Old well potential tapping process for old mining area of rock salt

A mining area and rock salt technology, which is applied in the field of digging the potential of old wells in old salt mine areas, can solve problems such as drilling difficulties, environmental protection pressure, and short production stabilization period, and achieve the effects of shortening the construction period, reducing land resources, and saving land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

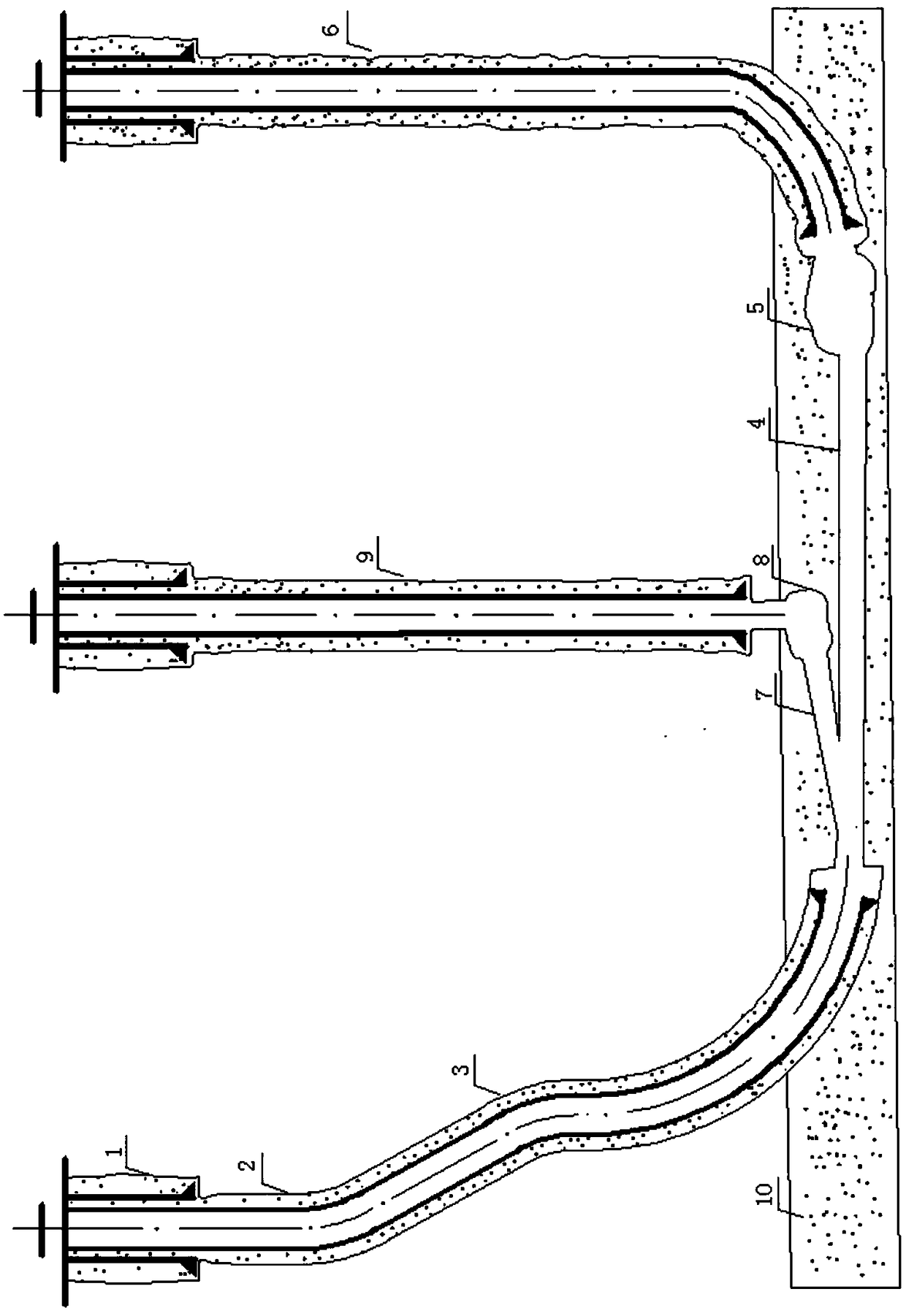

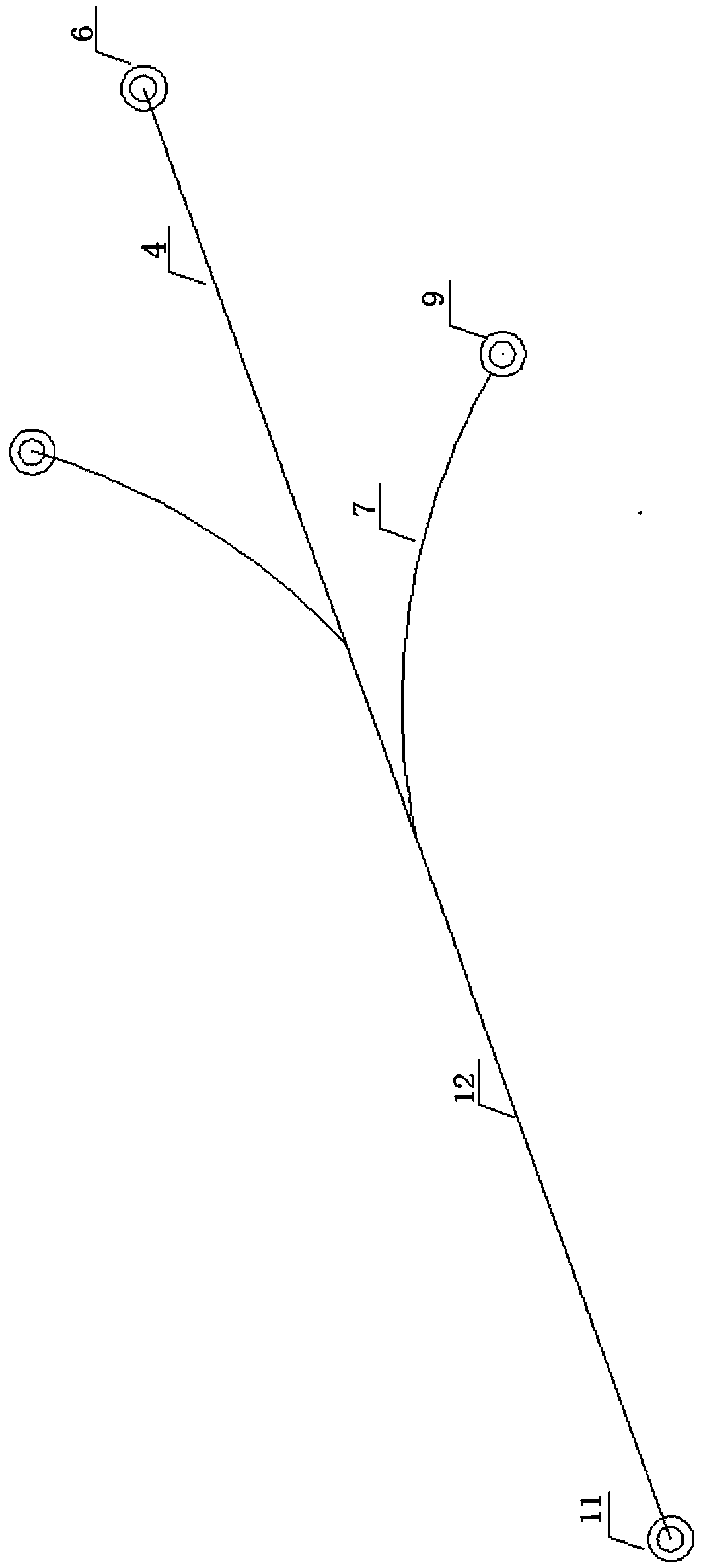

[0034] Take the docking of two target wells as an example, such as figure 1 , figure 2 Shown, the rock salt old mining area old well potential tapping technology of the present invention may further comprise the steps:

[0035] S1: Arrange well positions reasonably according to the existing well sites in the old rock salt mining area, and design the well body structure and potential tapping trajectory of the multi-branch horizontal well 11 connected to the existing well positions. Because it is an existing well site in an old mining area, there are many adjacent wells around the existing wells and the distance is very close. The actual drilling trajectory is criss-crossed and the drilling requirements are high. The position relationship with the docking target well, avoiding the old wellbore, old dissolved cavity and roof blow-by area of adjacent wells, and selecting the optimal well location and trajectory.

[0036] S2: According to the well location of the multi-branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com