Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Avoid overheating problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

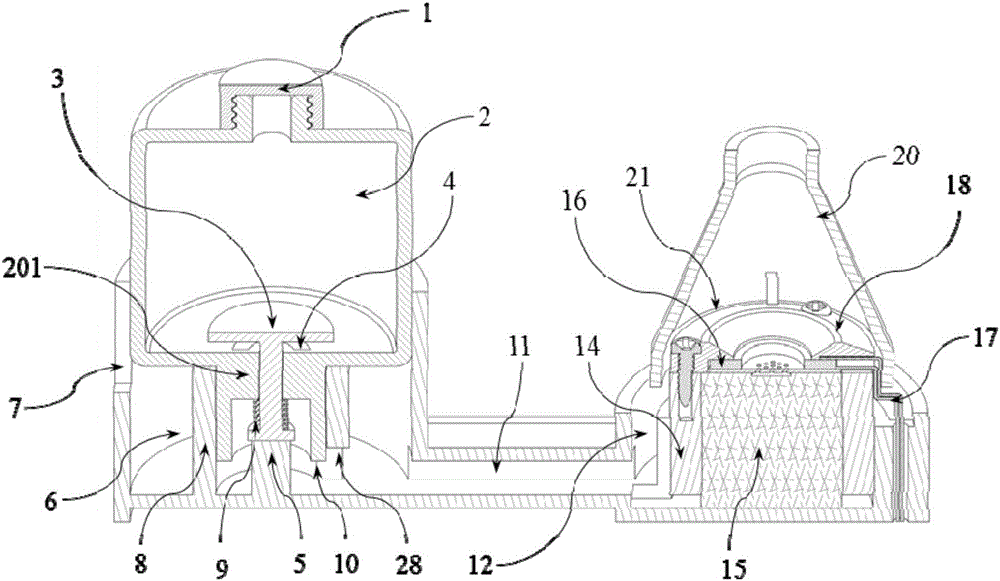

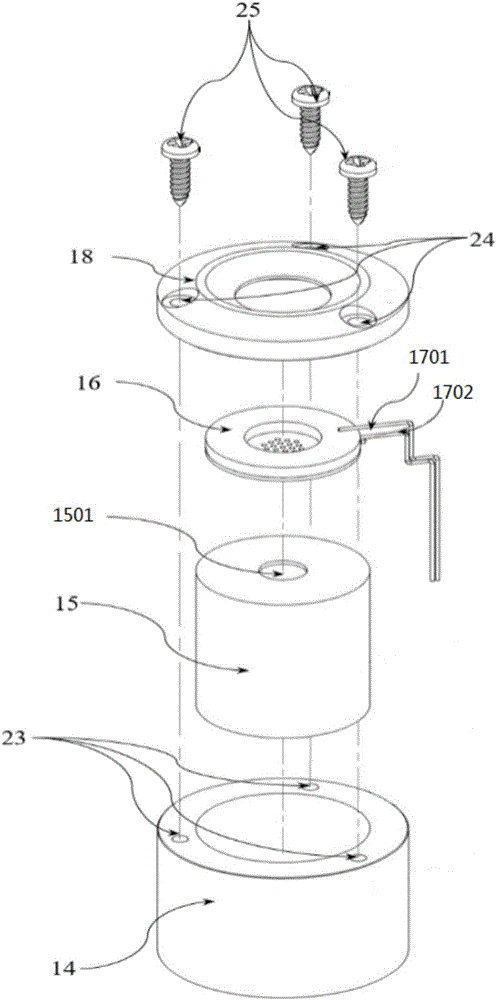

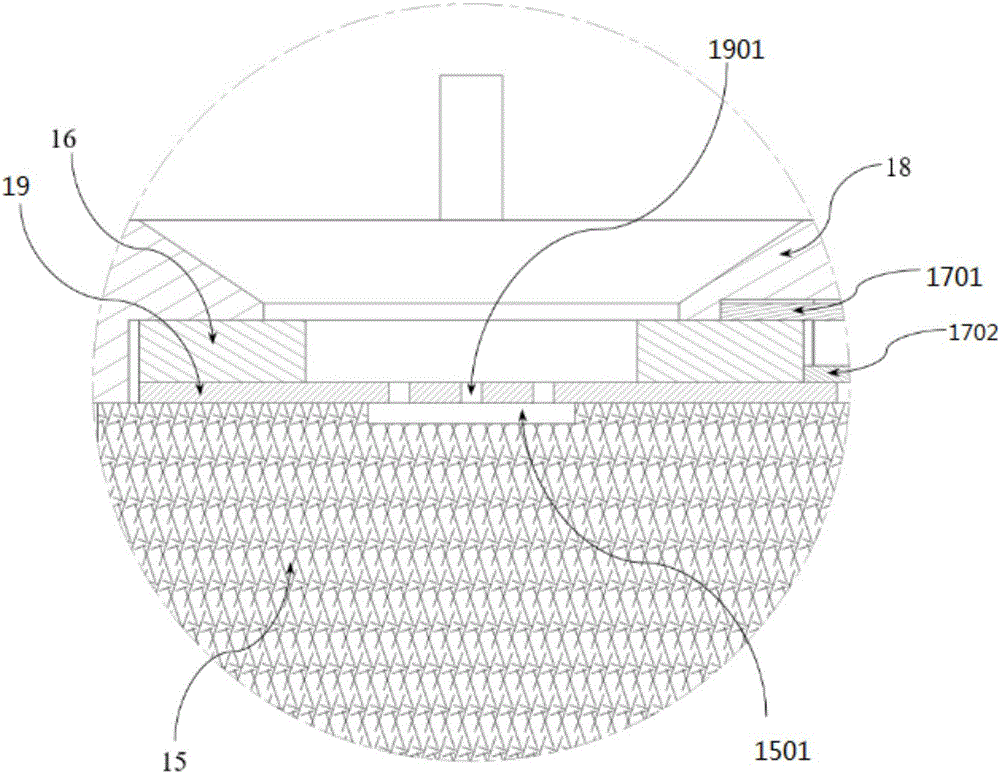

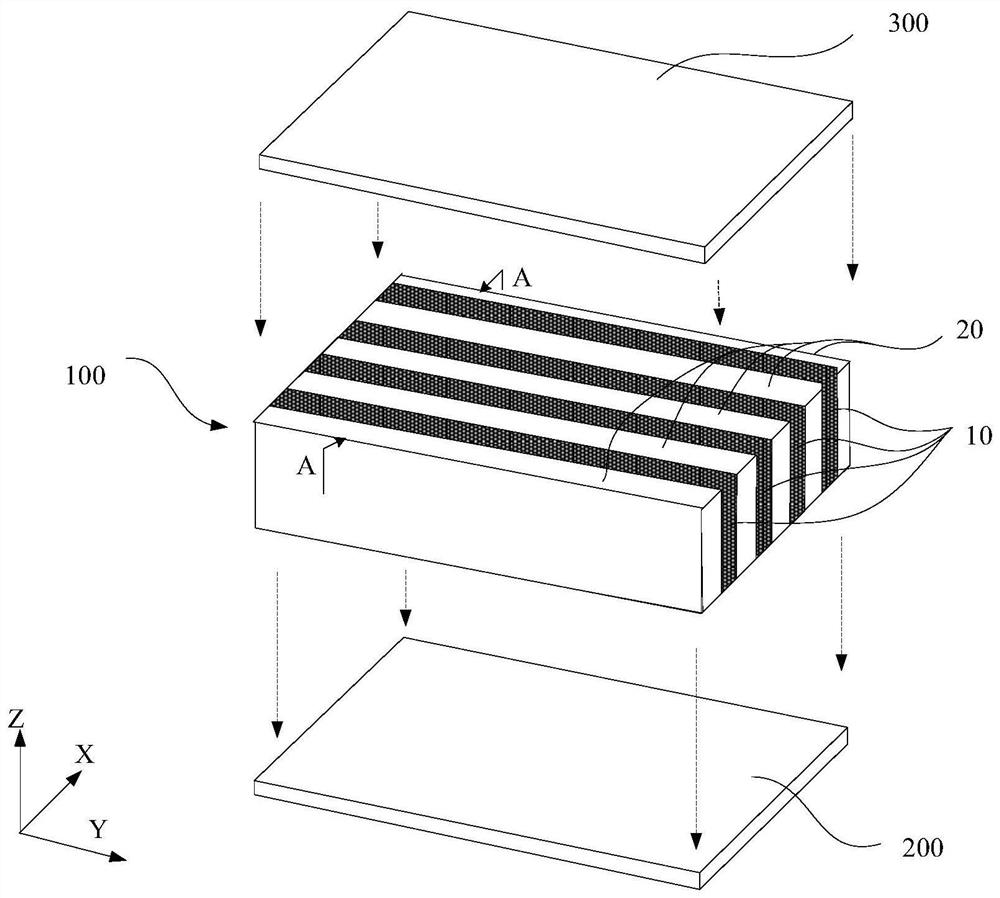

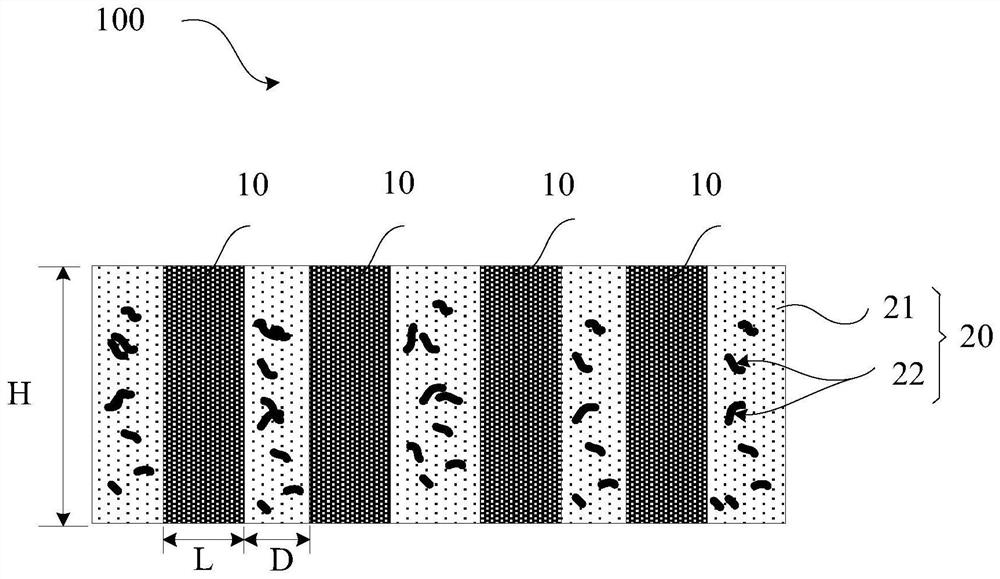

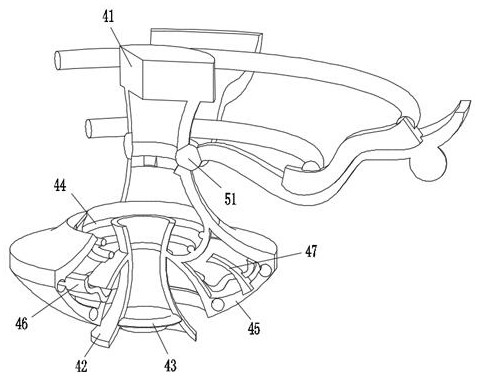

Ultrasonic atomization structure and ultrasonic atomization device using the same

ActiveCN106422005AAvoid overheating problemsChange spray directionEfficient regulation technologiesMedical atomisersEngineeringUltrasonic atomization

The invention discloses an ultrasonic atomization structure and an ultrasonic atomization device using the same. The ultrasonic atomization structure comprises a liquid receiving tank 12, a liquid absorption medium 15 and an atomization unit, wherein the liquid absorption medium 15 is arranged in the liquid receiving tank 12, and the bottom surface of the liquid absorption medium 15 is immersed in liquid in the liquid receiving tank 12. When the ultrasonic atomization structure is used, the liquid absorption medium 15 absorbs the liquid in the liquid receiving tank 12 and conveys the liquid to one end of the liquid imbibition medium 15, far from the bottom surface of the liquid absorption medium 15, the atomization unit is attached to the end of the liquid absorption medium 15, far from the bottom surface of the liquid absorption medium 15, and the end of the liquid absorption medium 15, far from the bottom surface of the liquid absorption medium 15, is provided with a groove 1501. The ultrasonic atomization structure and the ultrasonic atomization device using the same can atomize the high viscosity liquid into fine drops, and can not cause a superheating phenomenon to the atomization unit.

Owner:アコースティックアークインターナショナルリミテッド

Wall-mounted gas boiler, hot water supply system and control method

ActiveCN106595026AIncreased ability to heat domestic waterImprove utilization efficiencyWater heatersHot-water central heatingProcess engineeringThermal water

The invention relates to a wall-mounted gas boiler comprising a heat exchanger, a first water inlet pipe, a first water outlet pipe, a second water inlet pipe and a second water outlet pipe. The heat exchanger comprises a first passage and a second passage which are used for carrying out heat exchange with smoke generated by gas combustion, and both the first passage and the second passage can allow a fluid to pass through and do not intercommunicate; the first water inlet pipe and the first water outlet pipe respectively communicate with two ends of the first passage to form a first heat supply unit; the second water inlet pipe and the second water outlet pipe respectively communicate with two ends of the second passage to form a second heat supply unit; and the first heat supply unit and the second heat supply unit can independently or simultaneously output a heat source. By using the wall-mounted gas boiler, hot water for heating and daily use can be simultaneously supplied, and the problems of insufficient heat exchange amount in a heating space and temperature reduction caused by overhigh water consumption of hot water for daily use are avoided.

Owner:GREE ELECTRIC APPLIANCES INC

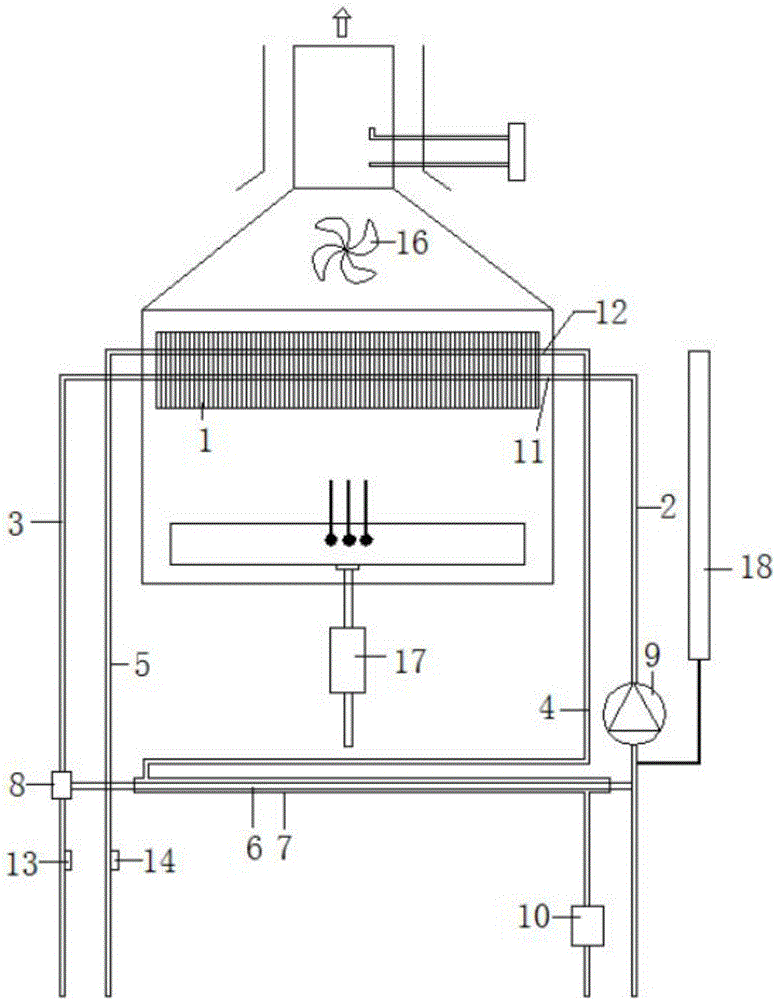

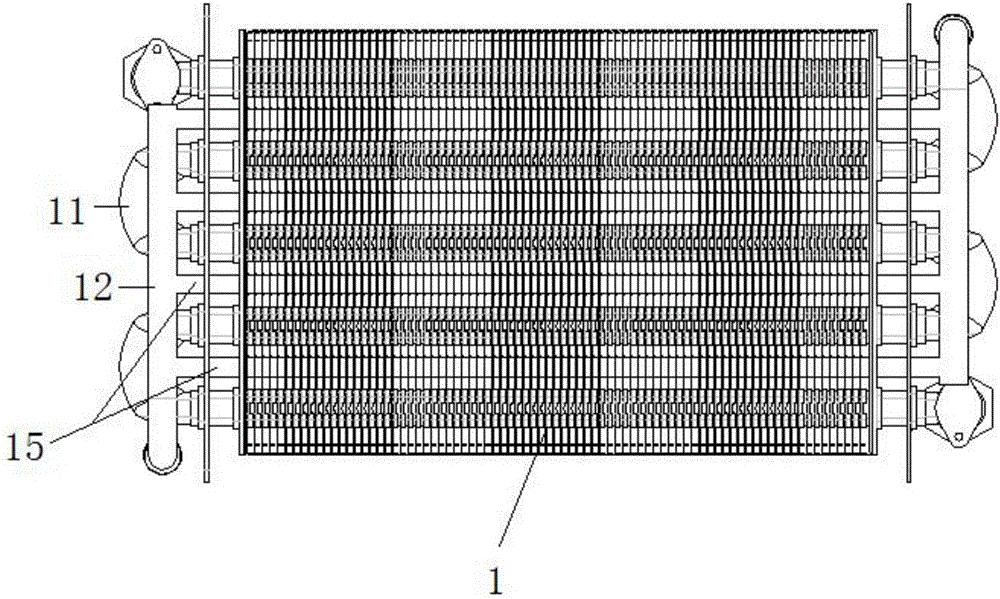

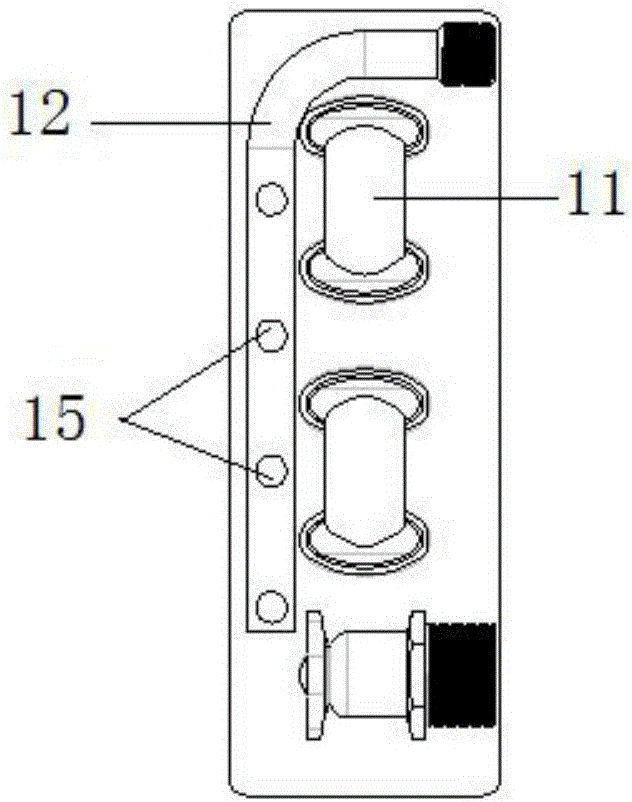

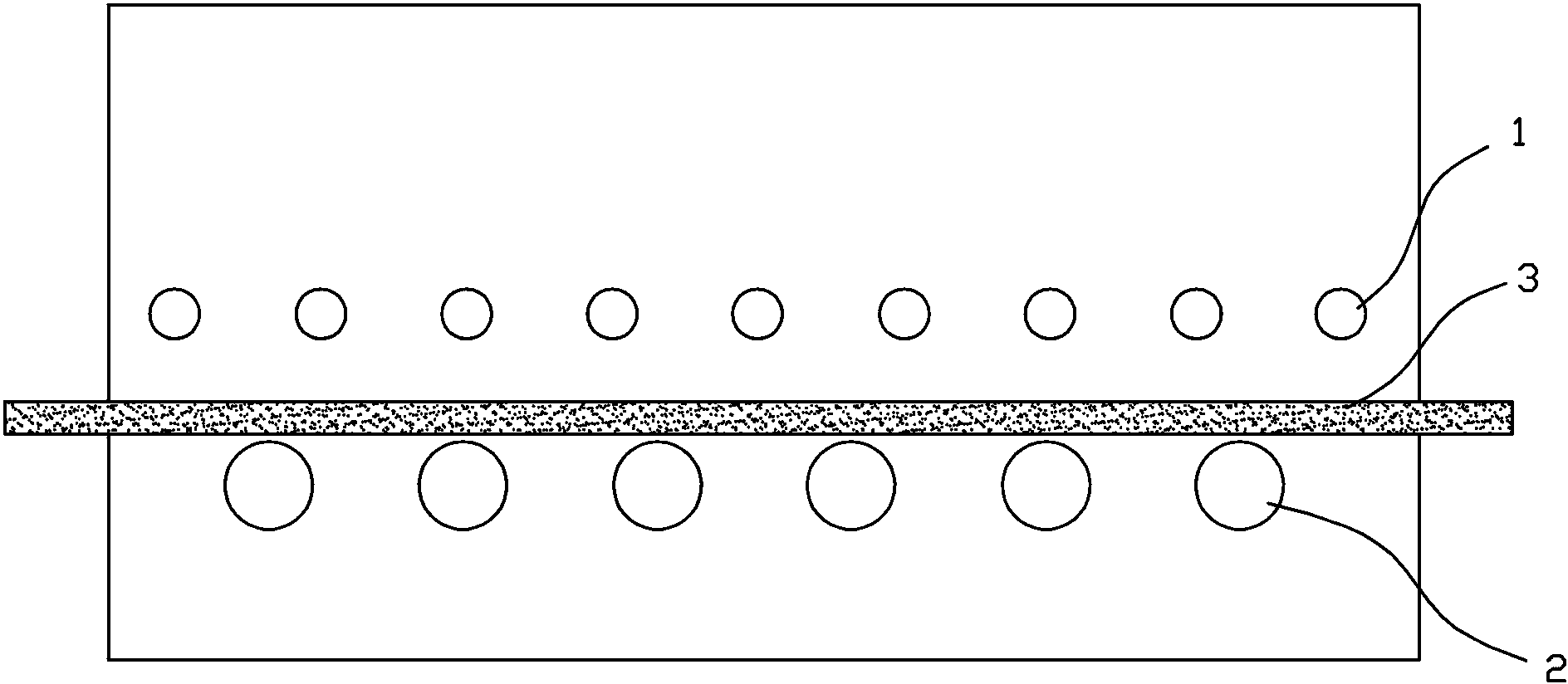

Coating machine oven system

The invention discloses a coating machine oven system comprising an infrared heating unit and a steam heating unit arranged in succession. The infrared heating unit comprises a plurality of infrared heating tubes. The steam heating unit comprises an intake passage, an air heating cavity, a base material heating cavity, an exhaust passage and a return air passage; a heating coil is disposed in the air heating cavity; an upper nozzle and a lower nozzle are disposed in the base material heating cavity; air enters the air heating cavity from the intake passage; the heating coil with steam heats up the air in the air heating cavity; the heated air is blown out of an air outlet of the upper nozzle and an air outlet of the lower nozzle; base material successively passes by one side of the infrared heating tubes between the upper nozzle and the lower nozzle; part of the air in the base material heating cavity is discharged from the exhaust passage, and the other part of the air returns from the return air passage to the intake passage. The coating machine oven system has the advantages that preheating is not required, heat conversion efficiency is high, energy consumption is low and temperature is even.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

