Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Easy to take modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

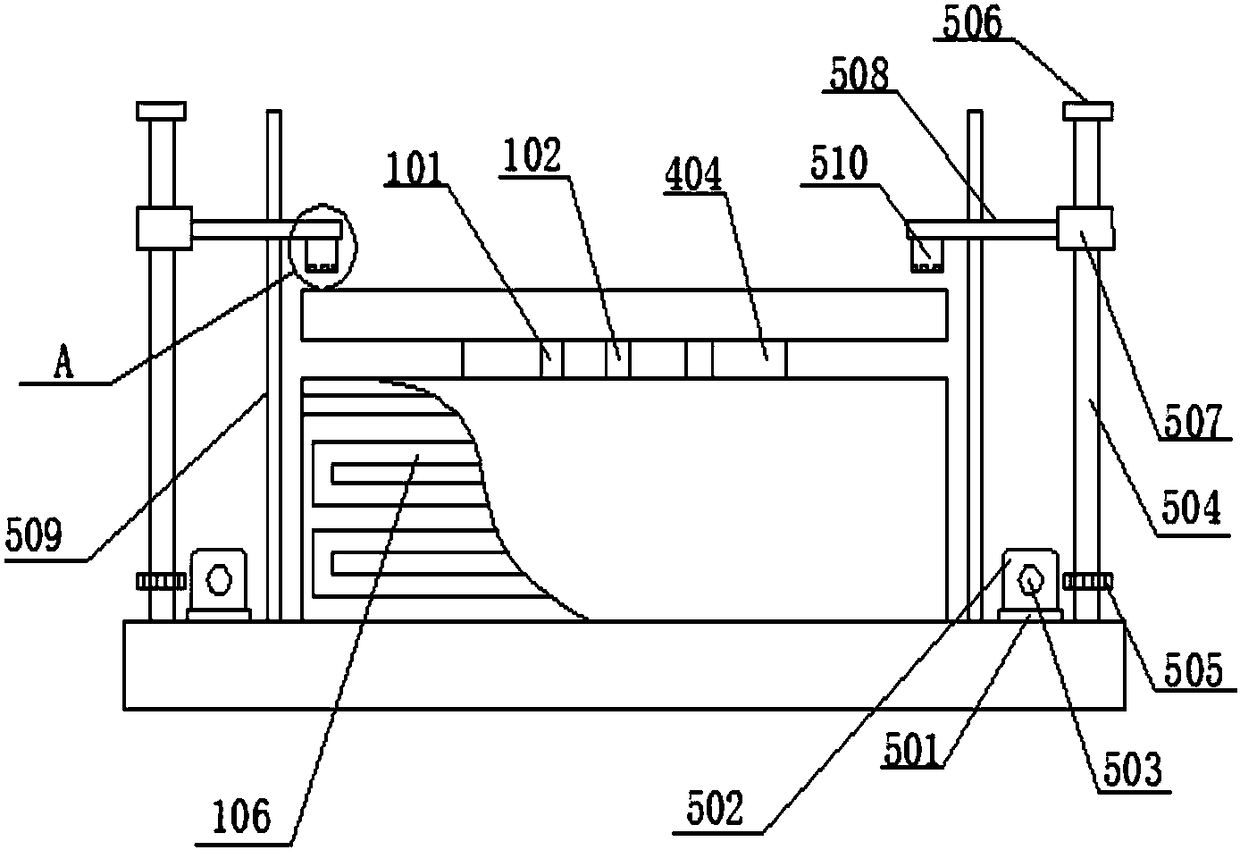

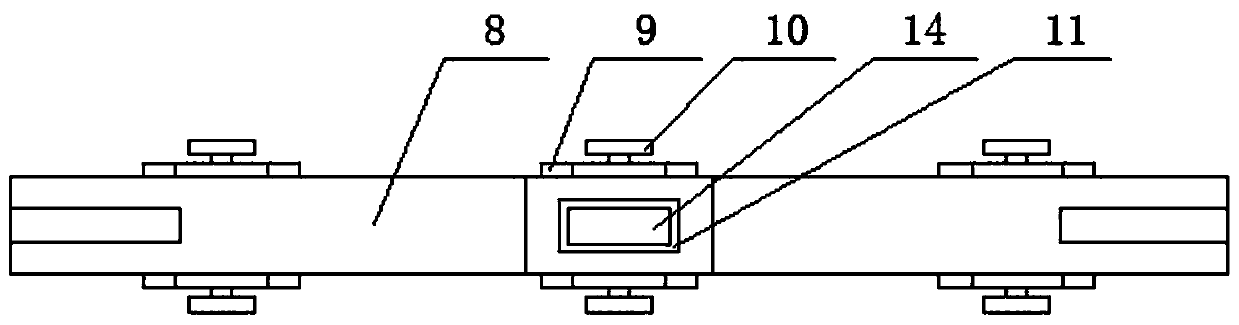

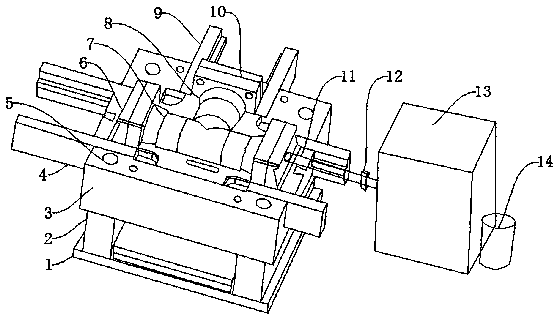

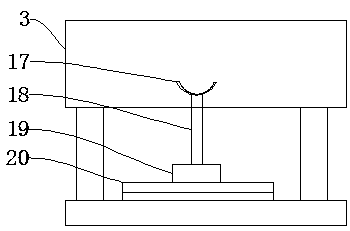

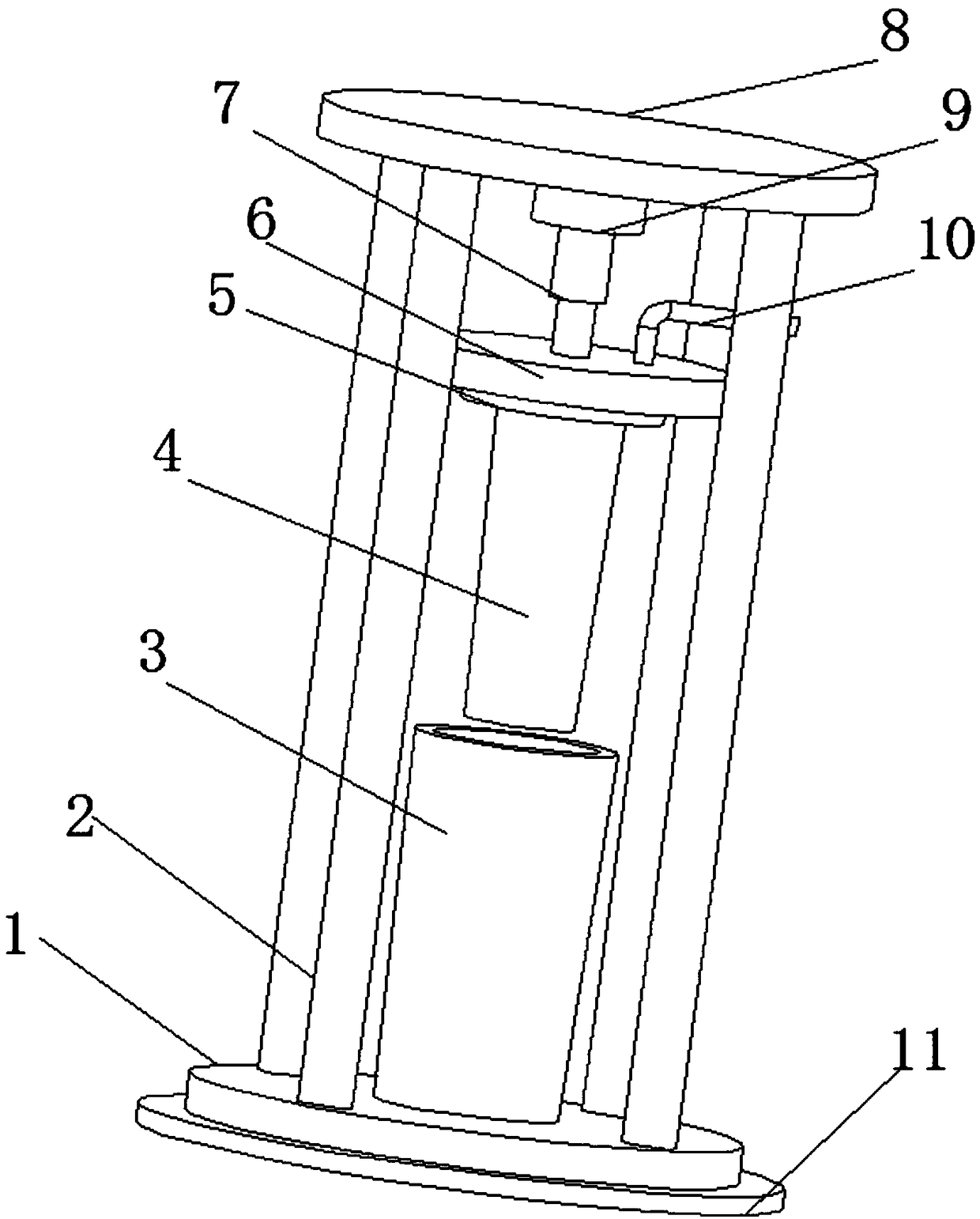

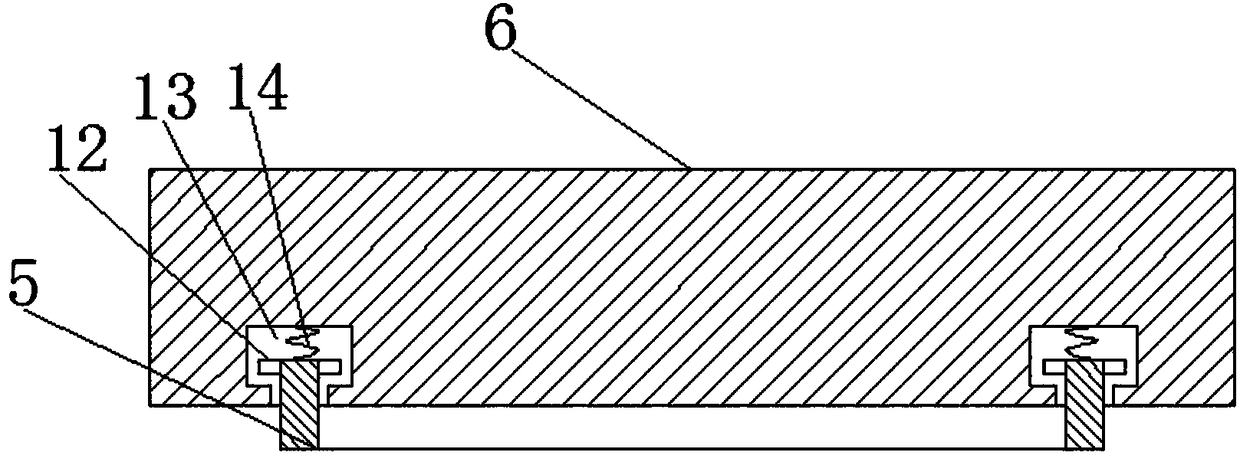

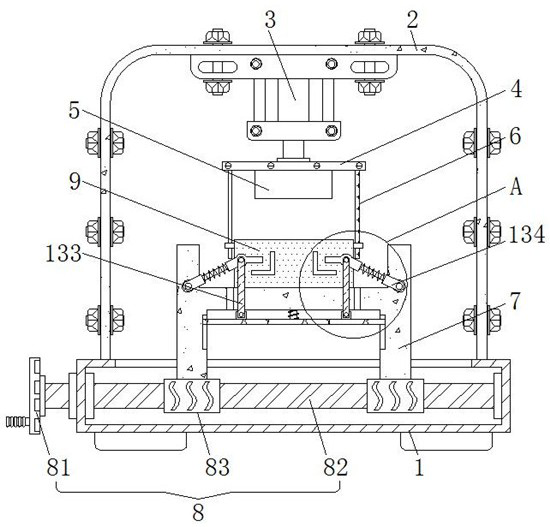

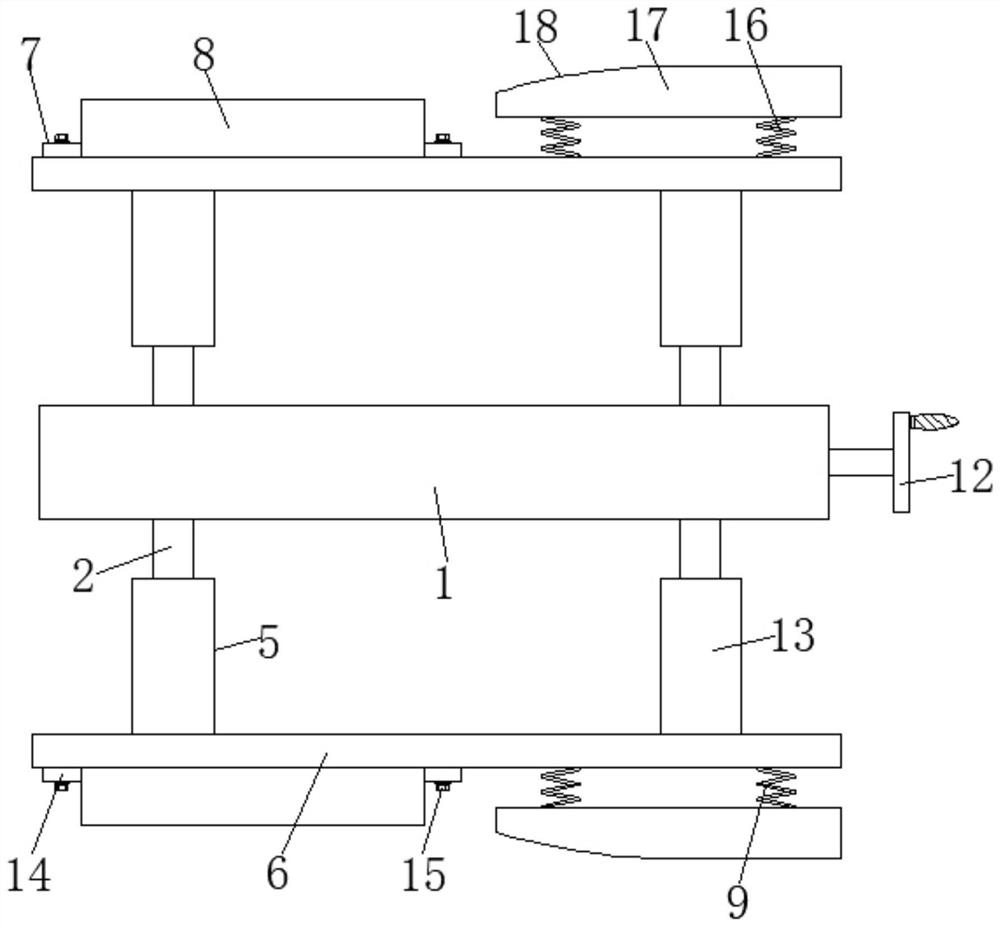

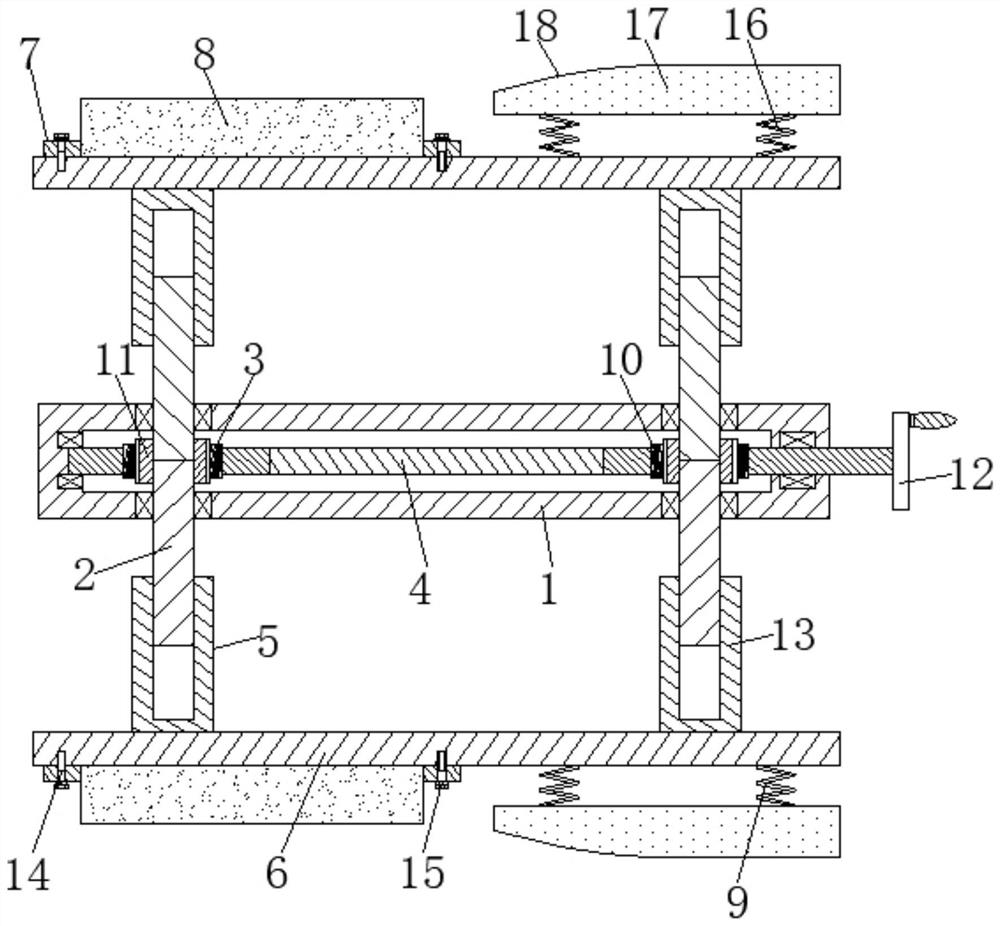

Punching machine with high vibration resisting capacity

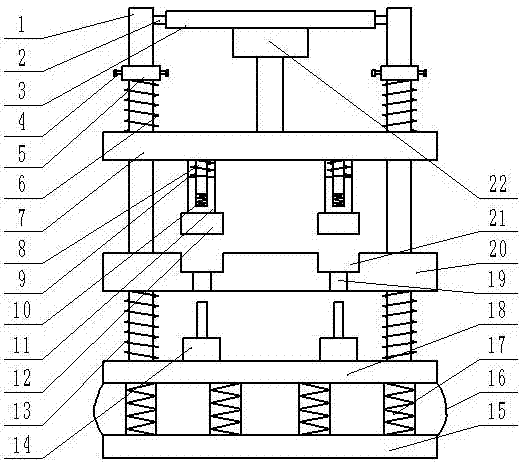

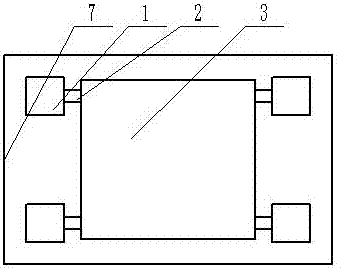

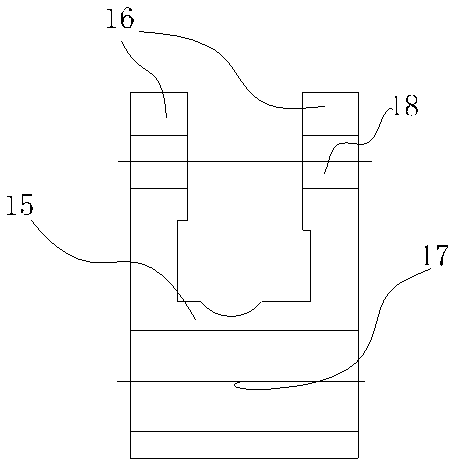

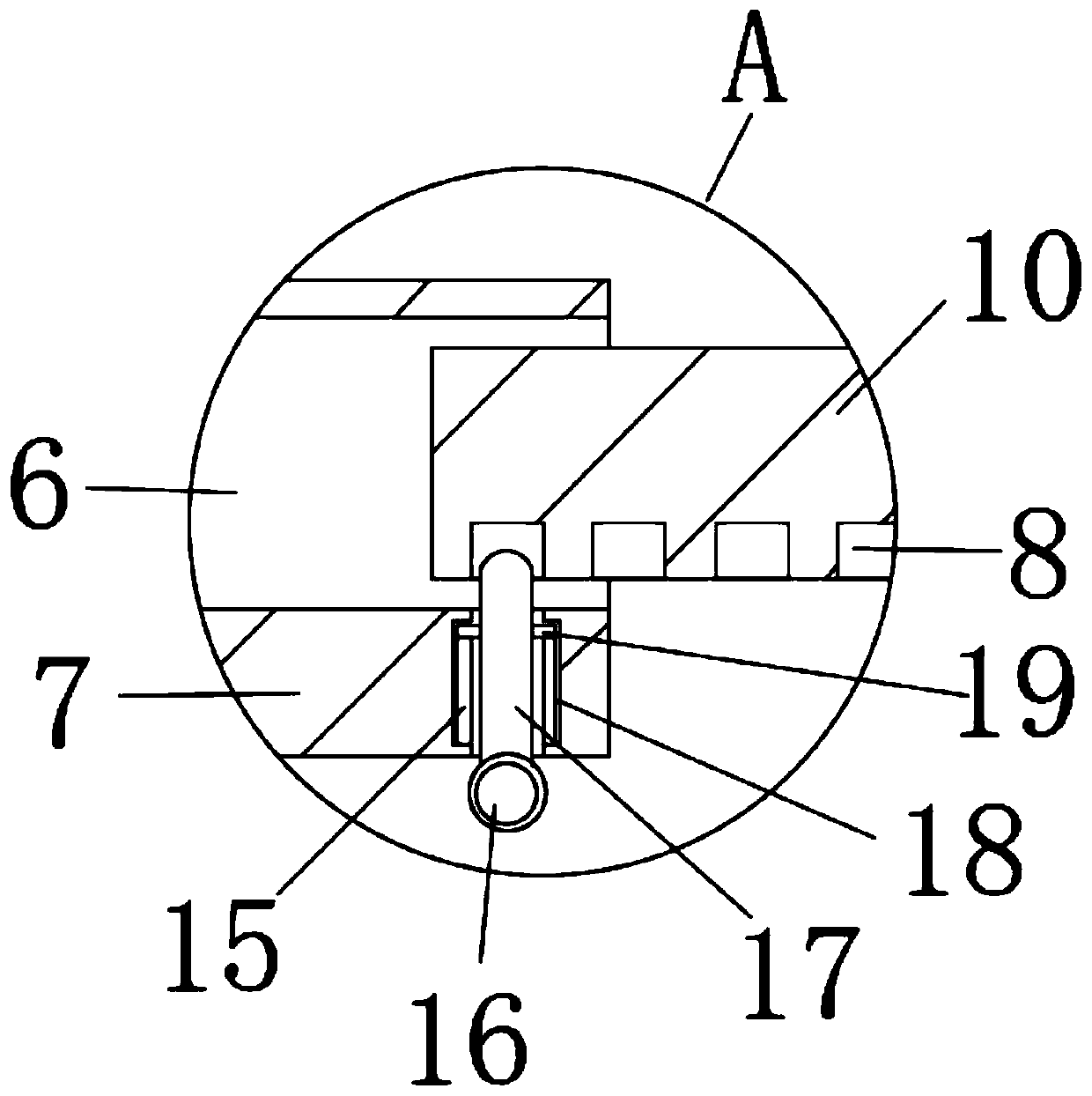

The invention discloses a punching machine with high vibration resisting capacity. The punching machine comprises a lower baseplate; an upper baseplate is arranged at the upper end of the lower baseplate; four stand columns are fixedly connected to four corners of the upper end of the upper baseplate; the stand columns are sleeved with a support plate and a slide plate in sequence from bottom to top; a first vibration reducing spring is sleeved on the stand columns between the upper baseplate and the support plate; multiple ejection cylinders are fixedly mounted at the upper end of the upper baseplate; multiple concave molds are arranged on the upper surface of the support plate; multiple fixed rods are fixedly connected to the lower end of the slide plate; a fixed sleeve is arranged on the outer sides of the fixed rods; the outer side of the lower end of the fixed sleeve is fixedly connected with a convex mold; a lantern ring is sleeved on the stand columns above the slide plate; and a second vibration reducing spring is sleeved on the stand columns between the lantern ring and the slide plate. The punching machine is simple in structure and reasonable in design, can greatly reduce vibration generated during working, and prolongs the service life.

