Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Avoid affecting processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional mechanical working table capable of working in multi-angle mode

ActiveCN108067886AVersatileFunctionalOther manufacturing equipments/toolsPneumatic cylinderEngineering

The invention discloses a multifunctional mechanical working table capable of working in multi-angle mode. The working table comprises a machine tool, a mounting plate is arranged on one side of the machine tool, and first electromagnetic sliding rails are arranged on the two sides above the mounting plate; the top of the first electromagnetic sliding rail is provided with two sets of first electromagnetic sliding blocks, and a first installation base is arranged above the first electromagnetic sliding block; an installation groove is formed in the top of the first installation base, and foursets of lifting pneumatic cylinders are arranged in the installation grooves, the top of the lifting pneumatic cylinder is provided with a piston rod, and the top of the piston rod is provided with afixing block; and a second installation base is arranged at the top of the fixed block, and an installation hole is formed in the inner side of the second installation base. The workbench is providedwith a cutting table and a grinding table, a cutting structure and a grinding structure on the mechanical table cooperate, so that the function of the working table is more comprehensive, the polishing operation of the hardware can be realized, the cutting operation of the hardware can be realized, and the functionality is stronger.

Owner:肇庆市高要区博斯五金制品有限公司

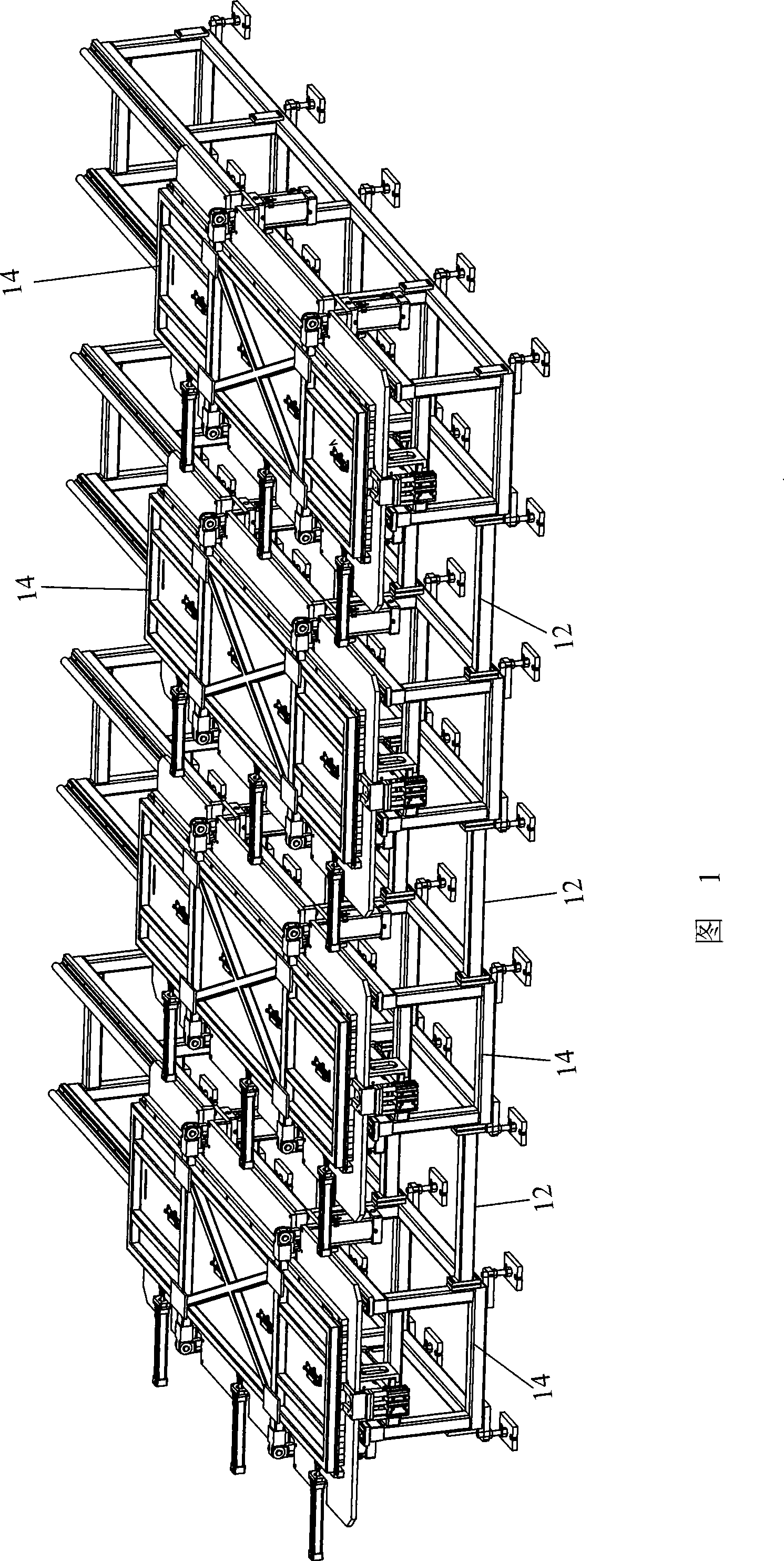

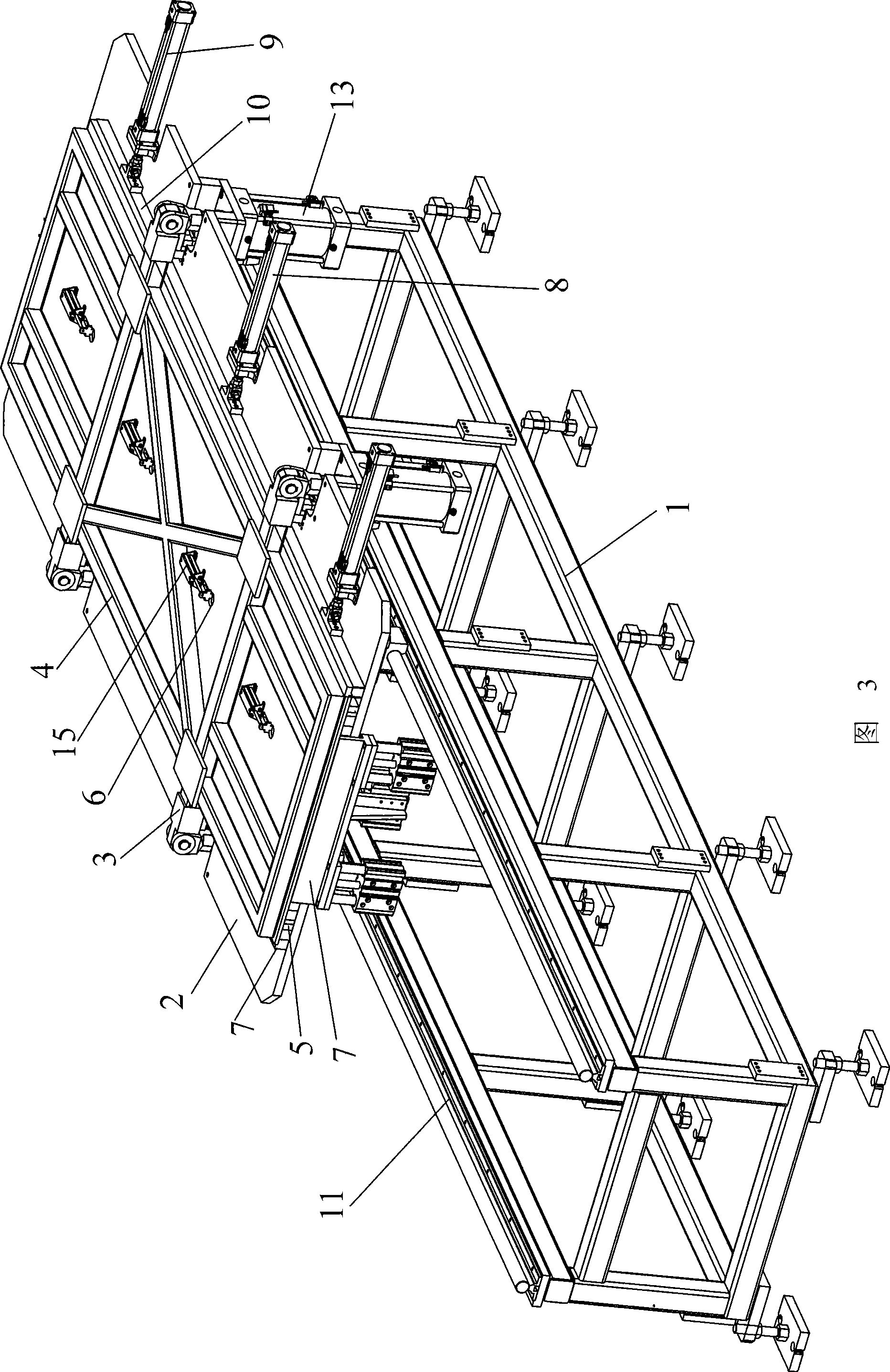

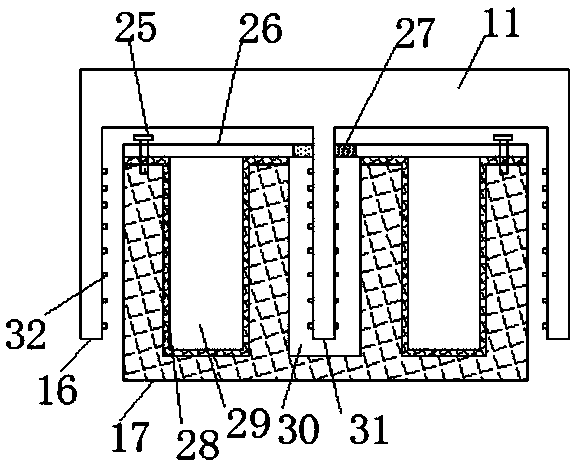

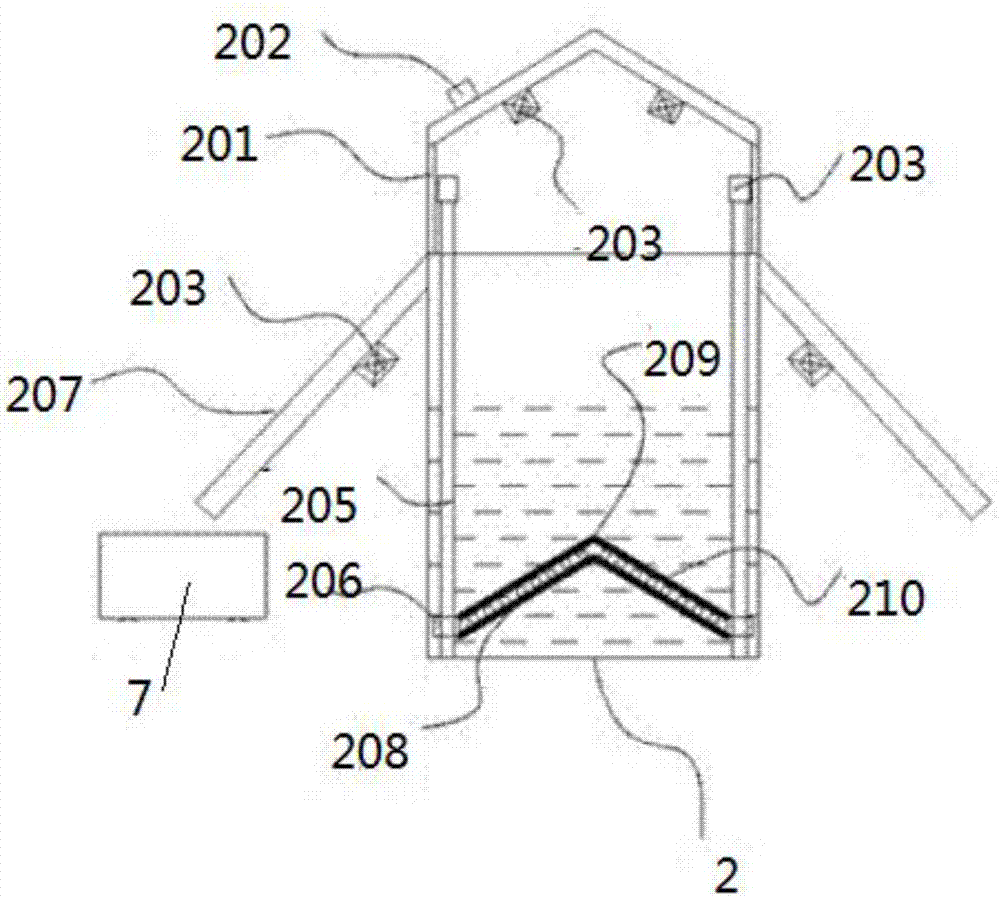

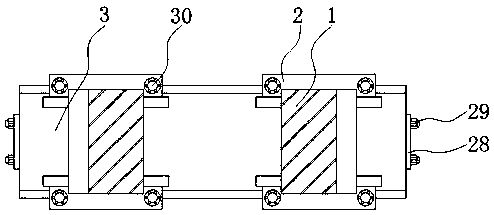

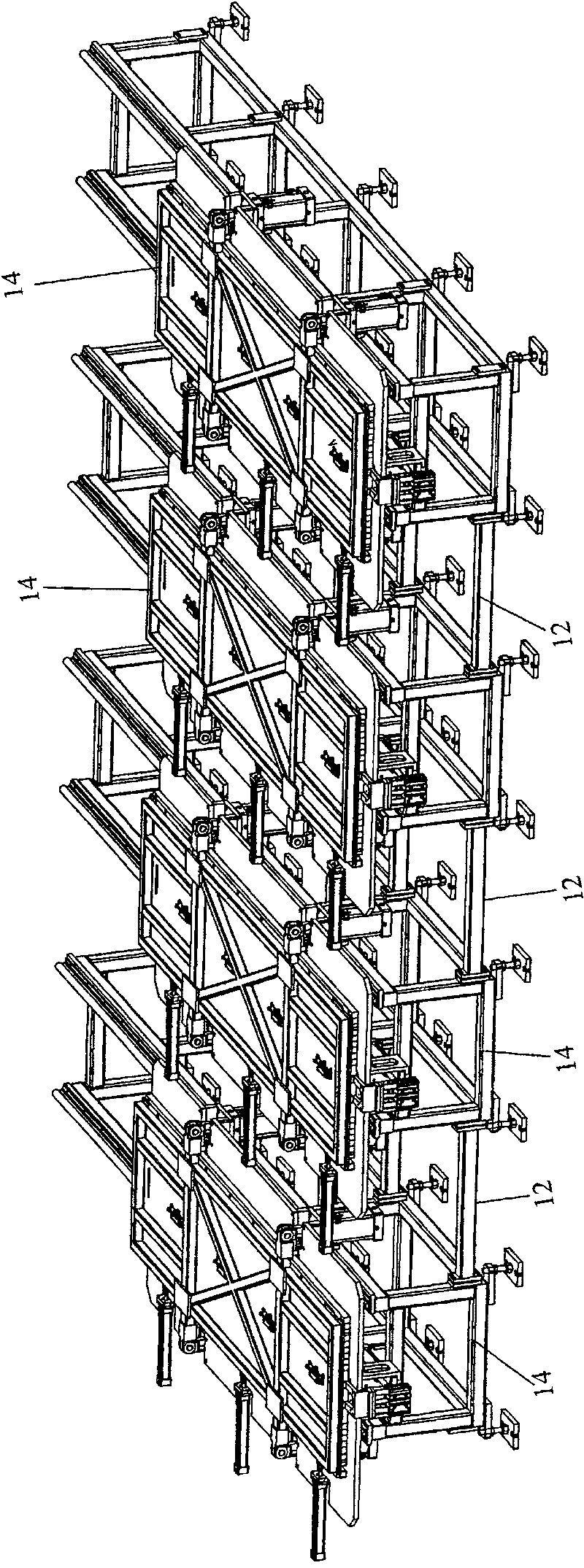

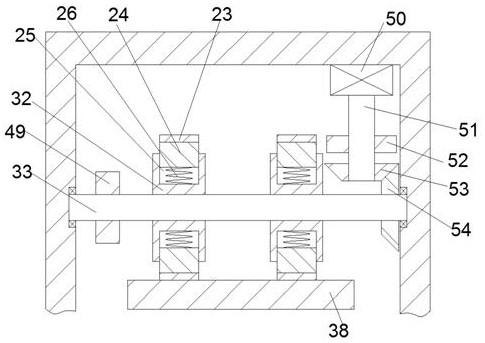

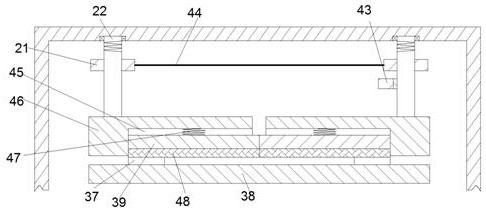

Continuous production method of foam filling panel

The invention discloses a foaming infill panel series manufacturing device, comprising at least one monoblock worktable. Each monoblock worktable comprises a stander and a worktable surface on the stander used for placing a workpiece to be processed. The worktable surface is fixed with a pressure plate erector, a lifting part of which is connected with a pressure plate which can rise and descend above the worktable surface. The pressure plate is provided with an injection hole that is on the workpiece to be processed and corresponds to a foam filling hole. The worktable surface is provided with a spacing fixed block at the periphery along the thickness direction of the workpiece to be processed. The invention can clamp the front wall and the back wall of the workpiece to be processed neatly in the middle and does not lead to expansion and deformation caused by foaming heat in filling noise deadening foam; simultaneously, as the device comprises a plurality of monoblock worktables, a foam jet is always in operating condition, thus avoiding the solidification of foam on the foam jet when replacing manufacturing workpieces and having high processing efficiency.

Owner:SHENLONG ELEVATOR

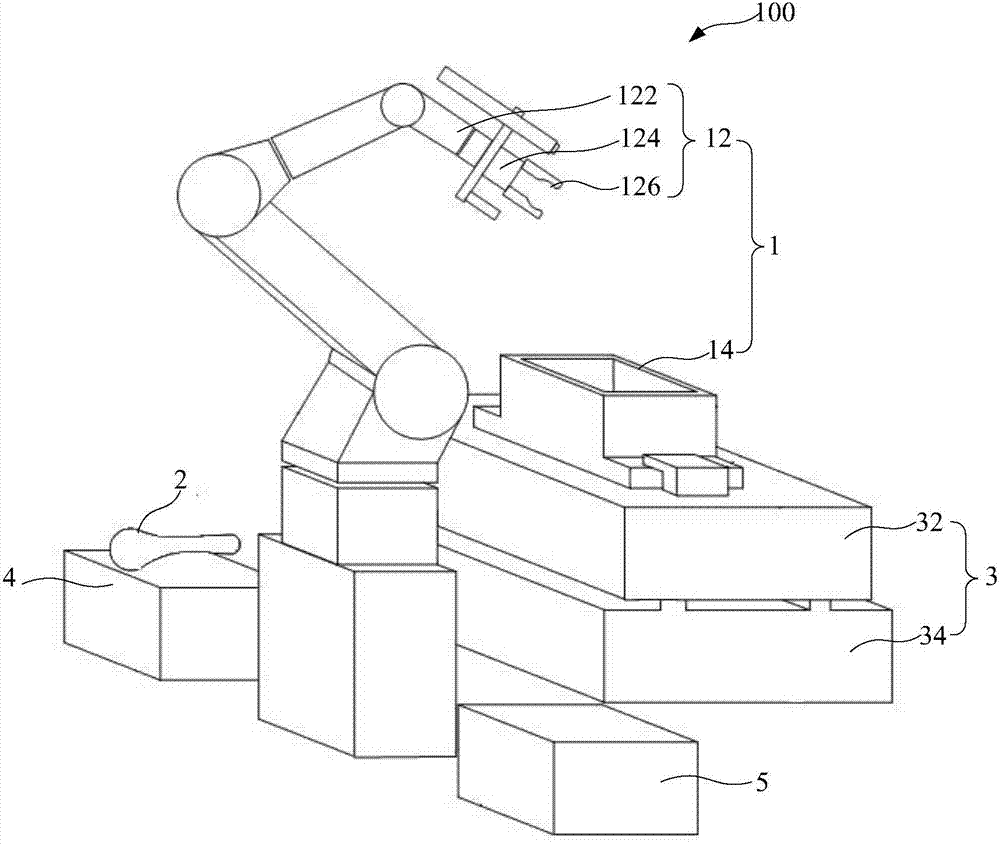

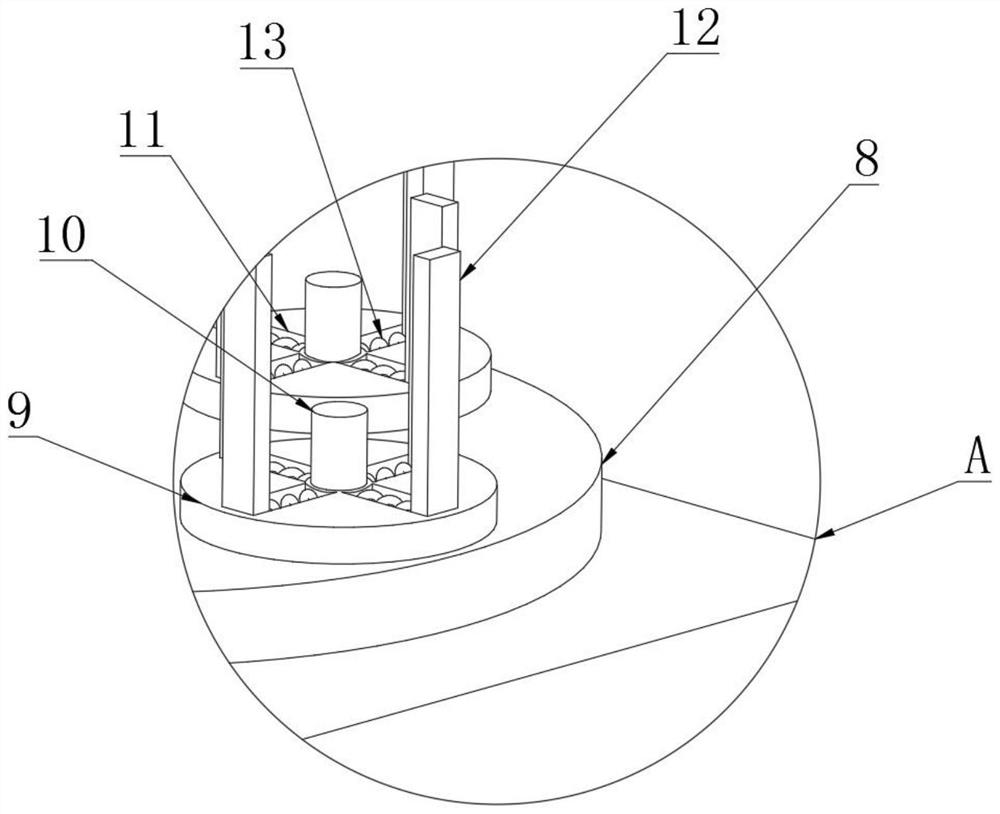

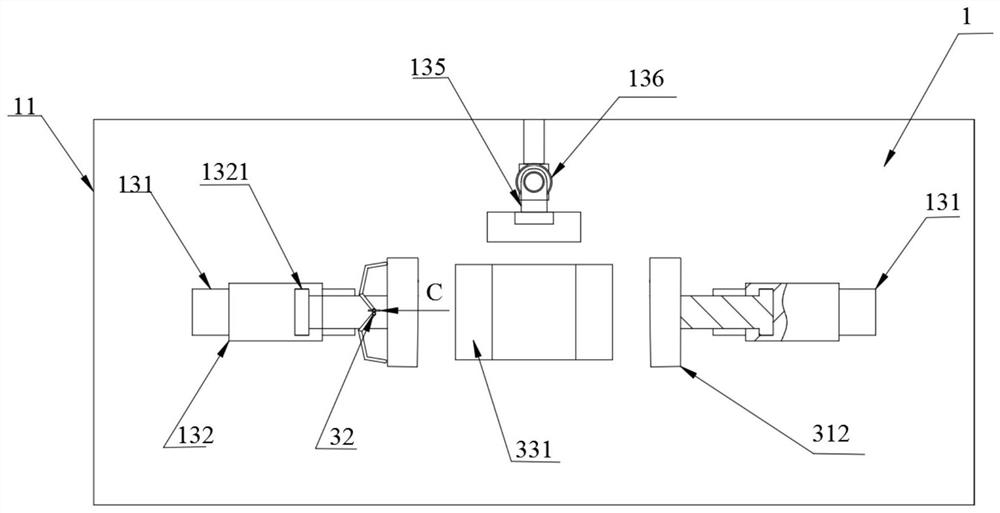

Clamp, machining assembly and application method of machining assembly

ActiveCN106862959AInfluence positioningImprove accuracyPositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

