Mold for graphite production

A mold and graphite technology, applied in the field of graphite processing, can solve the problems of long cooling time, mold damage, difficulty in mold replacement, etc., and achieve the effect of accelerating cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

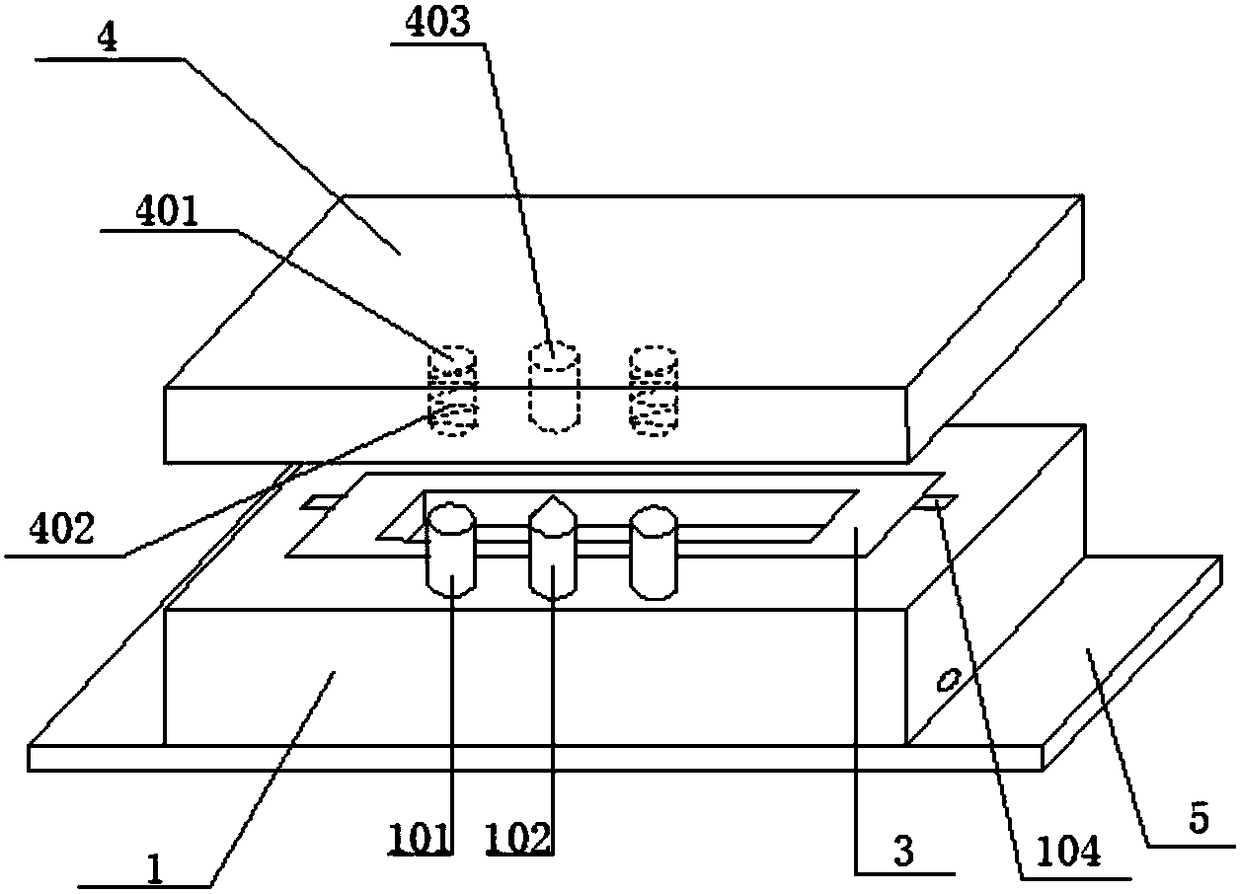

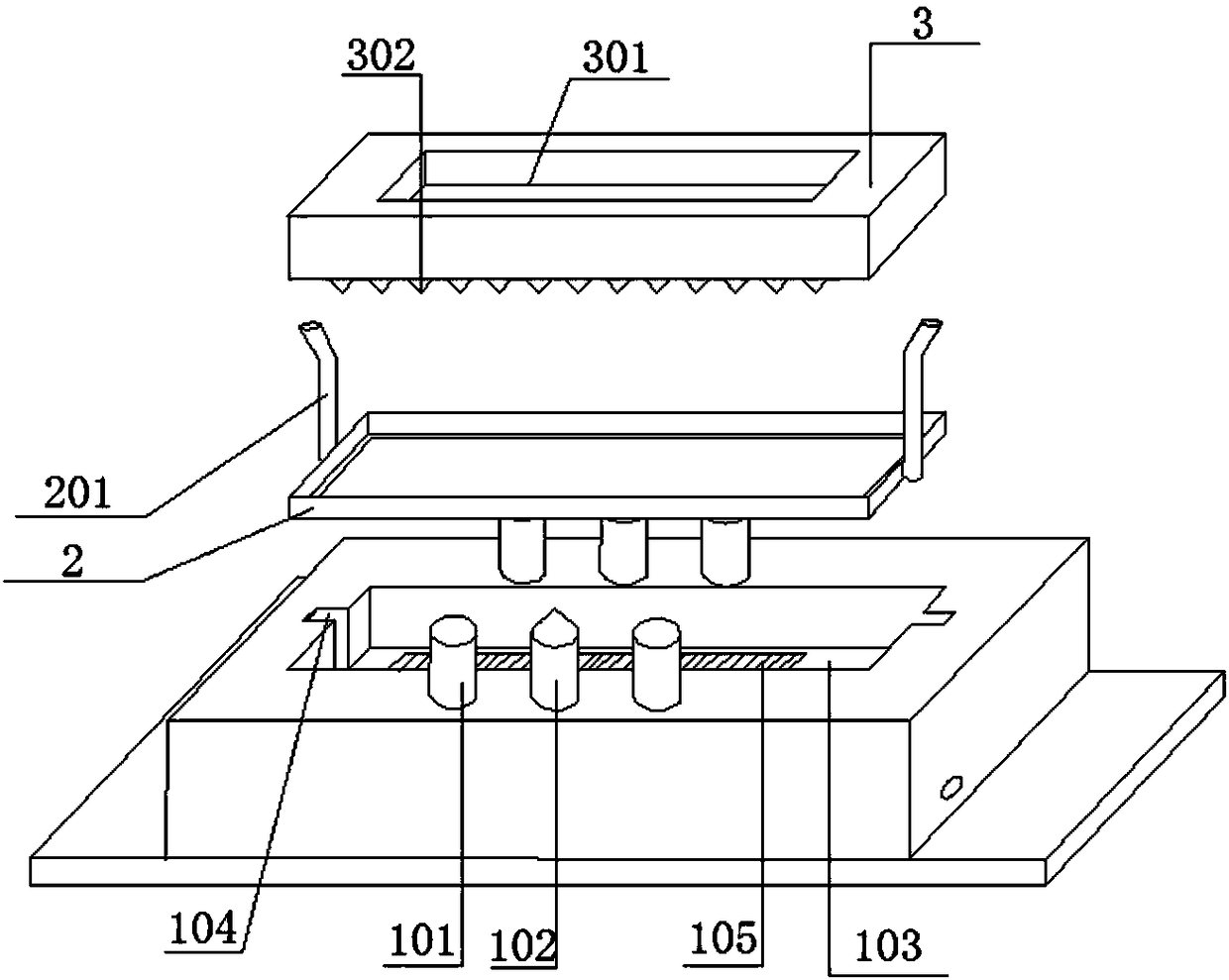

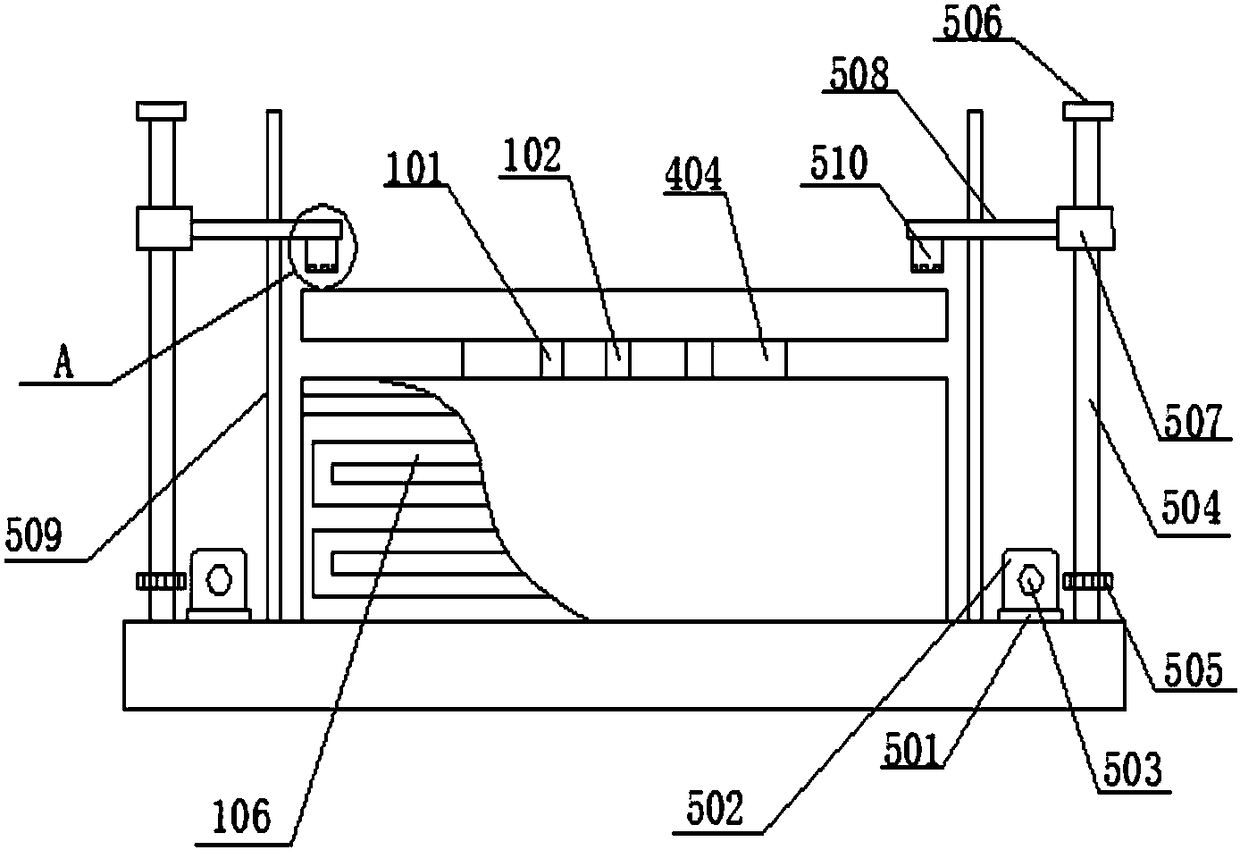

[0025] Such as Figure 1 to Figure 6 As shown, a mold for graphite production according to the present invention is characterized in that it includes an outer mold 1, a fixed column 101, a guide column 102, a placement groove 103, a groove 104, a first sawtooth groove 105, a water flow channel 106, Hollow supporting plate 2, lifting rod 201, inner mold 3, casting mold groove 301, second sawtooth groove 302, pressing plate 4, fixing column opening 401, spring 402, guide hole 403, hot pressing punch 404, mounting plate 5. Motor mounting base 501, motor 502, worm 503, threaded rod 504, gear 505, limit block 506, threaded sleeve 507, connecting rod 508, guide rod 509, pressure block 510, round hole 511, pressure sensor 512;

[0026] The front and rear sides of the upper end of the outer mold 1 are correspondingly provided with guide columns 102, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com