Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Drilling safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

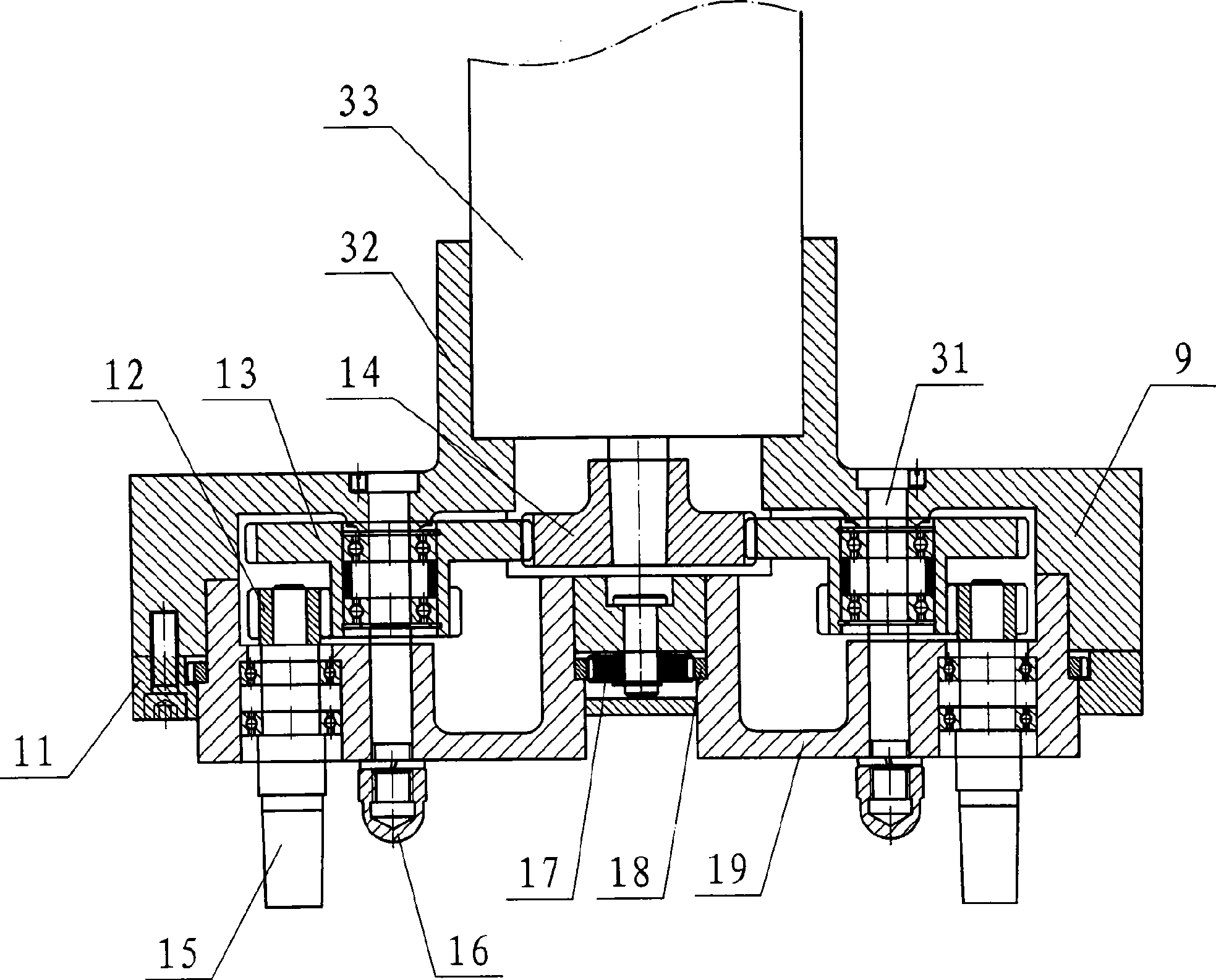

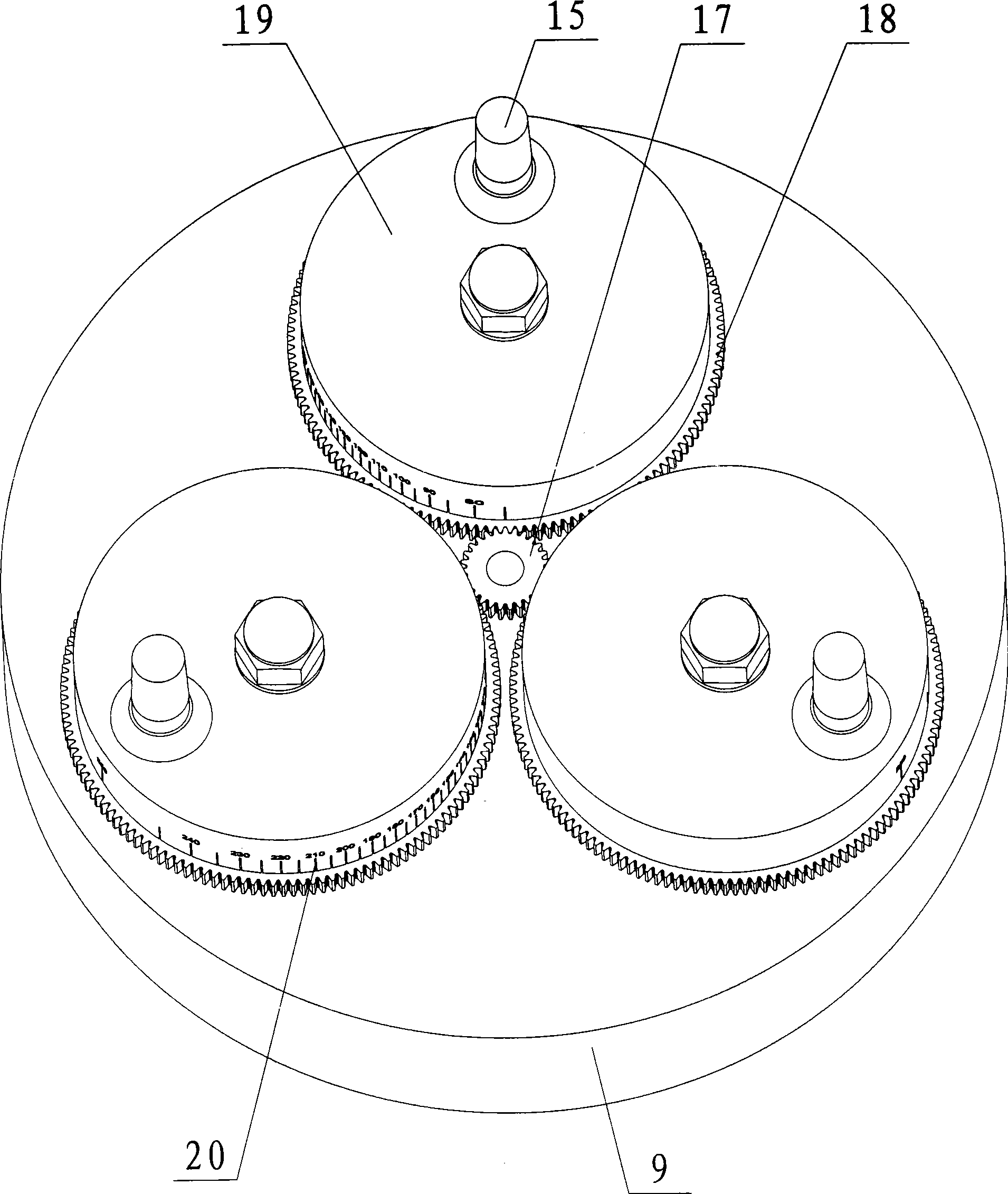

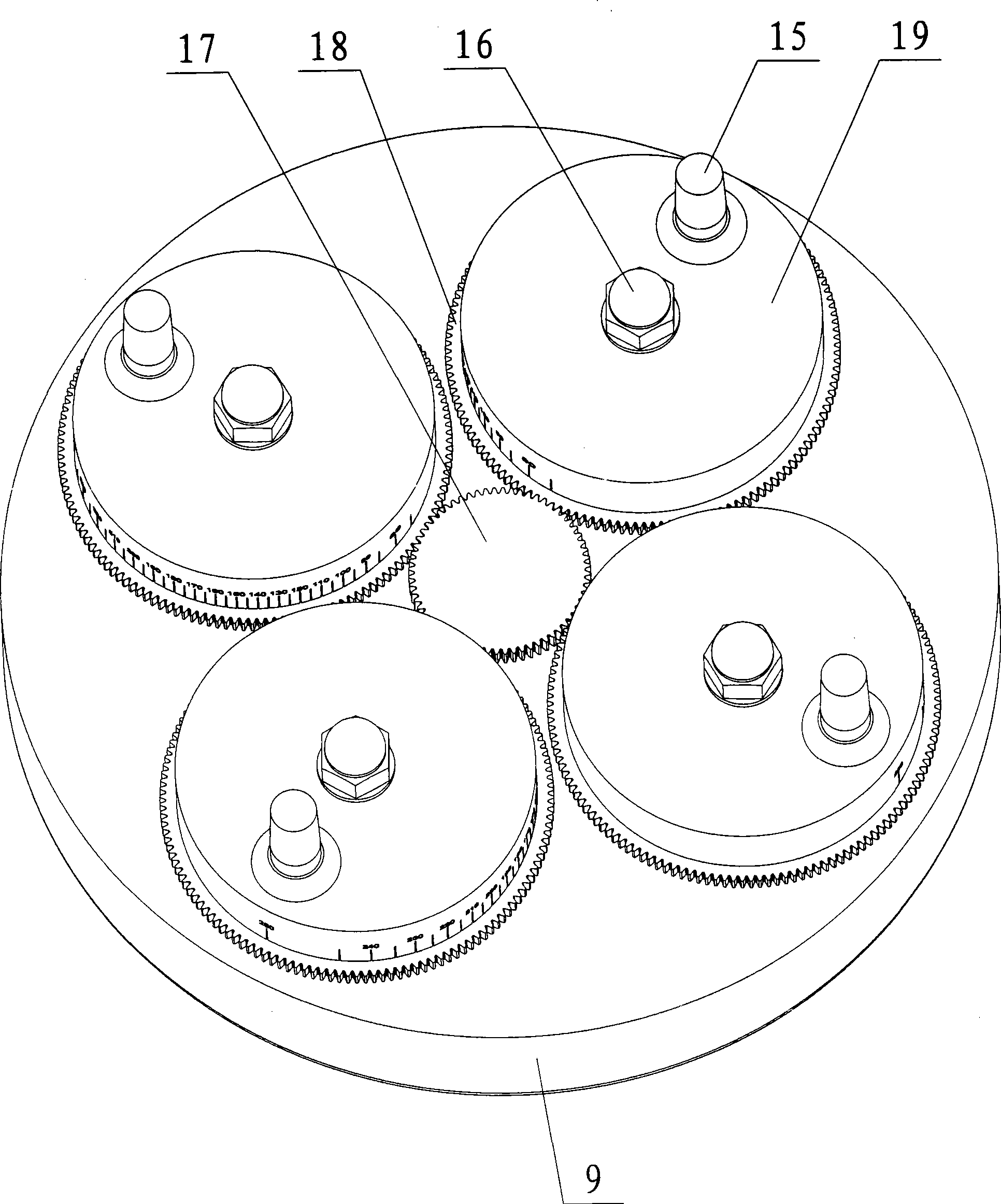

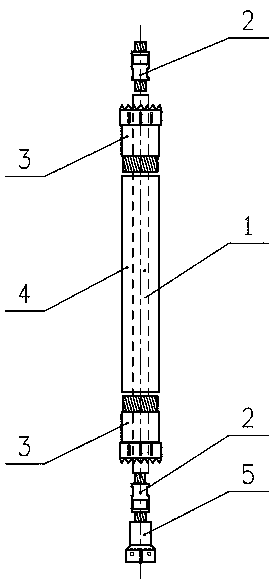

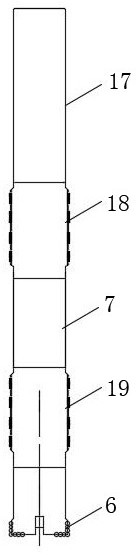

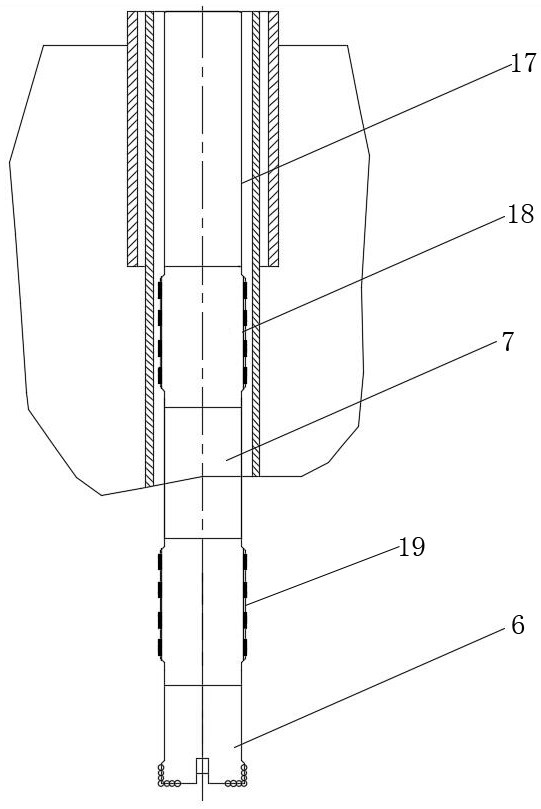

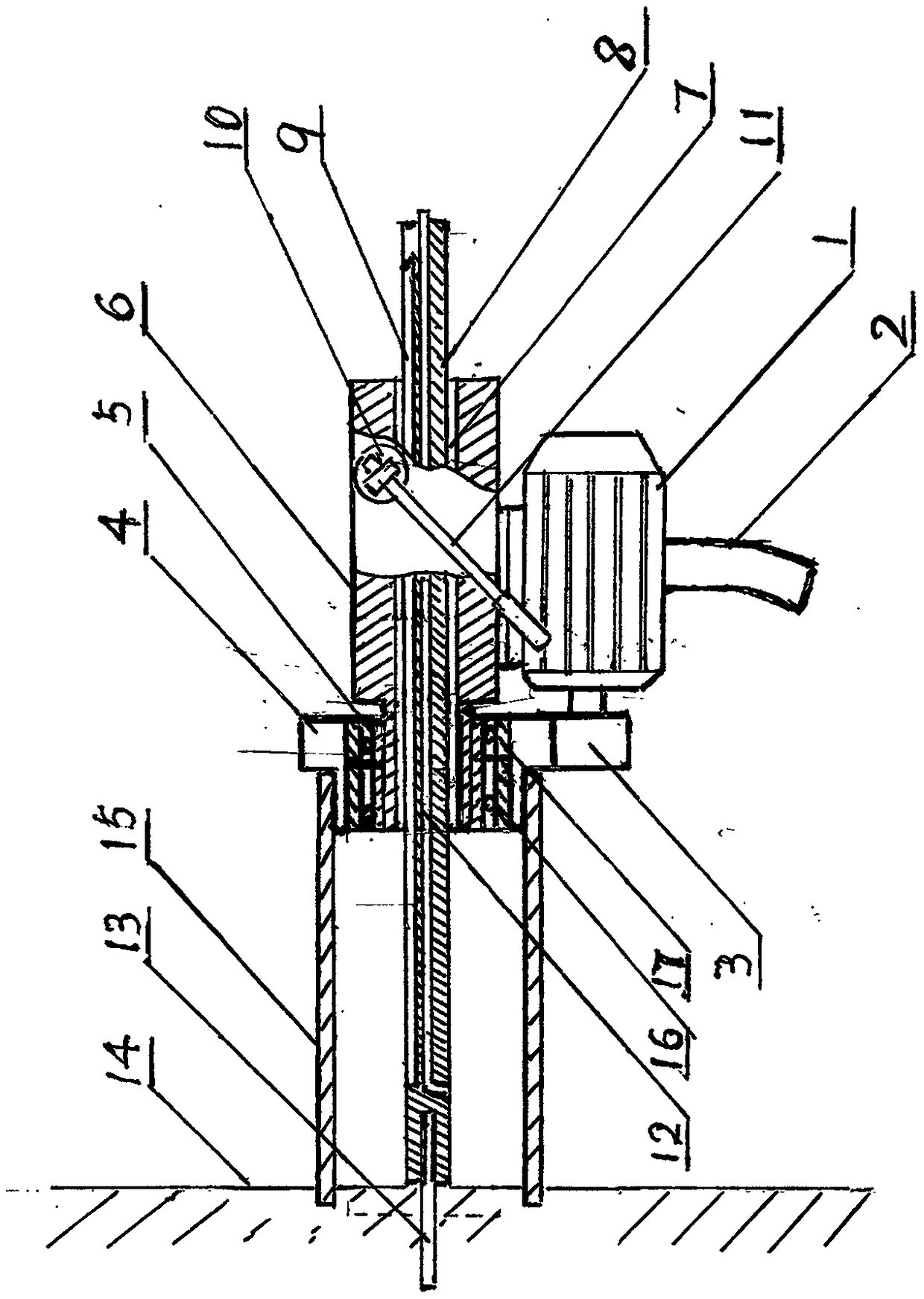

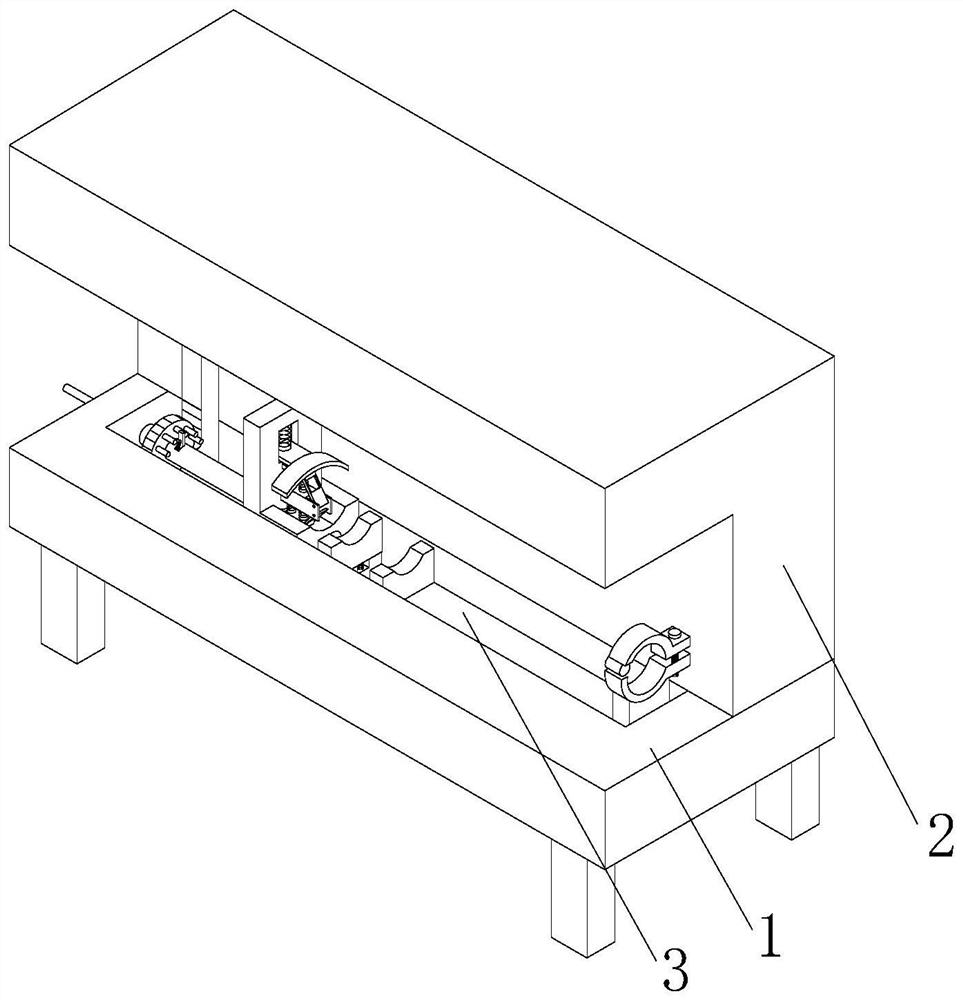

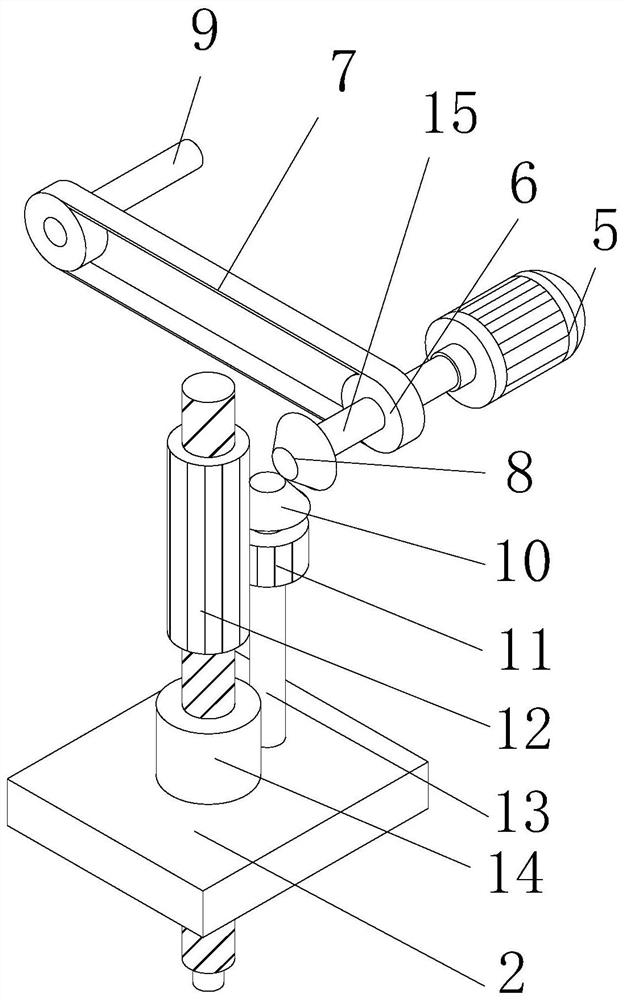

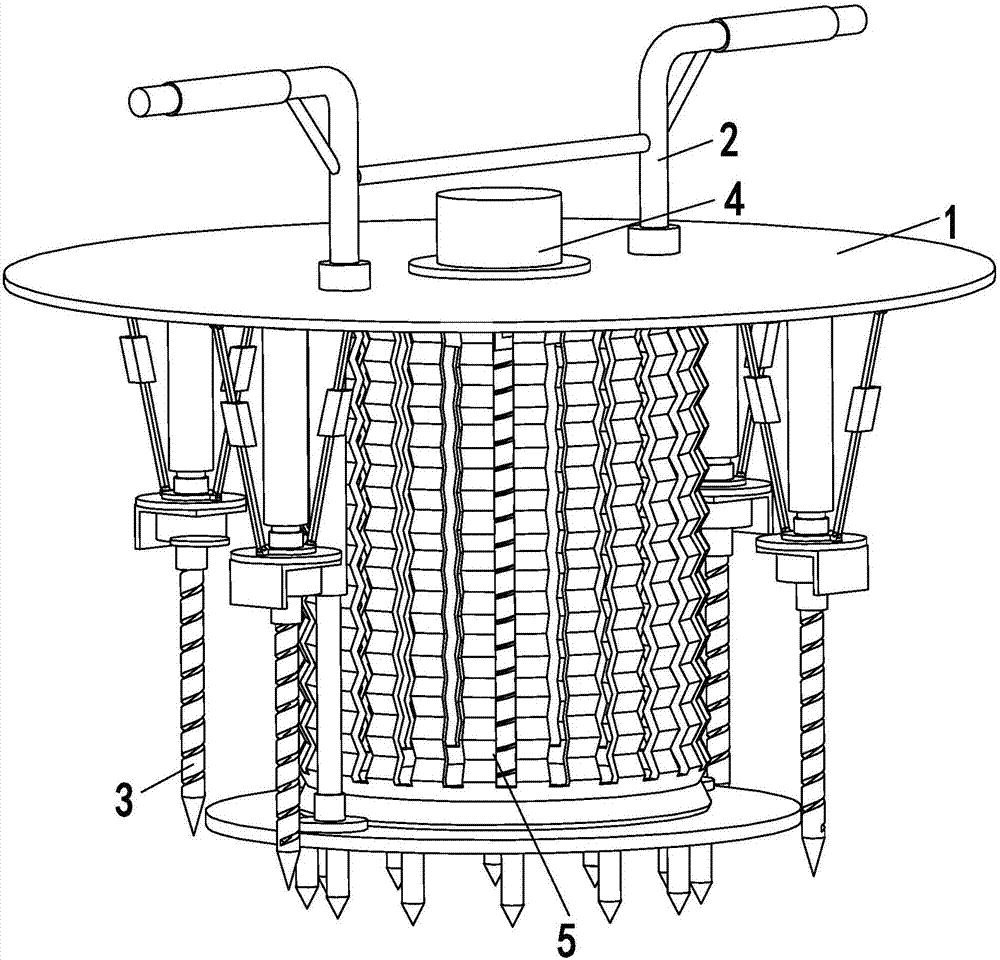

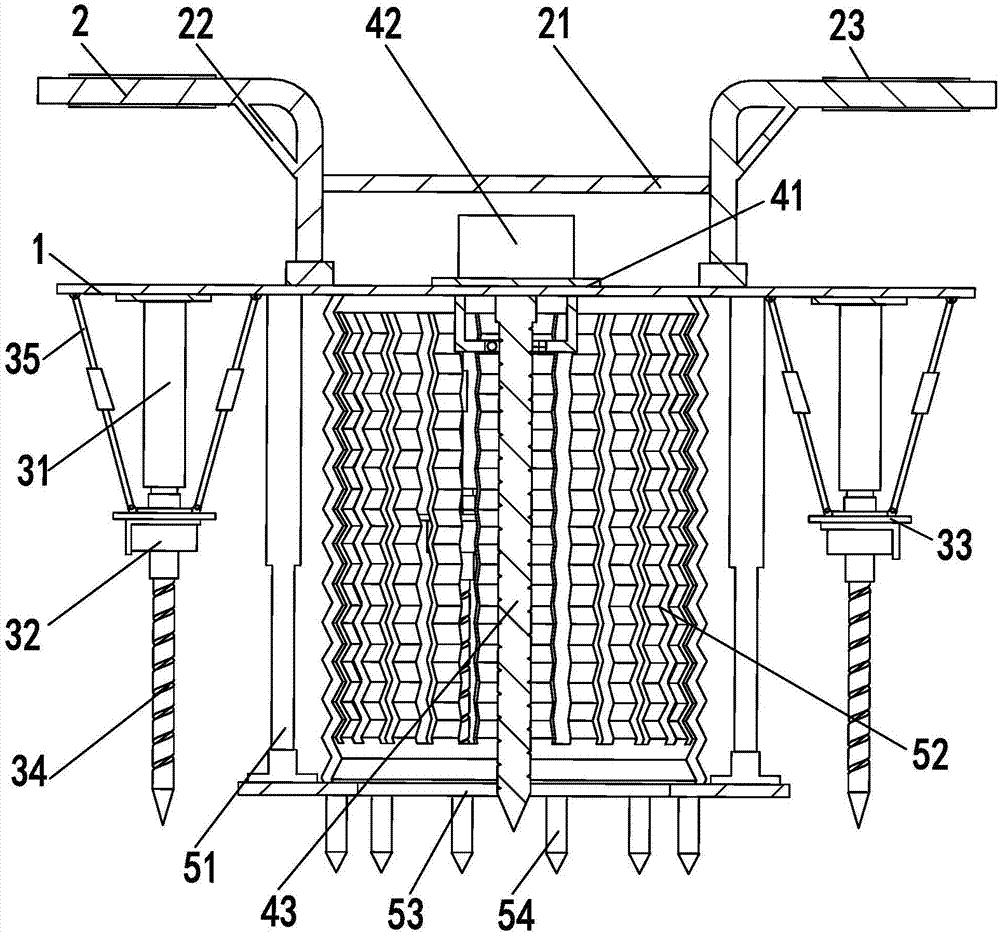

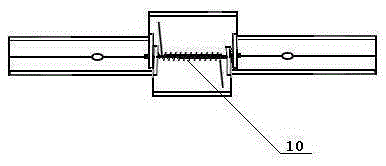

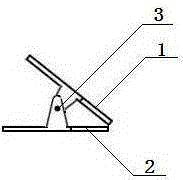

Synchronous adjustable multiple shaft machine

InactiveCN101372045APrecise drillingDrilling safetyBoring/drilling componentsBoring/drilling machinesGear wheelEngineering

A synchronous adjustable multi-axis machine is designed aiming at workpieces with pitch-row reference circle of different sizes and uniformly distributed angle, such as a shell of a small and medium motor and the drilling of an end closure. The synchronous adjustable multi-axis machine comprises a multi-axis machine shell, regulating cylinders, a drill pipe, a locknut, a drive gear, and a synchronous regulating mechanism, and the like. The multi-axis machine has a plurality of regulating cylinders which are internally provided with transition gears. One side of the transition gears is engaged with a drive gear, and the other side drives a drill pipe gear to lead the drill pipes to rotate; one end of axle of the transition gear is fixed in the multi-axis machine shell, and the other end is matched with the locknut which fixes the regulating cylinder; loosing the locknut so that the the regulating cylinder can rotate to lead the drill pipe locate on the needed position. In order to regulate the needed pitch-low synchronously, a linkage mechanism is arranged among a plurality of regulating cylinders; when the pitch-row of the drilling is adjusted, the regulating cylinders are rotate simultaneously to ensure that the distance of the drill pipe is evenly distributed along the circumference. The excircle of the regulating cylinder is cut with a value cue mark of the diameter (D) or the radius (R) of the drilling reference cycle.

