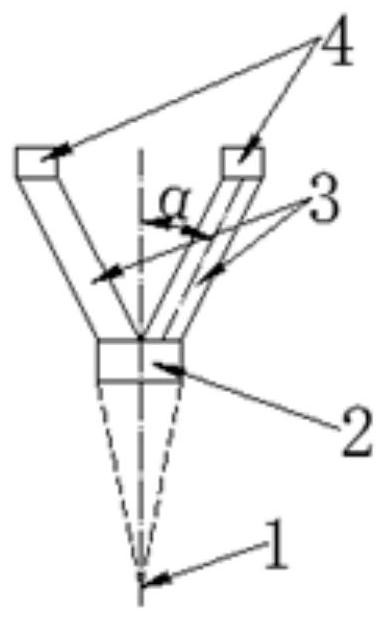

Upward-anticyclone UAV (unmanned aerial vehicle) pesticide sprayer

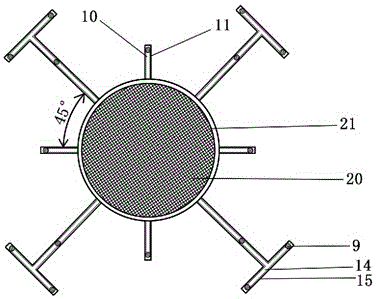

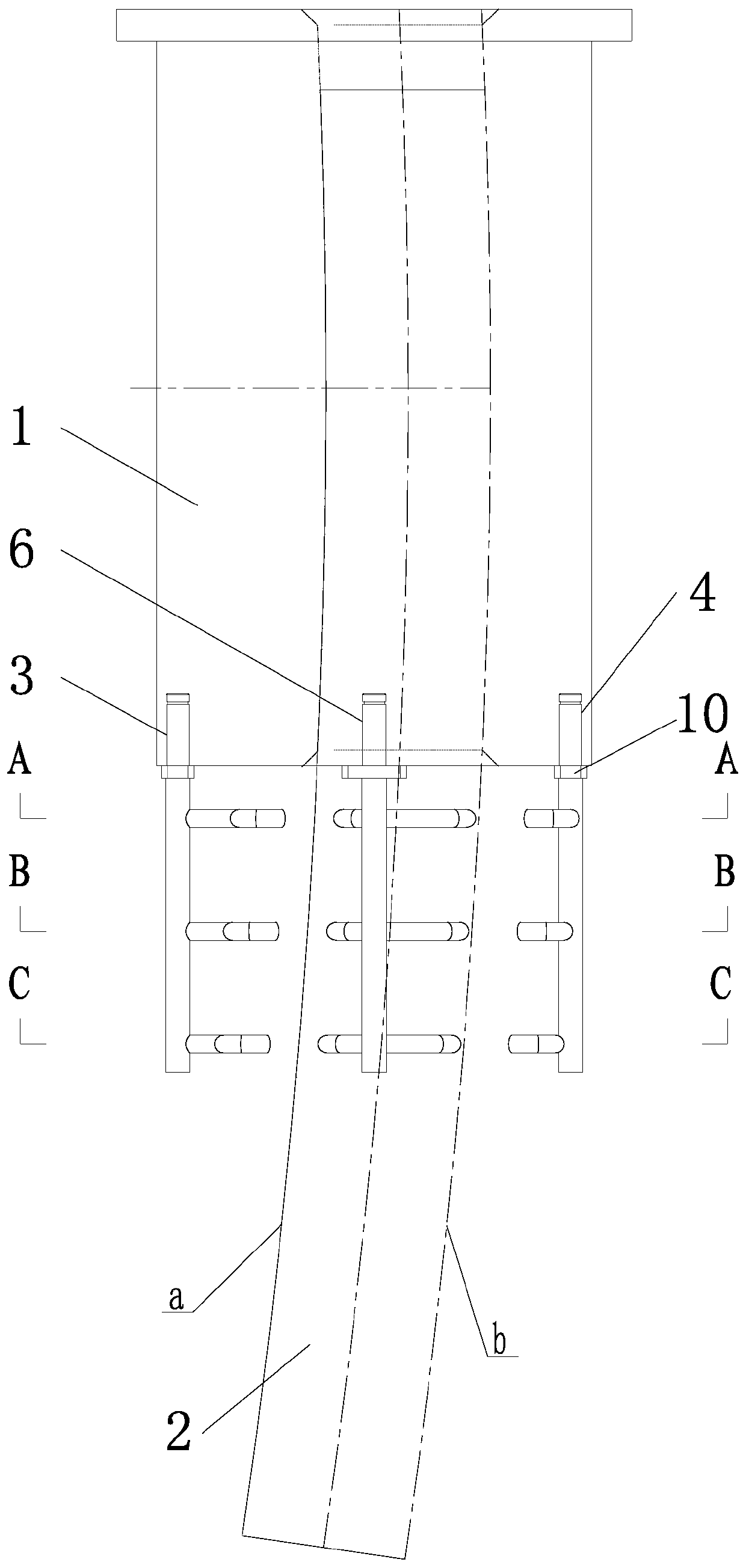

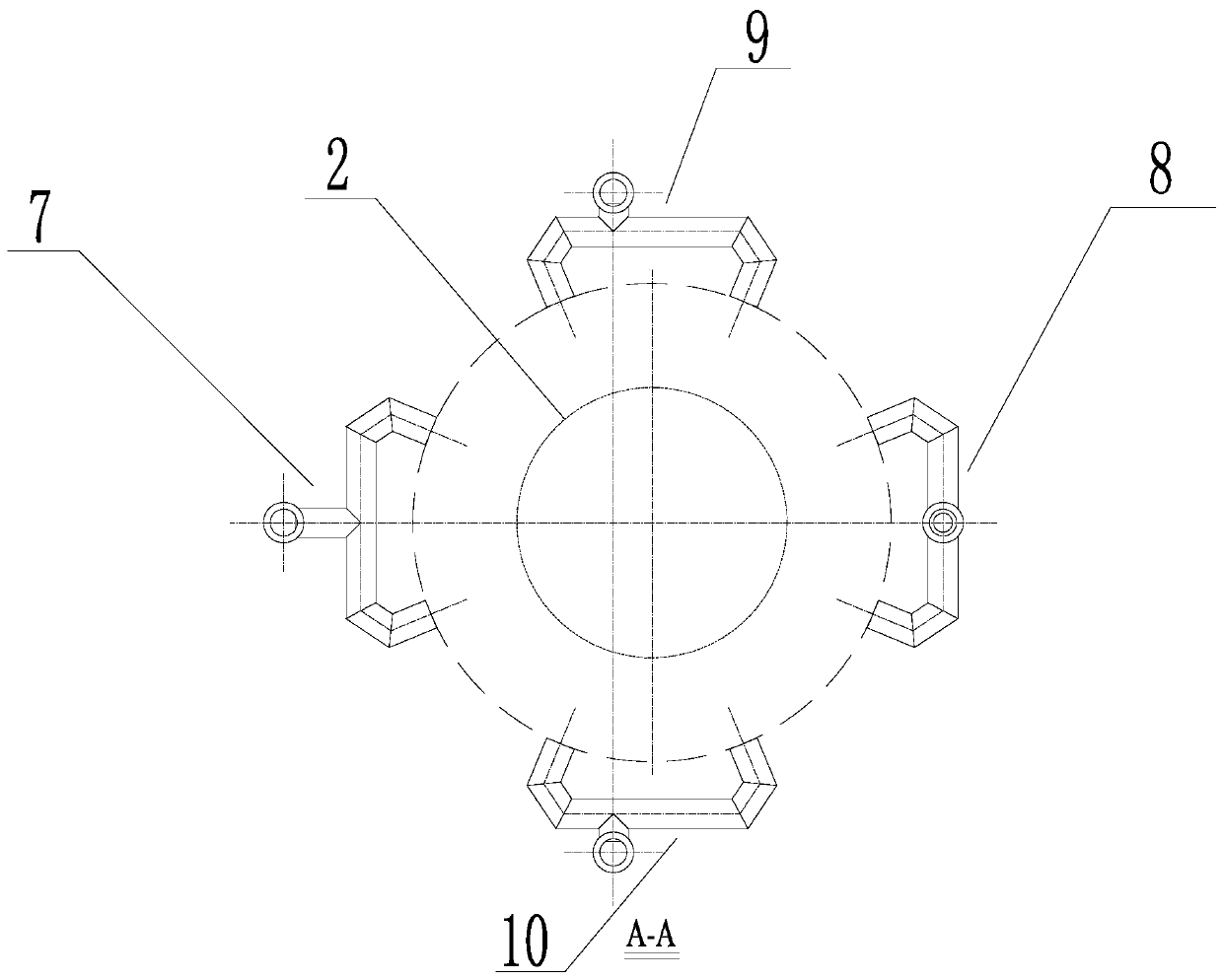

The invention discloses an upward-anticyclone UAV (unmanned aerial vehicle) pesticide sprayer comprising a support, a control unit, a propeller and a pesticide box. N supporting rods are symmetrically and evenly fixed around the support. A supporting base is fixed above the upper ends of the supporting rods. A propeller motor is mounted on the supporting base. The propeller is provided above a motor. The outer ends of at least two of the supporting rods are provided with spray rods which are adjustable, below the propeller. A nozzle is mounted on the lower portion of each spray rod and linearly mounted on the spray rod. The included angle a made by the axes of every spray rod and the propeller is 30 to 45 degrees. The upward-anticyclone UAV pesticide sprayer has the advantages that after sprayed out of the nozzles, pesticide particles are not directly sprayed to the ground but brought outside by air to the top of the propeller, pesticide is sprayed up and rotated down and is sprayed in parabolic curves, mists are evenly distributed by the air generated by the propeller and can be sprayed wider, spraying uniformity is guaranteed, and pesticide effect is greatly improved.

Owner:广西乐维科技有限公司

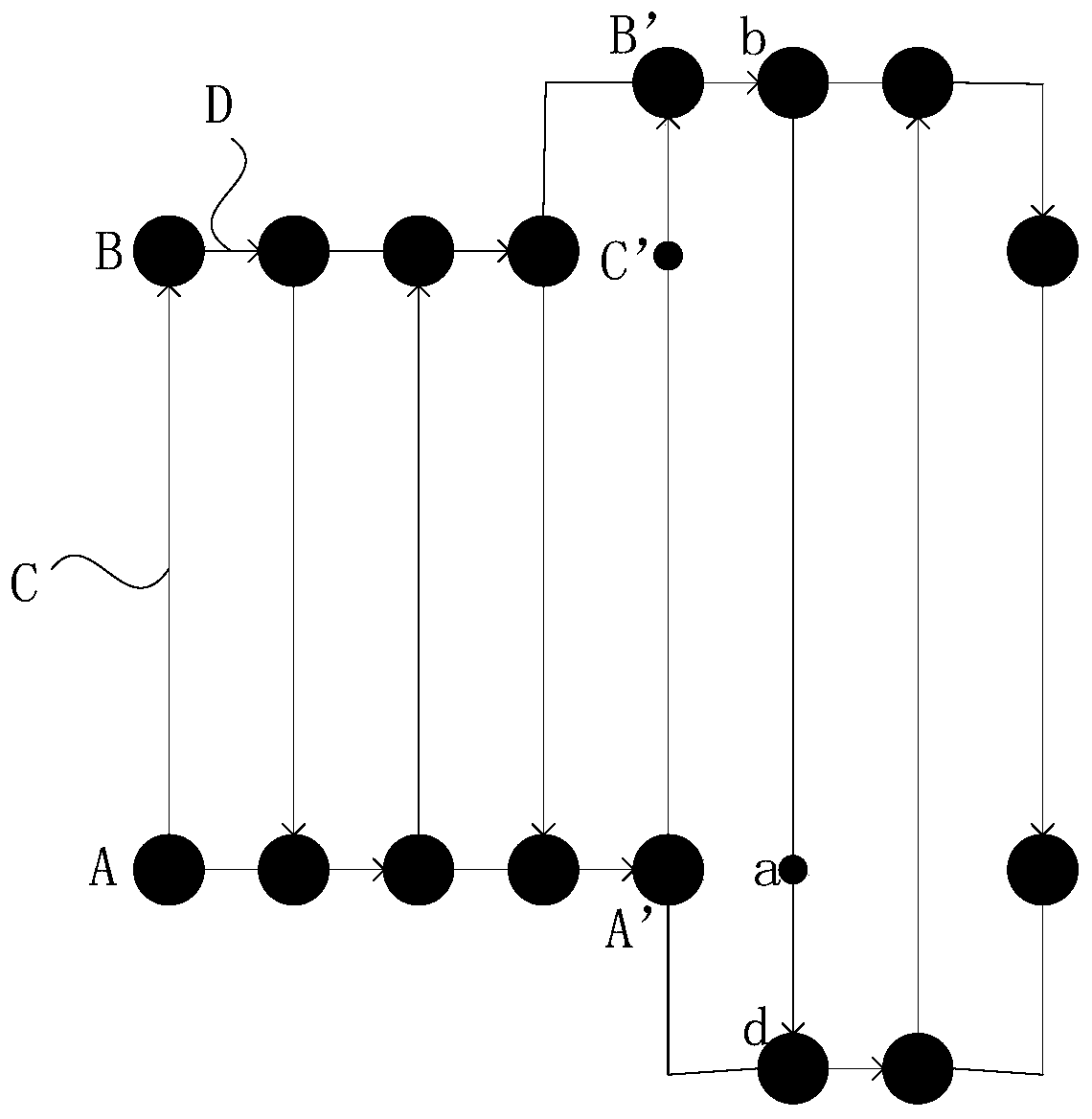

Plant protection operation method for unmanned aerial vehicle and unmanned aerial vehicle

ActiveCN109240337AEnsure spray uniformityImprove spraying effectAircraft componentsRemote controlled aircraftUncrewed vehicleRoute planning

Embodiments of the invention disclose a plant protection operation method for an unmanned aerial vehicle and the unmanned aerial vehicle. The plant protection operation method for the unmanned aerialvehicle comprises the following steps of carrying out flight route planning according to an operation area and acquiring a plant protection operation route; carrying out spraying according to the acquired plant protection operation route; and acquiring the flight speed in real time in a spraying process, and adjusting the spraying amount according to the flight speed. According to the embodimentsof the invention, the spraying uniformity can be ensured, the spraying effect can be optimized, and the pesticide utilization rate can be improved.