The invention provides a clamp, a machining assembly and an application method of the machining assembly. The clamp is matched with a machine tool for use and comprises a clamping mechanism and a fixing assembly. The clamping mechanism is arranged on the machine tool and comprises a mechanical arm, an elastic supporting assembly and a chuck. The elastic supporting assembly is connected with the mechanical arm and the chuck. The chuck is used for clamping a special-shaped part. The fixing assembly is installed on a workbench and comprises a container with the top being provided with an opening and a supporting piece. The container is used for containing a phase-change material, and the supporting piece is installed inside the container. When the chuck is used for clamping the special-shaped part, the special-shaped part can abut against the supporting piece through the opening position of the container according to the machining positioning requirements, and the special-shaped part, the supporting piece and the container are cured and fixedly connected together through the phase-change material. According to the clamp provided by the invention, the problem of posture uncertainty of the special-shaped part in the positioning process is avoided, the clamp with high fixing strength and rigidity and good machining datum repeatability is provided for finish machining, and the degree of using satisfaction by users is increased.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

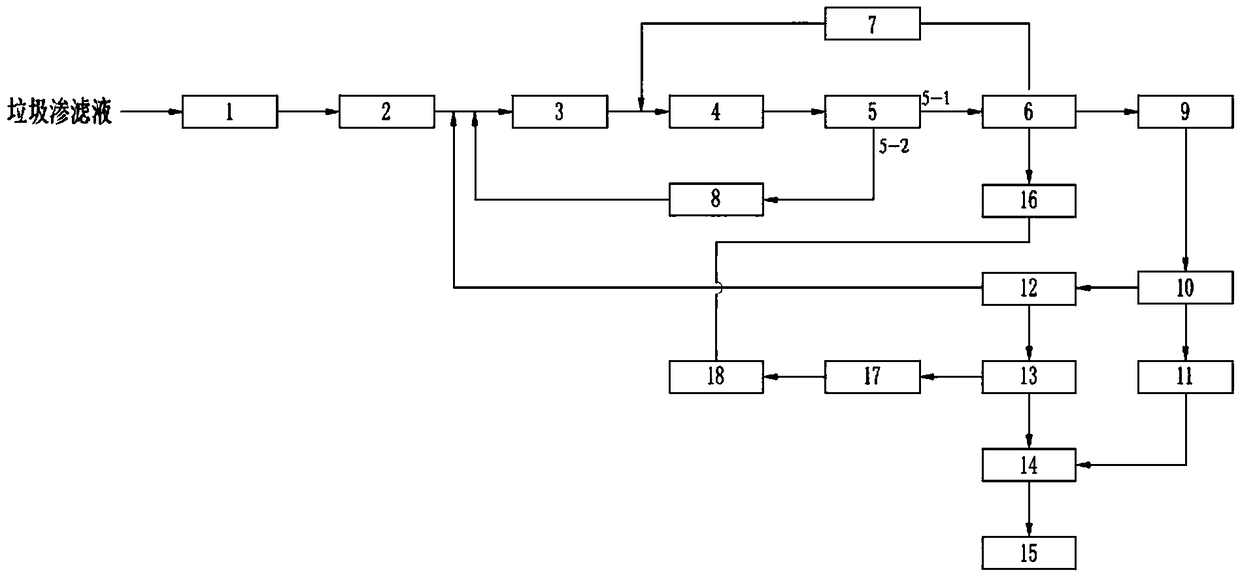

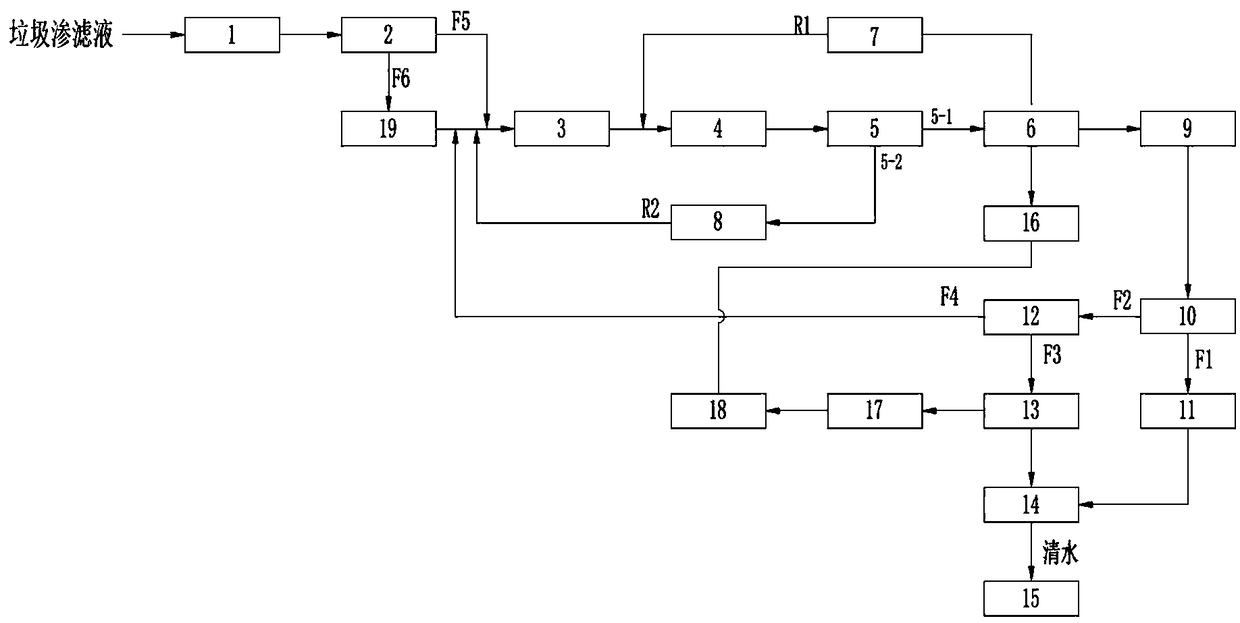

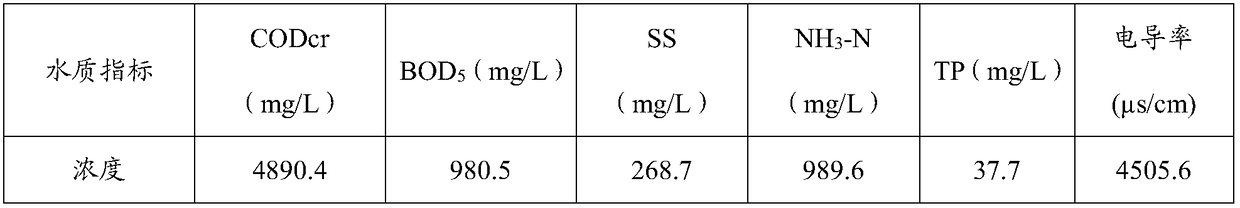

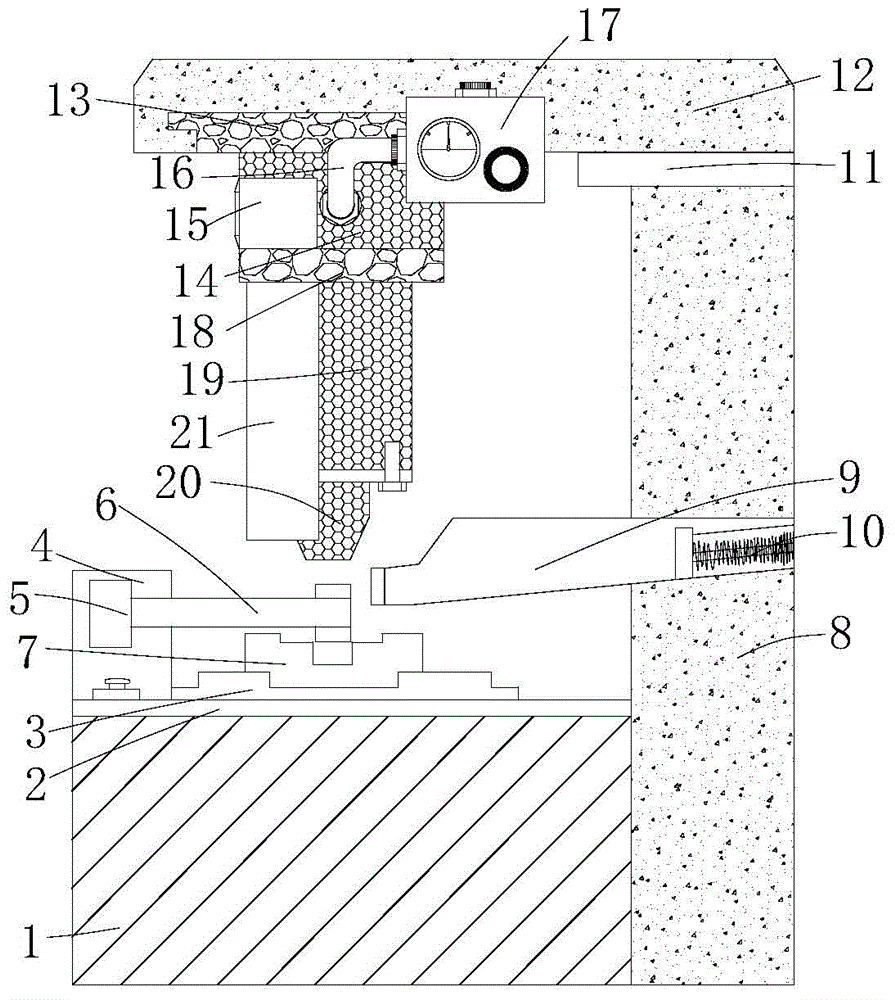

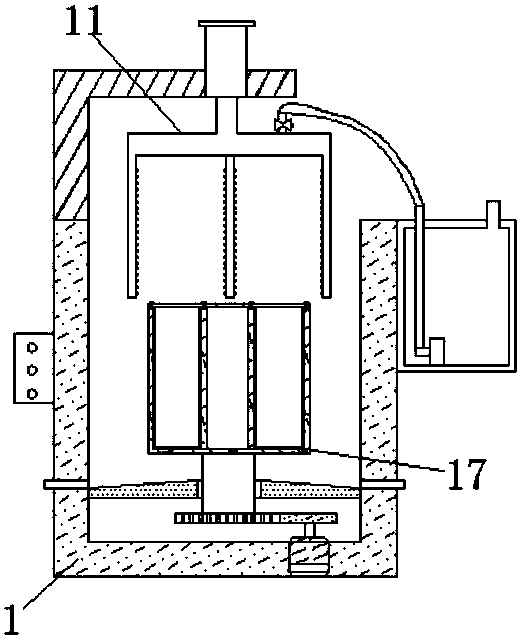

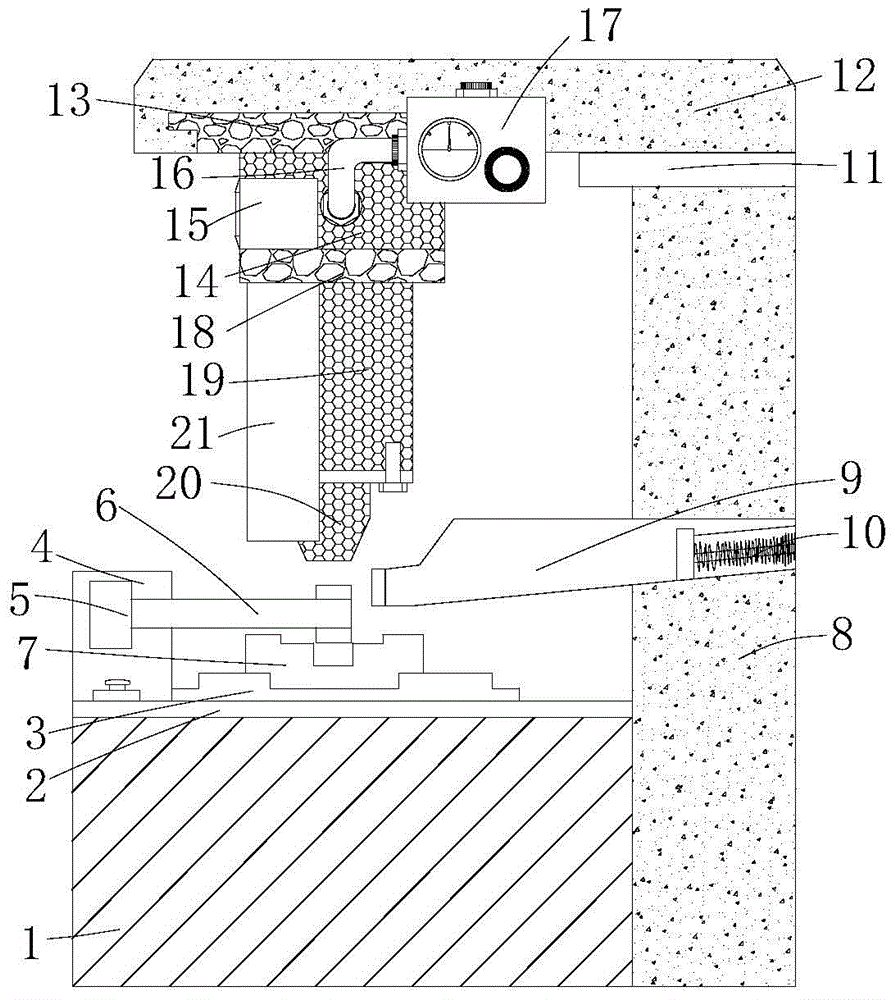

Municipal solid waste landfill waste leachate treatment device and method

ActiveCN109081522AImprove qualityAvoid affecting processing efficiencySpecific water treatment objectivesWater contaminantsHigh concentrationEmission standard

The invention provides a municipal solid waste landfill waste leachate treatment device, and belongs to the field of wastewater treatment. A system is high in internal circulation ratio and strong inimpact load resistance, an external carbon source is omitted, organic matters in waste leachate are preferentially used for nitrogen removal by pre-denitrification, electrocatalytic oxidation nitrogenremoval serves as supplement and gate-keeping, and the total nitrogen removal rate of the system can meet emission standards. Total nitrogen is removed by electrocatalytic oxidation, and total nitrogen removal cost is lower than that of nitrogen removal by adding the carbon source. The system does not generate high-salinity concentrated liquor, and investment and operation of high-cost high-salinity concentrated liquor treatment equipment are omitted. A screening system with a low ion rejection rate is selected, screened high-concentration wastewater and low-concentration wastewater are subjected to electrocatalytic oxidation, the salt content of the system can be controlled, the influence of inorganic salt over-accumulation on biochemical treatment efficiency is avoided, the device is suitable for industrial application, and final discharge outlet water quality is superior to municipal solid waste landfill pollution control standards (GB 16889-2008).