Owner:吴为国

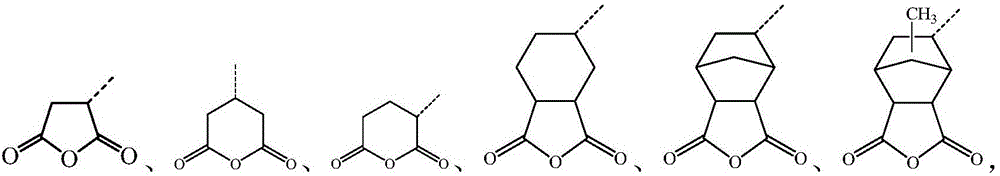

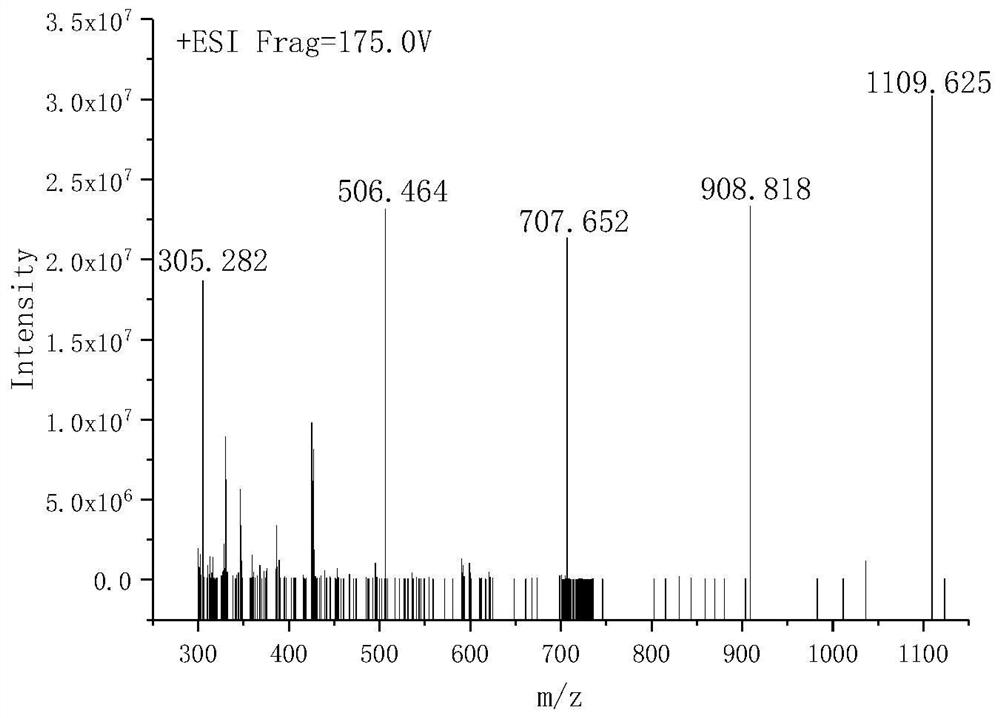

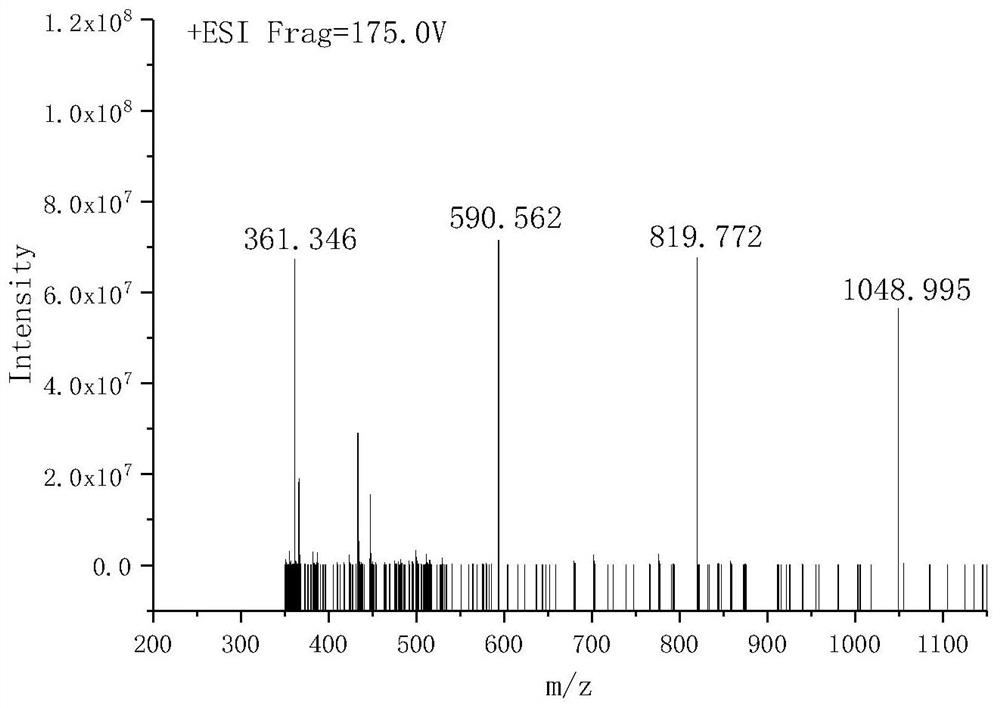

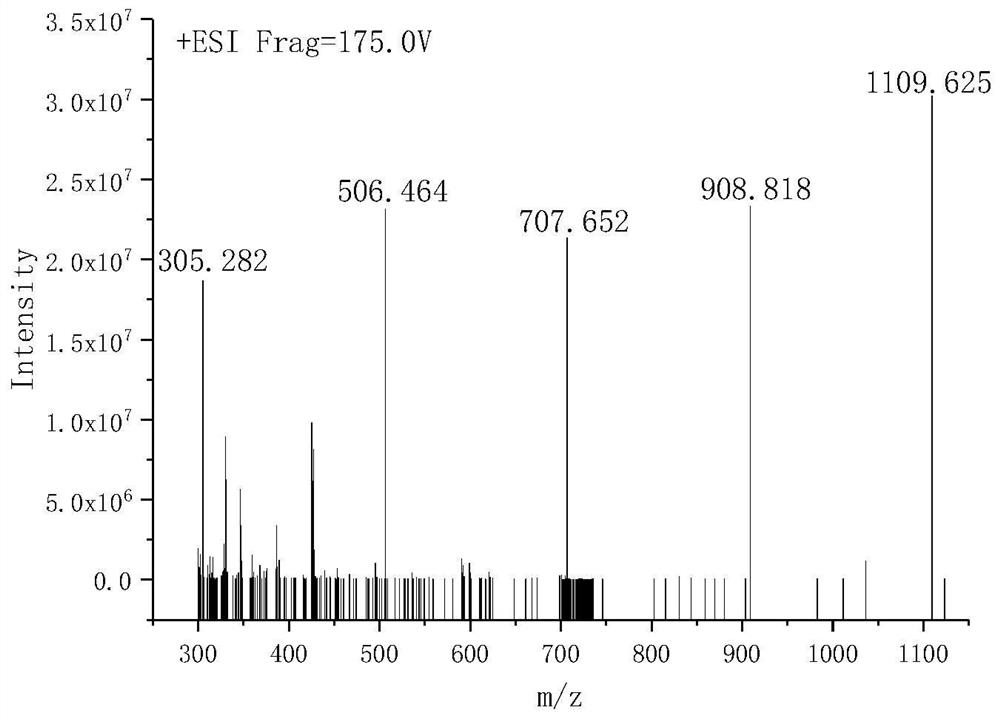

Additive composition applicable to viscosity reduction of oil-based drilling fluid and application thereof, and oil-based drilling fluid and application thereof

ActiveCN106634881AReduce apparent viscosityReduce drilling difficultyDrilling compositionApparent viscosityWell drilling

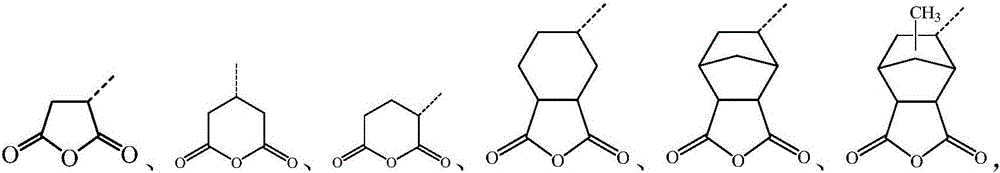

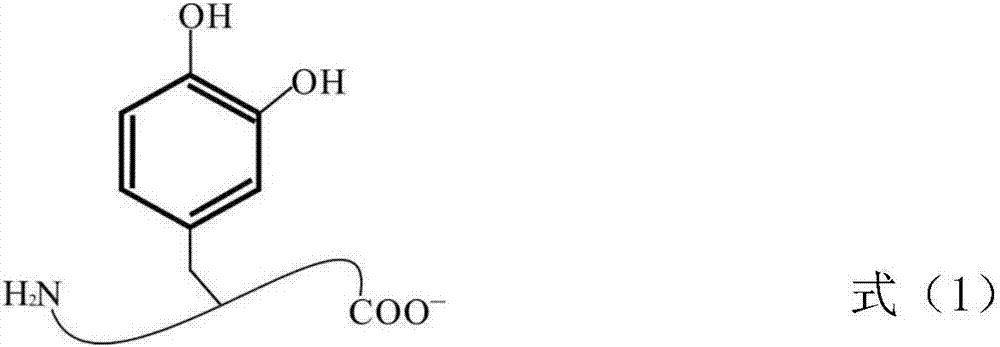

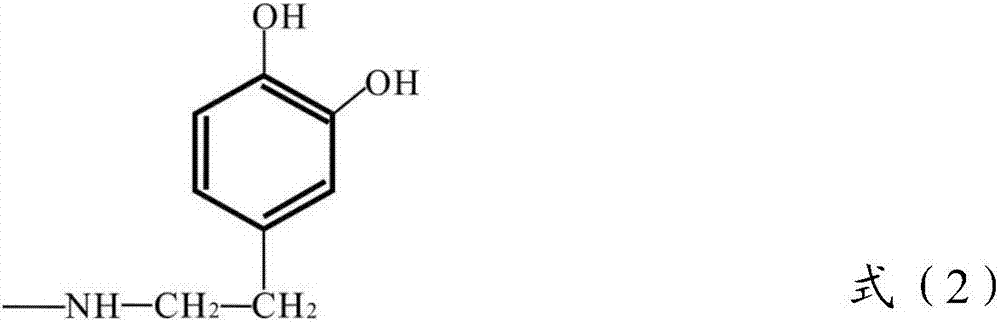

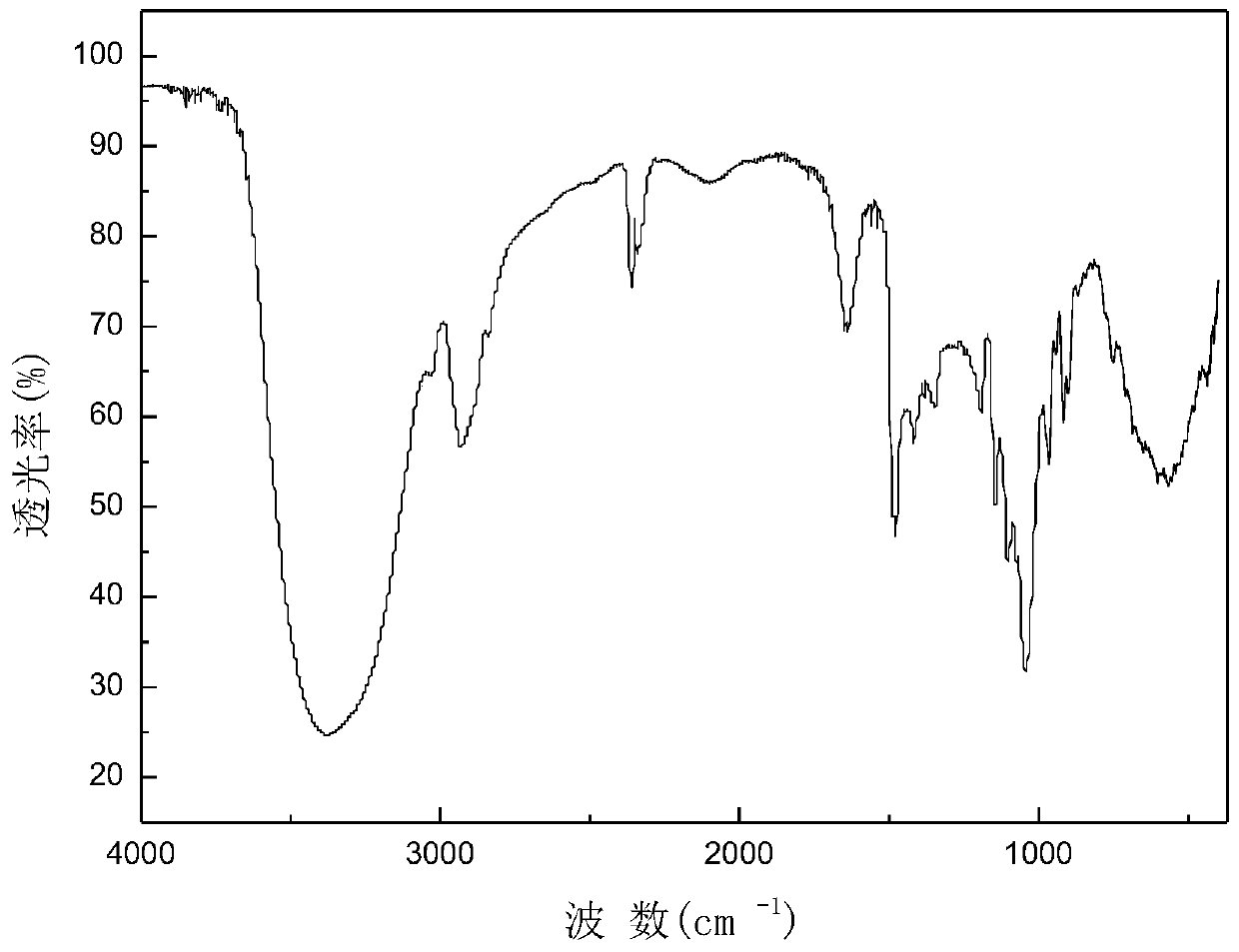

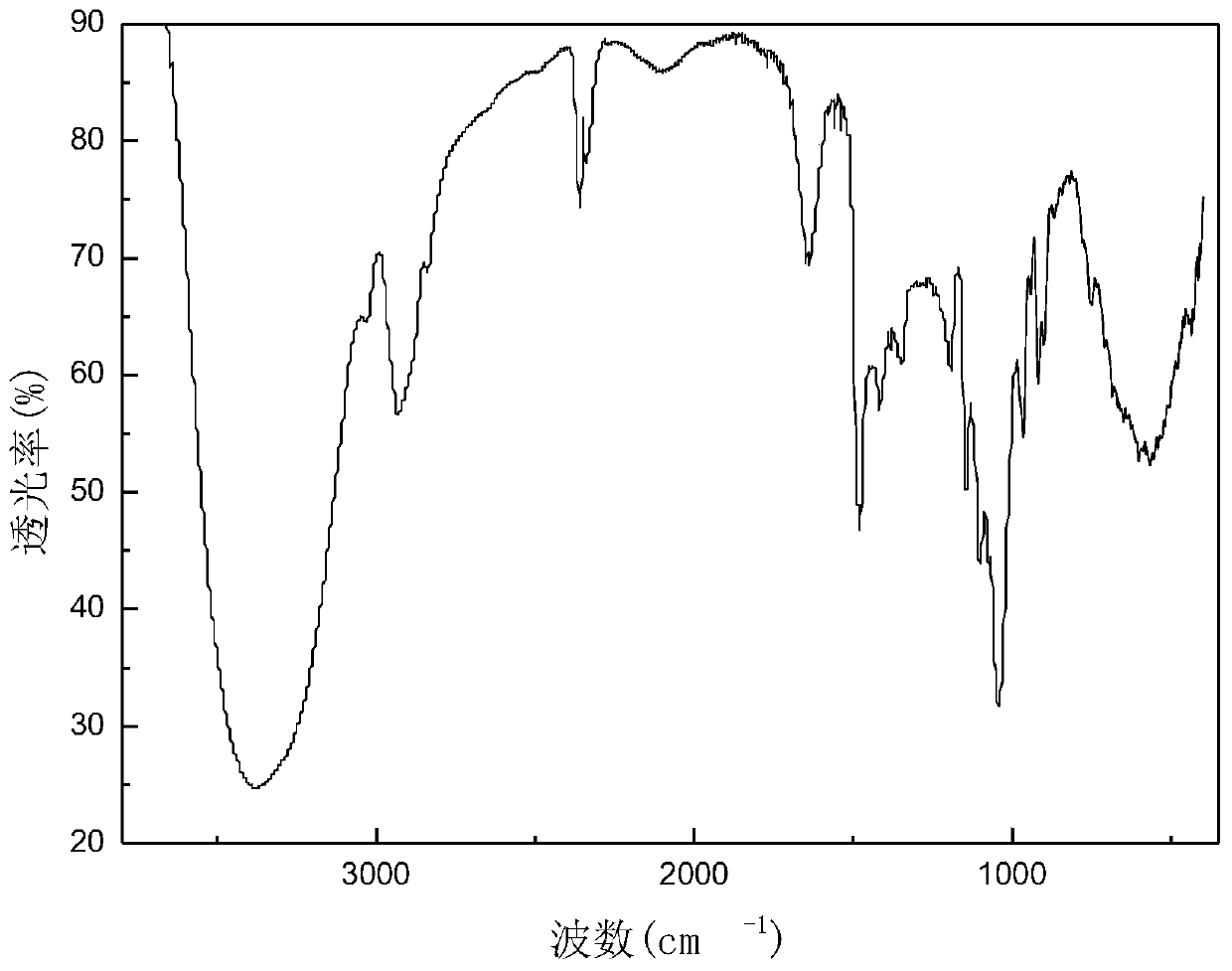

The invention specifically relates to an additive composition applicable to viscosity reduction of an oil-based drilling fluid and application thereof, and the oil-based drilling fluid and application thereof. The additive composition is a double block copolymer which is composed of a block A and a block B, wherein the block A is composed of a constitutional unit as shown in a formula (1) which is described in the specification and has a number-average molecular weight of 1500 to 10000, and the block B is composed of a constitutional unit as shown in a formula (2) which is described in the specification. The double block copolymer can be used as a viscosity reducer for the oil-based drilling fluid, especially as a viscosity reducer for a high-density clay-free oil-based drilling fluid; and the double block copolymer can greatly reduce the apparent viscosity and plastic viscosity of the oil-based drilling fluid in high-temperature high-pressure strata while guaranteeing proper shearing force, so drilling speed can be conveniently accelerated and difficulty in well drilling can be reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

