Sprinkling irrigation machine capable of collecting rainwater for compensating irrigation

A technology for sprinkler irrigation and rain collection, which is applied in general water supply conservation, drinking water installations, climate change adaptation, etc. It can solve the problems of water saving such as different sprinkler water superposition methods, uneven distribution of single sprinkler water, and no rain collection. Equipment and other issues, to achieve the effect of ensuring uniformity of spraying, easy storage and portability, and light volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

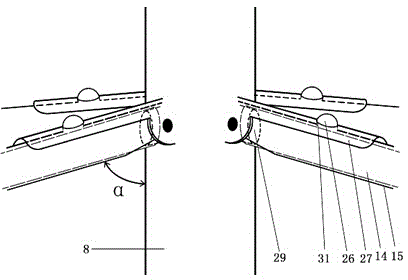

[0037] Embodiment 1: as Figure 1-5 As shown, a sprinkling irrigation machine capable of collecting rain and compensating irrigation includes a rain collecting box 18, a main rod 8, a sprinkler rod 11, a compensation rod 15, and a base 3; the main rod 8 is screwed into the base 3 through a threaded port 4, and the main The rod 8 is a hollow cylinder, and one side of the lower end of the main rod 8 has a water inlet I5. The upper end of the main rod 8 is divided into upper and lower layers. connection, the bottom of the sprinkler rod 11 is provided with a lower iron sheet 28, and the lower iron sheet 28 is fixedly connected with the main rod 8; The upper part of the rod 15 is provided with an upper iron plate 27 and is fixedly connected with the main rod 8. The branch pipe I10 is installed inside the sprinkler rod 11, and the branch pipe I10 communicates with the main rod 8 through the water outlet I29. The internal compensation rod 15 is equipped with a branch pipe II14, and t...

Embodiment 2

[0038] Embodiment 2: as Figure 1-5 As shown, a sprinkling irrigation machine capable of collecting rain and compensating irrigation includes a rain collecting box 18, a main rod 8, a sprinkler rod 11, a compensation rod 15, and a base 3; the main rod 8 is screwed into the base 3 through a threaded port 4, and the main The rod 8 is a hollow cylinder, and one side of the lower end of the main rod 8 has a water inlet I5. The upper end of the main rod 8 is divided into upper and lower layers. connection, the bottom of the sprinkler rod 11 is provided with a lower iron sheet 28, and the lower iron sheet 28 is fixedly connected with the main rod 8; The upper part of the rod 15 is provided with an upper iron plate 27 and is fixedly connected with the main rod 8. The branch pipe I10 is installed inside the sprinkler rod 11, and the branch pipe I10 communicates with the main rod 8 through the water outlet I29. The internal compensation rod 15 is equipped with a branch pipe II14, and t...

Embodiment 3

[0040] Embodiment 3: as Figure 1-5 As shown, a sprinkling irrigation machine capable of collecting rain and compensating irrigation includes a rain collecting box 18, a main rod 8, a sprinkler rod 11, a compensation rod 15, and a base 3; the main rod 8 is screwed into the base 3 through a threaded port 4, and the main The rod 8 is a hollow cylinder, and one side of the lower end of the main rod 8 has a water inlet I5. The upper end of the main rod 8 is divided into upper and lower layers. connection, the bottom of the sprinkler rod 11 is provided with a lower iron sheet 28, and the lower iron sheet 28 is fixedly connected with the main rod 8; The upper part of the rod 15 is provided with an upper iron plate 27 and is fixedly connected with the main rod 8. The branch pipe I10 is installed inside the sprinkler rod 11, and the branch pipe I10 communicates with the main rod 8 through the water outlet I29. The internal compensation rod 15 is equipped with a branch pipe II14, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com