Suspended bed hydrogenation discharge process

A suspension bed and process technology, applied in the petroleum industry, hydrocarbon oil cracking, chemical instruments and methods, etc., can solve the problems of difficult reactor temperature, high cost, low safety factor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

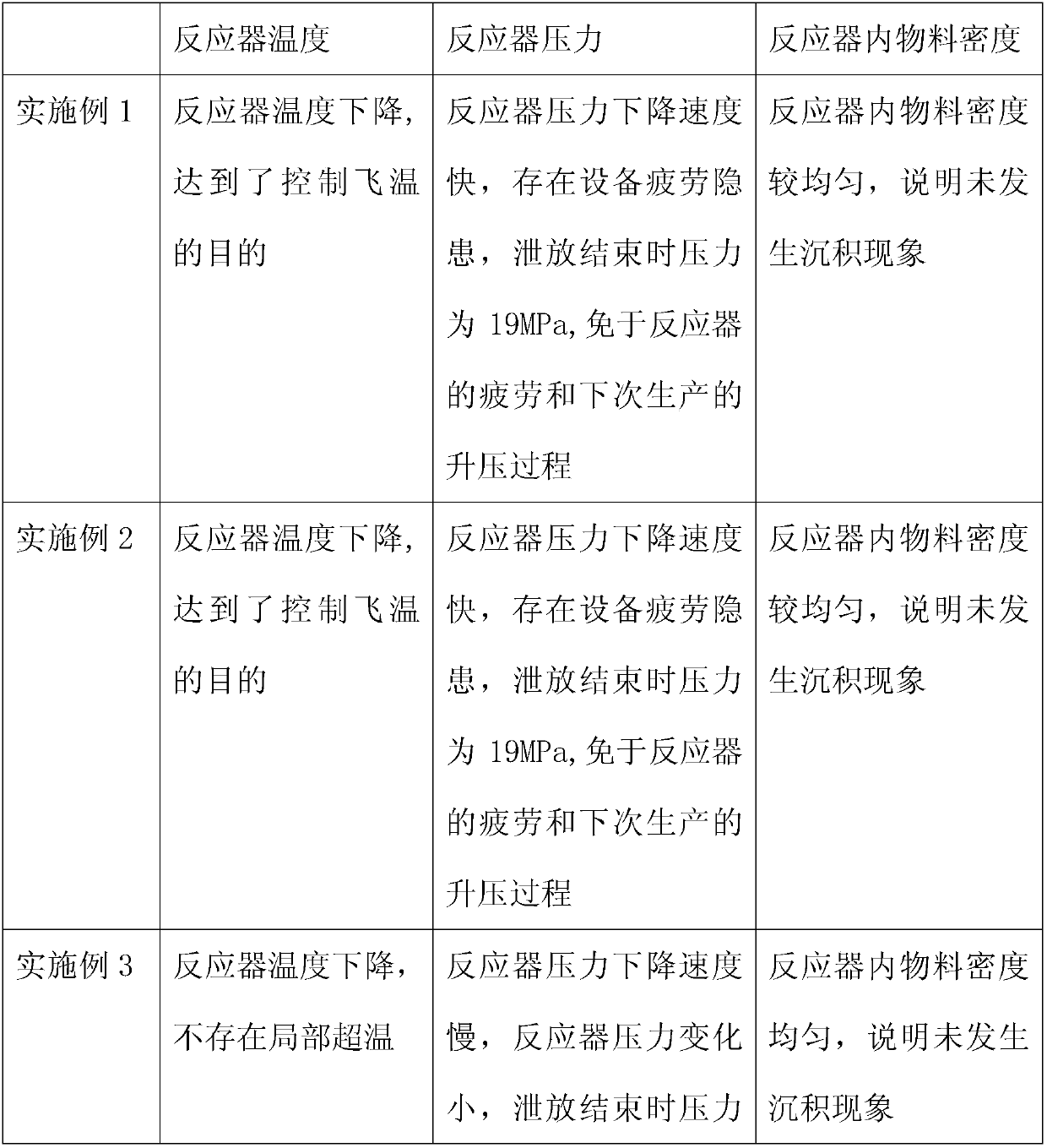

Embodiment 1

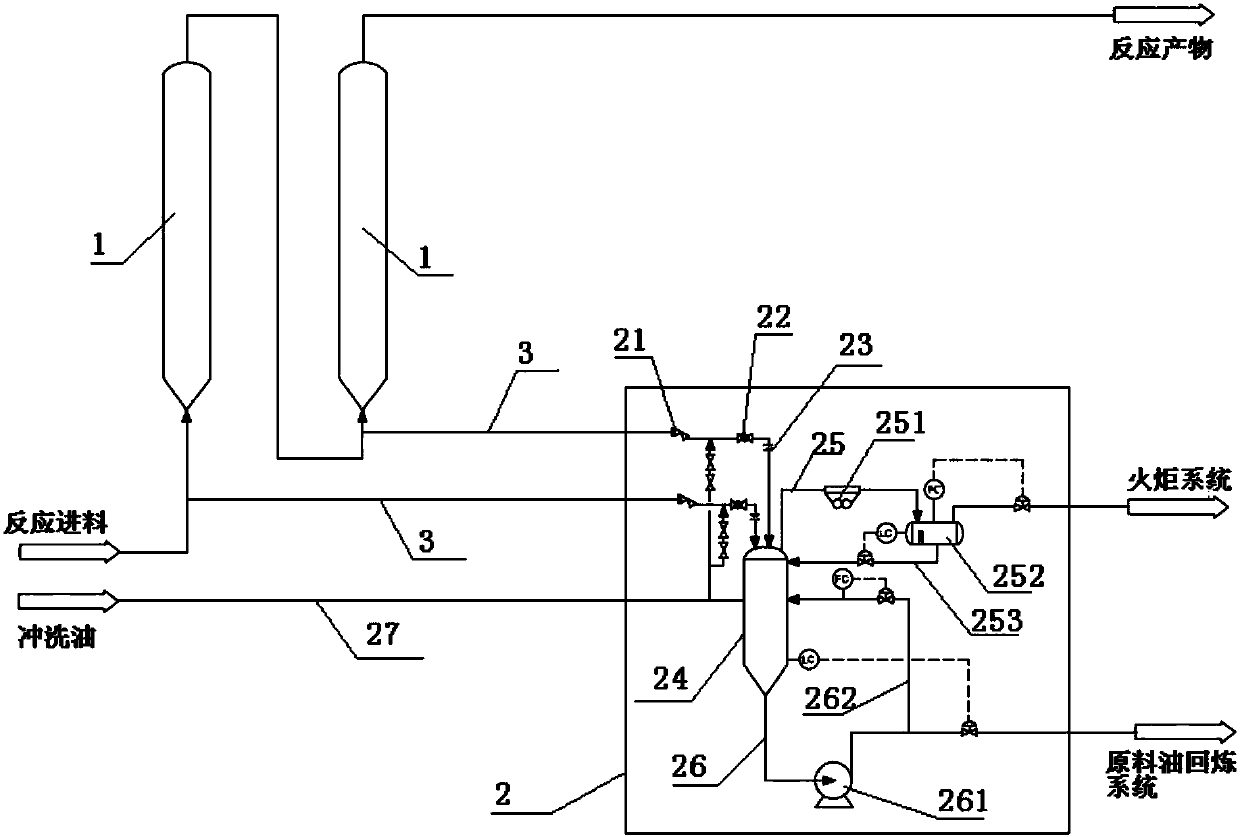

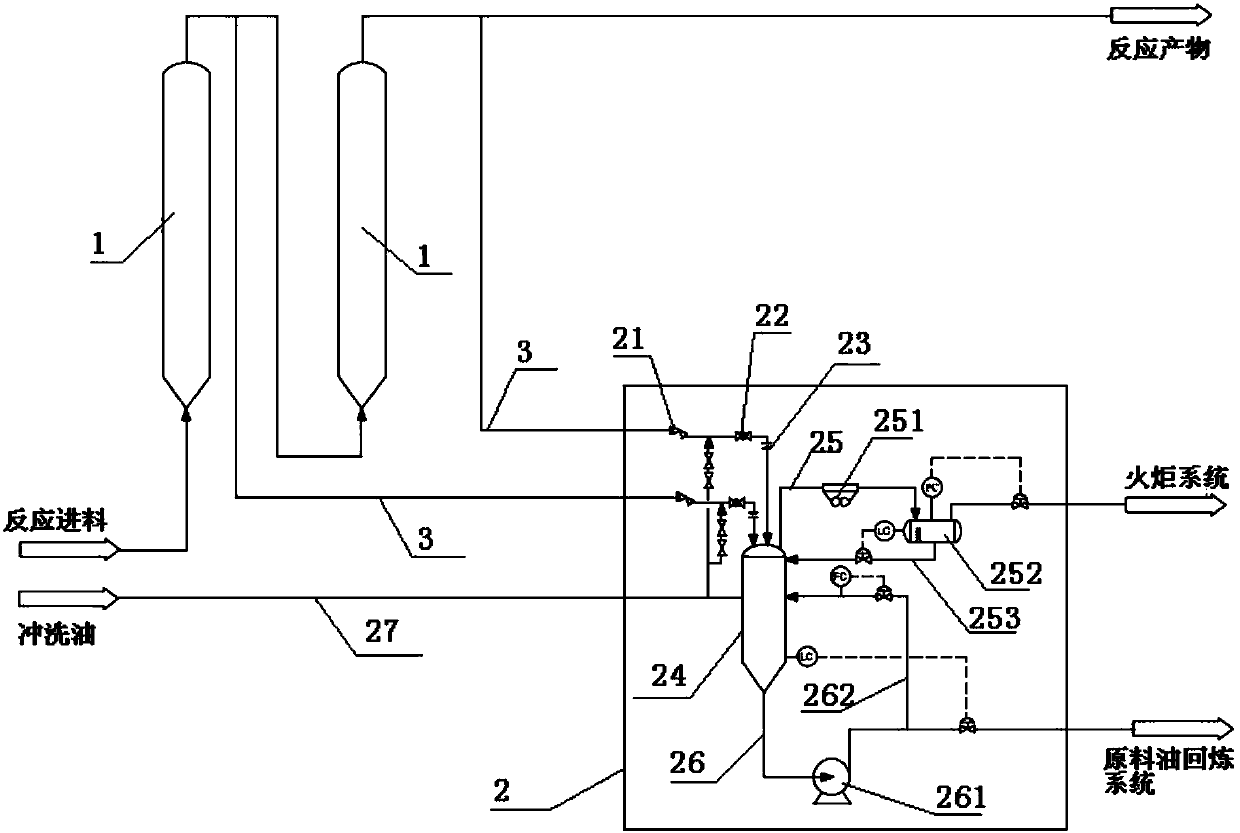

[0033] The suspension bed hydrogenation bleeding process described in this embodiment, the suspension bed hydrogenation bleeding process includes a suspension bed hydrogenation reactor 1, a bleeding pipeline 3, a cooling separation system 2, a flare system, and a raw oil refining system , when the temperature of the suspended bed hydrogenation reactor 1 rises instantaneously and exceeds the normal reaction temperature, close the feed valve on the feed pipeline connected to the bottom of the suspended bed hydrogenation reactor 1, and open the suspended bed hydrogenation reactor The discharge valve group in the cooling separation system 2 connected to the bottom of the hydrogen reactor 1 through the