Sand gravel stratum drilling device and drilling process

A drilling device and sand and gravel technology, which is applied in the direction of extracting undisturbed core devices, drill pipes, drill pipes, etc., can solve the problems of unsmooth cuttings removal, cuttings sinking, and prone to sticky drilling, etc., to increase the passing area , High core recovery rate, and the effect of reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

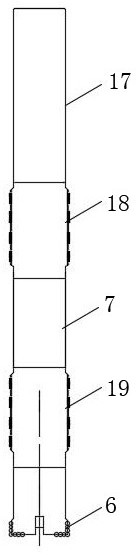

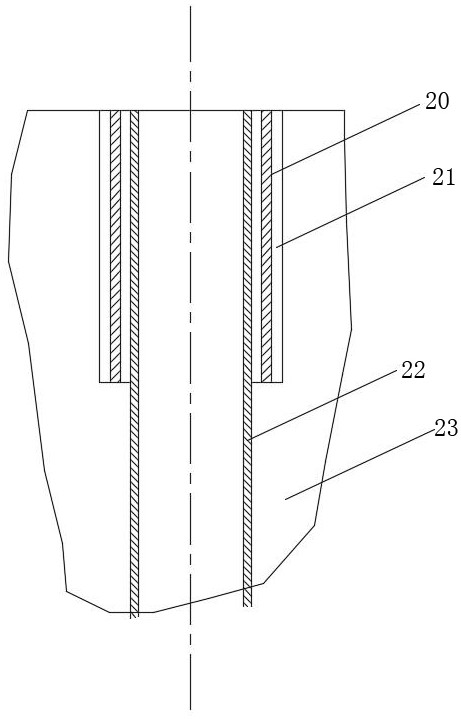

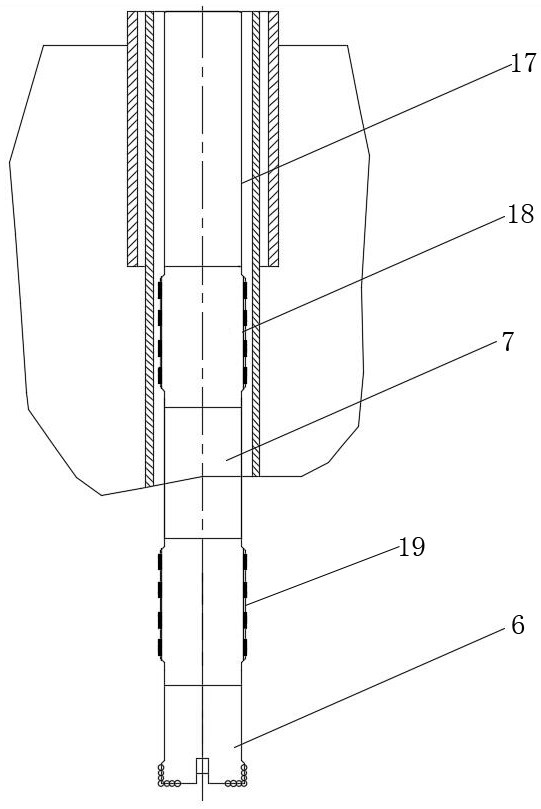

[0035] A sand and gravel formation drilling device, comprising casing one 20, casing two 22, drill pipe 17 and drilling tool 7, casing two 22 is arranged in casing one 20, casing one 20 and casing two 22 and Cement slurry 21 is provided between the sand and gravel formations 23; the drilling tool 7 and the drill pipe 17 are both arranged in the second casing 22, and the top of the drilling tool 7 is connected to the drill pipe 17; the drilling tool 7 includes a cartridge recovery pipe 2. Eject card plate 3, eject card seat 12, adapter 13, suspension joint 14, suspension ring 4, outer pipe 5, inner pipe 8 and centralizer, outer pipe 5 and inner pipe 8 are tubular structures, and the ejector card assembly The recovery pipe 2, the ejection card plate 3, the ejection card seat 12, the adapter 13, the suspension joint 14 and the inner pipe 8 are succ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com