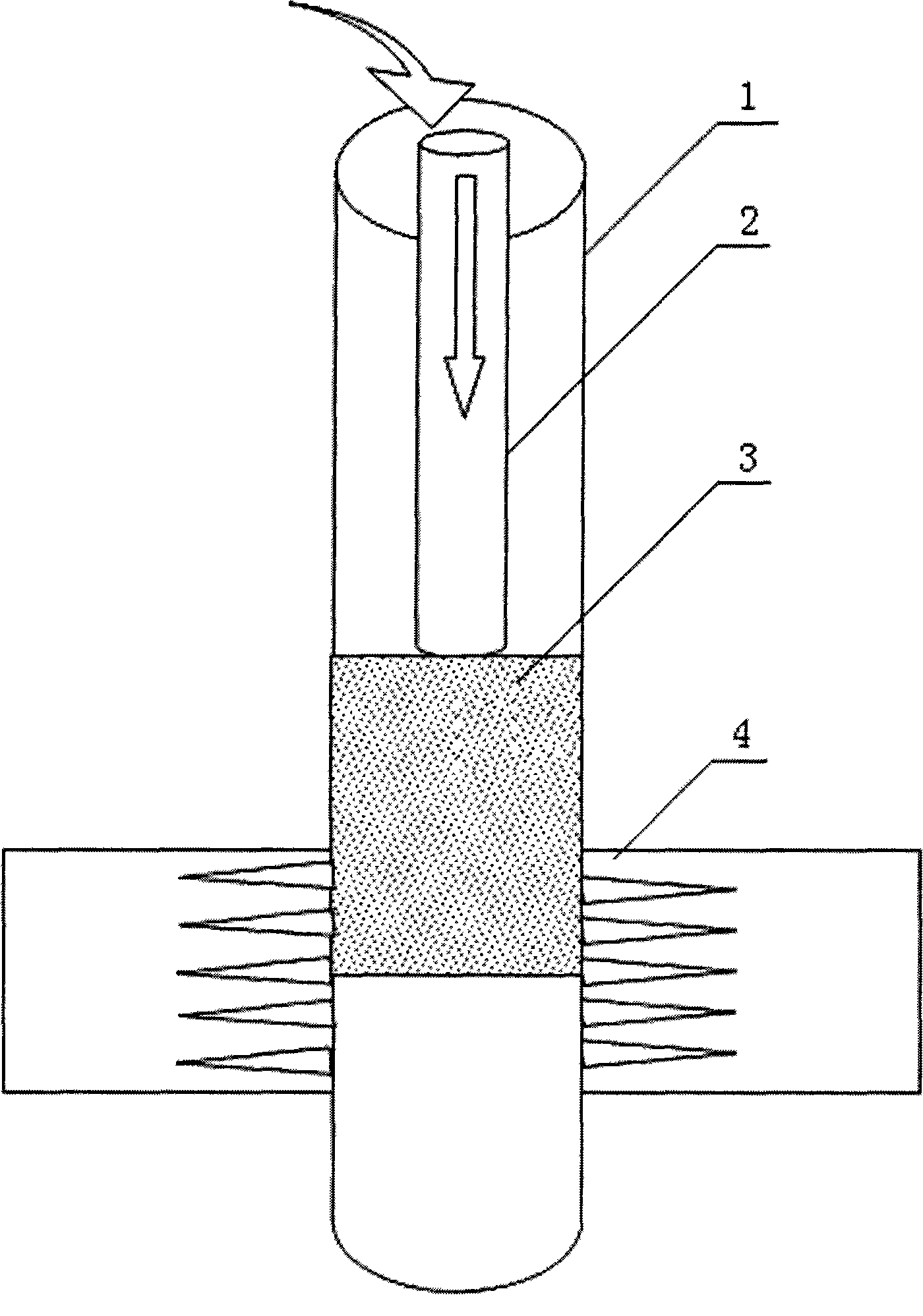

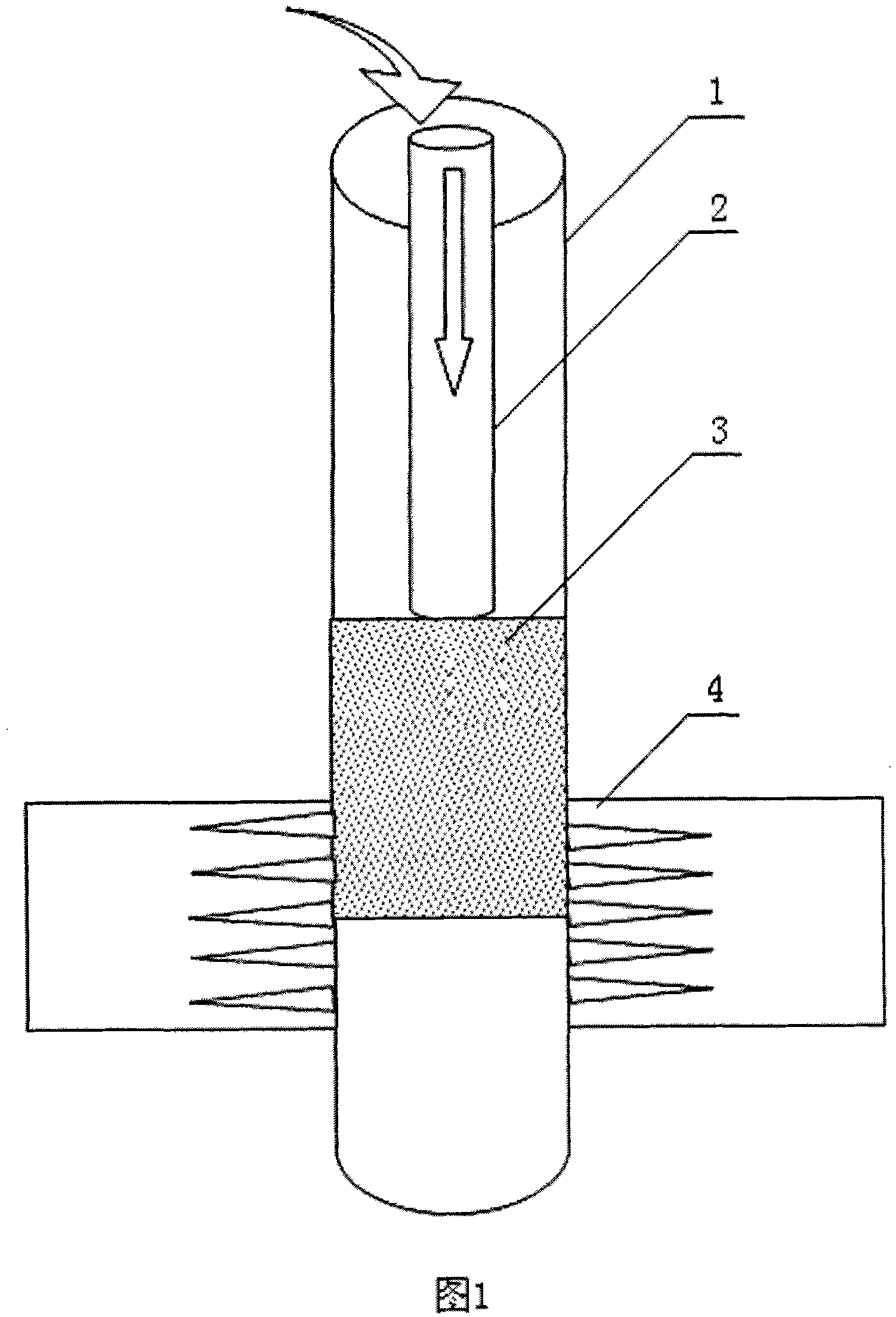

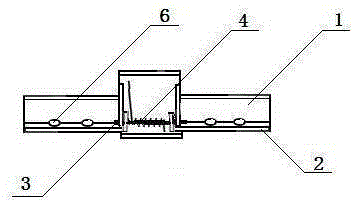

Gas discharge collecting device for drilling construction

InactiveCN103195470AImprove average progressGuaranteed continuous normalGas removalSealing/packingGas-discharge lampSlag

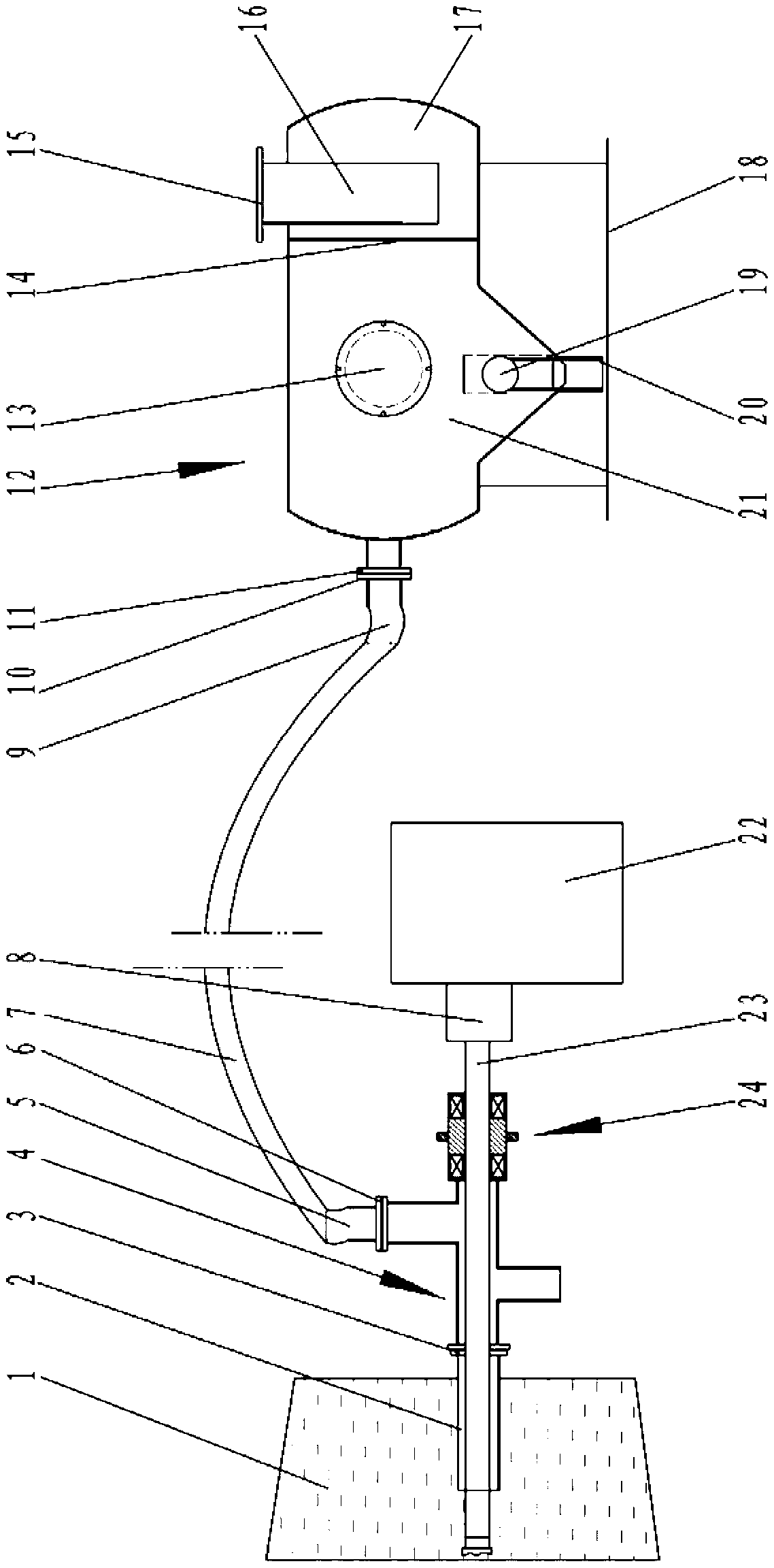

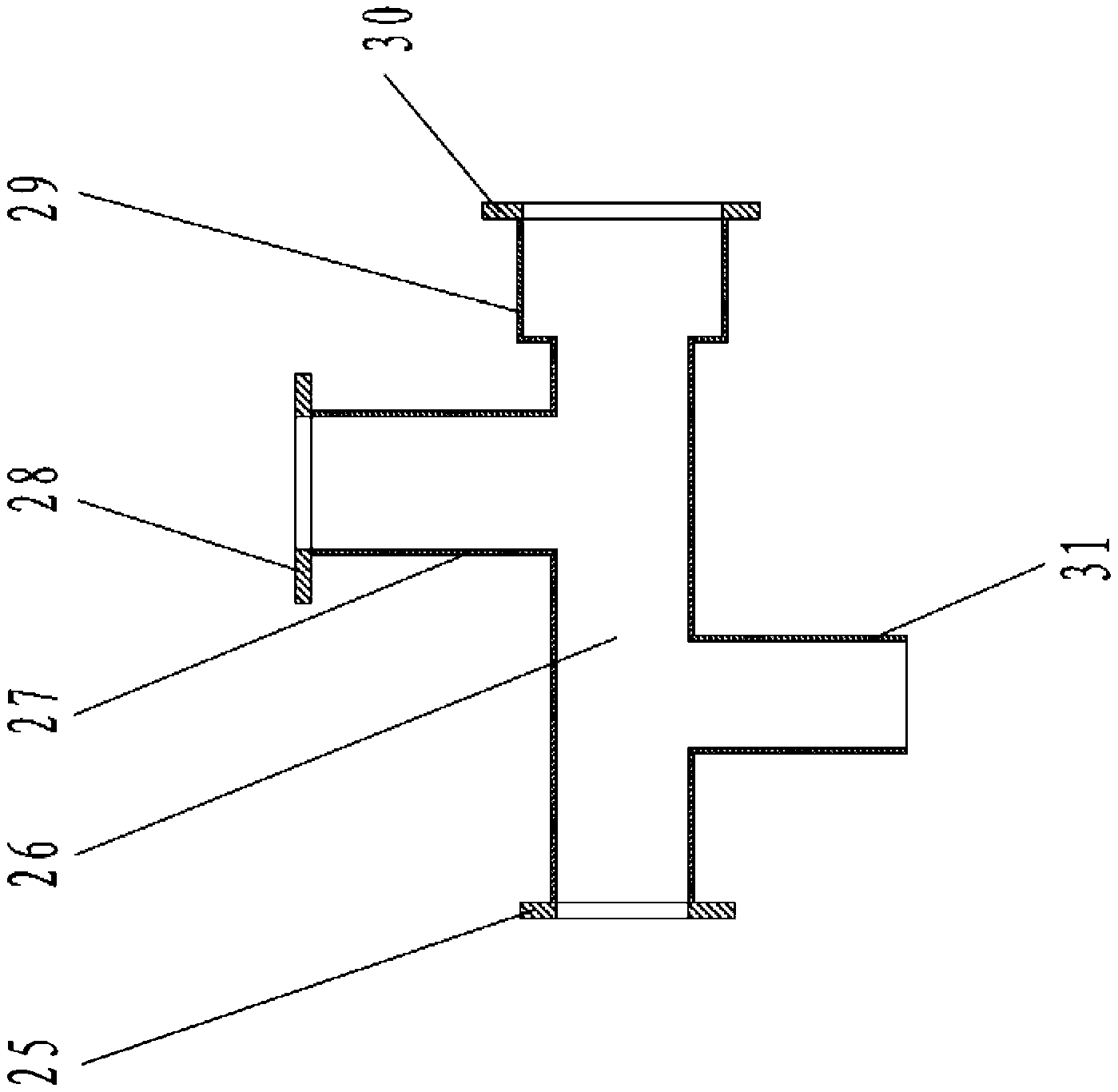

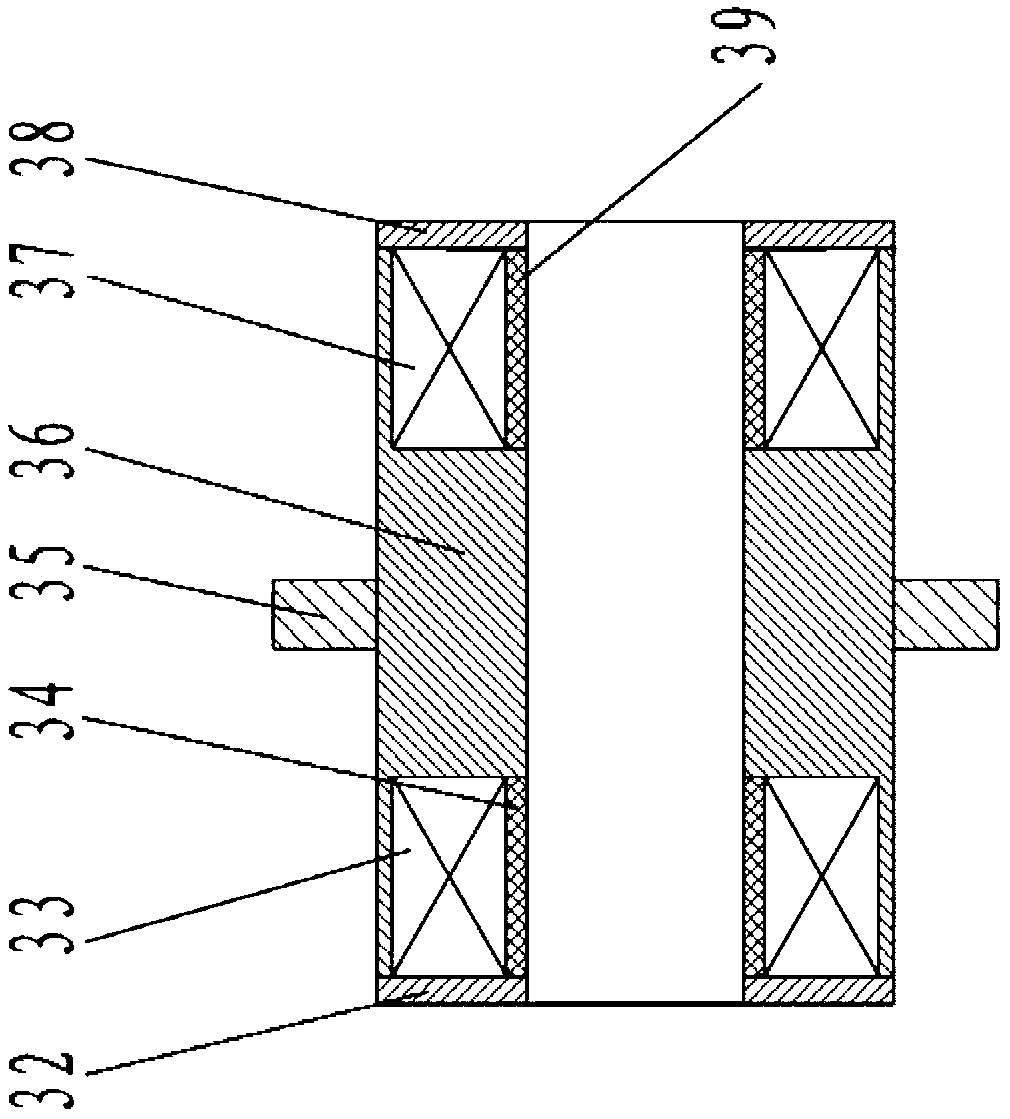

A gas discharge collecting device for drilling construction comprises drill hole sealing nests, a gas, water and slag discharge component, follow-up sealing components, a gas collecting component and a connecting pipe. The drill hole sealing nests and the follow-up sealing component are fixedly matched with two ends of the gas, water and slag discharge component. The connecting pipe is connected between the gas, water and slag discharge component and the gas collecting component. The gas discharge collecting device for drilling construction has no need for injecting high-pressure gas or water during drilling, a drilling machine can continuously operate in normal pressure state, the follow-up sealing component is rotationally sealed along with the drill rod, gas, water and slag discharged from the drilled holes are guaranteed to be in a closed cavity, gas is extracted out by negative pressure of a mine gas extraction and discharge system, and slag and water can flow out under the action of gravity. Drilling is safe and reliable, safety potential hazards are eliminated, drilling construction is guaranteed to carry out continuously and normally, and average drilling speed is greatly increased.

Owner:双鸭山市吉昌机械制造有限公司

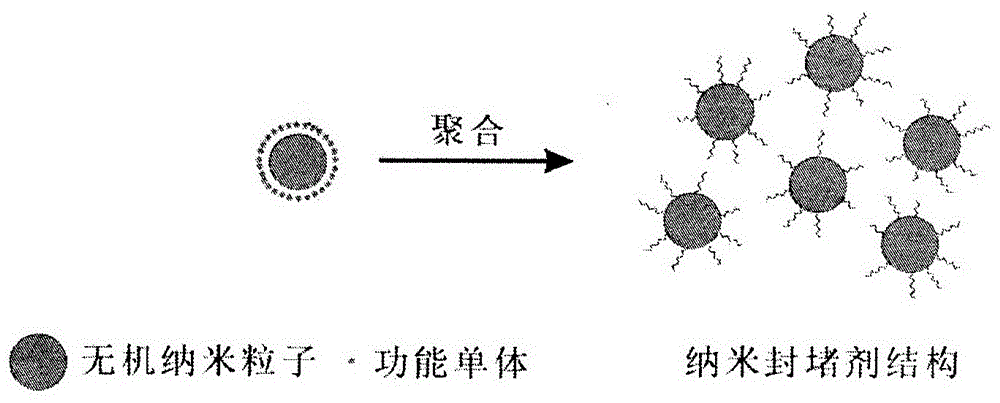

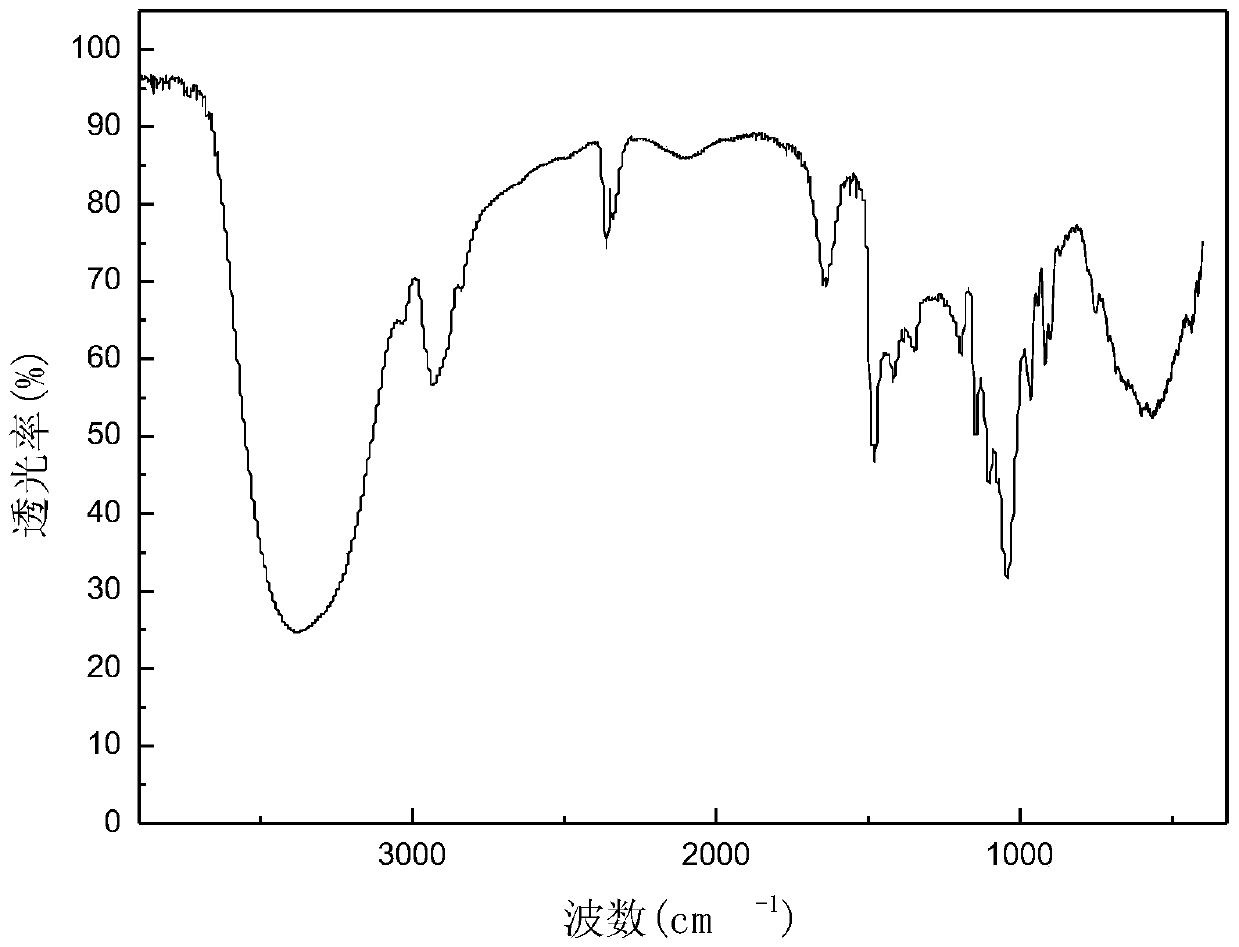

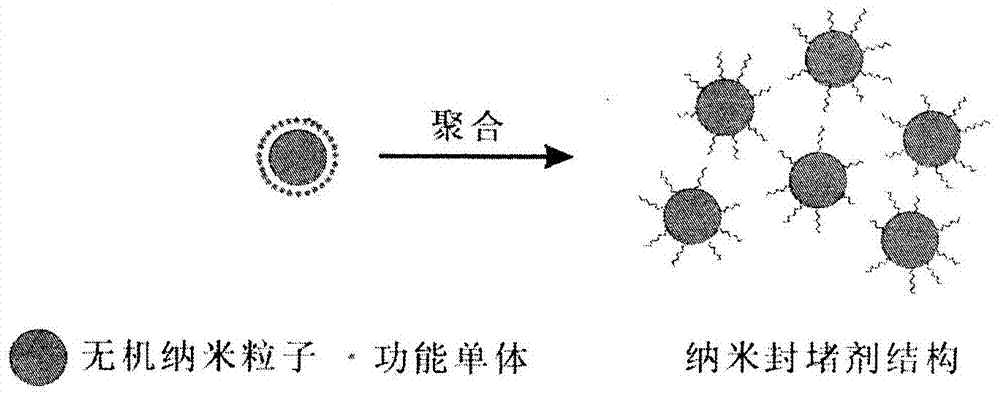

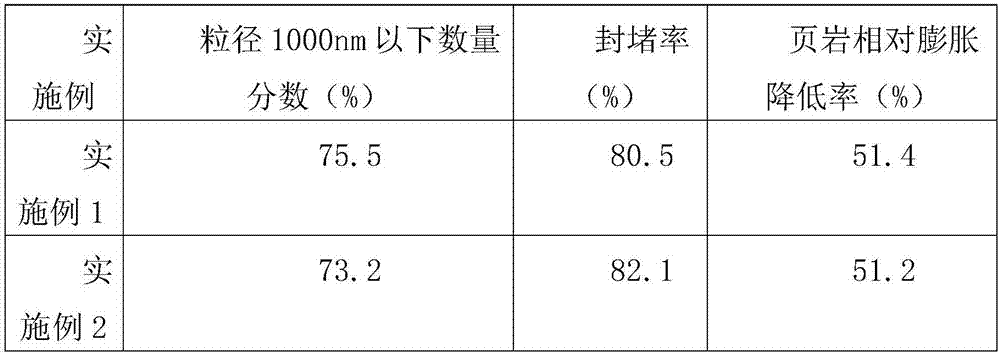

Bionic nanometer blocking agent for drilling fluid and preparation method thereof

ActiveCN106634879AImprove performanceImprove stabilityDrilling compositionPotassium persulfateCross-link

The invention relates to a bionic nanometer blocking agent for drilling fluid and a preparation method thereof. The bionic nanometer blocking agent is prepared from the following raw materials in parts by weight: 60 to 70 parts of distilled water, 1 to 2 parts of 2-acrylamide-2-methylpropanesulfonic acid, 20 to 30 parts of lactic acid, 5 to 10 parts of cross-linking agent, 0.7 to 1.5 parts of nanometer titania, 0.7 to 1.5 parts of molecular weight regulator, 0.1 to 0.5 part of potassium persulfate and 0.2 to 0.5 part of sodium hydroxide. The cross-linking agent is one of ethylene glycol dimethacrylate, polyethylene glycol and trimethylolpropane; the molecular weight regulator is isooctyl 3-mercaptopropionate. The preparation method comprises the following process steps of preparing alkyl solution; preparing titanium-based solution; preparing the bionic nanometer blocking agent. The bionic nanometer blocking agent for the drilling fluid, which is disclosed by the invention, solves the problems of shale hydration and extraneous water erosion in the existing drilling process; meanwhile, the bionic nanometer blocking agent has high biodegradability, so that pollution to a reservoir is effectively reduced.