Owner:TOPXGUN NAN JING ROBOTICS CO LTD

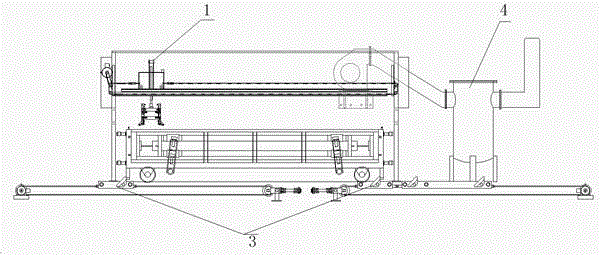

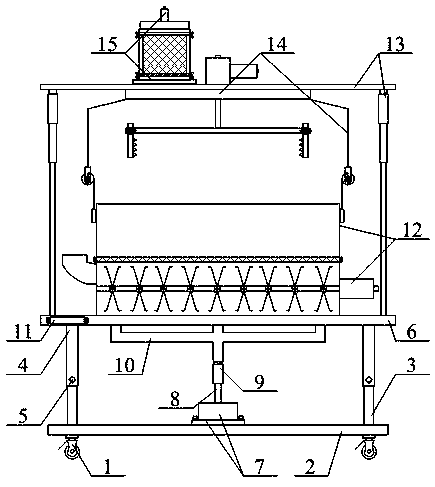

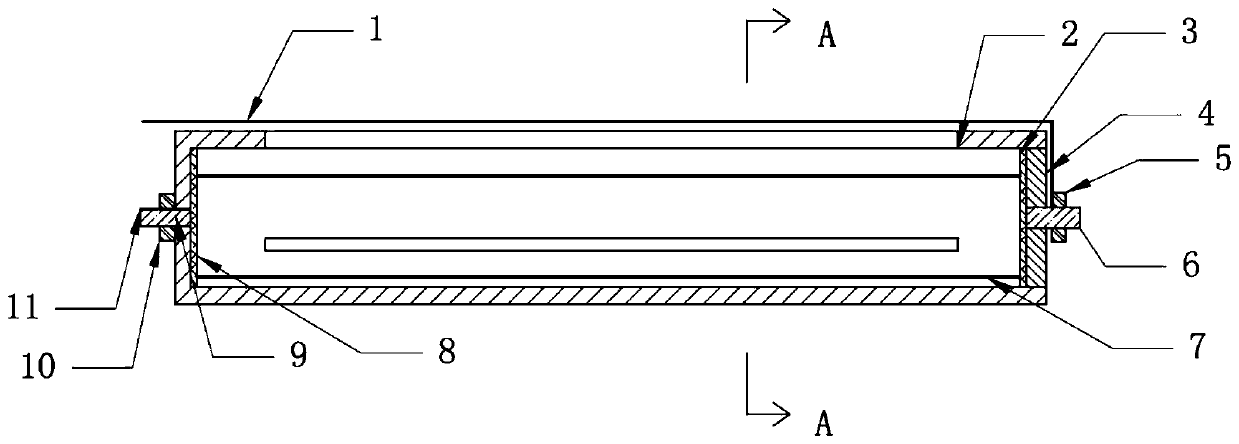

Automatic mold oil spraying system for mold frame

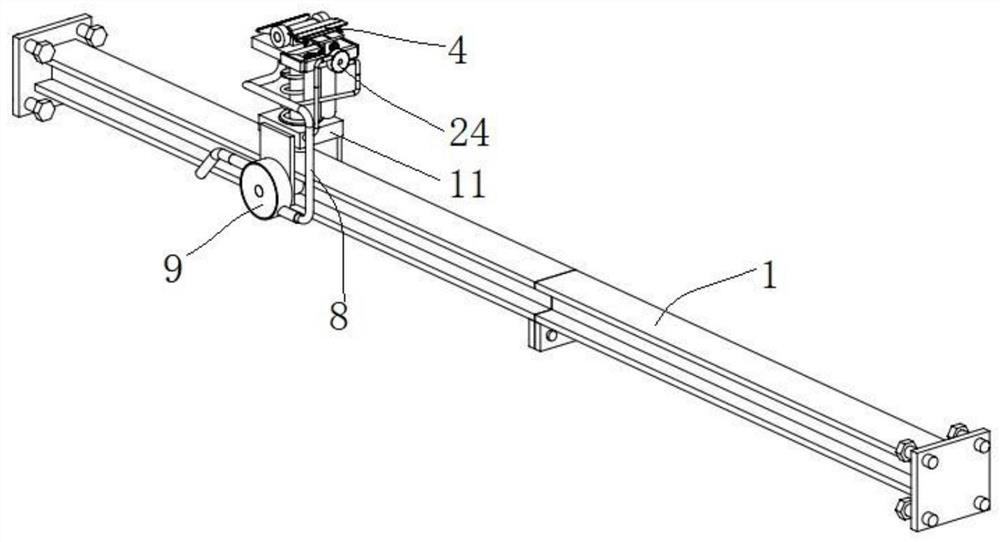

InactiveCN104802292AReduce wasteIncrease the number ofCeramic shaping apparatusSprayerElectric machine

The invention discloses an automatic mold oil spraying system for a mold frame. The system comprises an oil spraying system (1), an oil supply system (2), a mold frame positioning system (3), an exhaust purification system (4) and an electric control system (5), wherein the oil spraying system (1) consists of a traveling mechanism erected on a main oil spraying system architecture (6) and a spraying mechanism; the traveling mechanism comprises a horizontal moving driving motor (7), a synchronizing wheel (8) connected with the driving motor (7), a synchronous belt (9), a rail (10) and a horizontal moving trolley (11); the horizontal moving trolley (11) is connected with the synchronous belt (9) through synchronous belt connectors (12); the spraying mechanism comprises a cylinder (13) and a sprayer connected onto the cylinder (13); the sprayer comprises CYL motion control electromagnetic valves (14) fixedly arranged on a bracket (17), valve terminals (15) and front, rear, left and right rows of spraying guns (16). The system has the characteristics of uniform spraying, high controllability, high efficiency and easiness in popularization.