Owner:桂润环境科技股份有限公司

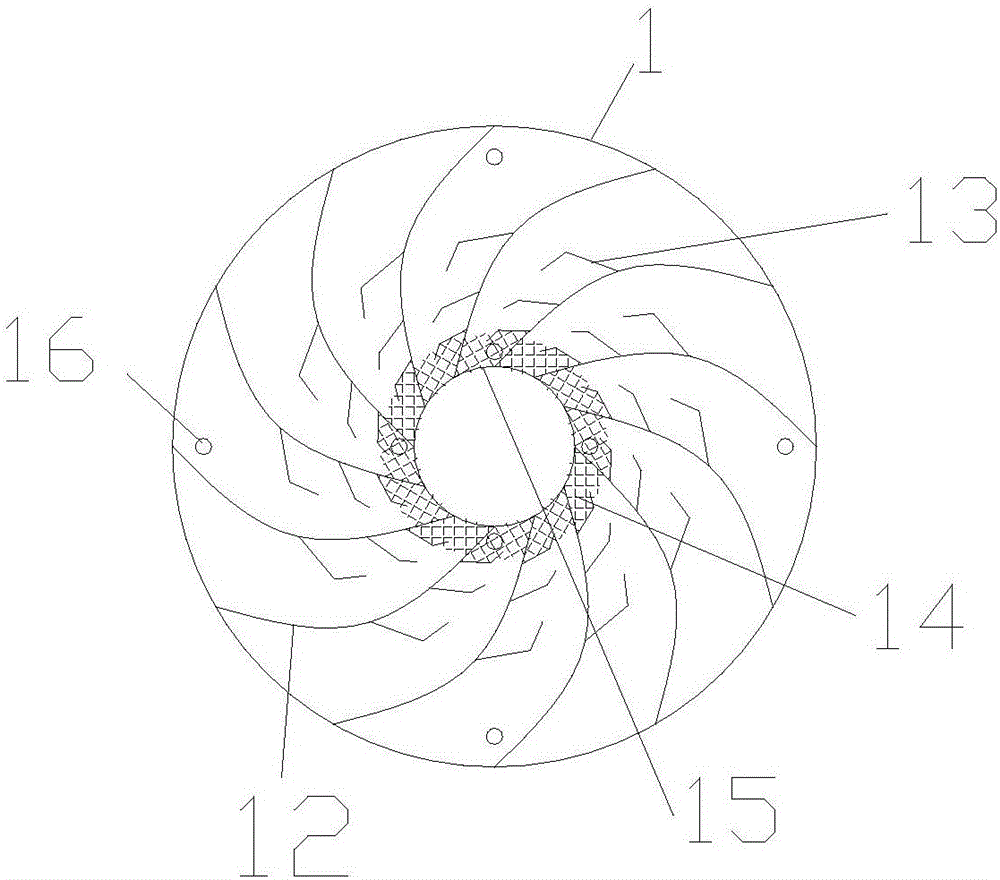

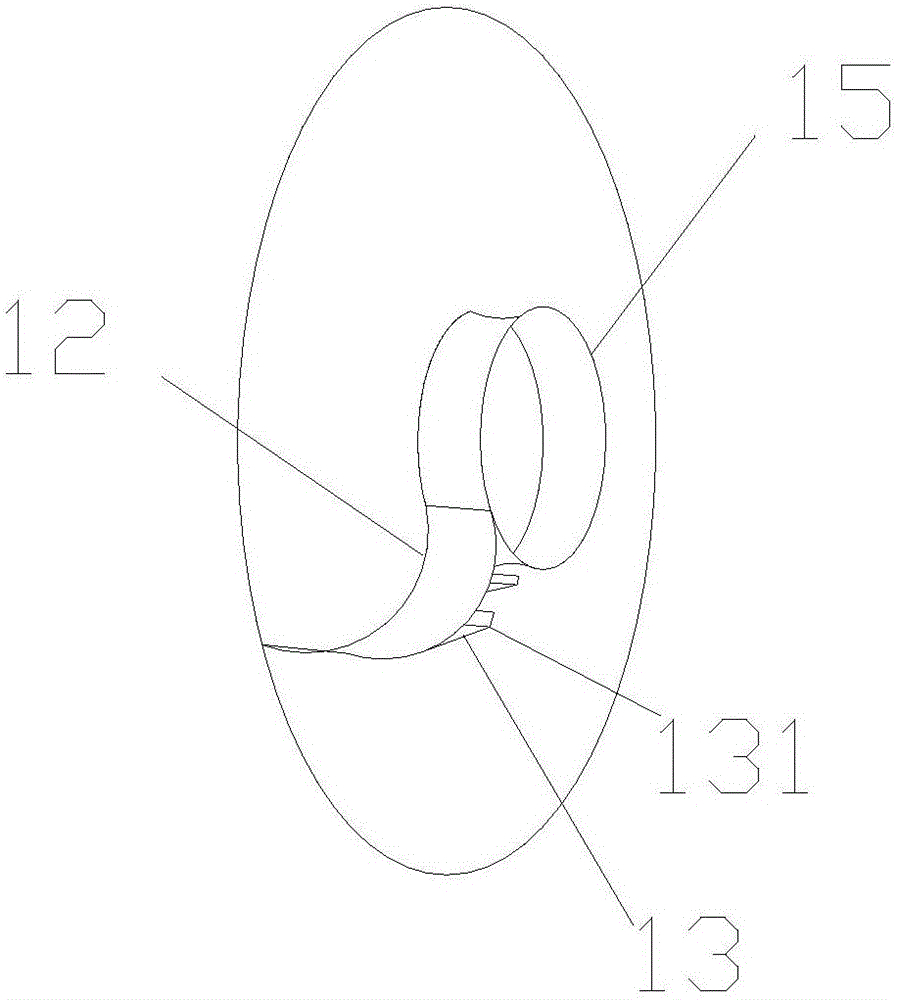

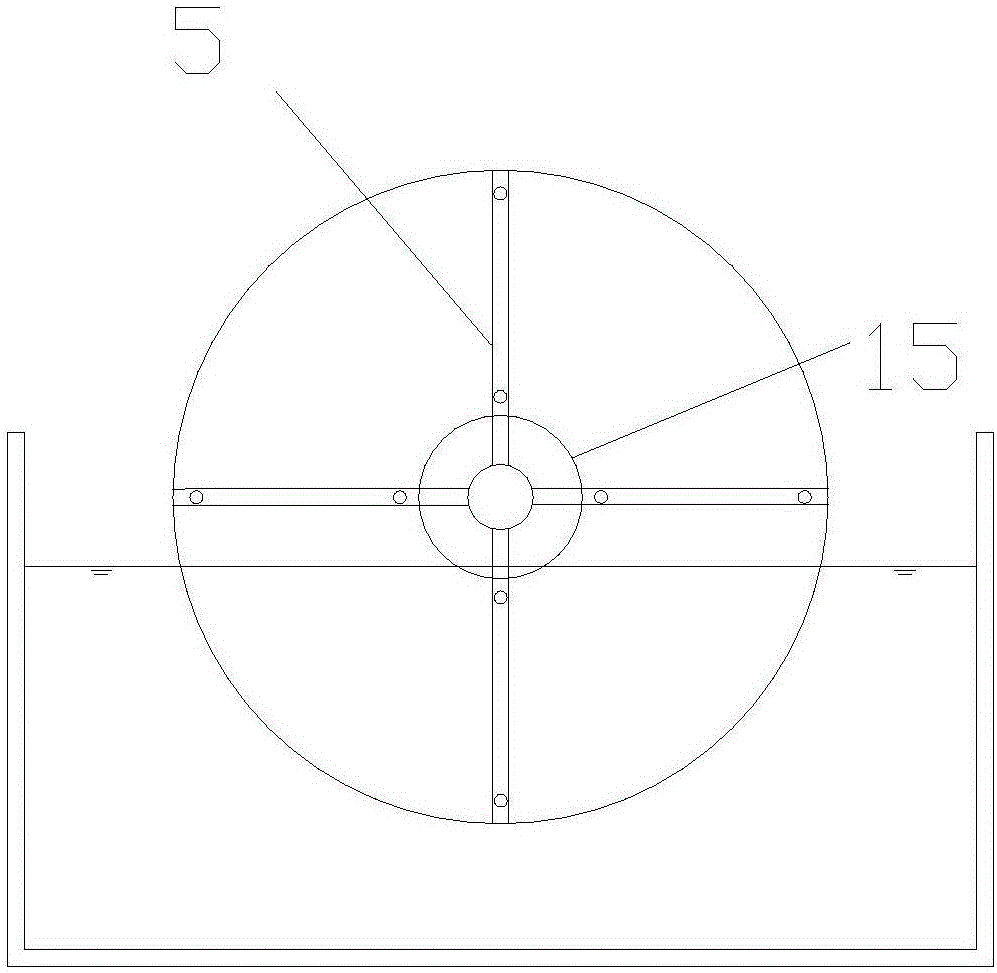

Biological disk and biological rotating disk formed by same

ActiveCN106007011ALarge specific surface areaAvoid deformationTreatment using aerobic processesBiological treatment apparatusBiochemical engineeringWater quality

The invention discloses a biological disk and a biological rotating disk formed by same. The biological disk is an annular disk body; a plurality of arc baffle plates are uniformly arranged on the disk surface of the biological disk along the circumferential direction; two ends of the arc baffle plates respectively stretch towards an inner ring and an outer ring of the biological disk; a plurality of corresponding folding plates are arranged on the convex surfaces of the arc baffle plates; each folding plate is formed by splicing two plates which are arranged in an obtuse angle; one end of each folding plate is connected with the corresponding arc baffle plate and is in obtuse arrangement with the corresponding arc baffle plate; the other end of each folding plate points to the inner ring of the biological disk; the folding plate, which is closest to the inner ring, on the disk body and the disk surface around the inner ring are provided with net-shaped layers. The biological rotating disk is formed by the biological disk. According to the biological disk and the biological rotating disk disclosed by the invention, the hydraulic retention time can be increased, the varieties and the quantity of microbial communities can be enriched, the oxygen content of sewage can also be increased, the water quality can be homogenized, the growth environment of organisms can be optimized, and increment of sewage treatment efficiency can be finally realized.

Owner:YANGTZE UNIVERSITY

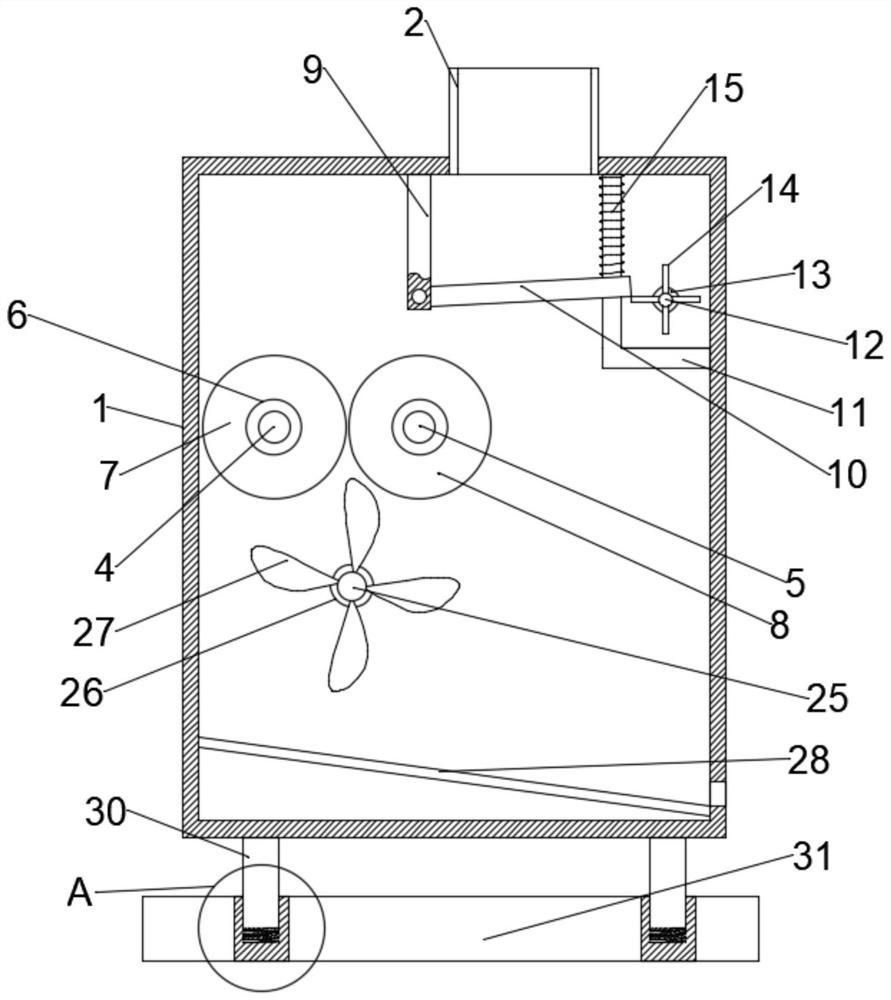

Silk cloth mildew-proof treatment device for textile fabric

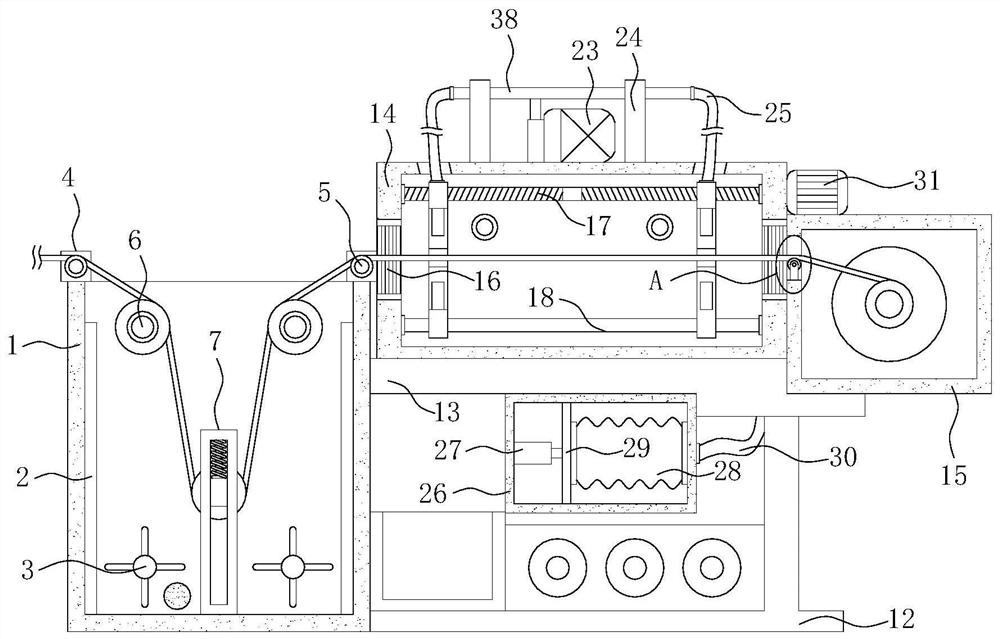

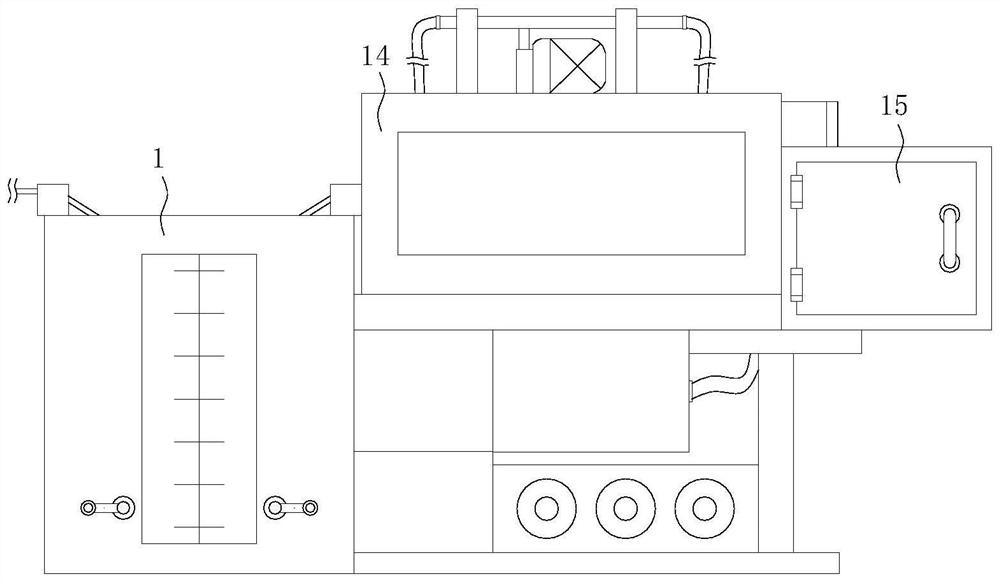

ActiveCN112251954AAvoid lengthFusion speedLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalPolymer scienceSilk cloth

The invention discloses a silk cloth mildew-proof treatment device for textile fabric, and relates to the technical field of textile. The silk cloth mildew-proof treatment device for the textile fabric comprises a box body, wherein a heating plate is fixedly mounted on the inner wall of the box body, a rotating rod is rotationally mounted in the box body, fan blades are welded to the outer wall ofthe rotating rod, four mounting blocks are welded to the outer surface of the top of the box body, and every two mounting blocks form a group. Through cooperative use of the box body, the mounting blocks, rolling shafts, rollers, mounting plates, sliding blocks, springs, fixed blocks and mounting columns, silk can enter the box body to be soaked while being transported, a certain tensioning effect is achieved, the soaking effect is better, the error-tolerant rate during transportation is increased, accidents are avoided, the way is effectively paved for the next step of processing and mildew-proof treatment, the soaking speed is high due to soaking in transportation, and the phenomena of slight fading and length shrinkage of the silk due to overlong soaking time are avoided.

Owner:湖州恒晨纺织品有限公司

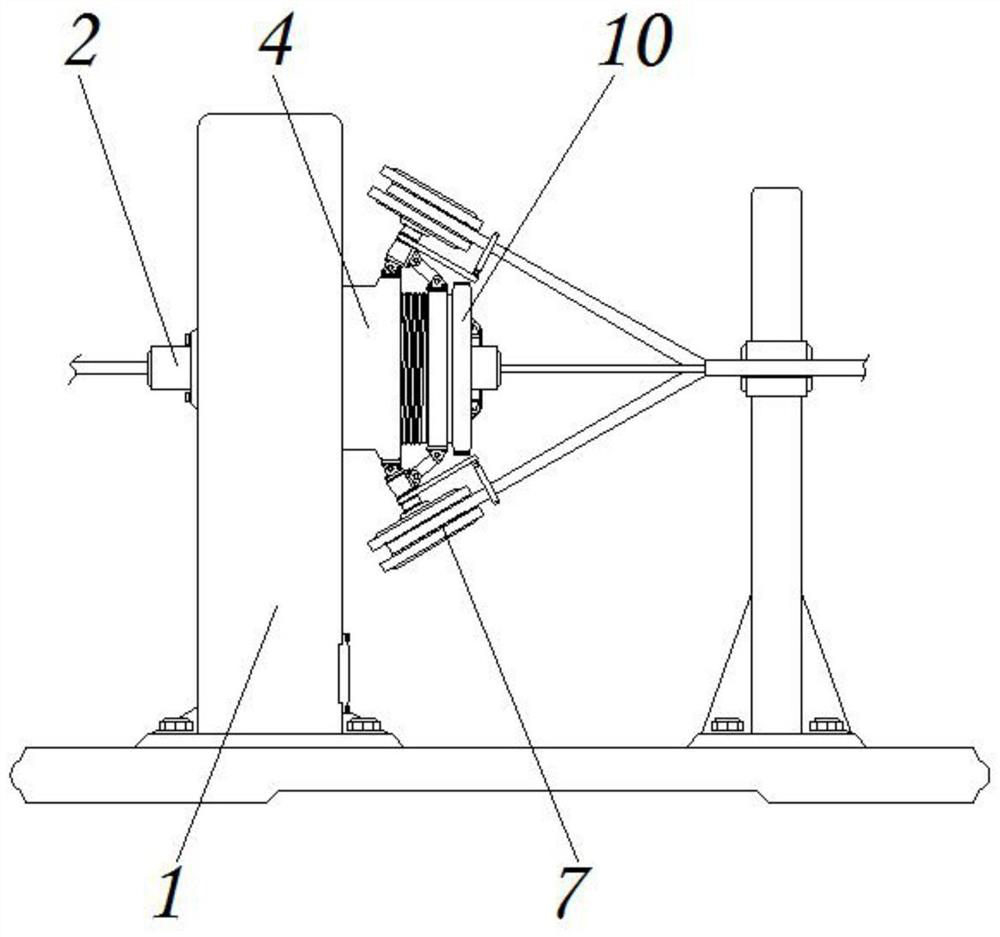

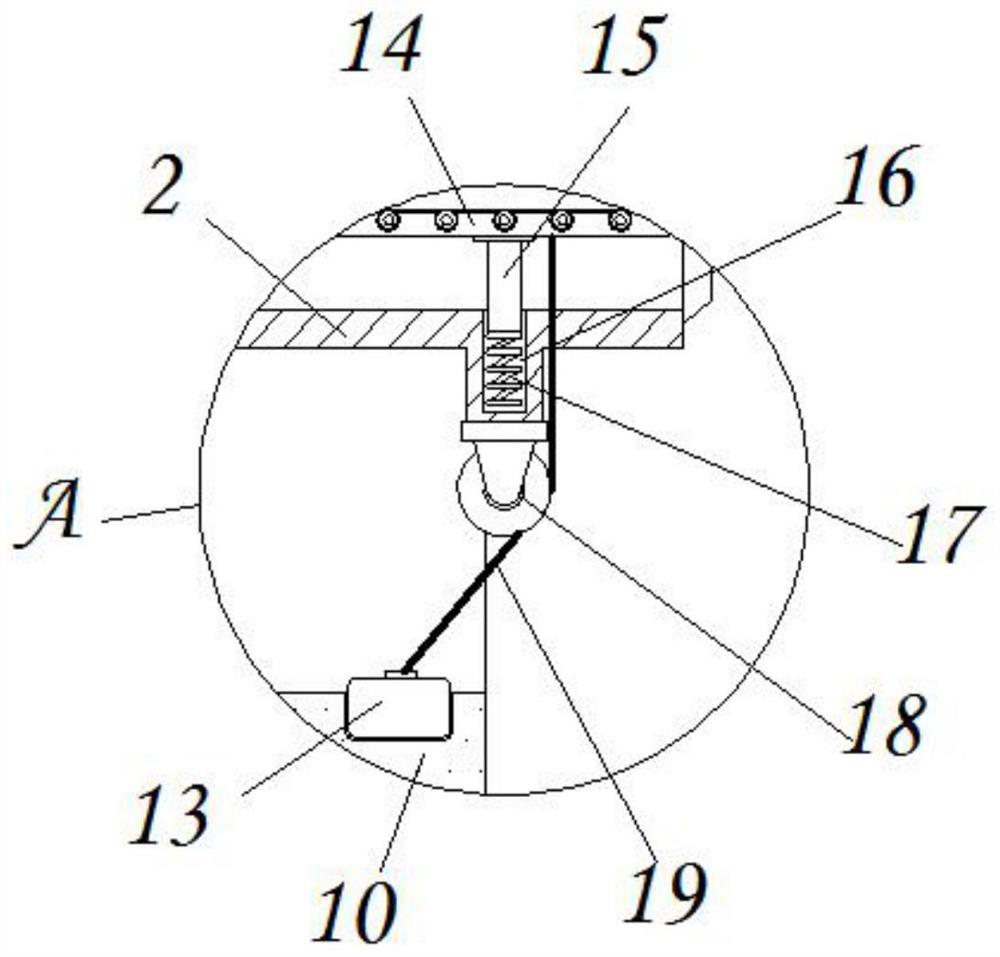

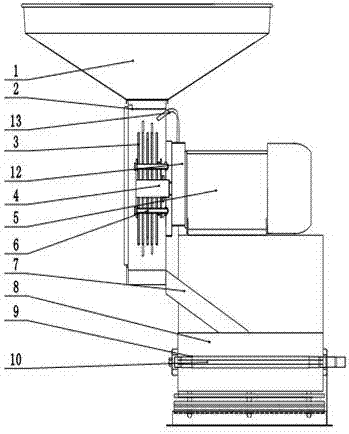

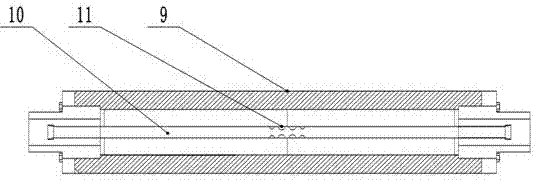

Wrapping device for production of ultralow-temperature insulated superconducting electromagnetic wire

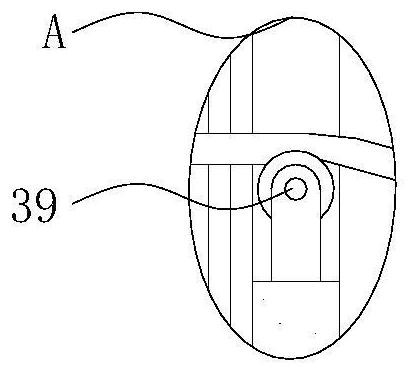

PendingCN112509751AAvoid breakingImprove the wrapping effectInsulating conductors/cablesEngineeringMagnet wire

The invention discloses a wrapping device for production of an ultralow-temperature insulated superconducting electromagnetic wire. The device comprises a wrapping bracket, a movable cylinder, a wrapping cylinder, an adjusting cylinder, a pull rod and a clamping plate, a threading cylinder is mounted in the middle of the wrapping bracket through a bolt, the adjusting cylinder is arranged at the right end of the wrapping cylinder, and a first lantern ring is arranged on the outer wall of the adjusting cylinder; and a clamping plate is arranged on the inner side of the threading cylinder, a guide column is connected to the outer side of the clamping plate through a bolt, and a supporting frame is arranged on the side face of the wrapping bracket. According to the wrapping device for ultralow-temperature insulated superconducting electromagnetic wire production, the mounting angles of the multiple wrapping cylinders can be synchronously adjusted, so that the device can be suitable for wrapping superconducting wire cores of different sizes at different angles, the tension of a wrapping tape can be automatically adjusted in the wrapping process, the wrapping tape is prevented from beingbroken, and meanwhile, a limiting structure of the device can be synchronously and automatically adjusted in the wrapping angle adjusting process, so that the wrapping effect of the device is furtherimproved.

