Injection mold for three-way pipe

A technology for injection molds and three-way pipe fittings, which is applied in the direction of household components, household appliances, and other household appliances. It can solve the problems of injection liquid condensation, failure to eject the mold, and blockage of injection pipes, so as to solve the problem of temperature reduction and solidification, and ensure molding. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

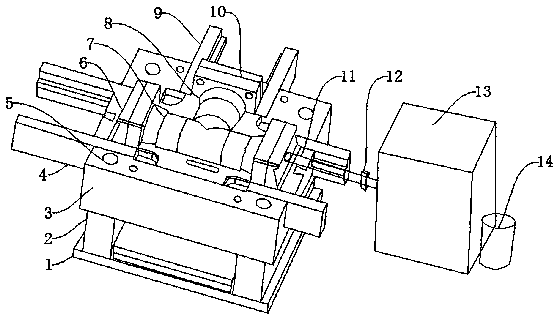

[0029] The present invention will be further described below in conjunction with accompanying drawing:

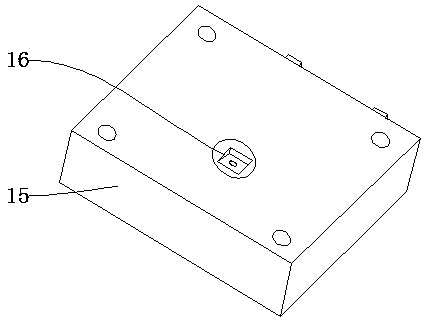

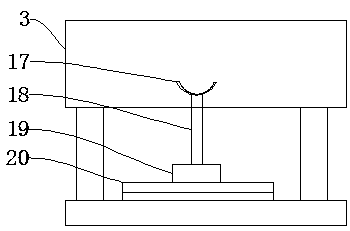

[0030] Such as Figure 1-Figure 5 As shown, a three-way pipe fitting injection mold includes a bottom fixing seat 1, a mold support leg 2, a hand-held moving plate 4, a mold core 7, and a supplementary sealing block 10. The bottom fixing seat 1 is provided with the above Mold support leg 2, a lower mold 3 is installed above the mold support leg 2, and the hand-held moving plate 4 is arranged on one side of the lower mold 3, and the hand-held moving plate 4 is convenient for moving the mould. 3 The top is provided with a mounting bolt hole 5, a core block 6 is installed on one side of the mounting bolt hole 5, and the mold core 7 is installed on one side of the core block 6, and the core block 6 The mold core 7 is fixed, and the mold core 7 is used to form the tee pipe fittings, and the pouring pipeline 8 is installed above the mold core 7, and the pouring pipeline 8 carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com