Owner:GUIZHOU CHANGTAIYUAN ENERGY SAVING BUILDING MATERIALS CO LTD

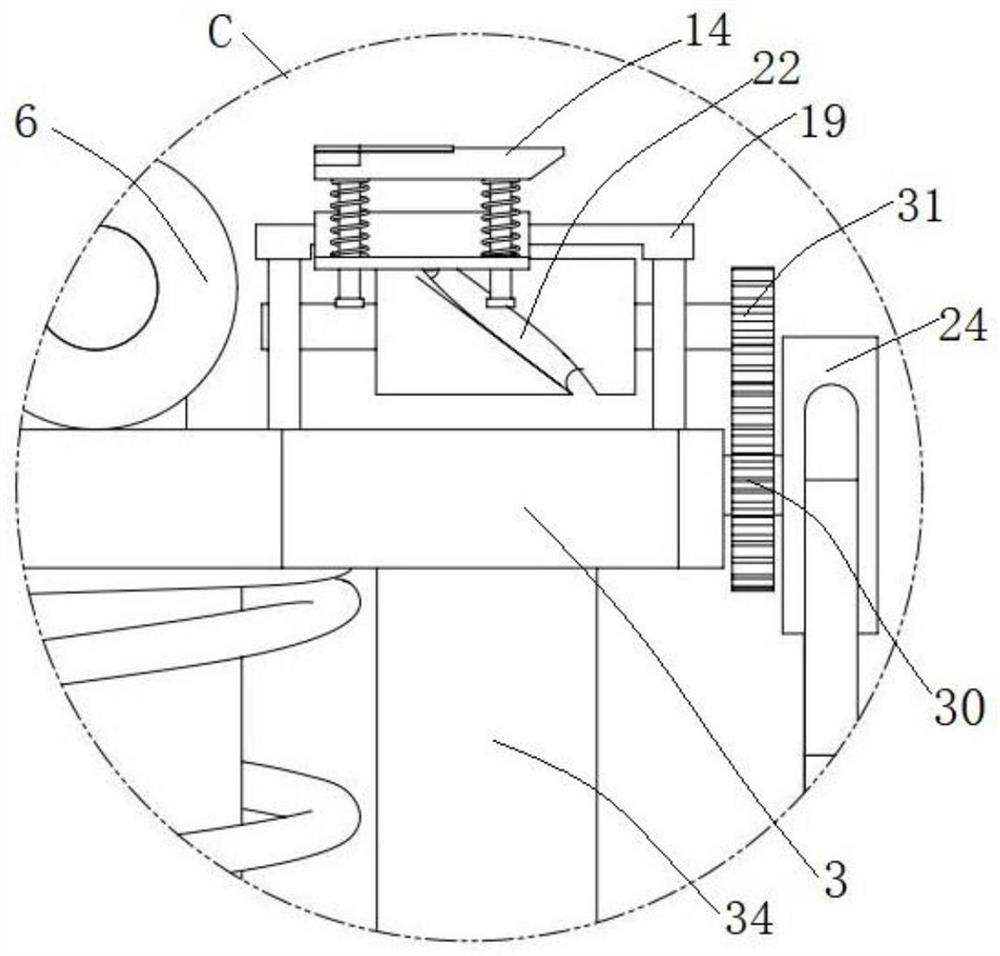

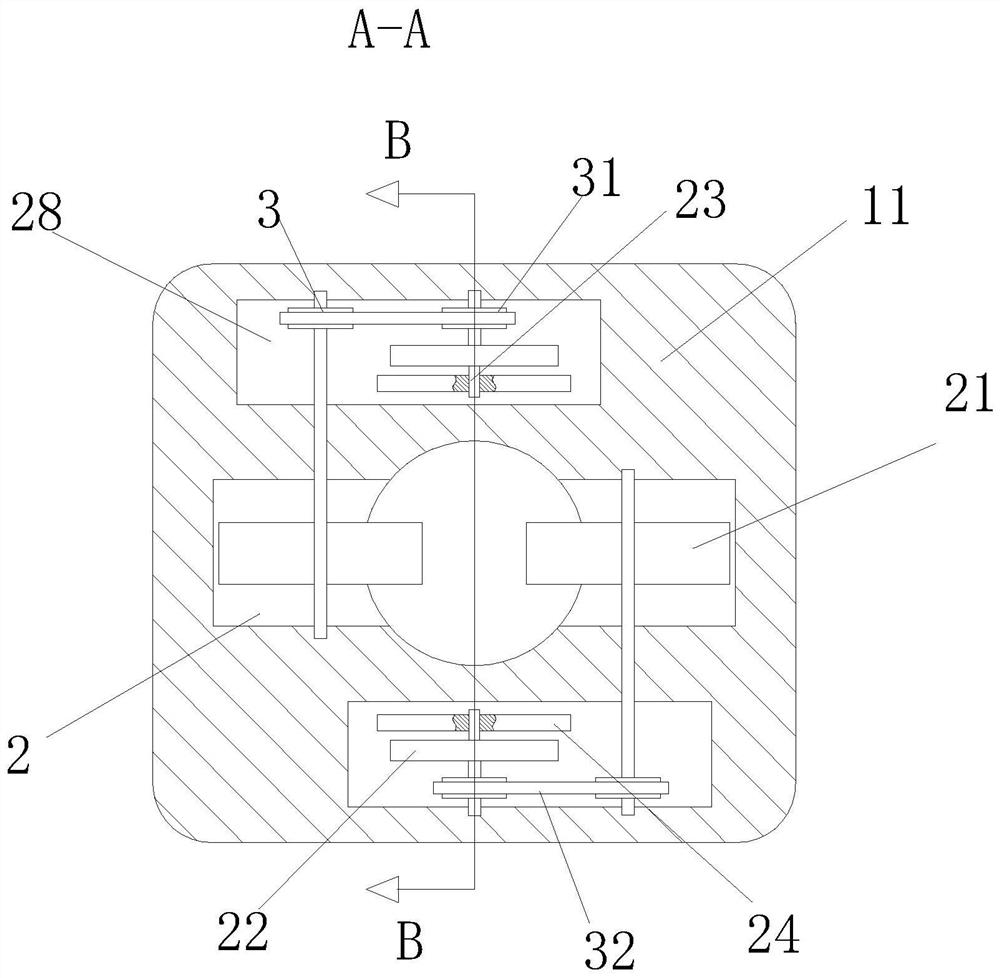

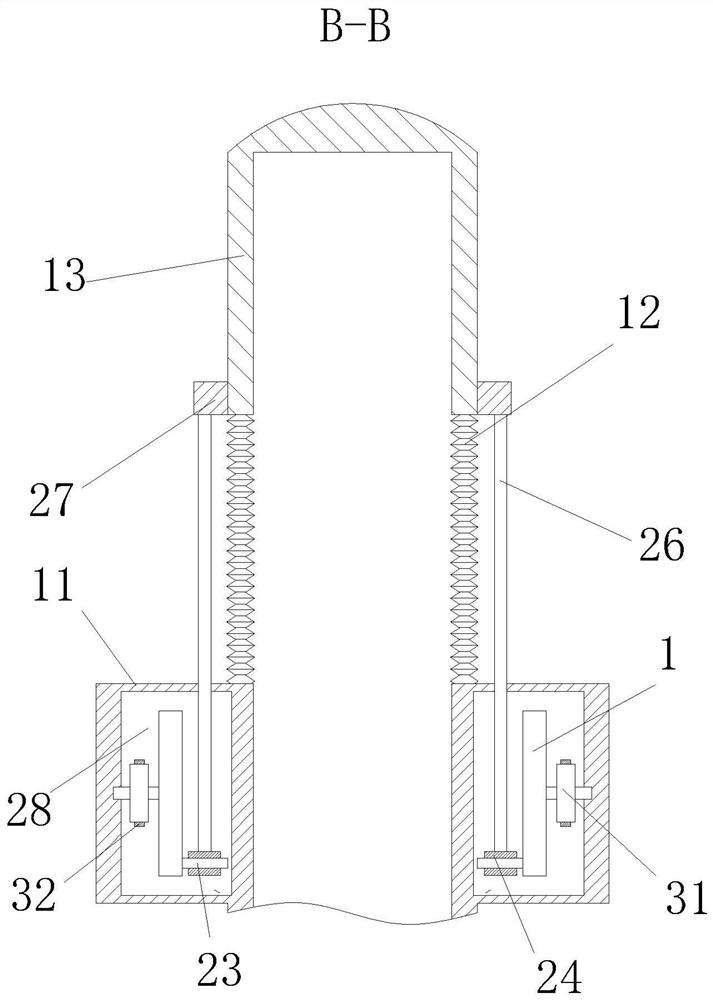

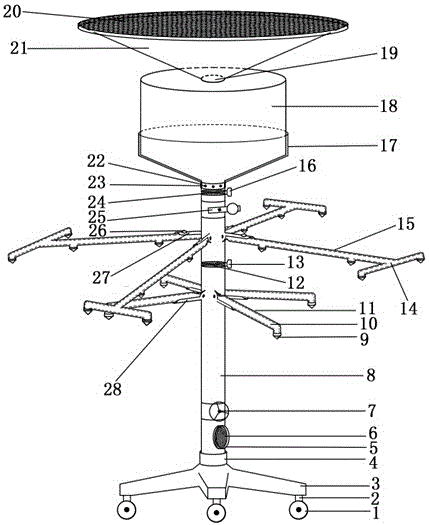

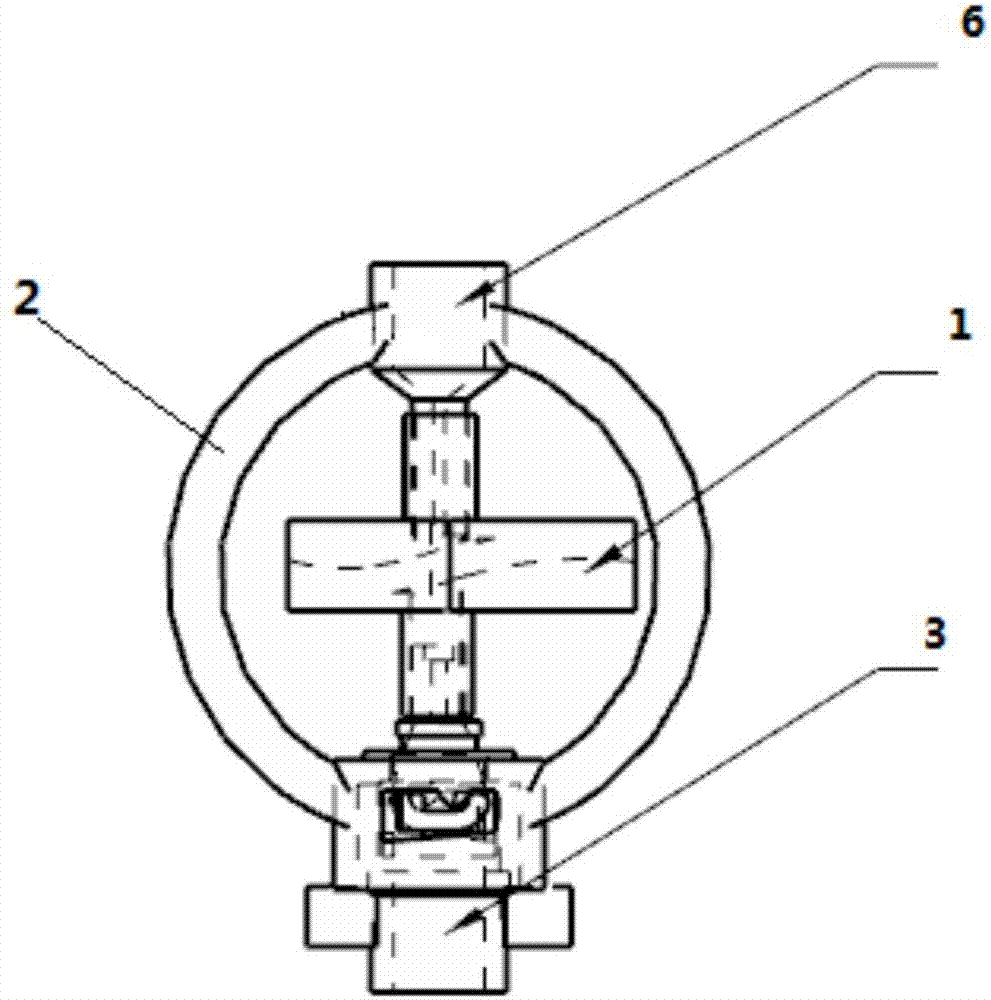

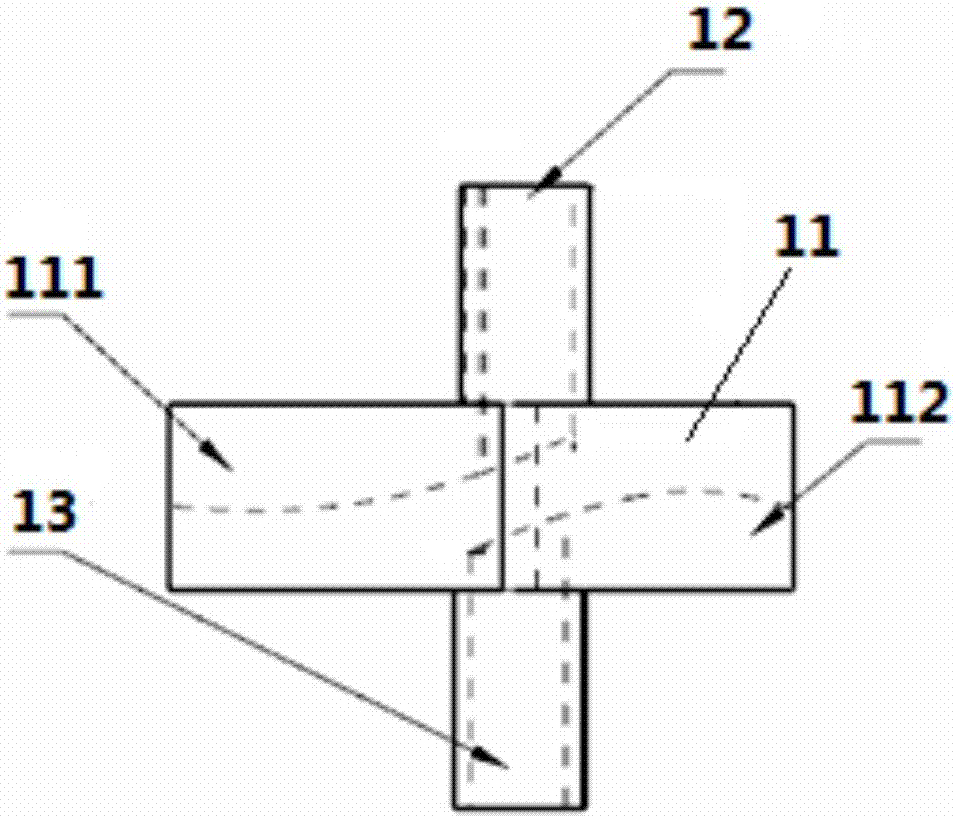

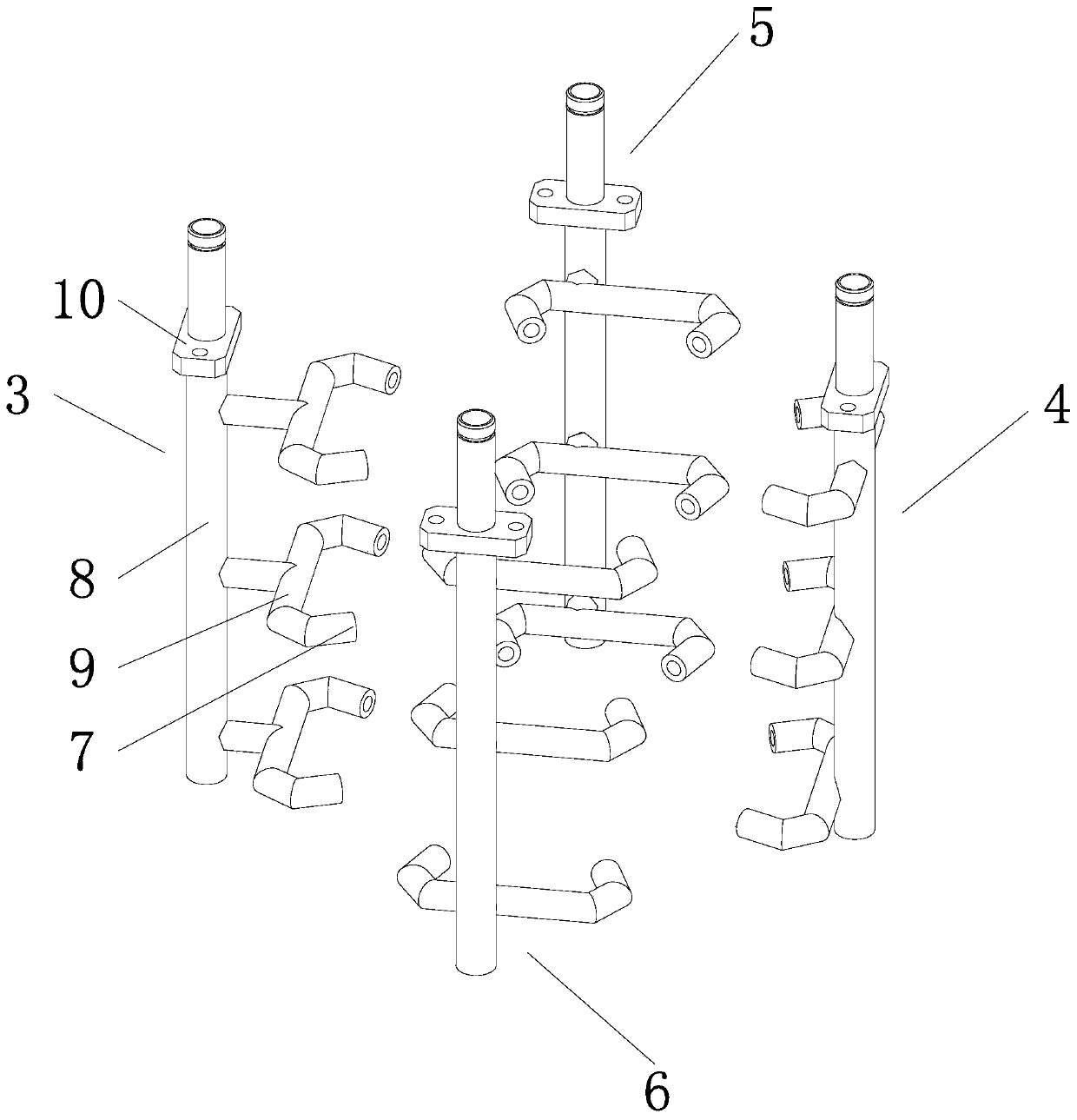

Sprinkling irrigation machine capable of collecting rainwater for compensating irrigation

ActiveCN104542191AImprove utilization efficiencyEnsure spray uniformityGeneral water supply conservationWatering devicesEngineeringWater saving irrigation

The invention relates to a sprinkling irrigation machine capable of collecting rainwater for compensating irrigation, and belongs to the technical field of water-saving irrigation of agriculture. The sprinkling irrigation machine comprises a rainwater collecting tank, a main rod, sprinkling irrigation rods, compensation rods and a base, wherein the main rod is rotated into the base through a thread opening, universal wheels are arranged under the base, one side of the lower end of the main rod is provided with a water inlet, the upper end of the main rod is provided with an upper layer and a lower layer, the four sprinkling irrigation rods are arranged at the lower layer and are movably connected with the main rod, the four compensation rods are arranged at the upper layer and are movably connected with the main rod, the top end of the main rod is communicated with the rainwater collecting tank, a support groove of the rainwater collecting tank is formed in the lower part of the rainwater collecting tank and is fixedly connected with the main rod, the upper part of the rainwater collecting tank is communicated with a conical rainwater collecting groove, a filtering net cover is arranged at the upper part of the conical rainwater collecting groove, a sprinkling nozzle is arranged at the tail end of each sprinkling irrigation rod, three sprinkling nozzles are respectively arranged at the tail end of each compensation rod and are distributed in a triangle shape, and a sprinkling nozzle is arranged at one end near the main rod. The sprinkling irrigation machine has the advantages that the operation is simple, the weight is light, the cost is low, the design structure is simple and reasonable, the practicality is high, the storage and carrying are convenient, and the sprinkling irrigation machine is suitable for being popularized and applied.