Owner:上海申茂电磁线有限公司

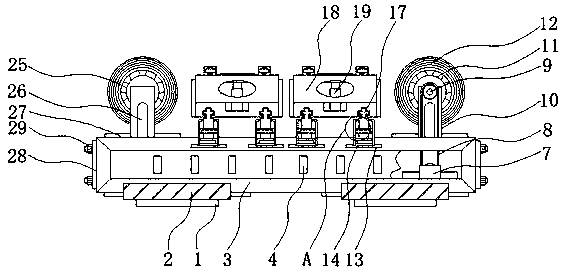

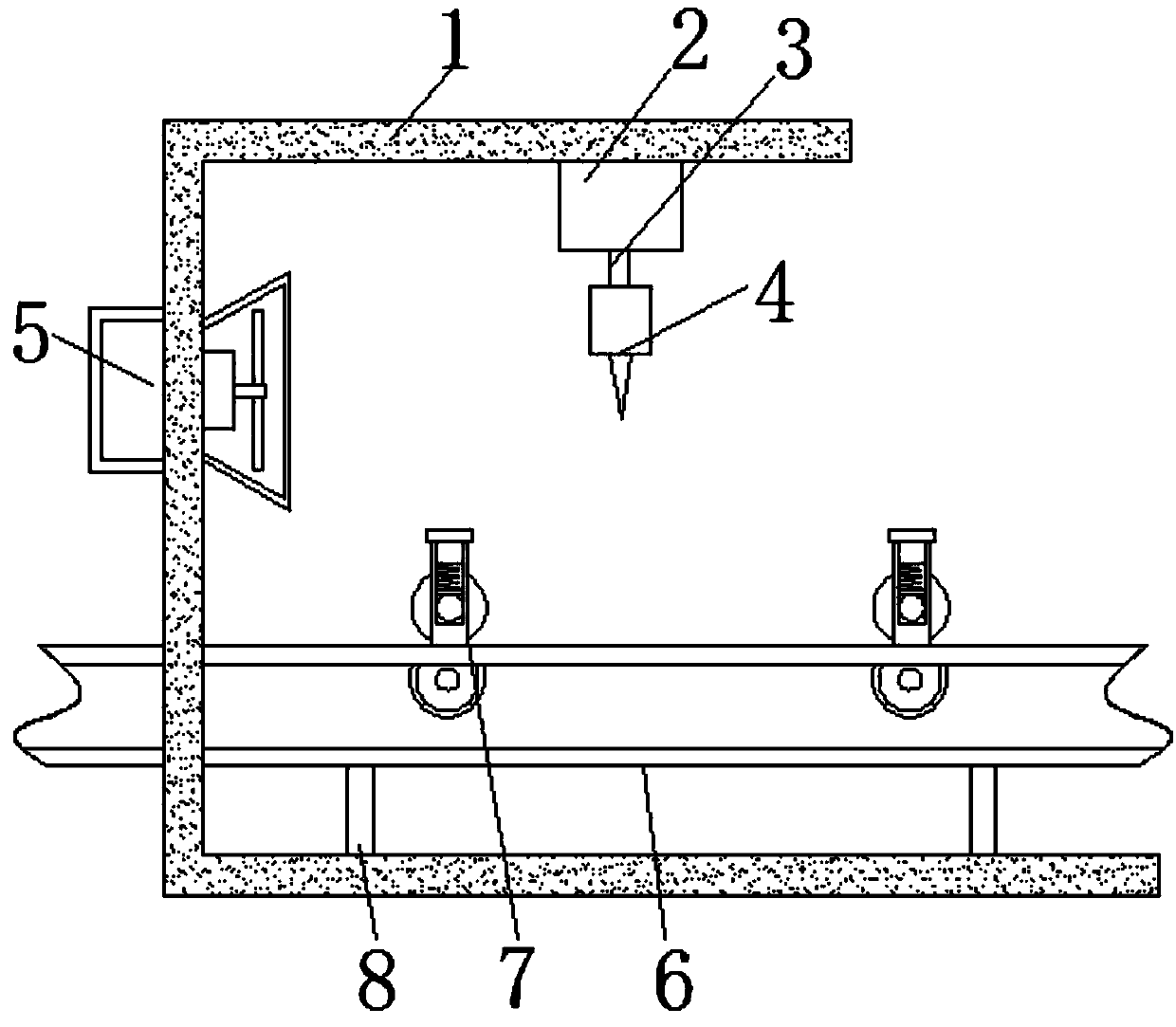

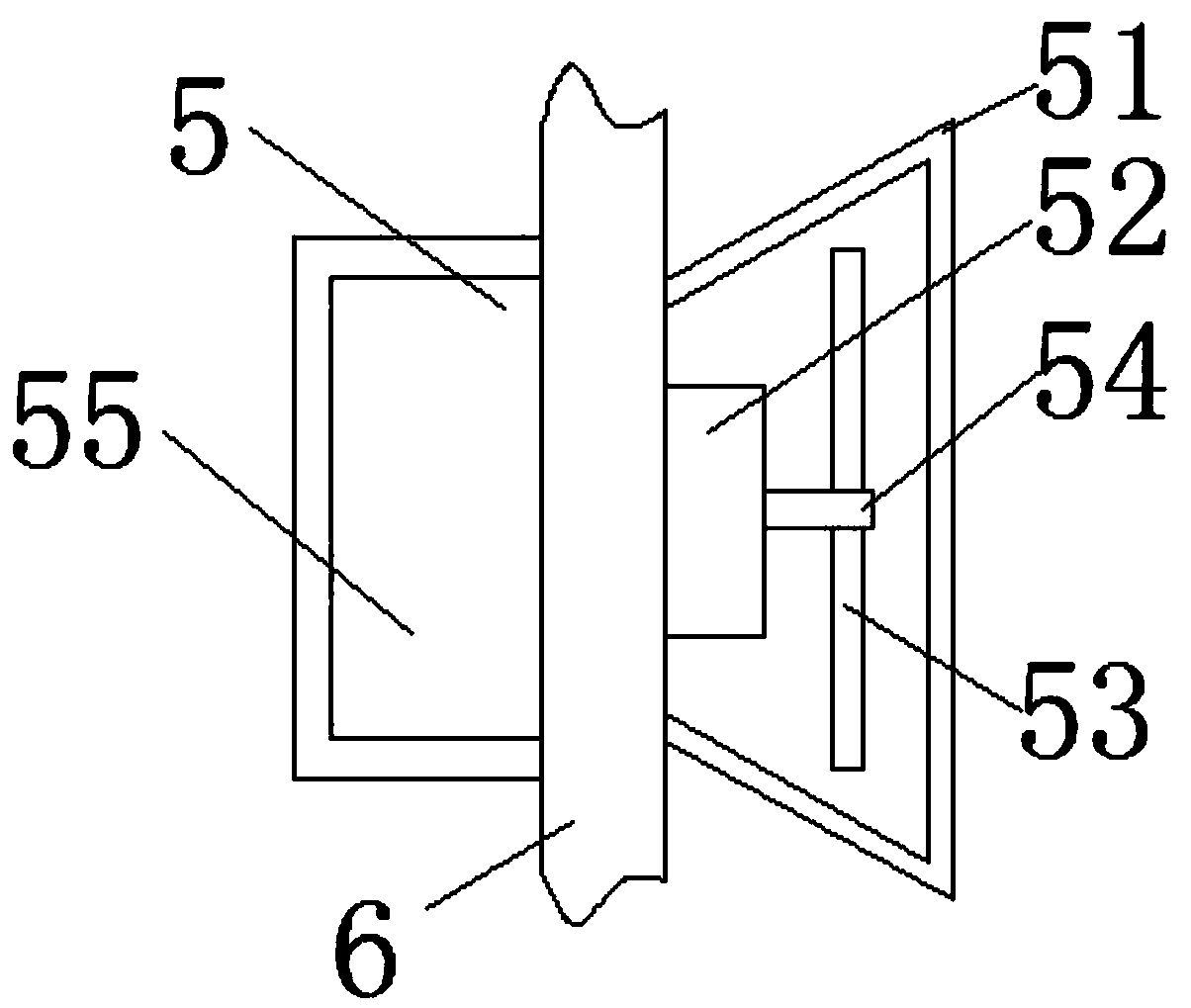

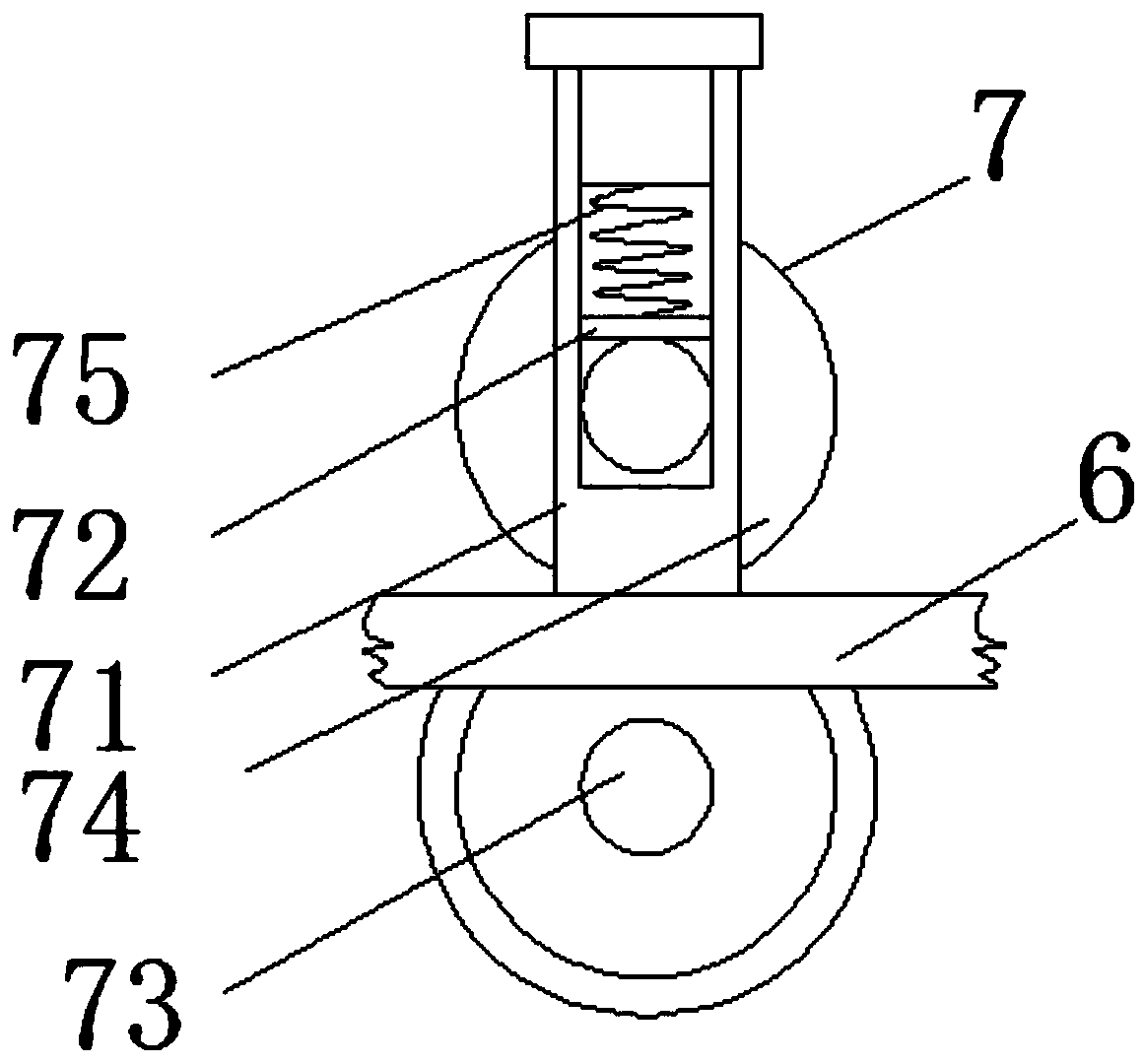

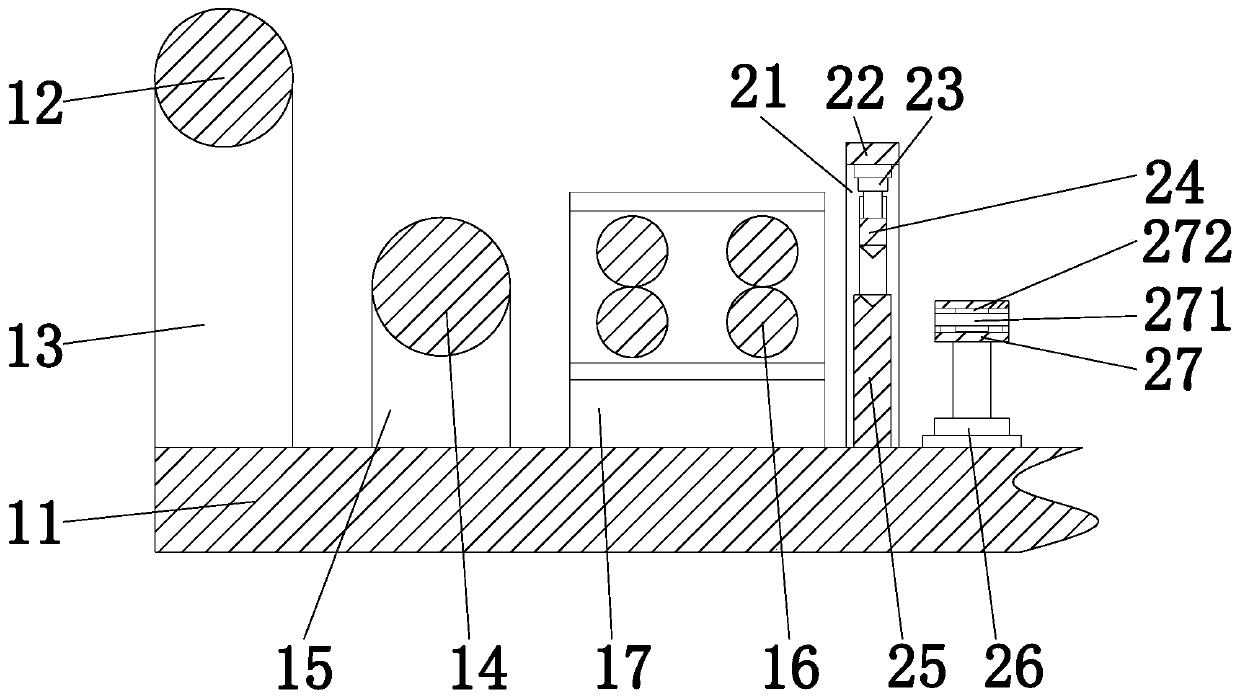

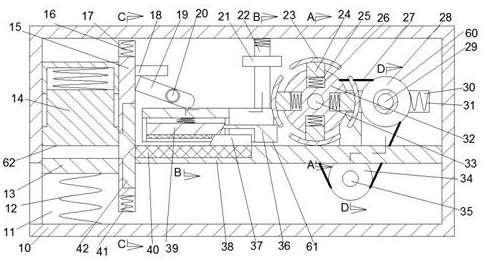

Automatic rivet punching machine

ActiveCN104959514AReduce safety hazard accidentsAvoid affecting processing efficiencyPunchingSynchronous control

The invention discloses an automatic rivet punching machine. The automatic rivet punching machine comprises a workbench, a main punching arm, a bearing cross beam and a punching buffer tank; the main punching arm is installed at the right side of the workbench, the bearing cross beam is installed at the top of a connecting plate, and the punching buffer tank is installed at the bottom of a punching arm bearing block. According to the automatic rivet punching machine, the pneumatic punching nailing technique is adopted, an installed workpiece fixing machine box can be combined with a workpiece fixing rod for locating and fixing a workpiece to be machined perfectly, an installed rivet carrying box can feed rivets automatically through an ejector pin, the manual fixing, uprighting and rivet mounting are replaced effectively, the accident potential safety hazards of the punching machine are reduced, a synchronous control timer is installed in an inner cavity of the punching buffer box, it can be convenient for operators to adjust the punching time voluntarily according to the variety requirements of the workpiece, and the punching machine and the workpiece fixing machine box can be effectively made to operate in a synchronous mode.