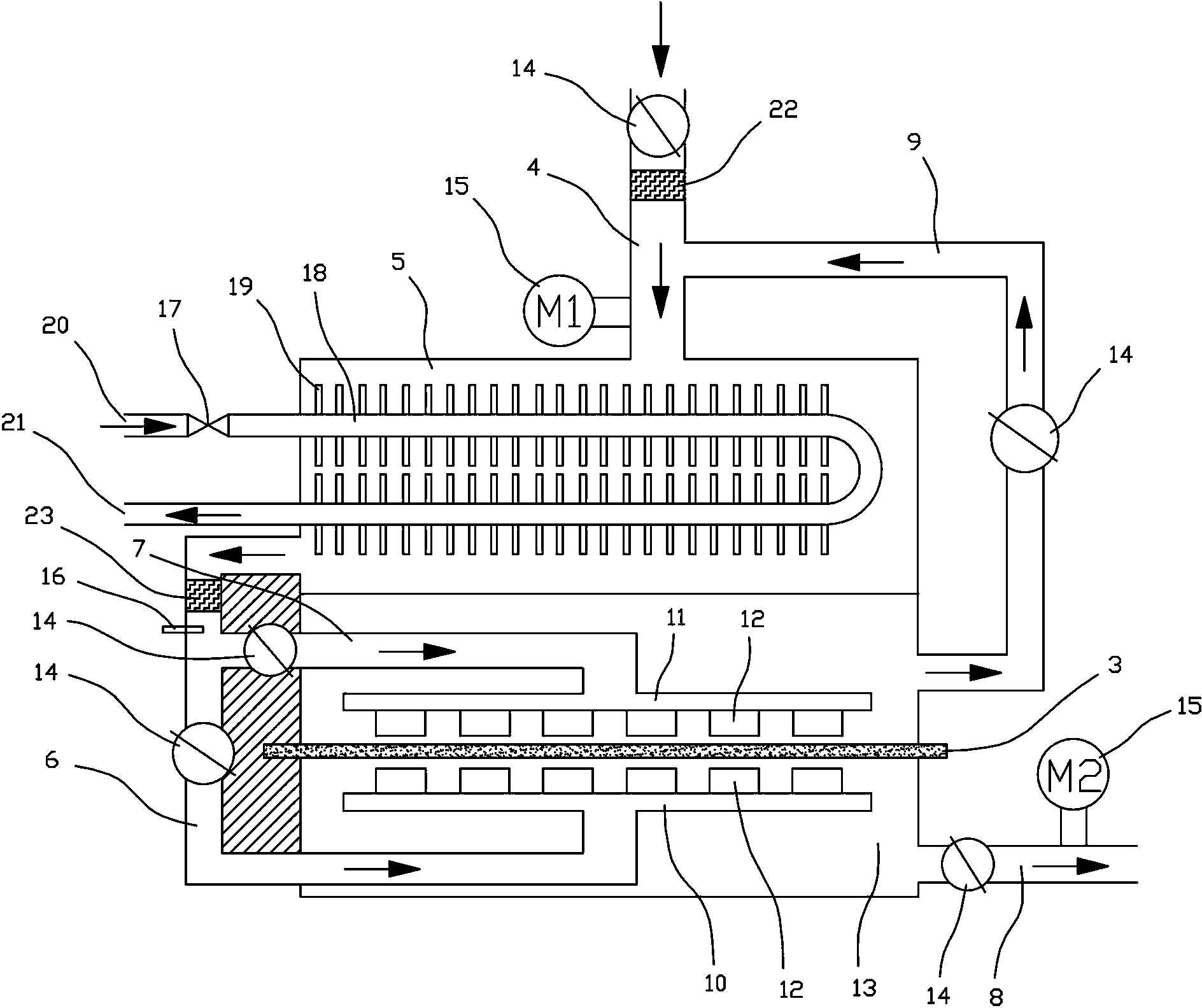

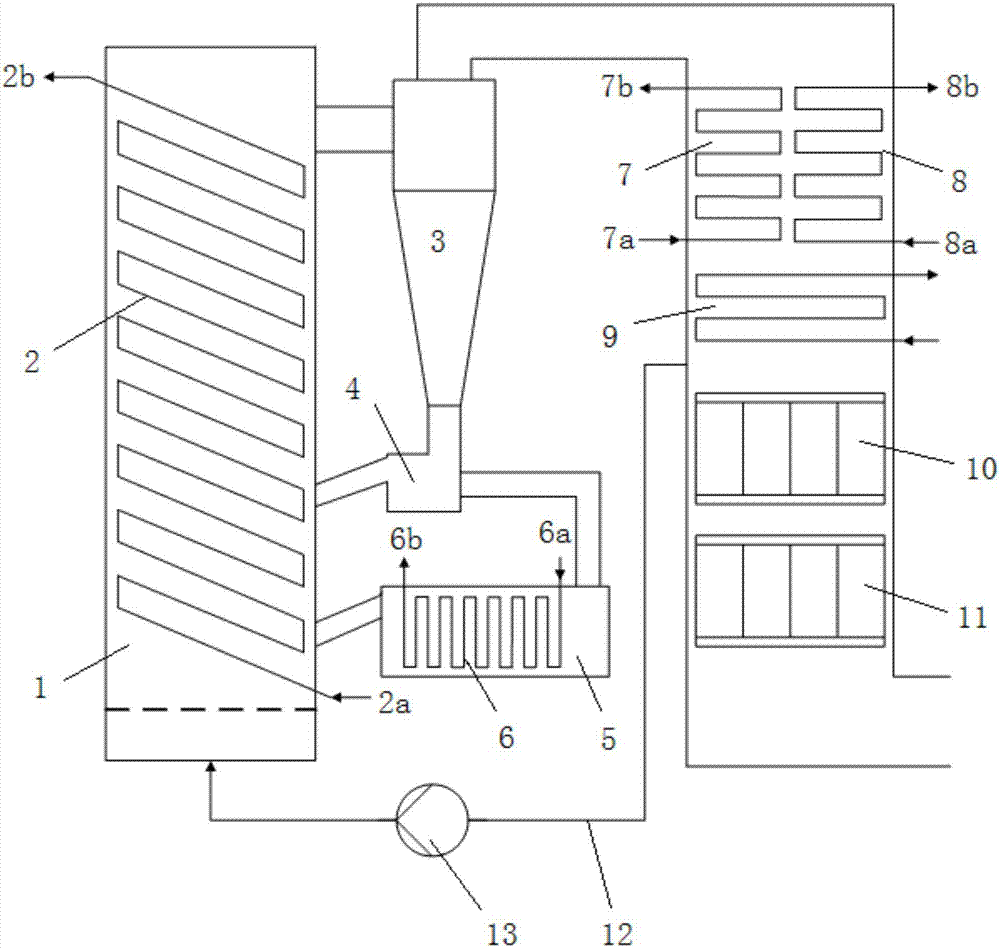

Supercritical-carbon-dioxide circulating fluidized bed boiler heating system and heating method

ActiveCN107120642AEasy to adjustAvoid Overheating ProblemsFluidized bed combustionIndirect carbon-dioxide mitigationSolid particleEngineering

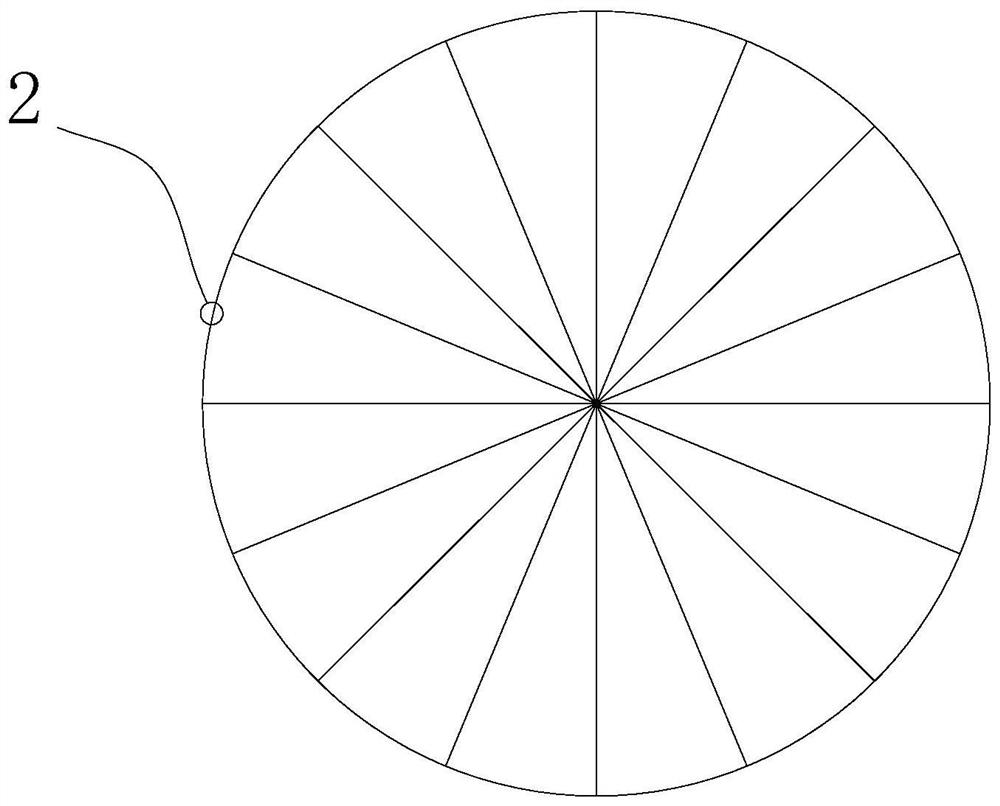

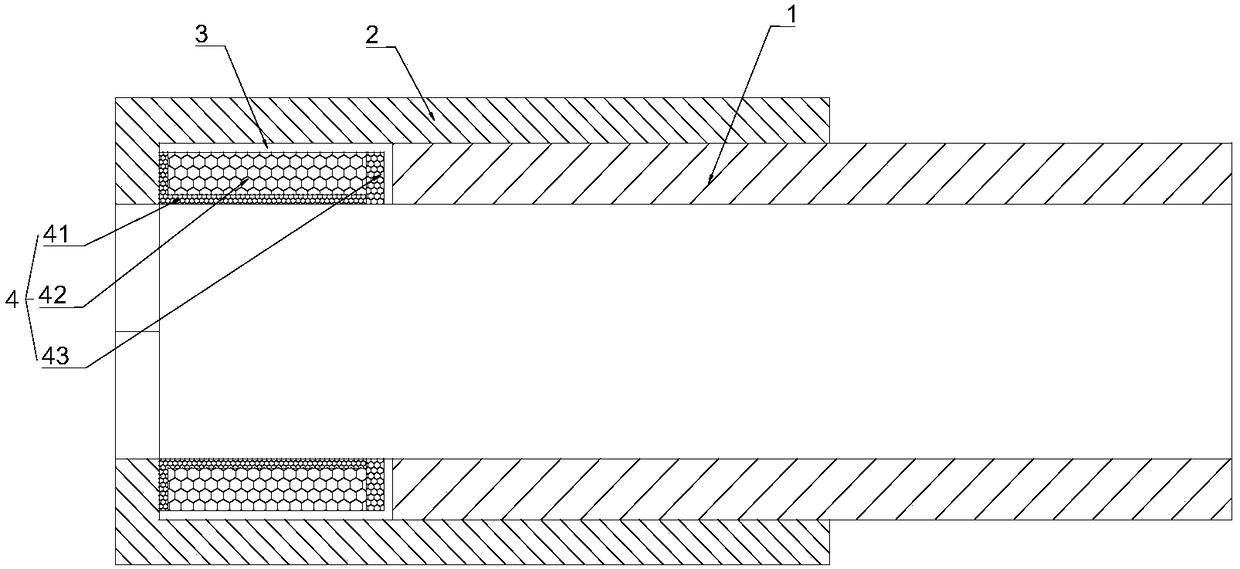

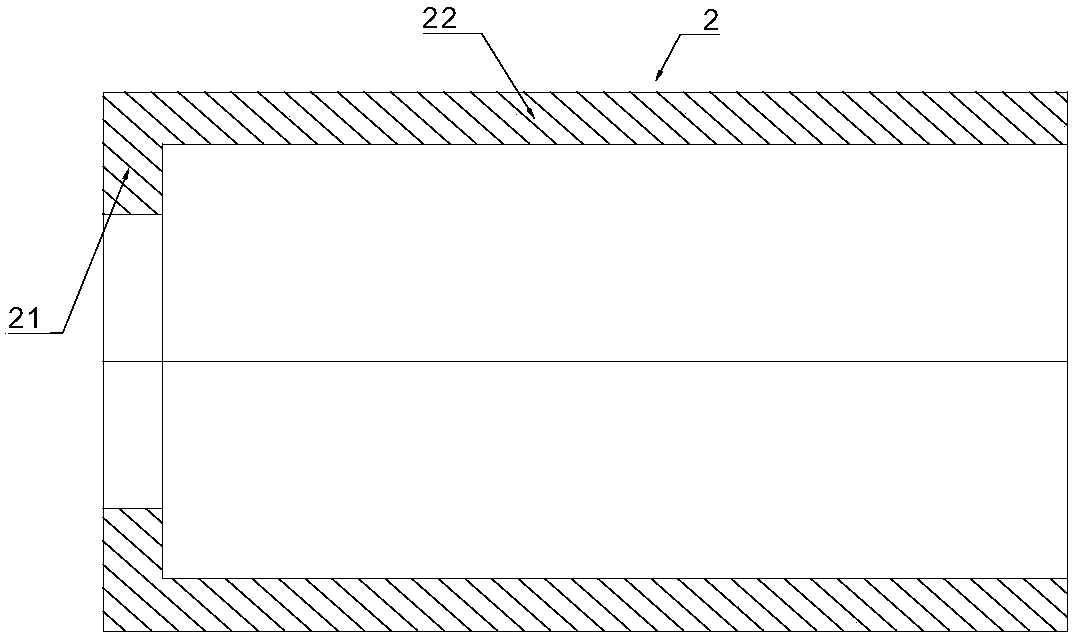

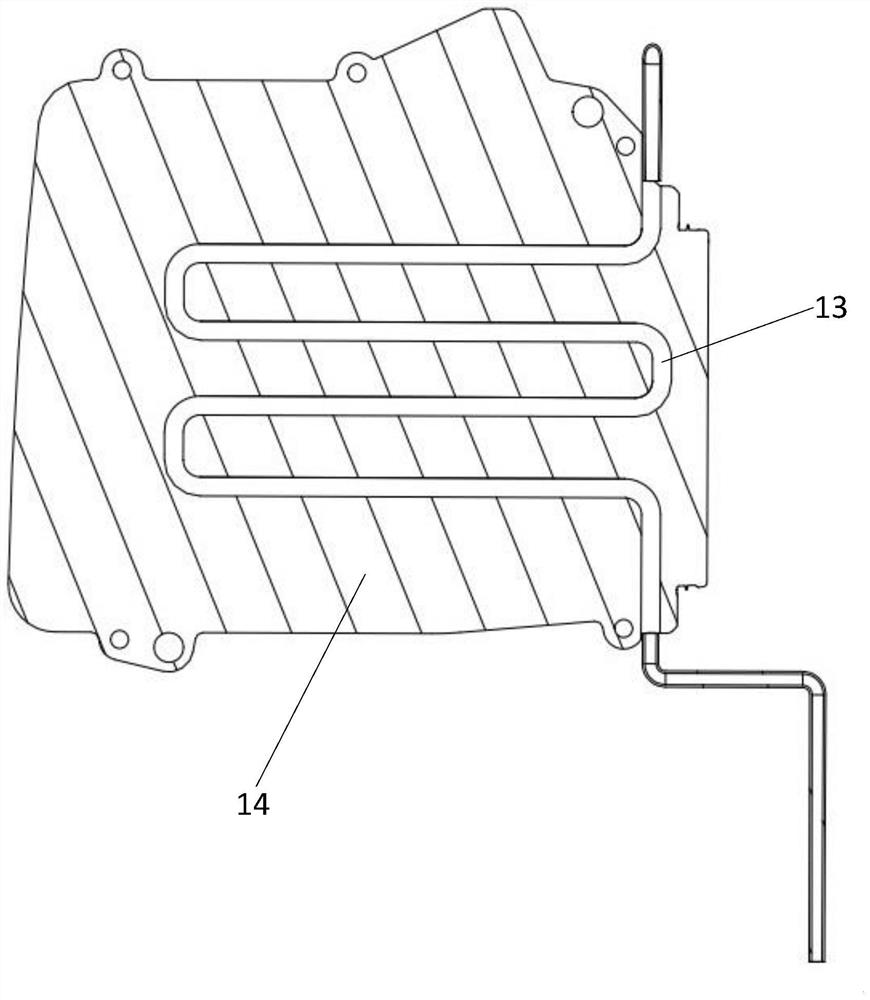

The invention discloses a supercritical-carbon-dioxide circulating fluidized bed boiler heating system and a heating method. The supercritical-carbon-dioxide circulating fluidized bed boiler heating system comprises a boiler, a spiral tube coil super-heater, a classifier, a gas pass and a convection super-heater, wherein the spiral tube coil super-heater is mounted in a boiler chamber of the boiler, and of a spiral tube coil structure, and a spiral tube coil provides a supercritical-carbon-dioxide circulating channel; the convection super-heater is mounted in the gas pass, and provides a supercritical-carbon-dioxide circulating channel; the upper end of the boiler chamber communicates with an inlet of the classifier, an smoke outlet of the classifier communicates with one end of the gas pass, and an solid-particle outlet of the classifier communicates with the boiler chamber of the boiler through a refeed valve; and the spiral tube coil super-heater and the convection super-heater are arranged in parallel or in series.

Owner:SHANDONG UNIV

Supercritical carbon dioxide boiler heating system and heating method

ActiveCN107101187AAvoid Overheating ProblemsSolve the lack of layout spaceIndirect carbon-dioxide mitigationSteam superheatersFlue gasEngineering

The invention discloses a supercritical carbon dioxide boiler heating system and a heating method. The supercritical carbon dioxide boiler heating system comprises a boiler, a spiral tube coil superheater, a separator, an external heat exchanger, an external reheater, a flue, a convection superheater and a convection reheater. The spiral tube coil superheater is installed inside a hearth of the boiler and is of a spiral tube coil structure, and a spiral tube coil provides a supercritical carbon dioxide circulating channel. The external reheater is installed inside the external heat exchanger. The convection superheater and the convection reheater are installed inside the flue. The upper end of the hearth communicates with an inlet of the separator. A flue gas outlet of the separator communicates with one end of the flue. A solid particle outlet of the separator communicates with an inlet of the external heat exchanger, and an outlet of the external heat exchanger communicates with the hearth of the boiler. The spiral tube coil superheater and the convection superheater are arranged in parallel. The external reheater and the convection reheater are arranged in parallel.