Owner:朱发平

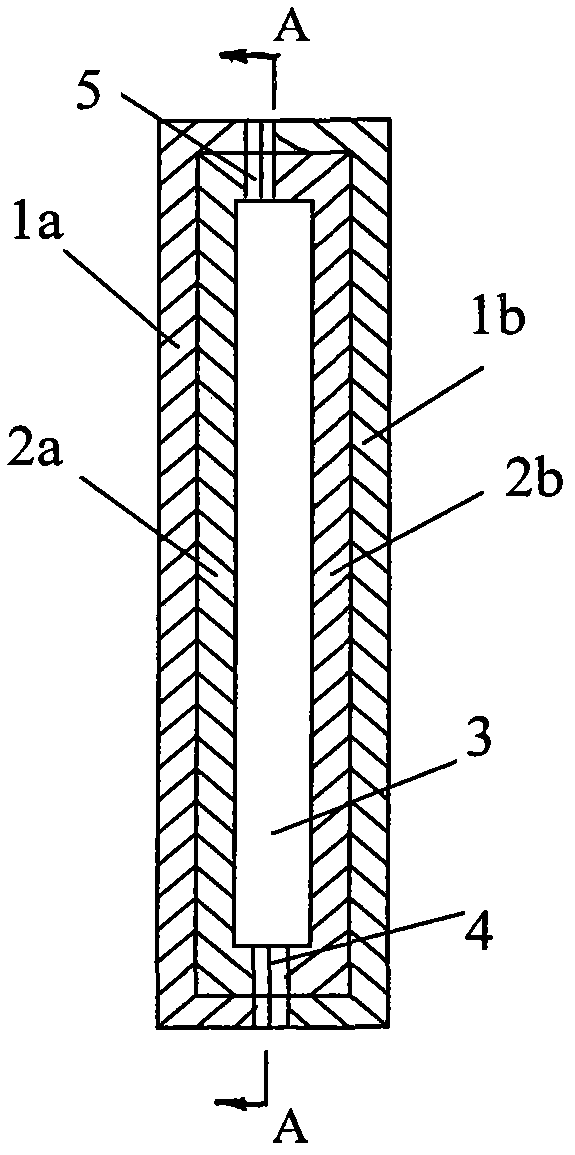

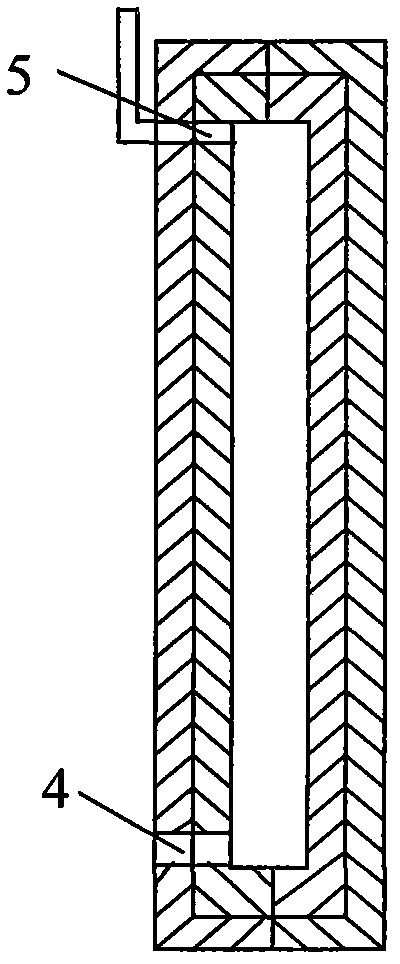

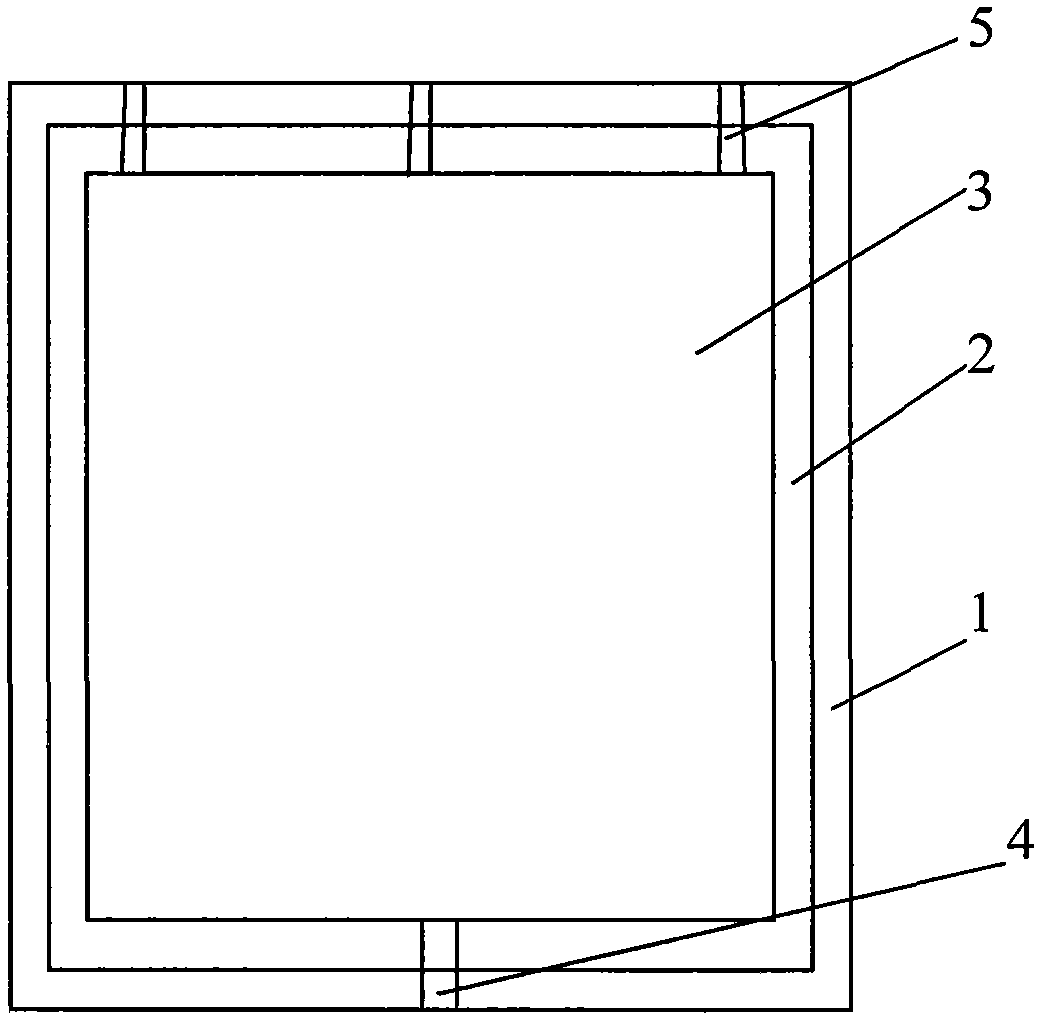

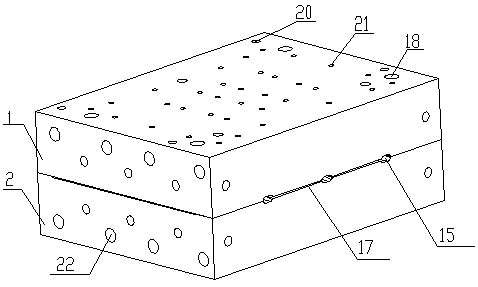

Vertical type pouring manufacturing method of decorative gypsum board

InactiveCN102380909AHigh dimensional accuracyReduce thicknessFeeding arrangmentsLeft halfInjection port

The invention relates to a vertical type pouring manufacturing method of a decorative gypsum board; a vertical rigid external mold and a flexible internal mold arranged in the external mold are adopted, injection ports (4) communicated to an inner cavity (3) of an internal mold are arranged at the bottoms of the external mold and the internal mold, air exhausts (5) communicated with the inner cavity are arranged at the tops of the external mold and the internal mold; the external mold is formed by a left half external mold (1a) and a right half external mold (1b) in an involution way; the internal mold is formed by a left half internal mold (2a) and a right half internal mold (2b) in the involution way; when in pouring, gypsum slurry is injected into the inner cavity through the injection ports until the inner cavity is full of the gypsum slurry; and after the gypsum slurry is solidified, the external mold is opened and the internal mold is taken down, so as to obtain a decorative gypsum board which is solidified and formed in the inner cavity. In the method, air bubbles can be effectively removed in the manufacturing process, so as to prevent air holes from being remained in the gypsum board; and a manufactured product has good quality, the mechanical and standard production can be realized and the production efficiency is high.

Owner:王志伟

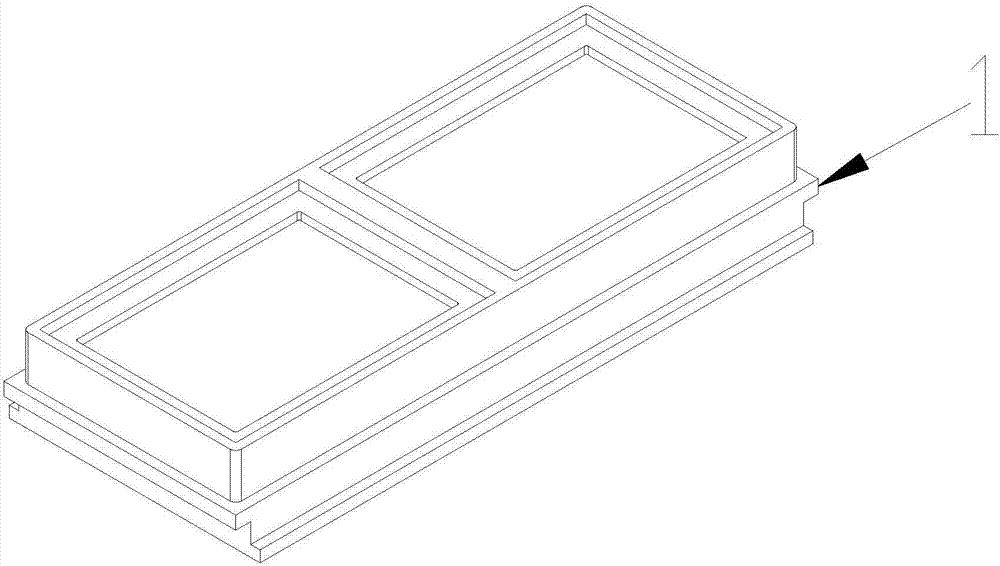

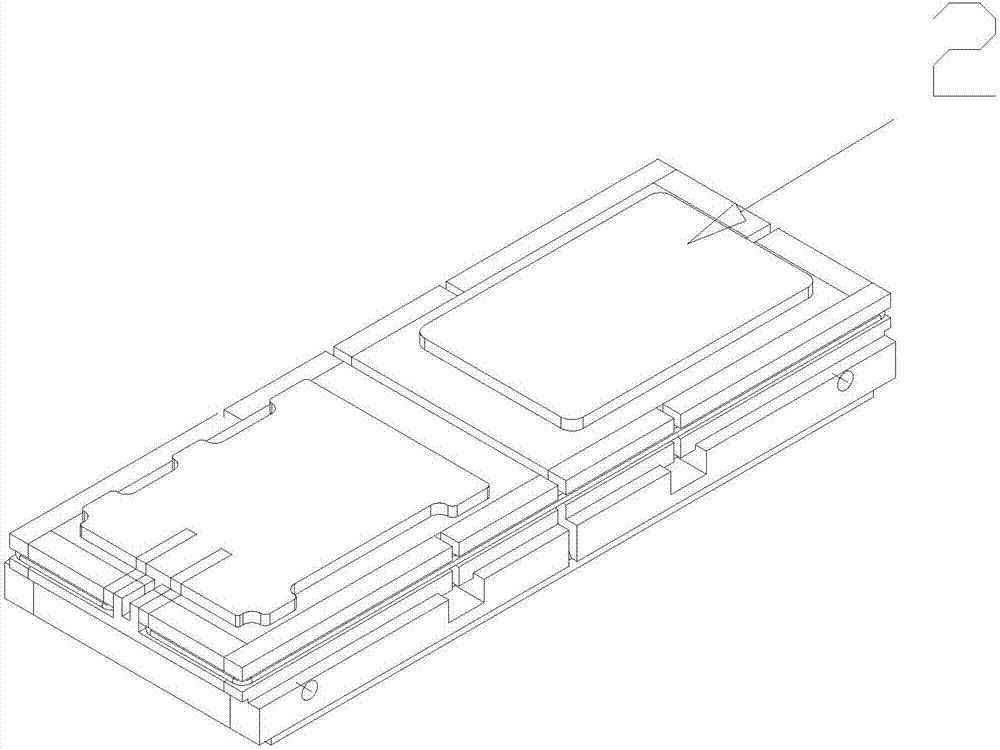

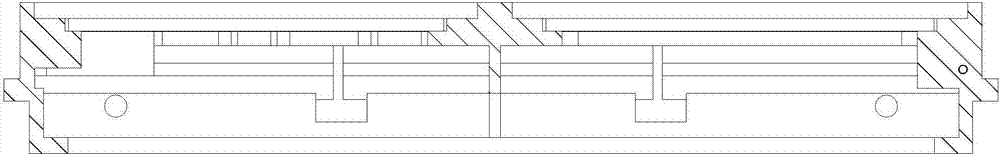

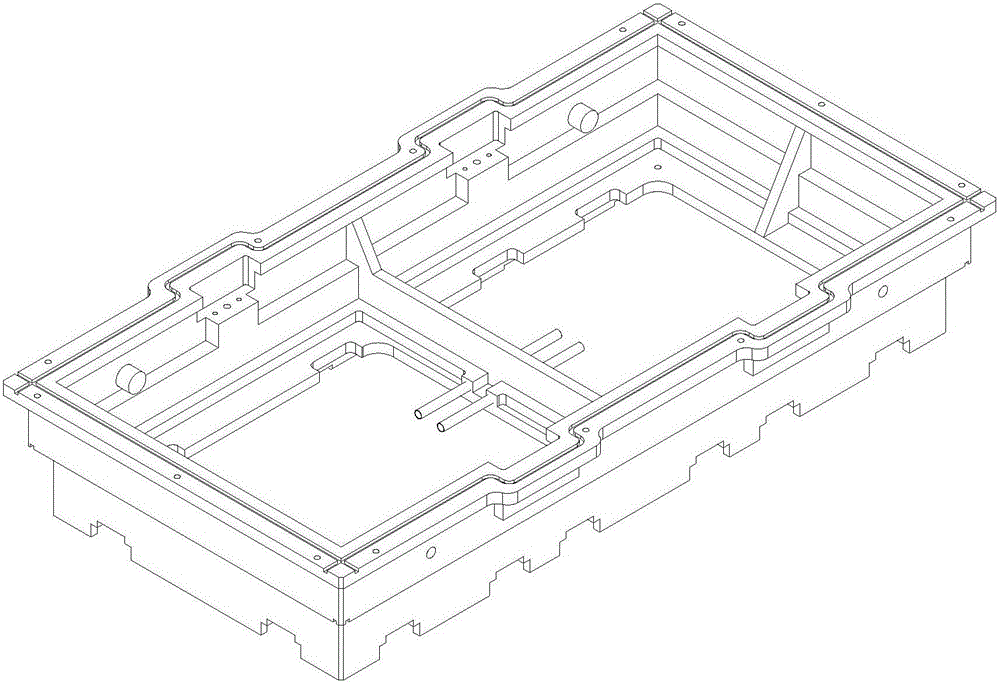

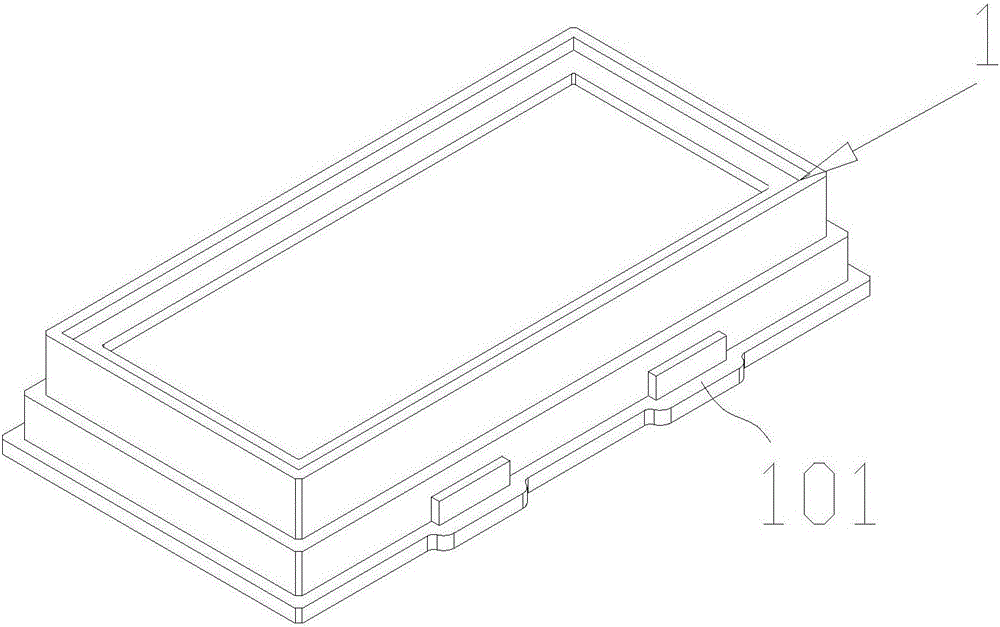

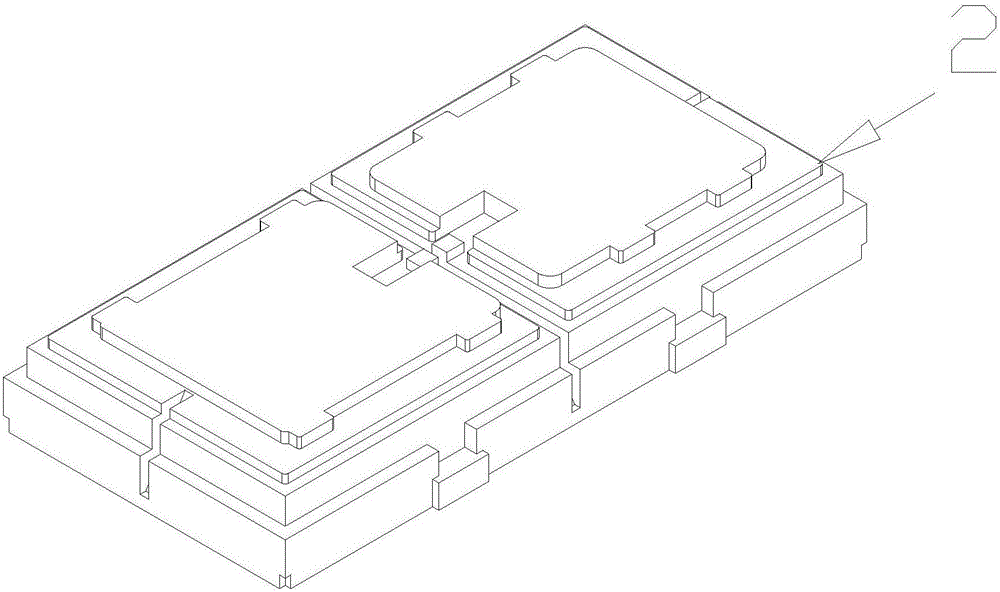

V-method mold casting technique for casting complicated pedestal of home appliance mold

ActiveCN107052262AFast formingQuality improvementFoundry mouldsFoundry coresWater channelRapid processing

The invention provides a V-method mold casting technique for casting a complicated pedestal of a home appliance mold. According to the casting technique, dry silica sand is adopted for V-method molding; the molding negative pressure is controlled to be 0.03Mpa to 0.07Mpa; a pedestal casting is made of aluminum alloy and is cast at the temperature of 690 DEG C; an internal pre-embedded water channel is a circular pipe made of red copper or stainless steel; the surface of the water pipe is coated with a high temperature resistant coating; after the design of the V-method mold is optimized, the mold can be conveniently quickly replaced and quick machining and molding of the mold can be realized; the V-method mold is applicable to a small-batch multi-type production mode; the V-method mold structure is characterized in that an inner die and an outer die are each a convex type; by adopting the method, the mold can be conveniently taken out after molding, and the technical problem that a female die needs a matching board is solved. A secondary molding method is adopted, and a convex cast sand mold can be obtained after secondary molding, and then the convex cast sand mold can be combined with a concave casting cavity to accomplish casting.

