Heat conduction structure and manufacturing method thereof, heat conduction system, chip packaging structure and electronic equipment

A heat-conducting structure and heat-conducting film technology are used in heat-conducting systems, heat-conducting structures and manufacturing methods thereof, and electronic equipment fields, and can solve the problem of high junction temperature of layered chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

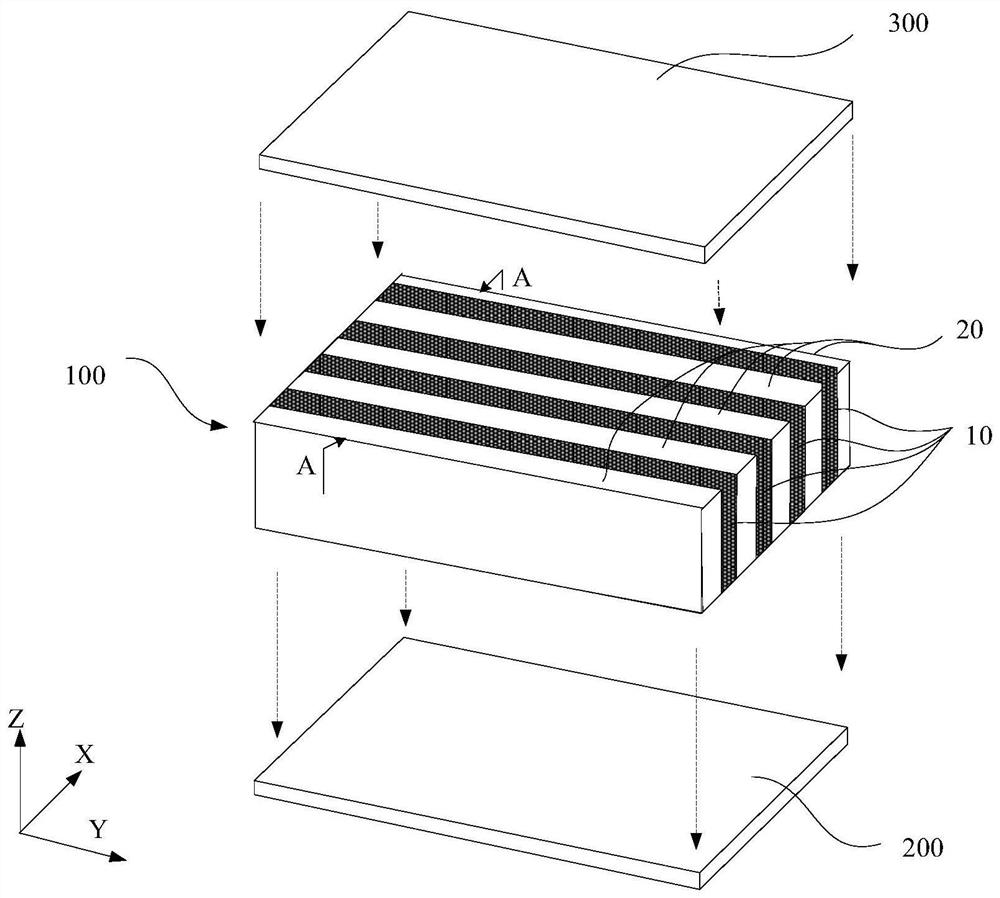

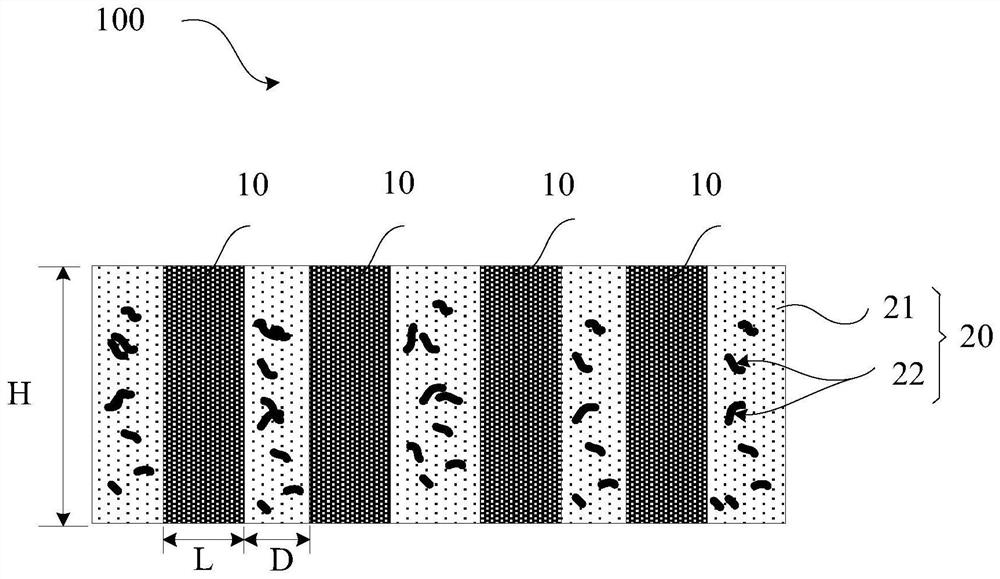

[0109] The heat conduction structure 100 provided by the embodiment of the present application can transfer the heat generated by the heating element 200 to the heat sink 300, see figure 1 As shown, the heat conducting structure 100 is located between the heating element 200 and the radiator 300, according to figure 1 After the arrow in the figure is assembled, one side of the heat conducting structure 100 is in contact with the heating element 200, and the other side of the heat conducting structure 100 can be in contact with the heat sink 300, so that the heat generated by the heating element 200 is transferred to the heat sink 300 through the heat conducting structure 100, thereby realizing the Heat dissipation of the heating element 200.

[0110] Wherein, the heating element 200 may be a chip or an electronic component that generates heat. In the embodiment of the present application, the heating element 200 is a chip as an example for illustration. The heat sink 300 can ...

Embodiment 2

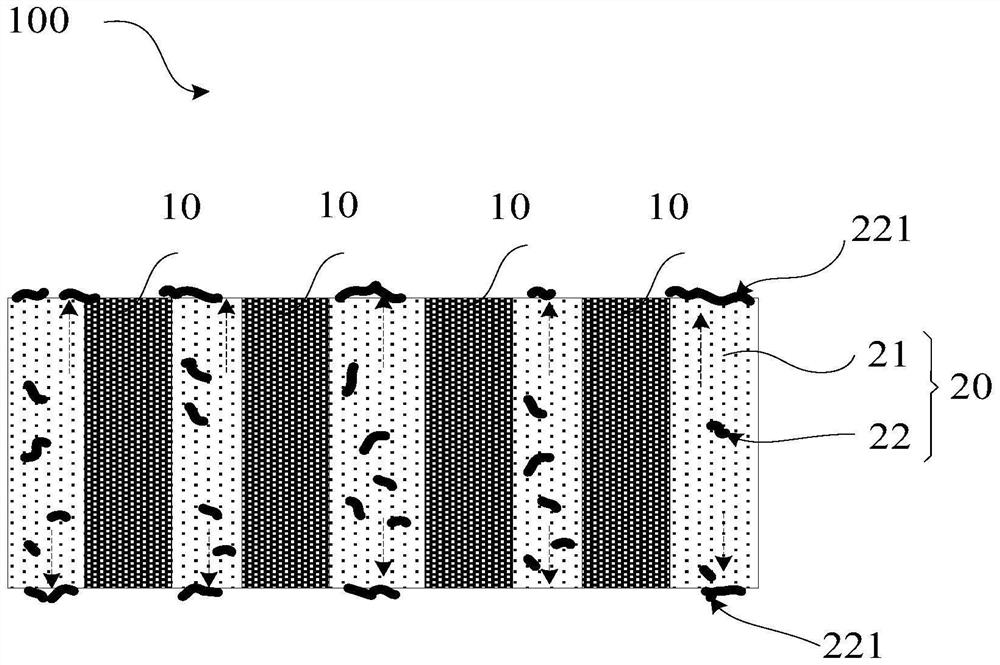

