Ultrasonic atomization structure and ultrasonic atomization device using the same

A technology of ultrasonic atomization and equipment, applied in the direction of nebulizers for treatment, etc., can solve problems such as damage, temperature rise and blockage of piezoelectric ceramic sheets, and achieve the effect of avoiding excessive heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0070] Specific structure description:

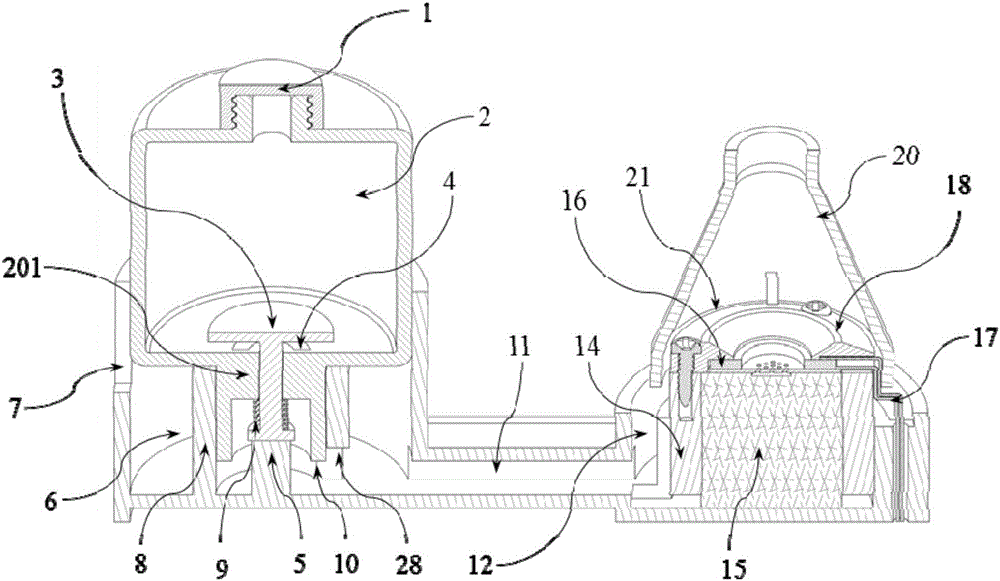

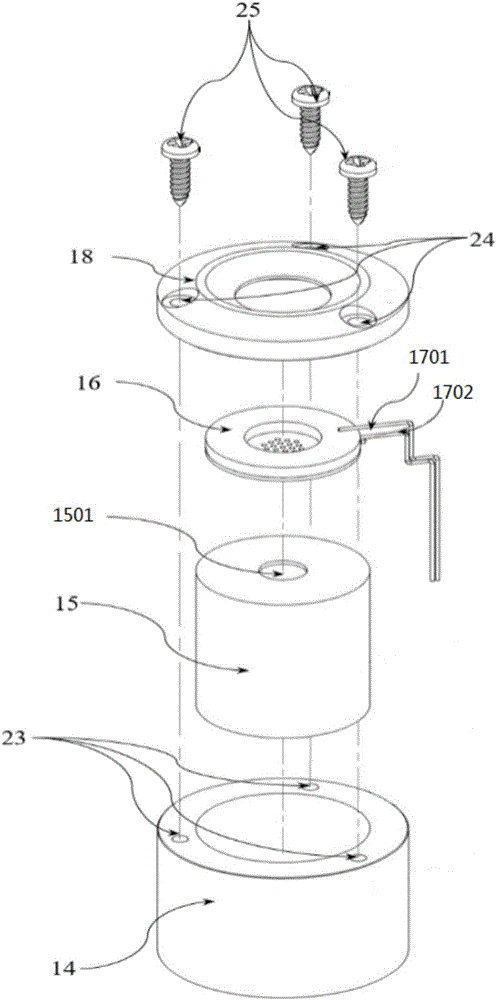

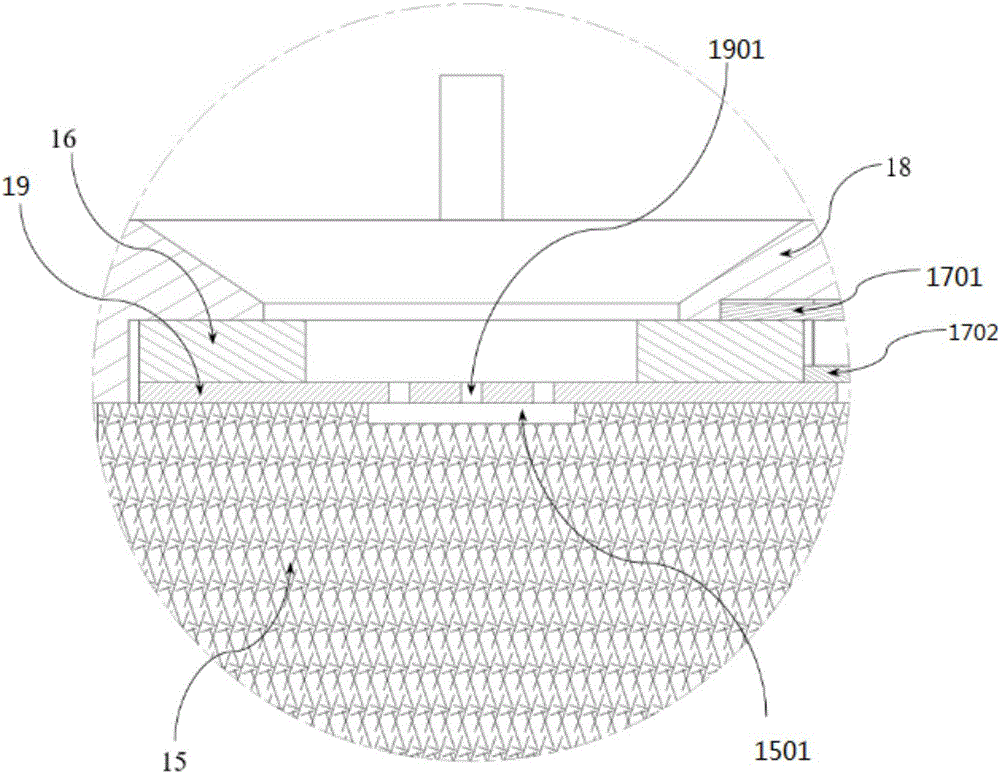

[0071] Such as figure 1 As shown, in this embodiment, an ultrasonic atomization device includes a liquid storage tank 2 and a liquid storage channel 6 arranged up and down, the outer side wall of the lower part of the liquid storage tank 2 and the inner side wall of the upper part of the liquid storage channel 6 Fitting, but relative rotation or sliding can occur between the two. The top of the liquid storage tank 2 is provided with an opening through which the liquid to be atomized can be added, and the opening is threadedly connected with the upper cover 1 , and of course it can also be designed as a quick connection such as a buckle connection. The bottom of the liquid storage tank 2 is provided with a discharge hole 4 below the upper part of the top plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com