Owner:滁州鑫诺实业有限公司

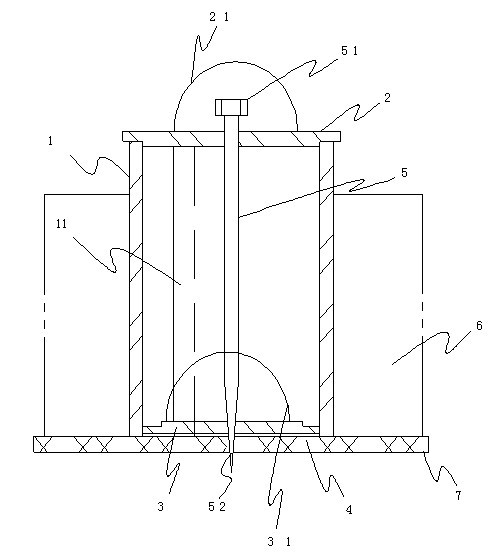

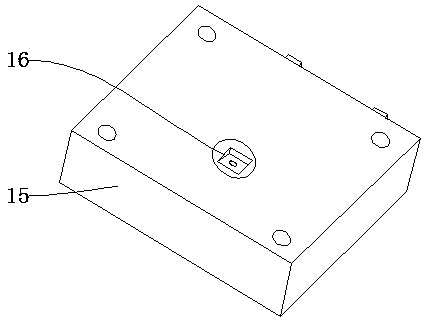

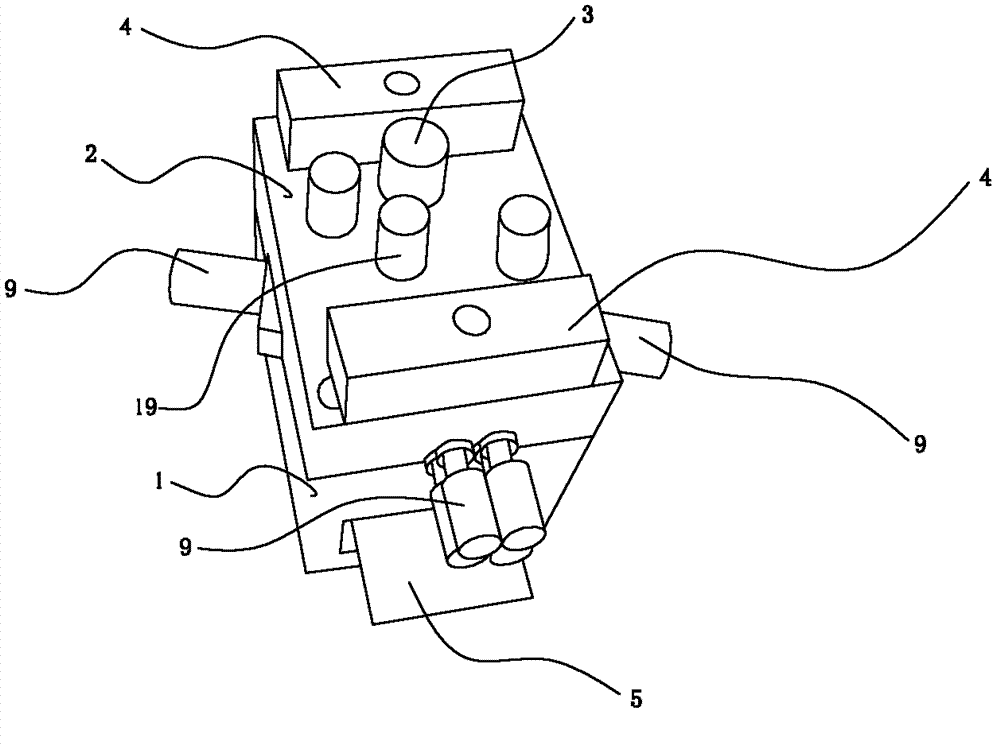

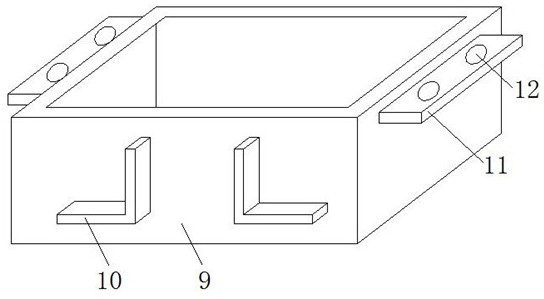

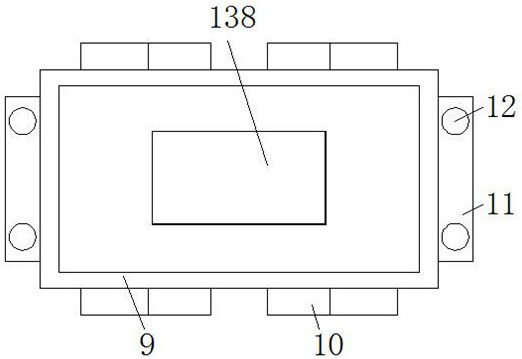

Mold for graphite production

The invention discloses a mold for graphite production, and belongs to the technical field of graphite processing. According to the mold for graphite production, the problems that an existing graphiteproduction die is difficult to replace and long in cooling time, die pressing fails due to die closing dislocation, and the pressure cannot be observed so that the die is damaged due to the fact thatthe pressure is too large are solved. The mold is characterized in that guide columns are correspondingly arranged on the front side and the rear side of the upper end surface of an outer mold, and fixing columns are correspondingly arranged on the left side and the right side of each guide column; a containing groove is formed in the center of the upper end of the outer mold, grooves are correspondingly formed in the left side and the right side of the containing groove, and a first saw tooth groove is formed in the center of the bottom of the containing groove; and a water flow channel is densely arranged in the side wall of the outer mold. According to the mold for graphite production, an inner mold is arranged, a hollow supporting plate arranged below the inner mold and a lifting rodcan be used for conveniently and rapidly replacing a mold, the fixing columns and the guiding columns on the outer mold can enable a mold pressing plate to be more smoothly and accurately pressed andprevented from dislocation, and after the mold pressing is finished, a spring in opening holes of the fixing columns push the mold pressing plate upwards due to the elasticity of elastic force, so that the mold taking is convenient.

Owner:黑龙江省牡丹江农垦奥宇石墨深加工有限公司

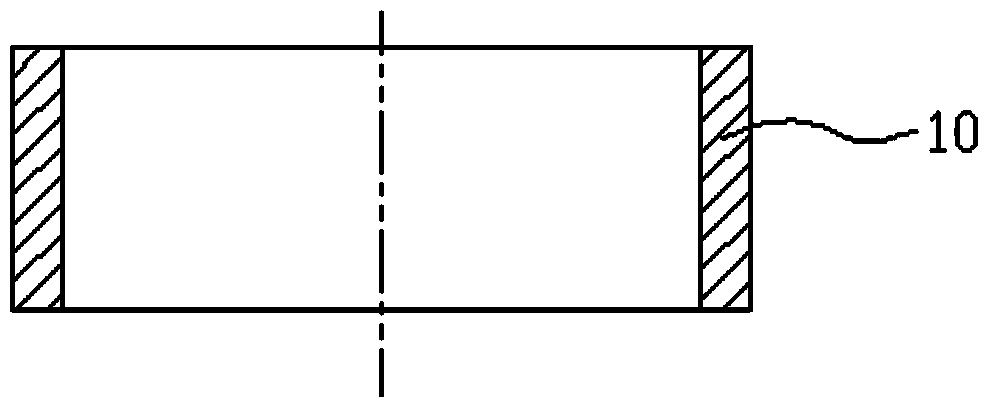

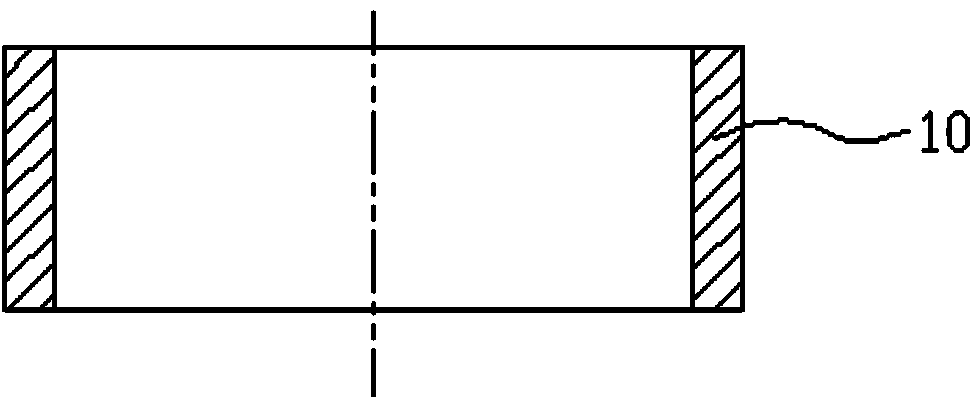

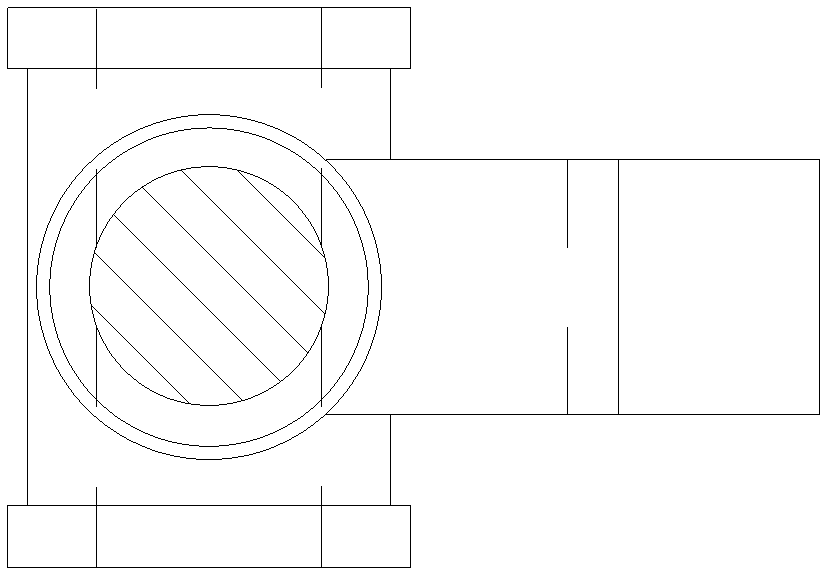

Heat bulging forming method for stainless steel rectangular cross section annular elements

ActiveCN103447377AHigh dimensional accuracyAchieve precision bulge formingShaping toolsProduction rateLarge deformation

The invention discloses a heat bulging forming method for stainless steel rectangular cross section annular elements. The method comprises the following steps that a preheated mold sleeve is fixed on a work table of a bulging machine, then, a heated stainless steel rectangular cross section annular element is sheathed on the periphery of a preheated bulging block in the bulging machine so that the heated stainless steel rectangular cross section annular element is positioned in an annular space surrounded by the outer circumference surface of the bulging block and the inner annular surface of the mold sleeve, the bulging machine is started so that the bulging block extrudes the annular element from the inner circumference surface of the annular element in the radial direction, deforms 10 percent to 13 percent, and is then extruded into the inner annular surface of the mold sleeve, a sealed die cavity surrounded by the outer circumference surface of the bulging block and the inner annular surface of the mold sleeve is fully filled, and the bulged rectangular cross section annular element is formed after the pressure preservation. The method adopts one-step large-deformation-quantity bulging forming, the operation is simplified, and the bulged rectangular cross section annular element with high dimension precision, high product quality and high productivity is obtained. The bulged rectangular cross section annular element is mainly used for rotating body parts of tubular casings and the like used in the fields of aeronautics and astronautics and the like.

Owner:GUIZHOU AVIATION TECHN DEV

V-method model casting process for casting household appliance base

InactiveCN106670385AFast formingQuality improvementFoundry mouldsFoundry coresWater channelRapid processing

The invention discloses a V-method model casting process for casting a household appliance base. Dry silica sand V-method modeling is adopted, modeling negative pressure is controlled to range from 0.03 Mpa to 0.05 Mpa, an aluminum alloy material is adopted in a base casting, and the pouring temperature is 690 DEG C; an inner pre-buried water channel is a round pipe of a red copper or stainless steel material, and the surface of a water pipe is coated with a high temperature resisting coating; after a V-method model is subjected to optimization design, fast model replacement and fast model processing forming are facilitated, and the process is suitable for small-batch multi-variety production modes; and according to the structure of the V-method model, an inner mold and an outer mold are both in a convex type, and by means of the method, mold taking is facilitated after modeling, and a process that a concave mold needs a matching plate is solved. By means of the adopted secondary modeling method, after secondary modeling, a convex pouring sand mould is obtained and can be combined with a concave pouring cavity for pouring.

Owner:马正松

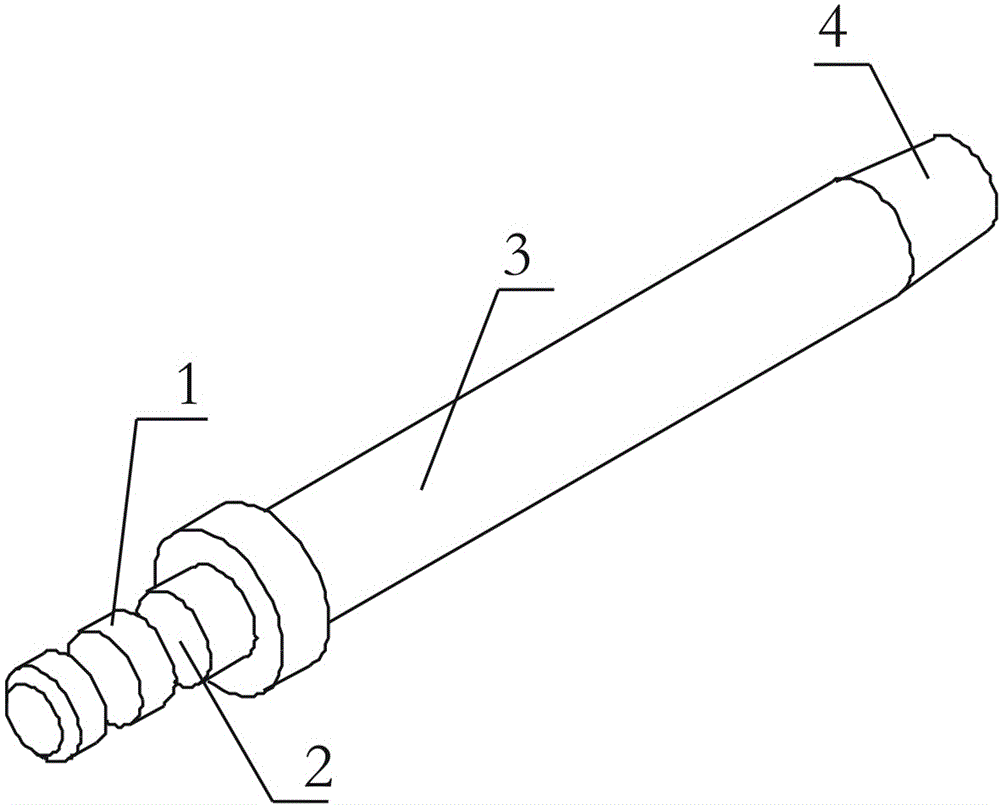

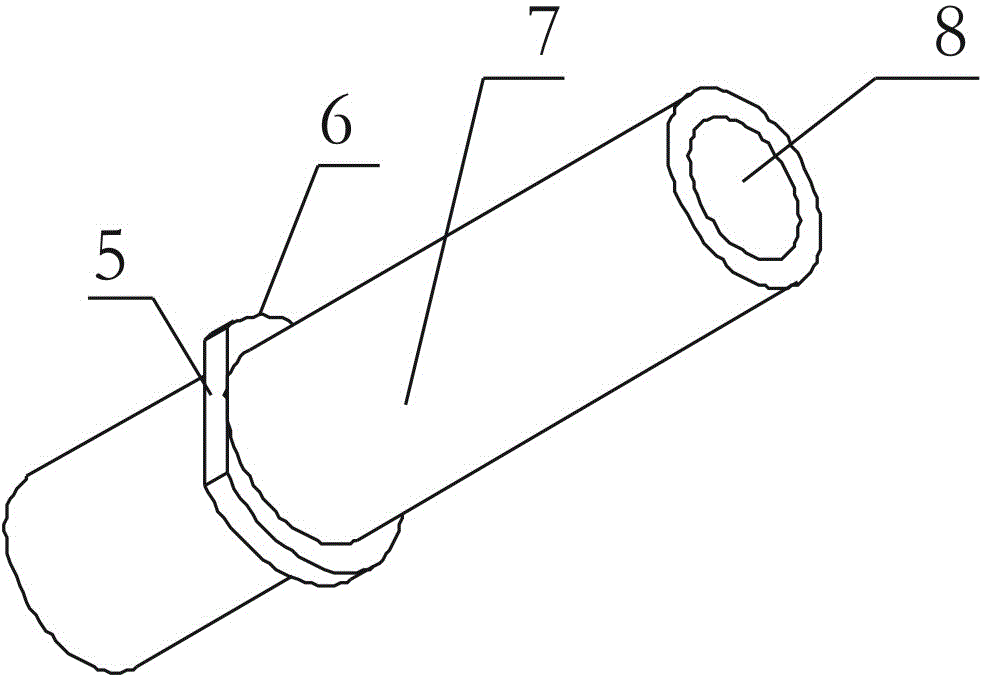

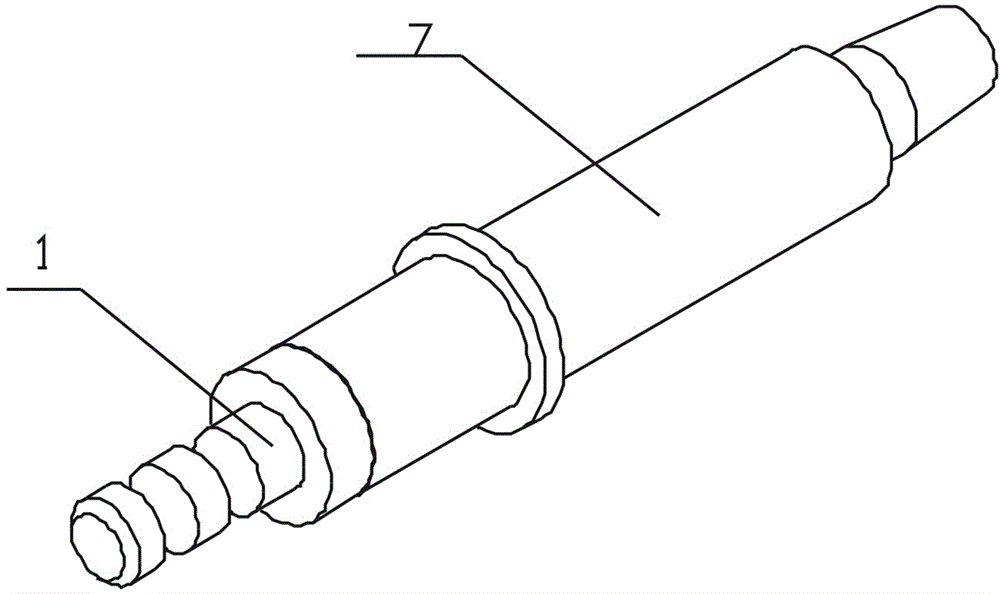

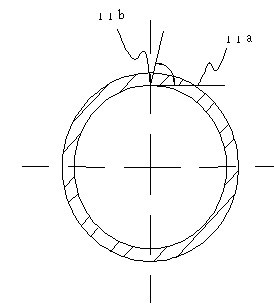

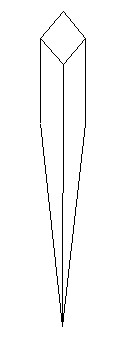

Model implanting nail with rubber jacket

InactiveCN104939937ASimple structureEasy to take modulusDental implantsDental prostheticsGypsumBinding force

The invention discloses a model implanting nail with a rubber jacket. The model implanting nail is characterized by comprising a tooth nail and a rubber jacket, wherein the tooth nail comprises a nail top and a nail body; and the rubber jacket sleeves the nail body. The model implanting nail with the rubber jacket is simple in structure; firstly, the rubber jacket is implanted into gypsum, and after the gypsum is solidified, the rubber jacket is solidified in the gypsum; and due to no binding force between the rubber jacket and the model implanting nail, the model can be taken conveniently and easily without damage.

Owner:武汉金光医疗科技有限公司

Method for manufacturing reserved concrete hole of floor and mold

The invention relates to a method for manufacturing a reserved concrete hole of a floor and a mold. The mold comprises a PE (polyethylene) mold barrel, a cover plate, a supporting plate and a positioning iron nail. During usage, the iron nail penetrates through circle centers of the cover plate and the supporting plate, the mold barrel is supported by the inner edge of the cover plate and the outer edge of the supporting plate, the mold barrel is nailed on a formwork of the floor by the iron nail, and then concrete pouring can be realized. When the mold is detached, the iron nail is taken out in a rotating manner at first, then the cover plate and the supporting plate are lifted up, and finally the mold is taken out. The mold has the advantages of simple structure, accurate positioning, convenience in operation, and reusability. In addition, the mold saves materials and working hours, and is suitable for batch production.

Owner:吴强

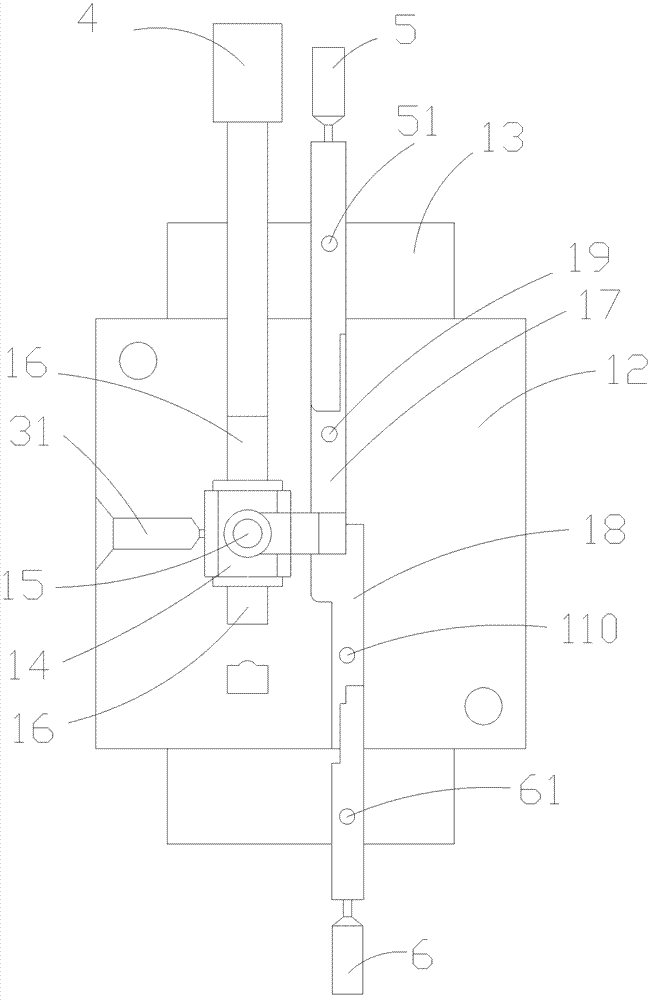

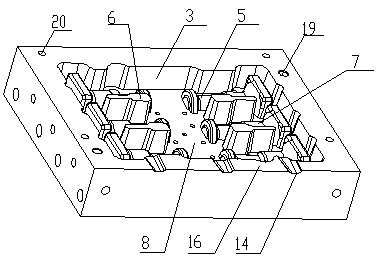

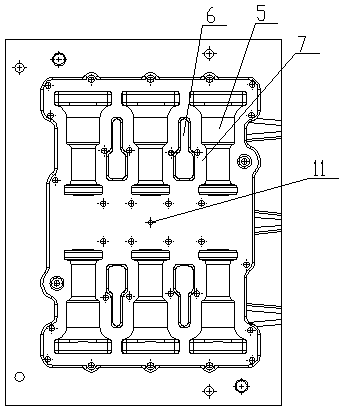

Edge cutting and bending one-time forming die for bracket of automobile fuel tank

InactiveCN110899506AEase of ejectionEasy to eject automaticallyShaping toolsVibration suppression adjustmentsFuel tankMotronic

The invention discloses an edge cutting and bending one-time forming die for a bracket of an automobile fuel tank, and belongs to the field of automobile fuel tanks. The edge cutting and bending one-time forming die comprises a base, wherein the side faces of the top of the base are fixedly connected with supporting frames, the top of each supporting frame is fixedly sleeved with a hydraulic mechanism, the bottom ends of the hydraulic mechanisms are fixedly connected with an extrusion block, each supporting frame is movably sleeved with a moving sleeve, one side of each moving sleeve is fixedly connected with the side face of the extrusion block through a connecting plate, the bottom of each moving sleeve is in transmission connection with the top of the base through a movable spring, andthe top of the base is fixedly connected with a module. By arranging a port, a containing cavity, an electric push rod and an ejector block, the formed bracket can be automatically ejected out in theproduction and manufacturing process of the bracket of the automobile fuel tank, the bracket is separated from the module, the problem that because the bracket is tightly attached to the module, it isdifficult to take out the die is avoided, and thus convenience is brought to die taking of the formed die.