Owner:石家庄华莱鼎盛科技有限公司

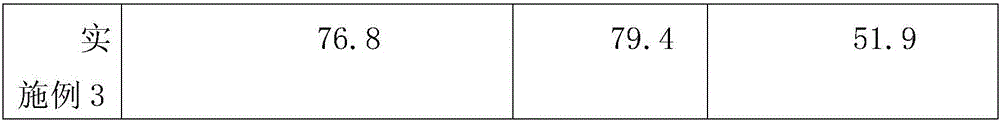

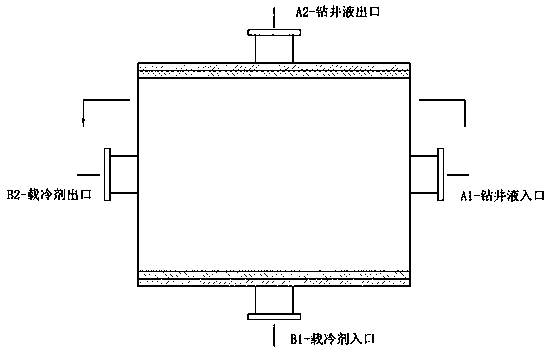

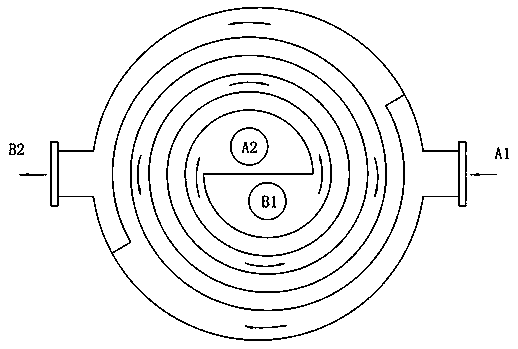

Drilling fluid forced-cooling device and low-temperature circulatory drilling method

PendingCN110284845ACycle temperature reductionLower the well temperatureLighting and heating apparatusFlushingConvection heatPetroleum engineering

The invention discloses a drilling fluid forced-cooling device and a low-temperature circulatory drilling method. The drilling fluid forced-cooling device comprises a refrigerating medium cooling system and a convection heat exchange system, wherein the refrigerating medium cooling system and the convection heat exchange system are connected in the device in series. The low-temperature circulatory drilling method for the drilling fluid forced-cooling device adopts the drilling fluid forced-cooling device to control an inside temperature of drilling fluid to be 40-50 DEG C, and comprises drilling fluid cooling cycle and refrigerating medium cooling cycle. The drilling technology can solve the technical bottleneck that a drilling fluid circulating temperature caused by an ultra-high underground temperature exceeds temperature-resistant limit of an underground tool, can effectively reduce the drilling fluid circulating temperature by reducing the inside temperature of the drilling fluid, prolongs the service life of the underground tool, is an effective means for safe and efficient well drilling of a high-temperature well, and is a key technology for deeper development of drilling operation. Process and equipment related can independently operate, so that normal drilling operation is not affected.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI

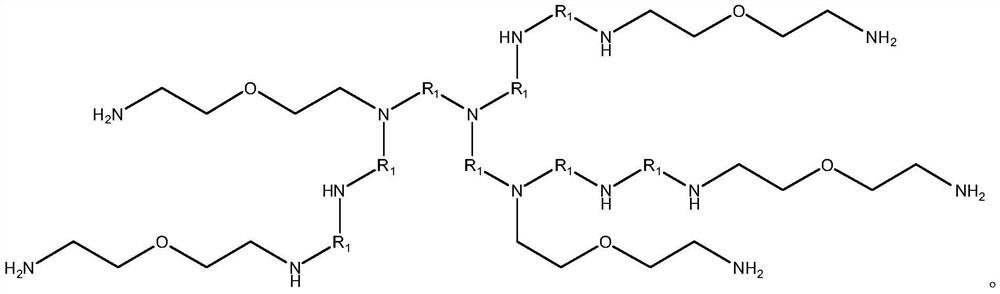

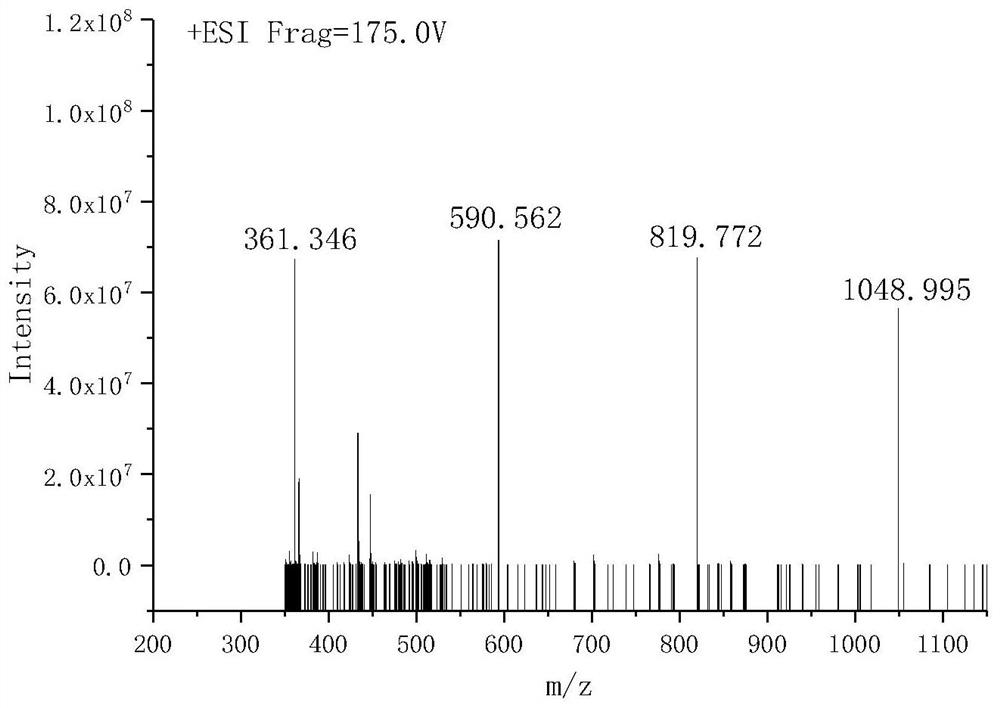

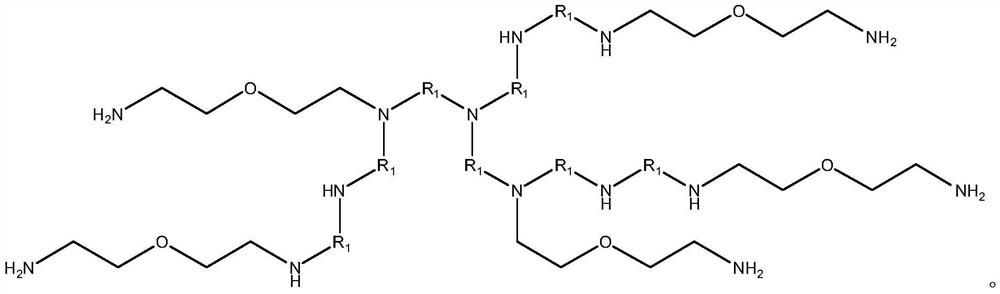

Hyperbranched polyether amine environment-friendly shale inhibitor, preparation method thereof and water-based drilling fluid

ActiveCN111718698AEnhanced inhibitory effectInhibits hydration swellingDrilling compositionOil fieldPolymer

The invention discloses a hyperbranched polyether amine environment-friendly shale inhibitor, a preparation method thereof and a water-based drilling fluid, and belongs to the technical field of oilfield chemistry. The shale inhibitor is prepared by taking diallylamine and a diether amine compound as raw materials through reaction. The shale inhibitor provided by the invention is a hyperbranched polymer, has good shale inhibition, clay stability and temperature resistance, is easy to biodegrade, and has good environmental protection performance; the preparation method provided by the inventionis simple in steps, easily available in synthetic raw materials and suitable for industrial production; the hyperbranched polyether amine shale inhibitor provided by the invention is good in component compatibility with other conventional drilling fluid treatment agents, the prepared water-based drilling fluid is suitable for a strong water-sensitive shale stratum, the expansion rate of shale canbe obviously reduced, the collapse of a well wall is prevented, the well wall is effectively stabilized, and the occurrence of underground complex conditions is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

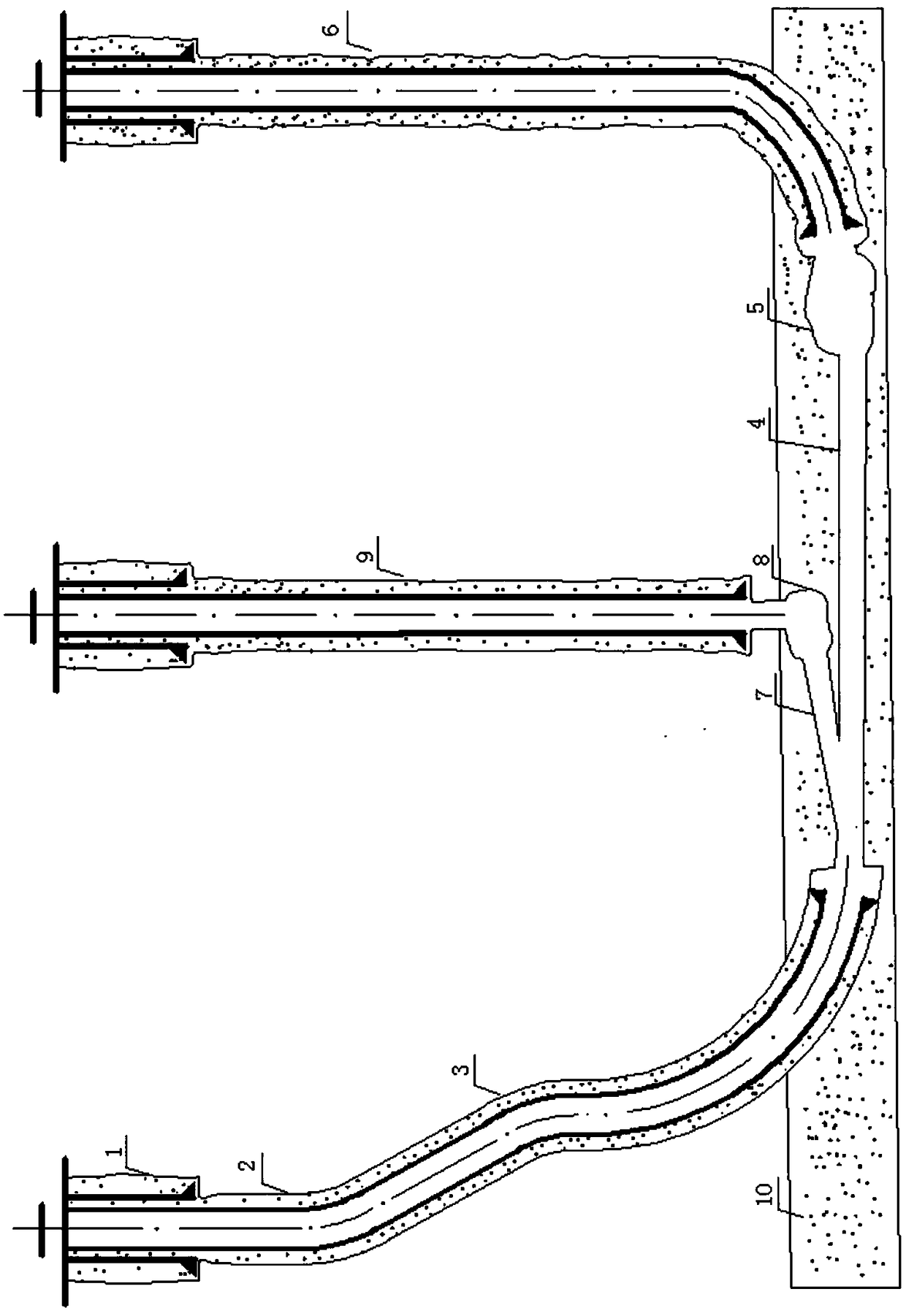

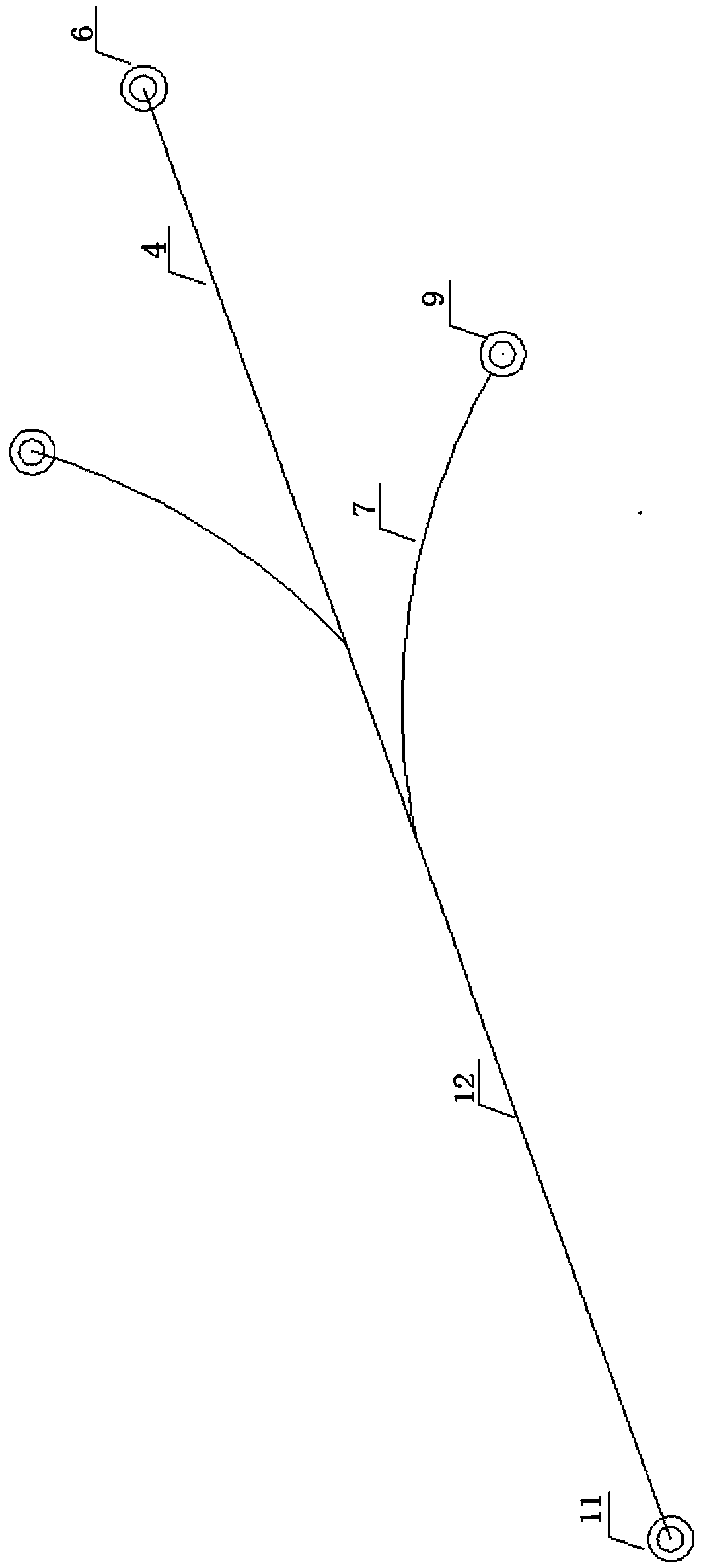

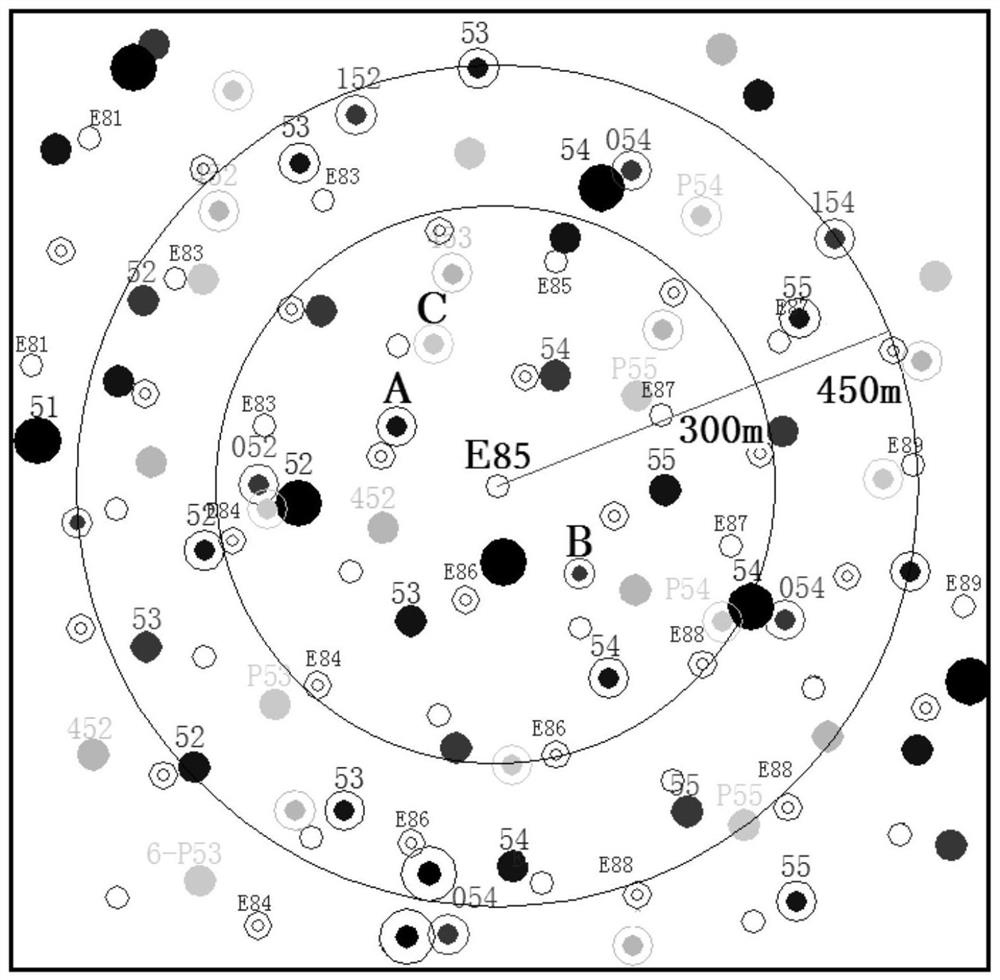

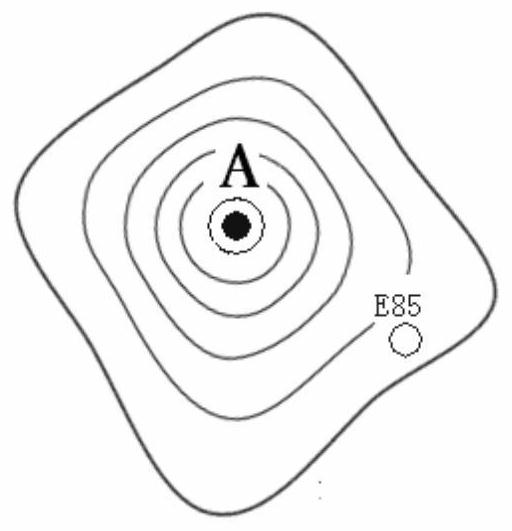

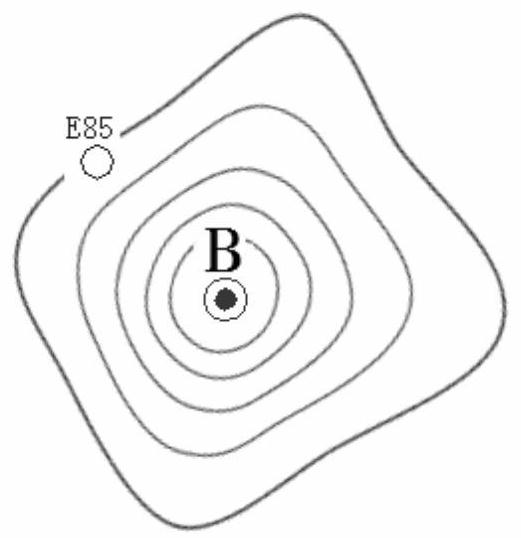

Old well potential tapping process for old mining area of rock salt

PendingCN109184693ASave land resourcesReduce occupancySurveyUnderground miningControl areaEnvironmental geology

The invention discloses an old well potential tapping process for an old mining area of rock salt. The process comprises the following steps: newly building a multi-branch horizontally butted well tobe communicated with salt cavities or horizontal sections of multiple old well groups with production reduction or shutdown at present for brine mining, monitoring and controlling the well track by using a clinometer during drilling of the vertical well section of the multi-branch horizontal well, controlling the well deflection azimuth by adopting a clinometer and a single-bend helicoid hydraulicmotor in the building-up section drilling process, adjusting the azimuth after getting round of old cavity or a roof blowby area towards a salt layer downdip direction, and drilling towards a buttedtarget well, and therefore, the safety drilling is facilitated, the salt control area is enlarged, and the brine production and brine density are increased.

