Mold releasing device

A demoulding device and mold technology, applied in the field of molds, can solve problems such as large installation area, difficult demoulding, product damage, etc., to achieve the effect of protecting the mold, convenient and quick demoulding, and preventing damage

Inactive Publication Date: 2020-06-09

重庆奥阳模具制造有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the need to install the oil cylinder, the space of the casting machine table is relatively large, the installation area is large, and the operating space of the casting site is also limited. In the prior art

[0003] After the traditional mold is processed and shaped, it is difficult to demould. If you are not careful, the product will be damaged. Therefore, it is necessary to invent a mold demoulding device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

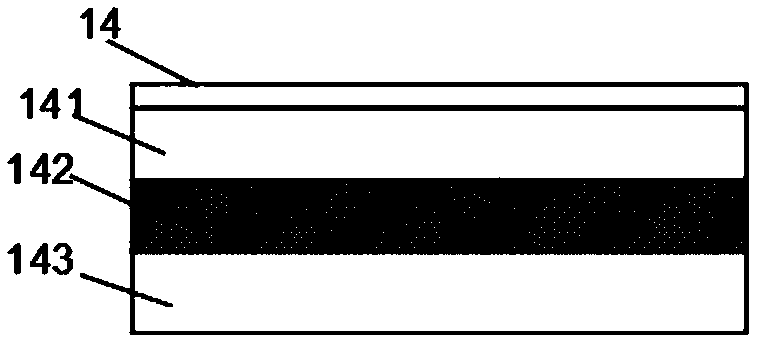

[0021] As a preferred embodiment of the present invention, the top membrane device 14 includes a push plate 141 , a sealing layer 142 and a gasket 143 , and the sealing layer 142 is placed between the push plate 141 and the gasket 143 .

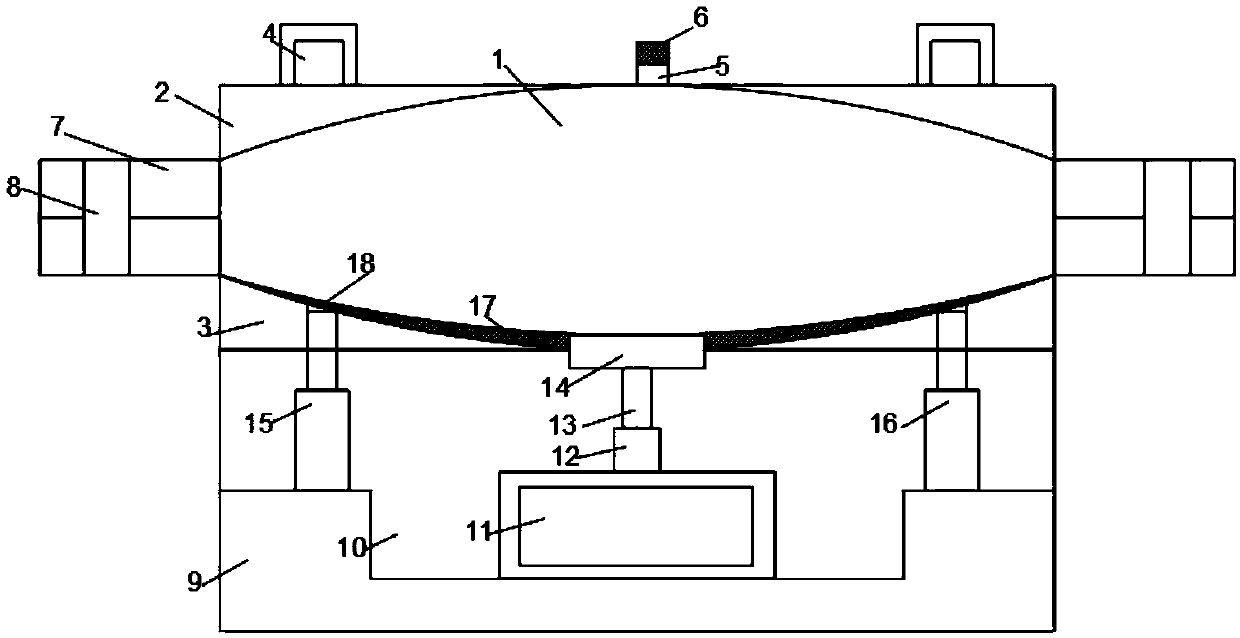

[0022] As a preferred embodiment of the present invention, a release layer 17 is fixedly installed on the inner wall of the lower mold 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a mold releasing device. The device comprises an upper mold and a lower mold, the upper mold and the lower mold jointly form a mold cavity, an injection molding opening is fixedly formed in the middle of the upper mold, a seal cover is fixedly mounted on the injection molding opening, through the upper mold and the lower mold, a product mold can be casted, through a drivingmotor and a mold ejecting device, mold taking can be facilitated, a thread screw is used for ejecting the mold, a left telescopic rod and a right telescopic rod are mounted to stably take out the mold, damage is prevented, through the injection molding opening, the mold can be achieved, a mold releasing layer is mounted, mold releasing is more convenient and rapid, and an anti-collision layer ismounted, in the mold taking process, the mold is protected.

Description

technical field [0001] The invention relates to the technical field of molds, in particular to a mold demoulding device. Background technique [0002] When casting barrel-shaped parts with complex side shapes such as automobile hubs, the molds used generally include upper and lower molds arranged above and below, and side molds arranged on the periphery of the upper and lower molds. Since the casting is relatively large, the mold used for casting is very large and heavy, and the pressure required for casting is involved. Generally, the structure of the mold similar to the automobile wheel hub casting is relatively complicated, and in order to be able to drive the side mold and the upper mold Or the movement of the lower mold to complete the opening and closing action of the mold such as the side mold, and a drive cylinder for driving the side mold to move outward is also specially arranged on the left and right spaces of each of the side molds. Due to the need to install th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22D17/26

CPCB22D17/263

Inventor 曾素容

Owner 重庆奥阳模具制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com