Owner:十堰沃森油箱附件有限公司

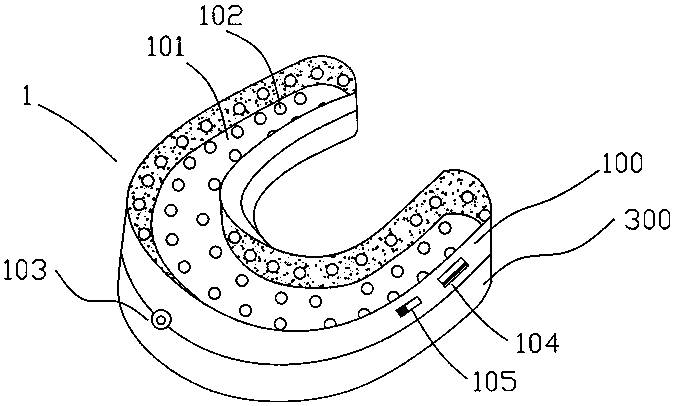

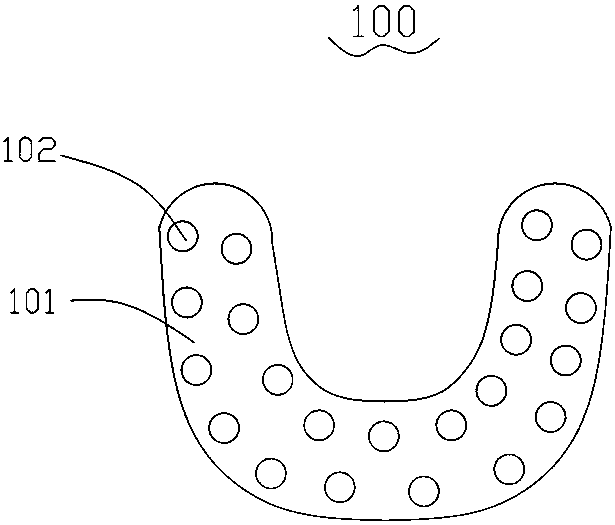

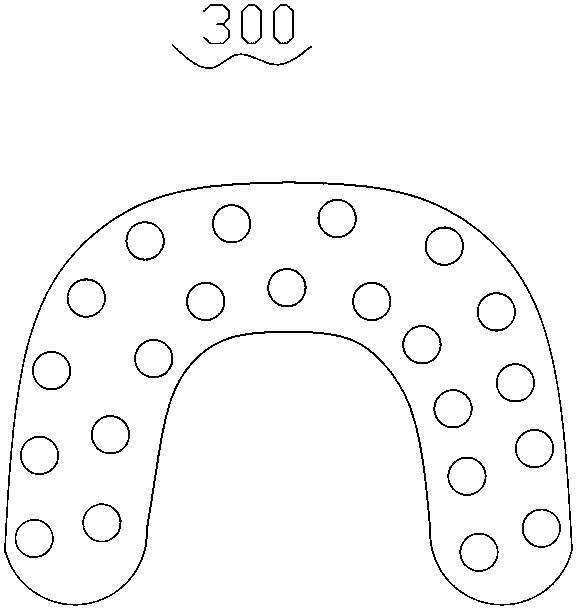

Oral cavity imaging device and use method thereof

PendingCN108354690AProtect normal useGuaranteed medical careDentistryDiagnostic recording/measuringDiseaseImaging processing

The invention discloses an oral cavity imaging device and a use method thereof. The oral cavity imaging device comprises an arc-shaped oral cavity imaging instrument and a wetting prevention sleeve matched with the oral cavity imaging instrument, wherein the oral cavity imaging instrument comprises an upper jaw imaging region and a lower jaw imaging region; the upper and lower jaw imaging regionsare provided with imaging grooves; imaging holes in uniform distribution are formed in the imaging grooves; imaging devices are arranged in the imaging holes; the wetting prevention sleeve comprises awetting prevention upper cover and a wetting prevention lower cover which are connected; the edges of the wetting prevention upper cover and the wetting prevention lower cover are clamped and connected to form a sealed accommodating cavity for accommodating the oral cavity imaging instrument; the wetting prevention sleeve is made of transparent plastics. The oral cavity imaging instrument performs imaging on each angle of the tooth; the images are subjected to image processing to obtain oral cavity tooth line three-dimensional number images; the accurate conditions of the teeth in the oral cavity can be conveniently judged. By using the wetting prevention sleeve, the normal use of the oral cavity imaging instrument is ensured; the oral cavity disease infection is prevented; generally, theoral cavity imaging is fast and accurate; the device is simple and convenient; the use is convenient; the oral cavity sanitation can be ensured.

Owner:深圳市一诺牙科技术有限公司

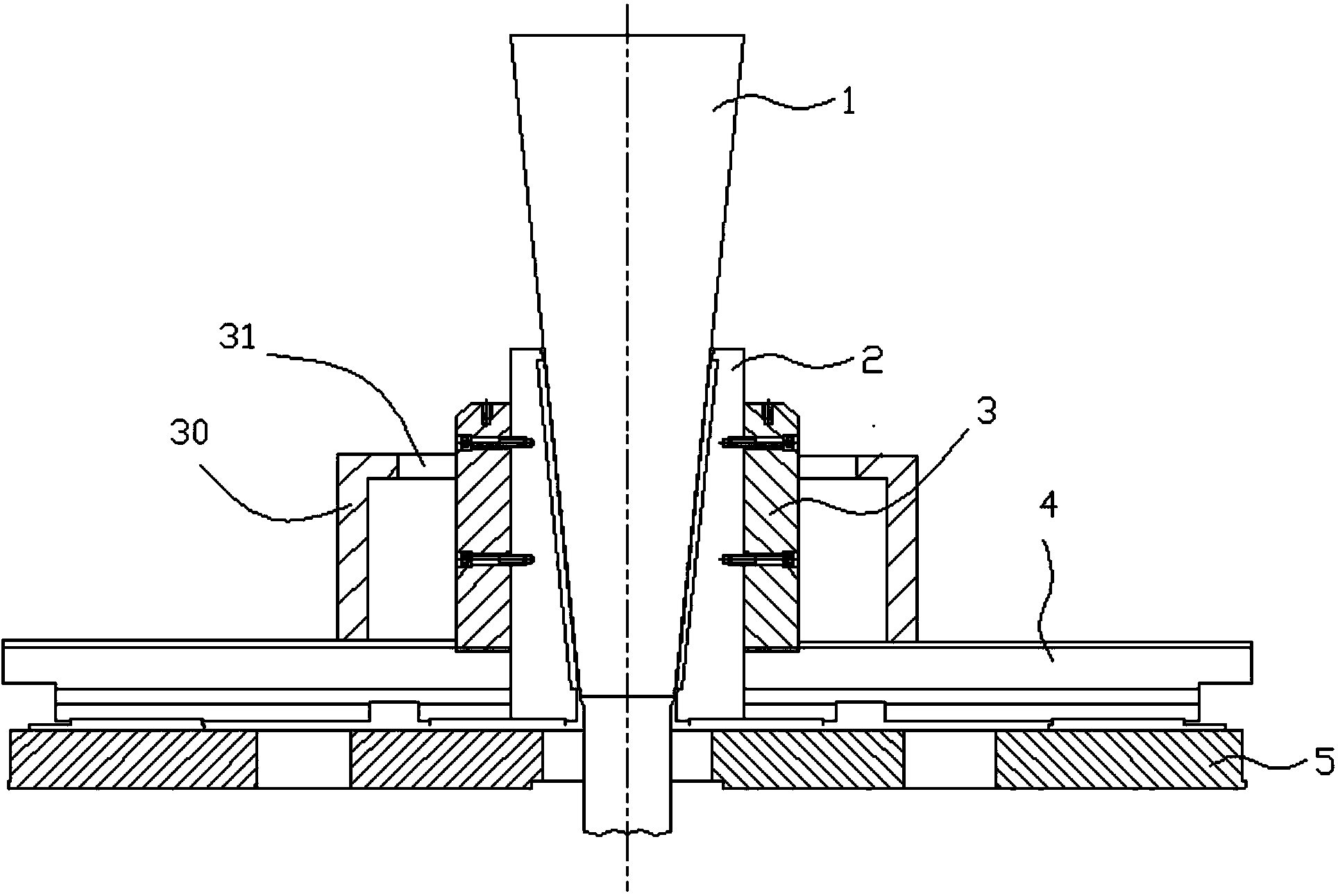

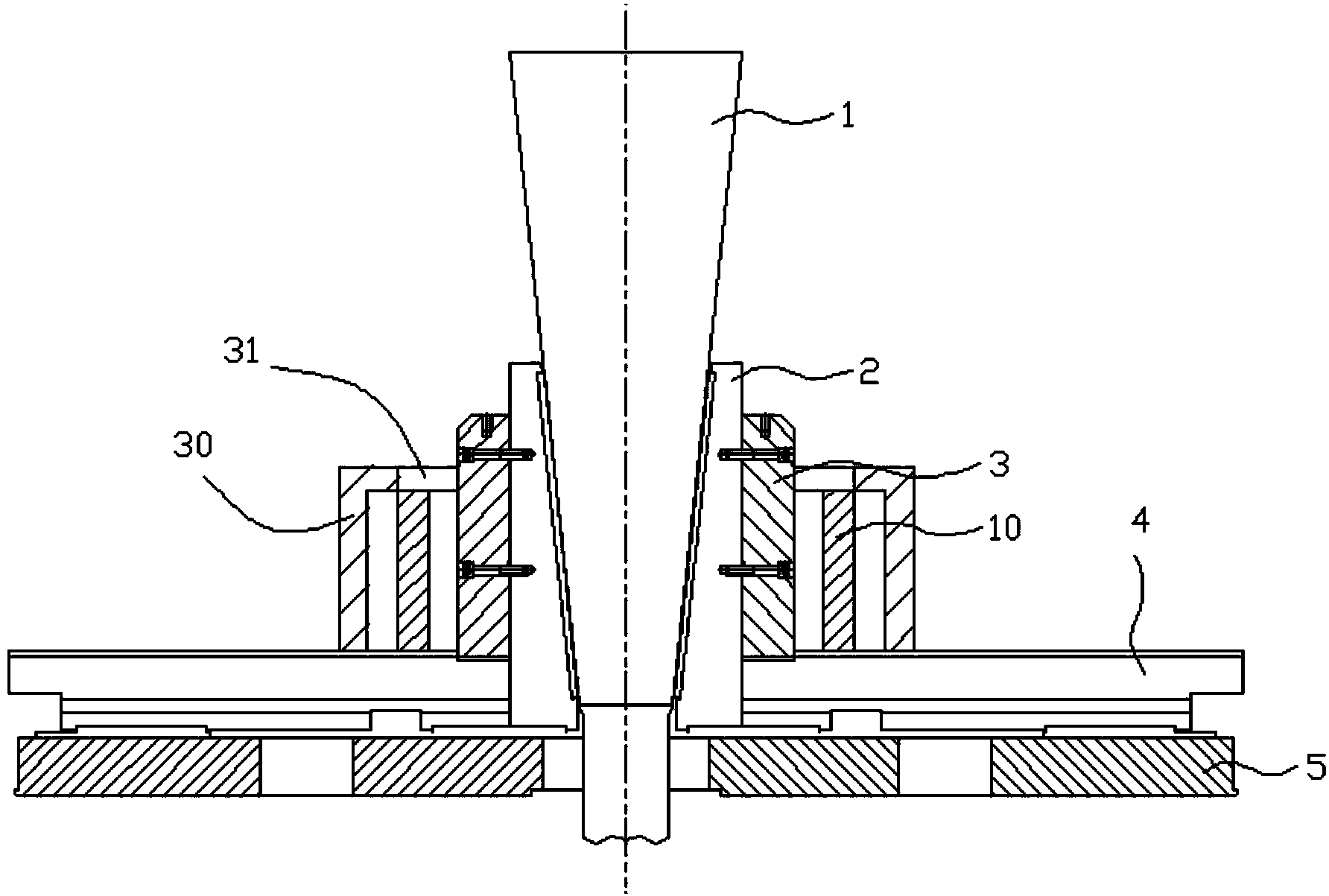

Injection mold for three-way pipe

InactiveCN109049523AEasy to take modulusSolve the problem of temperature reduction and solidificationDomestic articlesLiquid storage tankEngineering

The invention discloses an injection mold for a three-way pipe. The injection mold comprises a bottom fixing base, mold supporting legs, a handheld moving plate, a mold core and an afterteeming sealing stop block. The mold supporting legs are arranged on the bottom fixing base. A lower mold body is mounted on the mold supporting legs. The handheld moving plate is arranged on one side of the lowermold body. Bolt mounting holes are formed in the top of the lower mold body. A mold core stop block is mounted on one side of the bolt mounting holes. The mold core is mounted on one side of the moldcore stop block. An afterteeming pipeline is mounted above the mold core. The injection mold for the three-way pipe has the beneficial effects that an arc-shaped mold ejection head is arranged to eject the mold core so that the three-way pipe can be taken out of the mold conveniently after being formed; the temperature of an injection molding liquid storage tank can be maintained, so that the problem that injection molding liquid is solidified due to temperature drop is effectively solved; and the afterteeming pipeline is arranged so that afterteeming can be conducted when the three-way pipe is not completely cast, and the forming quality of the thee-way pipe is ensured.

Owner:张秀萍

Hot bulging forming method for bearing steel rectangular cross-section ring unit

ActiveCN103447378AHigh dimensional accuracySimplified bulging processShaping toolsProduction rateLarge deformation

The invention discloses a hot bulging forming method for a bearing steel rectangular cross-section ring unit. The hot bulging forming method comprises the following steps of fixing a preheated die sleeve on a worktable of a bulging machine, then, sleeving the periphery of a preheated bulging block in the bulging machine with the preheated bearing steel rectangular cross-section ring unit, and enabling the bearing steel rectangular cross-section ring unit to locate in an annular space formed by encircling the outer circumferential surface of the bulging block and the inner ring surface of the die sleeve; starting the bulging machine to enable the bulging block to extrude the ring unit along a radial direction from the inner circumferential surface of the ring unit and extruding into the inner ring surface of the die sleeve after the ring unit is deformed by 9-11 percent to fill a closed mold cavity formed by encircling the outer circumferential surface of the bulging block and the inner ring surface of the die sleeve, and retaining the pressure of the ring unit to enable the ring unit to become the bulged rectangular cross-section ring unit. According to the method, by adopting one-time large-deformation bulging forming, the operation is simplified, and the bulged rectangular cross-section ring unit which is high in dimensional accuracy, good in product quality and high in production rate is obtained. The bulged rectangular cross-section ring unit is mainly used for revolved body parts used in the fields of wind power generation and the like.

Owner:GUIZHOU AVIATION TECHN DEV

A multifunctional and convenient injection mold

Owner:南基塑胶模具(深圳)有限公司

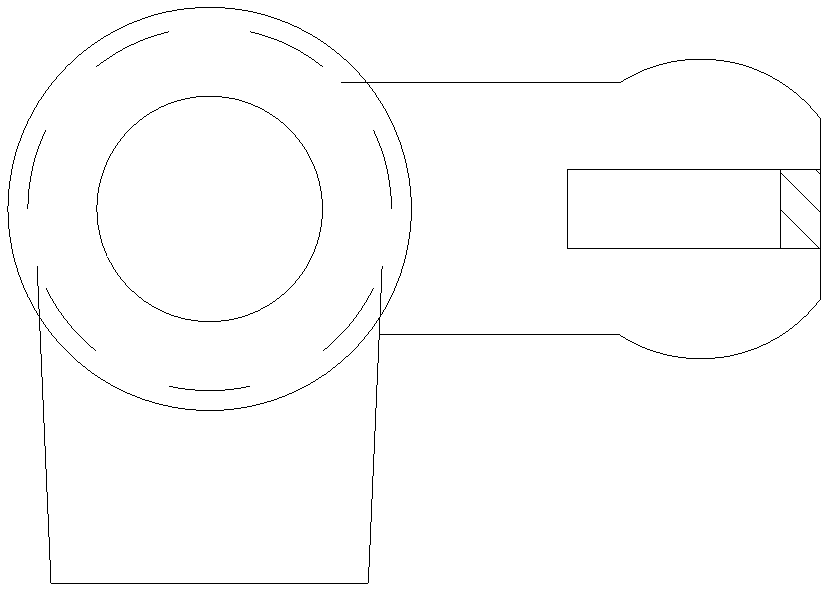

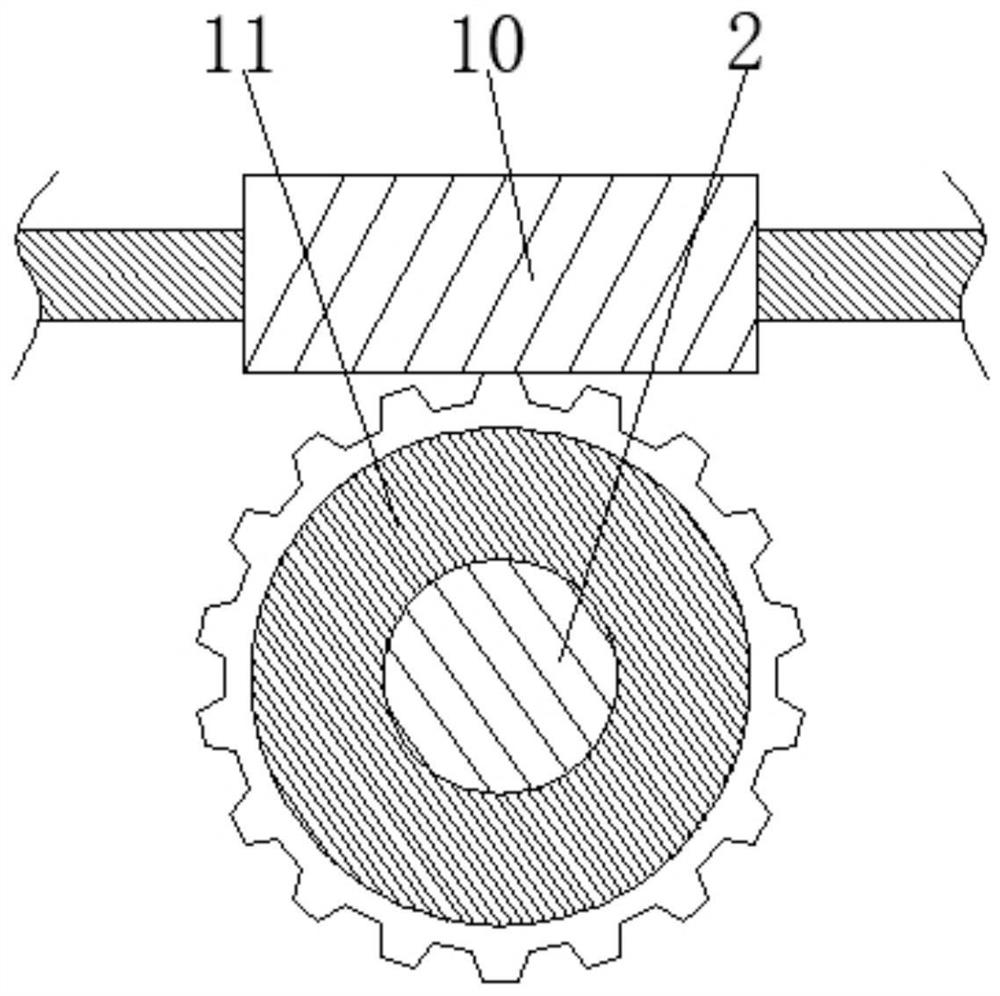

Injection mould for connecting rod

The invention provides an injection mould for a connecting rod. The injection mould comprises a fixed mold, a mold core in the fixed mold, and a movable mold which can be pressed on the fixed mold; a horizontal through hole is formed at the lower part of the fixed mold; a mold picking plate is arranged in the horizontal through hole along a horizontal direction; parting surfaces are formed on the combined part of the fixed mold and the movable mold; a first cavity is formed between the fixed mold and the mold core; a sliding chute is formed on the parting surface of the movable mold; a drawing block is arranged and can be slipped into the sliding chute; a second cavity is formed at the bottom part of the sliding chute; the first cavity and the second cavity can be closed to each other to form a complete cavity; pouring channels are formed and are used for communicating the first cavity and the second cavity with the outside; a hole channel is formed and can pass through the movable mold and then is inserted into the top part of the mold core; a drawing pin is arranged and can be inserted into the hole channel; and the bottom part of the mold core is connected with the mold picking plate. By adopting the injection mould for the connecting rod, the production efficiency of an enterprise is improved to a certain extent, the cost of the enterprise is saved, and the demand on processing of the connecting rod can be met better.

Owner:SUZHOU LASERHOWER PRECISION CASTING

Wax injection mold for bent needle bar shaft casing

ActiveCN102950246AEasy to operateSimple structureFoundry moulding apparatusEngineeringMechanical engineering

The invention discloses a wax injection mold for a bent needle bar shaft casing. Regarding the structure characteristics of a bent needle bar shaft casing part to be injected with wax, a movable mold and a fixed mold which are matched with each other to form a cavity which is in accordance with the bent needle bar shaft casing part to be injected with wax in shape; when wax injection is required, a fixed mold plate and a movable mold plate are closely matched correspondingly, and a draw pin, a first insert block and a second insert block are inserted in sequence; and liquid wax is injected into the cavity formed between the fixed mold and the movable mold through a water gap, the fixed mold is taken off after the liquid wax is cooled and formed, the draw pin, the first insert block and the second insert bloc are drawn out in sequence, two sides of a drawing module is pulled up, an injected wax mold is ejected by an ejector pin from a plurality of grooves of the movable mold plate, so that the mold can be taken out conveniently. The mold is simple in structure and convenient to operate, and can be used for producing a high-precision mold of the bent needle bar shaft casing part.

Owner:SUZHOU ZHICHENG MACHINERY

Double-layer refractory coating used for centrifugal casting process metal die and spraying process thereof

The invention relates to a double-layer refractory coating used for a centrifugal casting process metal die. The double-layer refractory coating used for the centrifugal casting process metal die is characterized by comprising a bottom-layer refractory coating body and a surface-layer refractory coating body; the bottom-layer refractory coating body comprises, by mass, 40%-50% of graphite powder, 9%-11% of a binder and 50%-40% of water; and the surface-layer refractory coating body comprises, by mass, 40%-50% of mullite powder, 9%-11% of a binder and 50%-40% of water. According to the double-layer refractory coating used for the centrifugal casting process metal die, the metal die coating used in the centrifugal casting process is studied, and the graphite refractory coating preparation method and the mullite refractory coating preparation method are adopted, so that not only is the problem that the two coating bodies are bonded with each other solved, but also mutual noninterference of the two coating bodies is ensured; functionally, the advantage that casting demolding is easy through the graphite refractory coating body and the advantage that the casting surface quality is ensured through the mullite refractory coating body are combined; a casting produced by centrifugal casting by using the metal die sprayed with the double-layer composite coating is easier to demold, and surface pores are decreased; and accordingly, the service life of the metal die is prolonged, and the production efficiency is improved.