Owner:SHANDONG UNIV

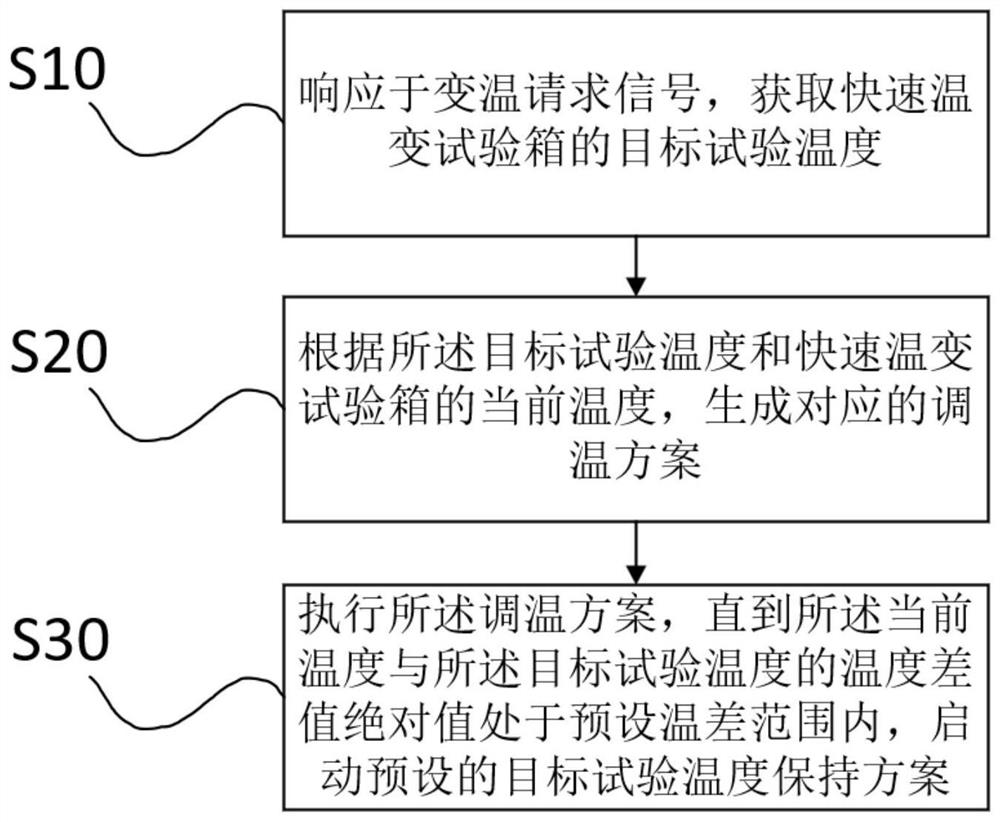

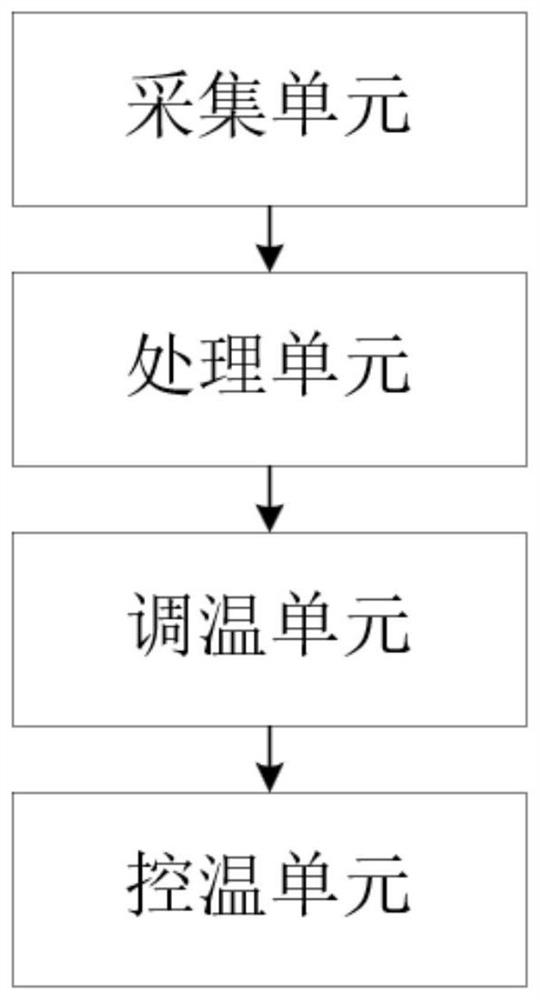

Temperature control method and system for rapid temperature change test box

ActiveCN114489187AAchieve dynamic balanceAvoids problems requiring continuous operation for temperature equilibrationAuxillary controllers with auxillary heating devicesTemperature controlProcess engineering

The embodiment of the invention provides a temperature control method and system for a rapid temperature change test box, and belongs to the technical field of rapid temperature change test boxes. The method comprises the steps of obtaining a target test temperature of a rapid temperature change test box in response to a temperature change request signal; generating a corresponding temperature adjustment scheme according to the target test temperature and the current temperature of the rapid temperature change test box; and executing the temperature adjusting scheme until the absolute value of the temperature difference value between the current temperature and the target test temperature is within a preset temperature difference range, and starting a preset target test temperature maintaining scheme. According to the scheme, the intelligence of temperature control is improved, energy waste is reduced, and meanwhile the test requirement of a user is met.

Owner:中航华东光电有限公司

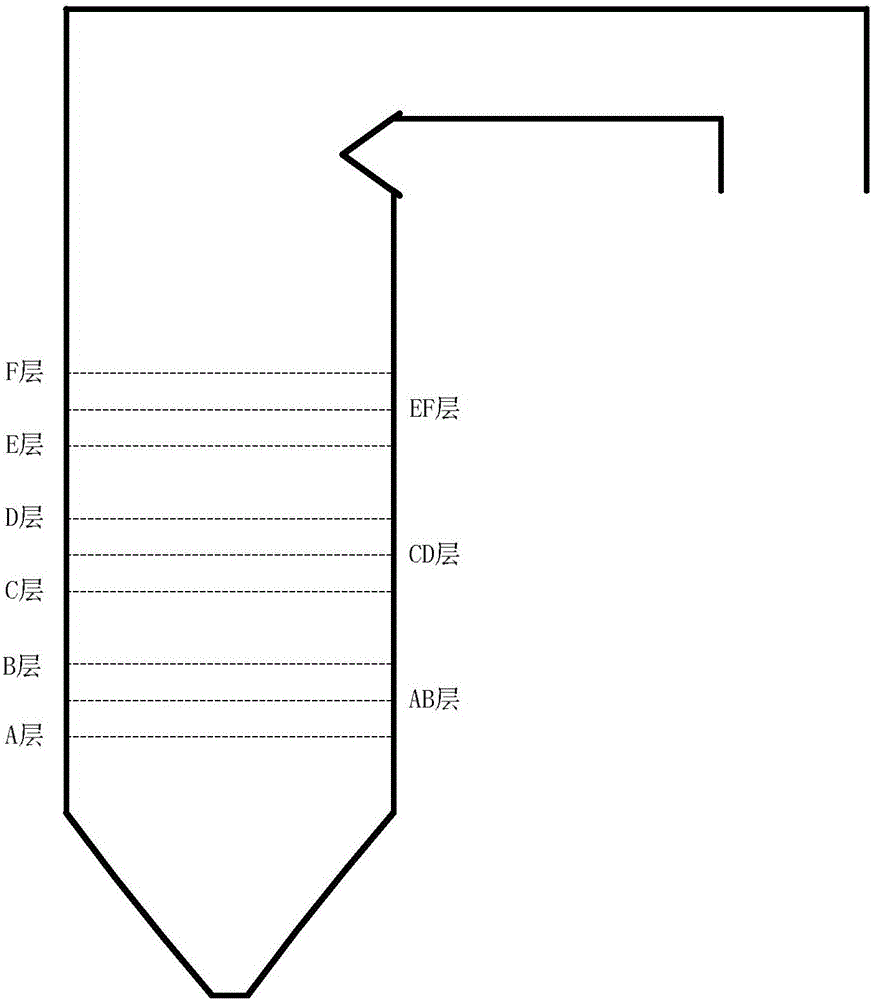

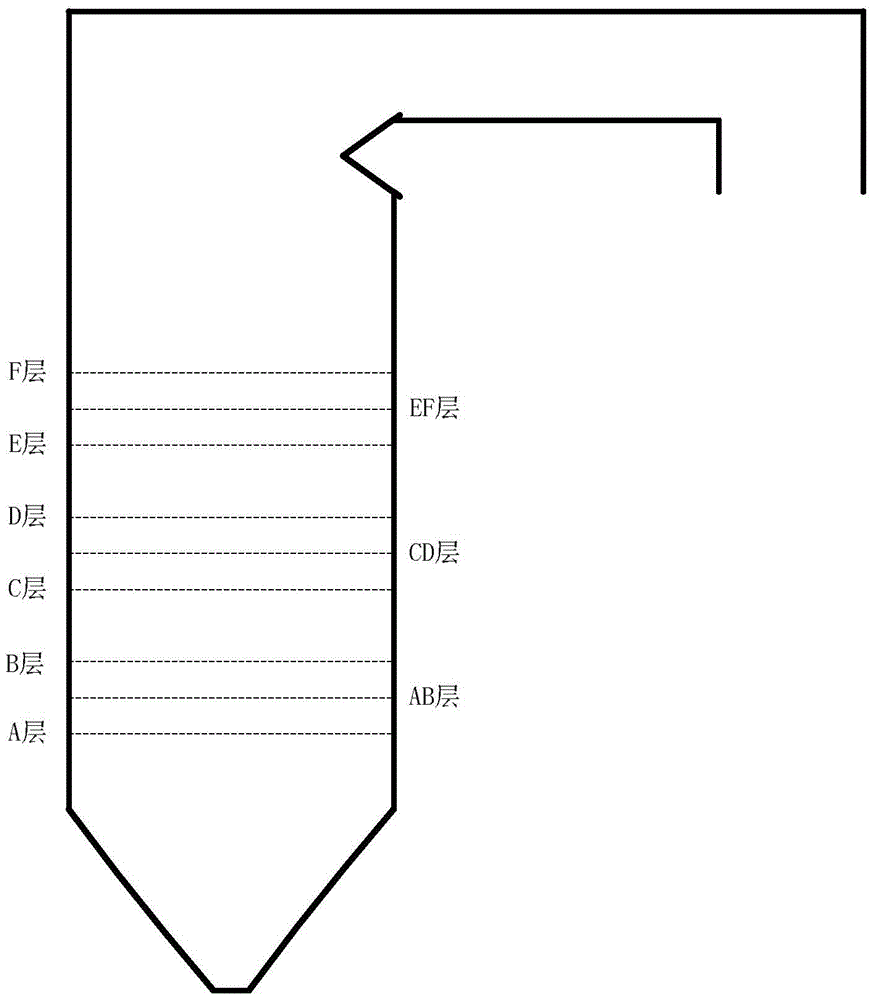

Boiler starting method for preventing oxide skin generation of 1,000 MW octagonal tangent circle boiler and secondary combustion accident of tail flue

The invention discloses a boiler starting method for preventing oxide skin generation of a 1,000 MW octagonal tangent circle boiler and a secondary combustion accident of a tail flue. Boiler warming is carried out before a combustor is put into operation, then, the combustor is put into operation, and the operation of the combustor is adopted according to the following operation principles that all large oil guns in an AB layer and part of large oil guns in a CD layer are put one by one, and when the outlet pressure of a boiler steam-water separator reaches 0.3 MPa, all micro oil guns in an A layer are put, and then a powder manufacturing system of the A layer is put into operation; and at the thermal state flushing and temperature rising and boosting stage, part of or all large oil guns quit one by one according to the pulverized coal combustion situation, and at the load rising stage, powder manufacturing systems are put into operation layer by layer according to the load situation. According to the method, the temperature rising rate of a heating surface of the boiler in the starting process can be controlled, and the good combustion effect of the pulverized coal in a hearth can be guaranteed; and generation of pipe oxide kin of the heating surface of the boiler is effectively prevented, and the purposes of preventing secondary combustion of the tail flue and the detonation accident of the hearth can be achieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

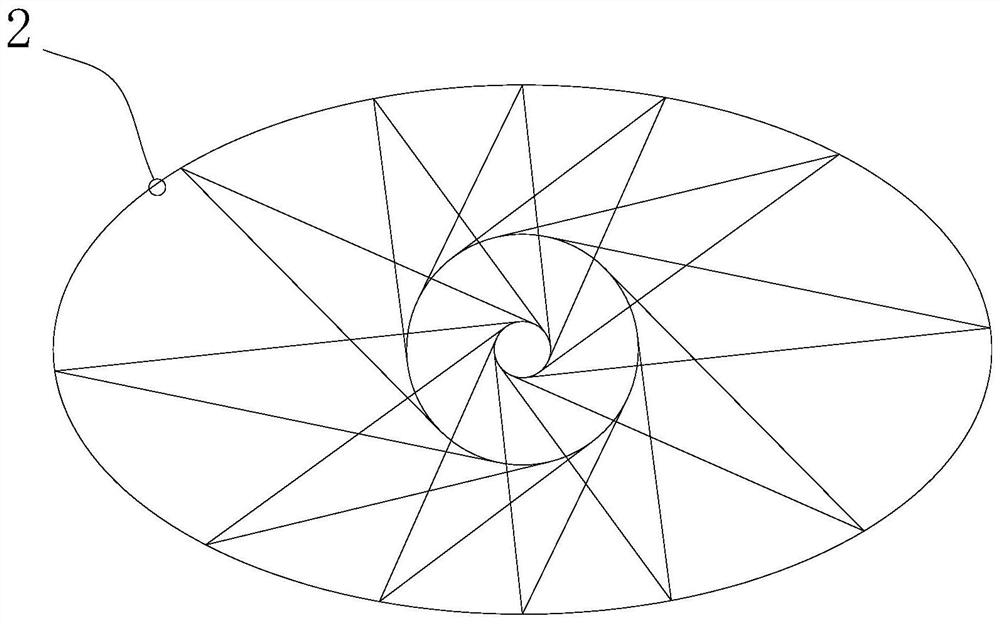

Supercritical CO2 boiler capable of realizing uniform combustion, corrosion resistance and coking resistance and boiler system

ActiveCN112161261AImprove uniformitySpray evenlyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSupercritical steam generatorCombustion chamber

The invention discloses a supercritical CO2 boiler capable of realizing uniform combustion, corrosion resistance and coking resistance and a boiler system. The supercritical CO2 boiler comprises a main combustion chamber, an upper hearth, a furnace arch and a flue; the cross section of the main combustion chamber is round, oval or N-sided, N is larger than 4, and at least four combustor groups arearranged on the main combustion chamber; each group of combustor nozzles corresponding to each combustor group include a recirculating air nozzle, a primary air nozzle and a secondary air nozzle, andside recirculating air nozzles which are symmetrically distributed are arranged on the two sides of the primary air nozzle; the recirculating air nozzles and the side recirculating air nozzles are used for feeding recirculating flue gas or mixed gas of the recirculating flue gas and secondary air into the main combustion chamber; the primary air nozzles are used for feeding primary air or mixed gas of the primary air and the recirculating flue gas into the main combustion chamber; and the secondary air nozzles are used for feeding secondary air or mixed gas of the secondary air and the recirculating flue gas into the main combustion chamber; the load of the supercritical CO2 boiler and the load of the boiler system are uniform, and high-temperature corrosion, coking and slagging on the wall surface of the boiler are avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

