Copper alloy surface coating structure based on rare earth nano-particles, device and method

A nanoparticle and surface coating technology, which is applied to the surface coating liquid device, special surface, spraying device, etc., can solve the problems of cumbersome work, increased workload, uneven layer thickness, etc., to avoid work efficiency low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0035] The present invention provides a copper alloy surface coating structure based on rare earth nanoparticles, which includes a copper alloy structure, the surface of the copper alloy structure has a rare earth nano coating structure, and the rare earth nano coating structure includes germanium-containing nanoparticles . The present invention introduces the rare earth nano-coating structure on the copper alloy structure, and through the characteristics of germanium nanoparticles, the surface properties of the copper alloy are improved, especially the characteristics of its residual marks and fingerprints are improved, and its application performance is enhanced. . Carry out contrast by experiment, the control group is the copper alloy structure that does not carry out nano particle coating, and the experimental group is the copper alloy structure that is coated with rare earth nano-coating structure of the present invention, through the contact touch experiment of hand, the...

no. 2 example

[0037] The present invention also provides a method for preparing a copper alloy surface coating structure based on rare earth nanoparticles, which includes the following steps:

[0038] S1: obtaining germanium-containing nanoparticles;

[0039] S2: Dissolving the germanium-containing nanoparticles in a solvent to form a nano-spray liquid to be sprayed;

[0040] S3: applying the nano-spray liquid to be sprayed on the surface of the copper alloy structure to form a rare-earth nano-coating structure.

[0041] The germanium-containing nanoparticles can be obtained by using the manufacturing methods of metal nanoparticles in the prior art, such as the method of etching through electrodes, or the method of reduction in solution or sol-gel method, which will not be repeated here. In addition, the nano-spray liquid to be sprayed by the germanium-containing nanoparticles can be prepared by the method in the prior art, and the solvent is preferably a nano-dispersion liquid, which will...

no. 3 example

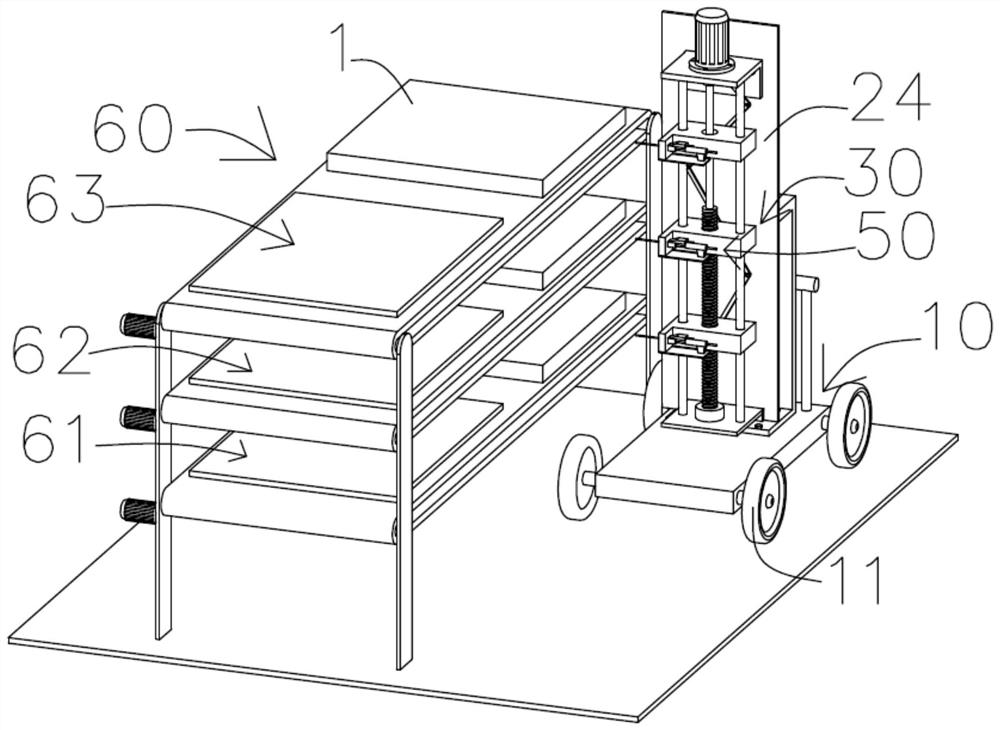

[0043] like Figure 1 to Figure 8 As shown, the coating device of the copper alloy surface coating structure based on rare earth nanoparticles in this embodiment includes a moving body 10 , a lifting assembly 20 , an adjusting assembly 30 , a multilayer spraying structure 50 and a multilayer platform assembly 60 .

[0044] The moving body 10 has moving wheels 11;

[0045] The lifting assembly 20 has a lifting motor 21, a lifting screw rod 22, a lifting sliding rod 23 and a lifting body 24, the lifting motor 21 is connected with the lifting screw rod 22, and the lifting body 24 is sleeved on the lifting screw rod 22 and the lifting sliding rod 23;

[0046] The adjustment assembly 30 has an upper fixed plate 31, an adjustment motor 32, an adjustment center rod 33, an adjustment sliding rod 34, a first sliding block 35, a second sliding block 36, an adjustment sliding block 37, a lower fixing plate 38 and a linkage lever group 39, and the upper The fixed plate 31 and the lower f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com