Novel 3D printer

A 3D printer, a new type of technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of single Y-axis drive shaft bending deformation, scratching, jamming, and difficult mold removal, etc., to achieve smooth appearance and system Unique, easy-to-take effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

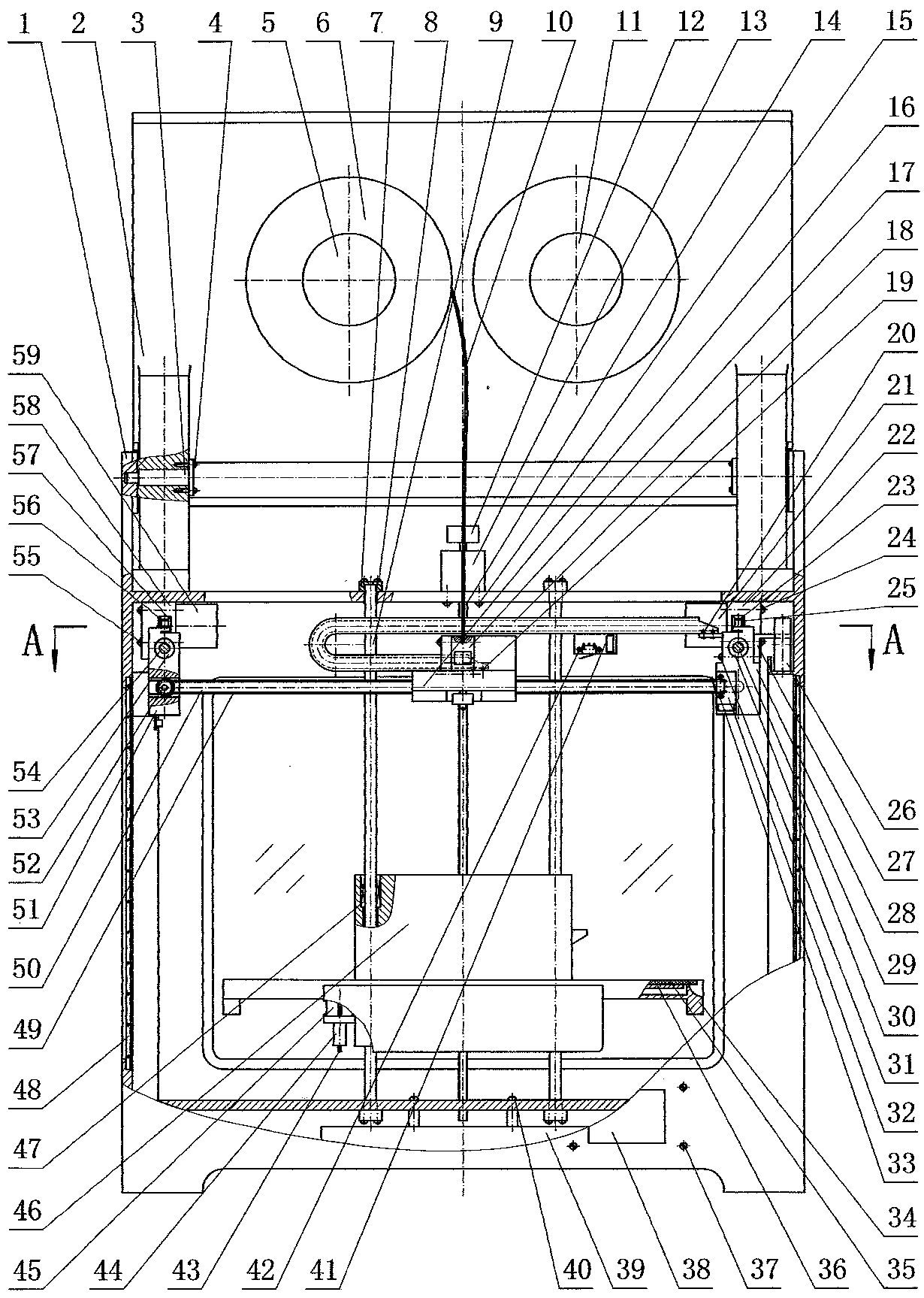

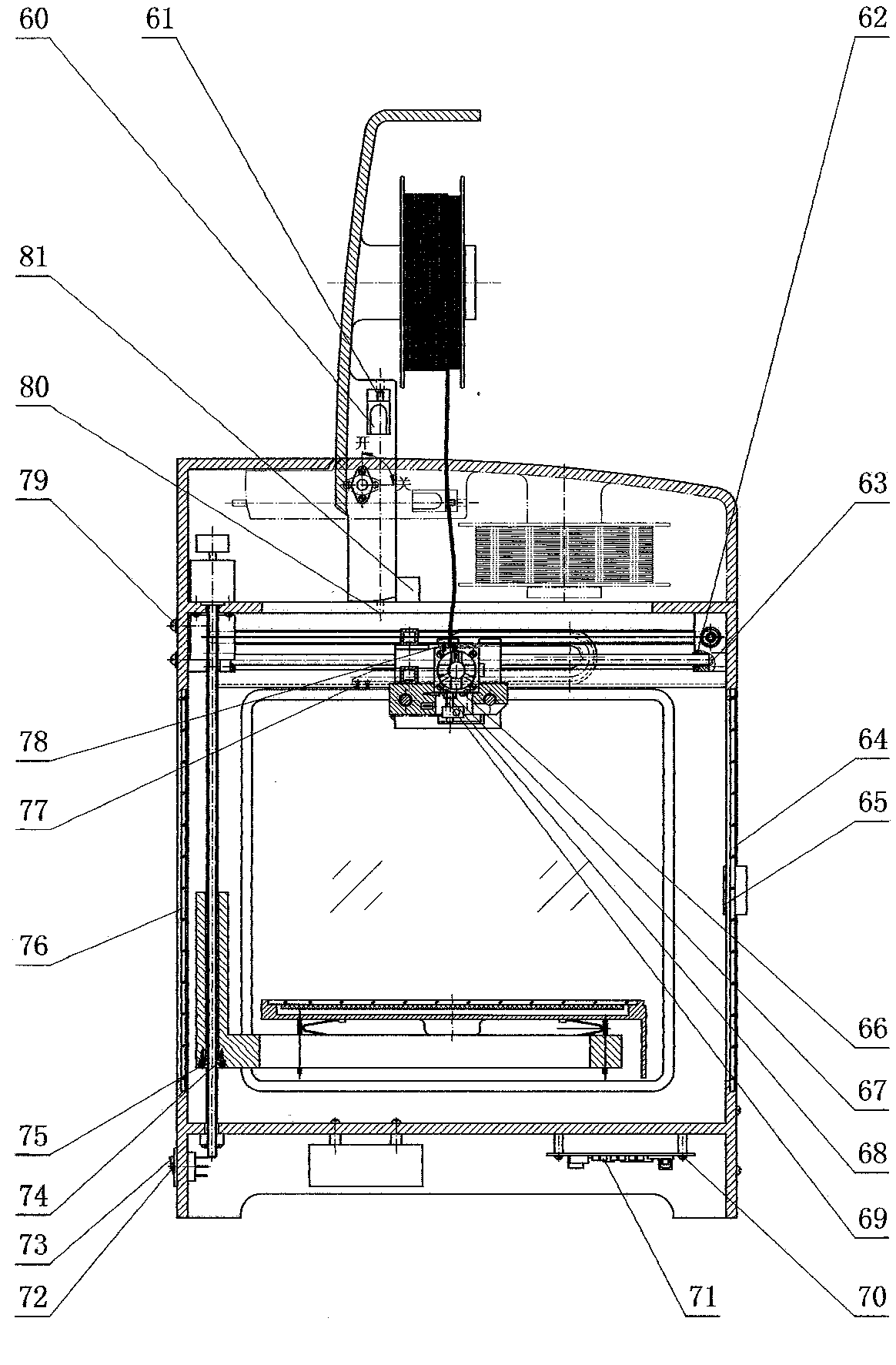

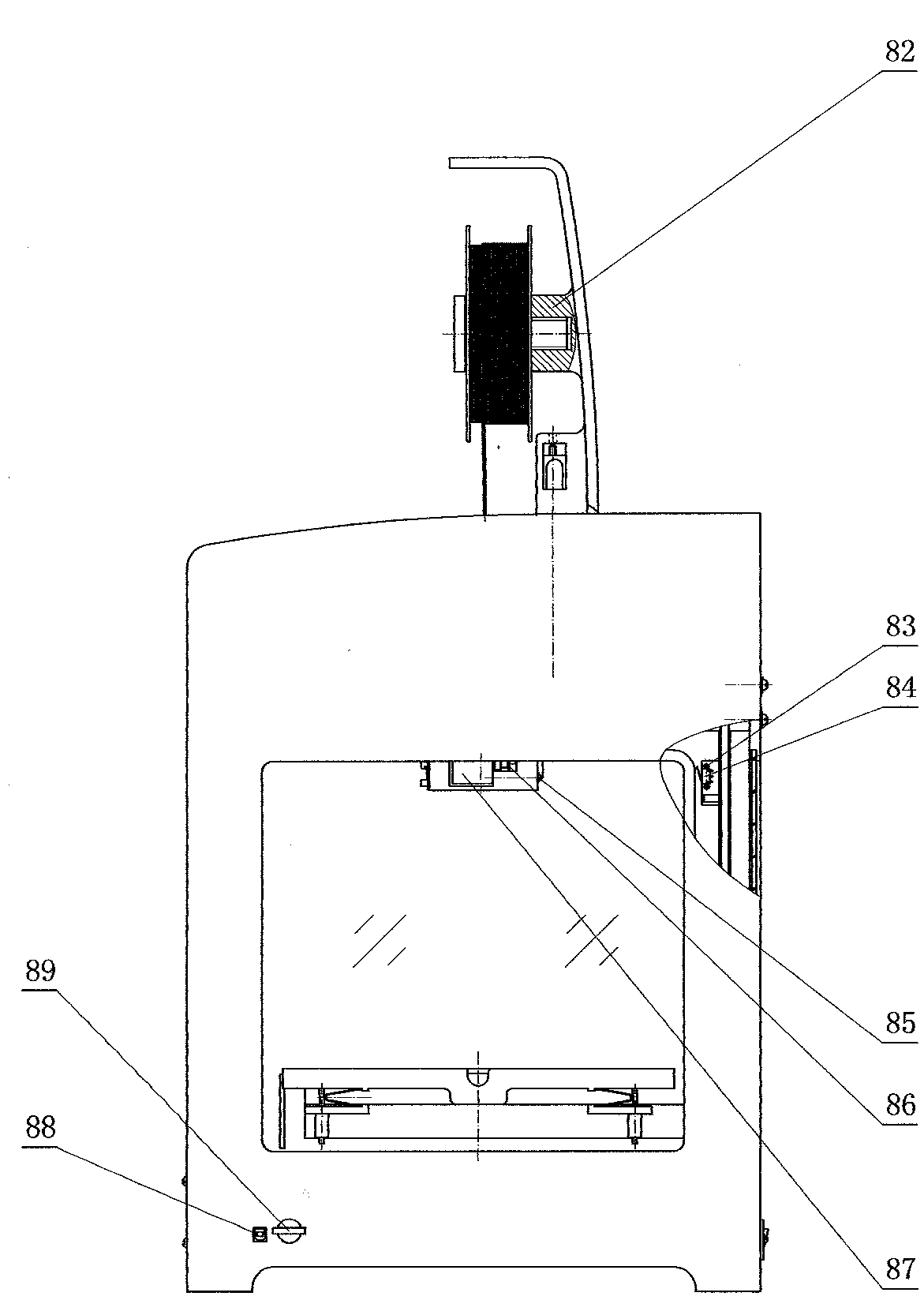

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

[0021] figure 1 , figure 2 Shows the shell part of the present invention, its structure is: the positioning slider (60) is placed in the rectangular hole of the upper cover (2), and the wire head of the positioning rod (61) is upwardly aligned with the positioning slider (60) Connection; the box body (1) and the upper cover (2) are connected through the connecting pin (3), and the connecting pin (3) is fixed on the upper cover (2) with bolts (4).

[0022] figure 1 , figure 2 It shows the Z-axis system of the present invention, its structure is: the trapezoidal nut (74) is connected to the Z-axis lifting bracket (46) through the bolt (75); the stepper motor (13) is connected to the box through the bolt (15) The body (1) is connected; the trapezoidal screw (14) is connected with the stepper motor (13); the Z-axis lifting bracket (46) is connected with the optical ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com