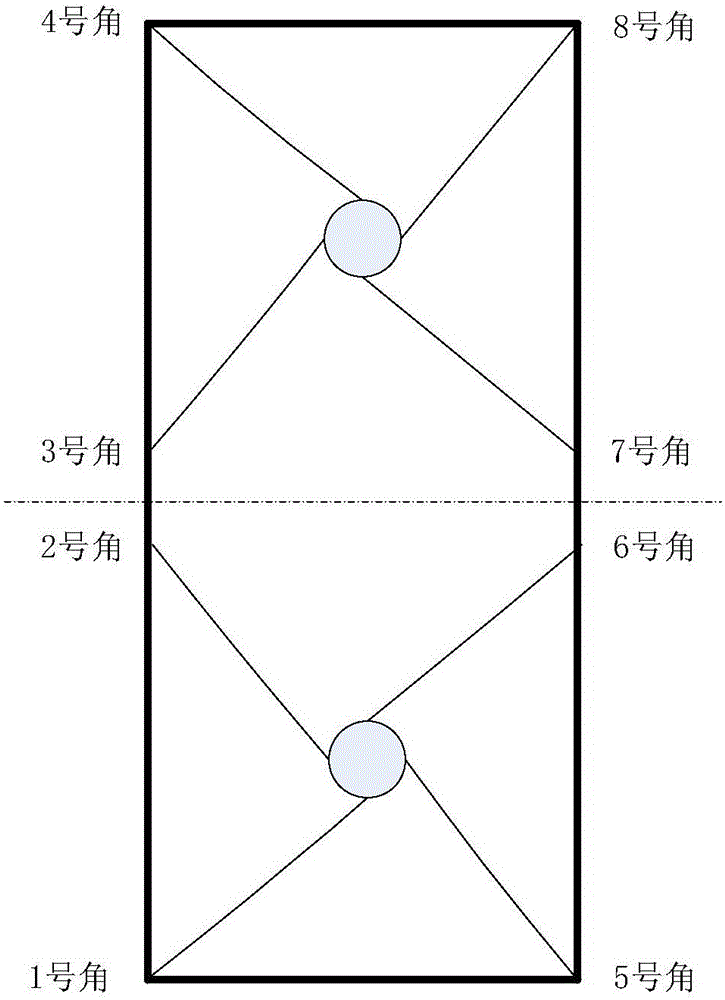

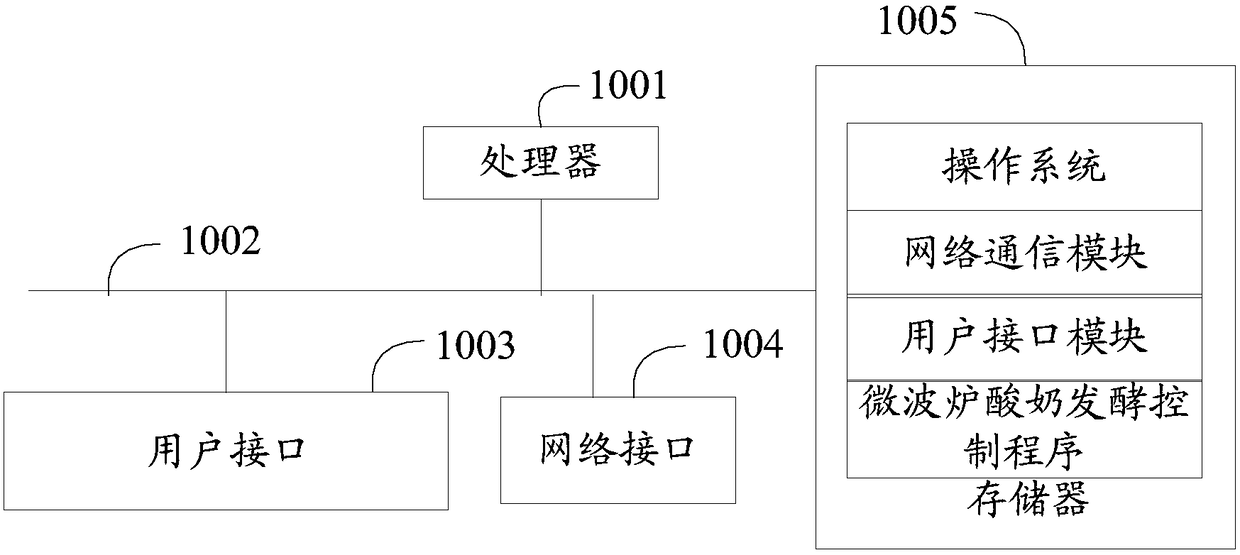

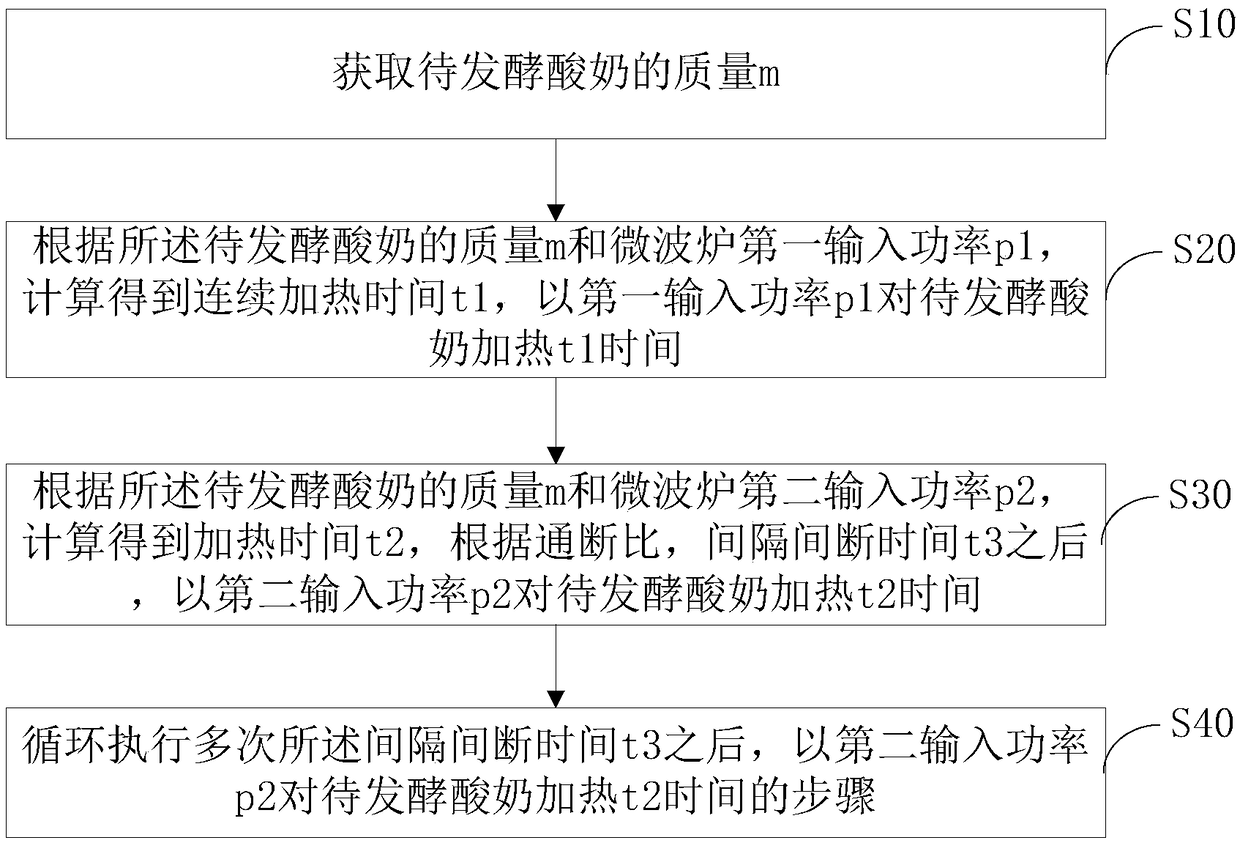

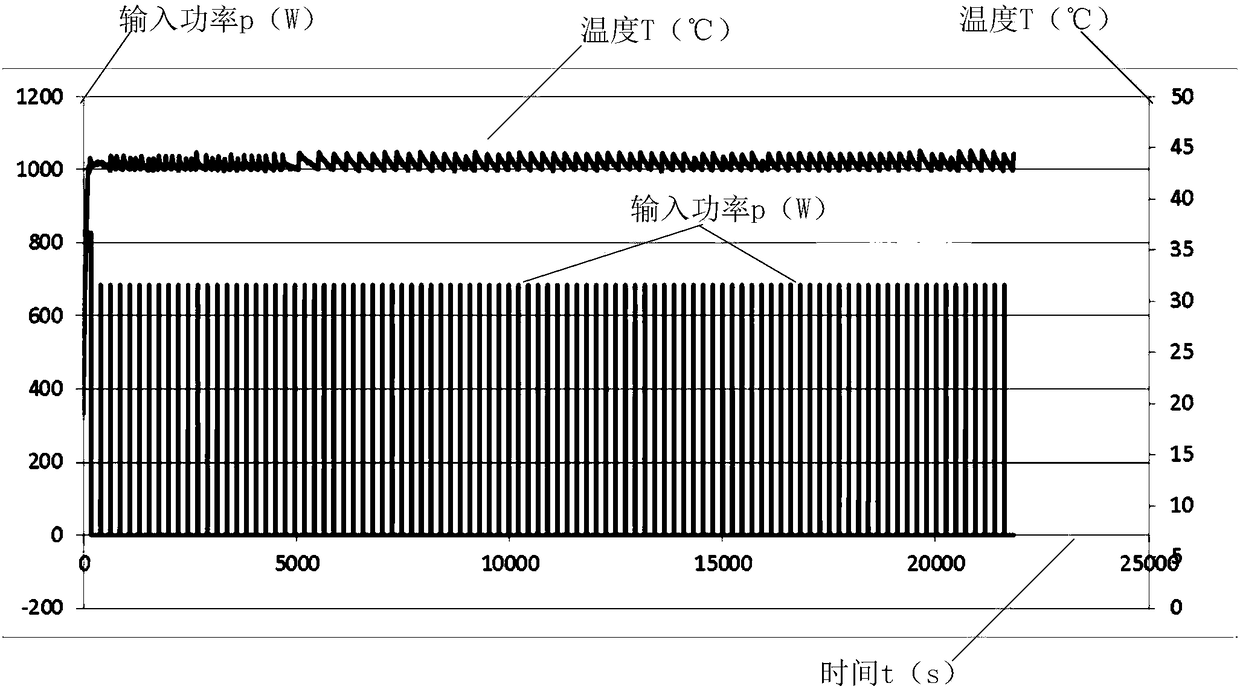

Microwave oven yogurt fermentation control method, microwave oven and computer readable storage medium

ActiveCN108594901AEfficient heatingAvoid overheating problemsMilk preparationAuxillary controllers with auxillary heating devicesHeating timeMicrowave oven

The invention discloses a microwave oven yogurt fermentation control method, a microwave oven and a computer readable storage medium, wherein the microwave oven yogurt fermentation control method comprises the following steps: acquiring the mass m of the yogurt to be fermented; according to the quality m of the yogurt to be fermented and the first input power p1 of the microwave oven, obtaining acontinuous heating time t1 through calculation, and heating the yogurt to be fermented for t1 time with the first input power p1; according to the mass m of the yogurt to be fermented and the second input power p2 of the microwave oven, obtaining the heating time t2 through calculation, and after the intermittent time t3, heating the yogurt to be fermented for t2 time with the second input power p2, and repeatedly executing the steps until the fermentation process is ended. In the yogurt fermentation process, microwave is powered on-off and heated, the problem that a traditional heating mode causes low heating efficiency and large electric resource consumption caused by continuous heating is solved, and meanwhile, and the problem that the yogurt is overheated in the yogurt fermentation process through short-time heating is solved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

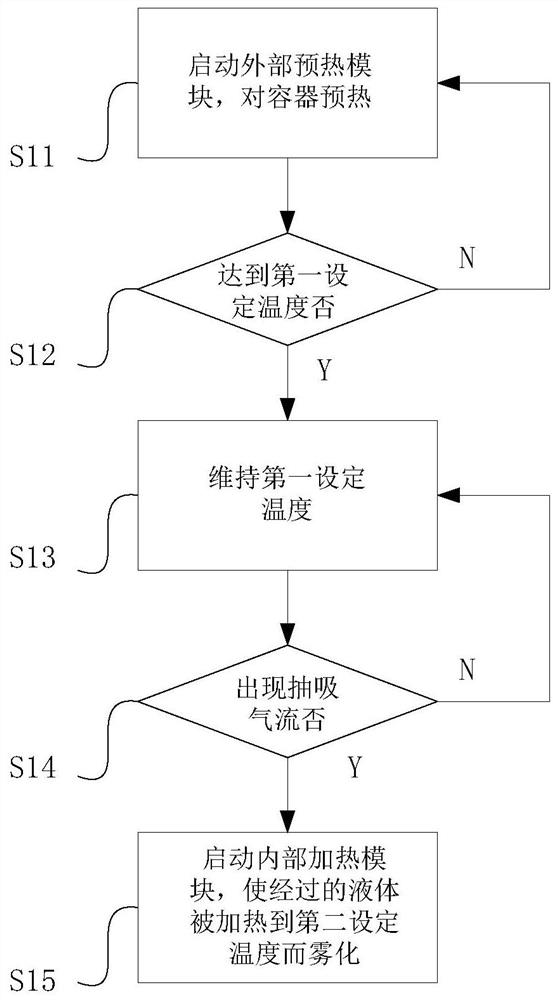

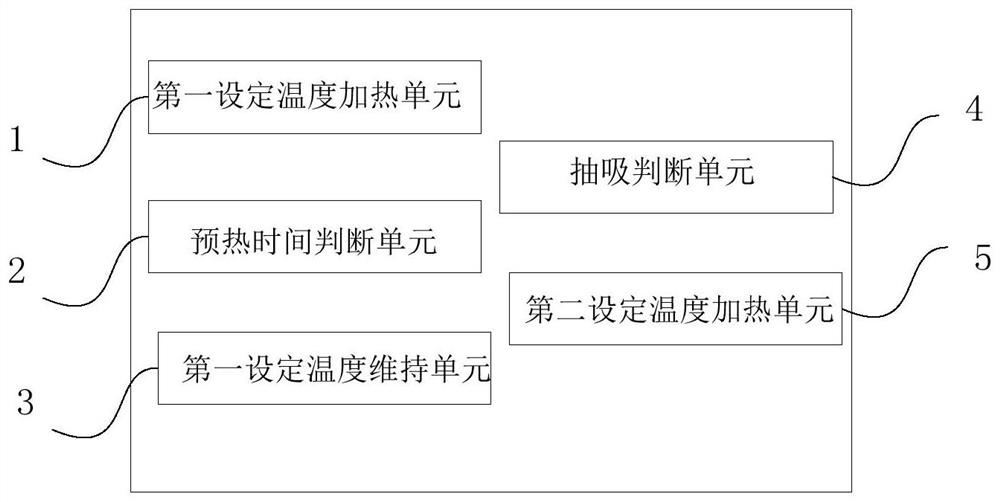

Method and device for heating atomized liquid and preheating circuit

PendingCN112205676AHeating evenlyImprove liquidityTobacco devicesTemperature controlProcess engineering

The invention relates to a method for heating atomized liquid. The method comprises the following steps of: preheating a container for containing atomized liquid through an external preheating module,so that the container and the atomized liquid in the container are heated to a first set temperature; controlling the heating power of the external preheating module so as to keep the temperature ofthe container and the atomized liquid in the container; determining whether suction airflow occurs or not, and if so, starting an internal preheating module arranged in a suction channel of the container, so that liquid passing through the channel is heated to a second set temperature to be atomized; otherwise, returning to maintain the first set temperature. The invention further relates to a device for implementing the method and a preheating circuit for the method. The method and the device for heating the atomized liquid and the preheating circuit have the beneficial effects that the method and the device are easy to control, and the problem of excessive or insufficient heating is avoided.

Owner:ALD GRP

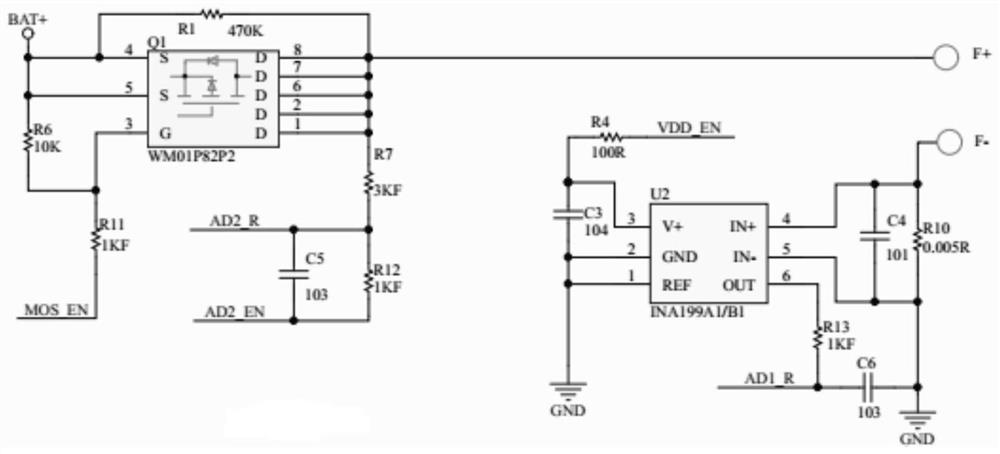

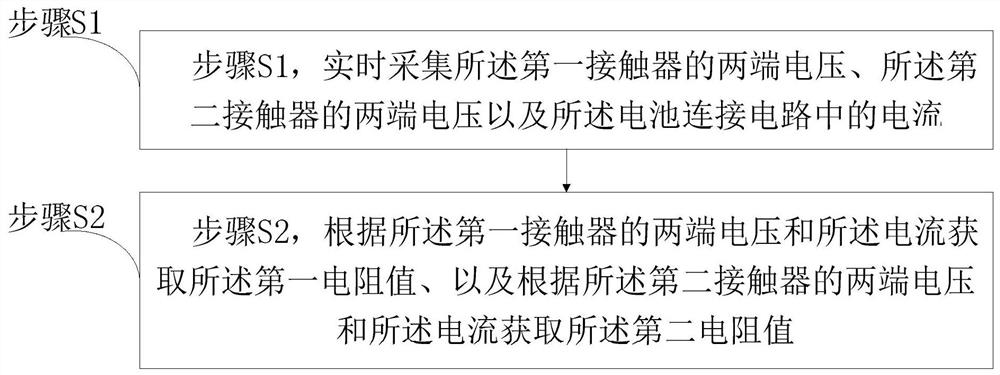

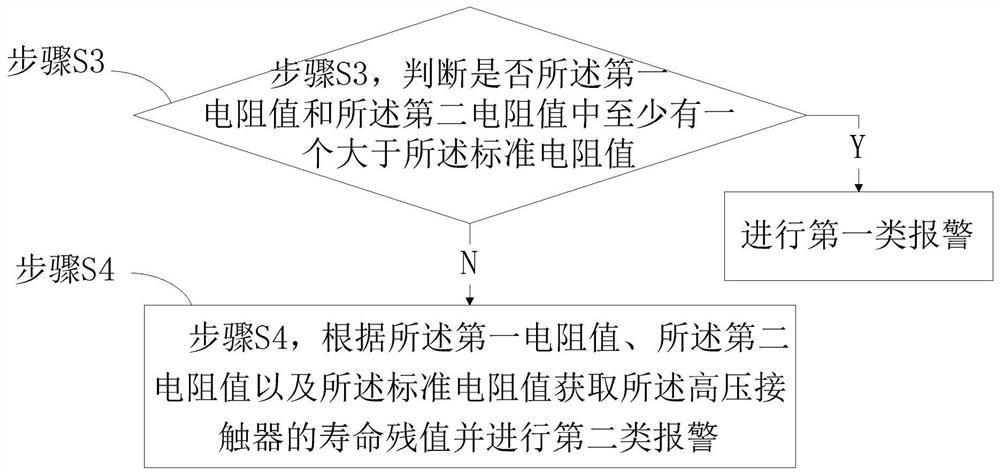

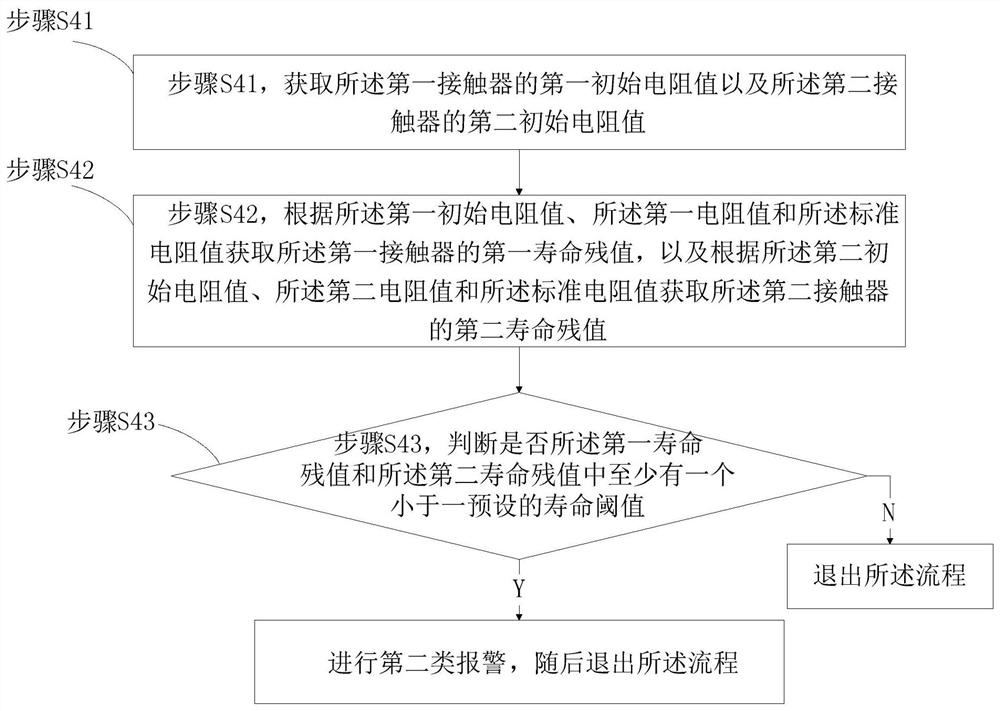

Real-time monitoring method and system for service life of high-voltage contactor

PendingCN112305415AAvoid overheating problemsAvoid the risk of functional failureCircuit interrupters testingHemt circuitsControl theory

The invention relates to the field of high-voltage contactors, in particular to a real-time monitoring method and system for the service life of a high-voltage contactor. The method is applied to a battery connection circuit, and comprises the following steps: providing a standard resistance value of the high-voltage contactor; obtaining a first resistance value of the first contactor and a secondresistance value of the second contactor in real time, and giving an alarm according to the first resistance value, the second resistance value and the standard resistance value. The technical schemeof the invention has the beneficial effects that the current service life condition of the high-voltage contactor can be accurately detected in real time, the problem of over-temperature caused by the fact that the high-voltage contactor cannot be predicted or warned in advance and is continuously used after the service life is ended can be avoided, and the risk caused by function failure of a battery or other high-voltage components can be further avoided.