Owner:四川盐业地质钻井大队

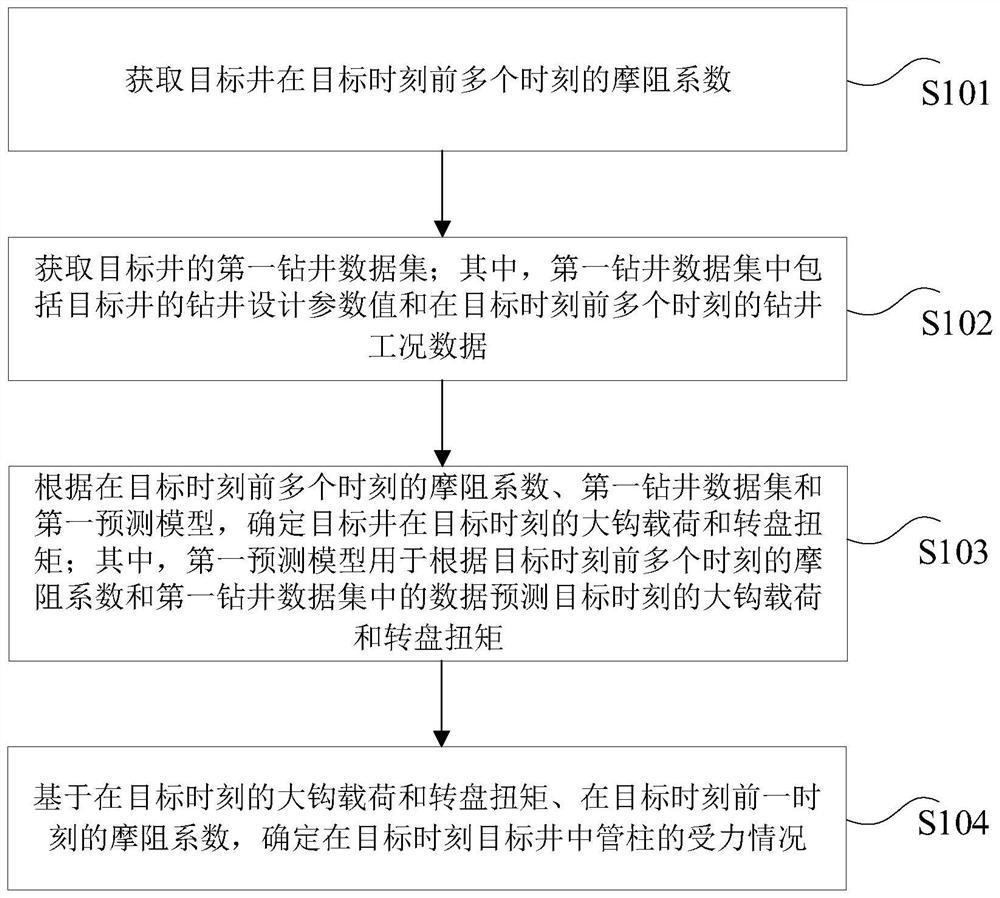

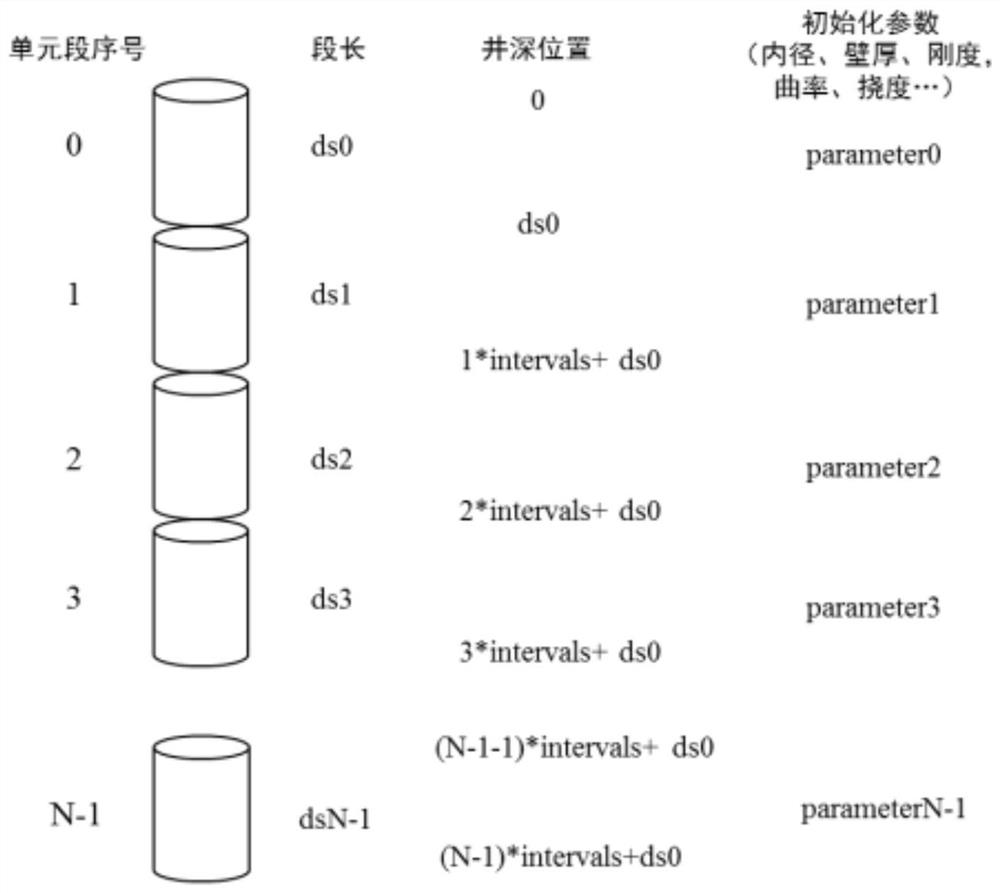

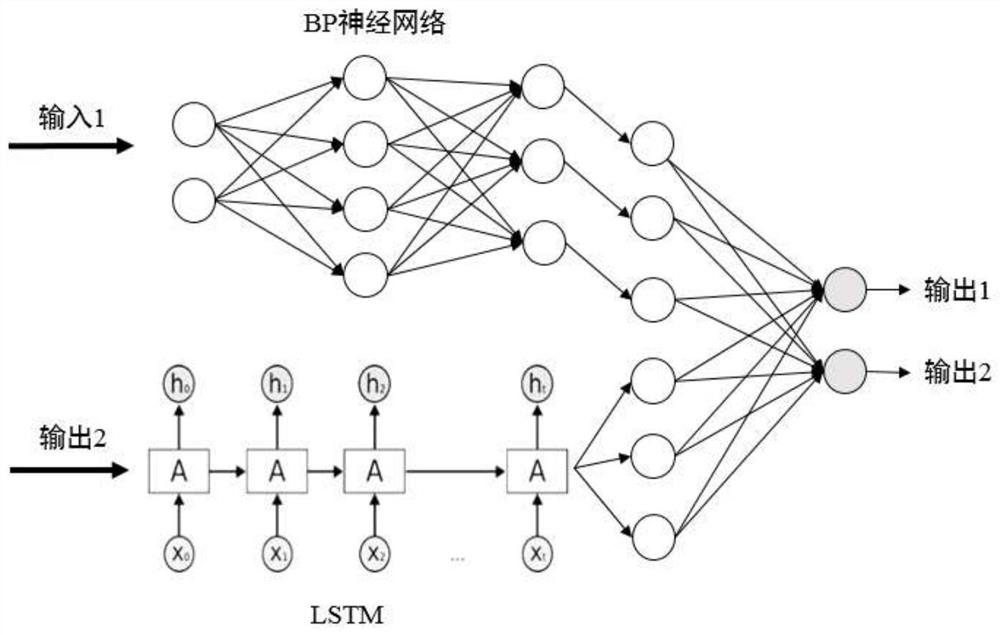

Method, device and equipment for determining stress condition of tubular column

PendingCN112330038AAvoid drilling sticking and other risksIncrease ROPForecastingDesign optimisation/simulationData setWell drilling

The embodiment of the invention provides a method, device and equipment for determining the stress condition of a tubular column. The method comprises steps of obtaining friction coefficients of a target well at a plurality of moments before a target moment; obtaining a first drilling data set of the target well; determining a hook load and a turntable torque of the target well at the target moment according to the friction coefficients at multiple moments before the target moment, the first drilling data set and a first prediction model; and based on the hook load and the turntable torque atthe target moment and the friction coefficient at the moment before the target moment, determining the stress condition of the tubular column in the target well at the target moment. In the embodimentof the invention, the stress condition of the tubular column in the target well at the target moment can be accurately determined at the previous moment of the target moment, and then early warning analysis can be carried out on drilling abnormal conditions such as jamming of a drilling tool at the target moment at the previous moment of the target moment so that safe and efficient drilling is guaranteed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

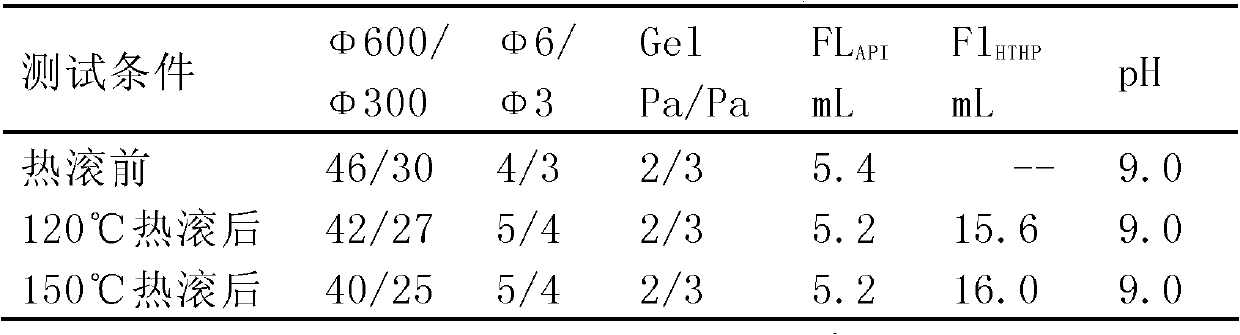

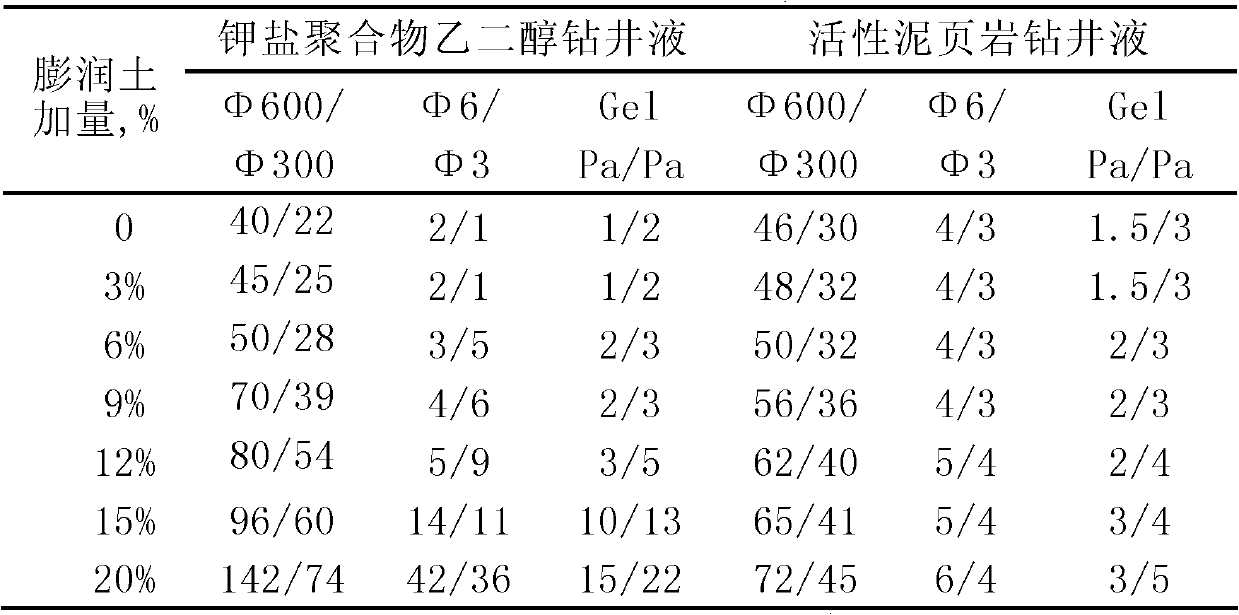

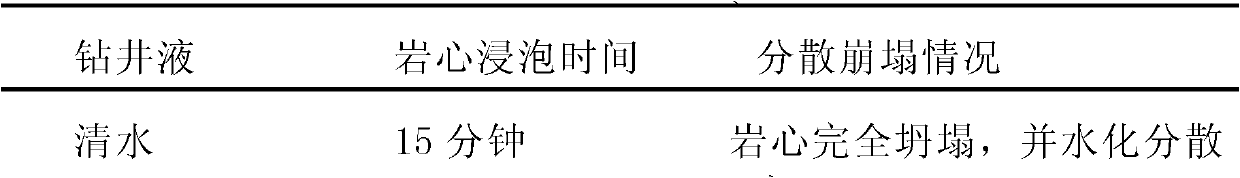

Drilling fluid used for active mud shale drilling

ActiveCN102250595BInhibition of hydration pulpingPrevent hydrationDrilling compositionHigh activityPolymer

The invention relates to a drilling fluid used for active mud shale drilling, and the drilling fluid is used in oilfield drilling. The drilling fluid comprises the following components in percentages by weight: 2-6% of bentonite, 0.2-0.5% of coated inhibitor, 0.2-1.0% of flow pattern regulator, 0.2-0.5% of high-temperature-resistant polymer filtrate reducer, 4-7% of potassium chloride, 1-3% of polymeric alcohol, 0.5-1.0% of polyamine inhibitor, 0.5-1.0% of anti-balling fast drilling agent and 45-85% of water. The drilling fluid has the inhibition property and lubricating property approximate to that of an oil-based drilling fluid, solves the problems that the mud making of the mud shale is severe, mud escapes from a vibrating screen, the viscous shearing of the drilling fluid increases and the rheological properties of the drilling fluid deteriorates during strong-mud-making active mud shale drilling, prevents destabilization of the active mud shale, dispersion of drill cuttings, balling of drill bit, and adhesion and coalescence of the mud shale, and increases the drilling speed of the active mud shale.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

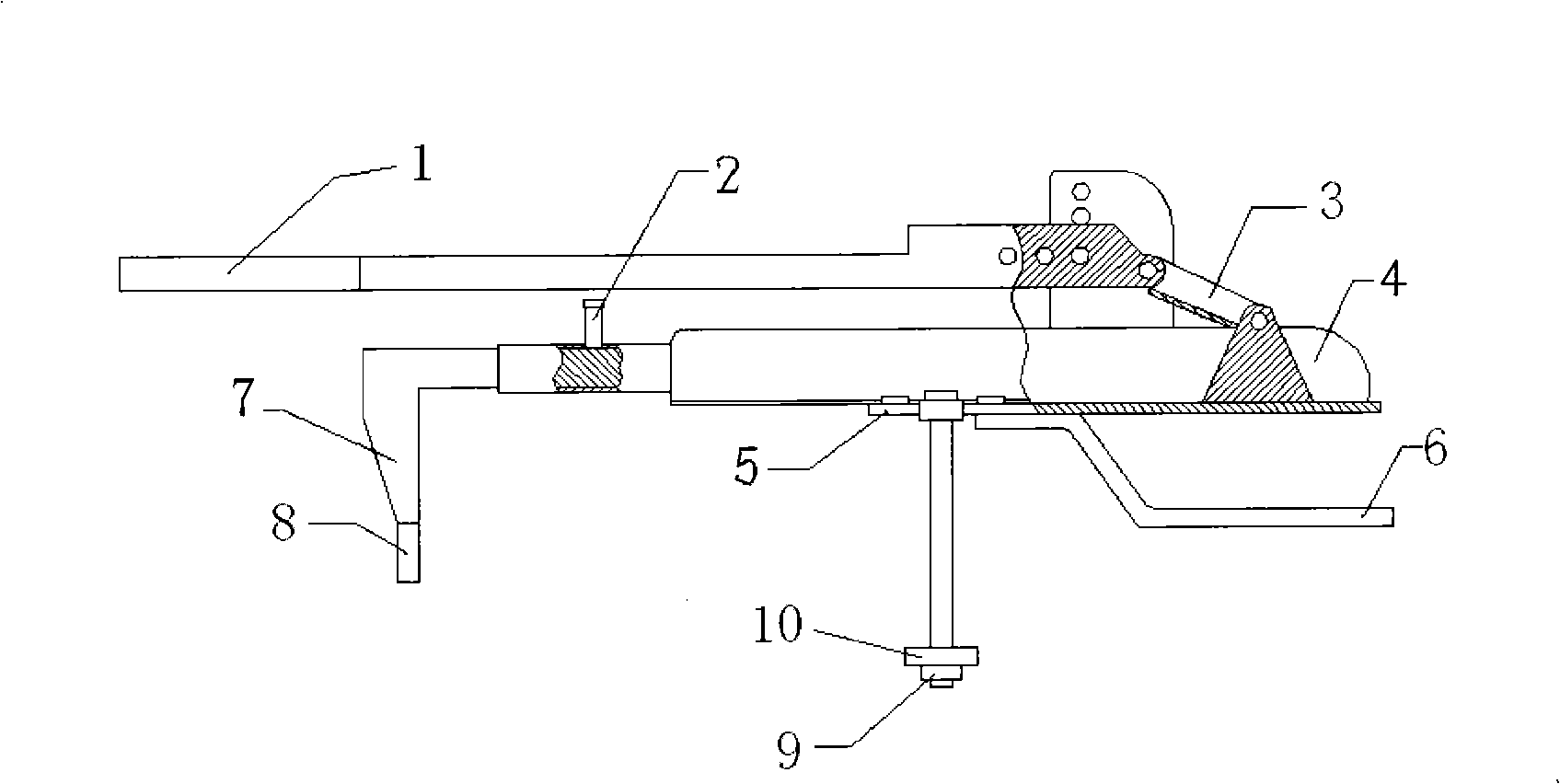

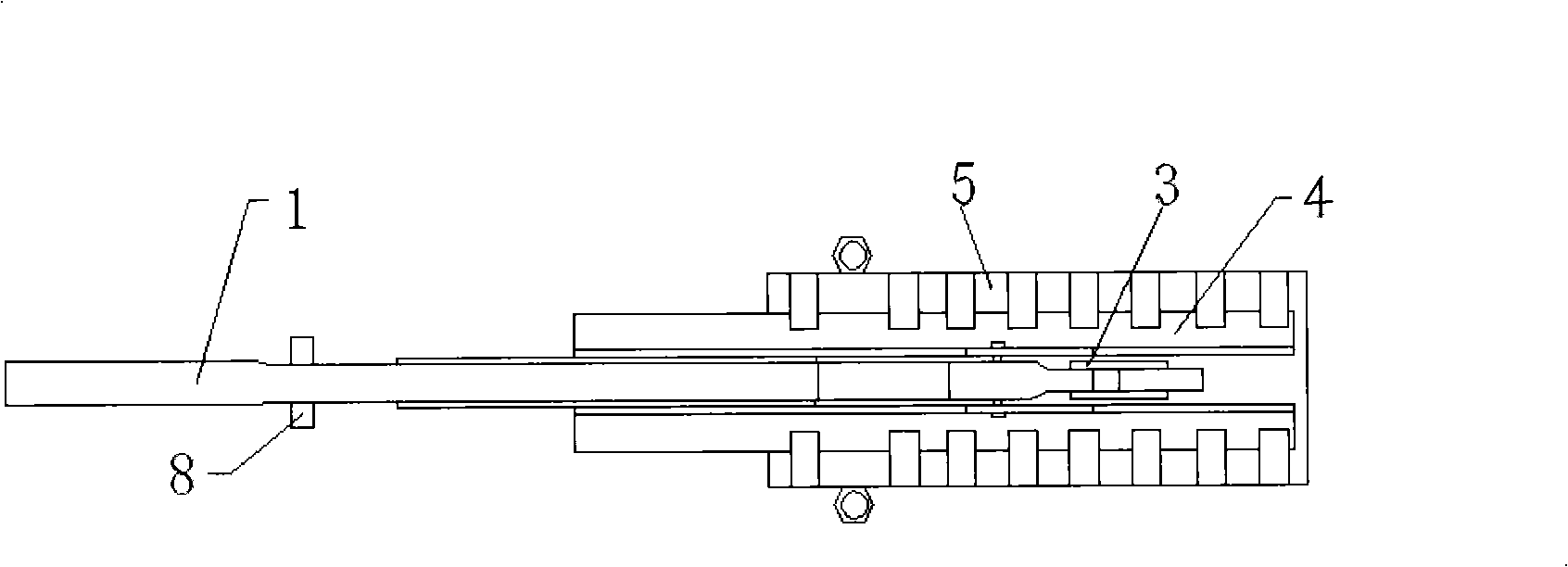

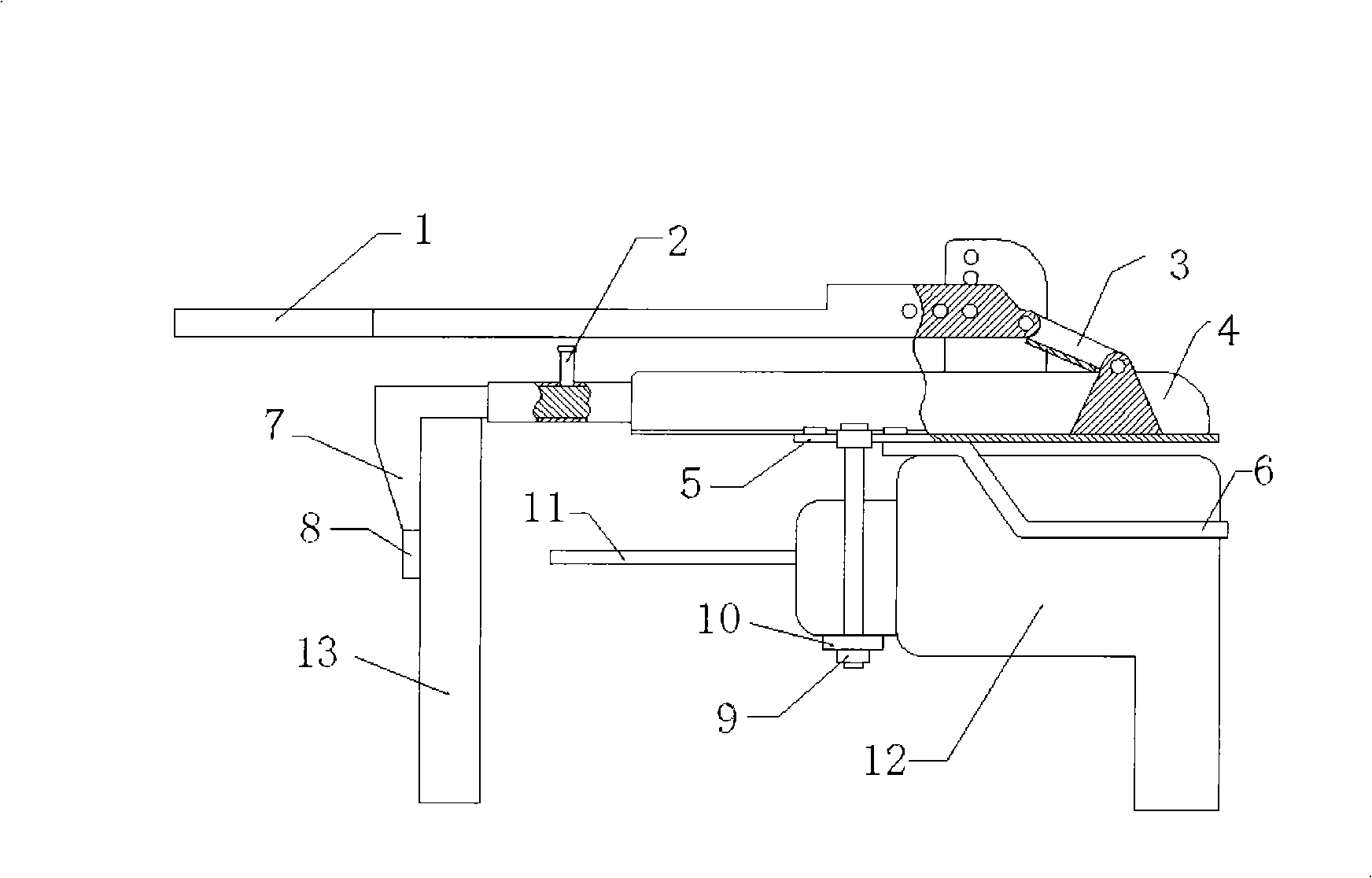

Device capable of making pistol drill more convenient to use and method of use thereof

InactiveCN101352764AEasy to useImprove drilling qualityPortable drilling machinesSheet steelSlide plate

The invention relates to a device which can lead a pistol drill to be more conveniently used and is characterized by including a long slide plate that can move front and back; one end of the long slide plate is connected with one end of a tension rod by a connection rod; the lower end of the long slide plate is provided with a long pressing plate and a bracket; a pressing plate which can lead the head of a drill pistol to penetrate is vertically arranged below the long pressing plate by a location nut; the other end of the long slide plate is provided with a draw hook with a round ring by a stud arranged on a loop bar. A method which can lead the pistol drill to be more conveniently used includes that: leading the body of the pistol drill to penetrate the pressing plate and simultaneously leading the body to closely cling on the long pressing plate and the bracket; hanging the draw hook on a steel plate which sticks closely; holding the tension rod by one hand, arranging the tension rod on the front and drawling slowly to the back until the aiguille of the drill butted with the steel plate; after starting the pistol drill, drawing the tension rod to the back by the other hand; the other end of the tension rod drives the connection rod to lead the long slide plate to slide to the front, which pushes the pistol drill to drill until the drilling is finished. The device has the advantages of reducing vibration when drilling as well as easier, more convenient, safer and more stable drilling.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

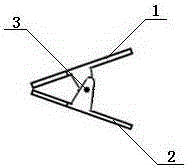

Two-way combined drilling rig

PendingCN109594917AAchieve joinImprove drilling efficiencyDrilling rodsDrilling casingsCouplingDrilling riser

The invention discloses a two-way combined drilling rig which comprises a drill rod (1) for intermediate support, drill rod couplings (2) disposed on ends of the drill rod (1), a small-diameter coreless drill bit (5) linked with one of the drill rod couplings (2), and a large-diameter coring drill bit (3) disposed on one of the drill rod couplings (2) and connected with the drill rod (1) in a sleeving manner; through the drill rod (1), the connection of the drill rod couplings (2) is realized; through the drill rod couplings (2), the connection of the large-diameter coring drill bit (3) and the small-diameter coreless drill bit (5) is realized, a drilling operation is implemented by the small-diameter coreless drill bit (5), and a reaming operation is implemented by the large-diameter coring drill bit (3), therefore, the two-way combined drilling rig is suitable for different geological drilling operations, and the drilling efficiency is improved.