Owner:KUNMING UNIV OF SCI & TECH

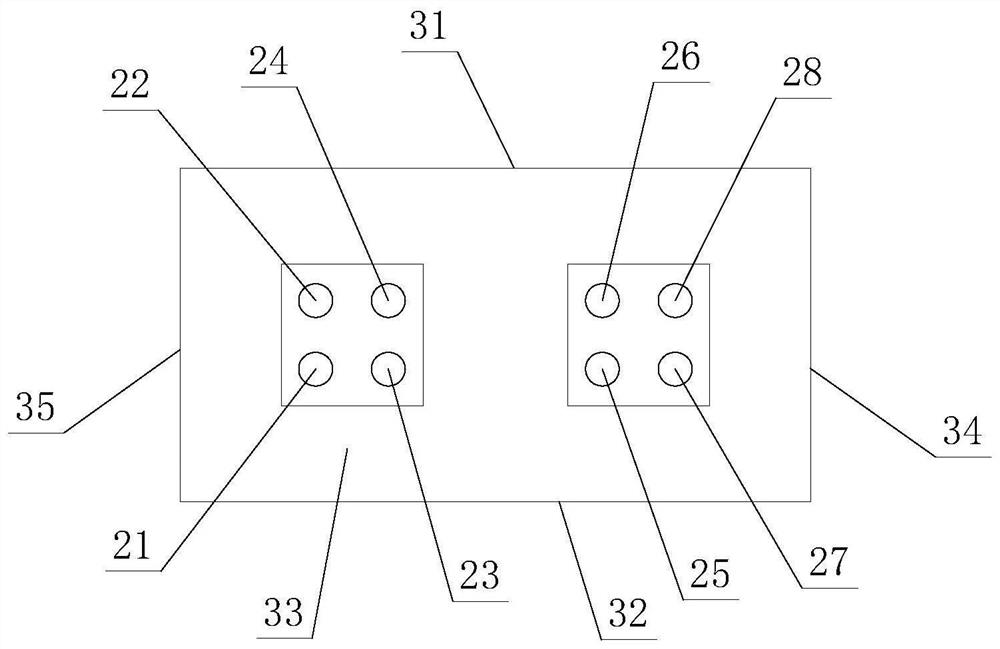

Method for spraying upper surface and outer side face of workpiece

PendingCN113680555AThe amount of coating remains consistentImprove pass rateSpraying apparatusStructural engineeringManufacturing engineering

The invention relates to a method for spraying the upper surface and the outer side face of a workpiece. The method comprises the workpiece, a conveying line for conveying the workpiece, a three-dimensional scanning system for scanning the length, the width and the height of the workpiece in the conveying process, a control system for processing scanning information of the three-dimensional scanning system, a first spraying support and a second spraying support, wherein the first spraying support and the second spraying support plan a spraying path through the control system; the first spraying support and the second spraying support transversely slide and vertically move in the workpiece conveying direction under the control of the control system; the first spraying support and the second spraying support are each provided with four spraying guns; and in the one-time conveying process of the workpiece, the four spraying guns of the first spraying support and the four spraying guns of the second spraying support spray the upper side face, the lower side face, the upper surface, the front side face and the rear side face of the workpiece respectively. By means of the method, the spraying efficiency and quality of work can be improved, meanwhile, spraying with the height larger than 5cm of the workpiece can be achieved, and practicability is high.

Owner:广东博硕涂装技术有限公司

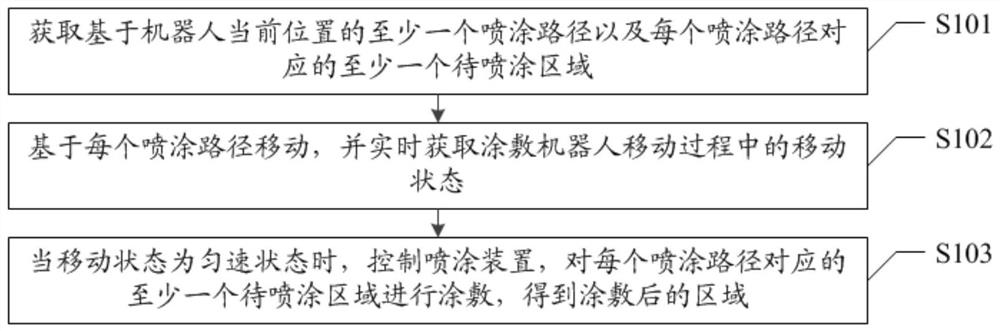

Moving coating method of spraying area and related equipment

PendingCN114798358APrevent saggingConsistent speedLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

The invention relates to the field of spraying, and provides a movable coating method for a spraying area and related equipment, which are used for improving the spraying effect. The mobile coating method is applied to a coating robot, the coating robot comprises a spraying device, and the mobile coating method for the spraying area comprises the steps that at least one spraying path based on the current position of the robot and at least one to-be-sprayed area corresponding to each spraying path are obtained; moving on the basis of each spraying path, and acquiring the moving state of the coating robot in the moving process in real time; and when the moving state is a constant-speed state, the spraying device is controlled, at least one to-be-sprayed area corresponding to each spraying path is coated, and the coated area is obtained.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

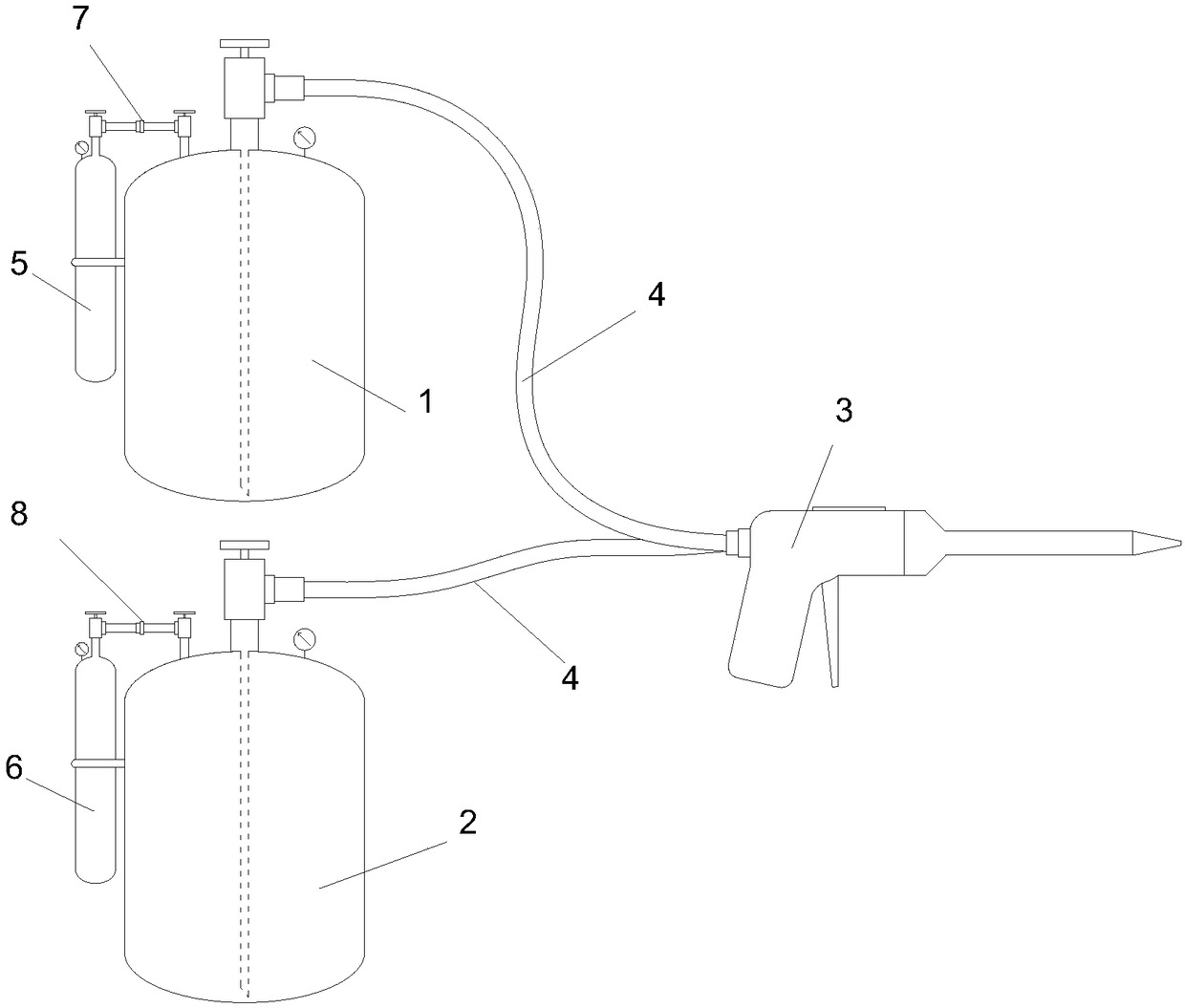

Fast sealing device used in mining and mixing spray gun of fast sealing device

PendingCN109046819AEnsure spray uniformityEnsure consistencyLiquid spraying apparatusSpray nozzleEngineering

The invention discloses a fast sealing device used in mining and a mixing spray gun of the fast sealing device. The fast sealing device comprises a first storage tank and a second storage tank, whichare connected with the mixing spray gun. The mixing spray gun comprises a gun body and a mixing spray nozzle, wherein the gun body comprises a gun grip and a gun barrel; a feeding mechanism, control mechanisms and a gun-barrel quick connector are arranged on the gun barrel; the feeding mechanism comprises a first feeding part and a second feeding part; each of the first feeding part and the secondfeeding part comprises a feeding inlet, a feeding pipe and a material bin; the two ends of each feeding pipe are respectively connected with the corresponding feeding inlet and the corresponding material bin; a discharge outlet is formed in each material bin; each control mechanism is provided with an open position and a closed position, relative to the corresponding discharge outlet; the mixingspray nozzle comprises a spray-nozzle quick connector, a pipe body and a mixing mechanism; the spray-nozzle quick connector is detachably connected with the gun-barrel quick connector; one end of thepipe body is connected with the spray-nozzle quick connector, and a mixing discharge outlet is formed in the other end of the pipe body; the mixing mechanism is mounted in the pipe body; a material-separating baffle plate is arranged between the mixing mechanism and the material bins and positioned between the discharge outlet of the material bin of the first feeding part and the discharge outletof the material bin of the second feeding part.