Owner:SHANGHAI SINOTEC

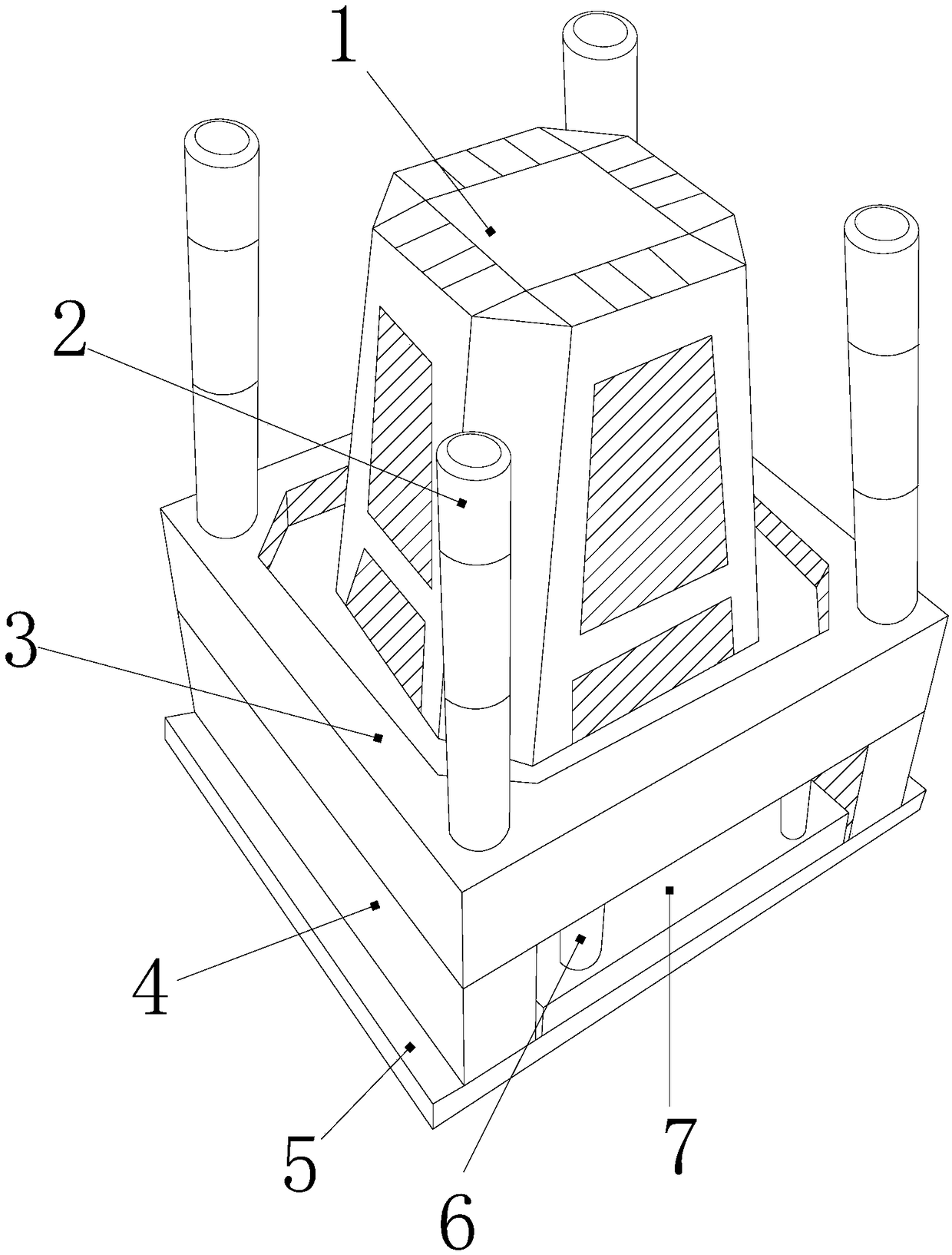

Plastic stool injection mold base for preventing reinforcing ribs from dragging damage during demolding

ActiveCN109352893AFlexible adjustment of inclinationPerfect for underprotected situationsDomestic articlesEngineeringSlide plate

The invention discloses a plastic stool injection mold for preventing reinforcing ribs from dragging damage during demolding. The plastic stool injection mold base structurally comprises a plastic mold shell board, a bolt column, an ejector sleeve ejector, two base cushion blocks, a pedestal, two torsion spring columns and a liner, wherein the two base cushion blocks are attached to the lower leftcorner and the lower right corner of the ejector sleeve ejector separately, the two torsion spring columns are inserted and embedded at the upper left corner and the upper right corner of the liner separately. The plastic mold shell board and the ejector sleeve ejector cooperate, a worker performs pushing and pressing with a thick push rod and a thin push rod of a bevel adjuster, the thick push rod is used for making a rotary lug plate to jack the front end of a sliding plate of a spring seat to tilt so as to push a finished product out, the effect of flexibly adjusting the inclination is achieved, and then the thin push rod pushes a steel reed pipe to balance the rear end of the sliding plate so as to prevent scratch loss, so that a linkage connection rod push frame has upward acting force on the plastic mold shell board in an ejector sleeve body, a product is discharged out of a mold with the inclination of the front side being well controlled, then the rear side is integrally jacked to lift the mold, the product protection effect of the mold is improved, and the stability of product quality is optimized.

Owner:重庆天骄塑料包装有限责任公司

Mold with rapid cooling function and convenient mold taking for bearing machining

InactiveCN111016079AIncrease frictionEasy to combineDomestic articlesEngineeringMechanical engineering

The invention discloses a mold with a rapid cooling function and convenient mold taking for bearing machining, and relates to the technical field of bearing machining. The mold comprises a lower mold,a mold cavity and a cooling mechanism, wherein an upper mold is arranged above the lower mold, and a rubber attaching layer is arranged on the outer side of the joint of the upper mold and the lowermold; supporting columns are fixed on the two sides of the lower part of the lower mold, and an anti-skid bottom plate is arranged at the bottoms of the supporting columns; an ejection mechanism is arranged above the middle of the anti-skid bottom plate, and an ejection groove is formed in the middle of the lower part of the lower mold; and clamping blocks are fixed below the four corners of the upper mold, and clamping grooves are formed in the four corners of the lower mold. The mold has the beneficial effects that the ejection mechanism is arranged, so that a formed bearing can be conveniently ejected out to be loosened so as to be convenient to take; and an electric telescopic rod is arranged, so that a push plate and an ejection block can be conveniently driven to ascend and descend,and therefore the formed bearing can be conveniently ejected out, and the ejection block is of an annular structure and is matched with the shape of the mold cavity of the bearing.

Owner:东莞市史雷帝三维数控科技有限公司

Novel dental impression tray for fine oral impression production

InactiveCN111214303AEasy to take modulusSolve the problem that the trouble of taking models affects work efficiencyImpression capsGonial angleImpression trays

The invention discloses a novel dental impression tray for fine oral impression production, and relates to the technical field of medical appliances. The tray includes a right supporting plate and a left supporting plate, a through hole is arranged in one side of the right supporting plate, a fixing groove is arranged in one side of the left supporting plate, a pin shaft is movably connected in the fixing groove, and the middle part of the pin shaft is movably connected with the inner wall of the through hole; and the top ends of the right supporting plate and the left supporting plate are fixedly connected with a tooth socket, a nano air cushion is fixedly connected in the tooth socket, and an air filling hole is arranged in the surface of the tooth socket. According to the tray, throughcooperation of the nano air cushion and the air filling hole, molding can be conveniently performed on patients with high arch of palatal caps and uneven dentition, the problem that work efficiency isaffected because molding is trouble is solved, and the work efficiency is improved; and through cooperation of clamping grooves, a spring, a fixing rod, a sliding groove and blocking blocks, the angle of the tooth socket can be adjusted, so that the problem of replacing the tooth socket back and forth is solved, and the work efficiency is improved.

Owner:长兴义捷电子器材有限公司

Mold releasing device

Owner:重庆奥阳模具制造有限公司

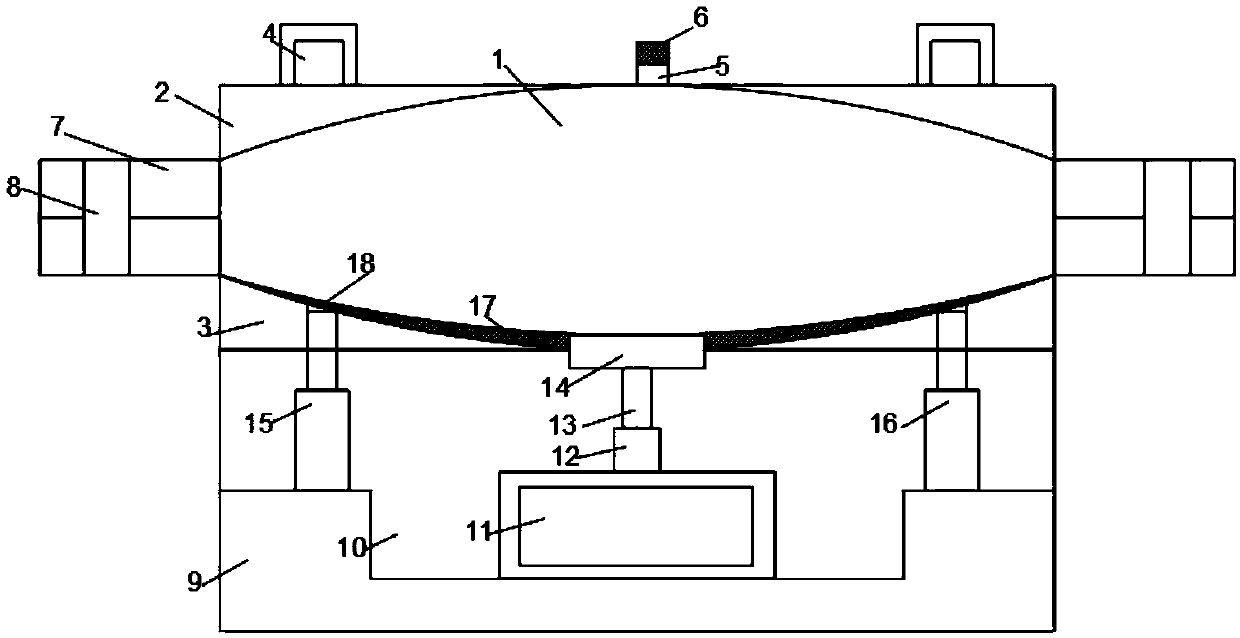

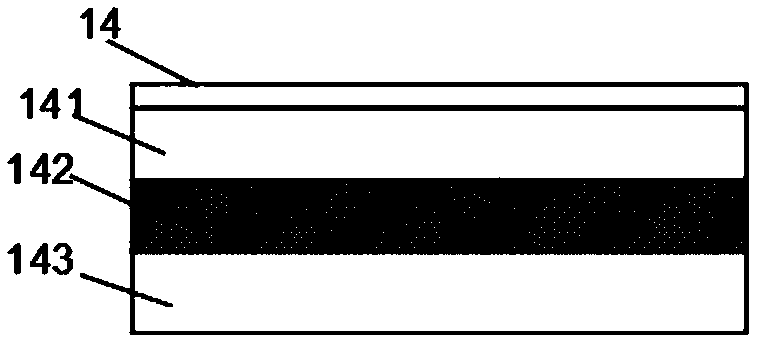

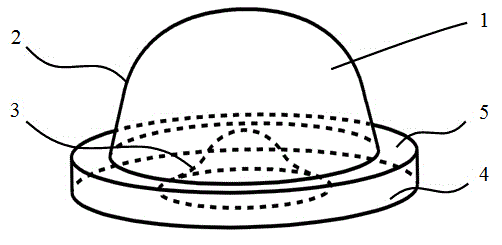

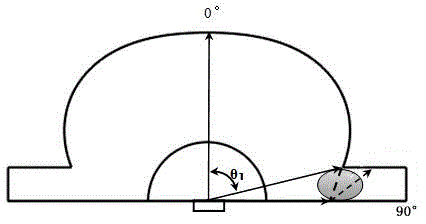

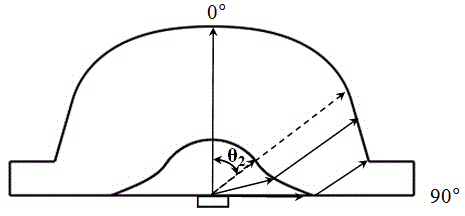

LED secondary optical lens and manufacturing method thereof

ActiveCN104534406AEasy to take modulusTake advantage ofPoint-like light sourceRefractorsLight spotEngineering

The invention relates to the technical field of optical lenses and discloses an LED secondary optical lens. The LED secondary optical lens comprises a lens body, the lens body is provided with a convex lens positive camber and a lens negative camber concaved into the lens, the convex initial end of the lens positive camber is connected with a circular lens installation ring, the surface, crossed with the lens positive camber, of the lens installation ring is an installation face, the surface opposite to the installation face is a base face, the convex lens positive camber is formed by rotating a positive camber curve and a positive camber straight line connected with the positive camber curve around the center axis of the lens, the positive camber straight line is crossed with the installation face, and the positive camber curve is crossed with the center axis of the lens. No inwards concave part is generated in the lens positive camber, so that a mould is convenient to take out in the injection molding process of the lens; by designing the position of the cross point of the positive camber straight line and the installation face through calculating, light rays originally located between the base face and the installation face are fully utilized, light rays near the 90-degree emergent rays of a light source are effectively utilized, and light spots of emitted light rays are uniform.

Owner:CHENGDU HERCULUX OPTOELECTRONICS TECH CO LTD

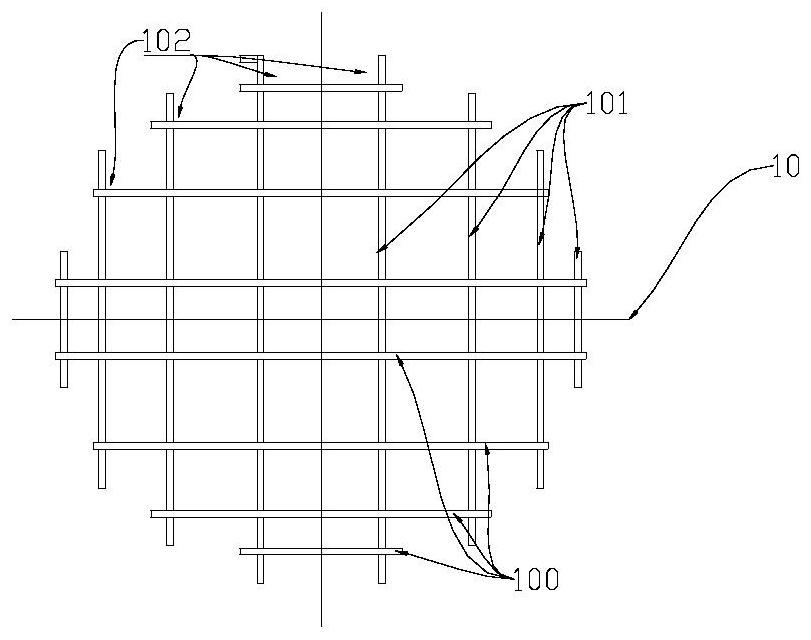

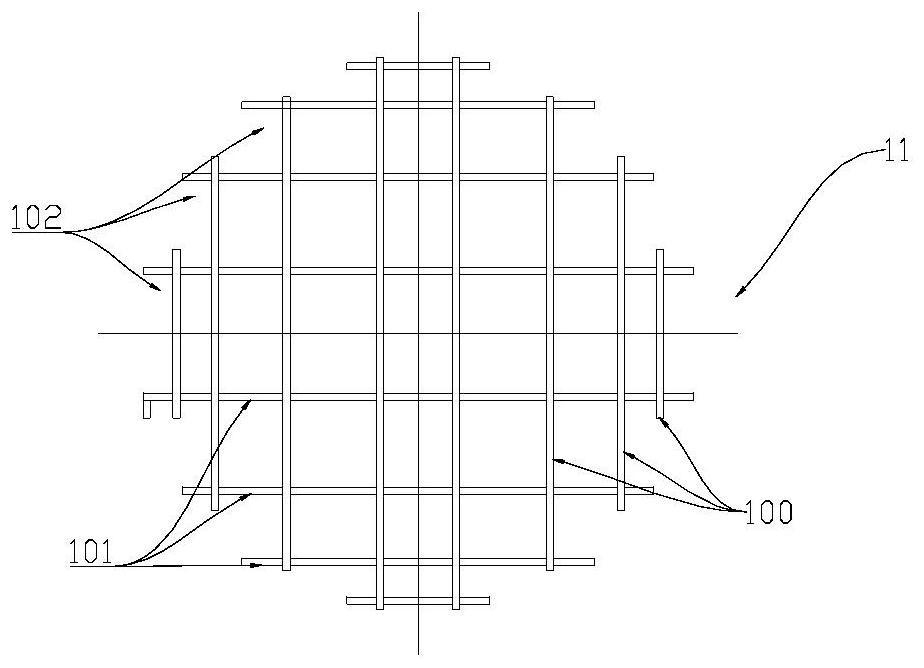

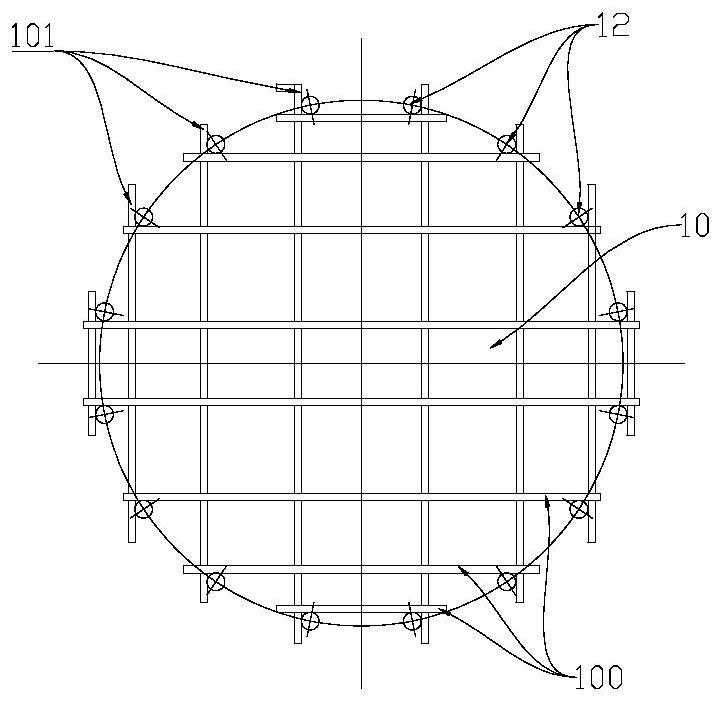

Foundation bolt pre-embedding positioning device and construction method thereof

PendingCN114033194ADoes not affect strengthSmall sizeBuilding material handlingArchitectural engineeringTower

The invention provides a foundation bolt pre-embedding positioning device and a construction method thereof, relates to the technical field of electric power iron towers and street lamp poles, and solves the technical problems that a foundation bolt pre-embedding construction method is high in working difficulty, a foundation bolt fixing mode is unreliable, and the perpendicularity of a foundation bolt cannot be guaranteed. The device comprises a first positioning support and a second positioning support, the first positioning support and the second positioning support are #-shaped frames formed by intersecting at least two longitudinal rods and at least two transverse rods, and the tail ends of the longitudinal rods protrude out of the outermost intersection points of the longitudinal rods and the transverse rods and extend outwards, and limiting structures for the foundation bolts in at least two directions are formed at the intersection points located on the outermost sides of the positioning supports, and the first positioning support and the second positioning support are stacked up and down in a crossed mode so as to position each foundation bolt in four directions. After positioning is conducted through the first positioning support and the second positioning support, the position size of the whole set of foundation bolts is accurate, and the overall stability is good.

Owner:启东市建筑机械厂有限公司

Rigid polyurethane foam plastic and preparation method thereof

The invention discloses a rigid polyurethane foam plastic. The rigid polyurethane foam plastic is characterized by comprising the following components in parts by weight: 1-2 parts of pentamethyldialkylene triamine, 60-80 parts of water, 10 to 26 parts of a flame retardant, 3-4 parts of a stabilizer, 20-30 parts of a foaming agent, 0.02 to 0.03 part of an organic metal catalyst, 40 to 50 parts ofvegetable oil polyether polyol, 20 to 30 parts of petroleum polyester polyol, and 10 to 20 parts of polyethylene oxide polyol. The rigid polyurethane foam plastic disclosed by the invention has the beneficial effects that a foaming body is a low-temperature thermal-insulation material with a pore cavity high in the percentage of close area and low in water absorption rate, and the rigid polyurethane foam plastic has the advantages of small heat conductivity coefficient, high strength, stable chemical performance and convenience in construction; according to the preparation method for the rigidpolyurethane foam plastic, a polyurethane foaming mold is adopted in the preparation process, so in the process of foaming, raw materials do not overflow, foam does not collapse or shrink, the arrangement of a bracket allows the mold to be convenient to take after foaming is finished, and manual operation is facilitated.