Owner:TANGSHAN ZHENGFENG IRON & STEEL CO LTD

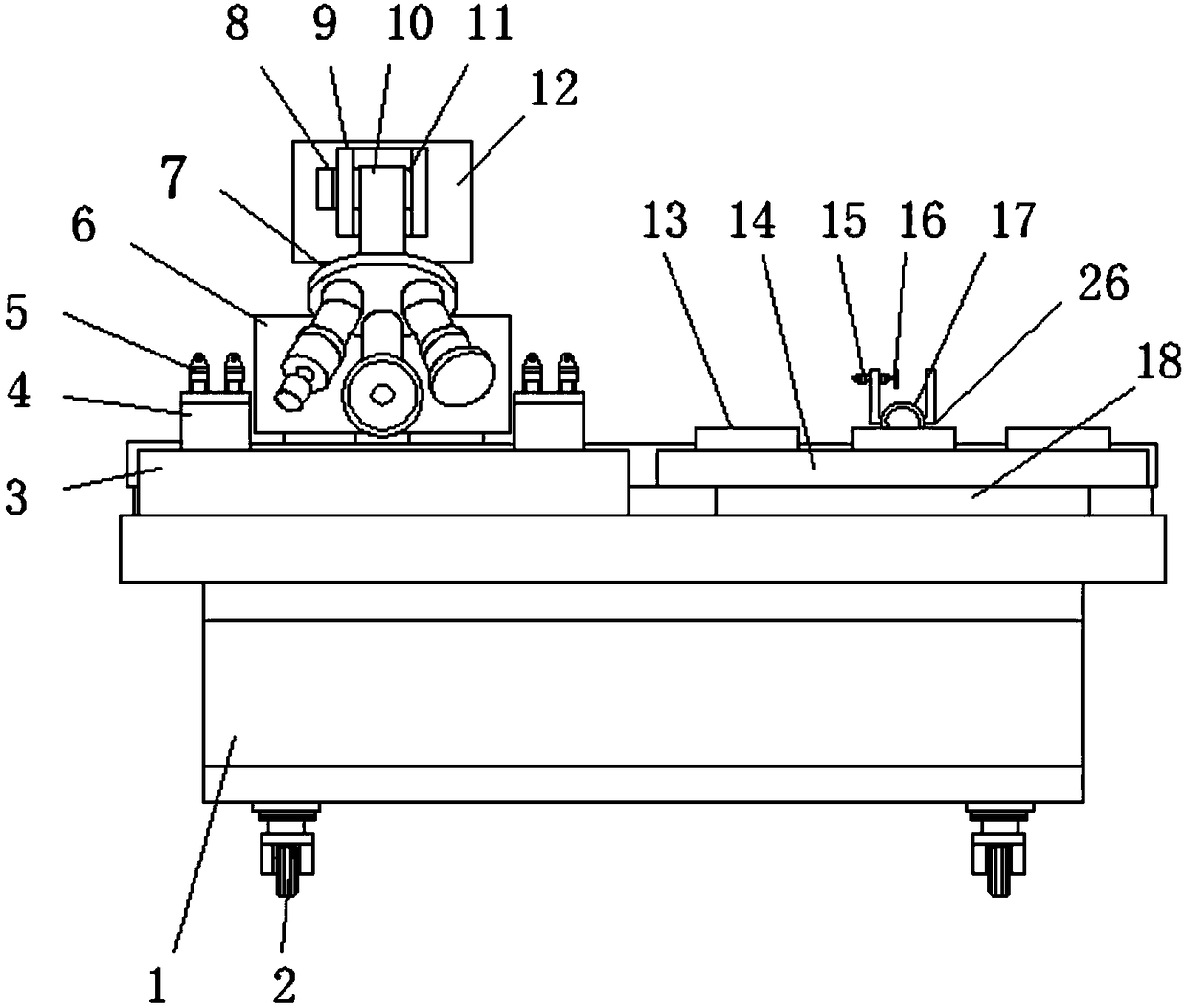

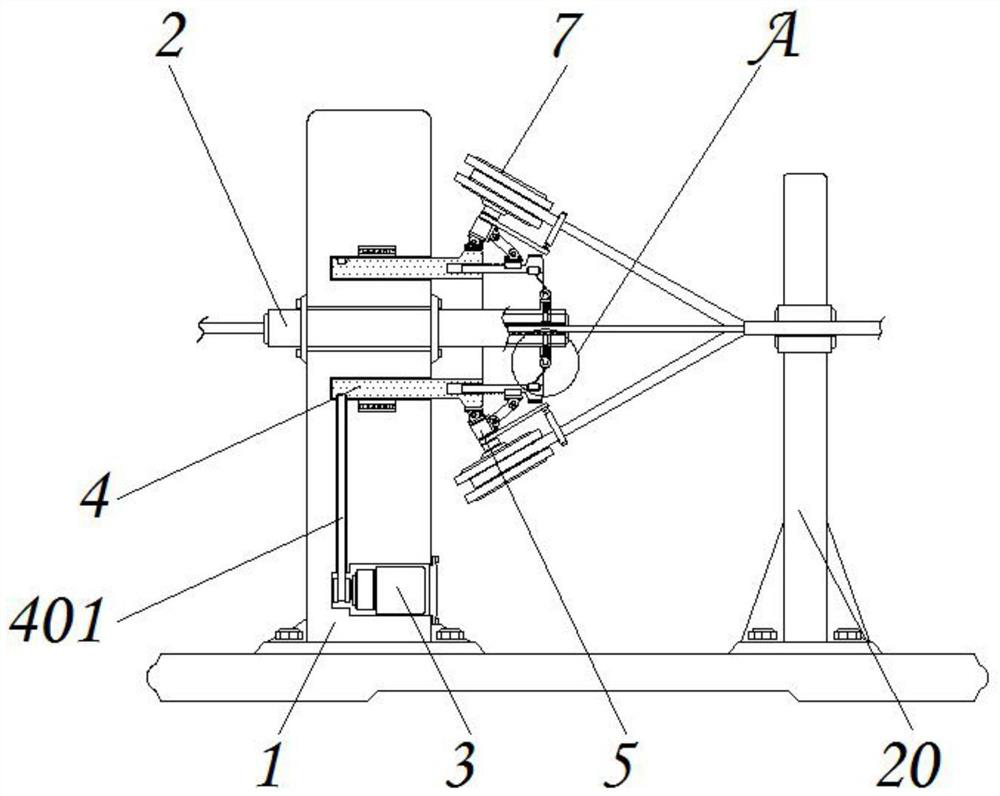

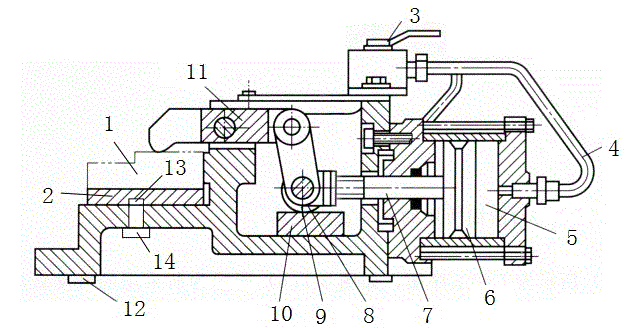

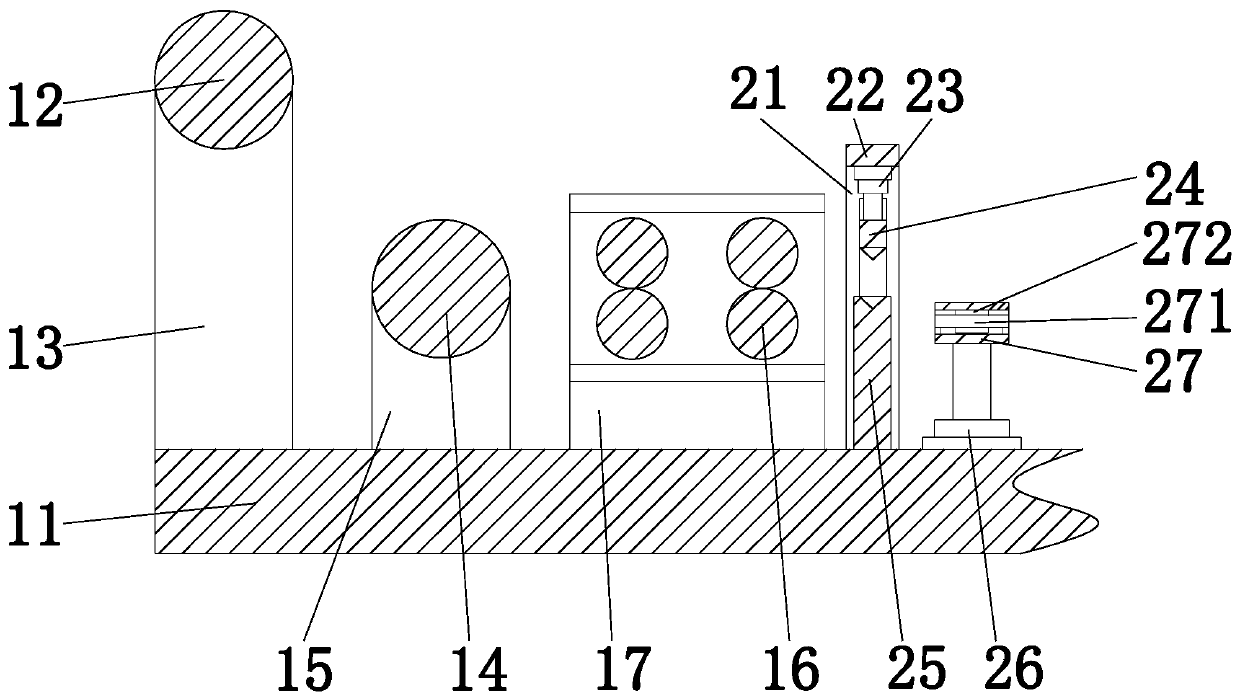

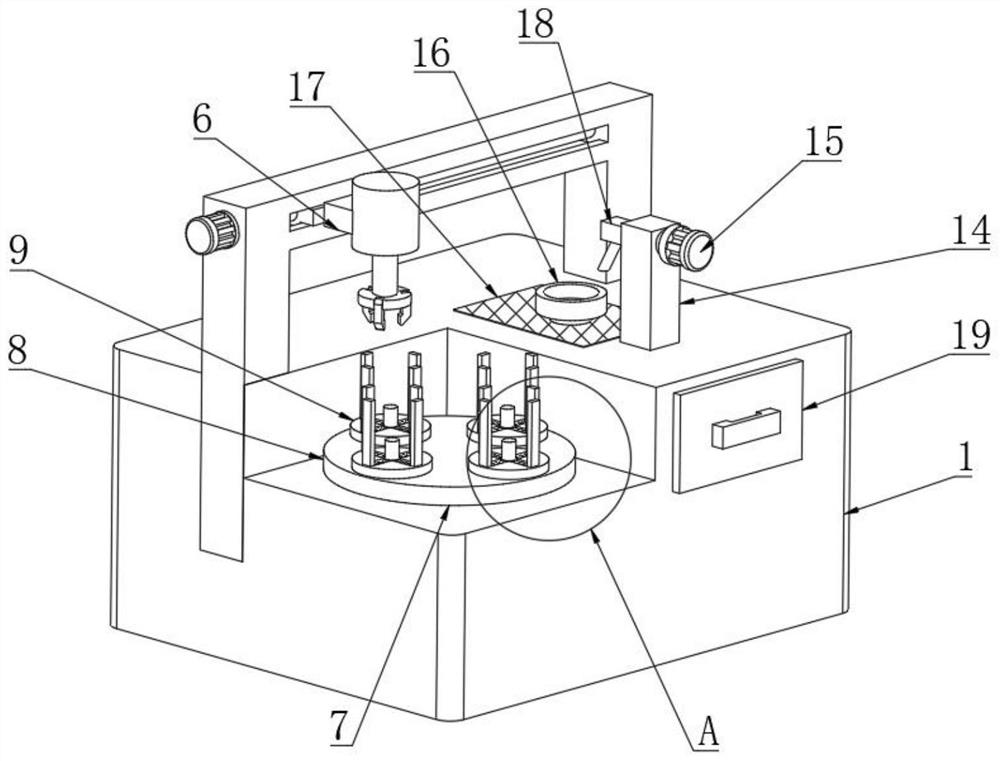

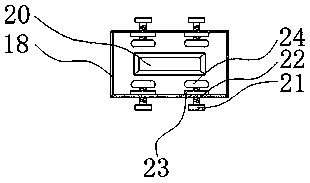

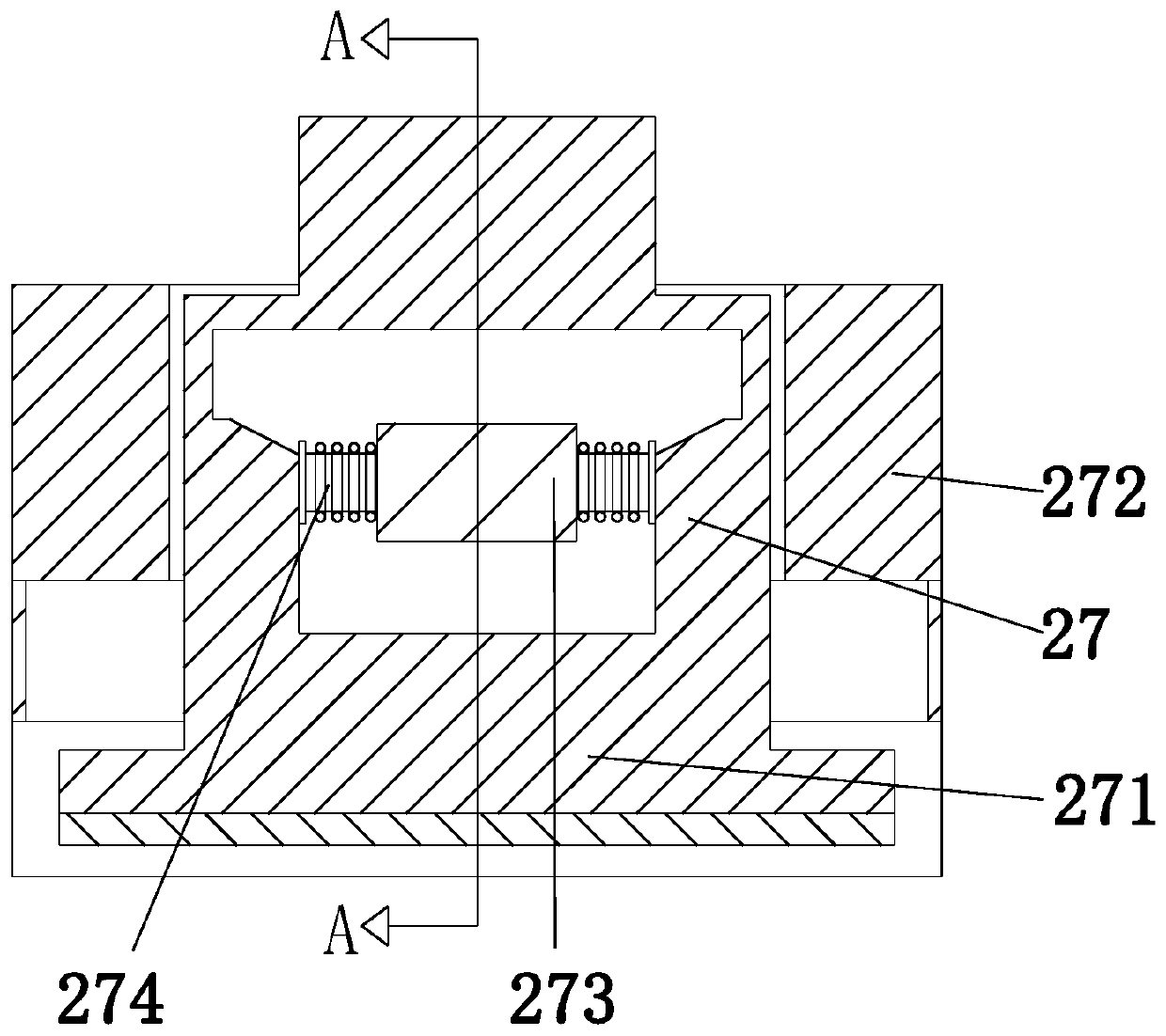

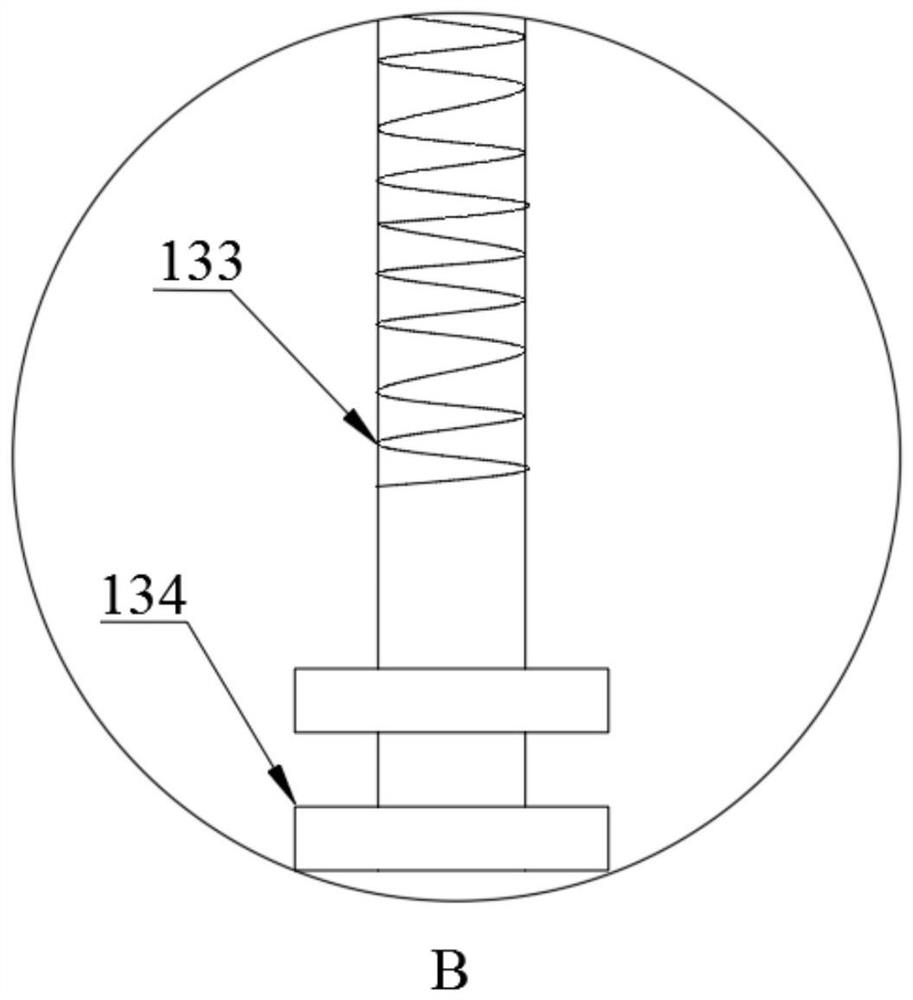

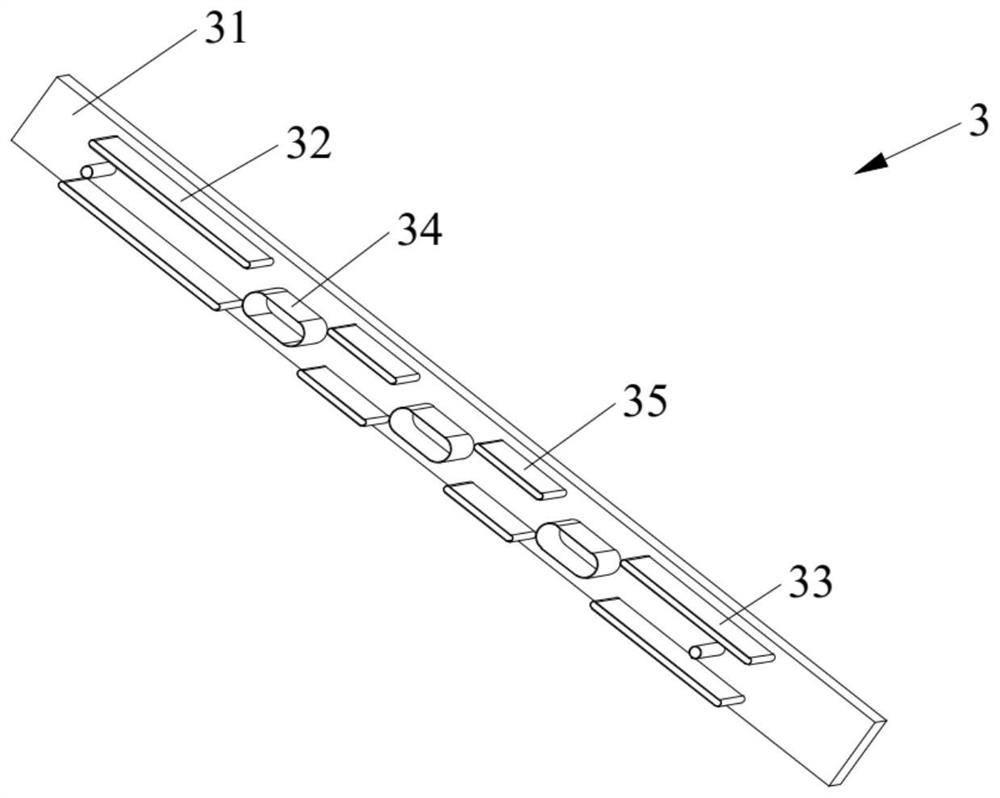

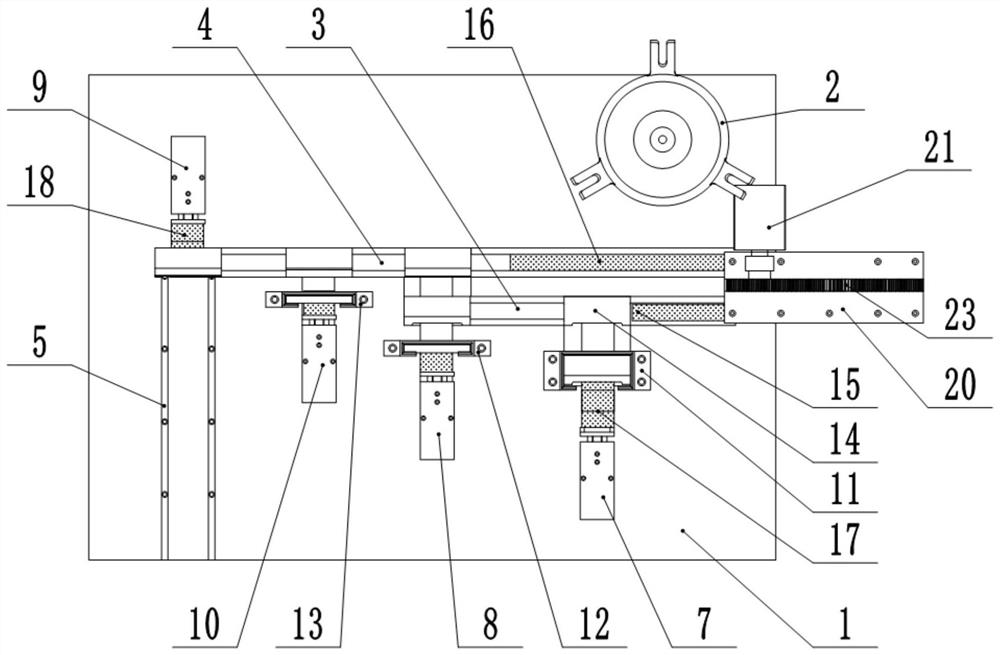

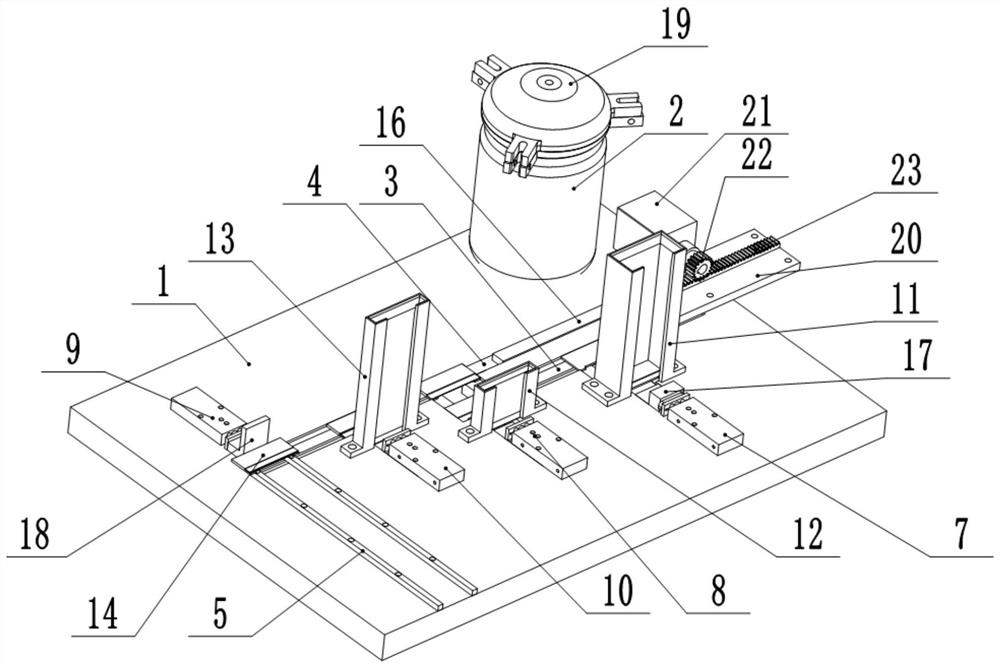

Adjustable pneumatic miller fixture

InactiveCN104802009AEasy clampingAvoid affecting processing efficiencyPositioning apparatusMetal-working holdersMechanical engineeringPiston rod

The invention discloses an adjustable pneumatic miller fixture. The adjustable pneumatic miller fixture is characterized by comprising an air distribution valve arranged on a fixture body, wherein the air distribution valve is connected with an air cylinder through a communicating pipe; a piston is arranged inside the air cylinder; the tail end of the piston rod is connected with a single-hinge lever through a roller; the other end of the lever is connected with a propping plate for compacting a surface of workpiece; a support block is arranged between the bottom of the roller and the fixture body; a support plate is arranged between the workpiece and the fixture body; a plurality of blind holes are formed in the bottom of the support plate and fixedly arranged on the fixture body through a plurality of screws. Preferably, a positioning key is arranged on the fixture body; the fixture body is connected with a T-shaped groove on a miller workbench through the positioning key. Clamping of workpieces at different heights is facilitated; impact of processing efficiency caused by replacement of the fixture is avoided and usage scope of the fixture is increased.