Owner:山西凝固力新型材料股份有限公司

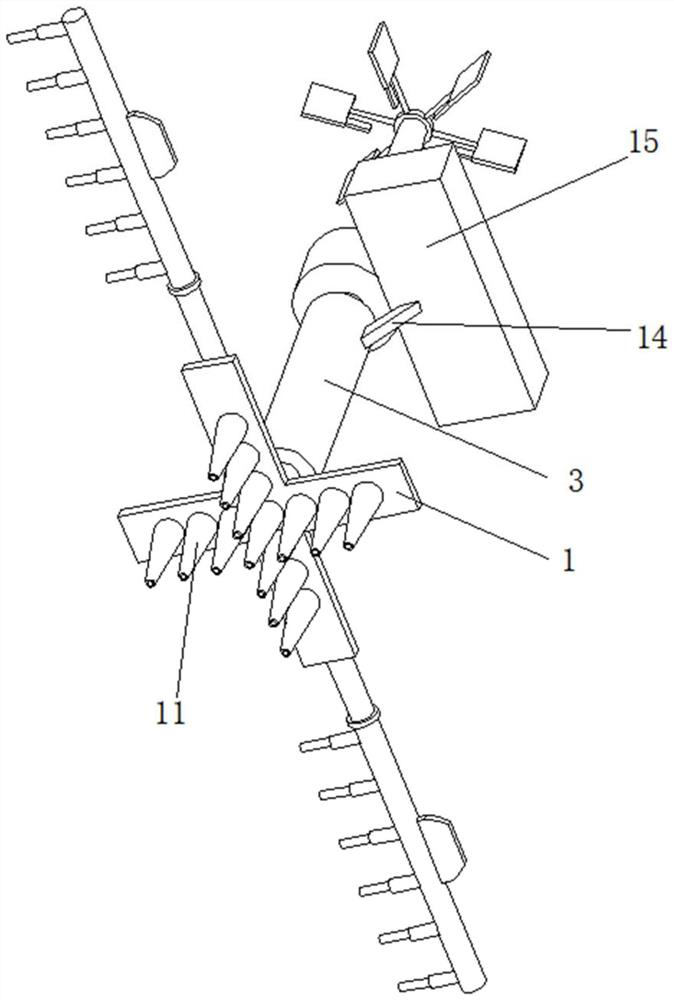

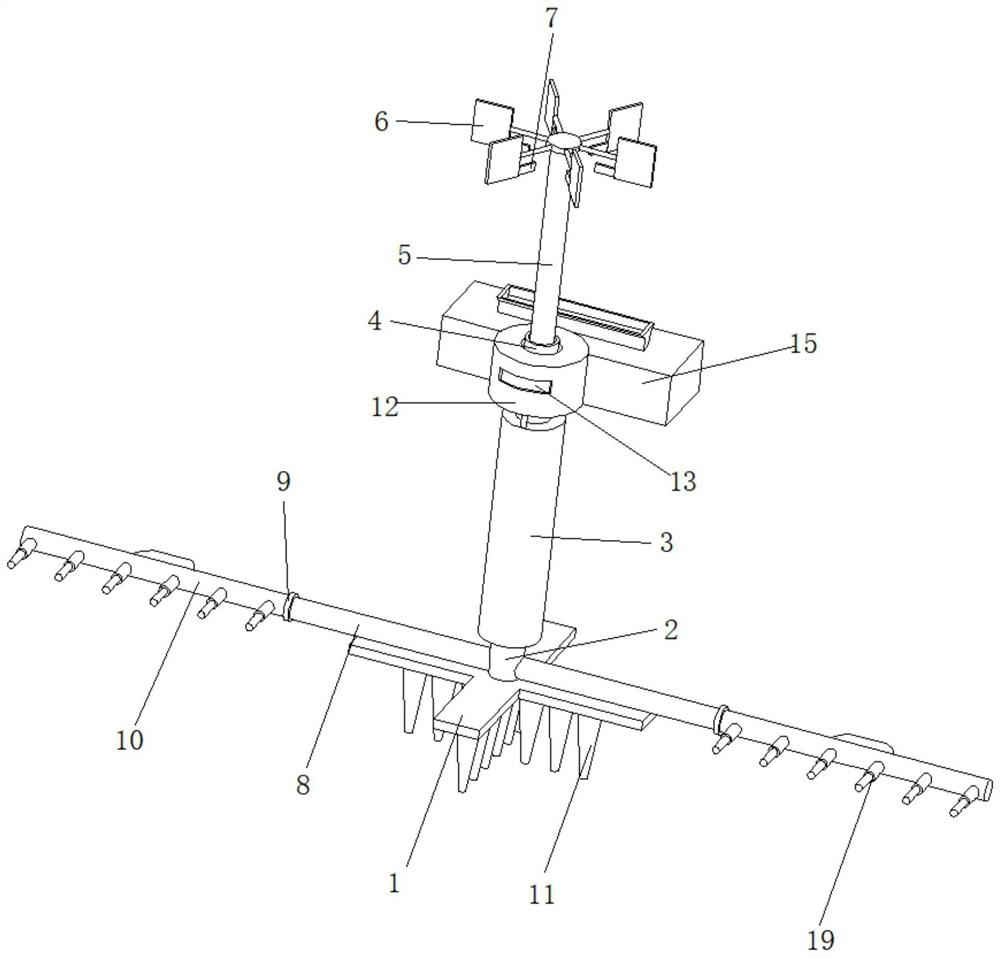

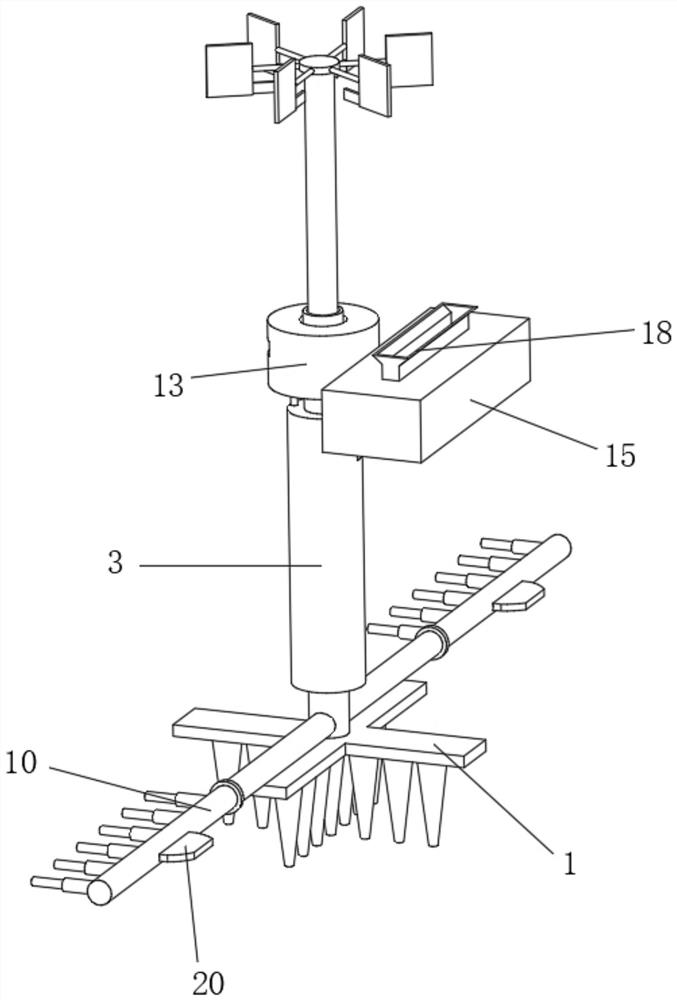

Active fertilizer based on wind-driven spraying for farmland

ActiveCN111972112AReduce consumptionContinuous transmissionFertiliser distributersPressurised distribution of liquid fertiliserAgricultural engineeringStructural engineering

The invention discloses an active fertilizer based on wind-driven spraying for farmland. The active fertilizer comprises a cross bottom plate, wherein a supply pipeline is fixedly connected to the topof the cross bottom plate, a reciprocating screw rod penetrates through inside of a drive inserted rod and is in threaded connection with the inside of the drive inserted rod, induced air blocking pieces are uniformly and fixedly connected with the periphery of the top end of the reciprocating screw rod, a beating rubber stick is fixedly connected with the lower part close to one side of the reciprocating screw rod, of each induced air blocking pieces, supporting through pipes are fixedly connected with the left side and the right side of the top of the cross bottom plate, input ends of the supporting through pipes communicate with the supply pipeline, the end, away from the supply pipeline, of each supporting through pipe is rotationally connected with a conveying rotary pipe through a sealing bearing, supporting conical rods are uniformly and fixedly connected with the surface of the bottom of the cross bottom plate, and a storage blocking door mechanism is arranged at one end of the outer side of a storage tank and close to the lower position. The invention relates to the technical field of fertilization. According to the active fertilizer based on wind-driven spraying for thefarmland, wind power replaces labor force for fertilization, and labor consumption for fertilization is reduced.

Owner:湖州博星科技有限公司

Intelligent environment-friendly plastic spraying equipment for electric control cabinet

InactiveCN111266270ASolve the problem that the uneven mixing affects the spraying efficiencyEnsure spray uniformityLiquid surface applicatorsDispersed particle filtrationElectrical controlElectric machinery

The invention provides intelligent environment-friendly plastic spraying equipment for an electric control cabinet. The intelligent environment-friendly plastic spraying equipment comprises movable trundles, a movable rack, supporting vertical rods, adjusting pipes, adjusting bolts, a machine base, a booster pump, a metal hose, a spraying gun, a three-head plastic spraying pipe and an intelligentcontrol main machine. According to the intelligent environment-friendly plastic spraying equipment, by arranging stirring rods, a stirring shaft, square-head bolts, a stirring motor, a plastic spraying box, a plastic powder feeding hopper and a protective net, the problem that the plastic spraying efficiency is affected due to the fact that plastic powder is treated and stirred unevenly in the plastic spraying process is solved, the plastic powder is put inside the plastic spraying box through the plastic powder feeding hopper, the intelligent control main machine controls the stirring motor to drive the stirring shaft to rotate, at the moment, the stirring rods start to stir the plastic powder so as to guarantee plastic spraying uniformity, the larger plastic powder can be filtered in anauxiliary mode through the protective net so as to guarantee the high-pressure plastic spraying efficiency, and the stirring rods and the stirring shaft can be separated by taking down the square-headbolts, uninstalling and cleaning are convenient, and replacement and maintenance are convenient.

Owner:张琦

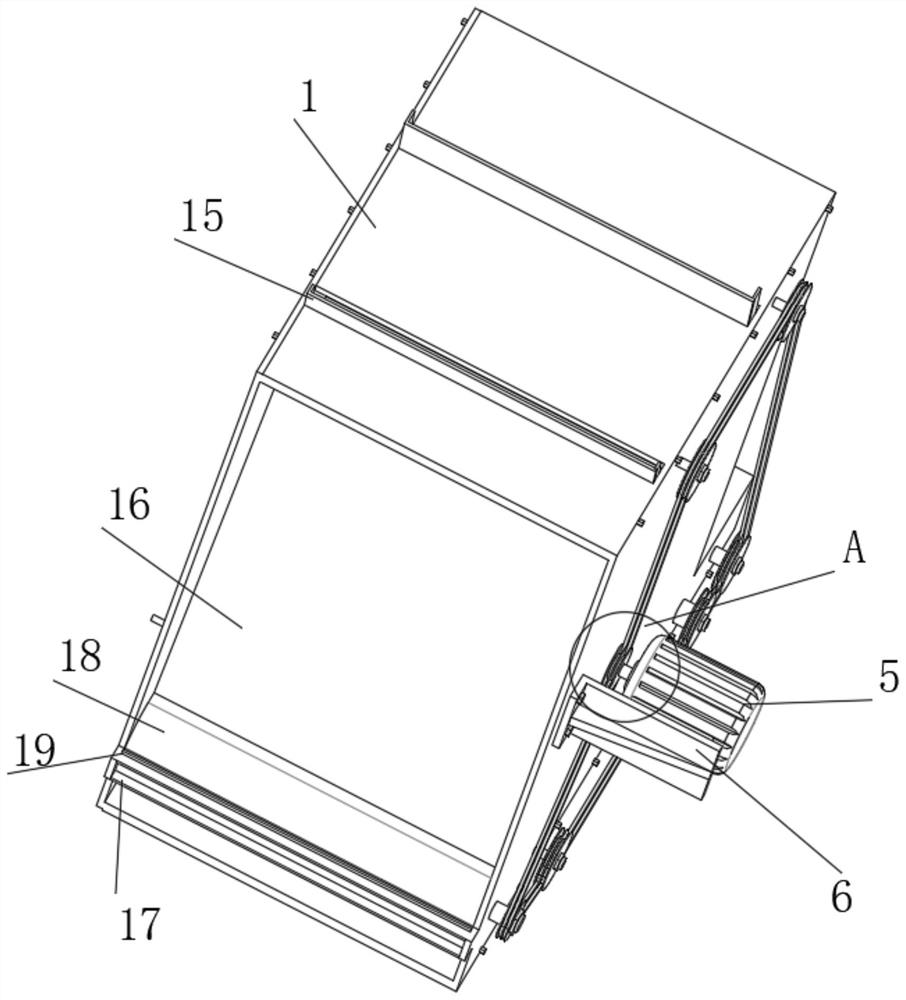

Coating spraying system for wall surface and surface spraying method for coating spraying system

ActiveCN111894240AGuaranteed stabilityEnsure spray uniformityGrinding drivesDirt cleaningMechanical engineeringMaterials science

The invention discloses a coating spraying system for a wall surface and a surface spraying method for the coating spraying system. The coating spraying system comprises supporting rails, a displacement mechanism, a spraying mechanism, a supporting plate, a grinding mechanism and a rolling wheel. The supporting rails are arranged below a top face wall to which a coating is sprayed at a parallel interval. The displacement mechanism is arranged on the supporting rails in the length direction in a reciprocating displacement manner, and a supporting plate is elastically arranged on the displacement mechanism in the direction perpendicular to the spraying face. The rolling wheel rolling in the displacement direction is arranged on the supporting plate, the rolling wheel elastically abuts against the spraying face, and the spraying mechanism comprises a pump body arranged on the ground and a spraying head connected to the pump body. The spraying head is arranged on the supporting plate towards the spraying face, a grinding mechanism is arranged on the supporting plate and arranged on the front side of the spraying head in the displacement direction, and the surface to which the coating is sprayed is ground by the grinding mechanism. Even spraying of the coating can be guaranteed, and the spraying quality is improved.