Owner:浙江大众隔热科技有限公司

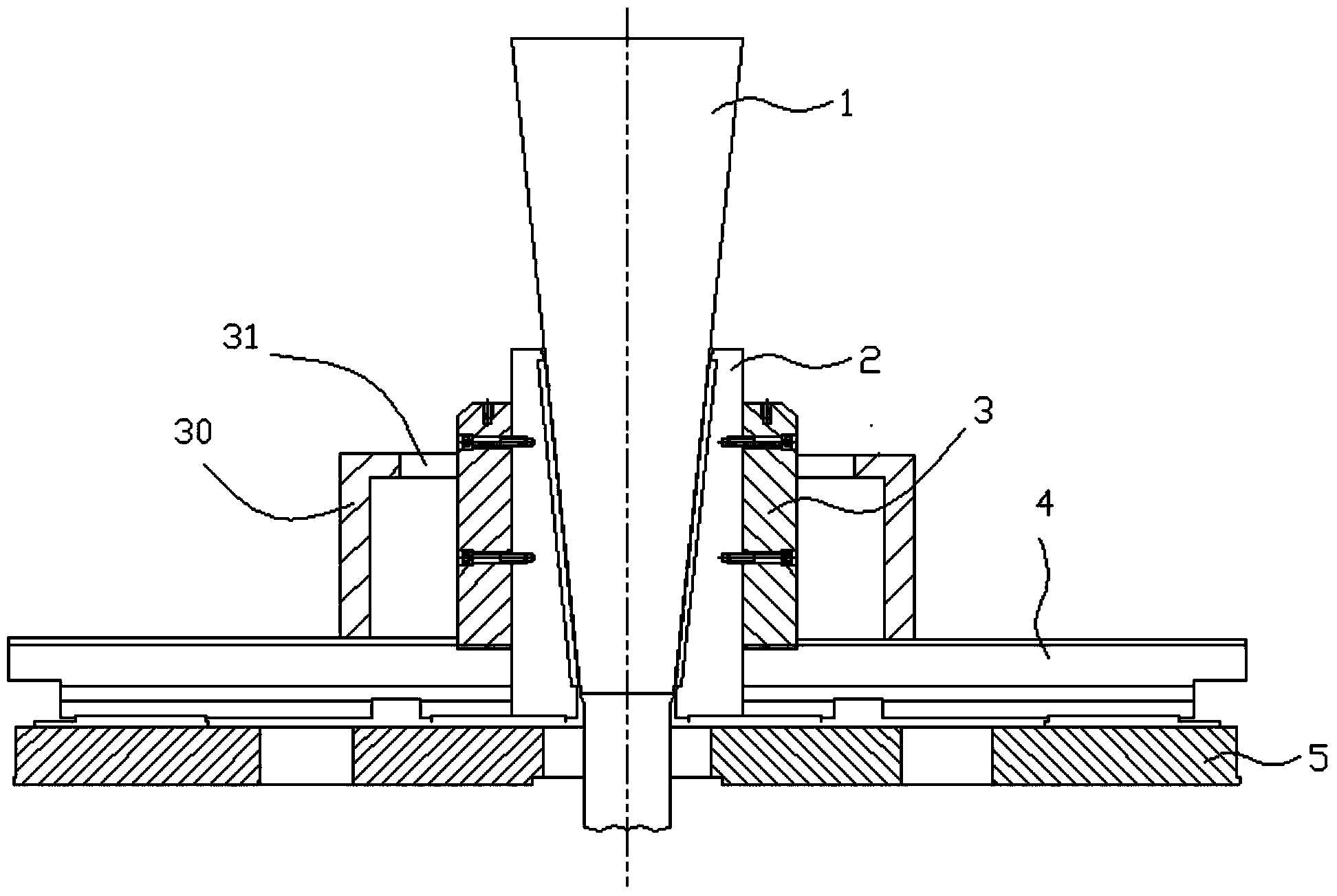

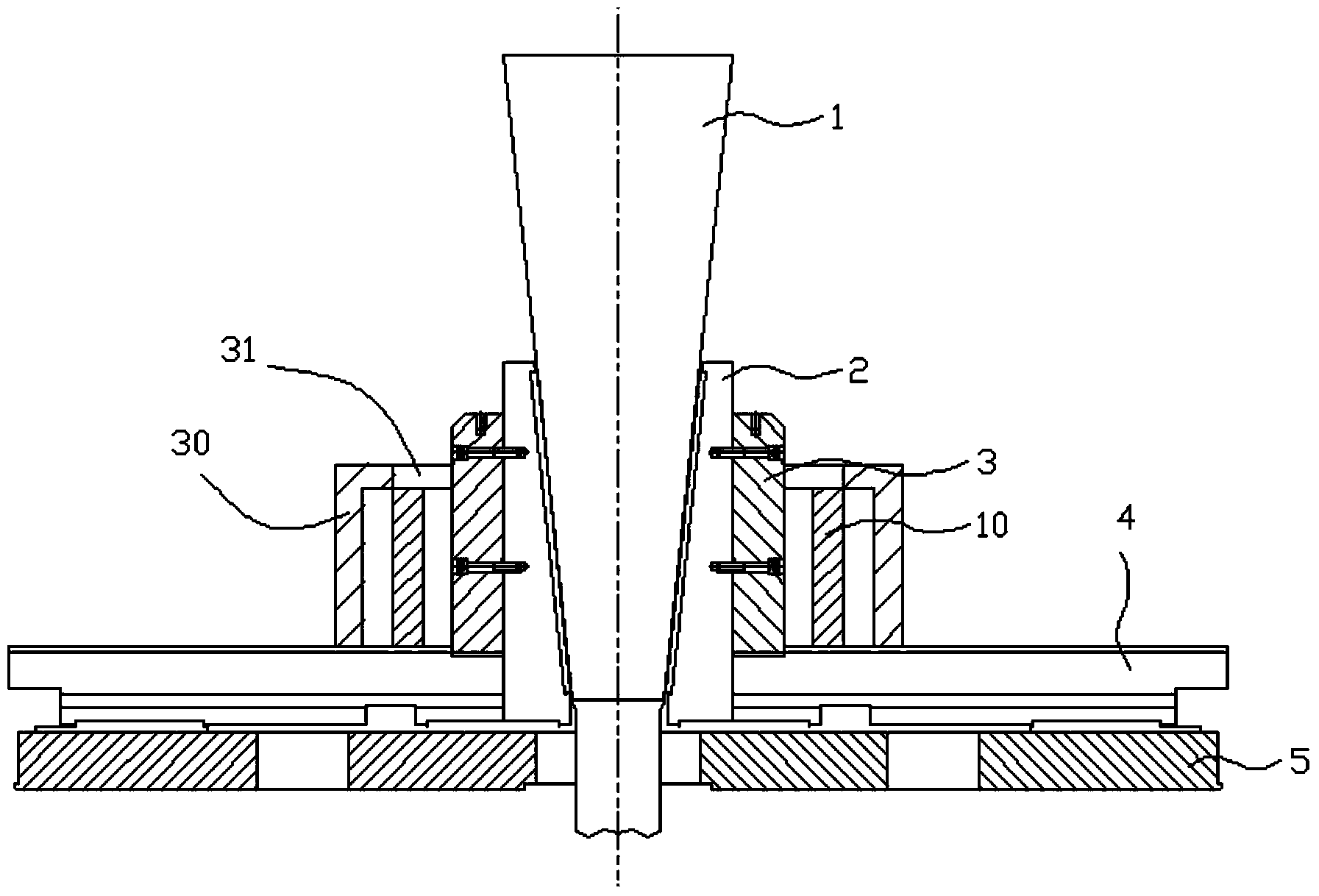

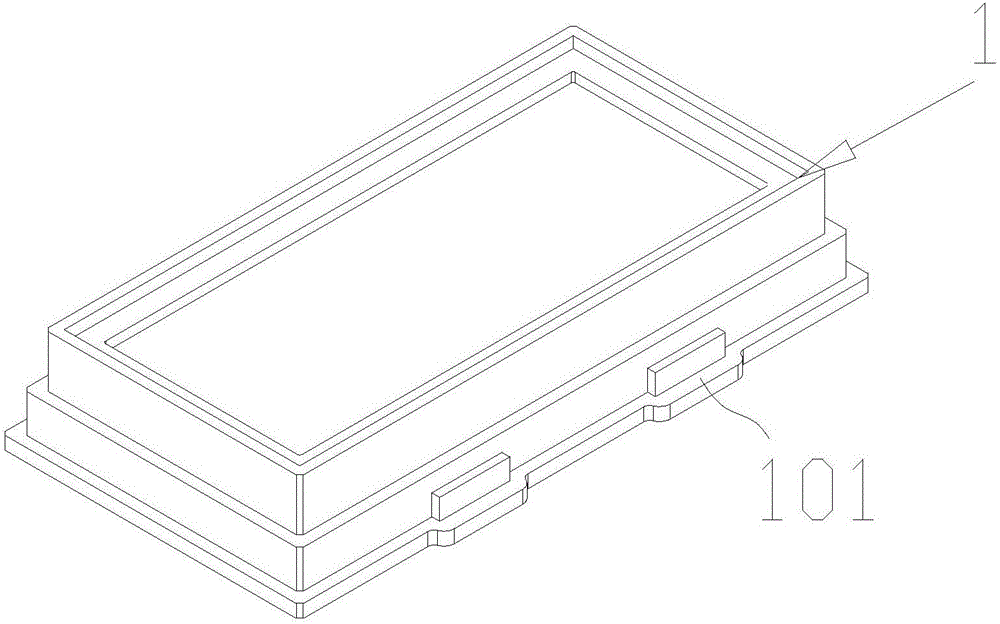

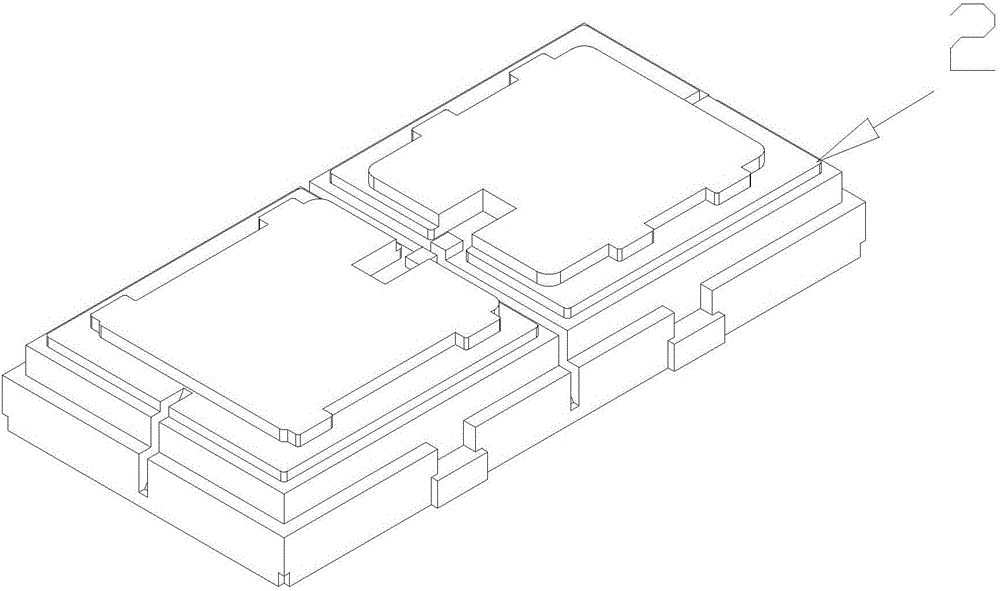

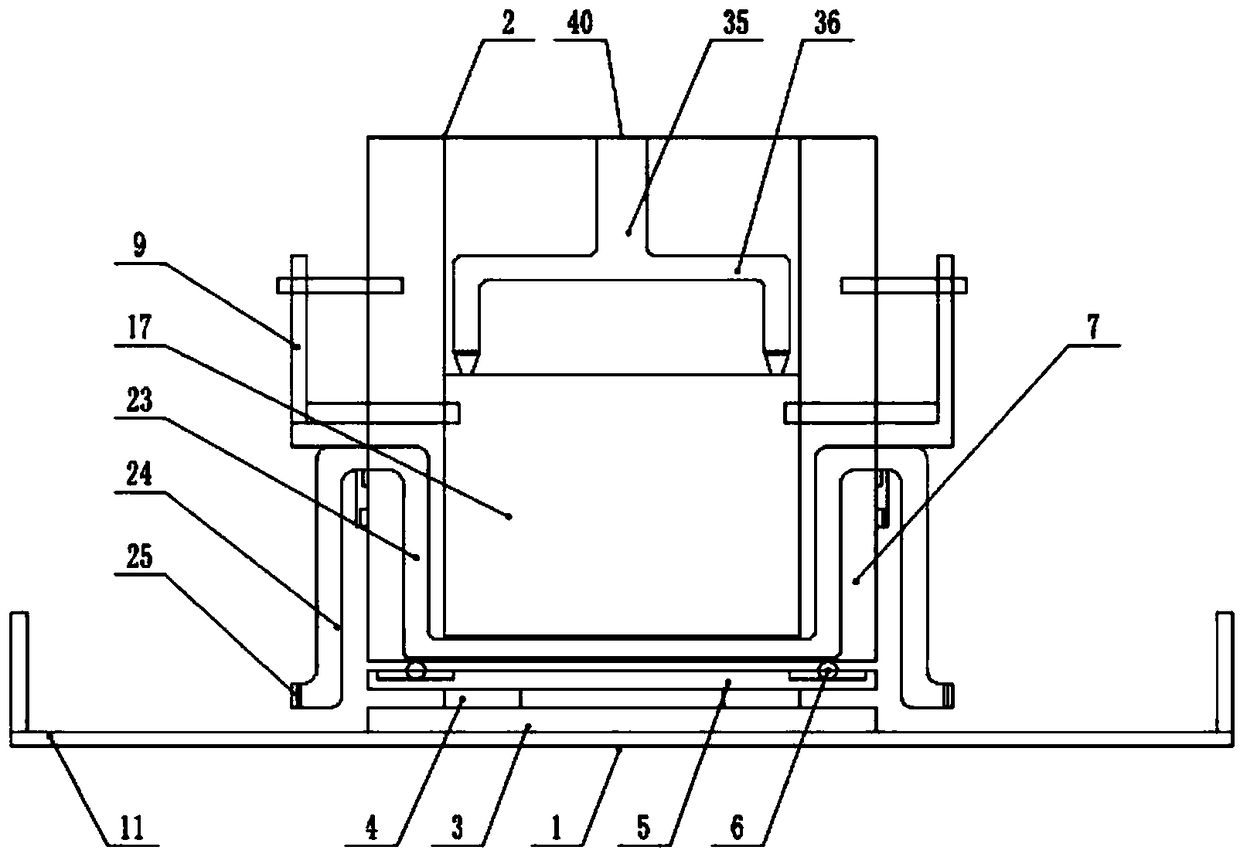

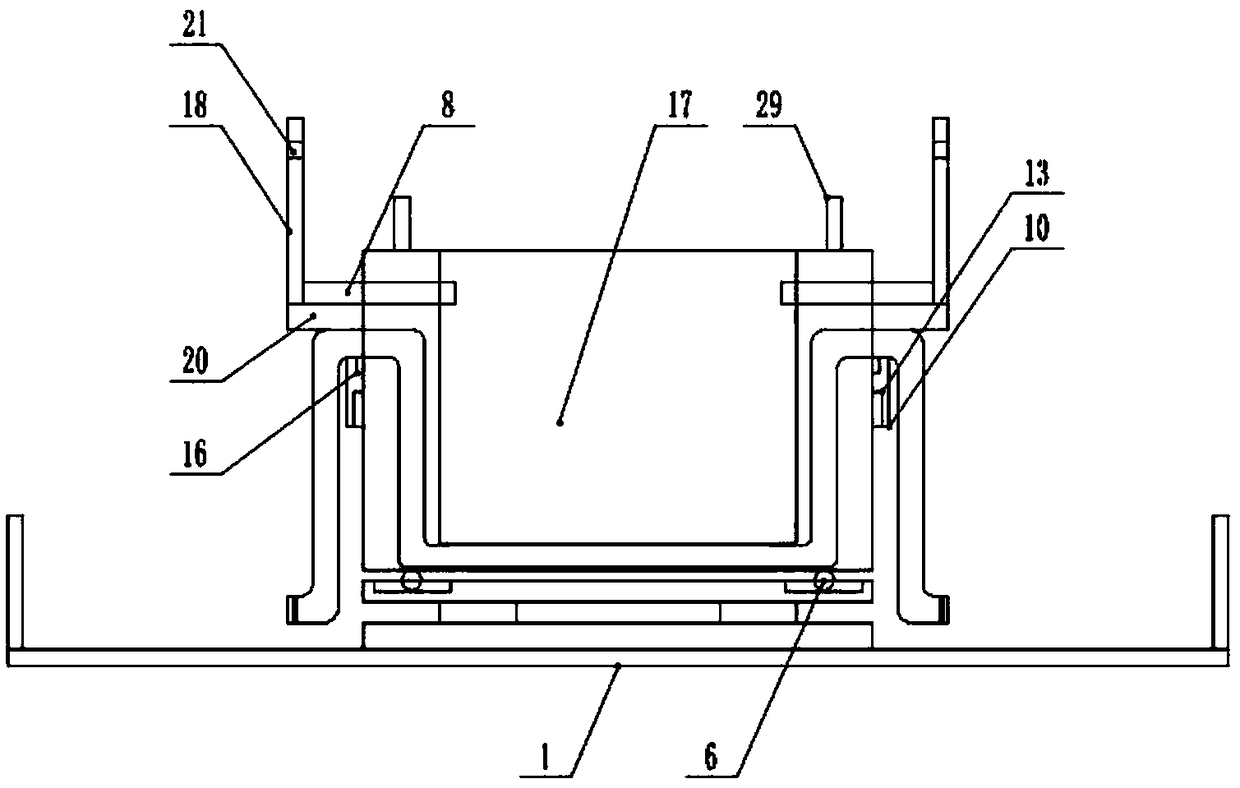

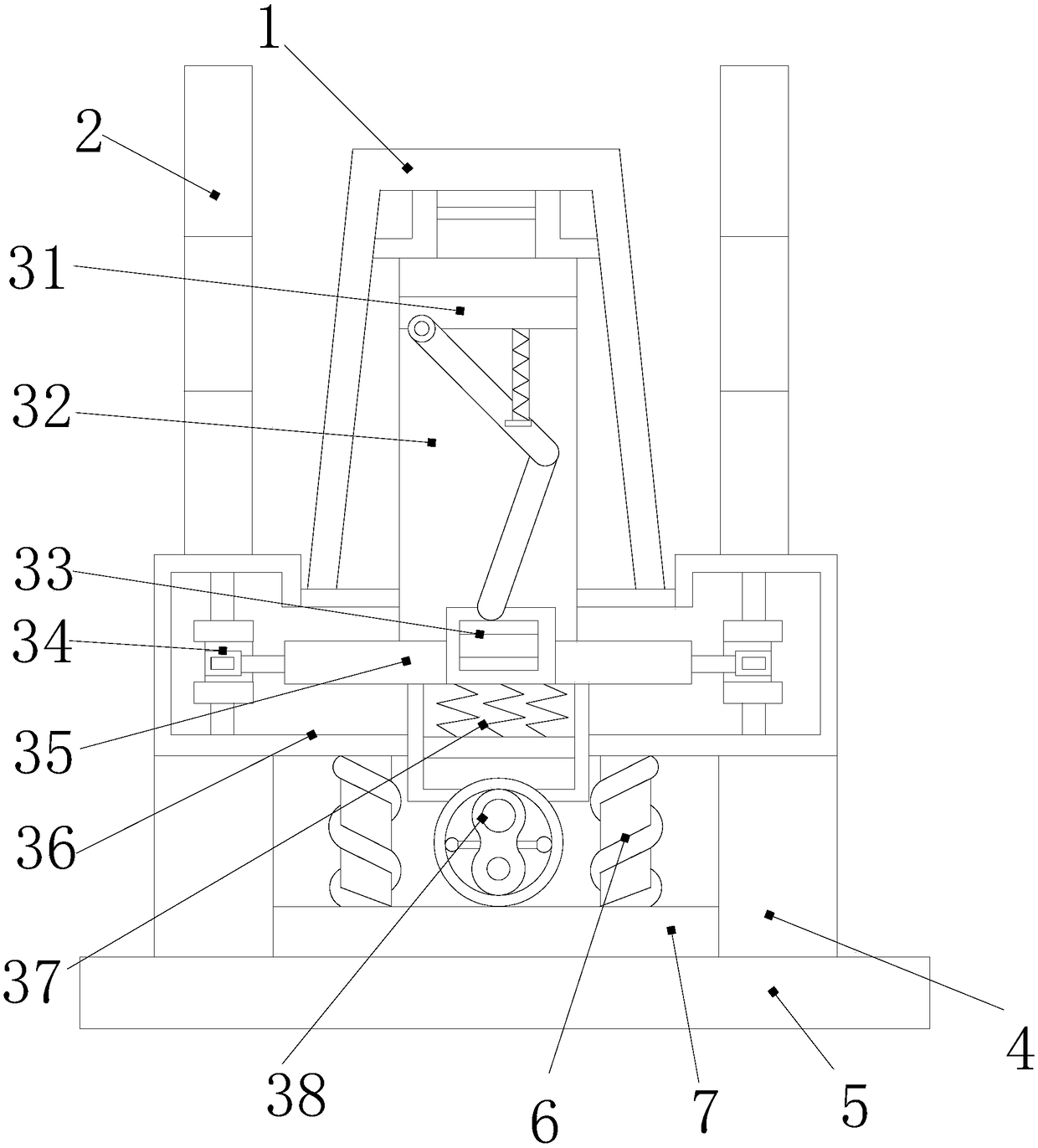

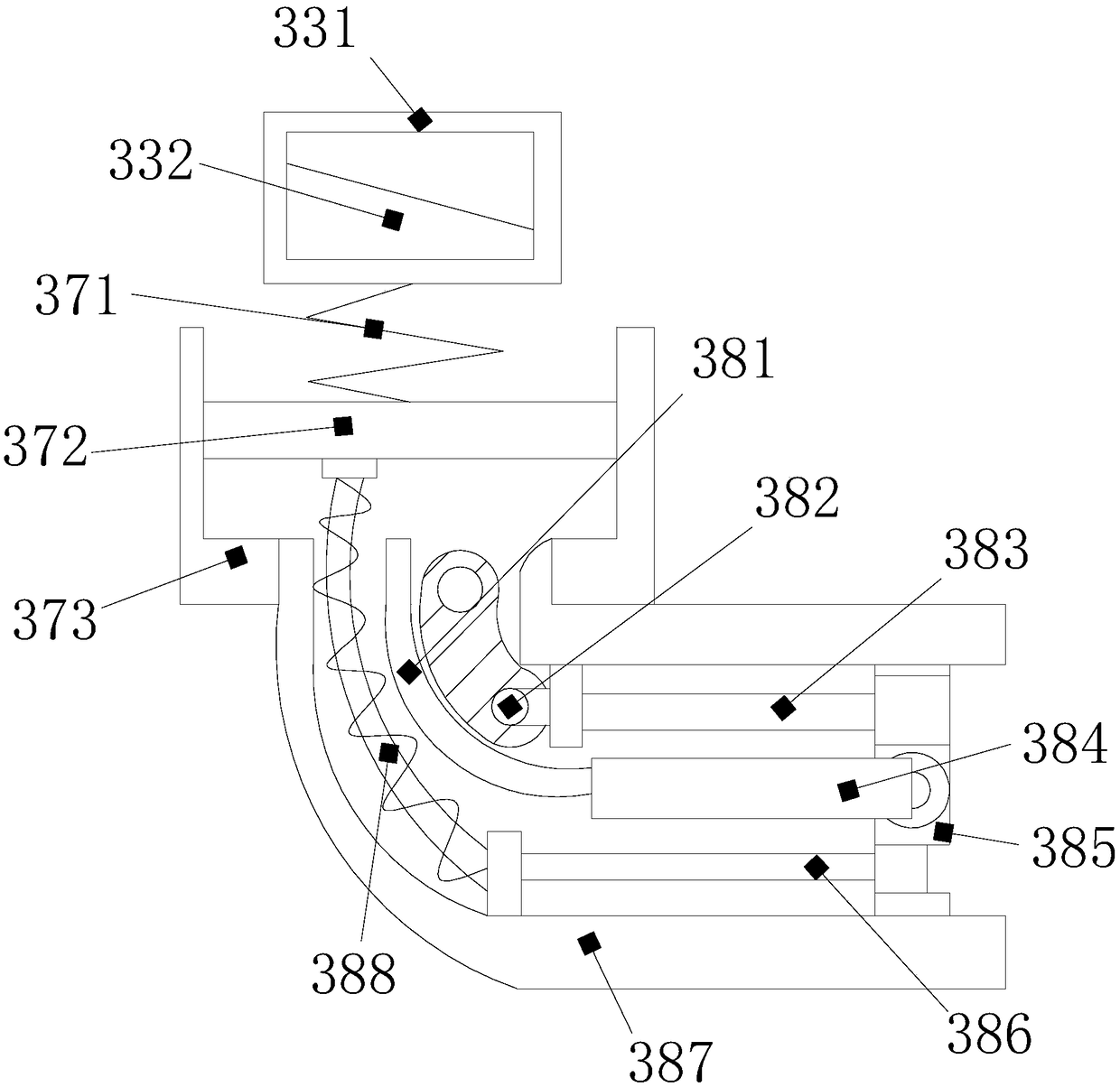

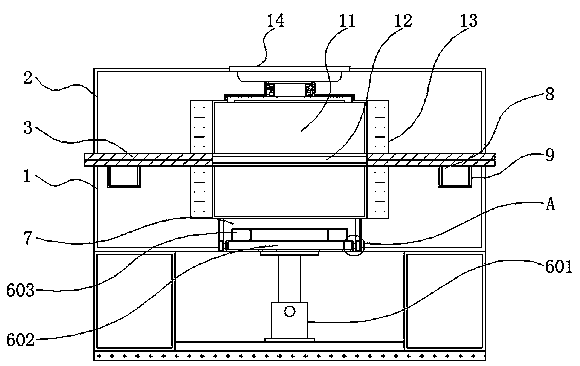

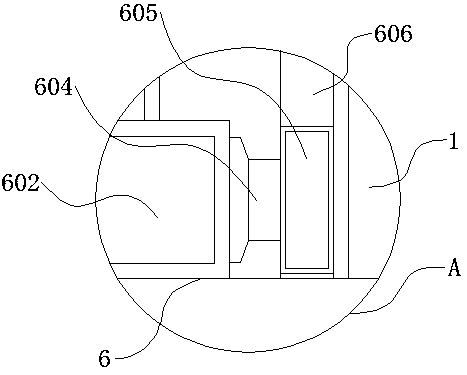

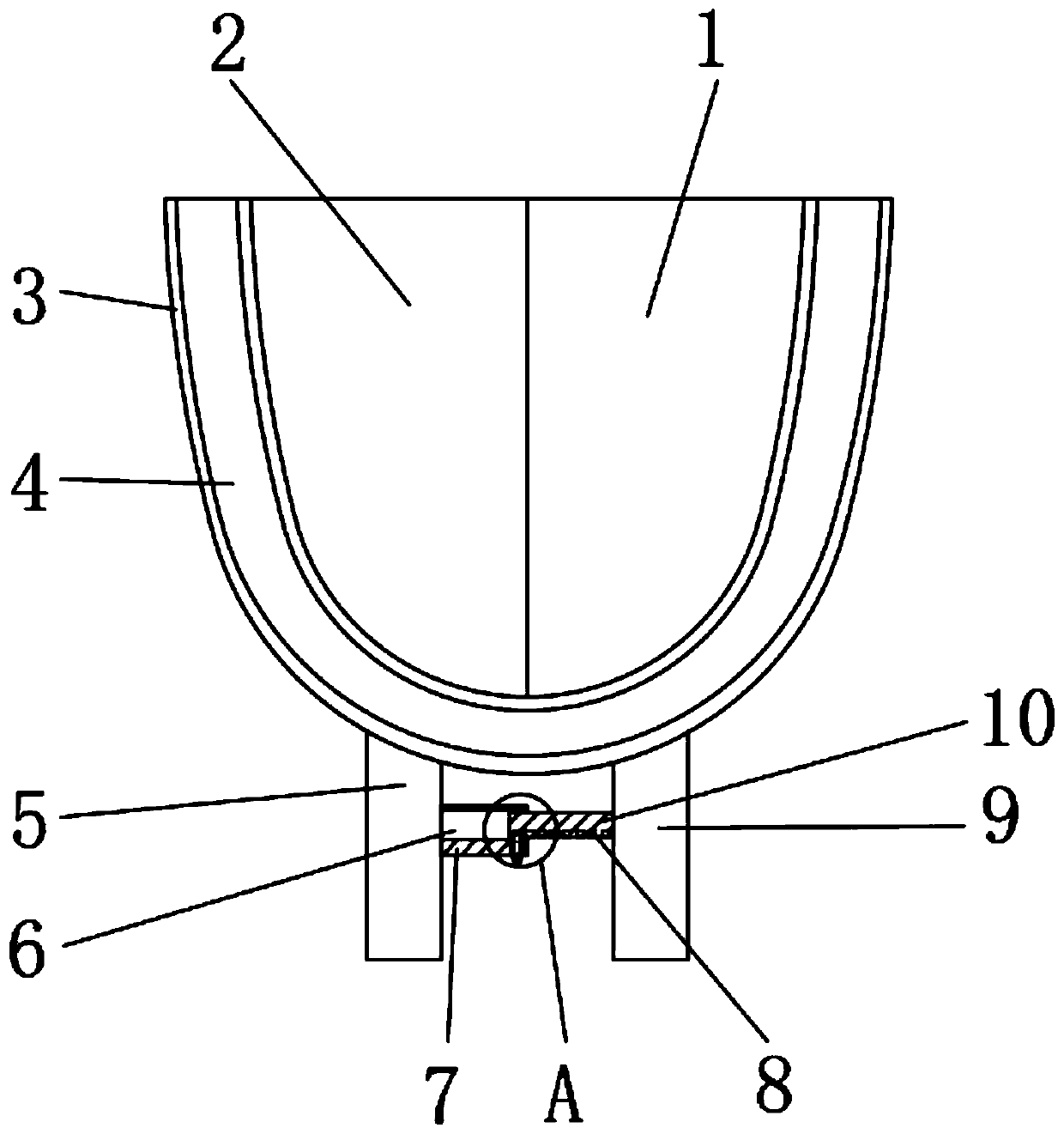

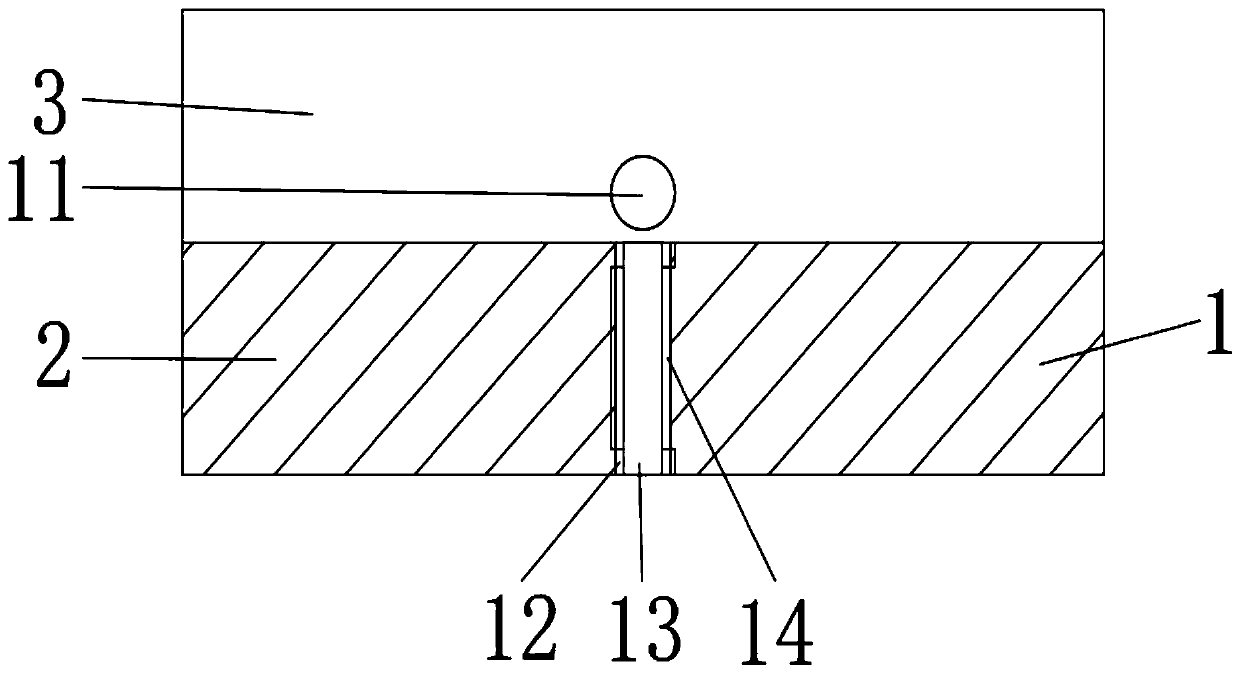

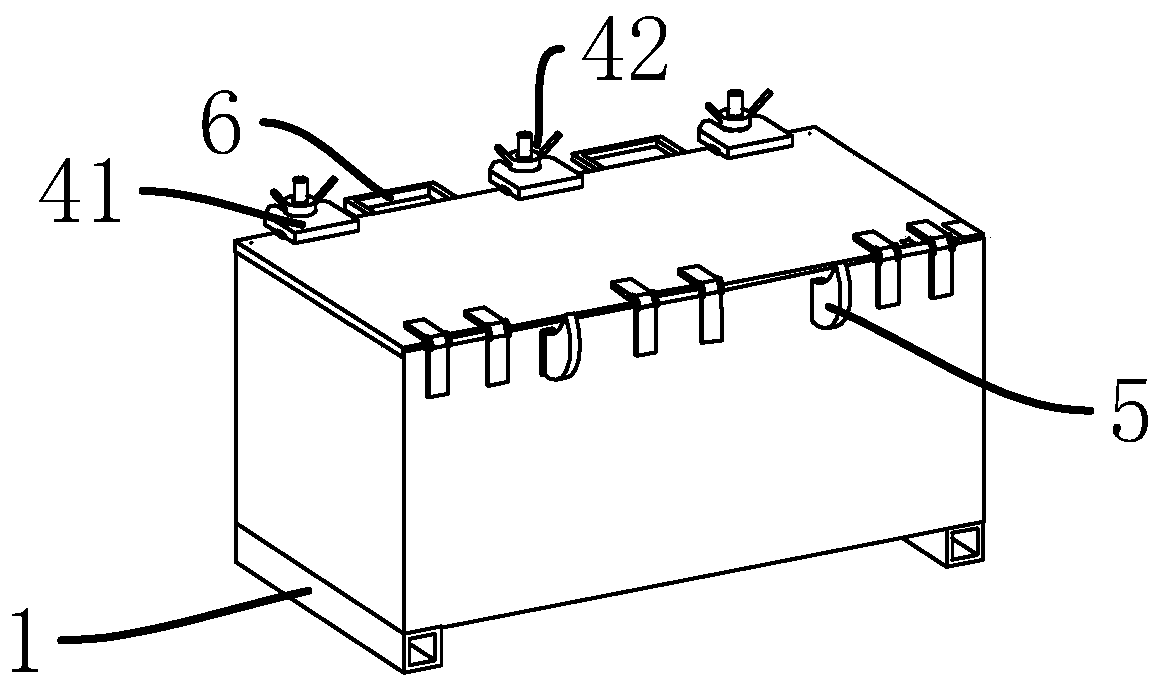

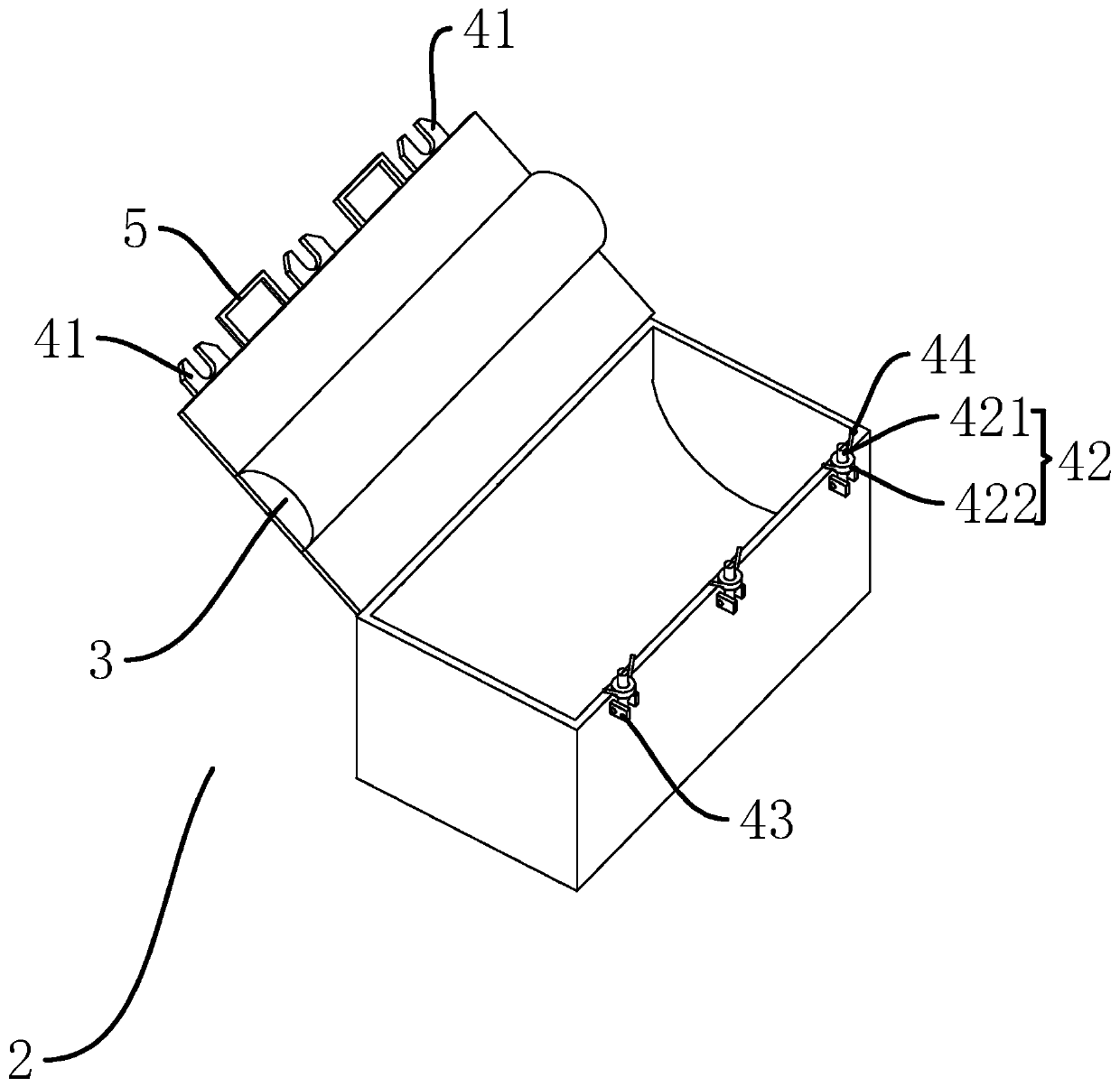

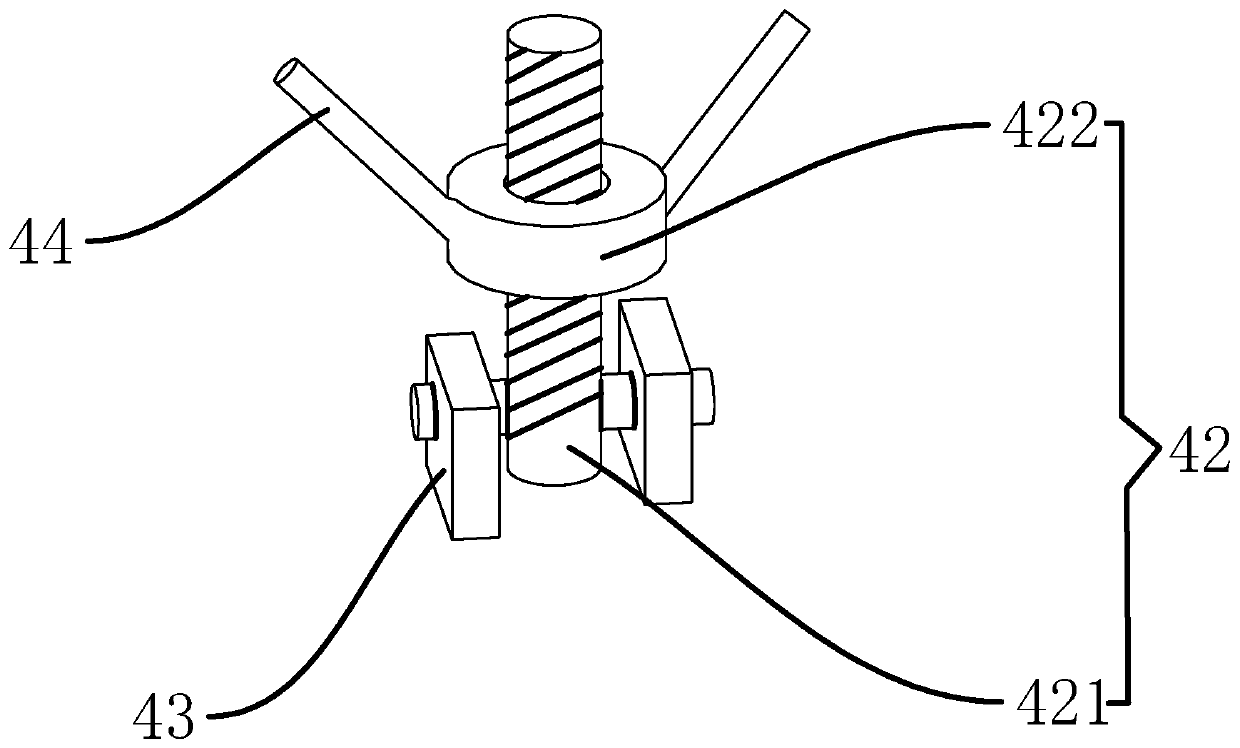

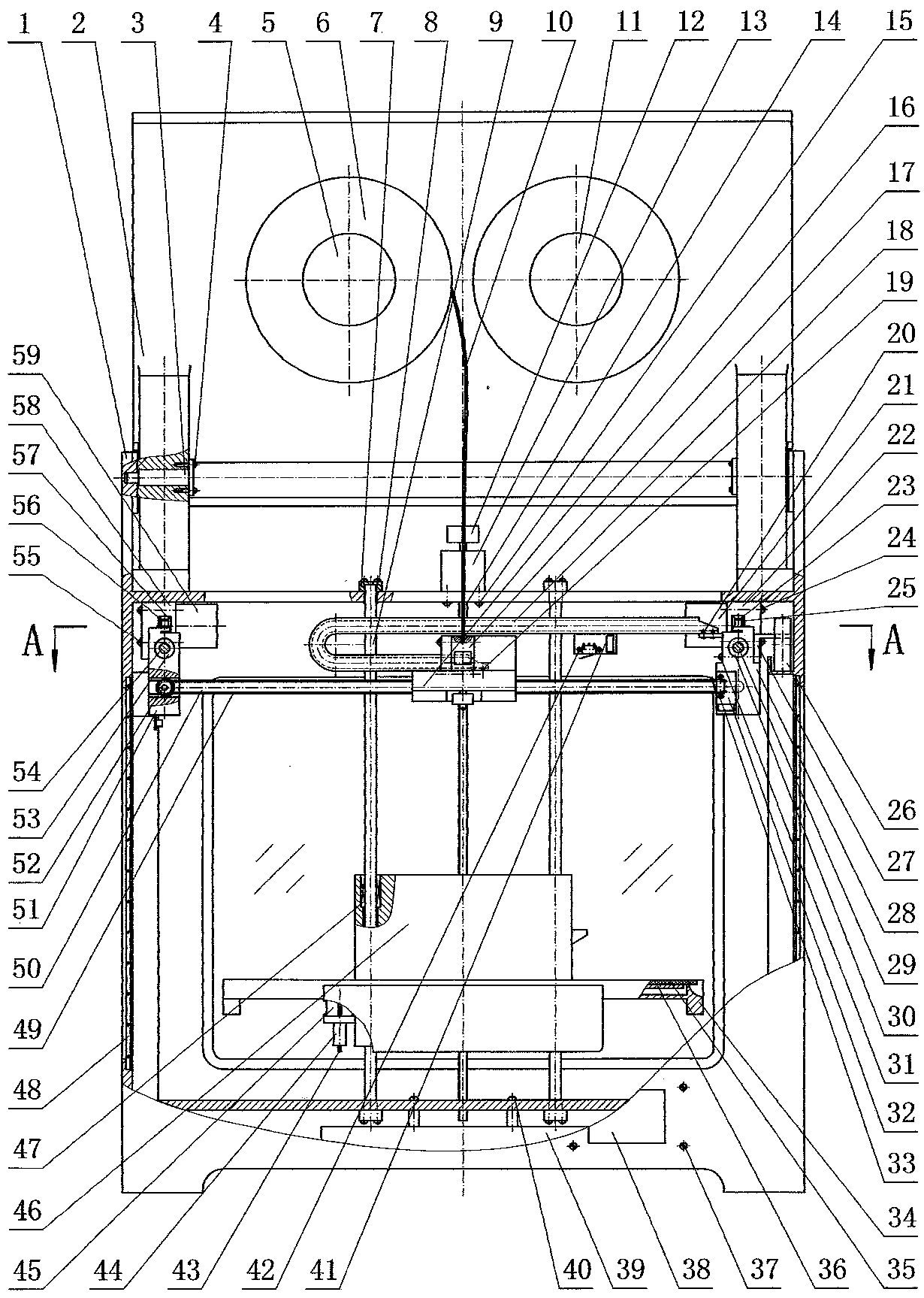

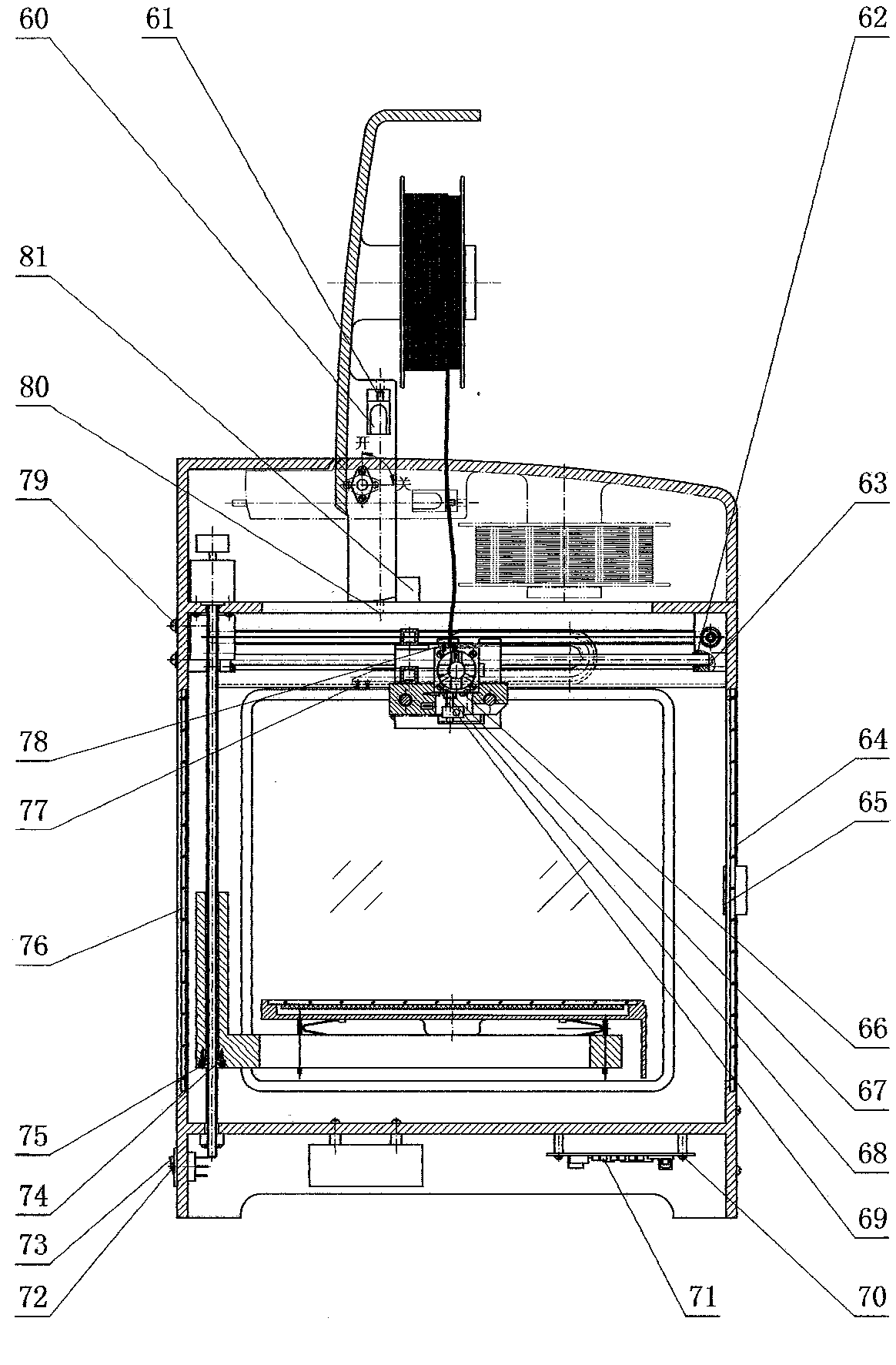

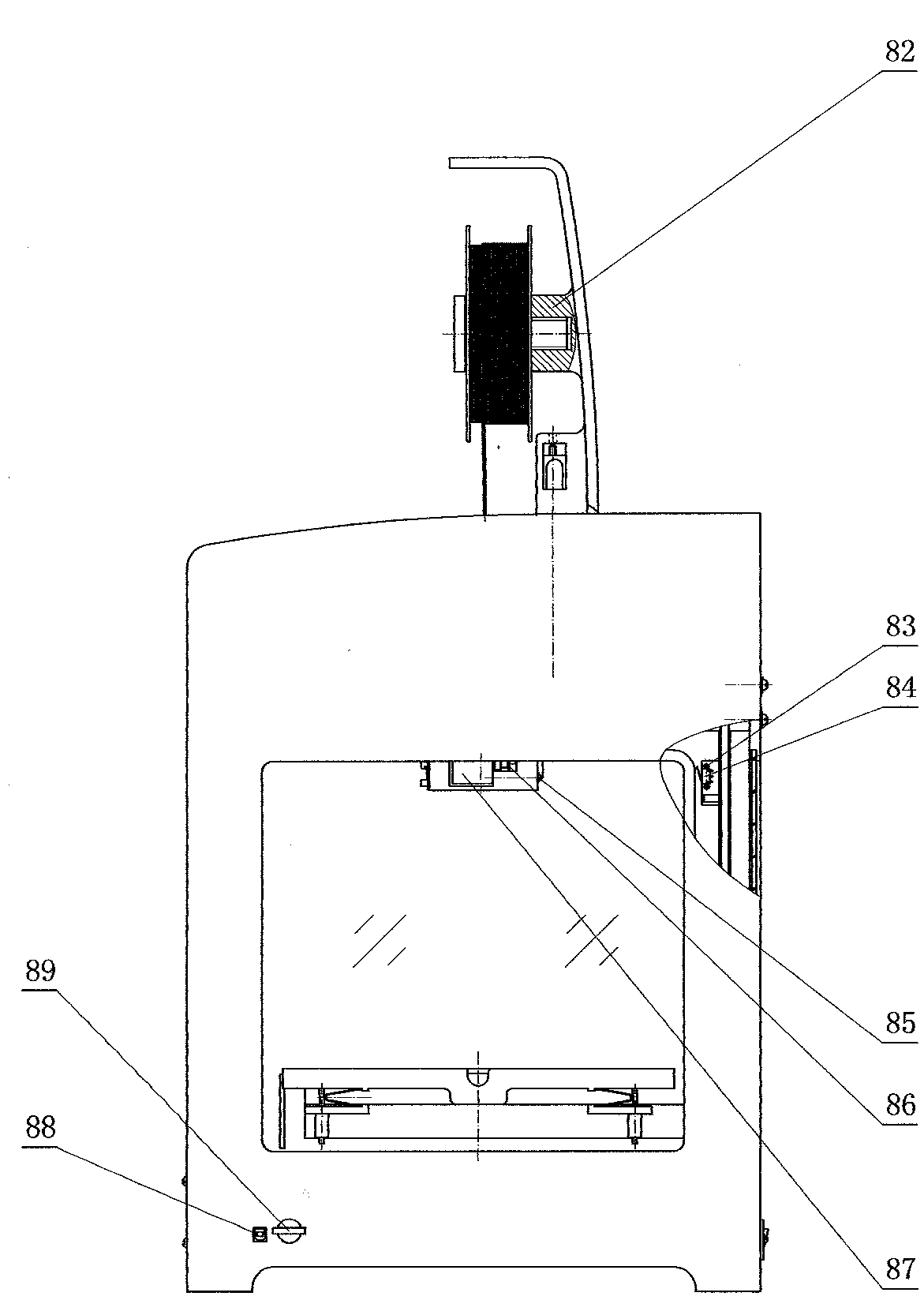

Novel 3D printer

PendingCN108724709AInnovative designSmooth appearanceAdditive manufacturing apparatus3D object support structuresSystems designControl system

The invention provides a novel 3D printer. The novel 3D printer is composed of a shell part, a Z-axis system, a right Y-axis system, a left Y-axis system, an X-axis system, a printing system and an electric control system. The shell part is designed to be of an integrated streamline structure. A shell box (1) and an upper cover (2) are provided with various integrated connecting structural parts.The Z-axis system, the right Y-axis system, the left Y-axis system, the X-axis system, the printing system, the electric control system and a shell are integrated. The upper cover (2) can rotate around a hinge pin (3) and is positioned through a positioning sliding block (60), a positioning rod (61) and a positioning hole (80). A left screw shaft (5) is of a right-hand thread structure. A right screw shaft (11) is of a left-hand thread structure. The Z-axis system is designed to be provided with a manual rotating wheel (12). A drag chain (26) is designed in the Y-axis direction. A drag chain (18) is designed in the X-axis direction. A printing tray rack (34) is provided with a limiting groove. A touch control screen (38) is provided with a Chinese-English interface.