[0191] The difference from the above embodiment is that in the embodiment of the present application, the second organic material 22 can be generated between the heat generating structure 200 and the heat conducting structure 100 and / or between the heat conducting structure 100 and the radiator 300 under preset reaction conditions. Polymerized materials. Moreover, the adhesive layer 221 formed after the polymerization reaction of the second organic material 22 has pressure-sensitive properties. That is, the generated adhesive layer 221 is a pressure-sensitive adhesive, so that by applying pressure to the heating element 200 and the heat sink 300, the heat conducting structure 100 and the heating element 200 and / or the heat conducting structure 100 and the heat sink 300 Close adhesion is achieved through the formed adhesive layer 221 .

[0192] The polymerization reaction of the second organic material 22 between the heat generating structure 200 and the heat conducting struct...

Embodiment 3

[0205] The embodiment of the present application also provides a method for manufacturing the heat conduction structure 100, such as Figure 6 As shown, the method includes the following steps:

[0206] S101. Provide a plurality of thermally conductive films 10, each thermally conductive film 10 has a first surface 11 and a second surface 12 opposite to the first surface 11;

[0207] see Figure 7A As shown, four thermally conductive films 10 are provided. Certainly, in some other examples, the number of the heat conduction film 10 includes but is not limited to four. The heat conduction film 10 can be a graphene film or an artificial graphite film.

[0208] Wherein, when the thermally conductive film 10 is a graphene film, the preparation method is as follows: use a single-layer graphene oxide microchip whose D50 size is 20 μm (that is, the longitudinal dimension of the graphene microchip is 20 μm), and weigh 500 mg of a single-layer graphene oxide microchip. The tablets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com