Owner:泉州台商投资区昇一科技有限公司

Agricultural field crop cultivation irrigation device

PendingCN113207634AExpand the spraying areaReduce layingWatering devicesCleaning using toolsField cropSprayer

The invention belongs to the technical field of water conservancy irrigation, and particularly relates to an agricultural field crop cultivation irrigation device which comprises a first water pipe; the bottom end of the first water pipe is connected to a water conveying pipeline; the top end of the first water pipe is rotationally connected with an annular block; the top end of the annular block is fixedly connected with a second water pipe through a telescopic pipe; a pair of symmetrically distributed water spraying pipes is arranged on the side wall of the second water pipe, and the water spraying pipes are obliquely and fixedly connected to the side wall of the second water pipe; a group of sprayers are arranged on each water spraying pipe, and the sprayers are perpendicular to the corresponding water spraying pipe; and lifting assembly is arranged in the annular block, and the annular block is connected with a second water pipe through the lifting assembly. The agricultural field crop cultivation irrigation device solves the problems that the spraying range of sprayers laid in farmland is close, the spraying range of water spraying pipes is in a fixed state, a large number of sprayers need to be laid in order to conduct comprehensive spraying on the farmland, raw materials are wasted, and meanwhile the installation burden is increased.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

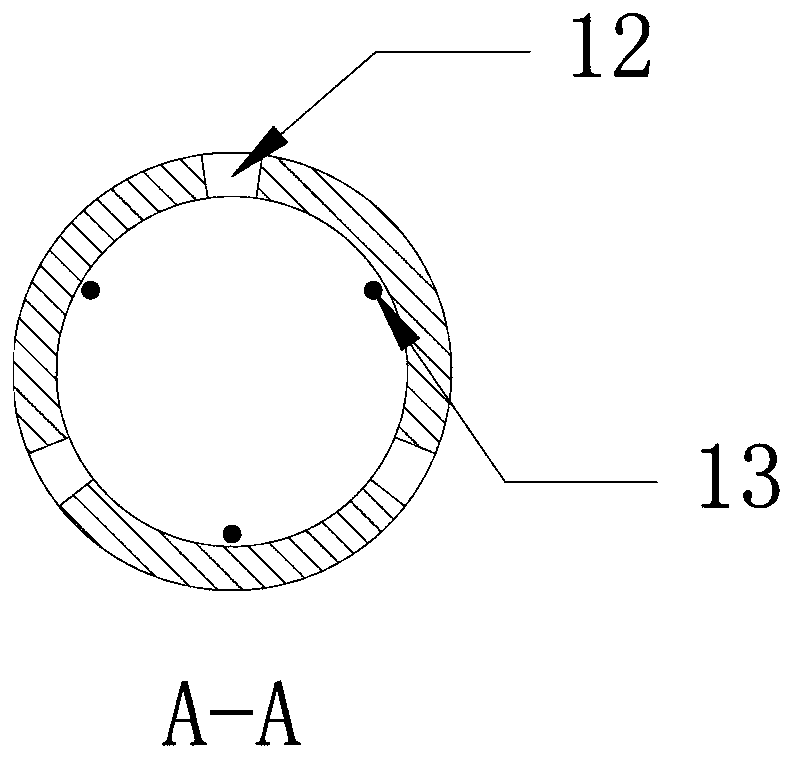

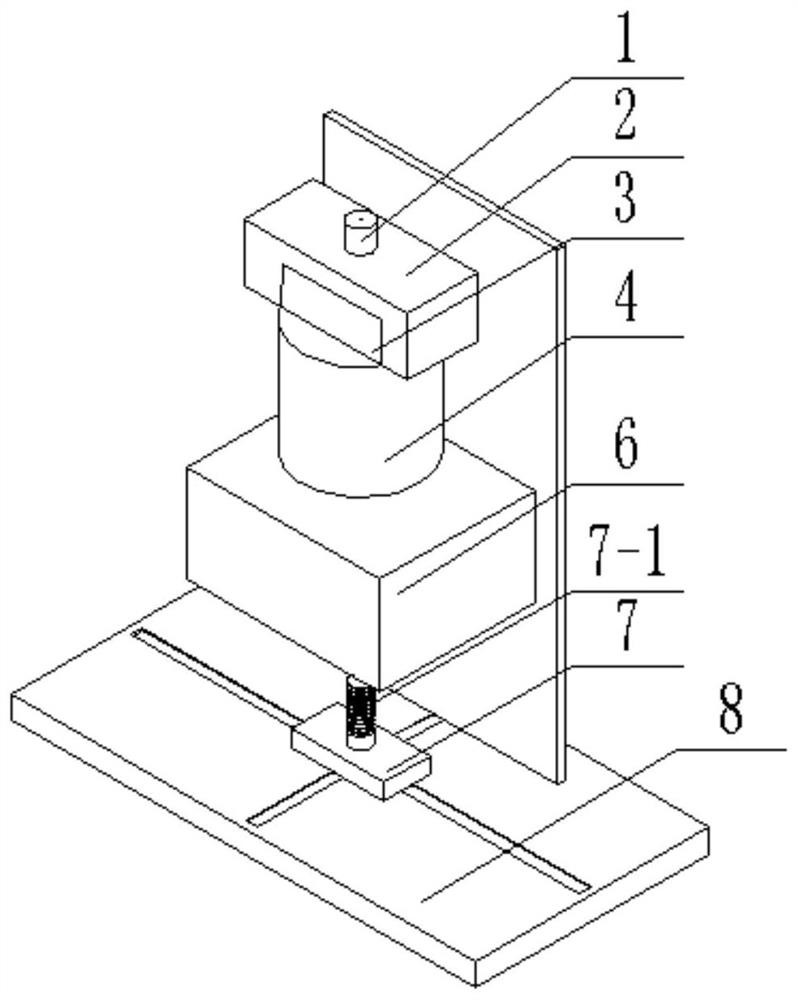

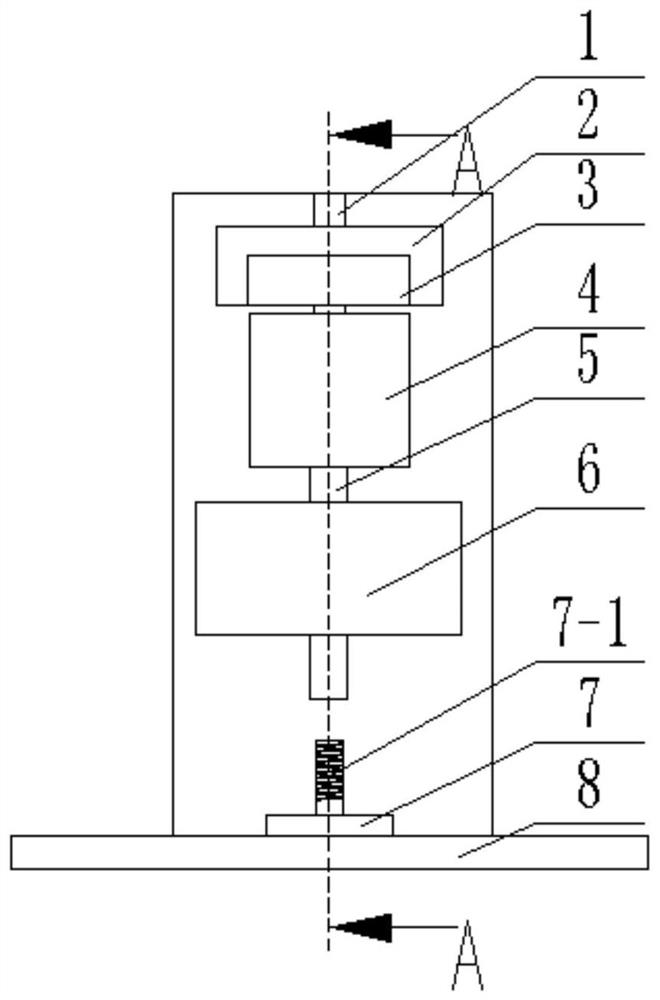

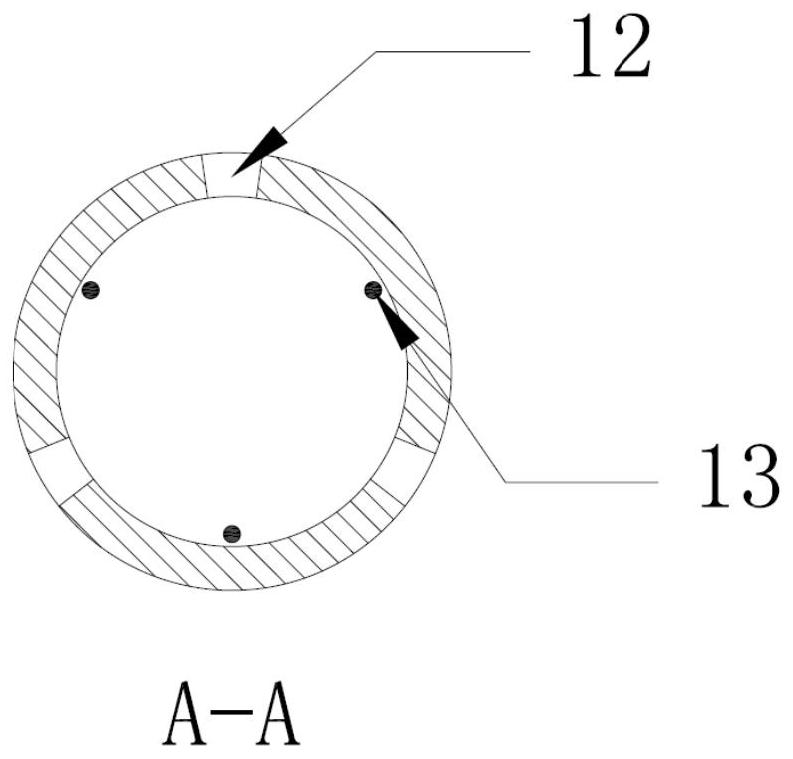

Cylindrical plasma generator and application thereof

ActiveCN110035595AIgnition pressure regulationIgnition pressure adjustmentBlasting cartridgesAmmunition fuzesPlasma generatorEngineering

The invention discloses a cylindrical plasma generator and an application thereof. The cylindrical plasma generator comprises a generator outer cylinder, wherein a positive pole disc and a negative pole disc are arranged at the two ends of the generator outer cylinder respectively; the positive pole disc is provided with a positive pole rod, wherein the positive pole rod extends out of the generator outer cylinder to form a generator positive pole; a negative pole rod is arranged on the negative pole disc; discharge metal wires are arranged in the generator outer cylinder, and the two ends ofthe discharge metal wires are connected with the positive pole disc and the negative pole disc respectively; and grooves communicated with the inside and outside of the generator outer cylinder are axially and symmetrically formed in the cylinder wall of the generator outer cylinder. According to the generator, the plasma ablation wall surface is large, the pressure in the ablation space is controllable, and the quantity of the generated plasma is large, the generator can be directly used for a plasma generator of gunpowder ignition, and the problems of uniformity, consistency and controllability in the process of igniting the propellant powder by the plasma are solved.