Owner:HUMAN HORIZONS (JIANGSU) TECH CO LTD

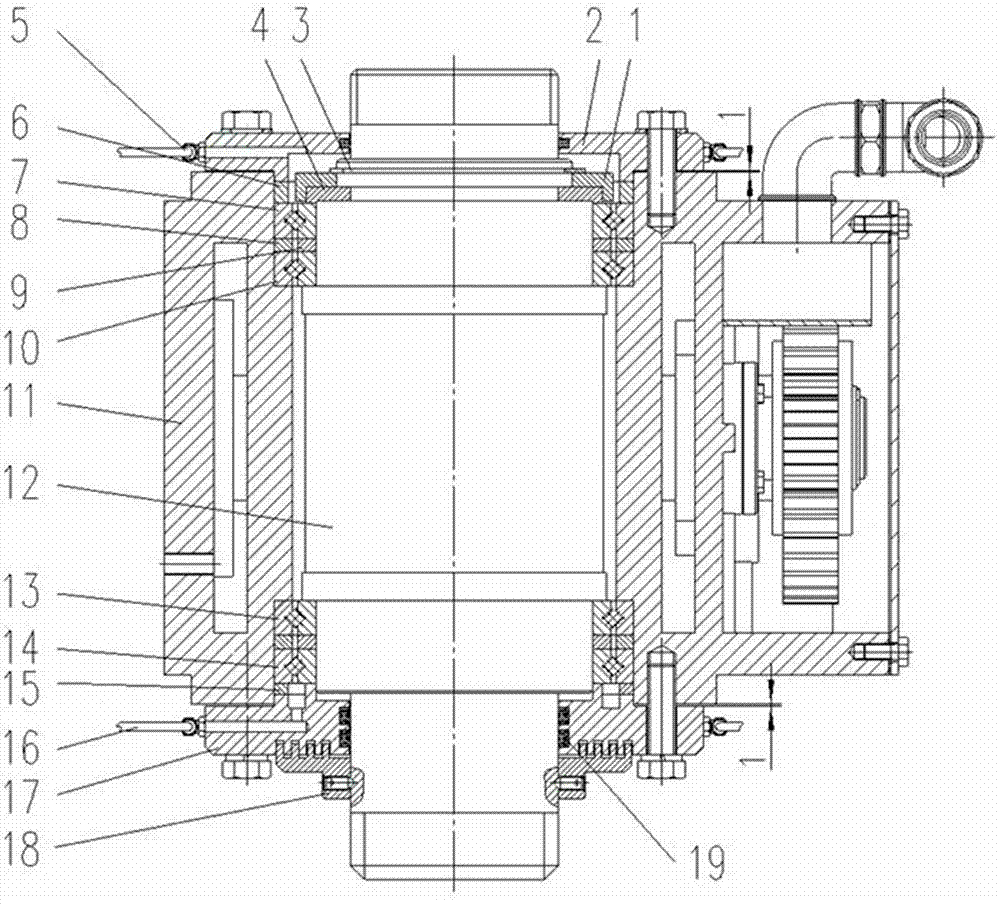

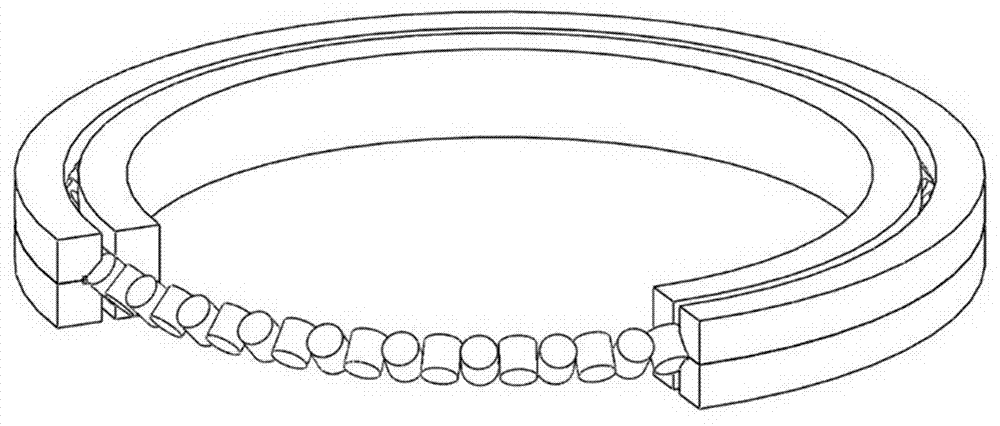

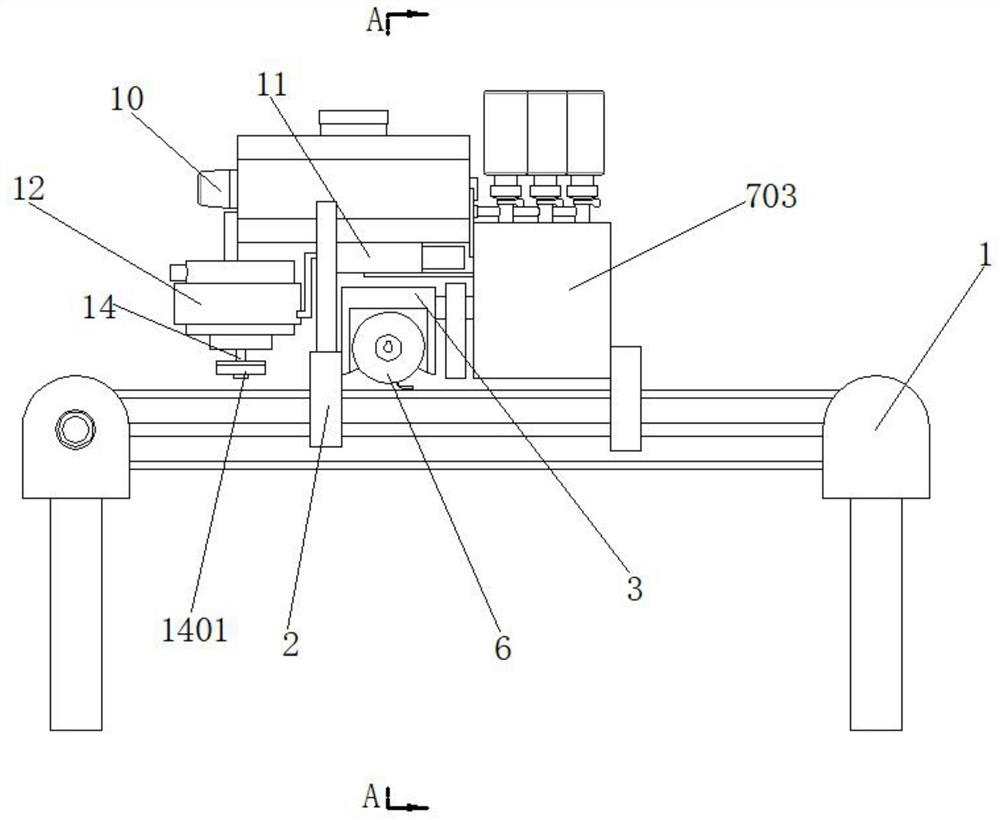

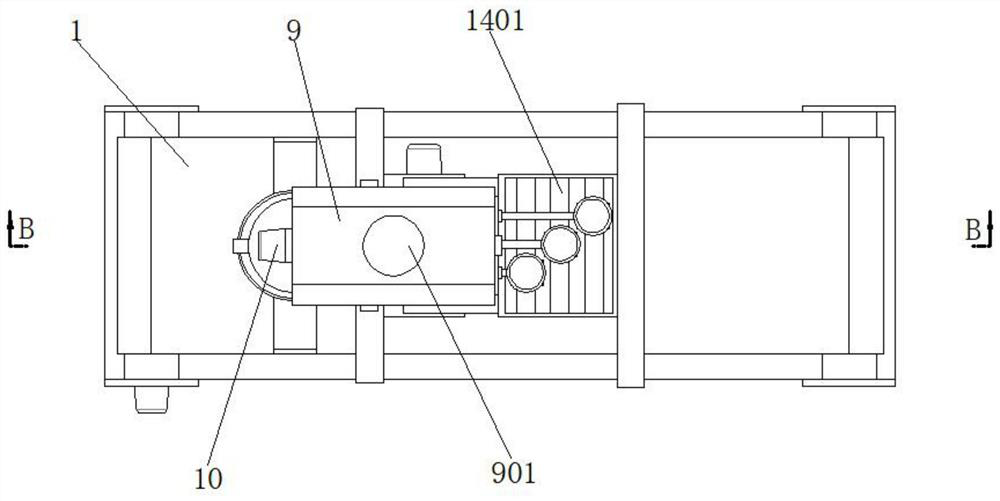

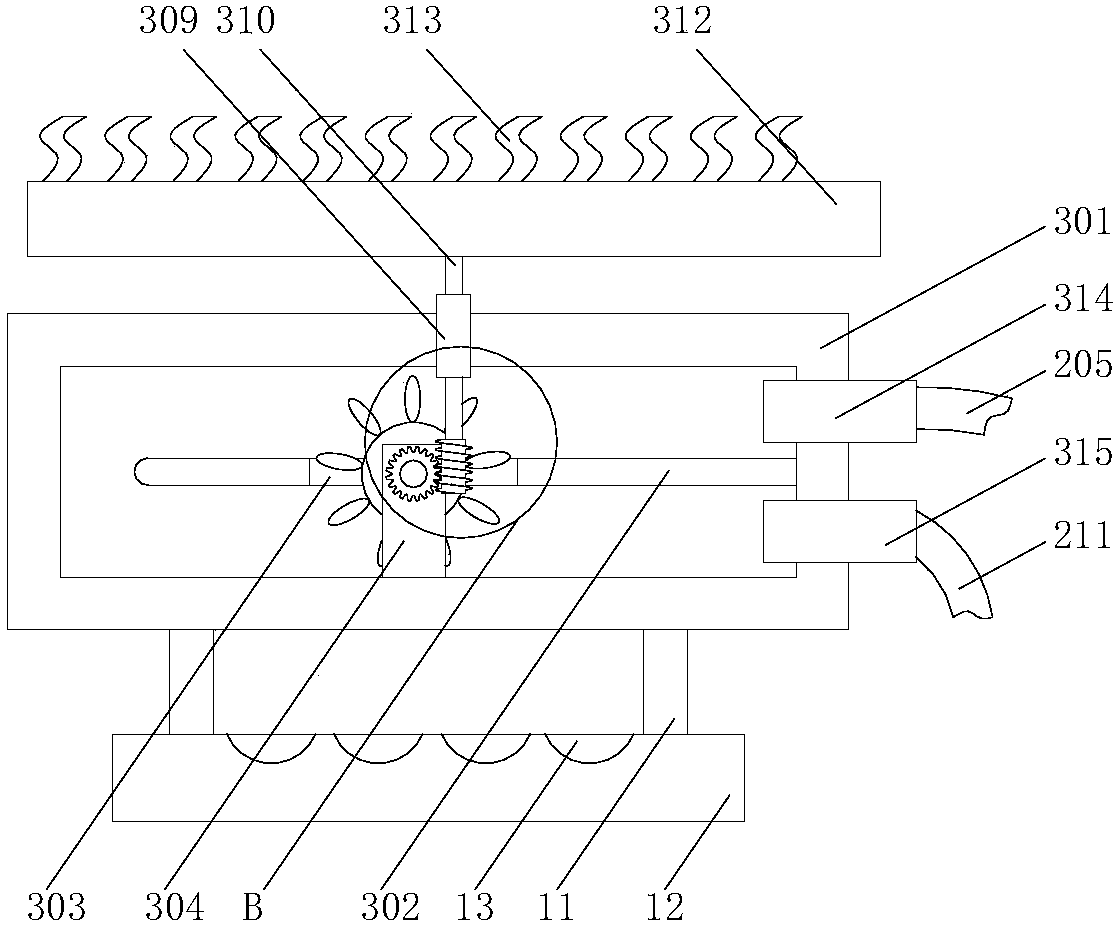

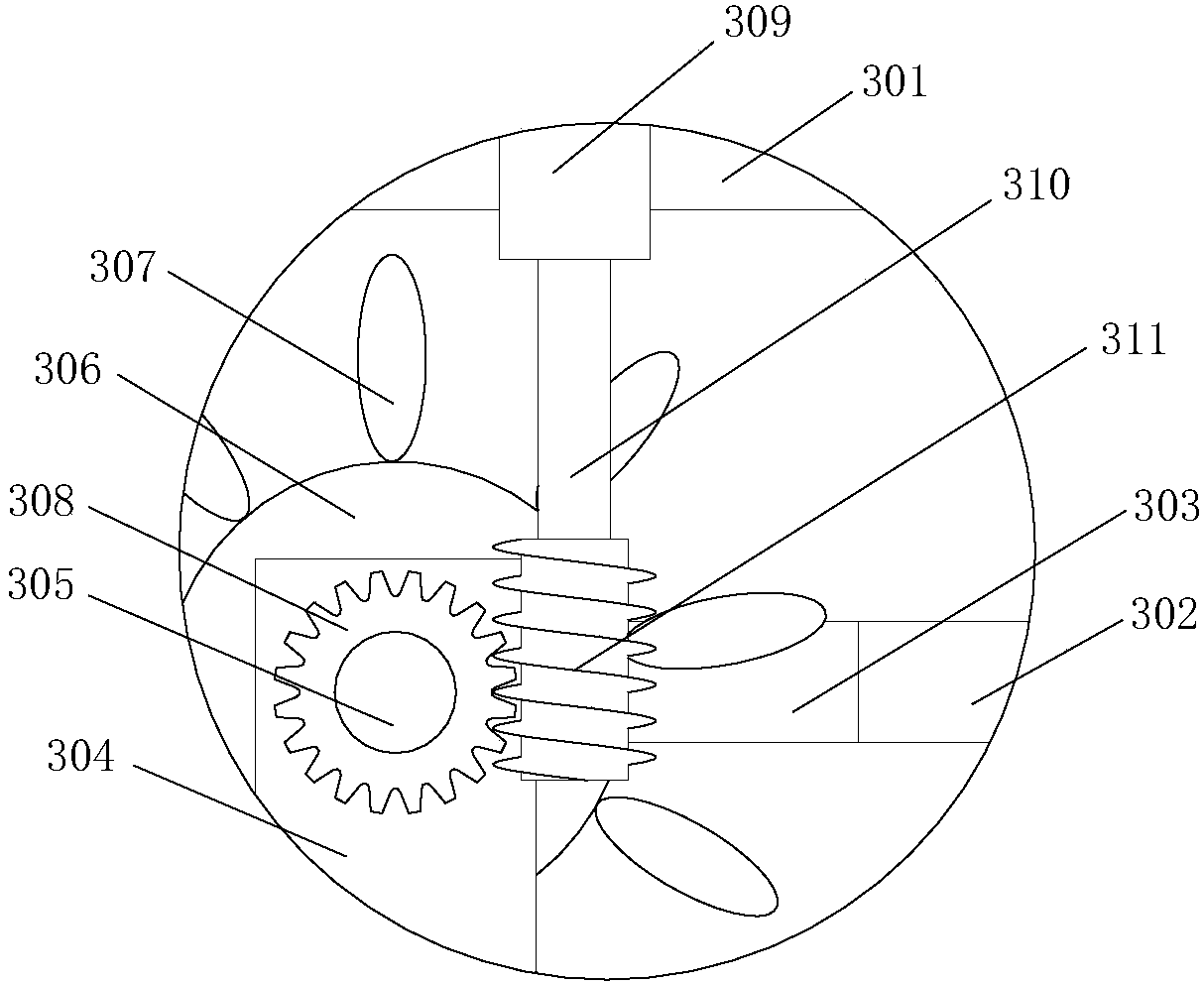

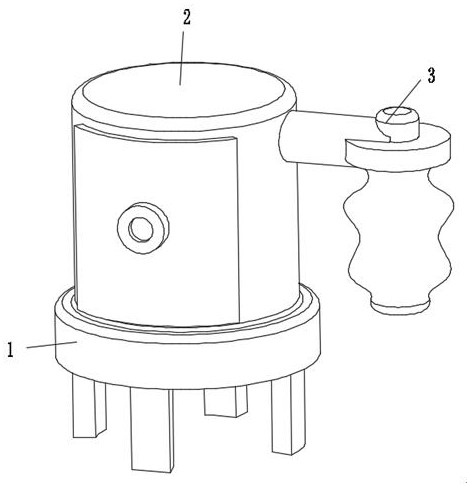

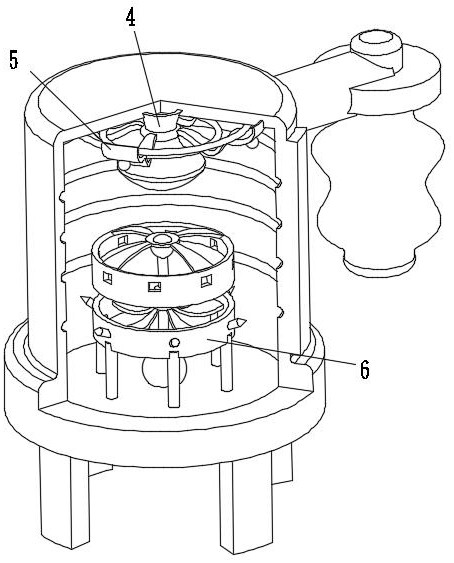

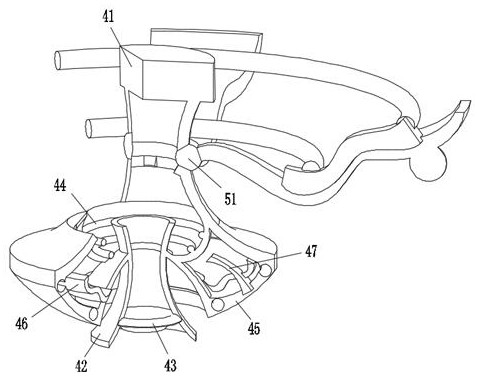

Rotary vibratory force head main shaft device

InactiveCN104747608AAvoid overheating problemsImprove sealingEngine sealsDrilling drivesNeedle roller bearingEndurance capacity

The invention discloses a rotary vibratory force head main shaft device. Shaft necks at the upper and lower ends of a main shaft are respectively provided with upper and lower crossed roller bearing pairs, wherein the inner end surface of an inner ring of an inner crossed roller bearing in each crossed roller bearing pair is adhered to the end surfaces of the shaft necks of the main shaft, the outer end surface of an inner ring of an outer crossed roller bearing in the upper crossed roller bearing pair is locked successively by virtue of a holding loop, a hoop and a circlip for a shaft so a to be locked, and an outer ring of the outer crossed roller bearing is locked by virtue of an upper gland and a locknut; the outer ring and inner ring of the outer crossed roller bearing in the lower crossed roller bearing pair are respectively locked by virtue of a lower gland and a locknut, the outer end of the lower gland is provided with a labyrinth sealing ring, and the upper gland and the lower gland are respectively provided with an upper oil passage and a lower oil passage. The rotary vibratory force head main shaft device is high in alternating stress endurance capacity, convenient to assemble, adjust and replace, and capable of improving the working stability of a rotary vibratory force head.

Owner:YUNNAN LAND & RESOURCES VOCATIONAL COLLEGE

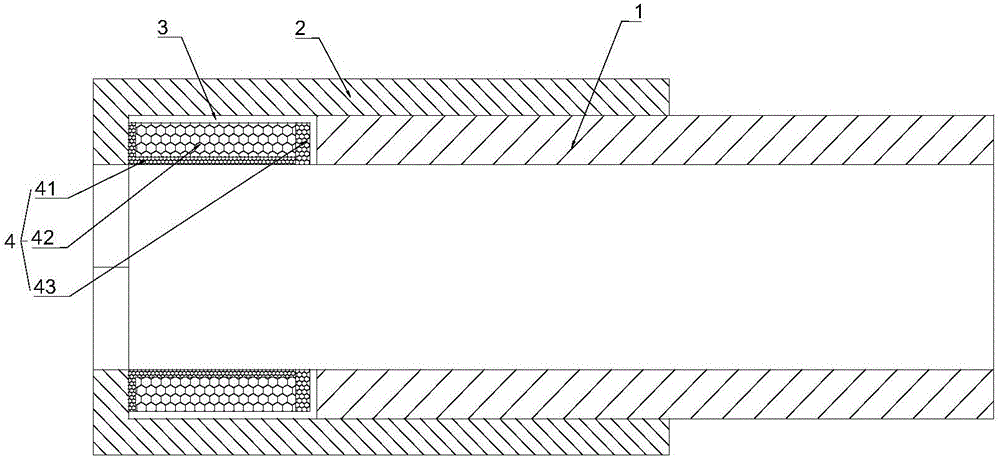

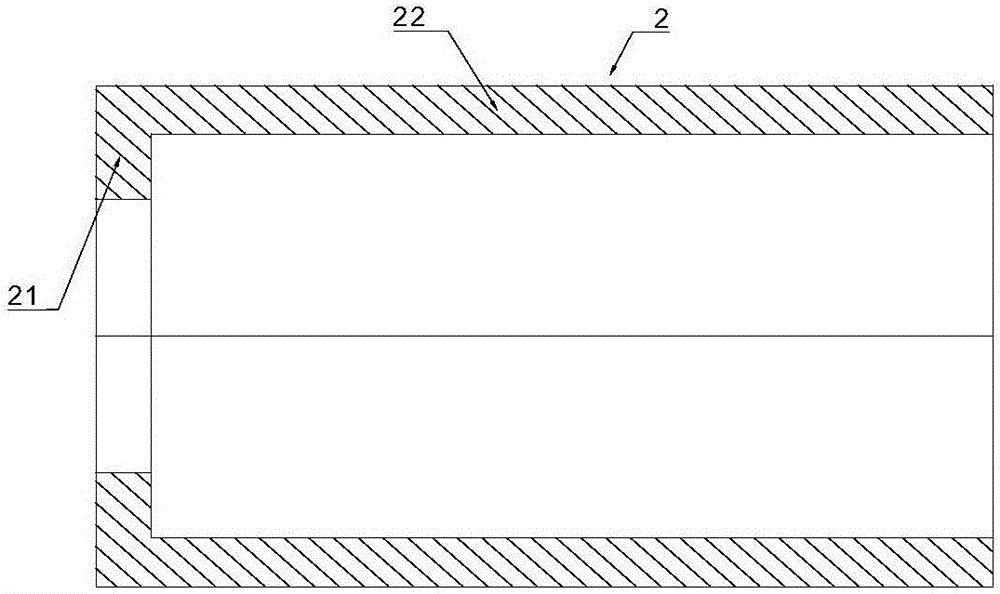

Manufacturing process of grinding, casing milling and well repairing tool and mold

InactiveCN106041257AImprove impact toughnessImprove wear resistanceWelding/cutting auxillary devicesArc welding apparatusFilling materialsEngineering

The invention discloses a manufacturing process of a grinding, casing milling and well repairing tool. Firstly, a to-be-machined casing is sleeved with a mold, the end portion of the mold is provided with inner edges extending towards the axis, and gaps are reserved between the inner edges and the end face of the to-be-machined casing; after the to-be-machined casing and the mold are preheated to a surfacing temperature, the end face of the to-be-machined casing is coated with soldering flux, and surfacing of priming weld layers is started; YD hard alloy particles are subjected to horizontal surfacing in the gaps; and after the surfacing is completed, the mold is dismantled, the welded tool is subjected to postwelding heat preservation and is cooled after heat preservation is performed for a period of time, and welding is completed. A filling material can flow in the gaps between the mold and the casing due to the welding manner, the particles are distributed evenly to achieve the purpose of the horizontal surfacing, the above welding temperature is stable, the temperature loss is avoided as much as possible, the welding strength and the welding efficiency are improved, and therefore the impact toughness, the abrasion resistance, the service life and other indexes of the tool are improved. The invention discloses the mold for manufacturing the grinding, casing milling and well repairing tool at the same time.