Owner:SUZHOU HUALAI PHOTOELECTRIC INSTR

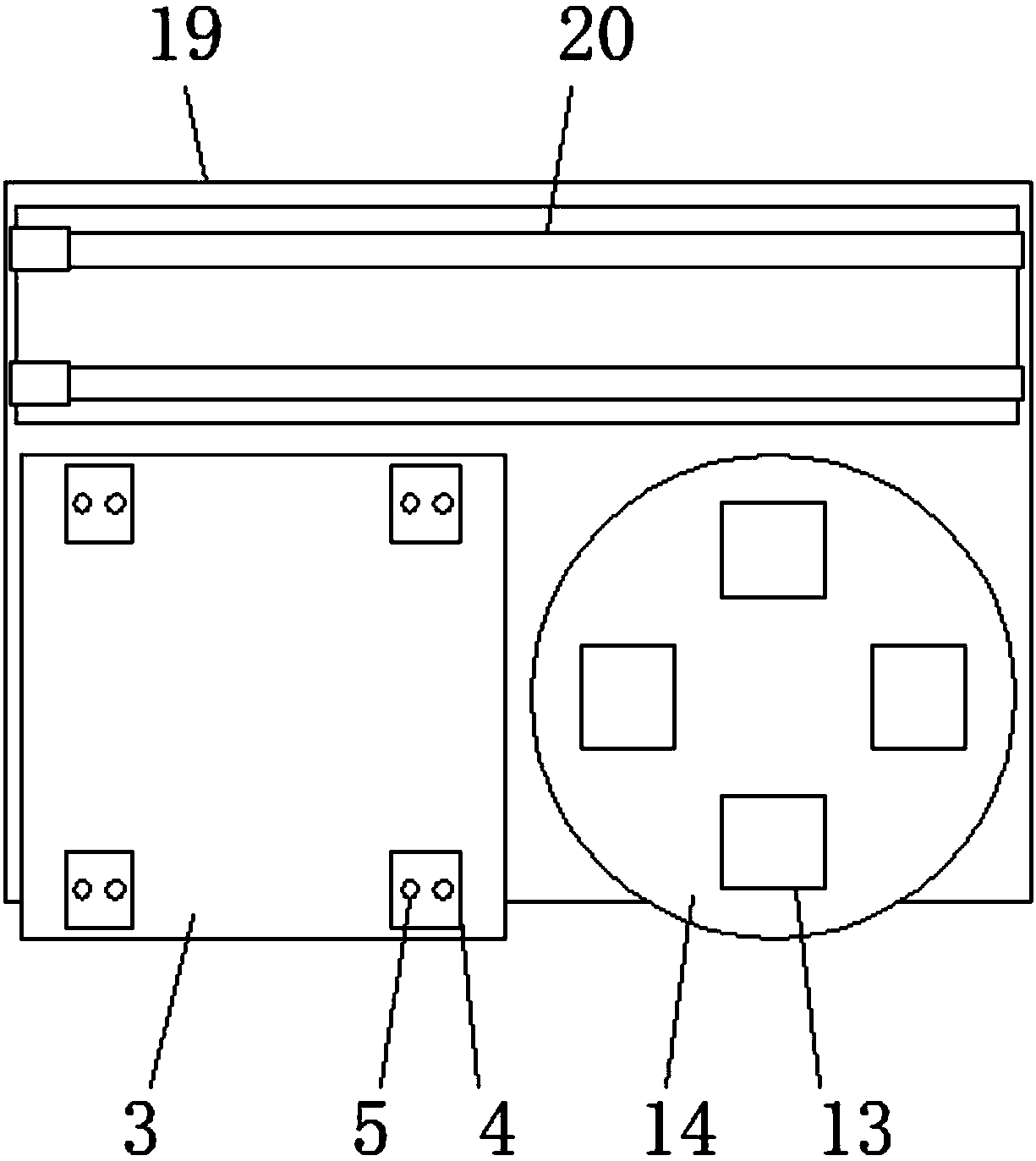

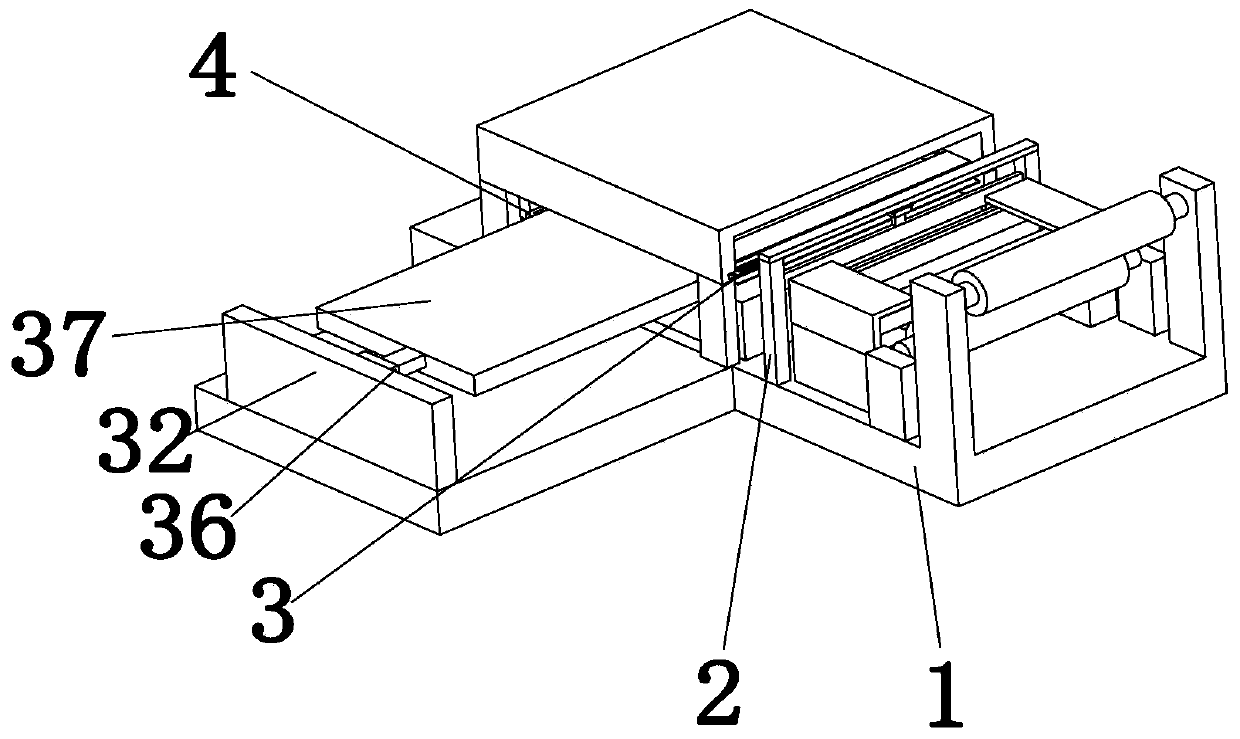

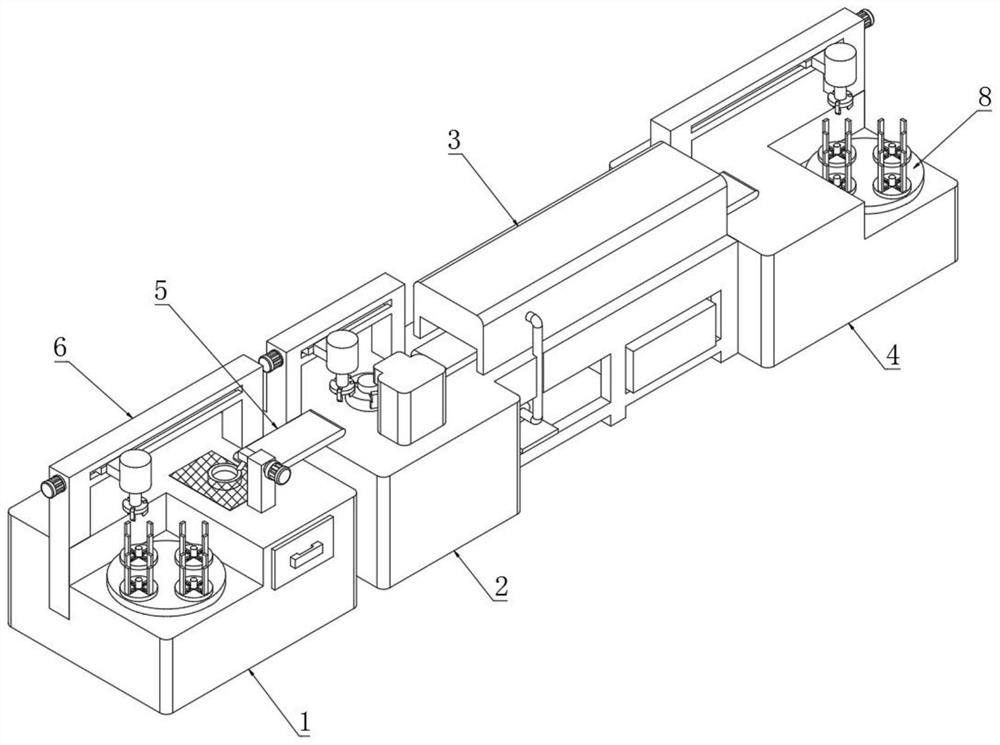

Equipment for spraying PTFE on framework oil seal lip and spraying method of spraying PTFE on framework oil seal lip

ActiveCN111715455AScientific and reasonable structureEasy to usePretreated surfacesCleaning using gasesEngineeringMechanical engineering

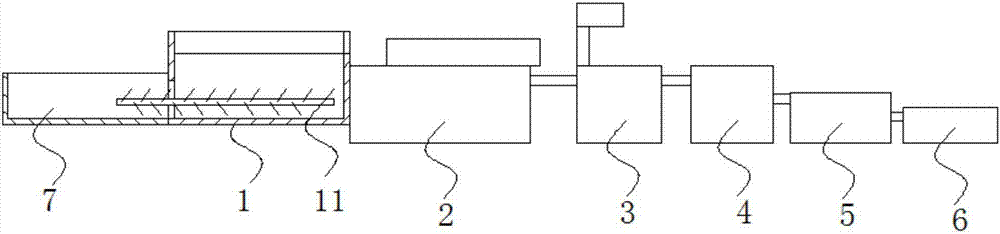

The invention discloses equipment for spraying PTFE on a framework oil seal lip and a spraying method of spraying the PTFE on the framework oil seal lip. The equipment comprises a feeding table, wherein a spraying table is fixedly connected to one end of the feeding table, a drying channel is fixedly connected to the other end of the spraying table, a discharging table is fixedly connected to theother end of the drying channel, and conveyors are fixedly connected to positions of adjacent sides of top end of the feeding table and the top end of the spraying table. The equipment is scientific and reasonable in structure and safe and convenient to use, station rotary discs, placement bases, fixing rods, clamping grooves, limiting rods and tension springs are arranged, and products are conveniently stacked in order through the station rotary discs on the feeding table and the discharging table, so that movable clamps conveniently grab the products, the product feeding and discharging speed is increased, the working efficiency is improved, and meanwhile, the limiting rods are pulled through the tension springs to drive the limiting rods to retract along the clamping grooves, and then the station rotary discs conveniently place the products with different specifications.

Owner:陕西奉航科技有限责任公司

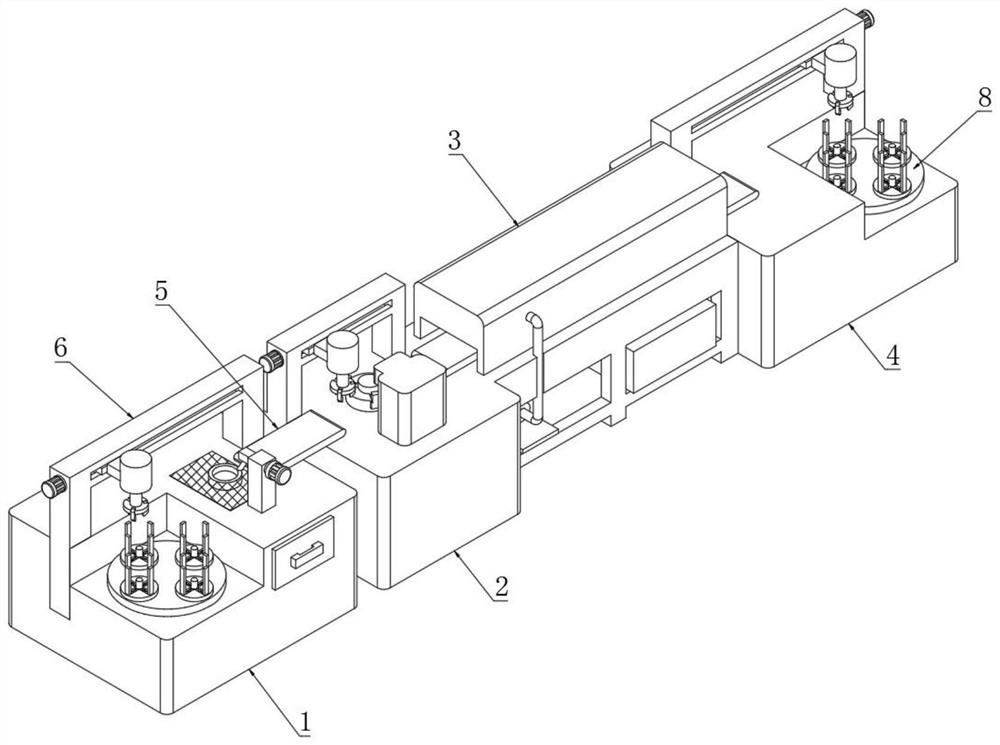

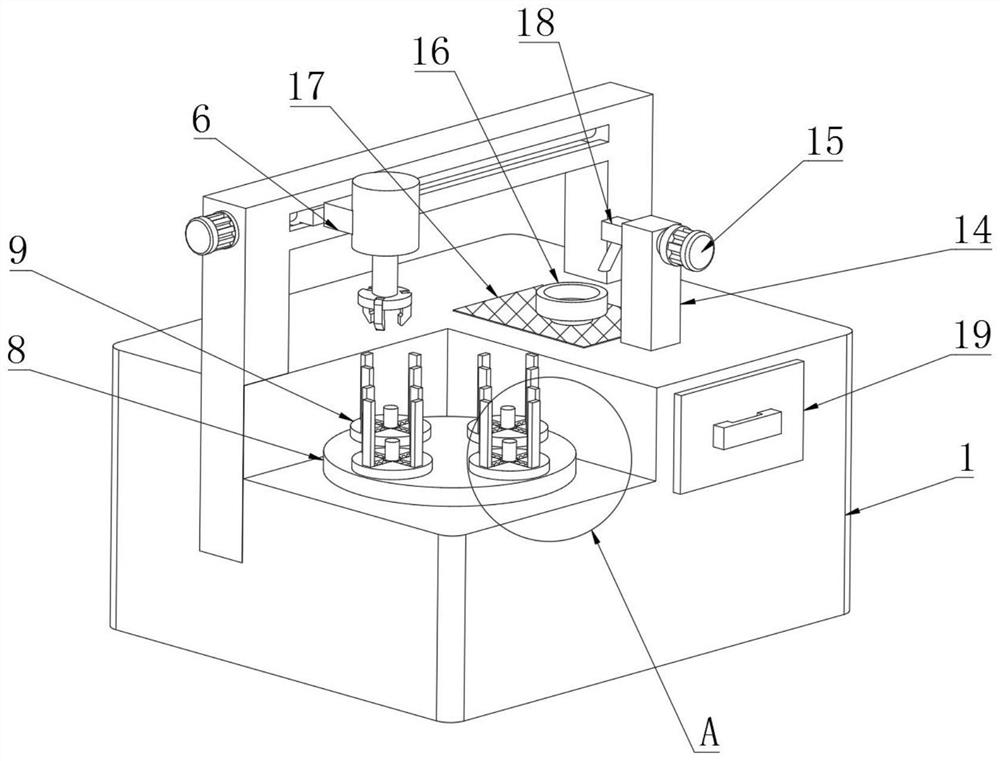

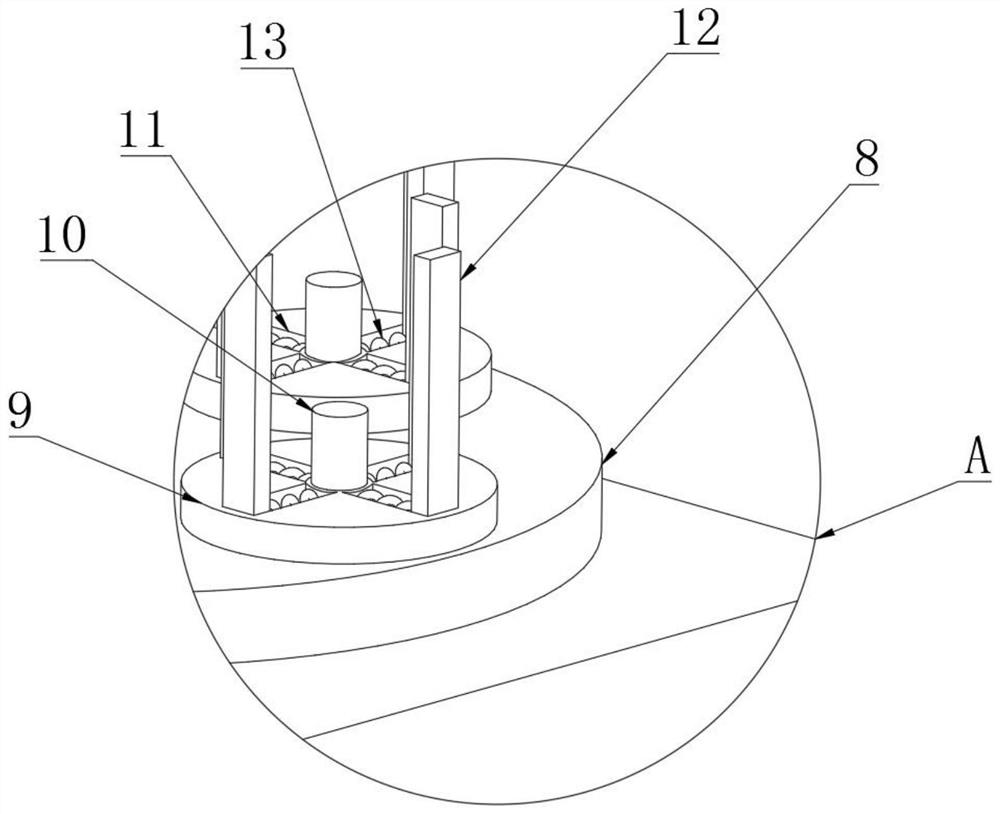

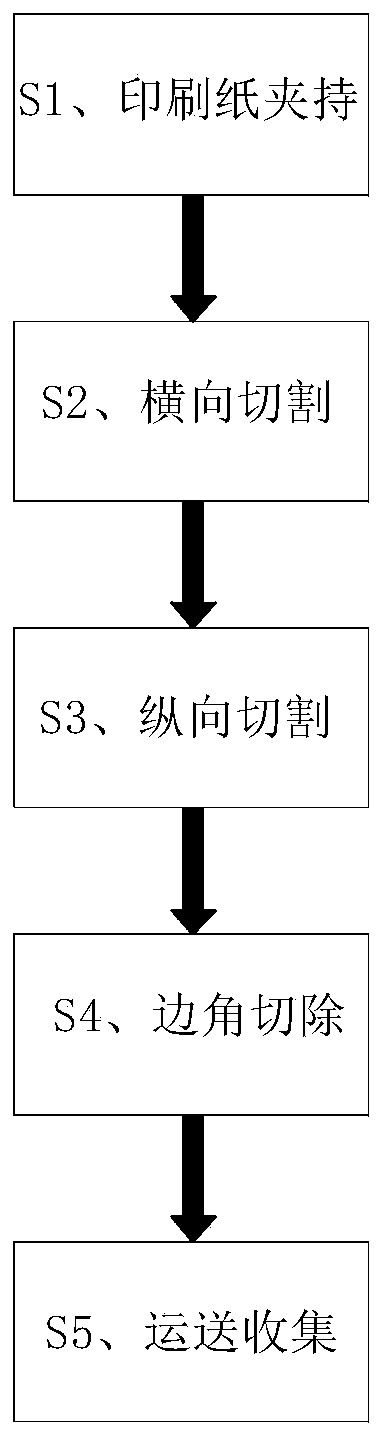

Processing technology for printing paper

ActiveCN111516037AAchieve horizontal cuttingAvoid the problem of frequent tool changesMetal working apparatusProcess engineeringManufacturing engineering

Owner:东莞市新锐源防伪科技有限公司

Tea processing and cleaning device

InactiveCN108554888AAffect qualityEconomic lossTea dryingDrying machines with non-progressive movementsEngineeringControl switch

The invention discloses a tea processing and cleaning device. The tea processing and cleaning device comprises a box frame with an upward opening and a cleaning screen frame, wherein a control panel is mounted on the middle part of the left side of the box frame; a lifting switch, a control switch and a speed regulating switch are sequentially mounted at the front side of the control panel from top to bottom; the left end of the top of the box frame is perpendicularly welded with a bracket which is in the shape of inverted L; and one end, away from the box frame, of the bracket is vertically equipped with an air cylinder in a downward penetrating mode. According to the tea processing and cleaning device disclosed by the invention, a speed regulating motor is engaged with a gear through a transmission gear, and a shaft rod on the bottom of the cleaning screen frame drives the cleaning screen frame to rotate to throw out a great deal of water in tea, so that the problem that time and labor are wasted and even processing efficiency is affected as tea is dehydrated by a dehydrating device after being cleaned and taken out is avoided. The tea processing and cleaning device is relativelypractical, and is suitable for being widely popularized and used.

Owner:NANAN TIANHONG ELECTRONICS TECH CO LTD

A kind of equipment and method for spraying PTFE on lip of skeleton oil seal

ActiveCN111715455BScientific and reasonable structureEasy to usePretreated surfacesCleaning using gasesMechanical engineeringIndustrial engineering

The invention discloses a device for spraying PTFE on the lip of a skeleton oil seal and a spraying method thereof. It includes a feeding table, one end of the feeding table is fixedly connected with a spraying table, and the other end of the spraying table is fixedly connected with a drying channel. The other end of the drying channel is fixedly connected with a blanking table, and the top of the feeding table and the adjacent side of the top of the spraying table are fixedly connected with a conveyor. The structure of the present invention is scientific and reasonable, and it is safe and convenient to use. Position turntable, placement seat, fixed rod, card slot, limit rod and tension spring, through the station turntable on the loading table and unloading table, it is convenient to stack the products neatly, so as to facilitate the mobile fixture to grab the products and improve the The speed of product loading and unloading is improved, and the efficiency of work is increased. At the same time, the limit rod is pulled by the tension spring, which drives the limit rod to shrink along the card slot, thereby facilitating the placement of products of different specifications on the station turntable.