Owner:XI AN JIAOTONG UNIV

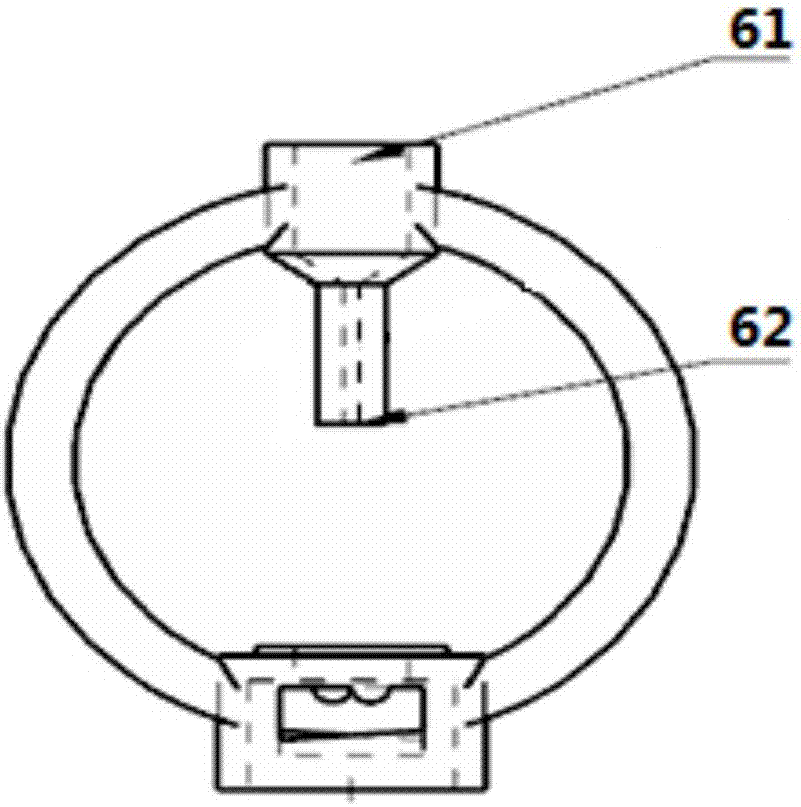

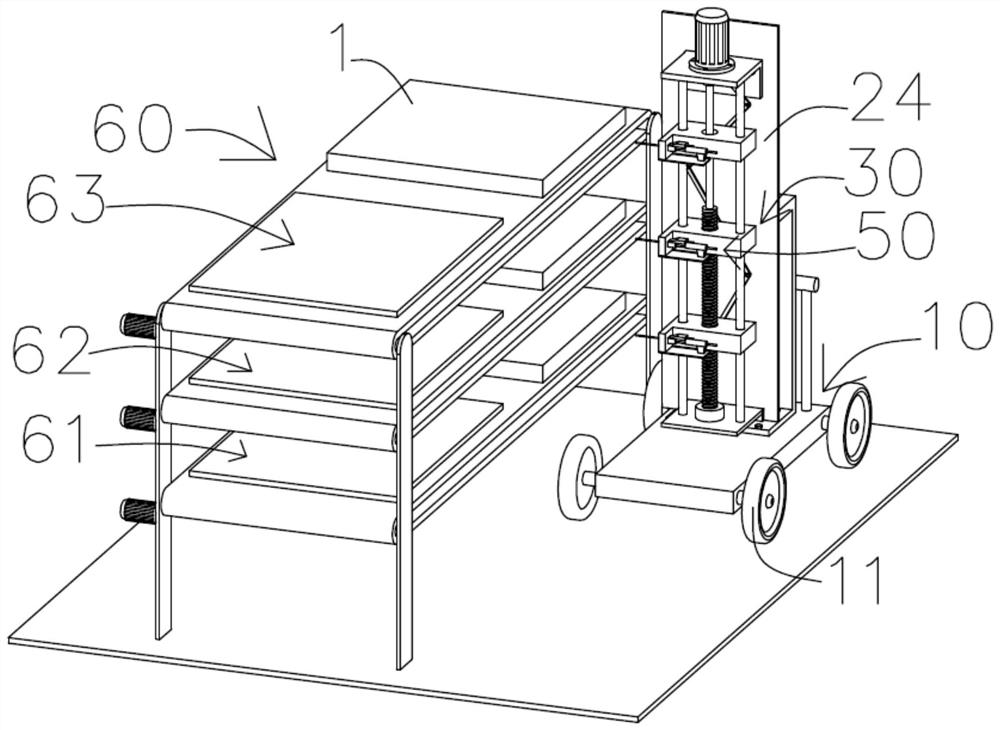

An electrode automatic spraying device

The invention discloses an automatic spraying device for an electrode and relates to the field of processing of fuel cells. The automatic spraying device comprises a slurry storage device, a control system, a parameter input module, an ultrasonic vibration device, a spraying device body, an electrode clamping device and a supporting frame; to-be-sprayed slurry is transferred to the slurry storagedevice, then the electrode is fixed on the electrode clamping device, and after the ultrasonic time, the material and diameter of the electrode and the slurry spraying amount are input through the parameter input module, the ultrasonic vibration device, the spraying device body and the electrode clamping device runs automatically, so that the operation purpose of spraying the slurry on the surfaceof the electrode is achieved. By means of the device, an efficient spraying effect can be achieved on the electrode, the test time is saved, the uniformity of spraying is ensured, and the differenceof experimental results caused by electrode spraying errors is avoided.

Owner:JIANGSU UNIV

A Sprinkler Irrigation Machine Capable of Collecting Rain and Compensating Irrigation

ActiveCN104542191BImprove utilization efficiencyEnsure spray uniformityGeneral water supply conservationWatering devicesEngineeringWater saving irrigation

The invention relates to a sprinkling irrigation machine capable of collecting rainwater for compensating irrigation, and belongs to the technical field of water-saving irrigation of agriculture. The sprinkling irrigation machine comprises a rainwater collecting tank, a main rod, sprinkling irrigation rods, compensation rods and a base, wherein the main rod is rotated into the base through a thread opening, universal wheels are arranged under the base, one side of the lower end of the main rod is provided with a water inlet, the upper end of the main rod is provided with an upper layer and a lower layer, the four sprinkling irrigation rods are arranged at the lower layer and are movably connected with the main rod, the four compensation rods are arranged at the upper layer and are movably connected with the main rod, the top end of the main rod is communicated with the rainwater collecting tank, a support groove of the rainwater collecting tank is formed in the lower part of the rainwater collecting tank and is fixedly connected with the main rod, the upper part of the rainwater collecting tank is communicated with a conical rainwater collecting groove, a filtering net cover is arranged at the upper part of the conical rainwater collecting groove, a sprinkling nozzle is arranged at the tail end of each sprinkling irrigation rod, three sprinkling nozzles are respectively arranged at the tail end of each compensation rod and are distributed in a triangle shape, and a sprinkling nozzle is arranged at one end near the main rod. The sprinkling irrigation machine has the advantages that the operation is simple, the weight is light, the cost is low, the design structure is simple and reasonable, the practicality is high, the storage and carrying are convenient, and the sprinkling irrigation machine is suitable for being popularized and applied.

Owner:KUNMING UNIV OF SCI & TECH

A kind of paint spraying system for wall surface and surface spraying method thereof

ActiveCN111894240BGuaranteed stabilityEnsure spray uniformityGrinding drivesDirt cleaningEngineeringMechanical engineering

The invention discloses a paint spraying system for the surface of a wall and a surface spraying method thereof, comprising a support rail, a displacement mechanism, a spraying mechanism, a support plate, a grinding mechanism and a rolling wheel. Below the top wall, the support rail is provided with the displacement mechanism along the length direction to move back and forth, and the displacement mechanism is elastically arranged with a support plate in the direction perpendicular to the spray surface, and the support plate is provided with There is a rolling wheel rolling along the displacement direction, the rolling wheel elastically presses against the spraying surface, and the spraying mechanism includes a pump body arranged on the ground and a spray head connected to the pump body, and the spray head is arranged on the spray surface toward the spraying surface. The support plate is provided with a grinding mechanism, and the grinding mechanism is disposed on the front side of the spray head in the displacement direction. The grinding mechanism grinds the surface to be sprayed, which can ensure uniform spraying of paint and improve spraying quality.

Owner:泉州台商投资区昇一科技有限公司

Assembled type polyurethane water landscape ecological cycle system for sponge city

InactiveCN113107060AFirmly connectedLow costFatty/oily/floating substances removal devicesSewerage structuresEcologyEngineering

The invention provides an assembled type polyurethane water landscape ecological cycle system for a sponge city. The system comprises a collecting box, a spraying box and a viewing box, a recycling opening is formed in the upper side face of the collecting box, a supporting column is fixedly arranged on the lower surface of the interior of the collecting box, a first filtering plate is fixedly arranged on the top end of the supporting column, the left end of the first filtering plate is in contact with the right inclined face of a left inclined arm, the right end of the first filtering plate is in contact with the left inclined face of a right inclined arm, the top end of the left inclined arm is connected with the bottom end of a left first longitudinal arm through a first spherical hinge, a first return spring is arranged on the left side face of the left first longitudinal arm, the top end of the left first longitudinal arm is fixedly connected with the right end of the lower side face of a left baffle, and the upper side face of the left baffle makes contact with the upper surface of the interior of the collecting box. According to the technical scheme, the technical problems that in the prior art, the capacity of collecting external rainwater and the like is not achieved, and rotary spraying, circulating irrigation and the like cannot be achieved are effectively solved, and application and popularization are facilitated.

Owner:刘川

A kind of adhesive spraying method

ActiveCN109530119BGuaranteed heating effectQuality assuranceLiquid spraying apparatusAdhesiveProcess engineering

Owner:河南中南工业有限责任公司

Double-channel micro sprinkler of different structure

InactiveCN106944275AEffective range is smallReduce water outputMovable spraying apparatusWater flowSpray nozzle

The invention provides a double-channel micro-spray head with different structures, the nozzle and the fixed nozzle are connected to the water supply hose through the joint, the water supply hose is connected to the water delivery main pipe, and the pressurized water flow enters the fixed nozzle from the water delivery main pipe through the water supply hose , at the same time, the pressurized water flow enters the nozzle from the water supply main pipe through the water supply hose; the water flow passes through the refraction of the first arc-shaped diversion groove and the second arc-shaped diversion groove, generating a backward thrust, pushing the rotating body to rotate around the axis at high speed, The refracted water flow is ejected and crushed at a certain angle along the tangential direction of the rotation of the rotating body, and sprayed within the effective range; compared with the second arc-shaped diversion groove, the straight line from the beginning to the end of the first arc-shaped diversion groove The distance is relatively large, and the spraying angle at the end of the first arc-shaped diversion groove is relatively large, so the effective range of the water sprayed along the end is small, and the first water outlet hole of the fixed nozzle is small in size, so the water output is small; The combination of aspects helps to maintain the uniformity of spraying in different ranges from near to far.

Owner:大禹节水(天津)有限公司

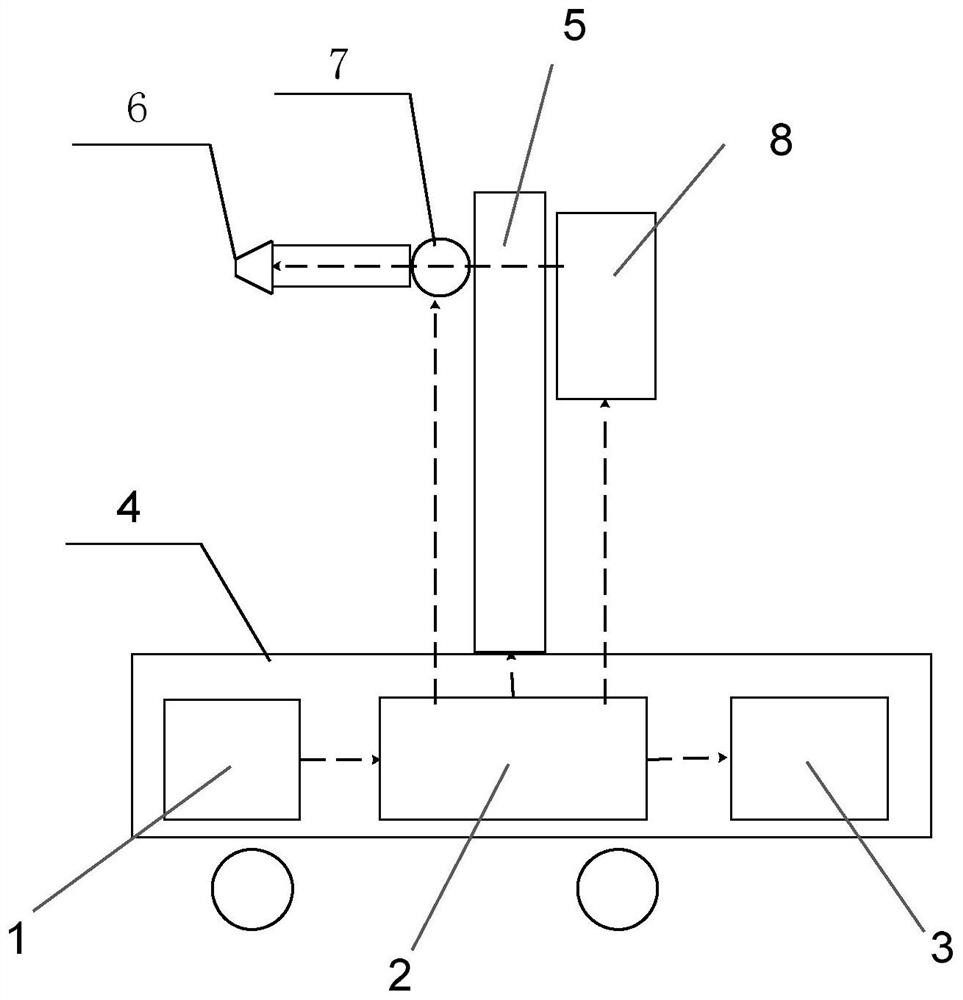

Electric disinfection vehicle

InactiveCN112076333AImprove spraying efficiencyEnsure spray uniformityLavatory sanitoryLiquid spraying apparatusProcess engineeringElectric cars

The invention discloses an electric disinfection vehicle. The electric disinfection vehicle comprises a movable electric vehicle body and a spraying system arranged on the electric vehicle body; the spraying system includes at least one liquid storage container used for storing disinfectant, a first spraying device, a second spraying device and a third spraying device, wherein the first spraying device includes a first sucking mechanism used for sucking the disinfectant, and at least two first spraying mechanisms; the second spraying device includes a second sucking mechanism for sucking the disinfectant, and a plurality of second spraying mechanisms; and the third spraying device includes a spraying gun with an extension pipe, and the extension pipe of the spraying gun communicates with the second sucking mechanism. Through the movement of the electric vehicle body, the electric disinfection vehicle can move indoors, and the disinfectant can be sprayed into the air through the first spraying mechanism; the disinfectant is sprayed to the ground through the second spraying device; and the disinfectant is sprayed through the third spraying mechanism to local places where the vehiclecannot reach, so that the disinfectant spraying efficiency is increased, the spraying uniformity is kept, and meanwhile, the needs of epidemic prevention and disinfection are also met.

Owner:GUANGDONG MARSHELL ELECTRIC VEHICLE

Copper alloy surface coating structure based on rare earth nano-particles, device and method

PendingCN113414084AEasy to adjustEnsure spray uniformitySpraying apparatusMetallic material coating processesMetallurgyNanoparticle

The invention provides a copper alloy surface coating structure based on rare earth nano-particles. The copper alloy surface coating structure comprises a copper alloy structure, wherein the surface of the copper alloy structure is provided with a rare earth nano-coating structure, and the rare earth nano-coating structure comprises germanium-containing nano-particles. According to the copper alloy surface coating structure, the rare earth nano-coating structure is introduced to the copper alloy structure, the surface property of the copper alloy is improved through the characteristics of the germanium nano-particles, and especially the characteristics of residual marks and fingerprints of the copper alloy are improved, so that the application performance of the copper alloy is enhanced. The invention further provides a preparation method of the copper alloy surface coating structure based on the rare earth nano-particles. The preparation method comprises the following steps that S1, the germanium-containing nano-particles are obtained; S2, the germanium-containing nano particles are dissolved in a solvent to form a nano spraying liquid to be sprayed; and S3, the nano spraying liquid to be sprayed acts on the surface of the copper alloy structure, so as to form the rare earth nano coating structure.