Owner:邵元龙

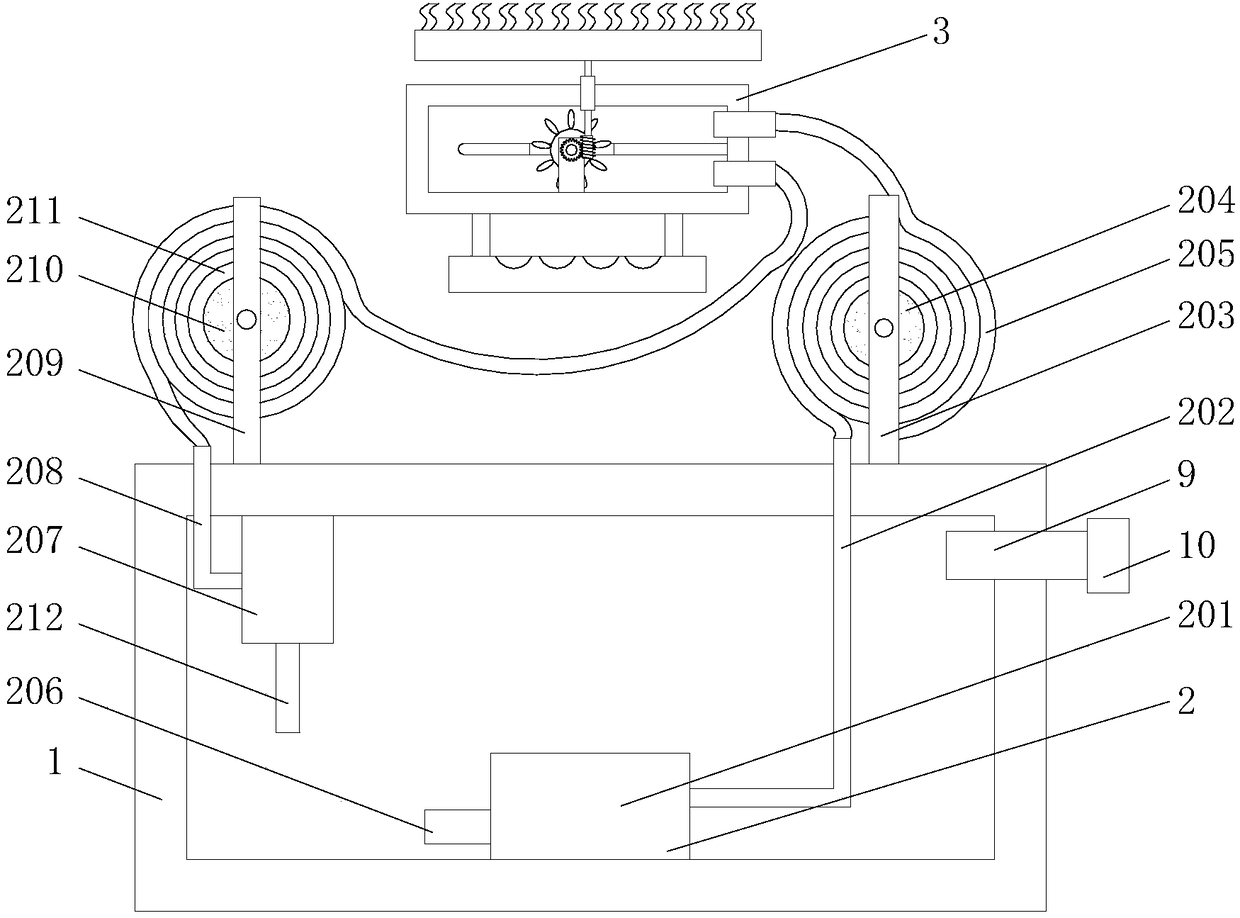

VCM composite plate production based spraying device

PendingCN111993677ARealize multi-batch spraying operationImprove uniformitySpray boothsAdhesive cementMotor drive

The invention discloses a VCM composite plate production based spraying device. The VCM composite plate production based spraying device realizes multi-batch spraying operation of paint and improves uniformity through matching effect of multiple groups of conveying tubes, a regulating valve, a drive motor pump B and an additive bottle, can control each group of additives according to different process needs to meet needs of different proportioning processes, and greatly expands practicability; a step motor A, a VCM film coating barrel, a coating barrel, a step motor B, a heater, an adhesive box, a motor drive pump A and the motor drive pump B are combined in design, so that assembly operation of a glue loading process, a film coating process and a spraying process is realized, and therefore, processing efficiency is greatly improved, operation of a worker is convenient; and while a passing composite plate is dried through low-end heating, the heater is radiated and cooled through upper-end refrigerating, so that the problem that the heater is heated up excessively is effectively avoided.

Owner:合肥禾盛新型材料有限公司

Intelligent energy-storage integrated device

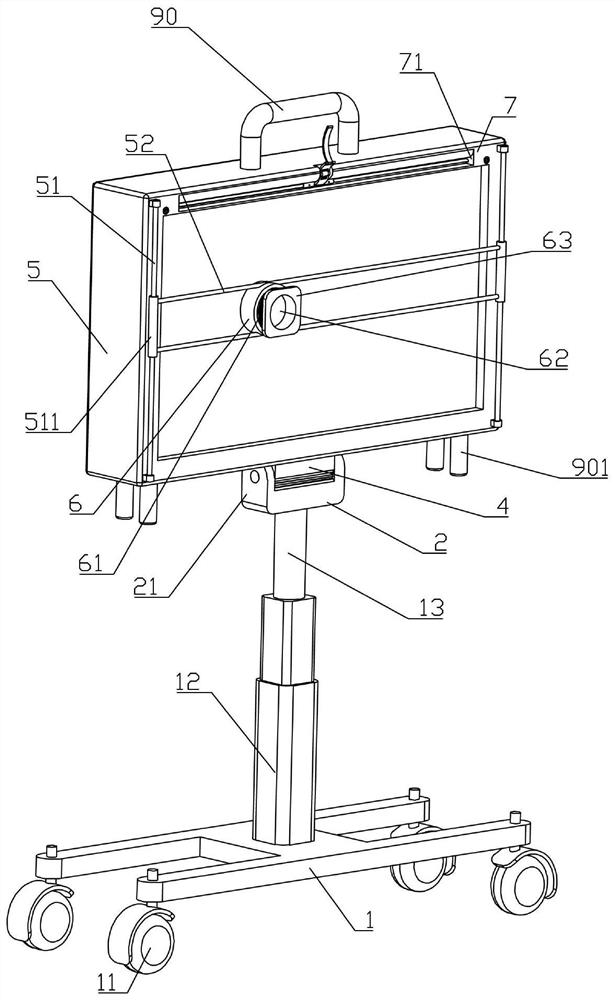

InactiveCN108711661AAvoid overheating problemsGuaranteed Temperature ConsistencyBatteries circuit arrangementsFire rescueAutomotive engineeringWorking temperature

The present invention discloses an intelligent energy-storage integrated device. The device comprises a box body, an energy-storage current converter, an energy management system, an energy storage device, a temperature controlling system and a fire-extinguishing system. The energy-storage current converter and the energy management system are linearly connected with the energy storage device separately, and the temperature controlling system and the fire-extinguishing system are located at one side of the energy storage device separately. The energy storage device comprises an energy storagebox and batteries arranged in the energy storage box. The temperature controlling system comprises an air conditioner and a flow-conducting tube, the air outlet of the air conditioner is provided witha flow-conducting cover, and the flow-conducting tube is horizontally arranged in the energy storage box or at the outside of the energy storage box separately. One end of the flow-conducting tube isconnected with the flow-conducting cover, the other end of the flow-conducting tube is provided with a plug to perform plugging, and the flow-conducting tube is radially provided with air-blowing pipes pointing to the batteries. According to the intelligent energy-storage integrated device, each battery is in the best working temperature environment, and the use security is improved.

Owner:JIANGSU NAVSTON ELECTRONICS TECH CO LTD

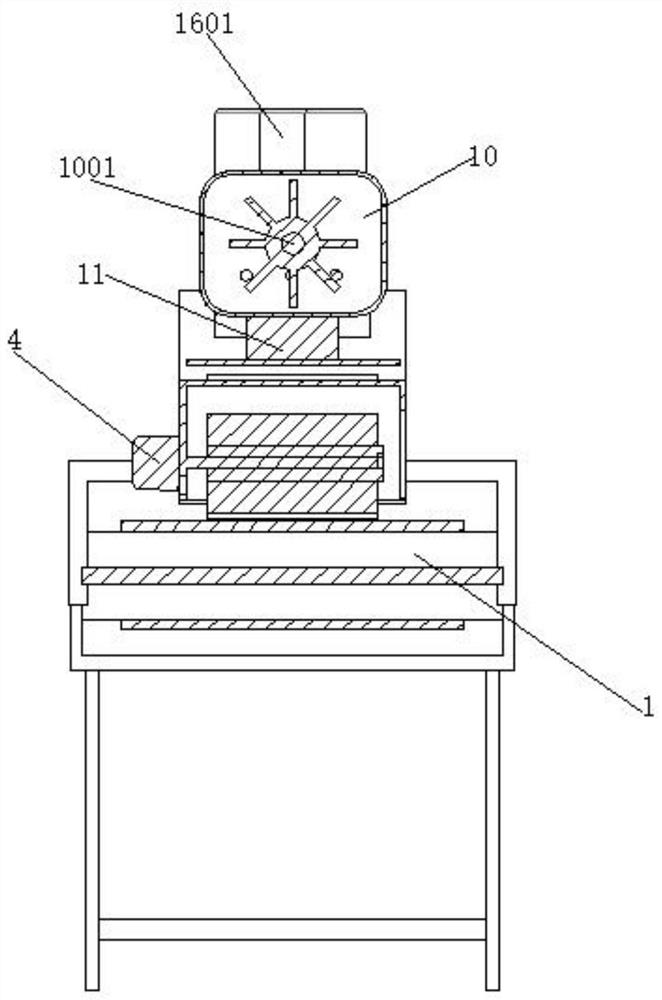

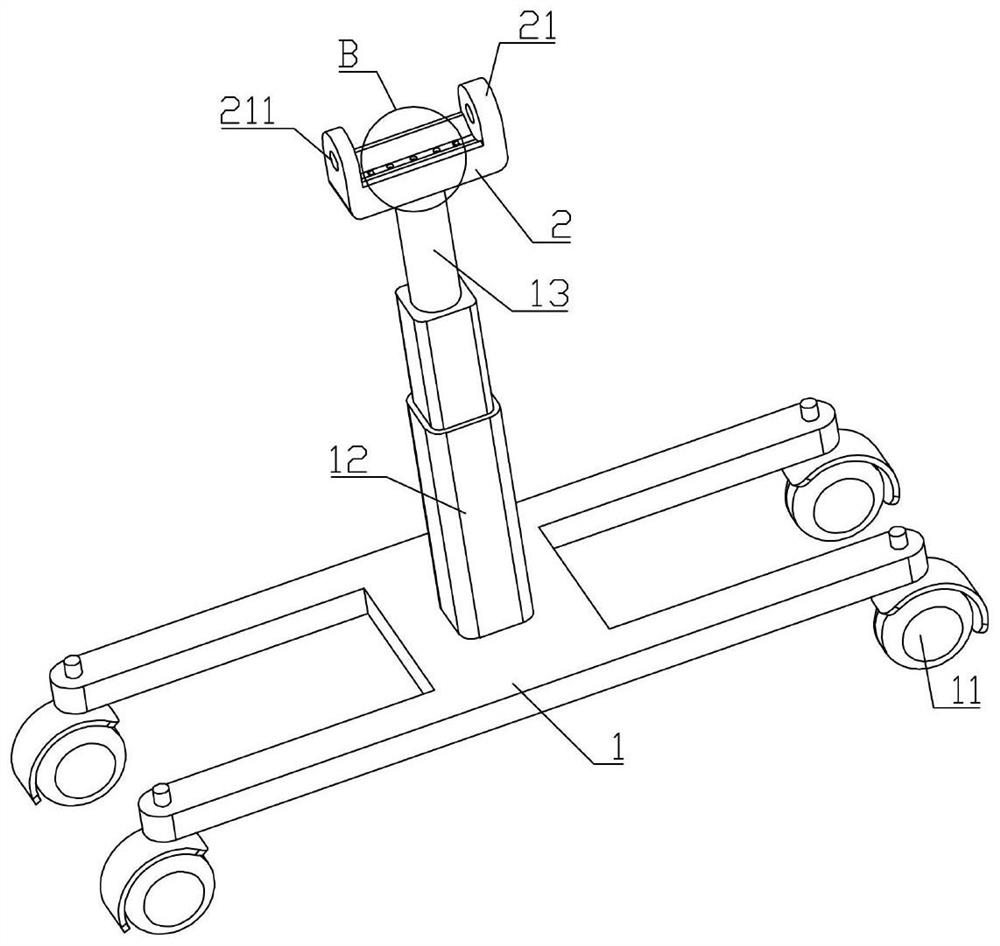

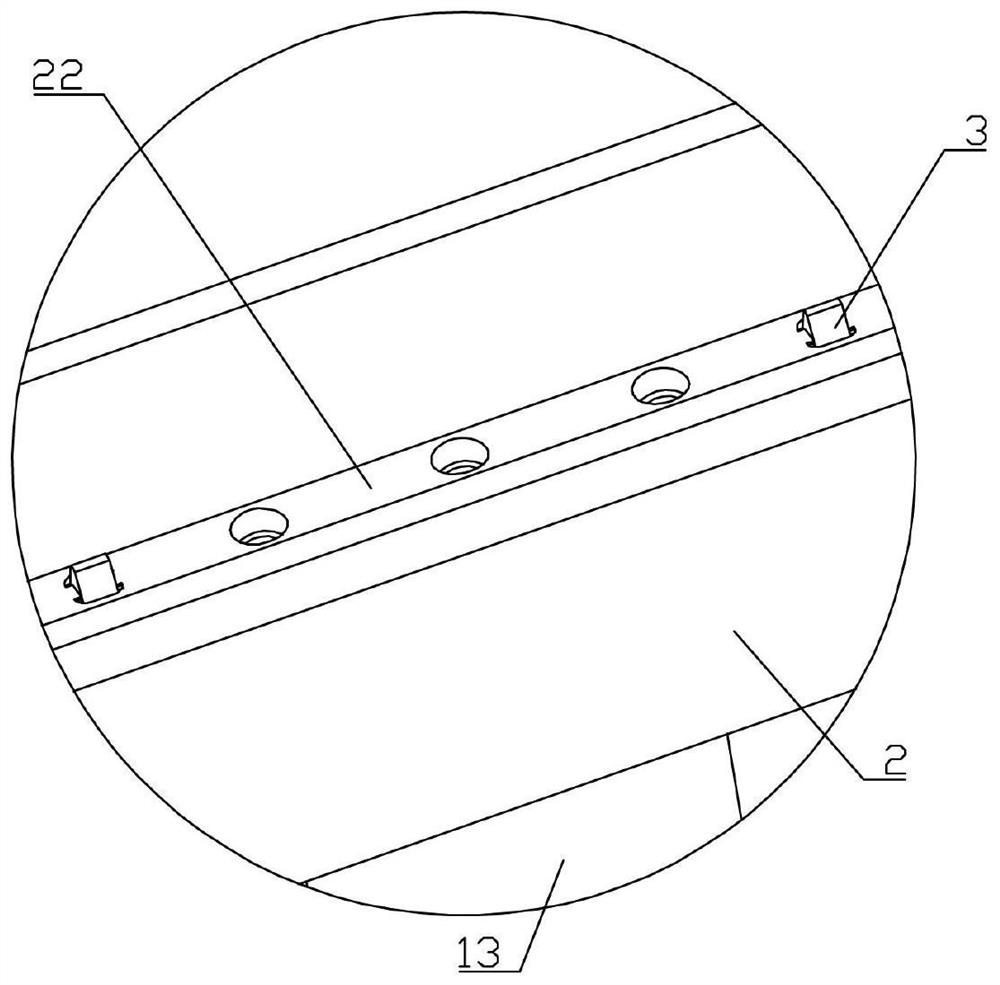

Wall surface polisher

InactiveCN108436647AIncrease speedAvoid overheatingPlane surface grinding machinesGrinding/polishing safety devicesWater flowEngineering

The invention discloses a wall surface polisher. The wall surface polisher comprises a water accumulation tank and a grinding device; the middle part of the internal bottom wall of the water accumulation tank is fixedly connected with a hydraulic device; the top of the right side of the water accumulation tank fixedly communicates with a water feeding pipe; the right side of the water feeding pipeis in threaded connection with a sealing cover; the bottom of the grinding device is fixedly connected with a hanging rod; and the bottom of the hanging rod is fixedly connected with a handheld handle. When the wall surface polisher is in use, the water in an inner chamber of the water accumulation tank is fed into a water charging pipe via a No.1 hose by starting a water feeding pump; the watercharging pipe is used for guiding water flow into an inner chamber of a flow guide tank so that the water flow flows leftwards at the top of a partition plate and pushes blades to rotate, and thus a polishing disc is used for driving a steel wire brush to rotate at a high speed so as to polish a wall; the grinding device is powered by adopting hydraulic power, so the problem about generation of over heat is prevented when the wall surface polisher is in use.

Owner:陶锋

Supercritical CO with uniform combustion and anti-corrosion and anti-coking 2 Boilers and Boiler Systems

ActiveCN112161261BImprove uniformitySpray evenlyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSupercritical steam generatorCombustion chamber

The supercritical CO with uniform combustion and anti-corrosion and anti-coking disclosed in the present invention 2 The boiler and boiler system include the main combustion chamber, the upper furnace, the folding flame angle and the flue. The cross-section of the main combustion chamber is circular, oval or N-shaped, and N>4, and there are at least four Burner group, each group of burner nozzles corresponding to each burner group includes recirculation air nozzles, primary air nozzles and secondary air nozzles, and there are symmetrically distributed side recirculation air nozzles on both sides of the primary air nozzles. The nozzles and side recirculation air nozzles are used to feed recirculated flue gas or a mixture of recirculated flue gas and secondary air into the main combustion chamber, and the primary air nozzles are used to feed primary air or primary air and secondary air into the main combustion chamber. The mixed gas of the circulating flue gas, the secondary air nozzle is used to send the secondary air or the mixed gas of the secondary air and the recirculating flue gas into the main combustion chamber, so that the supercritical carbon dioxide boiler and the boiler system are loaded evenly, and avoid the boiler wall High temperature corrosion and coking and slagging occur.

