An electrode automatic spraying device

A technology of automatic spraying and spraying devices, applied in spraying devices, liquid spraying devices, etc., to achieve efficient electrode spraying, avoid test errors, and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

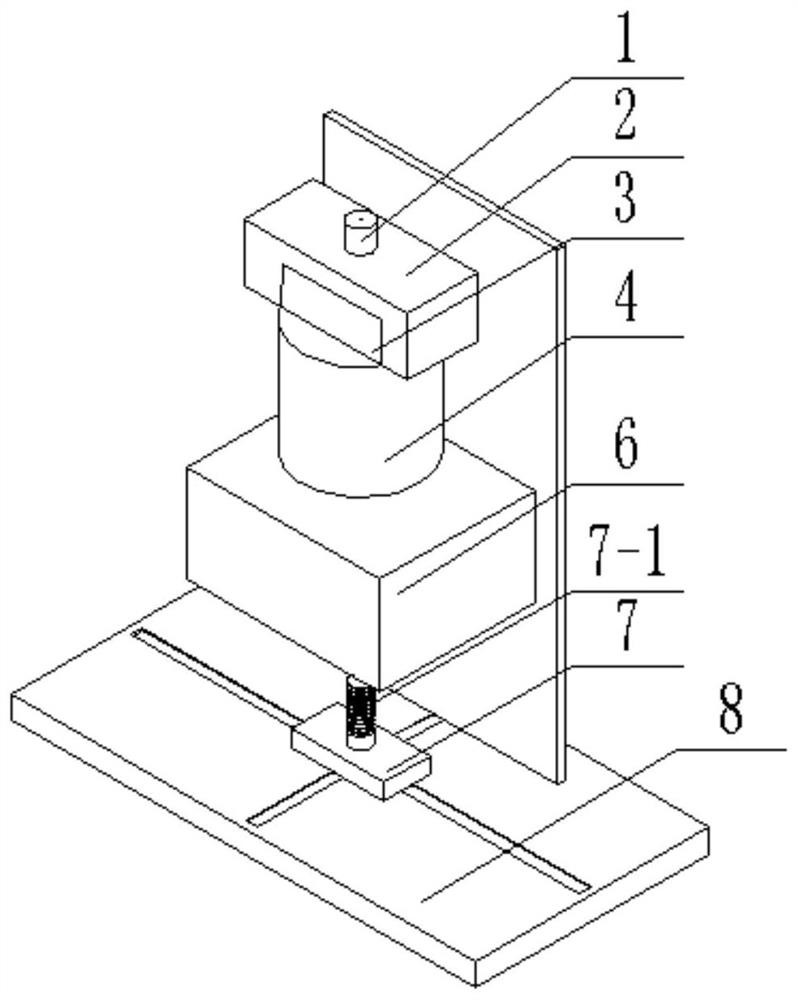

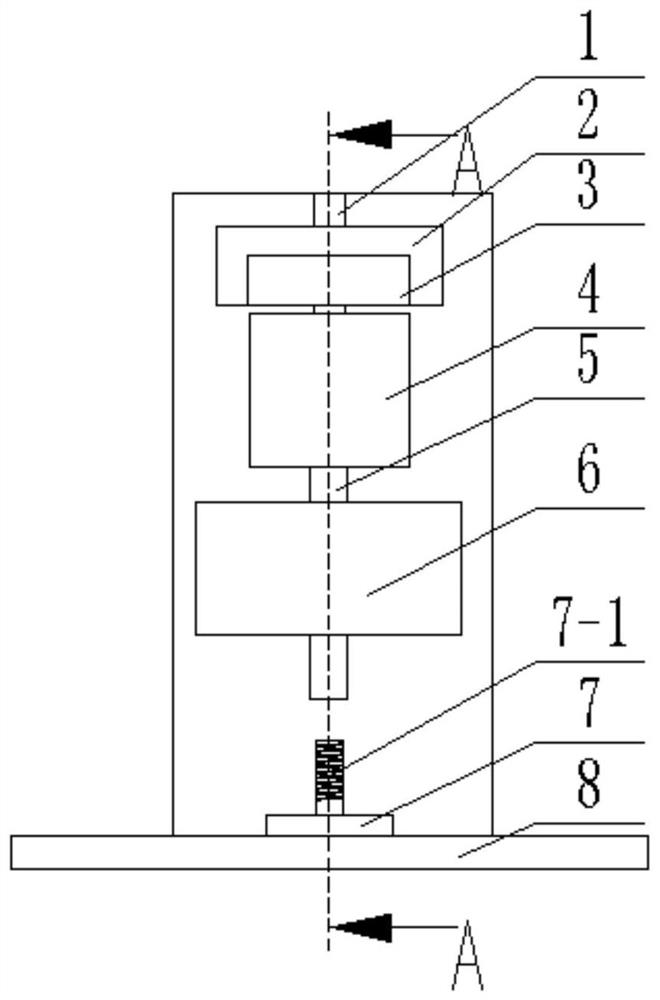

[0024] combined with figure 1 , 3 And 4, the present invention relates to an electrode automatic spraying device, including a slurry storage device 1, an automatic valve 1-1, a rotating shaft 1-2, a valve retention area 1-3, a control system 2, a parameter input module 3, an ultrasonic vibration Device 4, medium chamber 4-1, ultrasonic vibration chamber 4-2, flow meter 5, spraying device 6, electrode clamping device 7, external threaded electrode head 7-1, and support frame 8.

[0025] combined with figure 1 , 2 , 3, the control system 2, the ultrasonic vibration device 4, and the spraying device 6 are fixed on the support frame 8, and the electrode clamping device 7 is fixed on the support frame 8 by bolts; the slurry storage device 1 and the control system 2 are clearance fit, and the slurry The storage device 1 and the ultrasonic v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com