Owner:山东龙元地质工程有限公司

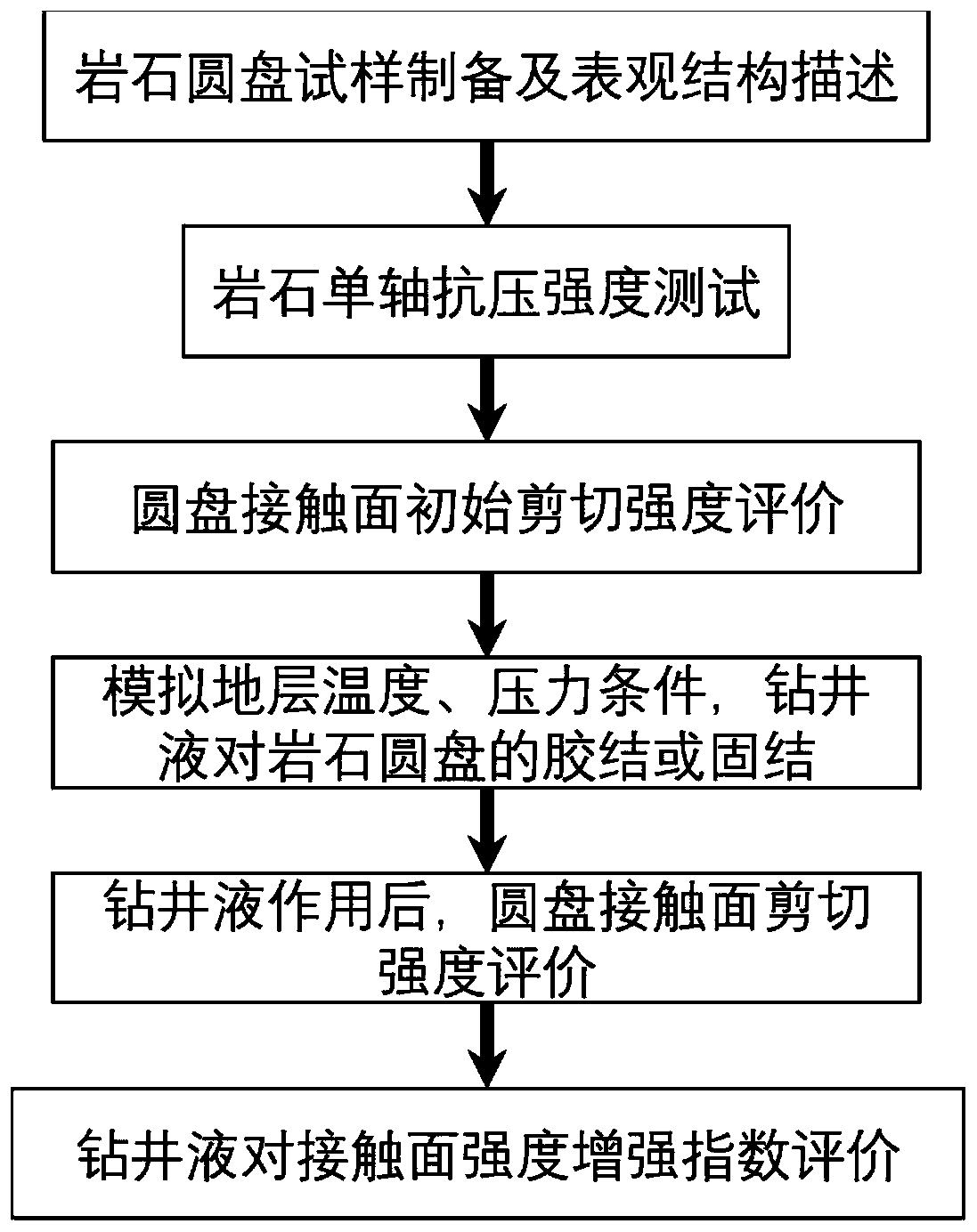

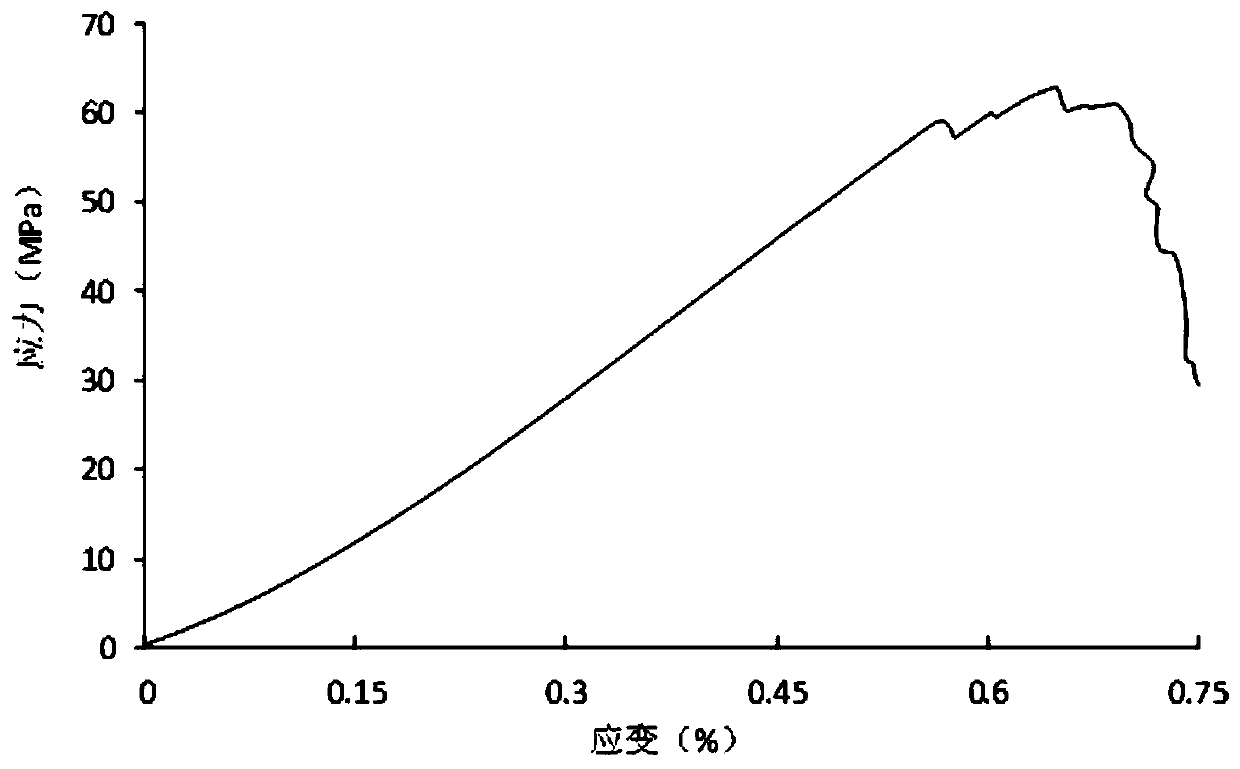

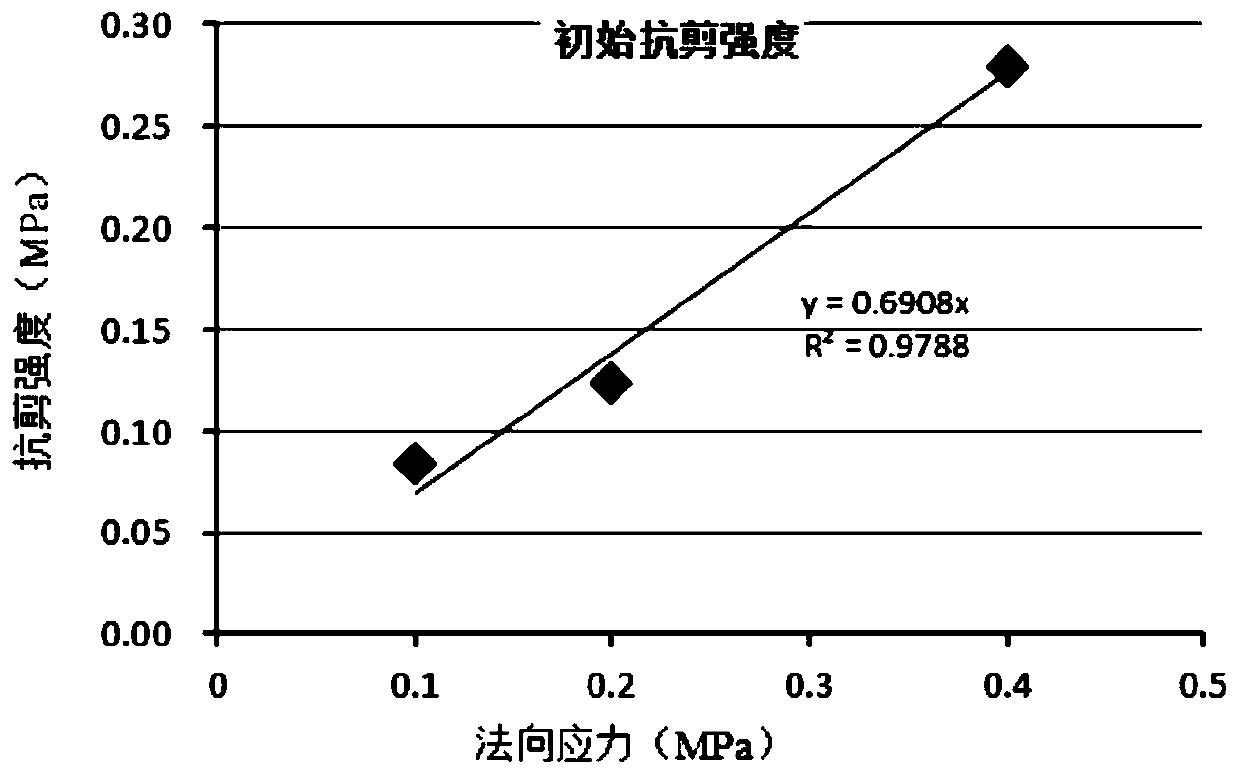

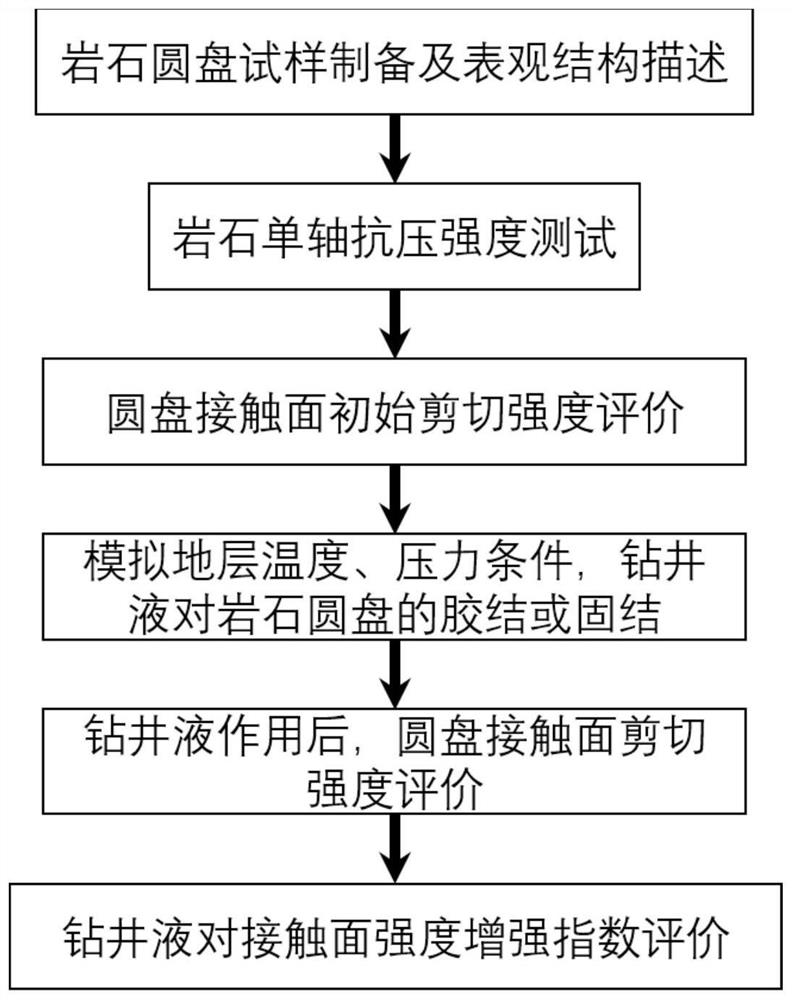

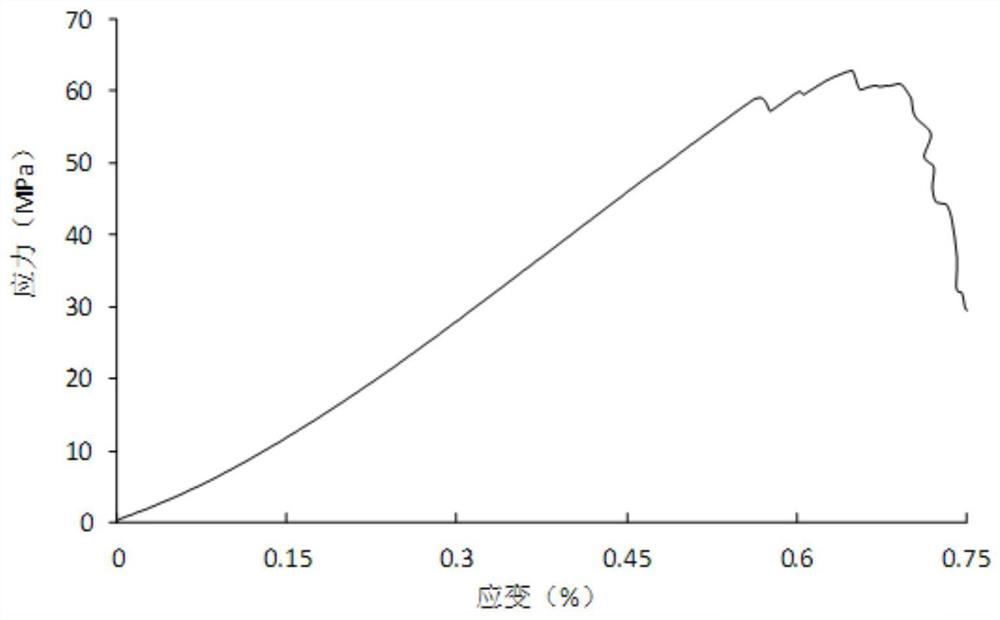

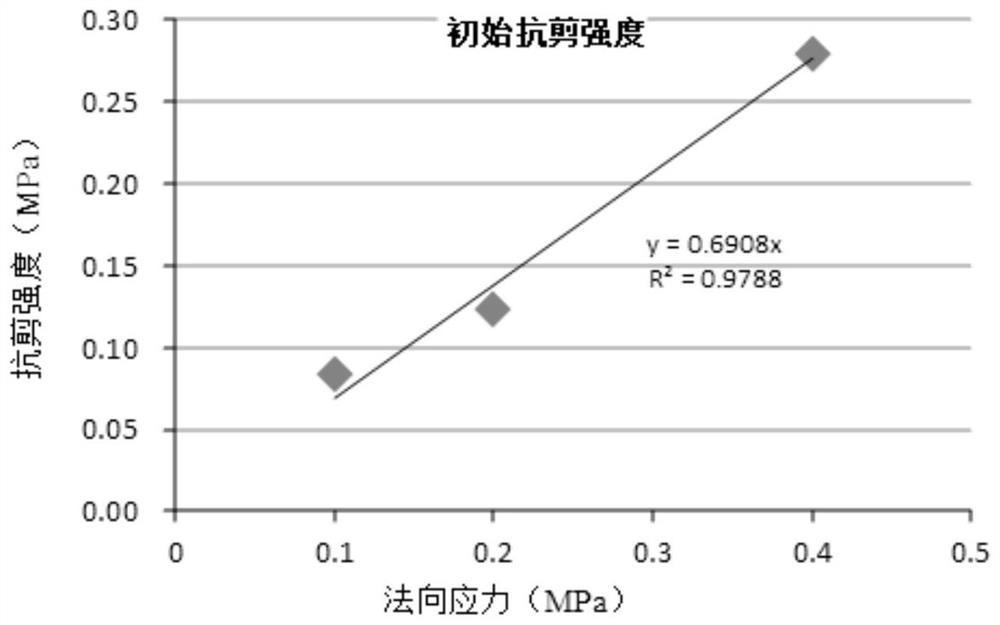

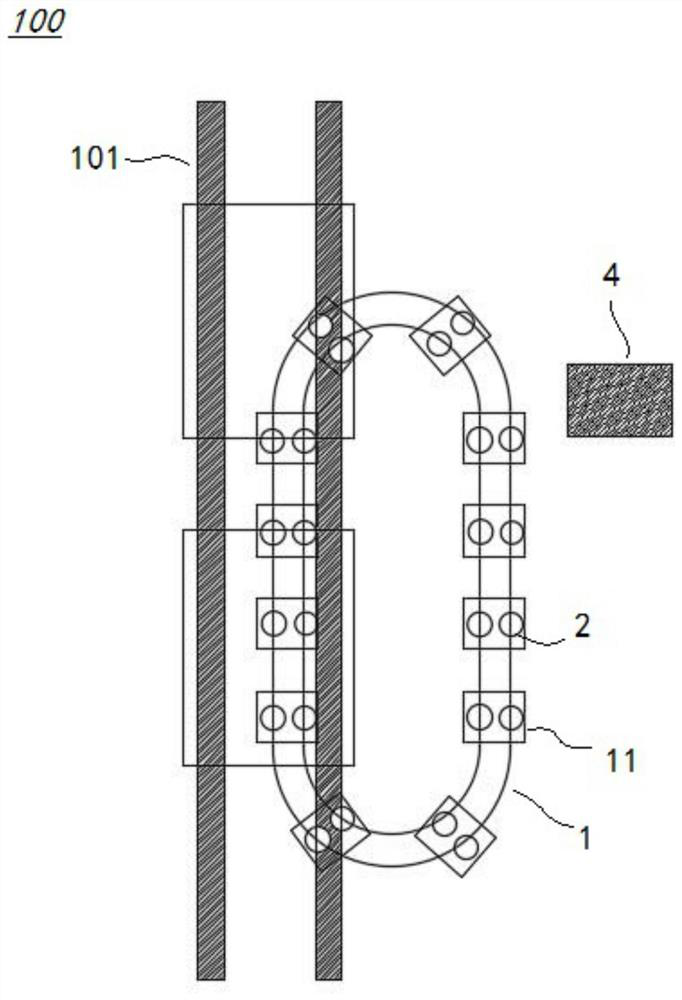

Evaluation method for ability of drilling fluid to consolidate well wall broken surrounding rock

ActiveCN110761779AImprove performanceIncreased shear strengthBorehole/well accessoriesWell drillingClassical mechanics

The invention discloses an evaluation method for the ability of drilling fluid to consolidate well wall broken surrounding rock. By means of the evaluation method for the ability of the drilling fluidto consolidate the well wall broken surrounding rock, quantitative evaluation for improving shear strength between broken blocks through the drilling fluid is realized, and reliable mechanical parameters are provided for the stability of the well wall of a fractured formation. Meanwhile, a scientific and effective experimental method is provided for performance optimization of the drilling fluidand optimization of the drilling fluid, a powerful support is provided for establishment of a fractured formation well wall stabilizing system technology, and the method is of great significance in safe and efficient drilling of deep oil and gas.

Owner:SOUTHWEST PETROLEUM UNIV

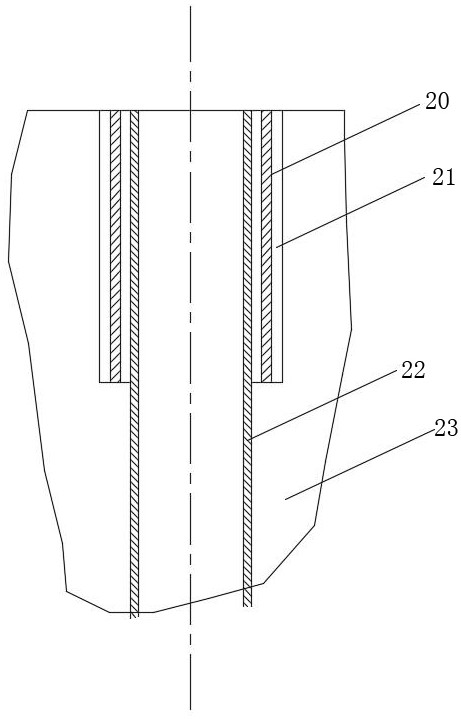

Sand gravel stratum drilling device and drilling process

ActiveCN112796678AImprove machining accuracyFavorable to passDrill bitsDrilling rodsPetrologyDrill pipe

The invention relates to a sand gravel stratum drilling device and a drilling process, and belongs to the technical field of geological drilling. According to the technical scheme, a second sleeve (22) is arranged in a first sleeve (20), and cement paste (21) is arranged between the first sleeve (20) and a sand gravel stratum (23) and between the second sleeve (22) and the sand gravel stratum (23); and a drilling tool (7) and a drilling rod (17) are arranged in the second sleeve (22), and the top end of the drilling tool (7) is connected with the drilling rod (17). The sand gravel stratum drilling device and the drilling process have the beneficial effects that the machining precision of the drilling rod is high, dynamic balance is kept in the drilling process, the inner surface and the outer surface of the drilling rod are smooth, rock debris can pass through the drilling rod easily, and the flowing resistance of the rock debris is reduced; a large outer annular gap is formed between the hole wall and an outer pipe of the drilling tool, rock powder is promoted to be rapidly discharged to the ground surface, and the situation that the rock debris is precipitated in a hole, and consequently the accidents of drill sticking and drill burning are caused is prevented; and the drilling efficiency in the sand gravel stratum is improved, the core recovery rate is high, accidents are reduced, and safe drilling is achieved.

