Hollow refractory brick forming equipment capable of conveniently calibrating center of core tool

A molding equipment and refractory brick technology, which is applied in the field of refractory bricks, can solve the problems of affecting the pressing accuracy, the offset of the lower mold, and the troublesome process of taking the mold, so as to achieve the effect of improving the pressing accuracy and avoiding the offset of the lower mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

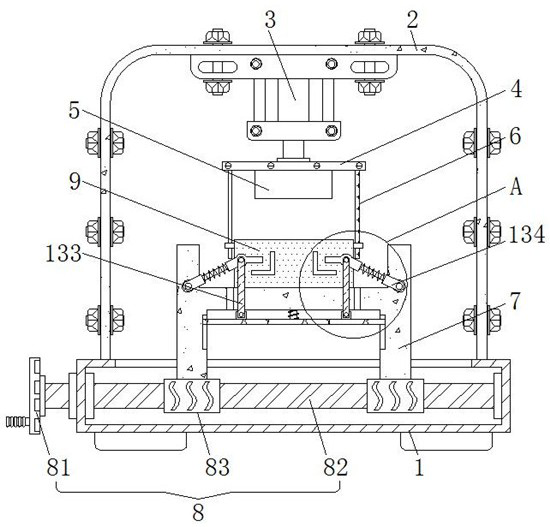

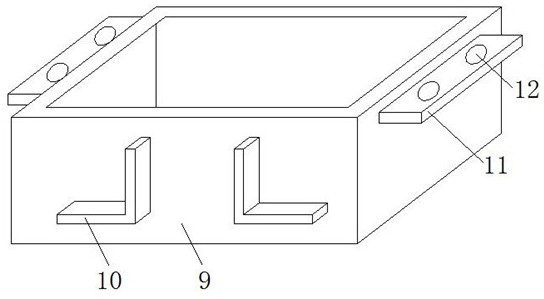

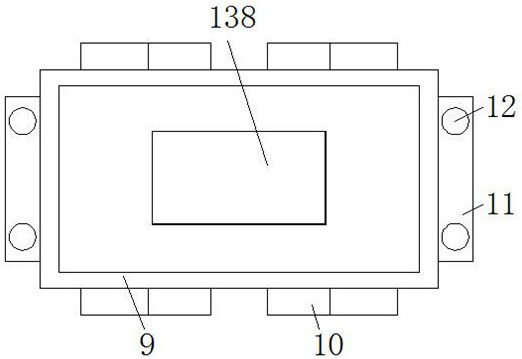

[0028] see Figure 1-6 , a kind of hollow refractory brick molding equipment that is convenient for calibrating the center of the core tool, including a fixed component 13, the inside of the fixed component 13 is provided with a vertical groove 131, the inside of the vertical groove 131 is slidably connected with a sliding plate 132, and the top of the sliding plate 132 is riveted with Connecting rod 133, connecting rod 133 is riveted with elastic expansion rod 134 away from the side of sliding plate 132, and elastic expansion rod 134 is riveted on the front of workbench 7 away from the side of connecting rod 133, and the left and right sides of workbench 7 front and The left and right sides of the back are riveted with elastic telescopic rods 134, and the left side of the elastic telescopic rods 134 is welded with a block 135, which is on the upper right of the L-shaped fixed plate 10, and the top of the sliding plate 132 is fixedly connected with a support spring 136 , the s...

Embodiment 2

[0032] see Figure 1-3 , a hollow refractory brick forming equipment that is convenient for calibrating the center of the core tool, including an adjustment assembly 8, a knob 81 is arranged inside the adjustment assembly 8, a screw rod 82 is welded on the right side of the knob 81, and the outer wall of the screw rod 82 is threaded with a transverse Slider 83, the inside of transverse slider 83 has the screw thread that is compatible with the outer wall of screw mandrel 82, and transverse slider 83 is welded on the bottom of workbench 7, and the left and right sides of workbench 7 bottoms are all welded with transverse slider 83.

[0033] Also includes a base 1, the top of the base 1 is welded with a support frame 2, the inside of the top of the support frame 2 is fixedly connected with a telescopic cylinder 3, the bottom of the telescopic cylinder 3 is fixedly connected with a horizontal plate 4, and the bottom of the horizontal plate 4 is welded with an upper mold 5 , the ...

Embodiment 3

[0037] see Figure 1-6 , a hollow refractory brick forming equipment that is convenient for calibrating the center of the core tool, including a fixed assembly 13, a vertical groove 131 is arranged inside the fixed assembly 13, and a sliding plate 132 is slidably connected to the inside of the vertical groove 131, and the limit rod 6 is on the sliding plate 132, the top of the sliding plate 132 is riveted with a connecting rod 133, and the side of the connecting rod 133 away from the sliding plate 132 is riveted with an elastic telescopic rod 134, and the side of the elastic telescopic rod 134 away from the connecting rod 133 is riveted on the front of the workbench 7 , and the left and right sides of the front of the workbench 7 and the left and right sides of the back are all riveted with elastic telescopic rods 134, the left side of the elastic telescopic rods 134 is welded with a block 135, and the block 135 is on the upper right of the L-shaped fixed plate 10, The top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com