discharge pipeline 3, the discharge valve group includes the high-pressure RAM valve 21 and the high-pressure ball valve 22, two suspended in series The liquid-solid phase reaction material in the bed hydrogenation reactor 1 enters the discharge pipeline 3 at the bottom of the suspens...

Embodiment 2

[0035] The suspension bed hydrogenation bleeding process described in this embodiment, the suspension bed hydrogenation bleeding process includes a suspension bed hydrogenation reactor 1, a bleeding pipeline 3, a cooling separation system 2, a flare system, and a raw oil refining system , when the temperature of the suspended bed hydrogenation reactor 1 rises instantaneously and exceeds the normal reaction temperature, close the feed valve on the feed pipeline connected to the bottom of the suspended bed hydrogenation reactor 1, and open the suspended bed hydrogenation reactor The discharge valve group in the cooling separation system 2 connected to the bottom of the hydrogen reactor 1 through the discharge pipeline 3, the discharge valve group includes the high-pressure RAM valve 21 and the high-pressure ball valve 22, two suspended in series The liquid-solid phase reaction material in the bed hydrogenation reactor 1 enters the discharge pipeline 3 at the bottom of the suspens...

Embodiment 3

[0037] The suspension bed hydrogenation bleeding process described in this embodiment, the suspension bed hydrogenation bleeding process includes a suspension bed hydrogenation reactor 1, a bleeding pipeline 3, a cooling separation system 2, a flare system, and a raw oil refining system , when the temperature of the suspended bed hydrogenation reactor 1 rises instantaneously and exceeds the normal reaction temperature, close the feed valve on the feed pipeline connected to the bottom of the suspended bed hydrogenation reactor 1, and open the suspended bed hydrogenation reactor The discharge valve group in the cooling separation system 2 connected to the bottom of the hydrogen reactor 1 through the discharge pipeline 3, the discharge valve group includes the high-pressure RAM valve 21 and the high-pressure ball valve 22, two suspended in series The liquid-solid phase reaction material in the bed hydrogenation reactor 1 enters the discharge pipeline 3 at the bottom of the suspend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com