Owner:HUAZHONG UNIV OF SCI & TECH

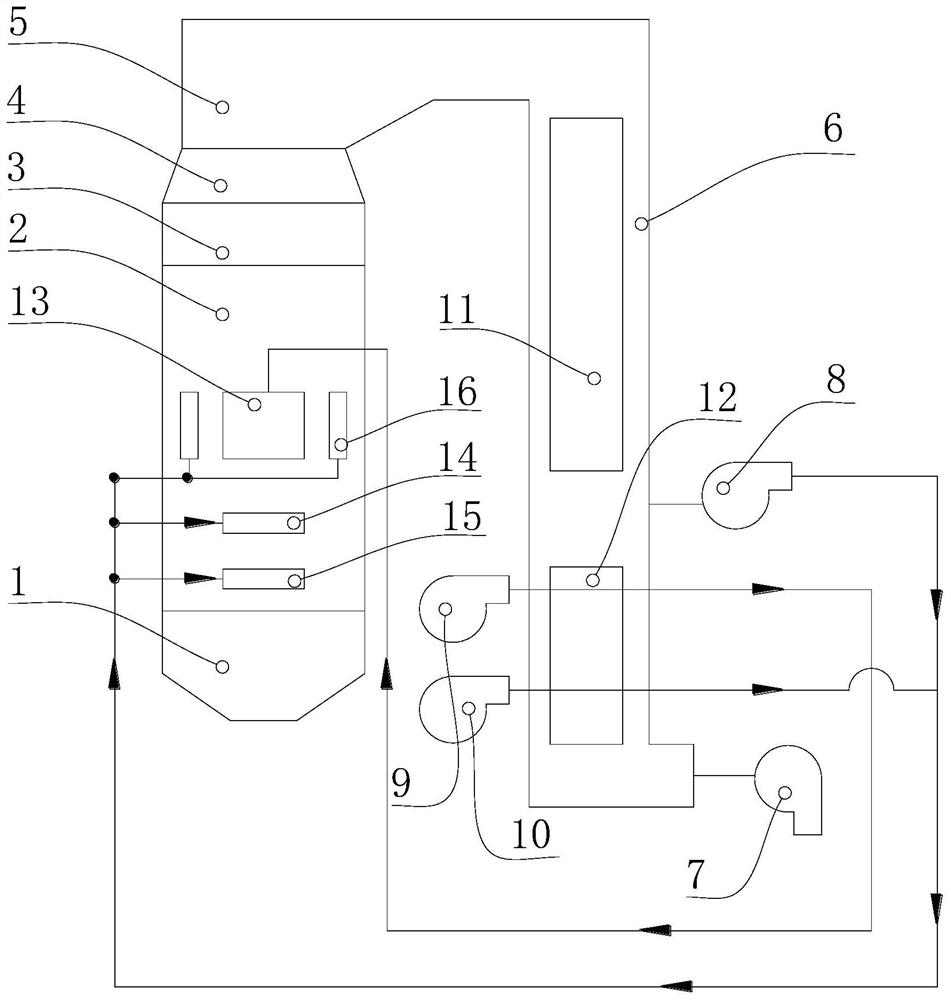

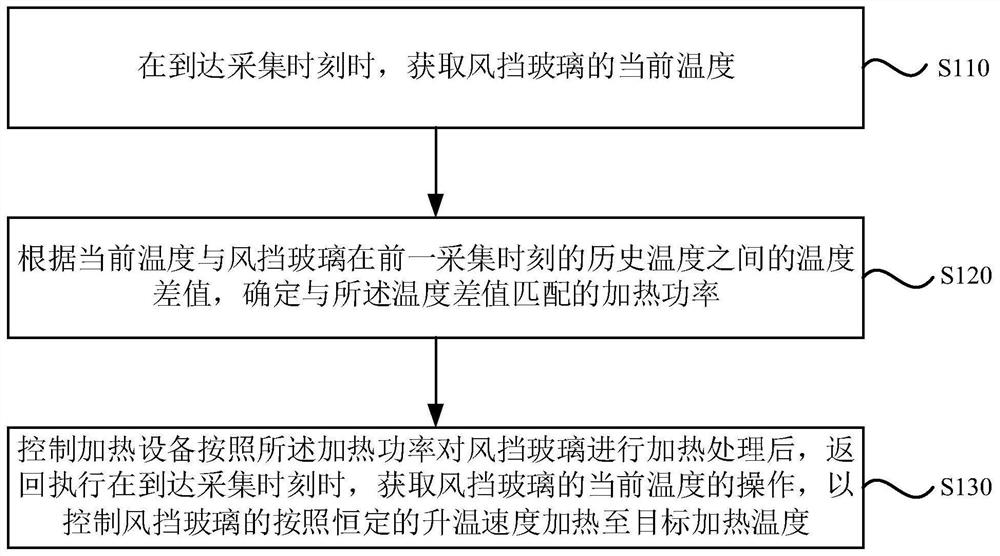

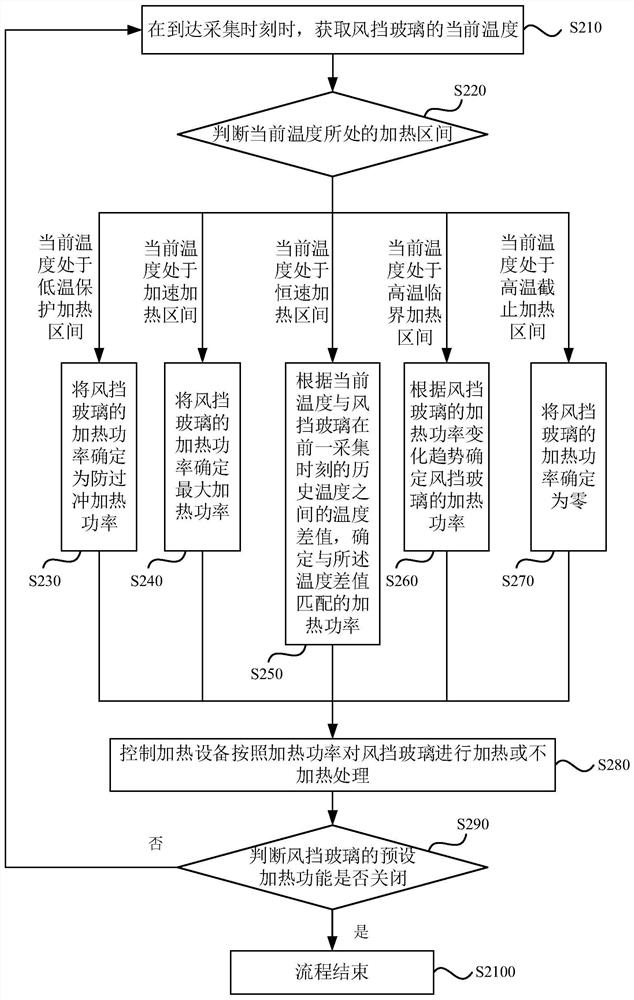

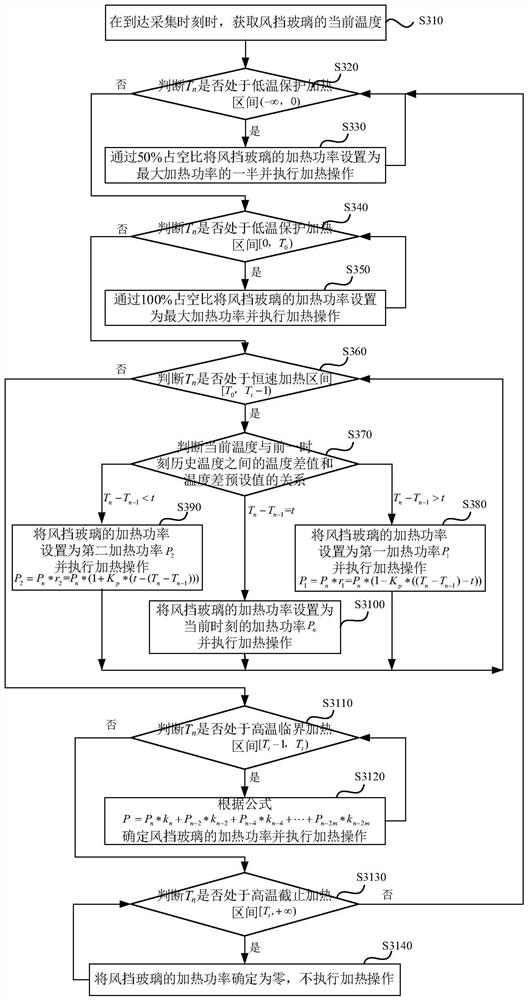

Heating control method, device, equipment and medium for helicopter windshield

ActiveCN110422312BImprove controllabilityGuaranteed to workAircraft accessoriesVehicle cleaningEngineeringHeat control

The embodiment of the invention discloses a heating control method, device, equipment and medium for a windshield glass of a helicopter. The method includes: acquiring the current temperature of the windshield when the collection time is reached; determining the temperature difference that matches the temperature difference according to the temperature difference between the current temperature and the historical temperature of the windshield at the previous collection time. heating power; after controlling the heating device to heat the windshield according to the heating power, return to the operation of obtaining the current temperature of the windshield when the collection time is reached, so as to control the windshield according to a constant temperature rise Speed heating to target heating temperature. The above technical solution improves the controllability of the windshield heating rate when the helicopter windshield glass defogging and anti-icing functions are turned on, ensures the normal operation of the windshield glass, and avoids the problem of overshooting of the windshield glass heating up.

Owner:北京神导科技股份有限公司

Organic waste gas heat accumulating type heating power incinerator inlet waste gas heating device

InactiveCN106678807AAvoid Overheating ProblemsAddress pressure fluctuationsIncinerator apparatusCombustion chamberCombustor

The invention relates to organic waste gas heat accumulating type heating power incinerator inlet waste gas heating device which comprises an incinerator body. A gas inlet is formed in the upper portion of the incinerator body, a gas outlet is formed in the back end of the incinerator body, a burner is arranged at the front end of the incinerator body, and a burning chamber is arranged at the front end of the interior of the incinerator body; an air supplementing device is arranged at the front portion of the burning chamber, a flame retardant layer is arranged on the exterior of the burning chamber, and an air flow uniform distribution chamber is arranged on the exterior of the flame retardant layer; and a mixing chamber is arranged at the back end of the interior of the incinerator body, and a waste water spraying gun is arranged at the front portion of the mixing chamber. According to the organic waste gas heat accumulating type heating power incinerator inlet waste gas heating device, pressure fluctuation in a hearth is small, and low concentration waste water can be treated.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

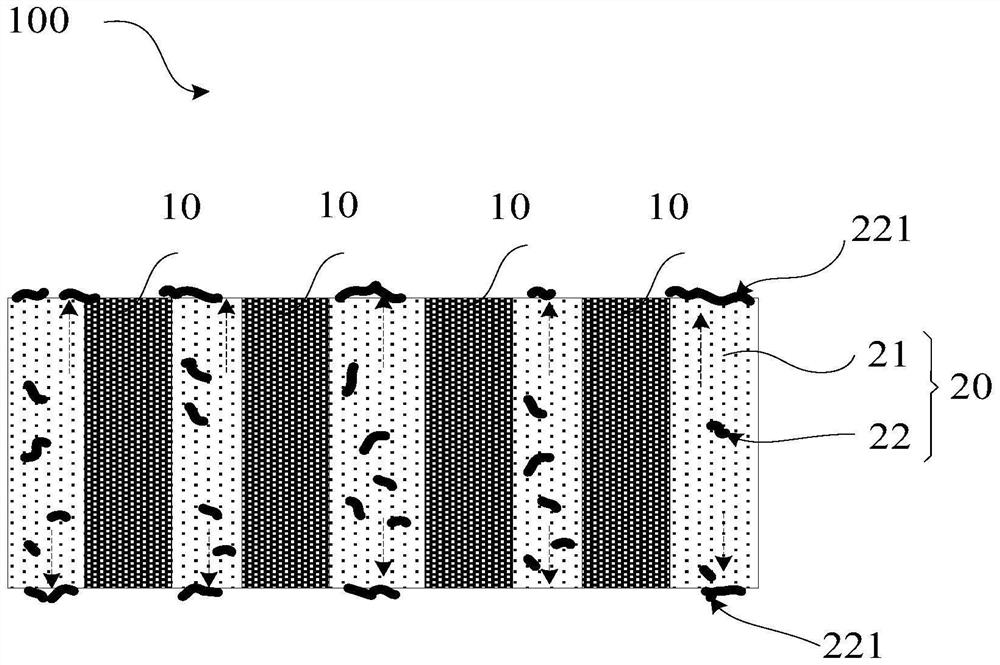

Heat conduction structure and manufacturing method thereof, heat conduction system, chip packaging structure and electronic equipment

PendingCN113889440AAvoid overheating problemsImprove microscopic wettabilitySemiconductor/solid-state device detailsSolid-state devicesThermodynamicsEngineering

The embodiment of the invention provides a heat conduction structure and a manufacturing method thereof, a heat conduction system, a chip packaging structure and electronic equipment. According to the invention, a second organic material in the heat conduction structure is diffused to the outer surface of the heat conduction structure, the second organic material diffused outwards forms a bonding layer between the heat conduction structure and a heating element and / or between the heat conduction structure and a radiator, and the bonding layer connects the heat conduction structure with the heating element and / or connects the heat conduction structure with the radiator, so that the heat conduction structure is ensured to be in close contact with the surface of the heating element / radiator so as to avoid the problem of overtemperature of the heating element caused by layering of an interface between the heat conduction structure and the heating element / radiator in the use process; and local micropores between the heat conduction structure and the heating element and between the heat conduction structure and the radiator can be filled with the second organic material which diffuses outwards, so that the micro wettability of the heat conduction structure is improved so as to reduce the interface contact thermal resistance and reduce the application thermal resistance of the heat conduction structure.

Owner:HUAWEI TECH CO LTD

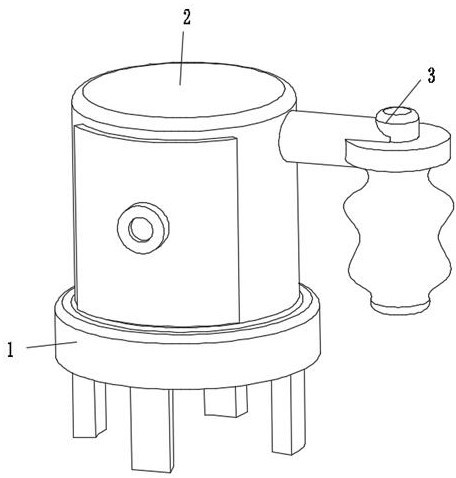

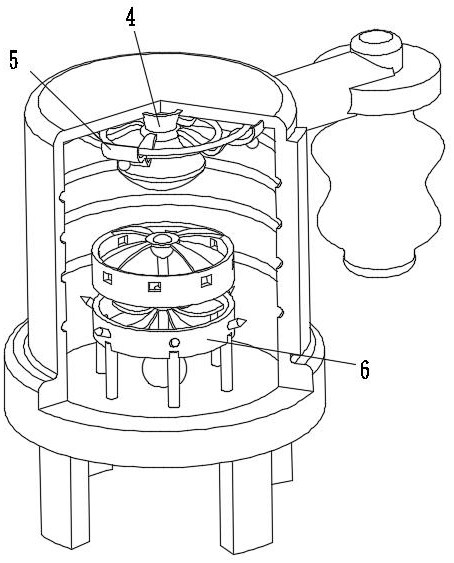

New energy power element surface plating device

ActiveCN113463016ASolve the problem of full contactStop work in timeVacuum evaporation coatingSputtering coatingPhysicsPumping vacuum

The invention discloses a new energy power element surface plating device, and relates to the technical field of new energy machines. The new energy power element surface plating device comprises a base, wherein the top of the base is fixedly connected with a tank body, the upper position of the surface of the tank body is fixedly connected with vacuumizing equipment, the top of the inner side surface of the tank body is fixedly connected with a bombardment mechanism, a dust settling mechanism is fixedly connected to the upper side of the surface of the bombardment mechanism, a stirring mechanism is fixedly connected to the bottom of the inner side face of the tank body, a mixing mechanism is fixedly connected to the top of the stirring mechanism, and the bombardment mechanism comprises a connecting wall. According to the new energy power element surface plating device, through cooperative use of the stirring mechanism, the mixing mechanism, the bombardment mechanism, the dust settling mechanism and other mechanisms, the problem of how to separately feed protective gases of all components and conduct effective stirring, the problem that the surface, making contact with a bearing table, of a plated element cannot be plated, and the problem of how to make target evaporation ions fully contact with the surface of an electric appliance element are solved.

Owner:南通正耀电气科技有限公司

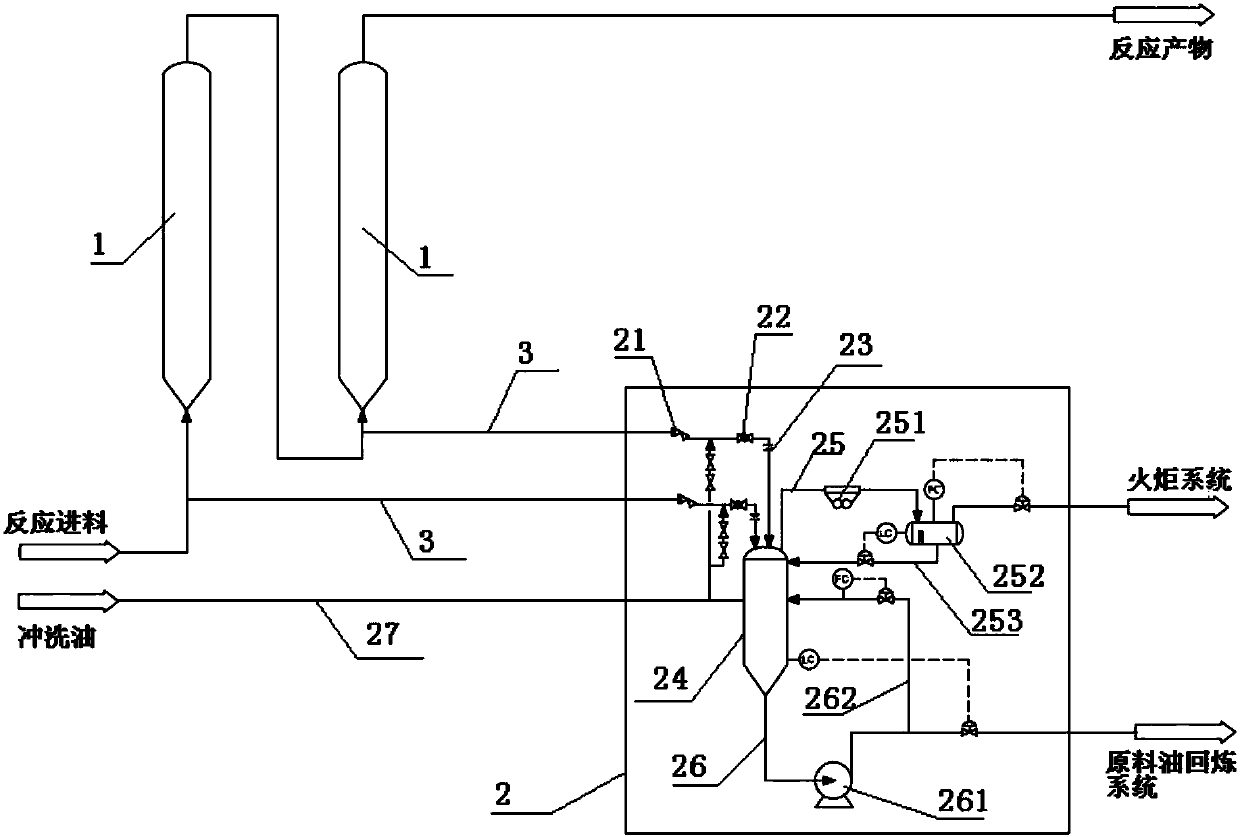

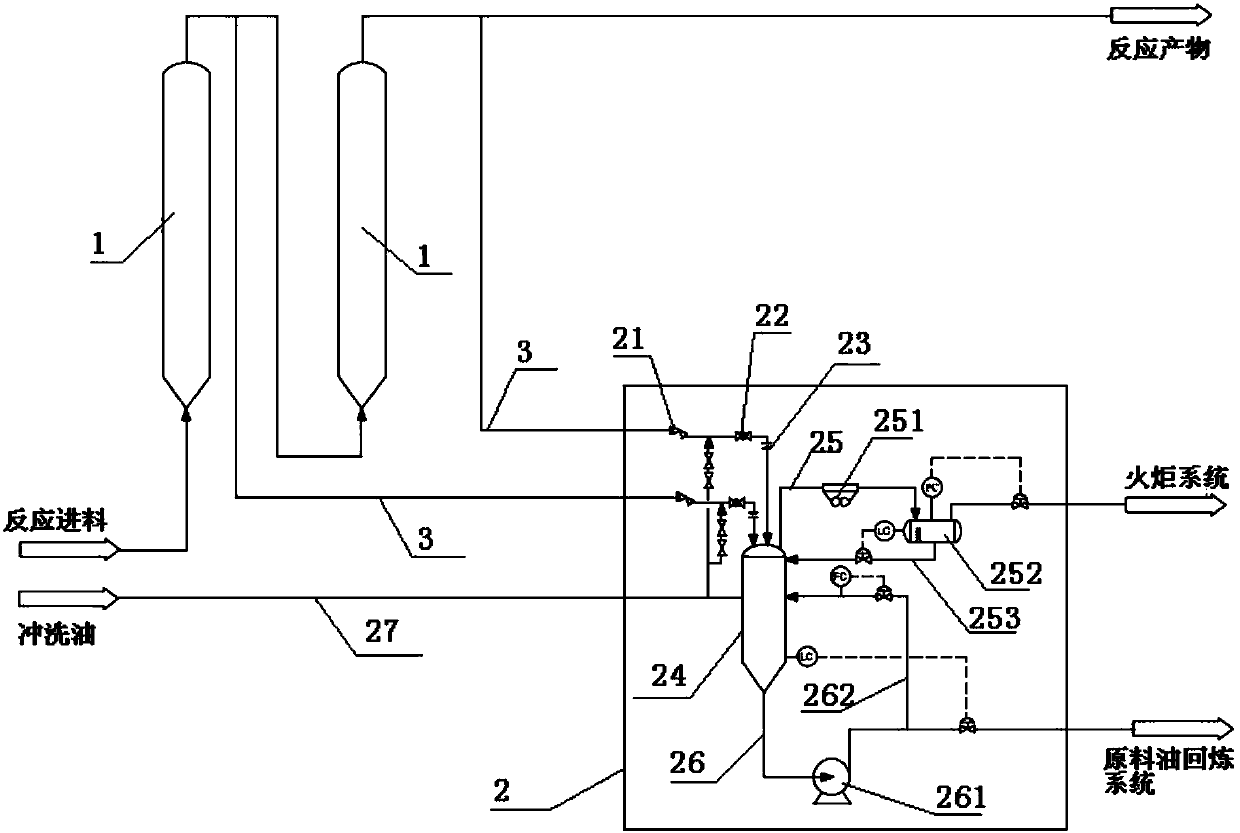

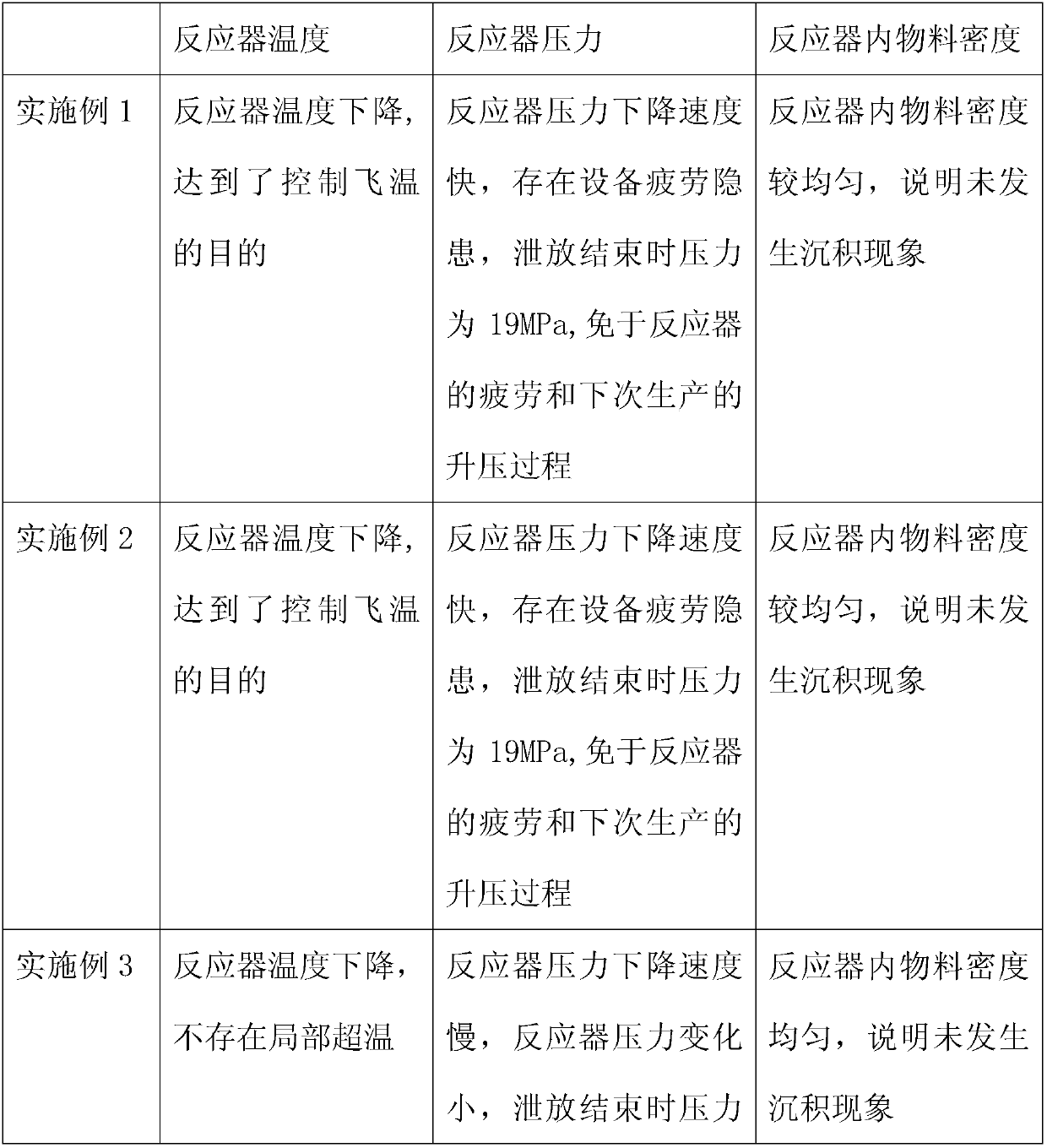

Suspended bed hydrogenation discharge process

ActiveCN107805520AReduce flow rateAvoid shockHydrocarbon oil crackingChemical/physical processesGas phaseTorch