Owner:陕西奉航科技有限责任公司

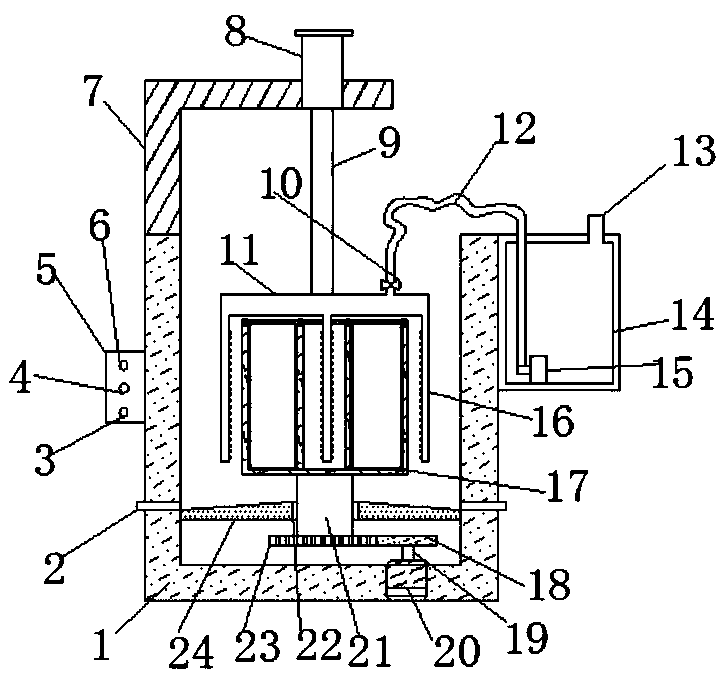

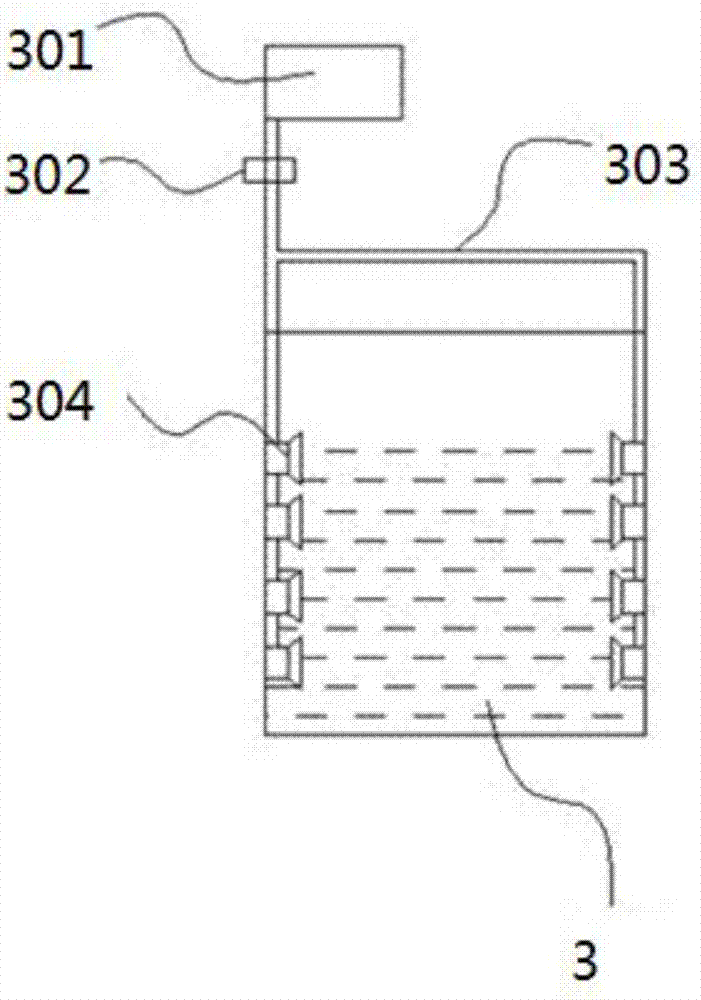

Integral intelligent industrial wastewater treatment system

InactiveCN107572730AAvoid problems such as clogged equipmentAvoid affecting processing efficiencyWater contaminantsClimate change adaptationIndustrial effluentWater quality

The invention discloses an integral intelligent industrial wastewater treatment system, belongs to the field of industrial wastewater treatment devices, and aims to implement effective comprehensive treatment on industrial wastewater and achieve relatively stable quality of effluent of treated industrial wastewater and relatively low cost. The system comprises a dry-wet separation tank, a primarytreatment tank, a hydrolysis treatment tank, a contact oxidation pond, a settling pond, a clean water tank and a sludge fermentation tank, wherein the primary treatment tank, the hydrolysis treatmenttank, the contact oxidation pond, the settling pond and the clean water tank are sequentially connected through pipelines; the dry-wet separation tank is communicated with the sludge fermentation tankthrough a pipeline; the dry-wet separation tank and the primary treatment tank are arranged together; the primary treatment tank is 0.5m lower than the dry-wet separation tank; and sludge hoppers arearranged at the bottom of the dry-wet separation tank and inside a communicating pipeline between the dry-wet separation tank and the sludge fermentation tank. The system is mainly applied to industrial wastewater treatment on primary processing of farm products and pasture products.

Owner:内江市旭日环境科技有限公司

Spun yarn waxing device used for spinning and capable of preventing yarn breakage

The invention discloses a spun yarn waxing device used for spinning and capable of preventing yarn breakage and relates to the technical field of spun yarn waxing. The device comprises an anti-slidingblock and a first connecting rod, a support block is mounted above the anti-sliding block, a base is arranged above the support block, and vent holes are formed in the outer side of the base. A fixing block, an air cylinder, a piston, a straight rod, an ejector rod, a casing, a hydraulic rod and a wax groove are arranged in the spun yarn waxing device used for spinning and capable of preventing yarn breakage, a user can fix the air cylinder above the base through the fixing block, the user can slide the piston up and down in the air cylinder, the piston can well support the straight rod, thestraight rod can well support the ejector block, then, during use, the hydraulic rod can drive the wax groove to telescope upwards with reduction of a wax block so as to enable the wax block to make contact with spun yarn, the user can use the device conveniently, non-uniform waxing of the spun yarn due to reduction of the wax block can be well avoided, and the processing quality of the device isenhanced.

Owner:杨国丽

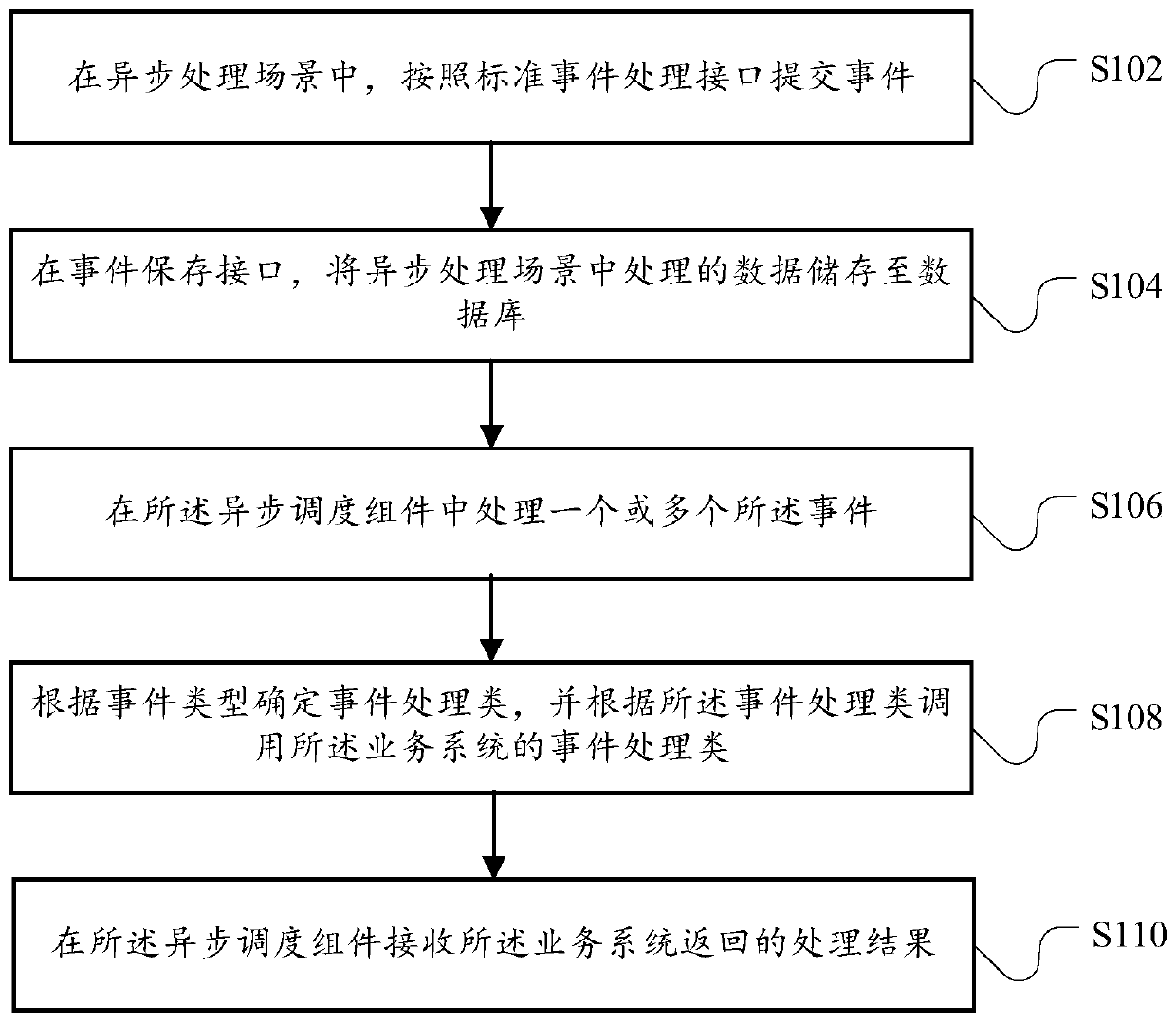

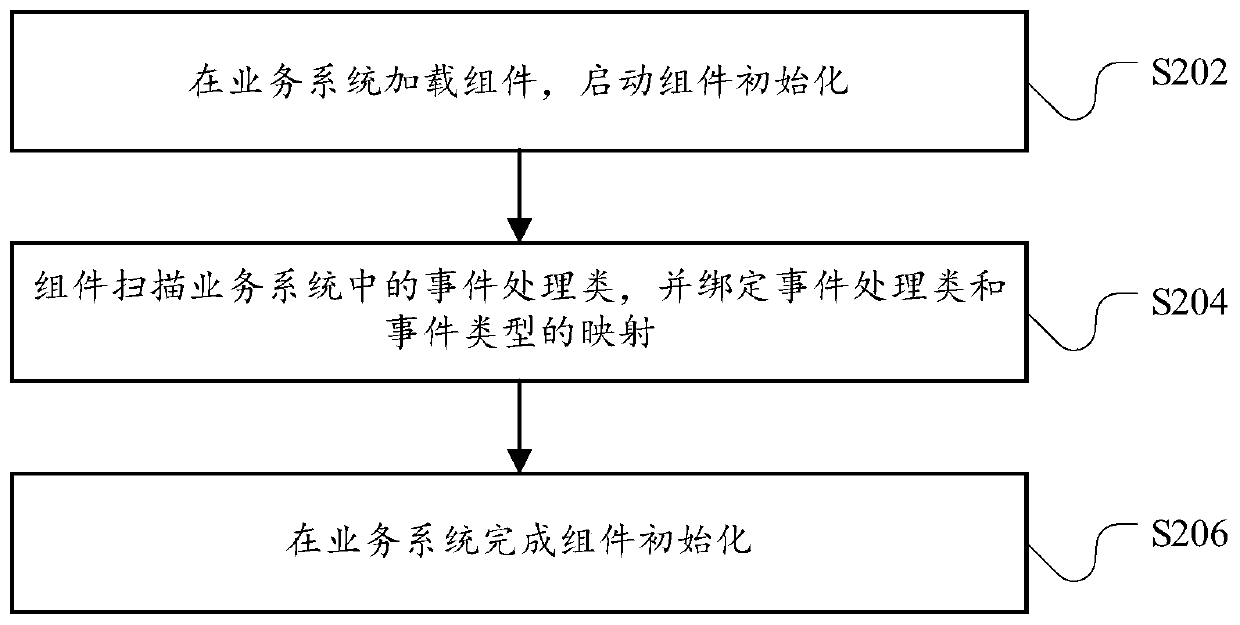

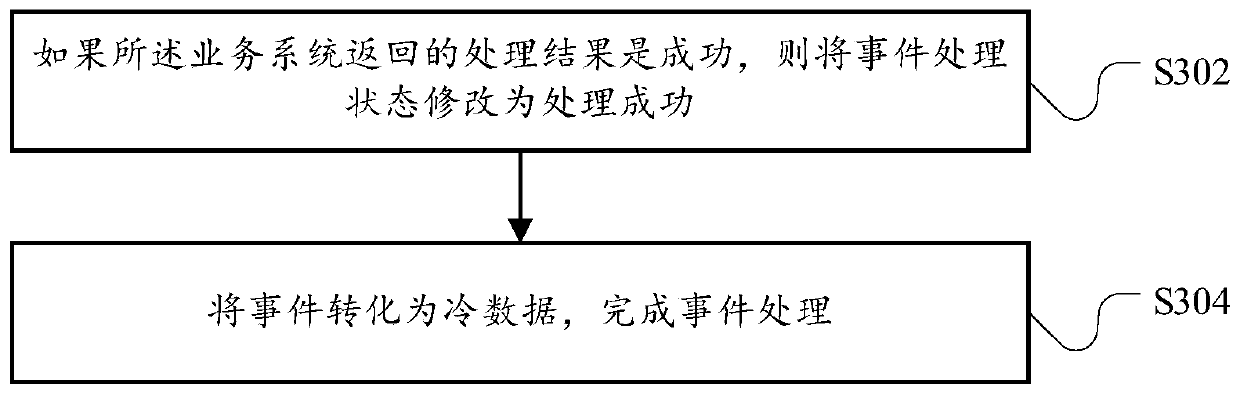

Asynchronous scheduling method and device for service system

ActiveCN110321211ARealize the standardization of the whole processSolve costly technical problemsProgram initiation/switchingEvent typeOperating system

The invention discloses an asynchronous scheduling method and device for a service system. The method comprises the following steps: in an asynchronous processing scene, submitting an event accordingto a standard event processing interface; storing the data processed in the asynchronous processing scene to a database at an event storage interface; processing one or more of the events in the asynchronous scheduling component; determining an event processing class according to the event type, and calling the event processing class of the business system according to the event processing class;and receiving a processing result returned by the service system at the asynchronous scheduling component. The technical problem of high asynchronous processing cost is solved. According to the invention, an asynchronous processing scene is conceptualized and abstracted. The embedded component in the application is easy to be integrated with a service system. Extra deployment is not needed, so that hardware resources are saved.

Owner:上海数禾信息科技有限公司

Spandex fiber chipping device

InactiveCN109989132AKeep healthyAvoid affecting slice processing efficiencySevering to form staple fibresMetal working apparatusHydraulic cylinderFiber

The invention relates to the technical field of spandex processing and discloses a spandex fiber chipping device, comprising a body. A hydraulic cylinder is fixedly connected to the top of an inner cavity of the body. A first connection rod is fixedly connected to the output end of the hydraulic cylinder; the bottom of the first connection rod is fixedly connected with the top of a cutting tool; adust remover is fixedly connected to the sidewall of the inner cavity of the body; a conveyer belt is arranged inside the body; a leveling device is fixedly connected to the upper surface of the conveyer belt and comprises a fixing rack; both ends of the fixing rack are fixedly connected to the two sides of the upper surface of the conveyer belt; an upper wheel is movably connected to the top endof the inside of the fixing rack; a lower wheel is movably connected to the bottom end of the inside of the fixing rack; an adjusting plate is fixedly connected to the top end of an upper wheel spindle. The dust remover of the spandex fiber chipping device helps drive blades to rotate through a motor, so that dust raised during chipping can be sucked into a dust collection box; it is avoided thatthe raised dust affects chipping efficiency, and physical health of workers is guaranteed.

Owner:JIANGSU QIAOXIN FIBER

Raw rubber cutting equipment and plastication method

InactiveCN111604967AImprove cutting efficiencyAvoid sliding frictionMetal working apparatusMechanical engineeringIndustrial engineering

The invention discloses raw rubber cutting equipment and a platication method, and relates to the field of raw rubber processing equipment. The raw rubber cutting equipment comprises a supporting assembly, a transportation device and at least one fretsaw cutting device; the transportation device is fixedly installed above the supporting assembly; the fretsaw cutting device is fixedly connected with the supporting assembly; raw rubber is placed on the transportation device; the fretsaw cutting device is connected with the raw rubber in an inserted mode; the transportation device drives the rawrubber to make transverse linear motion towards the direction of the fretsaw device; and the fretsaw cutting device makes vertical linear motion in a direction perpendicular to the motion direction ofthe transportation device. According to the equipment and the method, cutting of the raw rubber is realized by the fretsaw cutting device making high-speed linear motion, the raw rubber can be cut ina situation that the raw rubber is not baked for softening, the frequency of shutdown cleaning of the fretsaw cutting device is lowered, and the efficiency of rubber cutting is improved.

Owner:南京阿兹曼电子科技有限公司

Printing paper processing system

ActiveCN111531630AAchieve horizontal cuttingAvoid the problem of frequent tool changesMetal working apparatusProcess engineeringIndustrial engineering

The invention relates to a printing paper processing system which comprises a compression guiding rack, a transverse cut-off mechanism, a longitudinal cut-off mechanism and a stretching collecting mechanism. The printing paper processing system can solve the problems in a processing operation of printing paper that a, in a conventional printing paper cutting process, a process flow is relatively tedious as the printing paper of one specification needs to correspond to a set of tools and it is needed to replace tools for printing paper of different specifications; and b, the edge of the printing paper is treated unreasonably in existing equipment, and in a production process, subsequent use of the printing paper is affected as the edge of the printing paper may be damaged to different extents.

Owner:长兴天誉包装股份有限公司

Mincing processing device for supplied meat

InactiveCN107442231AChopped fullyReduce economic costsRotary stirring mixersTransportation and packagingElectric machineryFuel tank

The invention discloses a mincing processing device for supplied meat. The mincing processing device for supplied meat comprises a rack, a driving motor arranged on the rack, and a closed processing chamber. A mincing blade set is arranged in the closed processing chamber, and a feed hopper is arranged above the closed processing chamber. The mincing blade set is connected to the output end of the driving motor through a shaft sleeve. The mincing blade set is provided with long mincing blades and short mining blades, wherein the long mincing blades and the short mincing blades are arranged alternately, and the end of each long mincing blade and the end of each short mining blade are inlaid in the shaft sleeve and fixed through anti-throwing screws. A lubricating oil tank is further arranged on the rack, the lubricating oil tank is connected with a spraying head extending into the closed processing chamber, and the spraying head faces the mining blade set. By adoption of the mincing processing device for supplied meat, the efficiency in the meat processing process is effectively improved, and the situation that meat goes bad in a high-temperature environment for a long time is avoided.

Owner:XINDU MAJIAZHEN XINYUE MACHINERY FACTORY

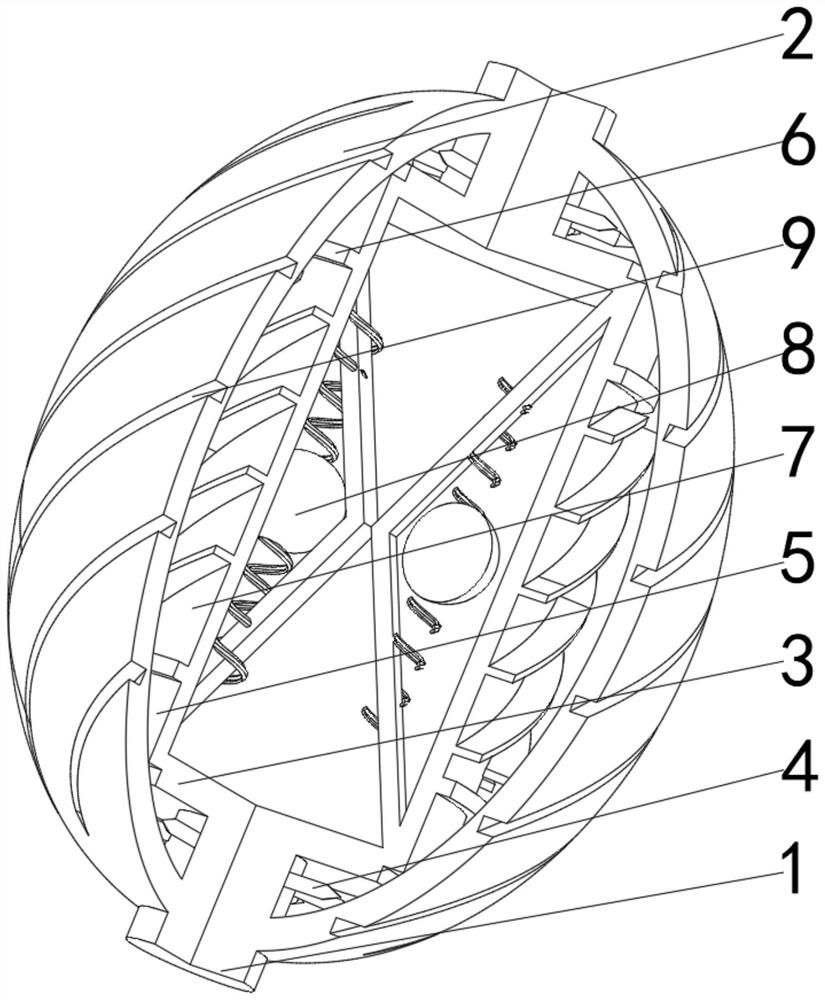

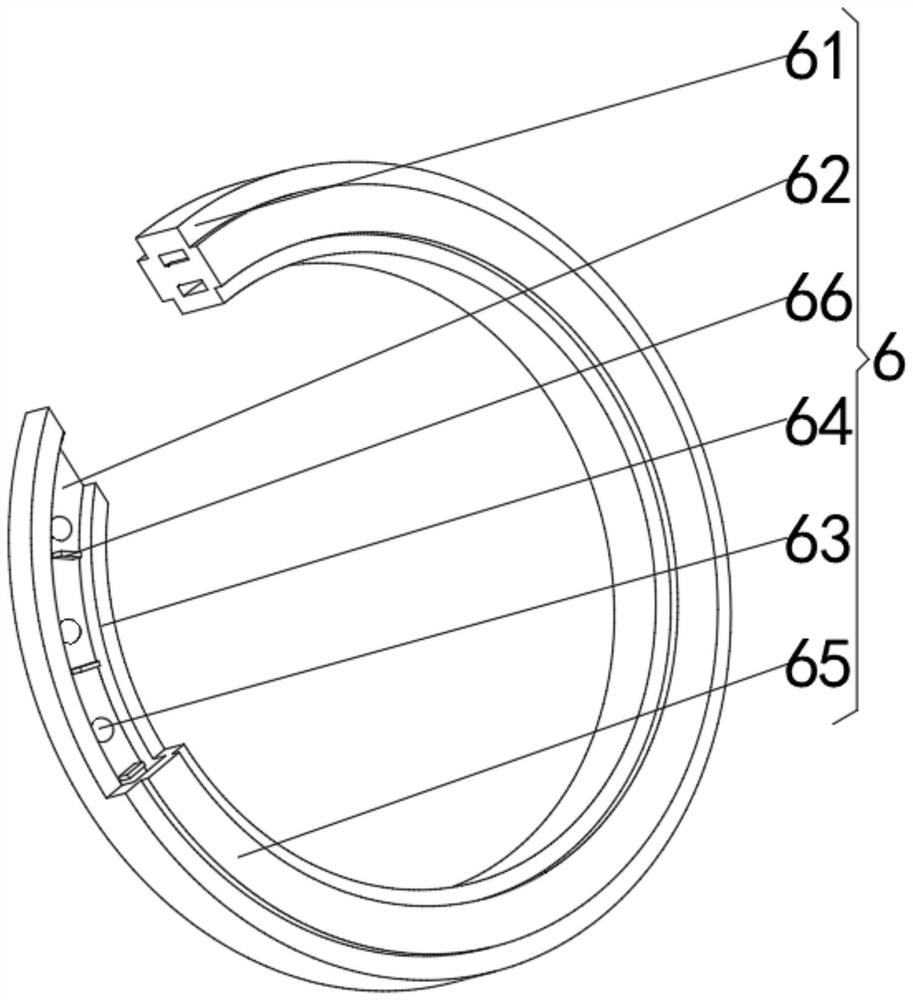

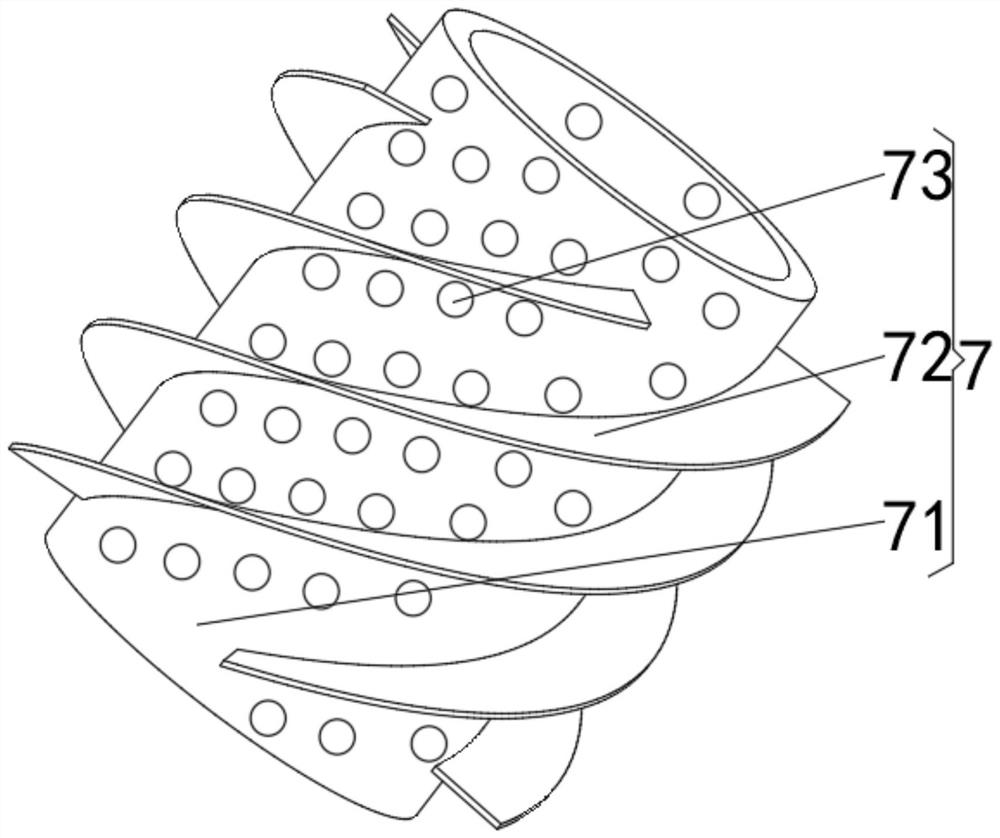

Metal surface oxidation device

PendingCN112522693AThorough processingPrevent leakageTransportation and packagingMetal-working apparatusMachine partsSurface oxidation

