Drainage type SCR denitration urea direct injection system

A urea and denitration technology, applied in fluid mixer, separation method, dispersed particle separation, etc., can solve the problems of the uniformity index of ammonia injection being difficult to meet the technical requirements, the mixing effect is difficult to guarantee, and the number of spray guns should not be too much, etc. Good promotion and application value, reliable effect, and the effect of increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

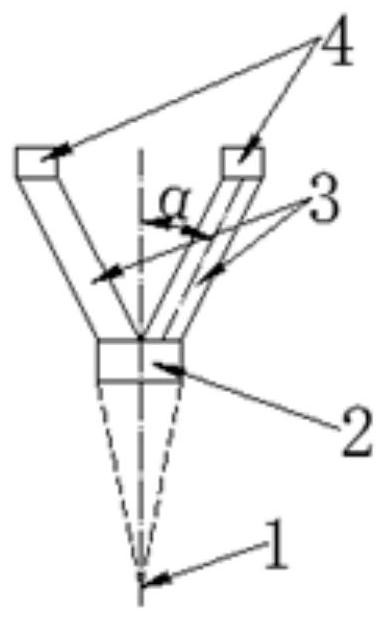

[0032] A drainage type SCR denitrification urea direct injection system of the present invention, such as figure 1 As shown, it includes a urea spray gun 1 and a mixing unit composed of an introduction chamber 2, four distribution pipes 3 and four injection chambers 4; the mixing unit is connected to the urea spray gun 1 one by one, and each mixing unit passes through The inlet connection of the introduction chamber 2 is set at the downstream outlet of each urea spray gun 1, and the flue section corresponding to a mixing unit is a rectangle of 4a×4b, a and b are the unit lengths of the length and width of the flue section respectively and are not greater than 500mm; the outlet of the introduction chamber 2 is connected to the inlets of the four injection chambers 4 through four distribution p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com