Owner:JILIN INST OF CHEM TECH

A cylindrical plasma generator and its application

ActiveCN110035595BIgnition pressure regulationIgnition pressure adjustmentBlasting cartridgesAmmunition fuzesPlasma generatorEngineering

The invention discloses a cylindrical plasma generator and an application thereof. The cylindrical plasma generator comprises a generator outer cylinder, wherein a positive pole disc and a negative pole disc are arranged at the two ends of the generator outer cylinder respectively; the positive pole disc is provided with a positive pole rod, wherein the positive pole rod extends out of the generator outer cylinder to form a generator positive pole; a negative pole rod is arranged on the negative pole disc; discharge metal wires are arranged in the generator outer cylinder, and the two ends ofthe discharge metal wires are connected with the positive pole disc and the negative pole disc respectively; and grooves communicated with the inside and outside of the generator outer cylinder are axially and symmetrically formed in the cylinder wall of the generator outer cylinder. According to the generator, the plasma ablation wall surface is large, the pressure in the ablation space is controllable, and the quantity of the generated plasma is large, the generator can be directly used for a plasma generator of gunpowder ignition, and the problems of uniformity, consistency and controllability in the process of igniting the propellant powder by the plasma are solved.

Owner:XI AN JIAOTONG UNIV

Drainage type SCR denitration urea direct injection system

ActiveCN113559705AImprove uniformityImprove the problem of uneven ammonia nitrogenInternal combustion piston enginesFlow mixersAmmoniacal nitrogenThermodynamics

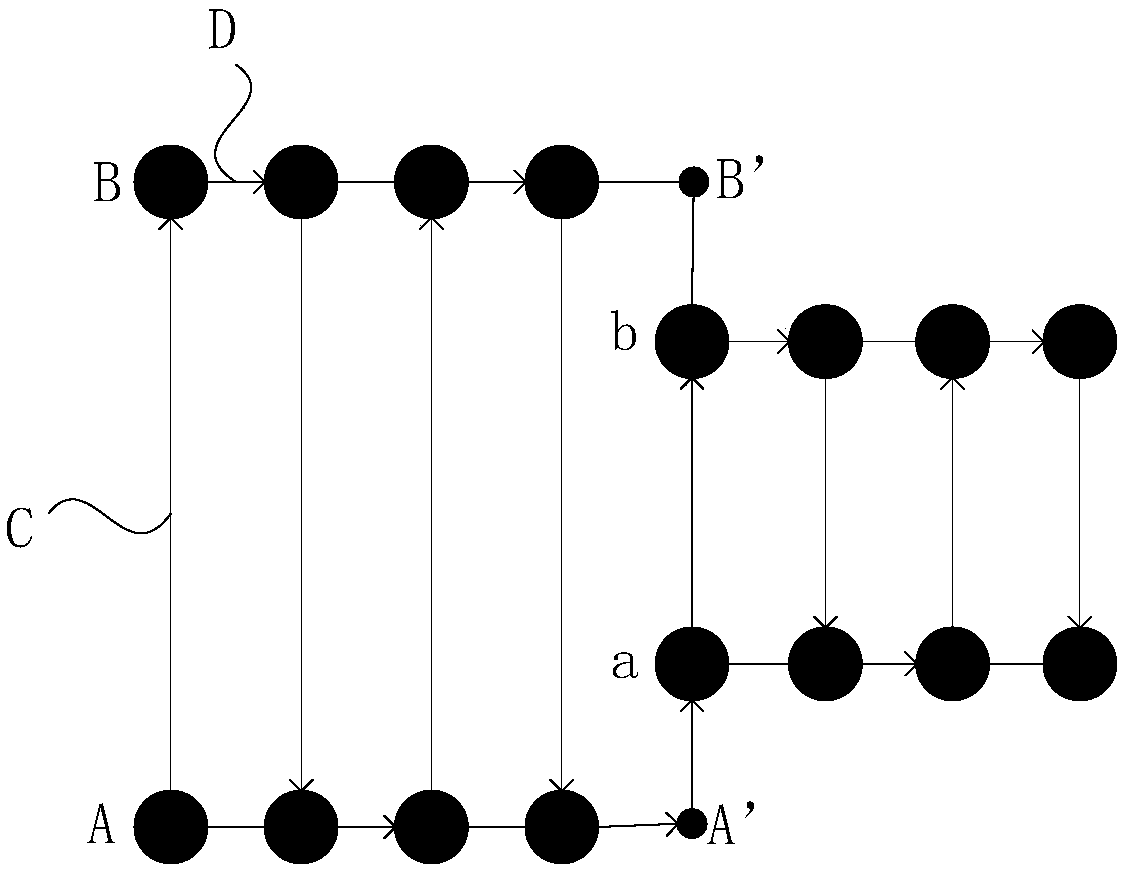

The invention relates to an SCR denitration urea direct injection system in the thermal power industry, and concretely relates to a drainage type SCR denitration urea direct injection system. The system comprises mixing units connected with urea spray guns in a one-to-one correspondence manner; each mixing unit comprises an introduction cavity, four distribution pipes and four injection cavities; the outlet of each introduction cavity is correspondingly connected with the inlets of the four injection cavities through the four distribution pipes respectively; each mixing unit is connected to the downstream outlet of each urea spray gun through the inlet end of the introduction cavity of the mixing unit; and the section of the flue corresponding to one mixing unit is a 4a * 4b rectangle, and a and b are unit lengths of the length and the width of the section of the flue respectively. The urea pyrolysis product spraying uniformity can be effectively improved, the problem of non-uniform ammonia nitrogen existing in a urea direct spraying system is solved, and the system has the advantages of being simple in principle, reliable in effect, easy to manufacture and install and the like and has good application and popularization value.

Owner:XIAN THERMAL POWER RES INST CO LTD

Surface treatment device and control method for wire coil

ActiveCN111250309BReduce defectsEnsure spray uniformitySpraying apparatusEngine lubricationWire rodMedicine

Owner:BAOSHAN IRON & STEEL CO LTD

A farmland active fertilizer applicator based on wind-driven spraying

ActiveCN111972112BReduce consumptionContinuous transmissionFertiliser distributersPressurised distribution of liquid fertiliserAgricultural scienceAgricultural engineering

The invention discloses a farmland active fertilizer applicator based on wind-driven spraying, comprising a cross bottom plate, a supply pipeline is fixedly connected to the top of the cross bottom plate, a reciprocating screw rod is penetrated through and threadedly connected to the inside of a transmission rod, and the top of the reciprocating screw rod is evenly around the top There is an air baffle fixedly connected, and a glue stick is fixedly connected to the lower part of the air baffle near the side of the reciprocating screw rod. The left and right sides of the top of the cross bottom plate are fixedly connected with support pipes, and the input ends of the support pipes are connected with the supply pipe. , the end of the support pipe away from the supply pipe is rotatably connected with the transmission coil through the sealing bearing, the surface of the bottom of the cross bottom plate is evenly and fixedly connected with the support cone rod, and the outer end of the storage tank and the position close to the bottom is provided with a storage door mechanism. The invention relates to the technical field of fertilization. The farmland active fertilizer applicator based on wind-driven spraying achieves the replacement of fertilization labor by wind power and reduces the fertilization labor consumption.

Owner:湖州博星科技有限公司

Continuous casting cooling spray device

The invention discloses a continuous casting cooling spray device. The continuous casting cooling spray device comprises an inner arc spray assembly, an outer arc spray assembly and a left spray assembly and a right spray assembly, wherein the inner arc spray assembly is arranged below an outlet of a crystallizer and is located on one side of an inner arc of a casting blank, the outer arc spray assembly is located on one side of an outer arc of the casting blank, and the left spray assembly and the right spray assembly are separately located on two sides of a plane where the casting blank curves in an arc shape; the inner arc spray assembly, the outer arc spray assembly and the left spray assembly and the right spray assembly are provided with a plurality of layers of nozzles in a spaced manner along the length direction of the casting blank, separately, the distances from the nozzles in each layer to the surface of the casting blank are equal, and the distances from the nozzles in different layers to the surface of the casting blank are equal, too. According to the continuous casting cooling spray device, the spray assemblies are separately arranged around the casting blank to guarantee that the casting blank is sprayed and cooled uniformly, so that the cooling effect is improved, the quality of a steel billet is guaranteed, and severe quality problems, such as center cracks,collapse, bulges and curved billets, of the steel billet are avoided. The surrounding spray assemblies which are relatively independent are convenient to maintain and replace, good in universality, suitable for casting blanks of different cross-section dimensions and long in service life.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Method for rapid reduction and smelting of titanium-containing slag

ActiveCN105256152BWell mixedIncrease contact areaProcess efficiency improvementHeat lossesFlash smelting

The invention belongs to the field of titanium smelting, and particularly relates to a method for quick reduction smelting of titaniferous furnace slag. The technical problems that in an existing titaniferous furnace slag reduction method, the smelting warm-up time is long, the time spent in adding reducing agents is long, the reducing agents and smelting slag are mixed unevenly, the smelting period is long, the transformation rate that titanic oxide is transformed into titanium carbide is low, and electric consumption is high are solved. According to the scheme for solving the technical problems, the method for quick reduction smelting of the titaniferous furnace slag comprises the following steps that a, a reducing agent and hot titaniferous furnace slag just discharged out of a furnace are mixed and then added into a reduction furnace together, and pre-reduction is carried out at the temperature of 1,500 DEG C-1,650 DEG C; b, after pre-reduction, temperature is raised to 1,600 DEG C-1,750 DEG C, the reducing agent is replenished, and high-temperature reduction smelting is further carried out; and c, after smelting is finished, heating is stopped, slag is discharged, and titanium carbide furnace slag is obtained. According to the method, in the whole process, heat losses are small, the reduction reaction is fast, time is short, and energy consumption is low.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of unmanned aerial vehicle plant protection operation method and unmanned aerial vehicle

ActiveCN109240337BEnsure spray uniformityImprove spraying effectAircraft componentsRemote controlled aircraftUncrewed vehicleBiology

Owner:TOPXGUN NAN JING ROBOTICS CO LTD

Multifunctional water and soil loss tester

The invention relates to a multifunctional water and soil loss tester, and belongs to the technical field of environment-friendly equipment. The multifunctional water and soil loss tester comprises anadjustable high liquid pump, a disk type spray device, an erosion groove, a rotating body and a motor, wherein the disk type spray device is connected with the adjustable high liquid pump through a pipeline; the rotating body is arranged at the bottom of the erosion groove; the motor drives the rotating body to drive the erosion groove to rotate at a uniform speed; the disk type spray device comprises a disk body and extension tubes which are respectively communicated with a plurality of spray heads located on the front surface of the disk body; the erosion groove comprises a bottom, a firstside surface, a second side surface, a third side surface, a first wing part, a second wing part and a third wing part; the first, second and third side surfaces are seamlessly connected with the bottom; and the first, second and third wing parts are seamlessly connected with the first, second and third side surfaces. The multifunctional water and soil loss tester has the advantages of being simple in structure, convenient, practical, stable in performance and uniform in water spray, and is capable of adjusting rainfall capacities and testing the influences, on water and soil loss, of rainwater under different rainfall capacities, different gradients and different runoffs.

Owner:贵阳市第三实验中学 +1

Device for improving mixing efficiency of slurry and soil of mixing pile

The invention discloses a device for improving the mixing efficiency of slurry and soil of a mixing pile. The device is mainly characterized in that slurry spraying holes are formed in the rear sides of mixing blades, and gaps formed by the viscosity of soft soil on the non-cutting sides of the blades after the soft soil is cut by the mixing blades are utilized, so that the slurry is conveniently and uniformly sprayed out in the axial direction of the mixing blades, and meanwhile, the problems that existing mixing equipment is uneven in slurry spraying and even the slurry spraying holes are often blocked are solved; the slurry spraying holes are controlled to be opened and closed by utilizing an elastic check valve, so that the slurry is prevented from being wasted; and the pressure of the slurry spraying holes is monitored in real time by means of a pressure sensor, so that the slurry conveying pressure of a slurry pump is adjusted, the stability of the pressure of the slurry spraying holes is guaranteed, and the slurry is prevented from being wasted due to the fact that the pressure is too large and the slurry supply amount is insufficient due to the fact that the pressure is too small.

Owner:南京瑞迪建设科技有限公司 +1

Powdery compound feed for adult Chinese softshell turtles and producing and processing device

The invention relates to a powdery compound feed for adult Chinese softshell turtles and a producing and processing device in the technical field of aquatic feeds. The producing and processing devicecomprise a box body, wherein the box body is provided with a feeding hopper, the feeding hopper is provided with second arc-shaped plates and a first stirring roller, the first stirring roller is provided with a fifth belt wheel, and the feeding hopper is provided with a smashing roller which is provided with fourth belt wheels; the box body is provided with transverse plates and L-shaped supporting plates; each transverse plate and each L-shaped supporting plate are respectively provided with a filter plate and a second filter plate; the box body is provided with first rotating shafts, each first rotating shaft is provided with a first belt wheel, each first rotating shaft is provided with a first conveying belt, and each first conveying belt is provided with a first push plate; the box body is provided with a first material collecting structure, an oil spraying structure and second rotating shafts, and each second rotating shaft is provided with a second belt wheel and a second conveying belt; and each second conveying belt is provided with a second push plate; the box body is provided with a second material collecting structure and a second stirring roller, the second stirring roller and a first arc-shaped plate are used in cooperation, and the second stirring roller is provided with a third belt wheel. The producing and processing device is beneficial to increase of benefits of enterprises.

Owner:福建大昌盛饲料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com