The invention provides a suspended bed hydrogenation discharge process, which comprises a suspended bed hydrogenation reactor, a discharge pipeline, a cooling separation system, a torch system and a raw oil recycling system. According to the process, when the temperature of the suspended bed hydrogenation reactor instantaneously rises and exceeds the normal reaction temperature, the material inletvalve on the material inlet pipeline is closed, and the discharge valve group is opened; the liquid-solid phase material in the suspended bed hydrogenation reactor is discharged into the cooling separation system through the bottom portion; and the cooled and separated gas phase material is discharged to the torch system, and the liquid-solid phase material is discharged to the raw material oil recycling system so as to achieve the emergency discharge of the suspended bed hydrogenation reactor. According to the present invention, the liquid phase and the catalyst solid in the suspended bed hydrogenation reactor are rapidly discharged during the emergency discharge to stop the occurrence of the reaction, such that the thermal runaway of the suspended bed hydrogenation reactor can be avoided, the temperature in the reactor can be effectively controlled, the safety can be improved, the pressure in the suspended bed hydrogenation reactor can be stabilized at the high pressure, the equipment fatigue caused by the frequent pressure increase and pressure reduce can be avoided, and the energy consumption and the cost can be reduced.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

Boiler start-up method to prevent scale formation and secondary combustion accidents in tail flue of 1000mw octagonal tangential boiler

The invention discloses a boiler starting method for preventing oxide skin generation of a 1,000 MW octagonal tangent circle boiler and a secondary combustion accident of a tail flue. Boiler warming is carried out before a combustor is put into operation, then, the combustor is put into operation, and the operation of the combustor is adopted according to the following operation principles that all large oil guns in an AB layer and part of large oil guns in a CD layer are put one by one, and when the outlet pressure of a boiler steam-water separator reaches 0.3 MPa, all micro oil guns in an A layer are put, and then a powder manufacturing system of the A layer is put into operation; and at the thermal state flushing and temperature rising and boosting stage, part of or all large oil guns quit one by one according to the pulverized coal combustion situation, and at the load rising stage, powder manufacturing systems are put into operation layer by layer according to the load situation. According to the method, the temperature rising rate of a heating surface of the boiler in the starting process can be controlled, and the good combustion effect of the pulverized coal in a hearth can be guaranteed; and generation of pipe oxide kin of the heating surface of the boiler is effectively prevented, and the purposes of preventing secondary combustion of the tail flue and the detonation accident of the hearth can be achieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

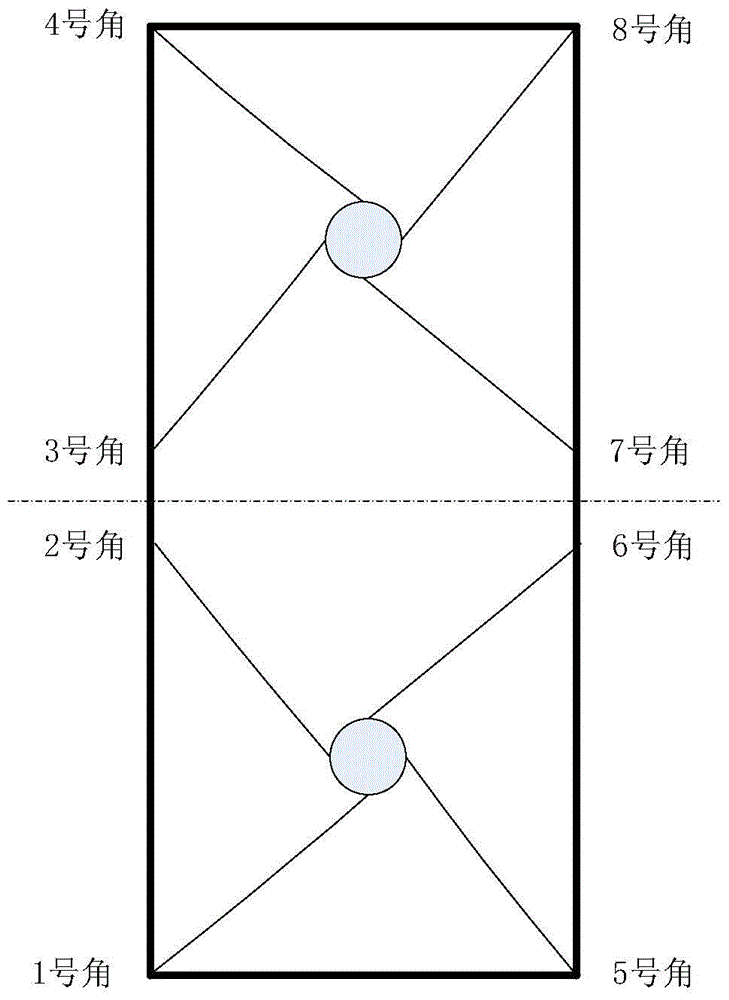

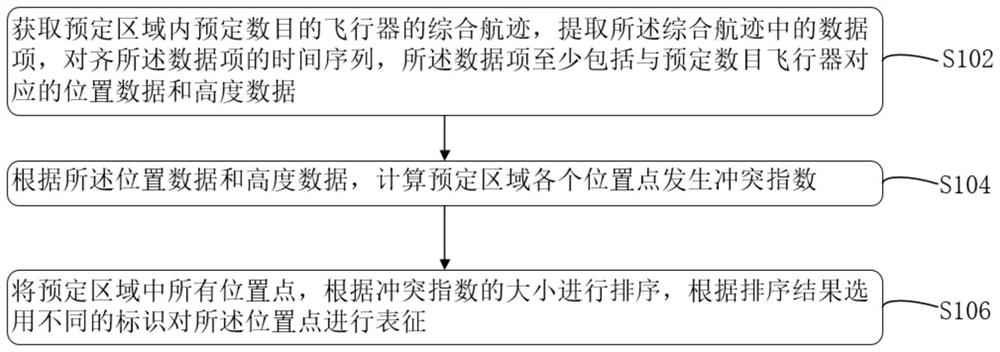

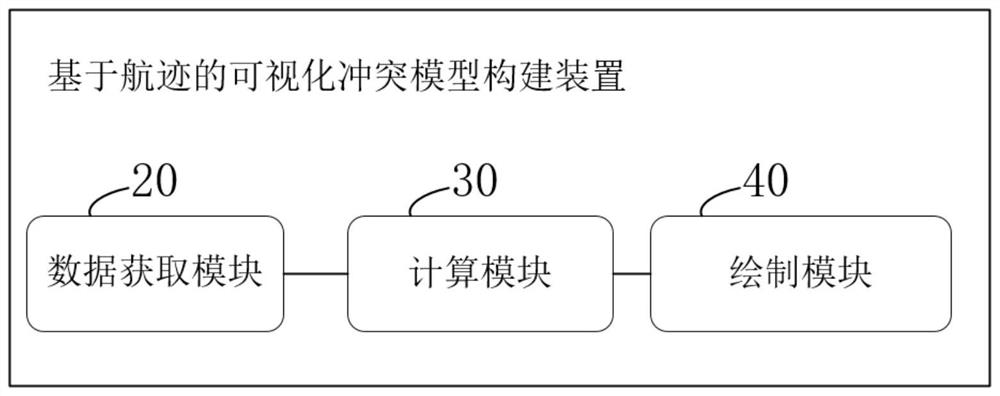

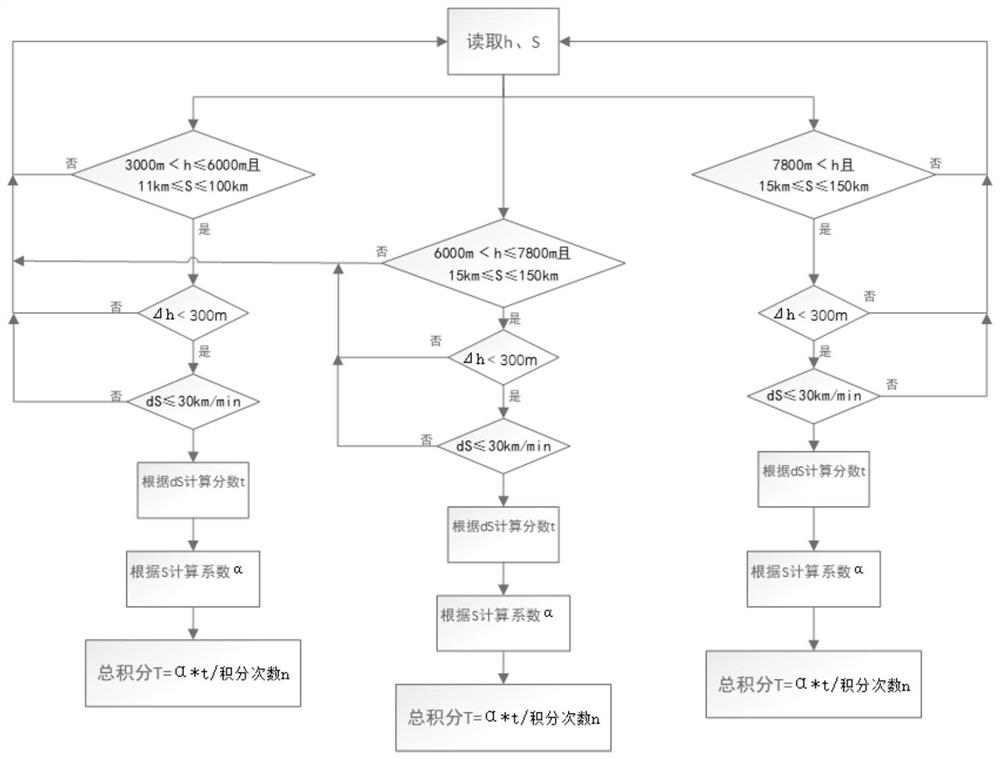

Visual conflict model construction method and device based on flight path, electronic equipment and storage medium

ActiveCN112231389AAccurate calculationAvoid overheating problemsVisual data miningStructured data browsingFlight vehicleRoad traffic control

The invention discloses a visual conflict model construction method and device based on a flight path, electronic equipment and a storage medium, and belongs to the technical field of air traffic management. The method comprises the following steps: acquiring comprehensive flight paths of a predetermined number of aircrafts in a predetermined area, extracting data items in the comprehensive flightpaths, and aligning a time sequence of the data items; according to the position data and the height data corresponding to the aircraft, calculating a conflict index of each position point in a predetermined area; sorting all the position points in the predetermined area according to the conflict indexes, selecting different identifiers according to the sorting result to represent the position points, establishing a conflict model based on track data, and drawing conflict thermodynamic diagrams of different height intervals by using actual operation data, so the control operation safety riskcan be effectively prompted, the air traffic control service efficiency is improved, and a certain reference is provided for airspace management planning.

Owner:EASTERN CHINA AIR TRAFFIC MANAGEMENT BUREAU CAAC

Grinding and casing milling workover tools manufacturing technology and mold

InactiveCN106041257BImprove impact toughnessImprove wear resistanceWelding/cutting auxillary devicesArc welding apparatusFilling materialsAlloy

The invention discloses a manufacturing process of a grinding, casing milling and well repairing tool. Firstly, a to-be-machined casing is sleeved with a mold, the end portion of the mold is provided with inner edges extending towards the axis, and gaps are reserved between the inner edges and the end face of the to-be-machined casing; after the to-be-machined casing and the mold are preheated to a surfacing temperature, the end face of the to-be-machined casing is coated with soldering flux, and surfacing of priming weld layers is started; YD hard alloy particles are subjected to horizontal surfacing in the gaps; and after the surfacing is completed, the mold is dismantled, the welded tool is subjected to postwelding heat preservation and is cooled after heat preservation is performed for a period of time, and welding is completed. A filling material can flow in the gaps between the mold and the casing due to the welding manner, the particles are distributed evenly to achieve the purpose of the horizontal surfacing, the above welding temperature is stable, the temperature loss is avoided as much as possible, the welding strength and the welding efficiency are improved, and therefore the impact toughness, the abrasion resistance, the service life and other indexes of the tool are improved. The invention discloses the mold for manufacturing the grinding, casing milling and well repairing tool at the same time.

Owner:邵元龙

Laundrytreatment equipment

PendingCN114075769AAvoid temperatureAvoid the problem of easily burning the userTextiles and paperLaundry driersThermodynamicsProcess engineering

The invention belongs to the technical field of clothes treatment, and particularly provides clothes treatment equipment, and aims at solving the problem that the temperature of a table top is too high due to the fact that the arrangement mode of a heating component of an existing drying device is not good. Therefore, the clothes processing equipment comprises a shell, a clothes processing barrel and a drying assembly, the drying assembly comprises a drying air channel, a condensation component, a drying fan and a heating component, the condensation component, the drying fan and the heating component are sequentially arranged in the drying air channel in the airflow direction, and an air inlet and an air outlet of the drying air channel communicate with the clothes processing barrel; a heat insulation cleaning component is arranged between the heating component and the shell, cooling liquid circulates in the heat insulation cleaning component to achieve the heat insulation effect, and therefore the problem that a user is scalded easily due to the fact that the temperature of the shell is too high is effectively avoided; the cooling liquid flowing out of the heat insulation cleaning component can be sprayed to the condensation component to achieve the cleaning effect, and then the dehumidification effect of the condensation component is effectively guaranteed.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

An image diagnostic device for radiology

InactiveCN108732768BAvoid overheating problemsAvoid wastingOptical elementsEngineeringMechanical engineering

The invention belongs to the technical field of medical devices, and in particular relates to a radiological image diagnostic reading device, which comprises an I-shaped base, a sleeve is set on the first sliding rod, and two second sliding rods are arranged between the two sleeves , the outer wall of the bottom cover is provided with a chute matching the second slide bar, the bottom cover is clamped between the two second slide bars through the chute, the inner cover of the bottom cover is provided with a middle cover, and a convex lens is installed in the middle cover, The front end of the strip plate is provided with a through groove, and the transparent plate is provided with a first strip groove at the corresponding position of the through groove. The length of the first strip groove is greater than the length of the through groove. The second bar-shaped slot matched with the bar-shaped slot, a pressing bar is arranged between the first bar-shaped slot and the second bar-shaped slot, and the button switch is installed on the wire between the storage battery and the lamp tube. Its purpose is to solve the problems of inconvenient use, easy drop of X-ray film, low life of lamp tube and inability to zoom in and view parts of the existing diagnostic film reading device caused by structural defects.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

A new energy power component surface coating device

ActiveCN113463016BSolve the problem of full contactStop work in timeVacuum evaporation coatingSputtering coatingNew energyPumping vacuum

The invention discloses a surface coating device for new energy power components. The invention relates to the technical field of new energy machinery and includes a base. Vacuum equipment, the top of the inner side of the tank is fixedly connected with a bombardment mechanism, the upper position of the surface of the bombardment mechanism is fixedly connected with a dust suppression mechanism, the bottom of the inner side of the tank is fixedly connected with a stirring mechanism, and the top of the stirring mechanism is fixed A mixing mechanism is connected, said bombardment mechanism comprising a connecting wall. The new energy power component surface coating device solves how to separate and effectively stir the protective gas of each component through the combined use of the stirring mechanism, the mixing mechanism, the bombardment mechanism and the dust reduction mechanism, and the coated component and the carrying platform The surface in contact cannot be coated, and how to make the evaporated ions of the target material fully contact the surface of the electrical component.

Owner:南通正耀电气科技有限公司

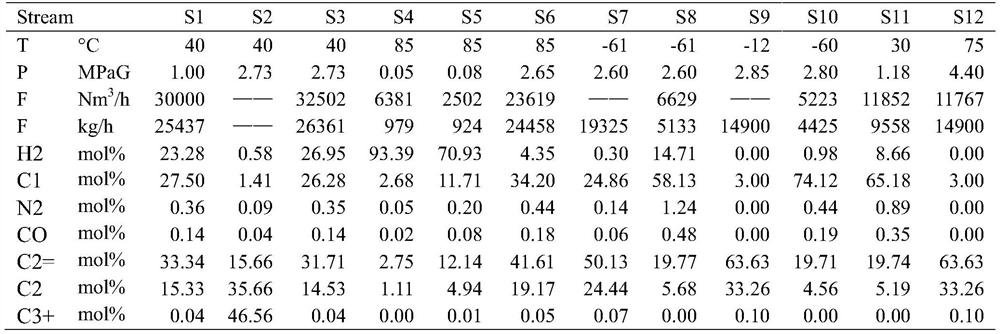

A separation process for ethylene-rich cracking dry gas classification used in ethylbenzene production equipment

ActiveCN110055098BImprove condensation effectMake full use ofHydrocarbon oils treatmentFluid phasePhysical chemistry

Owner:DALIAN UNIV OF TECH

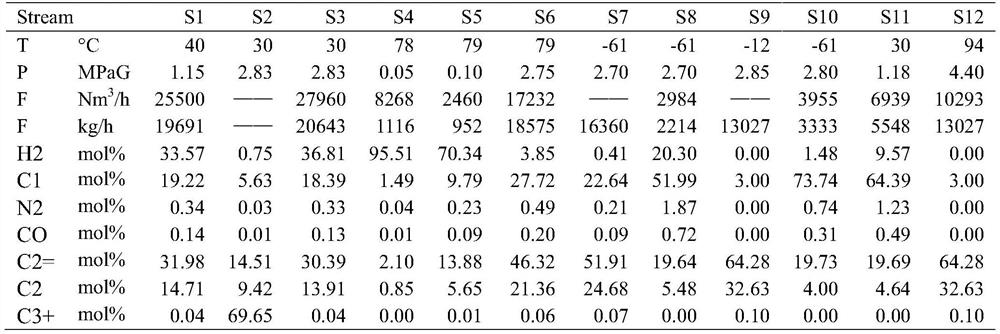

Refrigerator unfreezing control method and system and refrigerator

ActiveCN114061256AEasy time managementThaw evenlyLighting and heating apparatusCooling fluid circulationHeating timeIcebox

The invention discloses a refrigerator unfreezing control method and system and a refrigerator. The method comprises the following steps of: identifying a to-be-unfrozen article and an unfreezing mode preset by a user; determining an unfreezing time parameter of segmented unfreezing operation according to the weight of the to-be-unfrozen article and the unfreezing mode; and according to the unfreezing time parameter, performing segmented unfreezing operation on the to-be-unfrozen article. The invention provides a scheme for uniformly heating the to-be-unfrozen article in a segmented manner according to the weight of the to-be-unfrozen article and the unfreezing requirement of the user, so that the problem of overhigh surface temperature of food caused by overlong one-time heating time is avoided; food can be unfrozen uniformly inside and outside, and partial overheating is avoided; and the segmented unfreezing process has corresponding unfreezing time parameters, so that the user can master the unfreezing process, time management of the user is facilitated, and thus, the method is more user friendly.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com