Fast sealing device used in mining and mixing spray gun of fast sealing device

A technology of mixed spraying and gun barrel, which is applied in the direction of spraying device and liquid spraying device, etc. It can solve the problems of pressure imbalance, material discharge ratio imbalance, and failure to achieve the sealing effect of the closed wall of the mine, so as to ensure the uniformity of mixing , flexible use, good fast sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

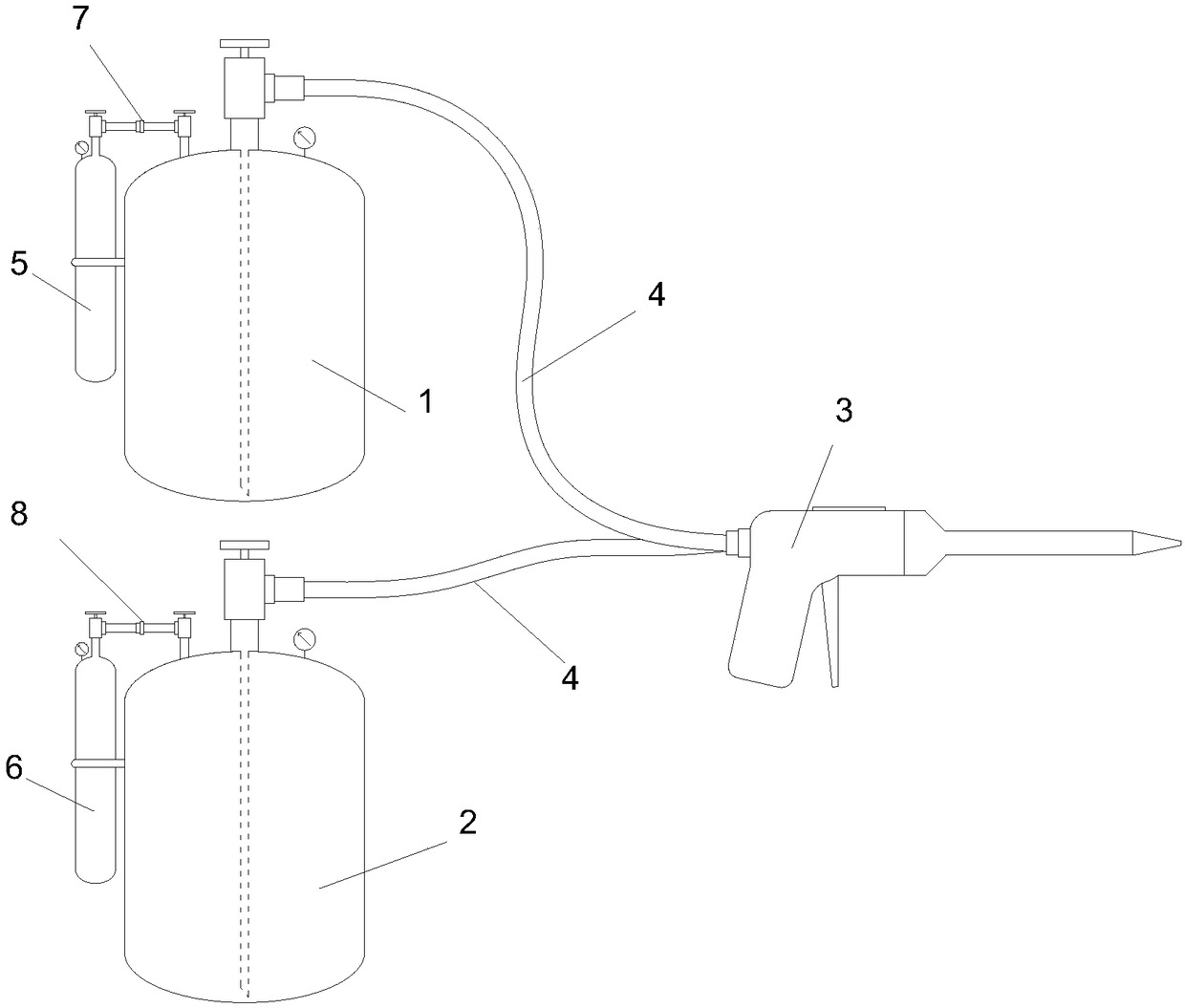

[0085] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0086] see figure 1 , figure 1 It is a structural schematic diagram of a quick sealing device for mines according to an embodiment of the present invention. The quick sealing device for mining of the present invention comprises a first storage tank 1, a second storage tank 2 and a mixing spray gun 3, and the first storage tank 1 and the second storage tank 2 communicate with the said first storage tank 1 through a pipeline 4 respectively. The mixing spray gun 3 is connected, the pipeline 4 is preferably a connecting hose, the first storage tank 1 is connected to the feed port 333 of the first feeding part 331 of the mixing spray gun 3, and the second storage The tank 2 is connected with the feeding port 333 of the second feeding part 332 of the mixing spray gun 3 . For example, both the first storage tank 1 and the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com