Owner:TANGSHAN JINSHI SUPER ABRASIVE

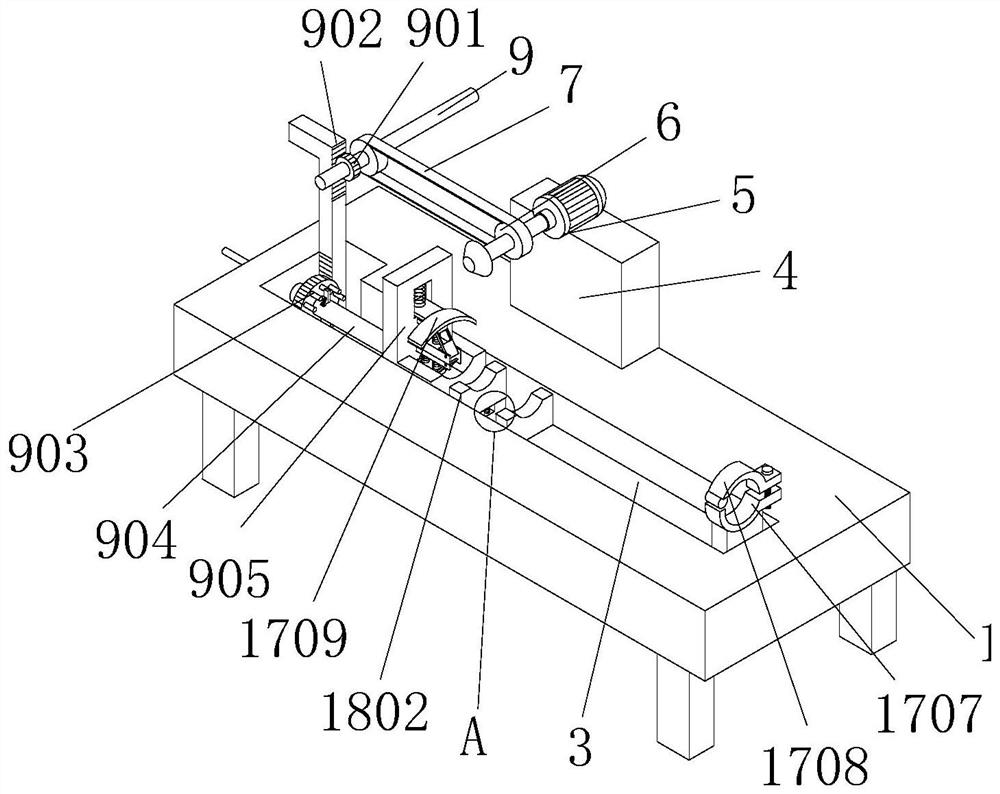

Wall traceless safety water drilling machine

PendingCN109291261ADrilling labor-savingDrilling stabilityWorking accessoriesStone-like material working toolsEngineeringPinion

The invention relates to drilling machinery, in particular to a wall traceless safety water drilling machine. The wall traceless safety water drilling machine comprises a motor, a transmission device,a water drill bit, a wall fixing device, a guide rail 8 and a water pipe, wherein the wall fixing device comprises an expansion screw which is fixed on a wall and the guide rail which is in threadedconnection with the expansion screw, and the expansion screw and the guide rail are fixed to the center of a drilling hole; a sliding block is provided with a longitudinal central cavity, and the guide rail penetrates through the central cavity of the sliding block; a rack is arranged on the top surface of the guide rail, and a pinion meshed with the rack is arranged at the rear end of the slidingblock; the front end of the sliding block is a hollow cylinder, a driven gear is installed through a bearing, the water drill bit is installed on the driven gear, and the driven gear is meshed with adriving gear of the output shaft of the motor. The wall traceless safety water drilling machine has the beneficial effect that the sliding block 6 with the longitudinal central cavity 7 are arranged,the sliding block 6 with the longitudinal central cavity 7 can move along the guide rail, the expansion screw is fixed to the center of a wall drilling hole, the guide rail is fixed on the expansionscrew, the water drill is drilled in the drill hole namely the center of the drill hole through, the drilling wall core is removed after drilling hole, and no fixed mark is left on the wall, then, thesliding block 6 of an installation motor moves along a center guide rail, so that the drilling is labor-saving, stable, safe and positive in drilling.

Owner:任聪磊

Bamboo processing device based on mechanical transmission

InactiveCN112706233AAchieve fixationEasy to process drillingDrilling machinesCane mechanical workingWorking environmentMechanical drive

The invention relates to the technical field of bamboo processing, and discloses a bamboo processing device based on mechanical transmission. The bamboo processing device comprises a workbench, the top of the workbench is fixedly connected with a supporting frame, the interior of the supporting frame is of a hollow structure, the supporting frame is in an inverted-L shape, and a moving groove is formed in the top of the workbench. According to the bamboo processing device based on mechanical transmission, bamboo penetrates through the interior of a first clamping plate, then a fixing plate enters the interior of the bamboo, meanwhile, due to the limitation of the internal space of the bamboo, the top end of a rotating plate rotates downwards and moves in a sliding groove, then the bamboo is fixed, a worker can more conveniently process and drill the bamboo, meanwhile, the bamboo is more stable and firmer during drilling and is not prone to deviation, and then the working environment is safer when the worker conducts drilling processing on the bamboo.

Owner:蔡根福

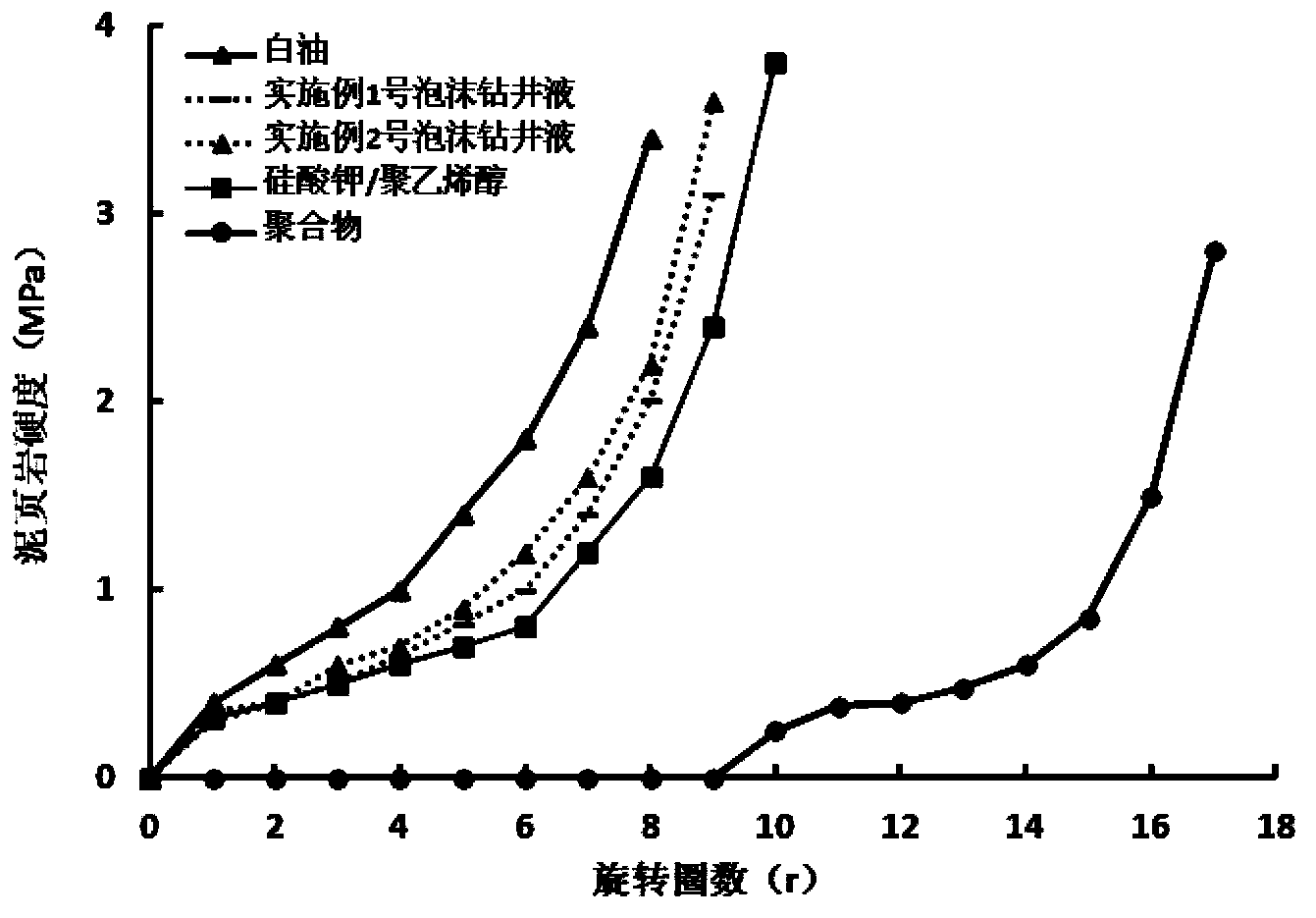

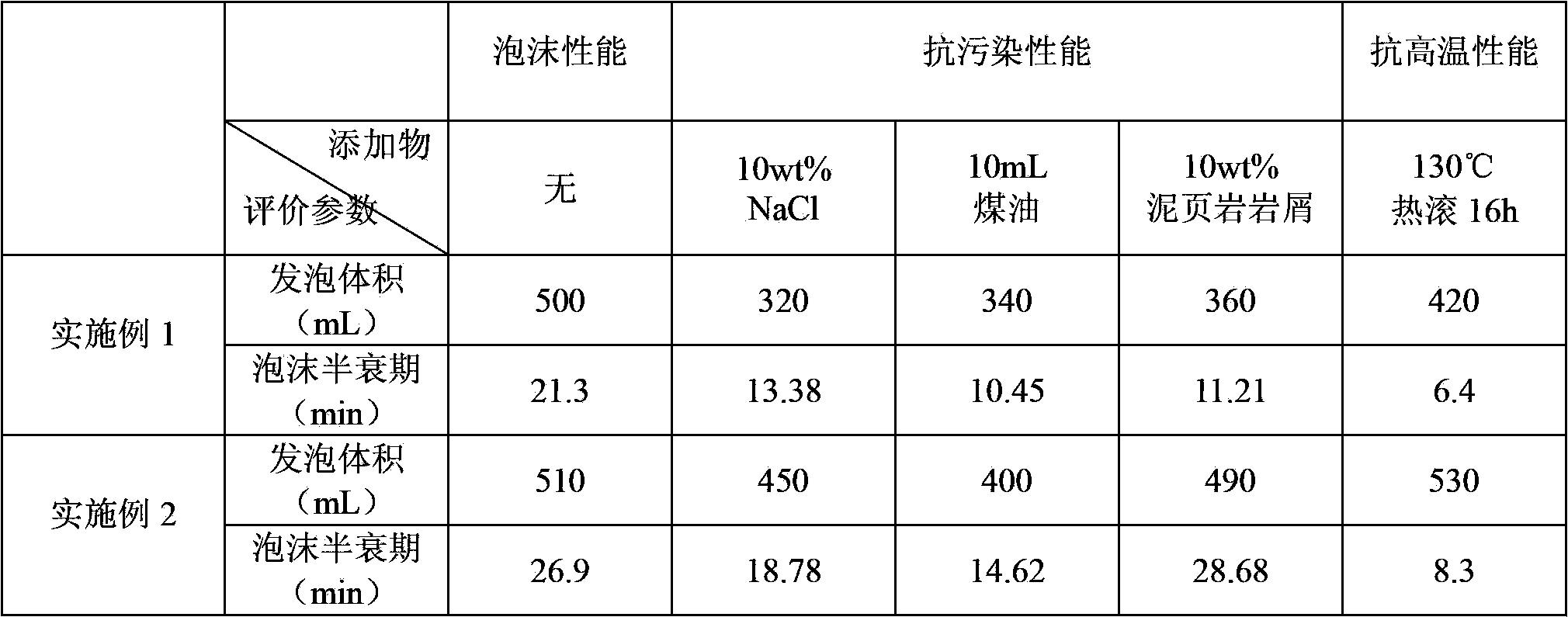

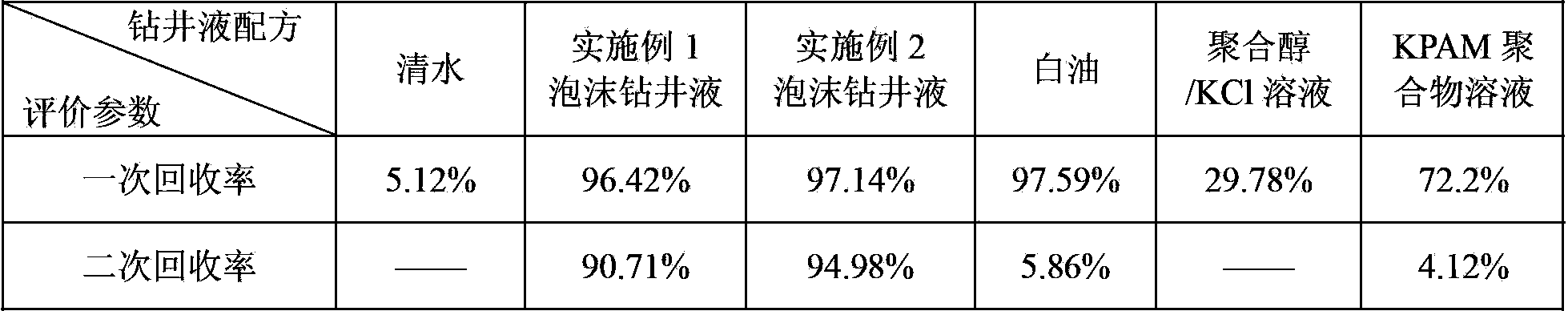

Foam drilling fluid

InactiveCN102796498BGood foaming performanceHigh temperature resistanceDrilling compositionFoaming agentWell drilling

The invention relates to the field of petroleum drilling, in particular to a foam drilling fluid, which is used for maintaining stability of a well wall, preventing bit balling and keeping continuous drilling after formation water occurs during gas drilling. According to the invention, the foam drilling fluid comprises the following components in percentage by mass: 0.5-2.0% of foaming agent, 0.2-0.5% of foam stabilizer, 2-10% of mud shale inhibitor and the balance of water; and pH value of the foam drilling fluid is 8-10. The foam drilling fluid provided by the invention has the advantages of excellent foam performance, stronger mud shale inhibiting ability and enduring mud shale inhibiting performance; and underground complicated problems, such as cutting-carrying and water carrying problems, well wall instability problems, sticking problems and the like, after the formation water occurs during gas drilling can be solved, so that safe and rapid drilling is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

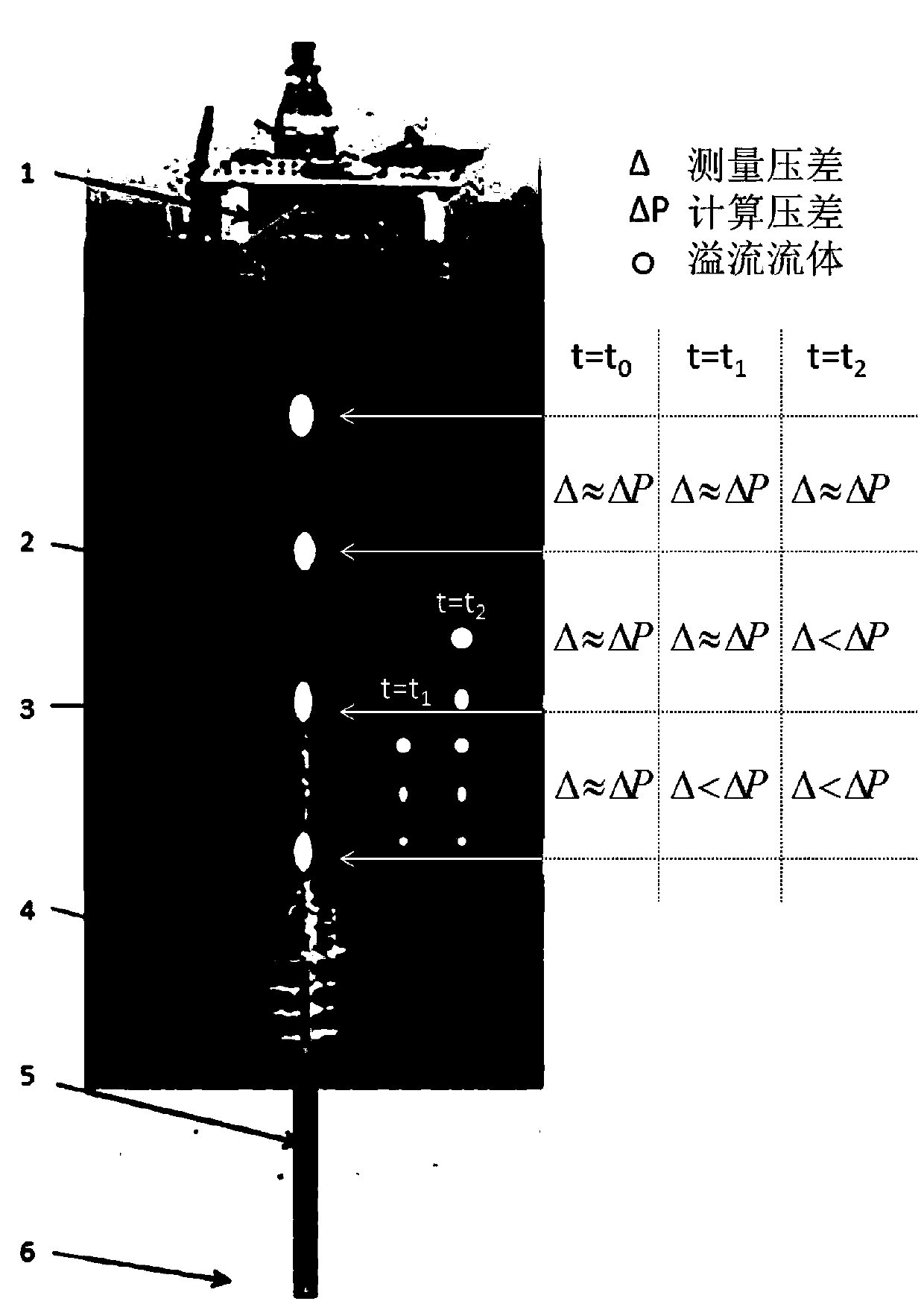

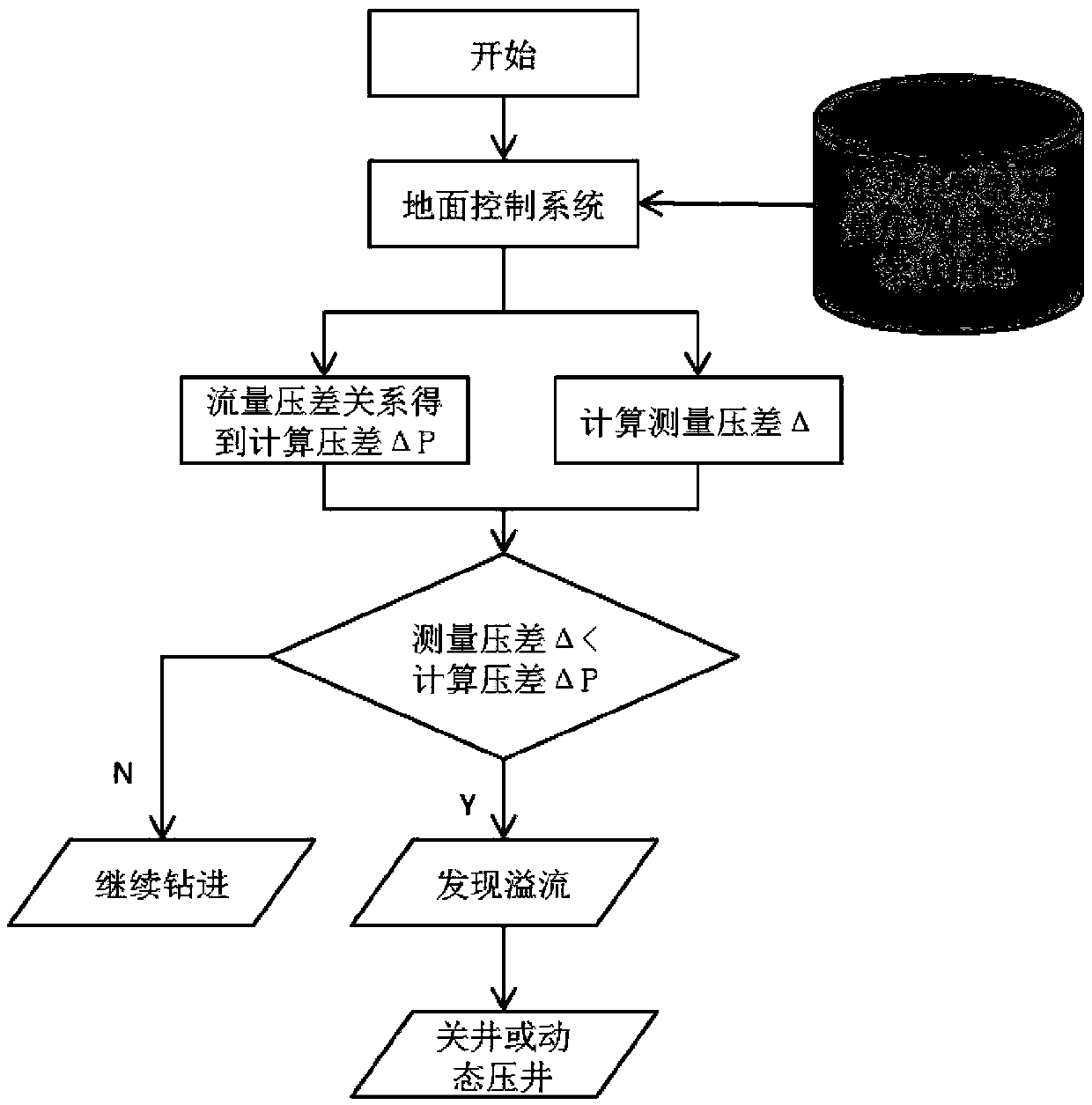

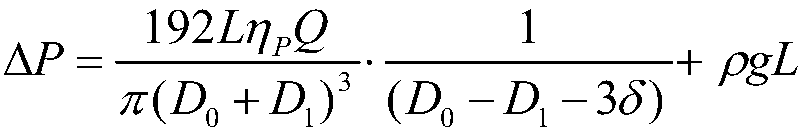

Deep water oil and gas well overflow monitoring method

The invention discloses a deep water oil and gas well overflow monitoring method. The deep water oil and gas well overflow monitoring method comprises the following steps: equidistantly mounting pressure sensors on a water spacing tube according to water depth, measuring circular fluid pressure in the water spacing tube in real time, then transmitting pressure information which is measured by thepressure sensors in real time to a ground control system, and processing and analyzing the measured information of the pressure sensors of the water spacing tube by the ground system to obtain measurement pressure difference between the two adjacent sensors. According to the ground system, drilling fluid is pumped in through a wellhead, the pressure difference between the two adjacent sensors is obtained in combination with a flow and pressure difference relation, the pressure difference measured by the pressure sensors is compared with the pressure difference calculated by the flow and pressure difference relation, overflow in the water spacing tube is monitored and recognized, an alarm is given, and a reasonable well control measure is provided. Underground early overflow monitoring precision is improved, underground early overflow can be recognized in time, the position of overflow fluid in the water spacing tube is determined, the reasonable well control measure is taken, and saferunning of drilling of oil and gas wells is ensured.

Owner:SOUTHWEST PETROLEUM UNIV

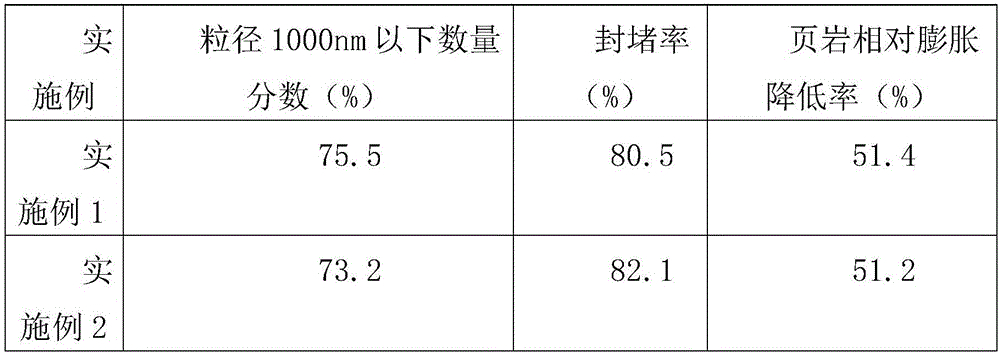

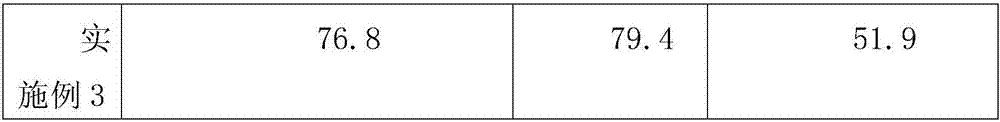

Bionic wall-solidifying agent for drilling fluid and preparation method thereof

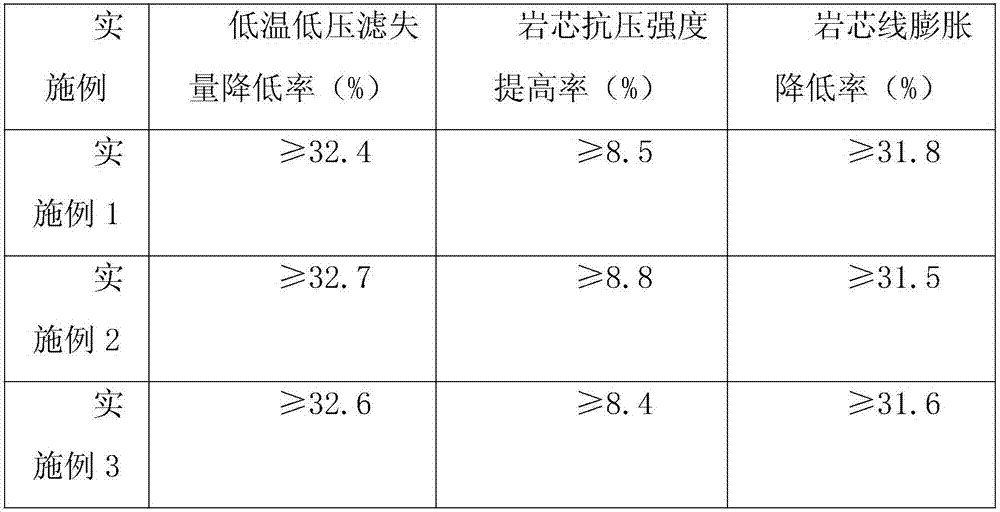

ActiveCN106634884BImprove performanceImprove protectionDrilling compositionPotassium persulfateReduction rate

The invention relates to a bionic wall reinforcer for drilling fluids and a preparation method thereof. The bionic wall reinforcer is prepared from the following raw materials in parts by weight: 85.215-85.237 parts of distilled water, 9.129-9.140 parts of polyphenol protein, 3.550-3.561 parts of acrylamide, 2.028-2.039 parts of dimethyldiallylammonium chloride and 0.072-0.083 part of potassium persulfate. The preparation method of the bionic wall reinforcer for drilling fluids comprises the following steps: preparing a bionic group solution; preparing a bionic wall reinforcer potential solution; and preparing the bionic wall reinforcer. The properties of the bionic wall reinforcer are as follows: the low-temperature low-pressure filter loss reduction rate is greater than or equal to 30%, the core compression strength increase rate is greater than or equal to 8%, and the core linear expansion reduction rate is greater than or equal to 30%. The bionic wall reinforcer solves the problems of high collapse tendency of the shaft wall and loss of the drilling fluid in the existing drilling process, has high biodegradability, and effectively lowers the reservoir pollution.