Owner:BEIJING WENZE TECH DEV

Blowing mold for plastic bottle production

The invention discloses a blowing mold for plastic bottle production, and belongs to the field of molds. The blowing mold comprises a base, wherein one side of the top of the base is fixedly connected with a supporting plate, one side of the supporting plate is fixedly connected with a mounting block, one side of the mounting block is fixedly connected with a main mold block, one side of the main mold block is provided with an auxiliary mold block, a mounting plate is fixedly connected to the top of one side of the supporting plate, a blow molding pipe fixedly sleeves the top of the mounting plate, a control valve is fixedly mounted outside the blow molding pipe, and the bottom end of the blow molding pipe extends into the main mode block and the auxiliary mode block. According to the blowing mold for plastic bottle production, by arranging an air conveying sleeve, an air outlet cover, an air inlet pipe, an air inlet valve and an air outlet hole, in the plastic bottle production process, blowing parts in the main mold block and the auxiliary mold block can be conveniently and rapidly cooled through cold air, in this way, the forming speed of the blowing parts can be increased, and convenience is brought to subsequent mold taking of the blowing parts.

Owner:山东莱宝空调设备有限公司

Precoated sand mold for door bolt

PendingCN109175234AFull accessSynchronous sand feeding amountFoundry moulding apparatusShell moldingMaterials science

The invention provides a precoated sand mold for a door bolt. The mold comprises a male mold and a female mold. A male mold molding cavity and a female mold molding cavity are formed in the upper surface of the male mold and the upper surface of the female mold respectively. A sand shell molding cavity is formed after mold closing is conducted on the male mold molding cavity and the female mold molding cavity. Two lines of equidistant embossments are arranged on the male mold molding cavity and the female mold molding cavity correspondingly. Structures of the embossments are of the same shapewith the hemisphere side of the door bolt. Partition embossments are also arranged between every two embossments of each line. The upper surfaces of the partition embossments are flush with the uppersurface of the female mold and the upper surface of the male mold. An installing position for a pouring channel is also arranged between every two lines of embossments. The precoated sand mold for thedoor bolt has the beneficial effects that reasonable molding cavities, the pouring channel and a sand-ejecting port are arranged; finished product rate of sand shells can be improved; and finished product rate of door bolts when molten iron is poured can be improved.

Owner:YUZHOU KUNLUN MOLD CO LTD

Cup injection mold

The invention discloses a cup injection mold. The cup injection mold comprises a base; a female mold body is fixedly connected to the center of the top of the base; four groups of supporting rods arefixedly connected to the top of the base; a top plate is fixedly connected to the tops of the supporting rods; a hydraulic cylinder is fixedly connected to the bottom of the top plate; a hydraulic telescopic rod is connected to the hydraulic cylinder; a positioning plate is fixedly connected to the bottom end of the hydraulic telescopic rod; a cavity is formed in the positioning plate; springs areconnected to the top wall of the cavity and abut against a damping ring; a male mold body is fixedly connected to the bottom of the positioning plate; a feeding pipe penetrates through the positioning plate; and the bottom end of the feeding pipe is located between the damping ring and the male mold body. The cup injection mold has the advantages of being simple in structure, capable of effectively damping the mold, low in cost and good in damping effect, in addition, the hydraulic telescopic rod can telescope to drive the male mold body to move, and therefore the mold can be taken very conveniently.

Owner:HEFEI DINGXIN MOLD

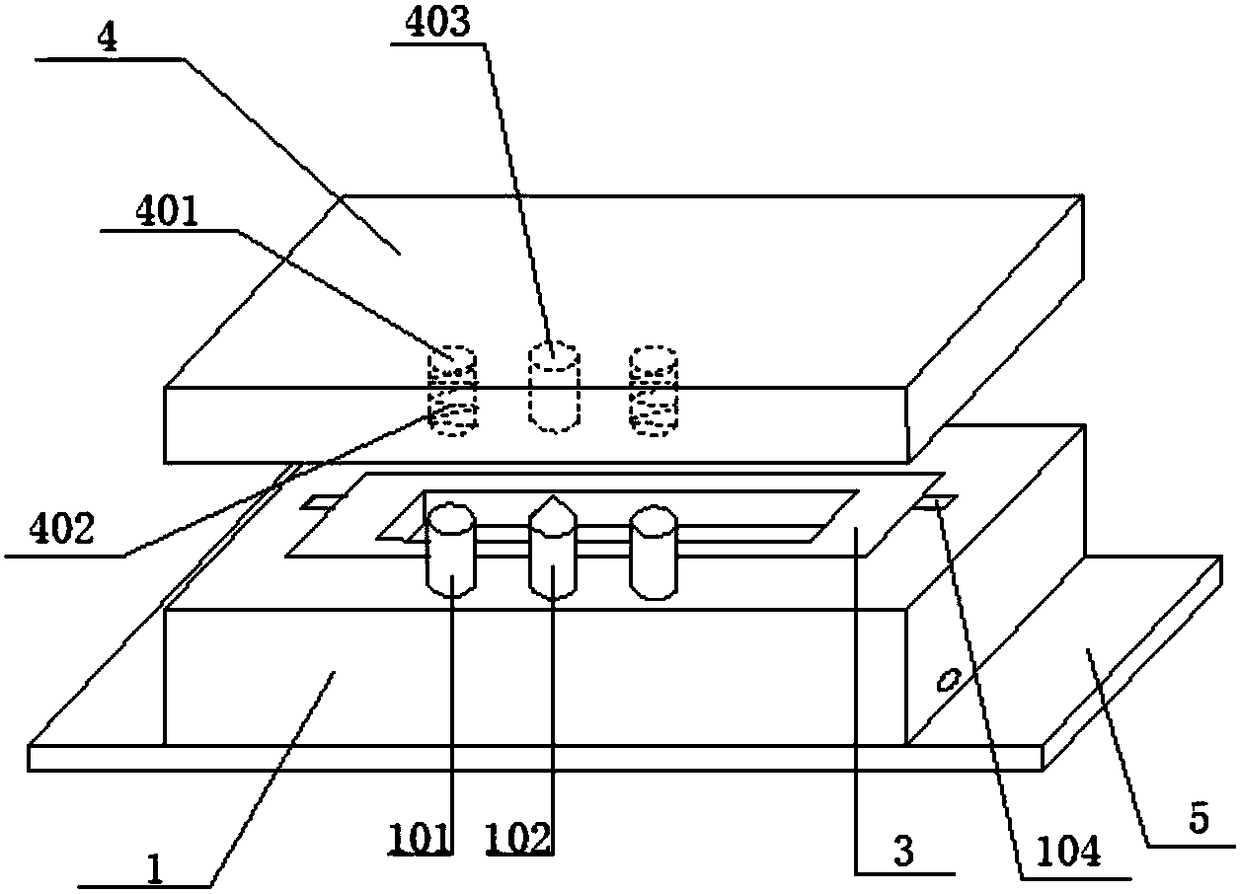

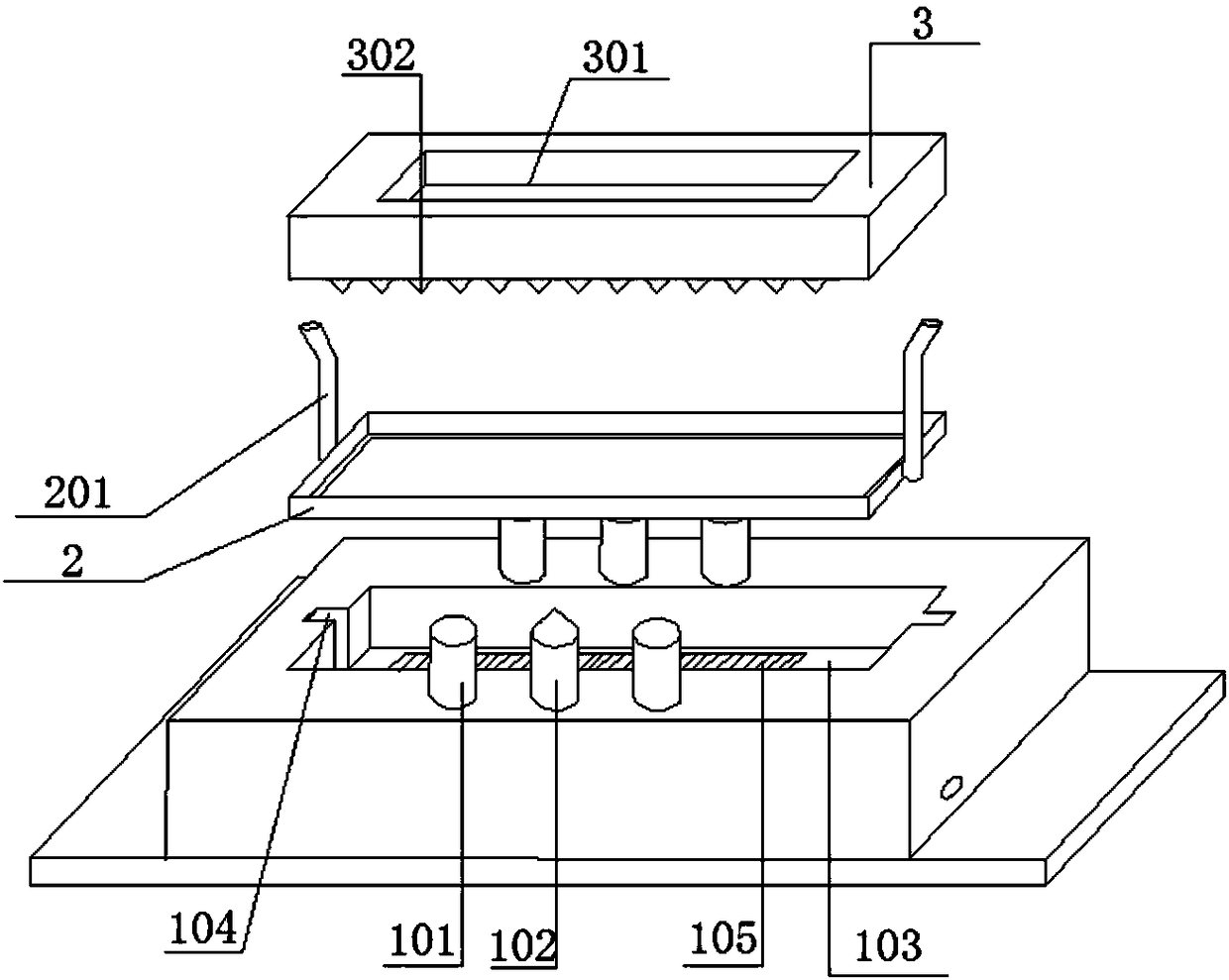

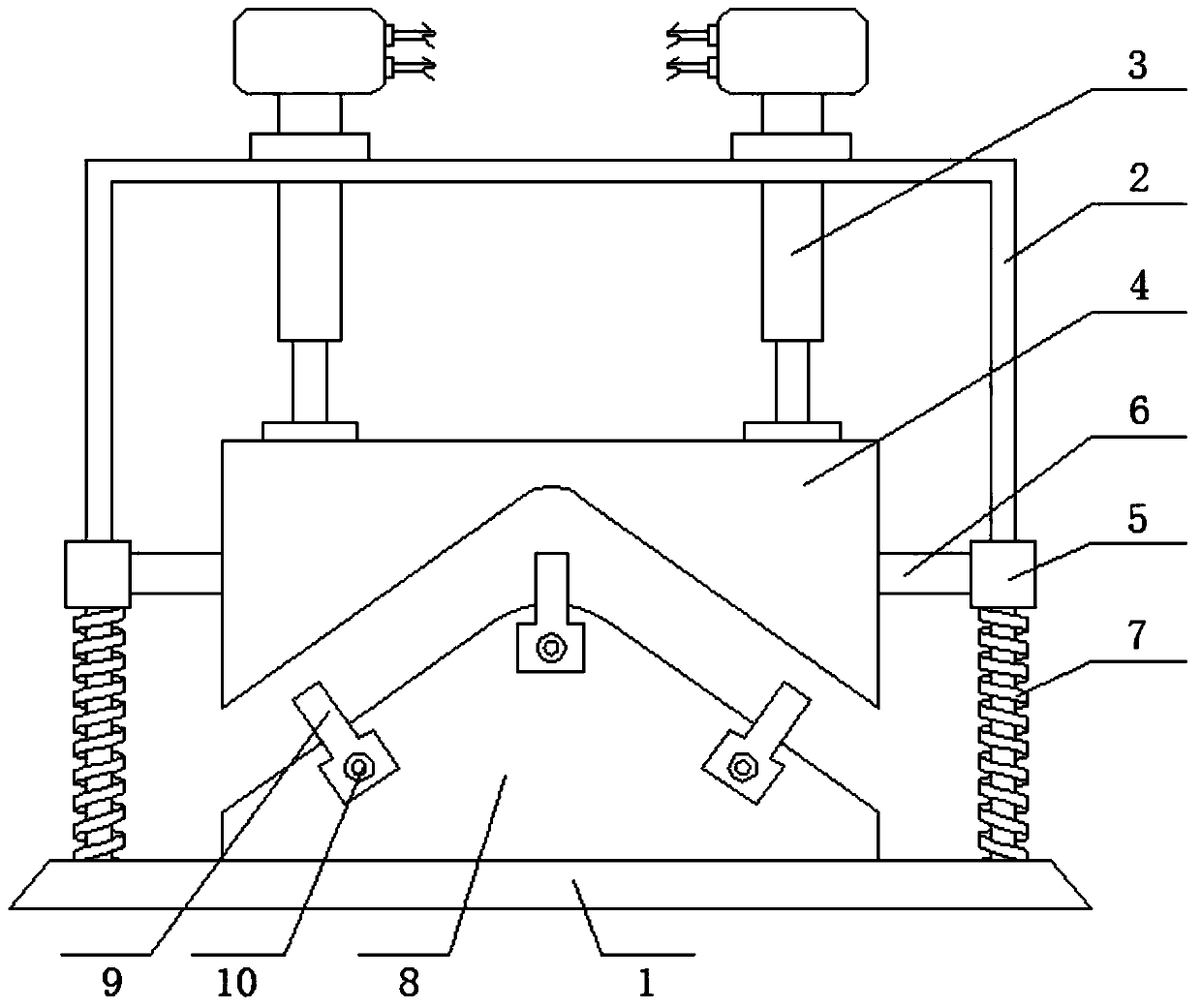

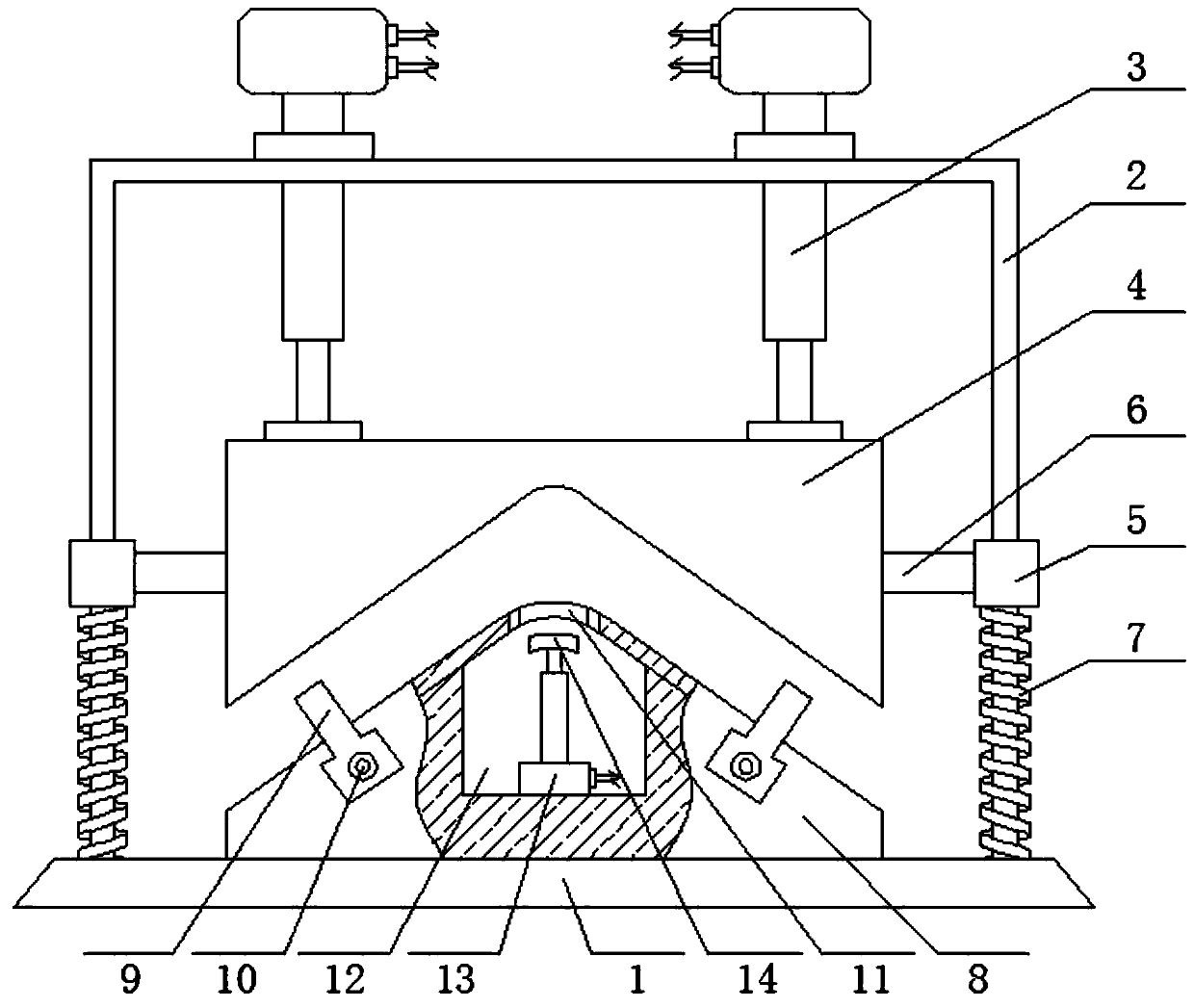

Automatic molding and casting device for home appliance base products

InactiveCN106734901AFast formingQuality improvementFoundry mouldsFoundry coresHome applianceRapid tooling

An automatic molding and casting device for home appliance base products is characterized by comprising a base, a vacuum molding countertop and a sand box; the base is arranged on the vacuum molding countertop and sleeved with the sand box; the base is divided into an upper molding model and a lower molding model; and the upper molding model is arranged in the lower molding model. After the V method models are optimized in design, the models can be rapidly replaced easily and fast machining forming of the models can be achieved easily, and the device is suitable for a small-batch multi-variety production mode.

Owner:CHUZHOU JINNUO INDAL

Hollow refractory brick forming equipment capable of conveniently calibrating center of core tool

The invention provides hollow refractory brick forming equipment capable of conveniently calibrating the center of a core tool, and relates to the technical field of refractory bricks. The hollow refractory brick forming equipment capable of conveniently calibrating the center of the core tool comprises a fixing assembly, and a vertical groove is formed in the fixing assembly. According to the hollow refractory brick forming equipment capable of conveniently calibrating the center of the core tool, a rotary knob is rotated, at the moment, a workbench drives a lower mold to move left and right, a limiting rod is inserted into a calibration hole, and therefore the effect that the core tool is conveniently calibrated and the core tool is prevented from being damaged during pressing due to core tool deviation is achieved. A telescopic air cylinder is started, at the moment, a clamping block can fix a lower die, and therefore the effects that the lower die is prevented from deviating due to too large pressure during pressing and the pressing precision is improved are achieved. After pressing is completed, the telescopic air cylinder is retracted, at the moment, a supporting plate can push out a pressed part pressed in the lower die, manual beating for die taking is not needed, and therefore the effects that after pressing is completed, the pressed part automatically pops up, die taking is convenient, and the working efficiency is improved are achieved.

Owner:李岁举

Positioning device of visual navigation system of oral implant robot

InactiveCN112274246AEasy to adapt to the mouthEasy to take modulusDental implantsImpression capsRobot visionImpression trays

The invention relates to a positioning device of a visual navigation system of an oral implantation robot, which comprises a fixing cylinder, bidirectional threaded rods are rotatably connected to theinteriors, close to the left side and the right side of the fixing cylinder, of the fixing cylinder through bearings correspondingly, and rotating assemblies used for rotating the bidirectional threaded rods are rotatably connected to the left side and the right side of the inner wall of the fixing cylinder through bearings correspondingly; and the two rotating assemblies are fixedly connected through a rotating shaft, moving parts are in threaded connection with the upper end and the lower end of the bidirectional threaded rod correspondingly, and moving plates are fixedly connected with theends, away from the fixed barrel, of the moving parts. Through cooperation of the structures, the distance between the two moving plates can be simply and rapidly adjusted, so that the positions of an impression tray and a medical rubber pad can be adjusted, the impression tray and the medical rubber pad can adapt to the oral cavities of different people conveniently, a patient can bite up and down through cooperation of a spring and the medical rubber pad, and dental column row mold taking operation for implant repair of a patient is facilitated.

Owner:石俊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com