Owner:石家庄华莱鼎盛科技有限公司

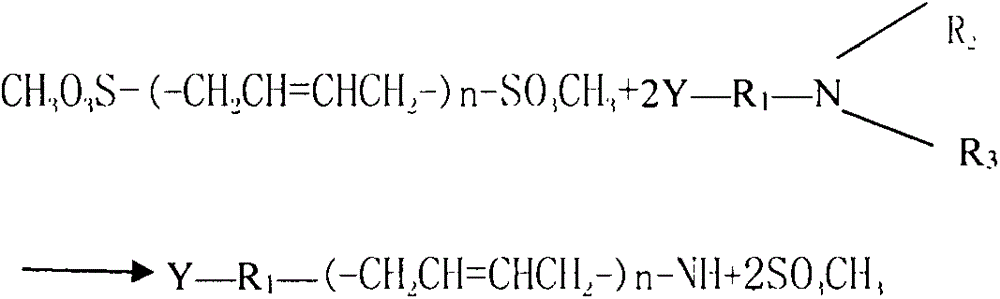

Shale inhibitor for drilling fluid and preparation method of shale inhibitor

The invention relates to a shale inhibitor for a drilling fluid and a preparation method of the shale inhibitor. The method comprises the following steps: putting an initiator into a reactor; dropwise adding a catalyst to the reactor under atmospheric pressure and nitrogen protection, and carrying out sulfonated esterification reaction at 0-30 DEG C for 10-12 hours; filtering a reactant, and dissolving a filtrate into water; taking lower liquid after standing and phase separating, and carrying out reduced pressure distillation to remove water, so as to obtain a sulphur ester compound; dropwise adding the sulphur ester compound into a reaction kettle containing an aminating agent, and carrying out amination at 70-90 DEG C for 2-3 hours; and filtering a product, and carrying out reduced pressure distillation to remove a solvent, so as to obtain the shale inhibitor. The additive is suitable for a plurality of water-based drilling fluids; hydration dispersion of shale can be well controlled; the problems such as thickening and performance deterioration of the drilling fluid caused by hydration dispersion of the shale are effectively reduced; and a certain guarantee is provided for safe and efficient drilling.

Owner:XIAN CHENGYU ENG TECH

Geotechnical engineering ore cutting mining drilling mechanical equipment

InactiveCN107503676AReduce workloadAvoidance of injuryEarth drilling toolsConstructionsCrushed stoneMechanical equipment

The invention relates to a mine drilling mechanical equipment for mining ore in geotechnical engineering, which includes a top plate, a handle, a fixing device, a drilling device and a protection device. The upper end of the top plate is equipped with a drilling device, the lower end of the top plate is symmetrically provided with two fixing devices, and the lower end of the top plate is equipped with a protective device. Due to the limited technical level, the current mining drilling equipment has poor stability, needs manual fixing, is easy to slip, poor drilling accuracy, and the gravel and soil clods generated during drilling are likely to cause harm to users, high work intensity, and low safety. Low disadvantage, the present invention can solve the above problems, realize the function of drilling and protecting the specific position of the mountain, reduce the work intensity and improve the safety.

Owner:俞樑兵

Method for preparing down-hole gel valve and construction method thereof

InactiveCN101135237BWater sensitiveStratum damageDrilling compositionSealing/packingCross-linkSlurry

The well gel valve preparing process and construction process is applied oil well construction. The gel fluid consists of base fluid 40-60 vol%, cross-linking fluid 20-35 vol%, and cracking fluid 20-35 vol%. The base fluid consists of guar gum 0.5-2.5 vol%, alkali 0.1-2 vol%, formaldehyde 0.2-0.6 vol% and water for the rest; the cross-linking fluid consists of borax 0.02-0.05 vol% and water for the rest; and the cracking fluid consists of hydrogen peroxide 0.001-0.005 vol% and water for the rest. The fluids for the well gel valve are in-situ prepared and injected into well to form the gel valve. The present invention is used in drilling well, completing well and repairing well to replace casing valve and other technological arrangements to separate slurry and kill fluid from the reservoirbed, to avoid the escape of hydrogen sulfide and other gases from the stratum, and to avoid contamination to the reservoir bed.

Owner:吐哈石油勘探开发指挥部工程技术研究院

A kind of hyperbranched polyetheramine environmental protection shale inhibitor and its preparation method and water-based drilling fluid

ActiveCN111718698BEnhanced inhibitory effectInhibits hydration swellingDrilling compositionOil fieldPolymer

The invention discloses a hyperbranched polyetheramine environmental protection shale inhibitor, a preparation method thereof and a water-based drilling fluid, belonging to the technical field of oil field chemistry. The shale inhibitor is prepared by reacting diallylamine and dietheramine compounds as raw materials. The shale inhibitor provided by the invention is a hyperbranched polymer, which has good shale inhibition, clay stability and temperature resistance, and is easy to biodegrade and has good environmental protection performance; the preparation method provided by the invention has simple steps , synthetic raw materials are easy to obtain, and are suitable for industrial production; the hyperbranched polyetheramine shale inhibitor provided by the invention has good compatibility with other conventional drilling fluid treatment agent components, and the configured water-based drilling fluid is suitable for strong water-sensitive mud shale It can significantly reduce the expansion rate of shale, prevent wellbore collapse, effectively stabilize the wellbore and reduce the occurrence of downhole complex situations.

Owner:SOUTHWEST PETROLEUM UNIV

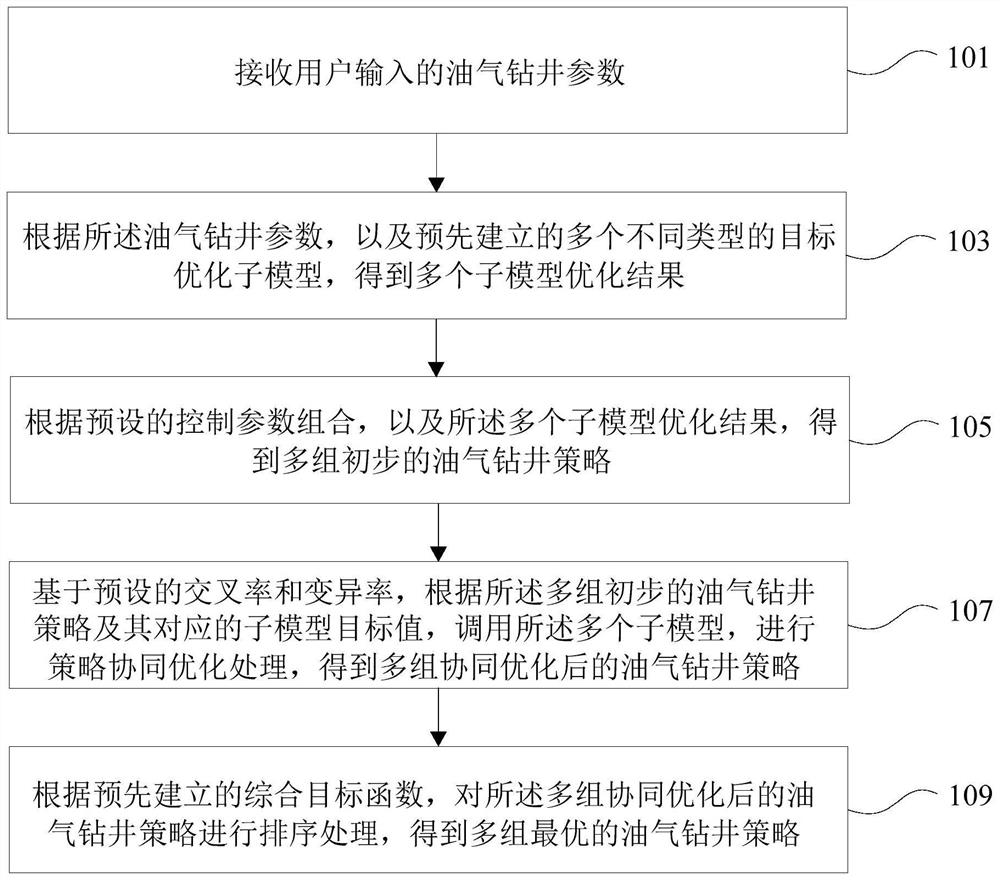

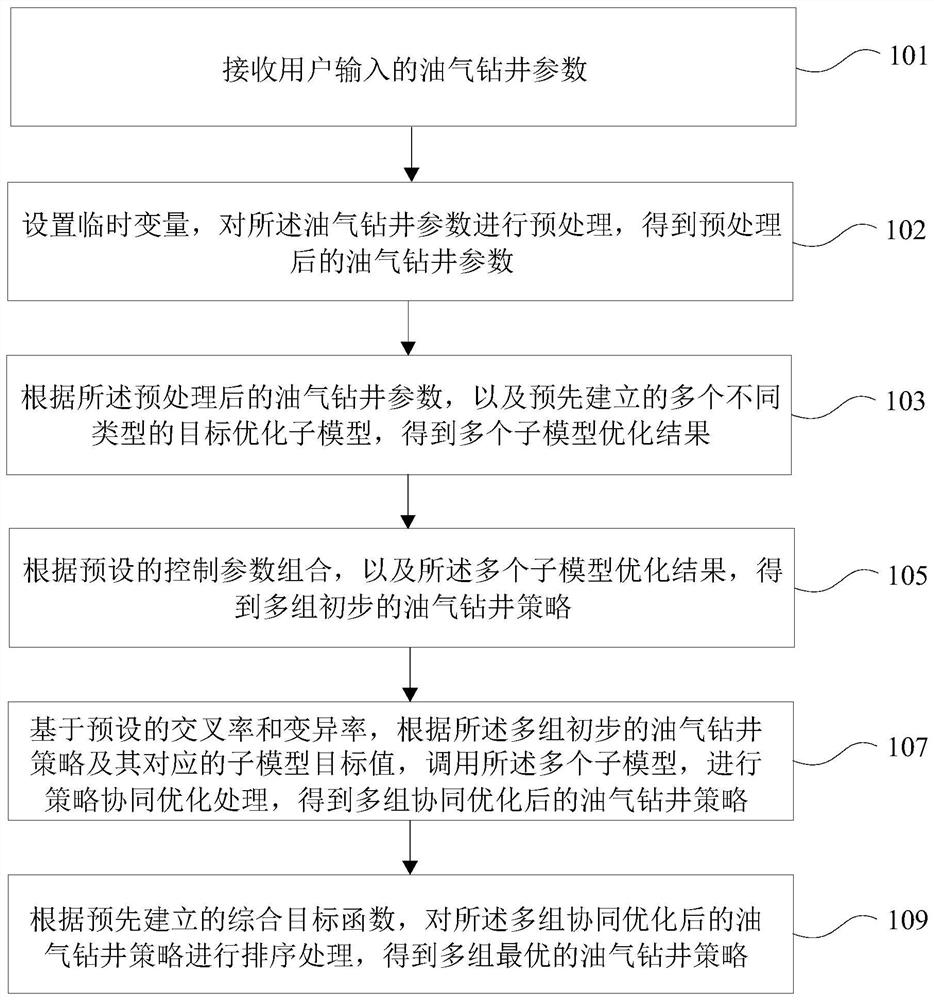

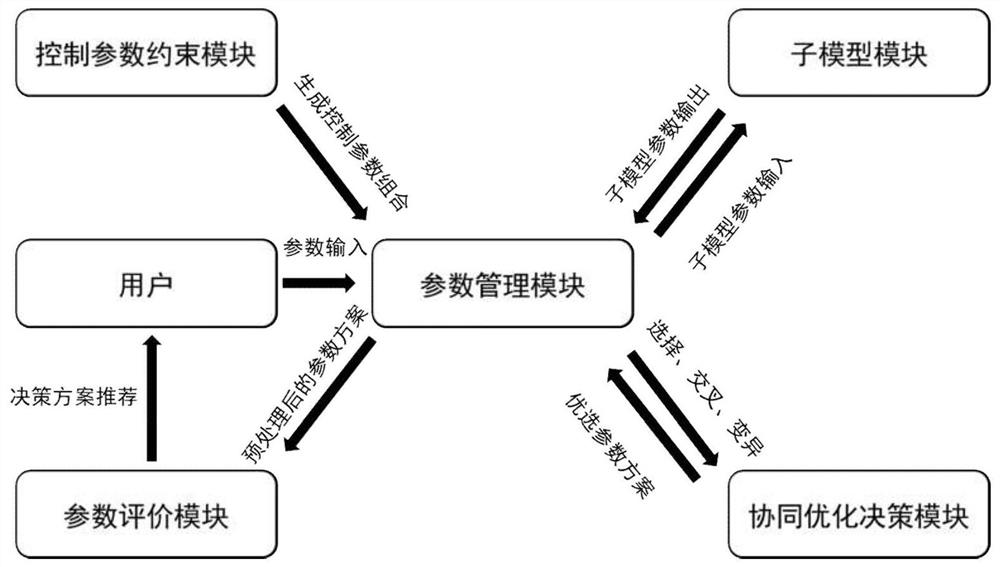

Oil and gas drilling strategy prediction method and device based on multiple targets

ActiveCN112796747AAccurate and Efficient PredictionEfficient and accurate drilling strategy predictionData processing applicationsDesign optimisation/simulationThermodynamicsWell drilling

The invention discloses an oil and gas drilling strategy prediction method and device based on multiple targets. The method comprises the steps that a plurality of sub-model optimization results are obtained according to oil and gas drilling parameters inputted by a user and a plurality of different types of target optimization sub-models; a plurality of groups of preliminary oil and gas drilling strategies are obtained according to a preset control parameter combination and the plurality of sub-model optimization results; based on a preset crossover rate and a preset mutation rate, according to the plurality of groups of preliminary oil and gas drilling strategies and the corresponding sub-model target values, a plurality of sub-models are called, and strategy collaborative optimization processing is performed to obtain the plurality of groups of collaboratively optimized oil and gas drilling strategies; and the plurality of groups of collaboratively optimized oil and gas drilling strategies are sorted to obtain the plurality groups of optimal oil and gas drilling strategies according to a pre-established comprehensive objective function. According to the oil and gas drilling strategy prediction method and the device, oil and gas drilling strategy prediction can be efficiently and accurately performed, so that more efficient, safer and low-cost drilling is realized, and scientific and effective guidance is provided for oil and gas drilling.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

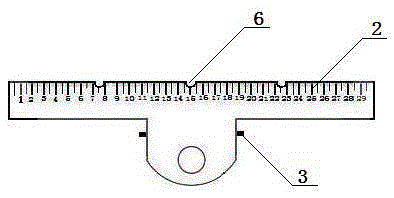

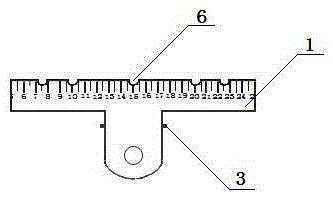

A clamper for archiving data binding

InactiveCN103350583BBinding steps simplifiedSimplify binding operationsSheet bindingEngineeringMechanical engineering

The invention relates to a clamper for filing data binding, which is composed of a scale clamp and a drilling pad. The scale clip is marked on the upper clip or the lower clip near the edge of the clip, and three semicircular holes are opened along the quartering points of the clip length as the drilling positions for binding and archiving data. The drilling pad is a cuboid with three strip-shaped hollow grooves, which correspond to the positions of the three semicircular holes on the scale clip one by one. The center of the semicircular holes is used as the drilling point for filing data. The side of the drilling pad is provided with a strip-shaped hollow groove on one side, and a pass is opened on the upper part, and the scale clamp extends into the pass to clamp the archived materials, and the clamping is firm. Utilizing the clamper for binding archives, the traditional "three points and one line" manual thread binding tool components are integrated, the binding steps are simplified, and the efficiency is improved.

Owner:QILU UNIV OF TECH

Evaluation Method of Drilling Fluid Consolidated Borehole Wall Breaking Surrounding Rock Ability

ActiveCN110761779BImprove performanceIncreased shear strengthBorehole/well accessoriesWell drillingClassical mechanics

The invention discloses an evaluation method for the ability of drilling fluid to consolidate the borehole wall to break surrounding rock. The method for evaluating the ability of the drilling fluid to consolidate the well wall to break the surrounding rock provided by the present invention realizes the quantitative evaluation of the drilling fluid to improve the shear strength between the broken blocks, and provides reliable mechanical parameters for the stability of the well wall in the fractured formation. At the same time, it also provides scientific and effective experimental methods for drilling fluid performance optimization and drilling fluid optimization, and provides strong support for the establishment of wellbore stabilization system technology in fractured formations, which is of great significance to safe and efficient deep oil and gas drilling.

Owner:SOUTHWEST PETROLEUM UNIV

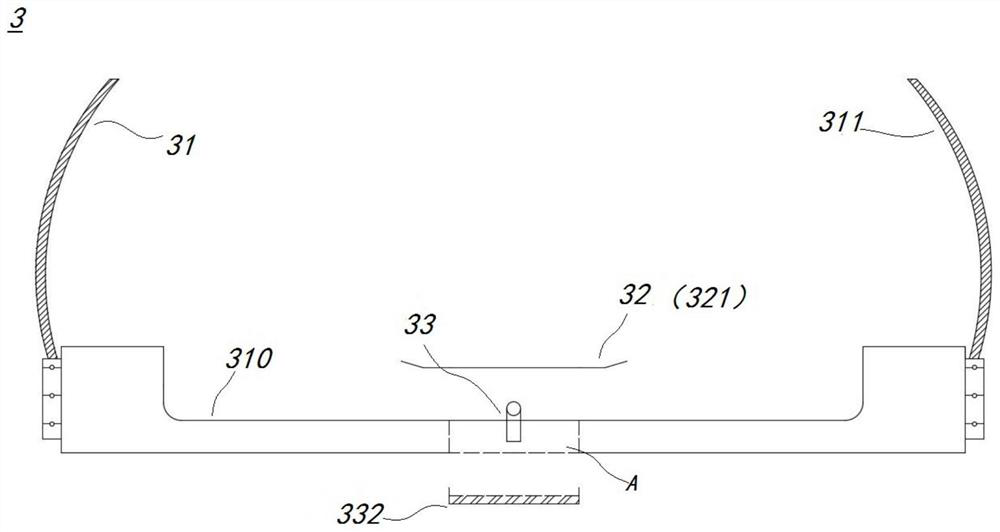

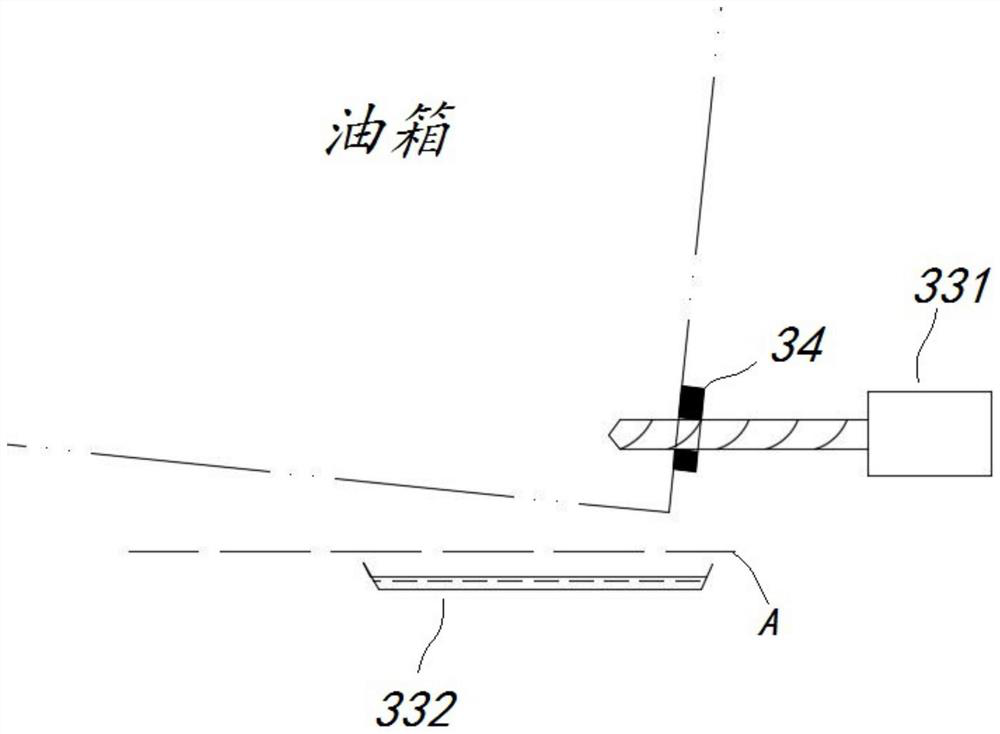

A double-track transportation residual oil recovery line for car dismantling

ActiveCN110171506BAvoid it happening againReduce the size of the siteVehicle dissasembly recoverySolid waste disposalFuel tankWaste oil

Owner:回收哥(武汉)互联网有限公司

Aryl-substituted saccharides or glycosides and their use in drilling fluid compositions

ActiveCN111320727APerformance is not affectedNo biological toxicitySugar derivativesDrilling compositionGlycosideAryl

The invention relates to aryl-substituted saccharides, glycosides, or mixtures of a plurality of aryl-substituted saccharides or glycosides, having at least good high-temperature resistance, salt resistance and filtrate loss reduction properties. The invention also relates to a drilling fluid composition prepared from the aryl-substituted saccharides or glycosides and a preparation method of the drilling fluid composition. The aryl-substituted saccharides, glycosides or a mixture of a plurality of aryl-substituted saccharides or glycosides have a substituent A and a substituent B, the structure of the substituent A comprises a unit O-R6-, and the definitions of substituents and numerical values of the units of the structure of the substituent B are as shown in the specification.

Owner:CHINA PETROCHEMICAL CORP +3

Bionic nano plugging agent for drilling fluid and preparation method thereof

ActiveCN106634879BImprove performanceImprove stabilityDrilling compositionCross-linkPotassium persulfate

The invention relates to a bionic nanometer blocking agent for drilling fluid and a preparation method thereof. The bionic nanometer blocking agent is prepared from the following raw materials in parts by weight: 60 to 70 parts of distilled water, 1 to 2 parts of 2-acrylamide-2-methylpropanesulfonic acid, 20 to 30 parts of lactic acid, 5 to 10 parts of cross-linking agent, 0.7 to 1.5 parts of nanometer titania, 0.7 to 1.5 parts of molecular weight regulator, 0.1 to 0.5 part of potassium persulfate and 0.2 to 0.5 part of sodium hydroxide. The cross-linking agent is one of ethylene glycol dimethacrylate, polyethylene glycol and trimethylolpropane; the molecular weight regulator is isooctyl 3-mercaptopropionate. The preparation method comprises the following process steps of preparing alkyl solution; preparing titanium-based solution; preparing the bionic nanometer blocking agent. The bionic nanometer blocking agent for the drilling fluid, which is disclosed by the invention, solves the problems of shale hydration and extraneous water erosion in the existing drilling process; meanwhile, the bionic nanometer blocking agent has high biodegradability, so that pollution to a reservoir is effectively reduced.

Owner:石家庄华莱鼎盛科技有限公司

A drilling and shut-off method for infill adjustment wells in oilfields

ActiveCN112796719BDrilling safetyDrill off to achieveDrawing from basic elementsFluid removalWater volumeWell drilling

The invention discloses a drilling and closing method for infill adjustment wells in oil fields, which is characterized in that: the safety pressure line of each water injection well in the well area is determined; if the well to be drilled is within the safety pressure line, the water injection well is closed or lowered. The water injection well is injected with pressure, otherwise, the normal water injection of the water injection well is maintained; all the water injection wells in a certain radius area centered on the well to be drilled are all shut down in the existing general drilling and closing technology, so that the water volume has a large impact and the pressure recovery is slow. Problems such as slug loosening in the third production well.

Owner:DAQING PETROLEUM ADMINISTRATION +1

An improved appliance for binding archives

InactiveCN103358764BBinding steps simplifiedSimplify binding operationsSheet bindingClassical mechanicsStructural engineering

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com