The invention discloses a metal surface oxidation device which comprises a mounting column, wherein an ellipsoid box is rotatably connected to the middle of the outer surface of the mounting column, friction electric plates are fixedly connected to the sides, close to each other, of the mounting column, and flow guide needles are fixedly connected to the outer surface of the mounting column and located between the ellipsoid box and the friction electric plates; a transmission ring plate is movably connected to the outer surfaces of the friction electric plates, a differential mechanism is movably connected to the side, away from the mounting column, of the transmission ring plate, a dialysis mechanism is movably connected to the side, away from the transmission ring plate, of the differential mechanism, and a reaction mechanism is movably connected to the side, away from the ellipsoidal box, of the transmission ring plate; and a spiral groove is formed in the outer surface of the ellipsoidal box. The invention relates to the technical field of oxidization. Self-rotation of internal equipment is conducted through wind power, a metal machined part is rotated through rotating torsionand intermittently subjected to an oxidation reaction with reaction liquid, so that machining is guaranteed to be more comprehensive and thorough.

Owner:万廷刚

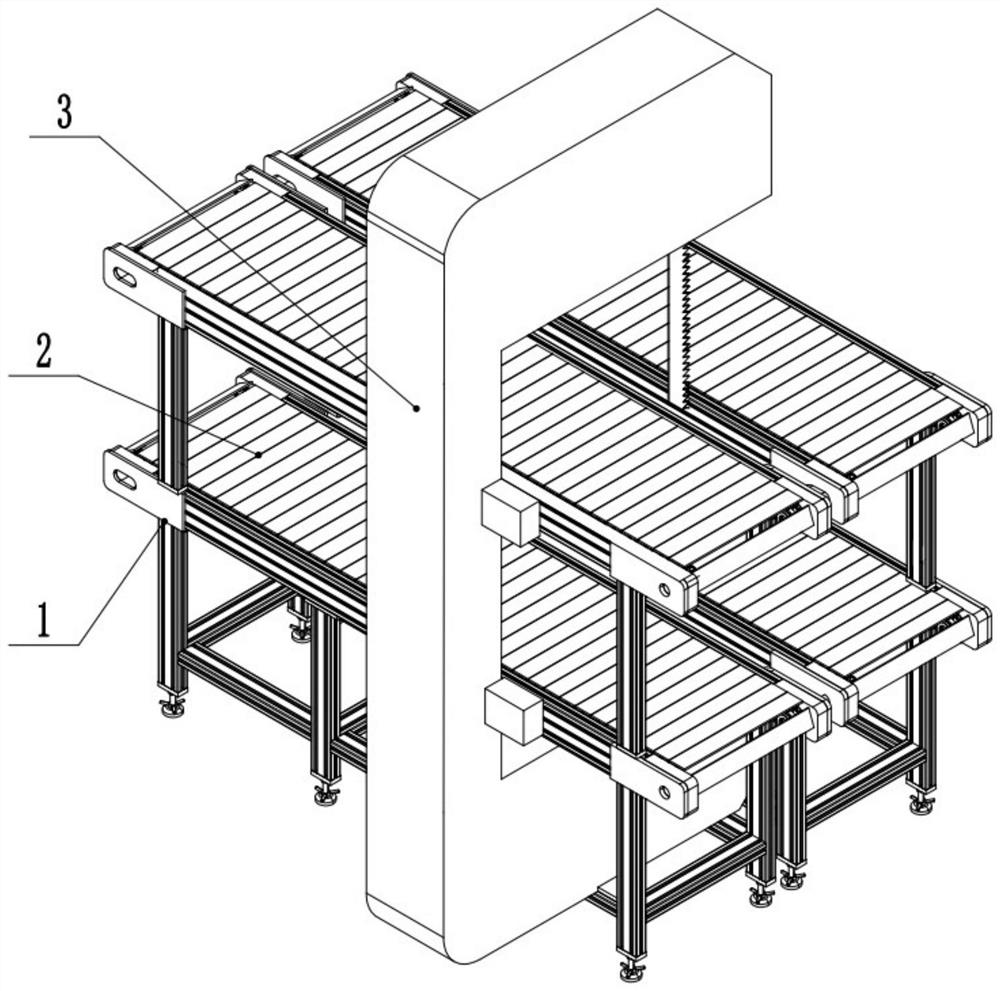

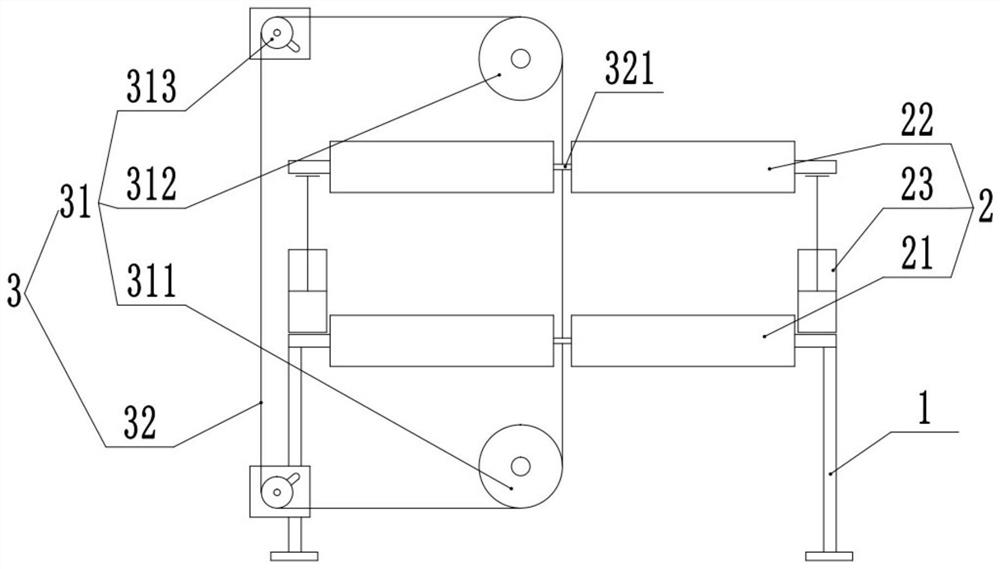

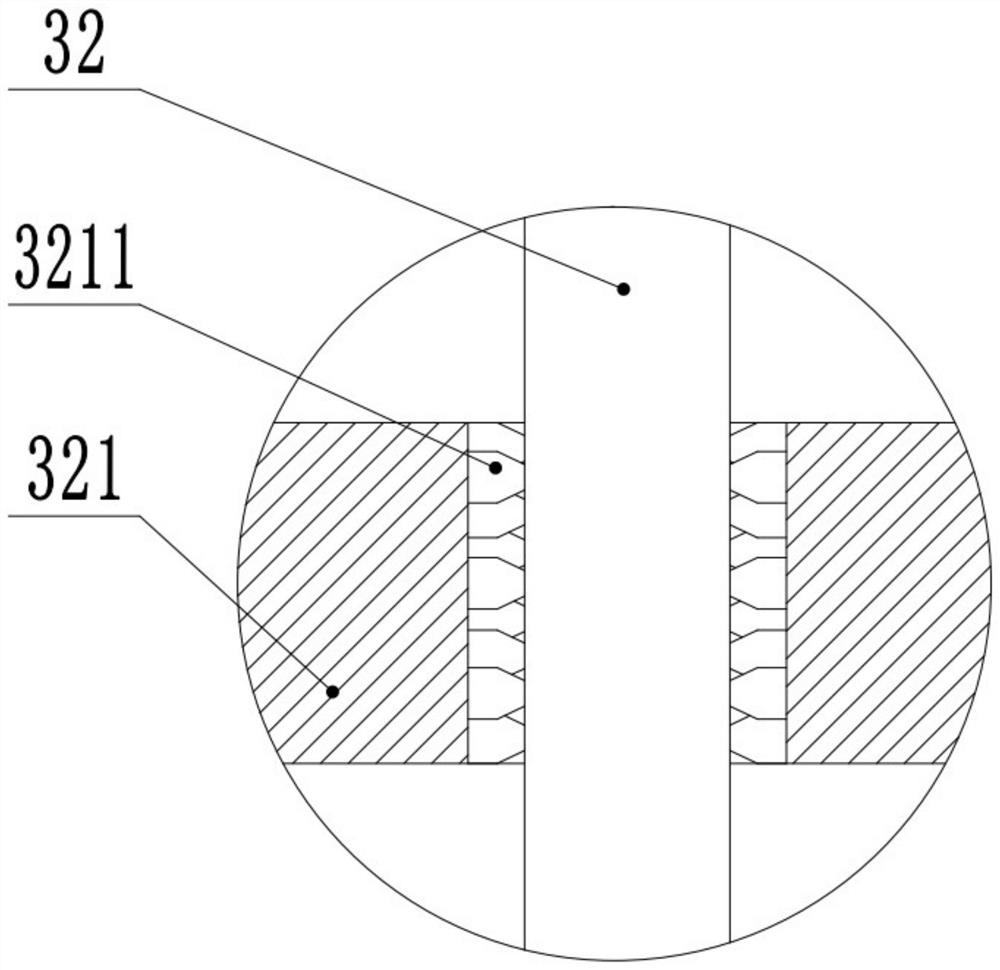

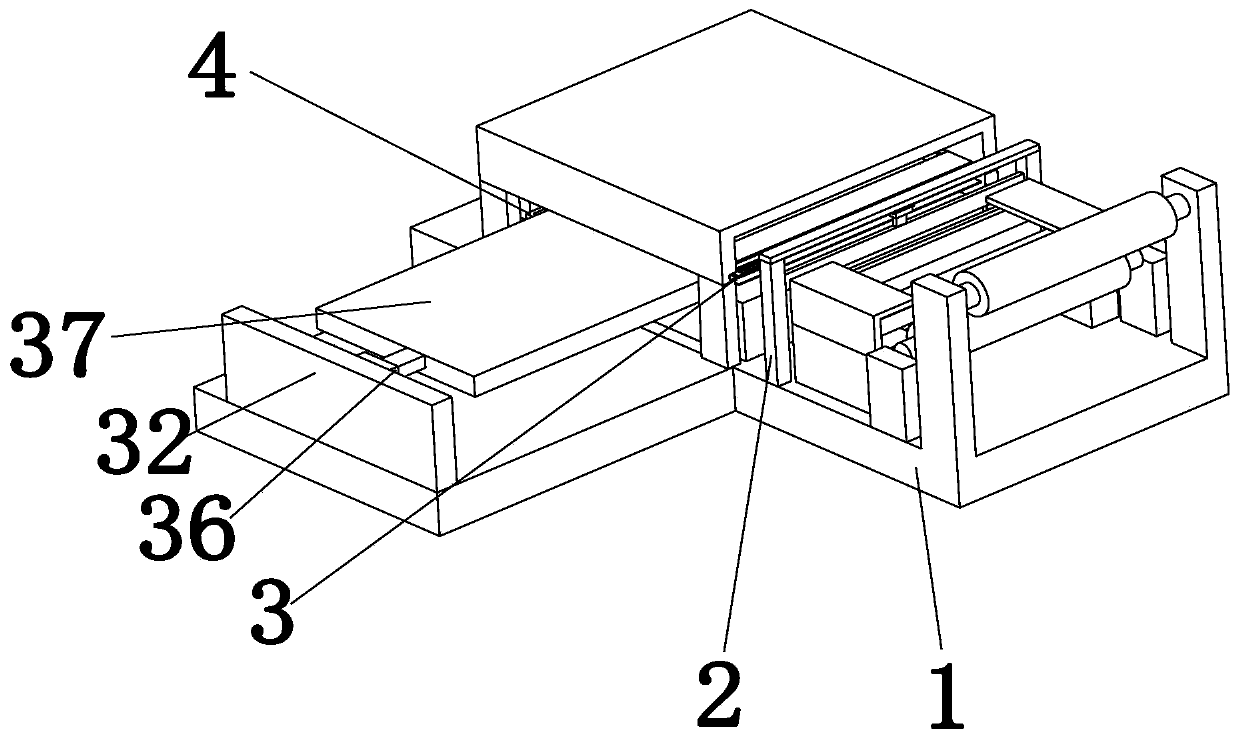

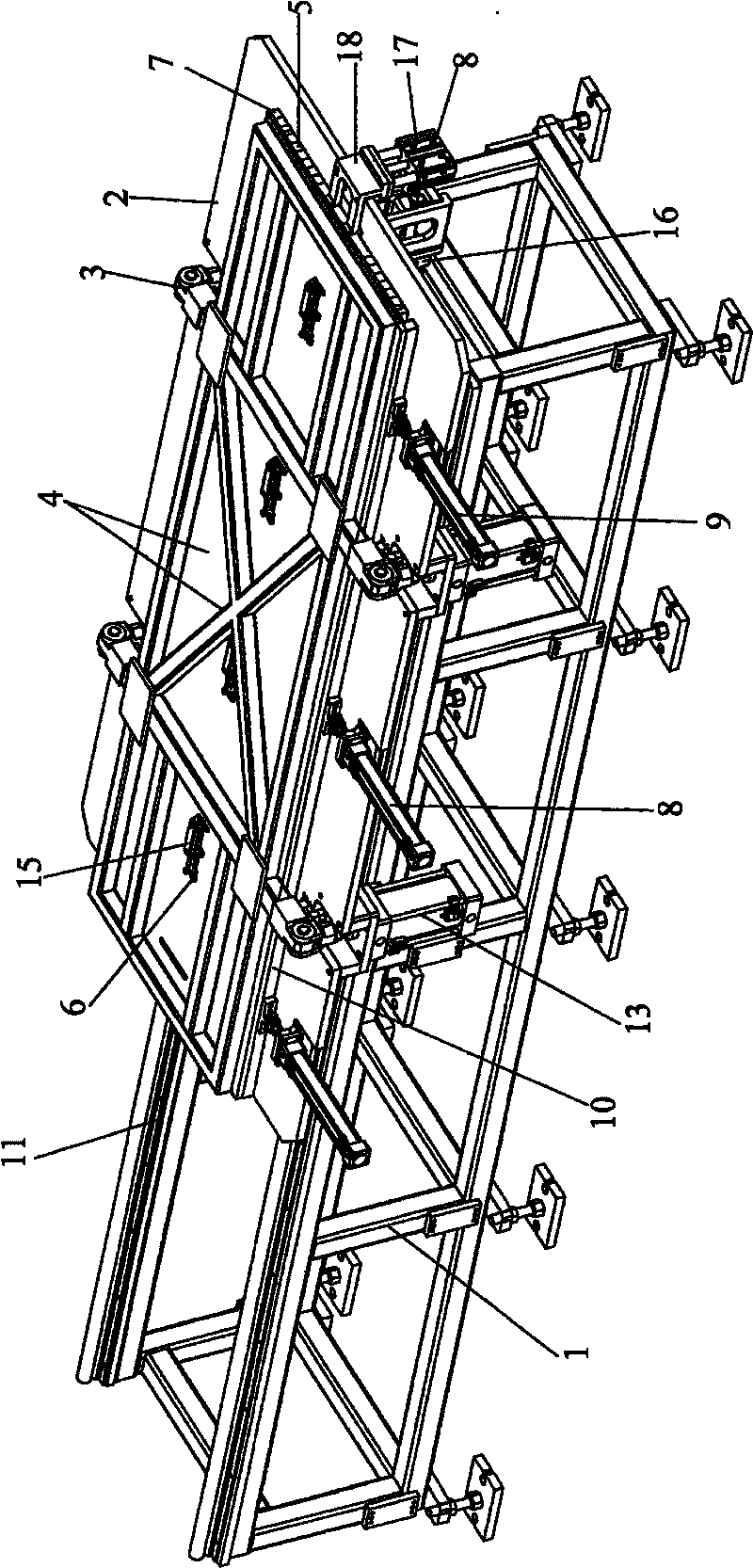

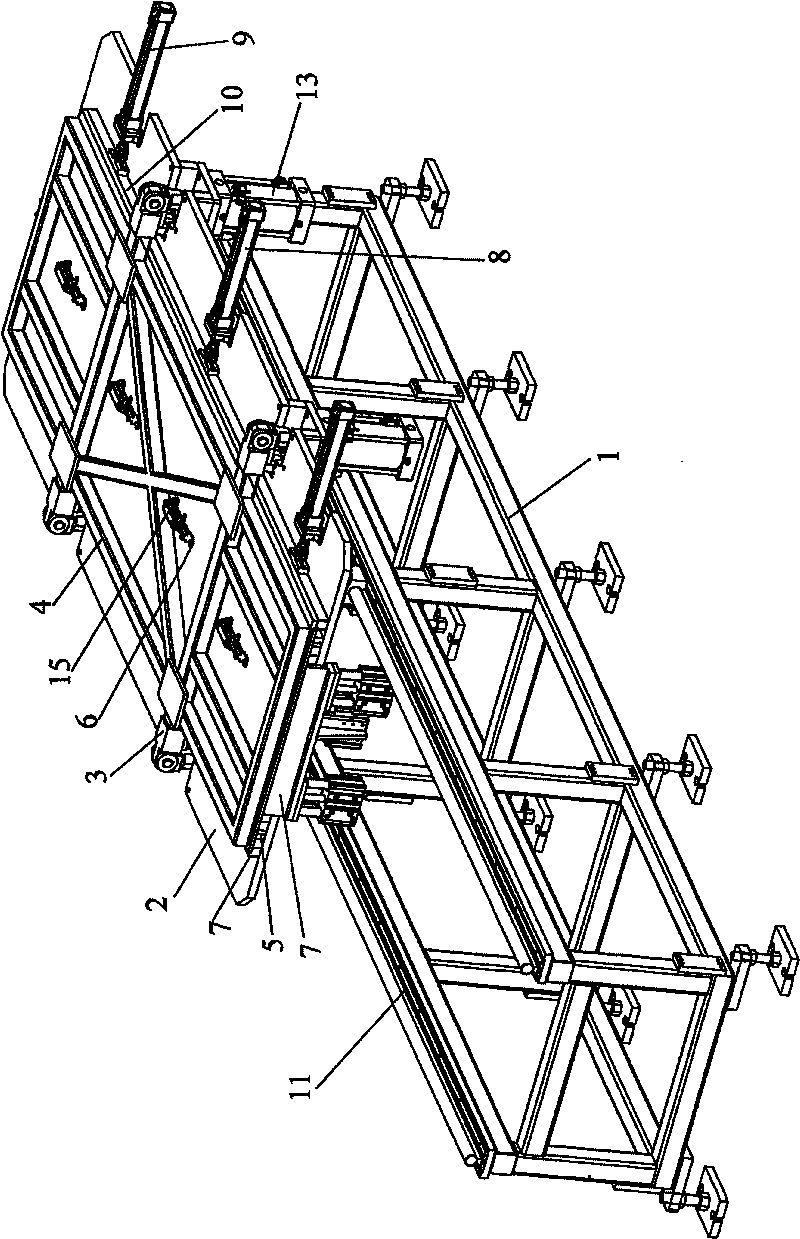

Continuous production method of foam filling panel

The invention discloses a foaming infill panel series manufacturing device, comprising at least one monoblock worktable. Each monoblock worktable comprises a stander and a worktable surface on the stander used for placing a workpiece to be processed. The worktable surface is fixed with a pressure plate erector, a lifting part of which is connected with a pressure plate which can rise and descend above the worktable surface. The pressure plate is provided with an injection hole that is on the workpiece to be processed and corresponds to a foam filling hole. The worktable surface is provided with a spacing fixed block at the periphery along the thickness direction of the workpiece to be processed. The invention can clamp the front wall and the back wall of the workpiece to be processed neatly in the middle and does not lead to expansion and deformation caused by foaming heat in filling noise deadening foam; simultaneously, as the device comprises a plurality of monoblock worktables, a foam jet is always in operating condition, thus avoiding the solidification of foam on the foam jet when replacing manufacturing workpieces and having high processing efficiency.

Owner:SHENLONG ELEVATOR

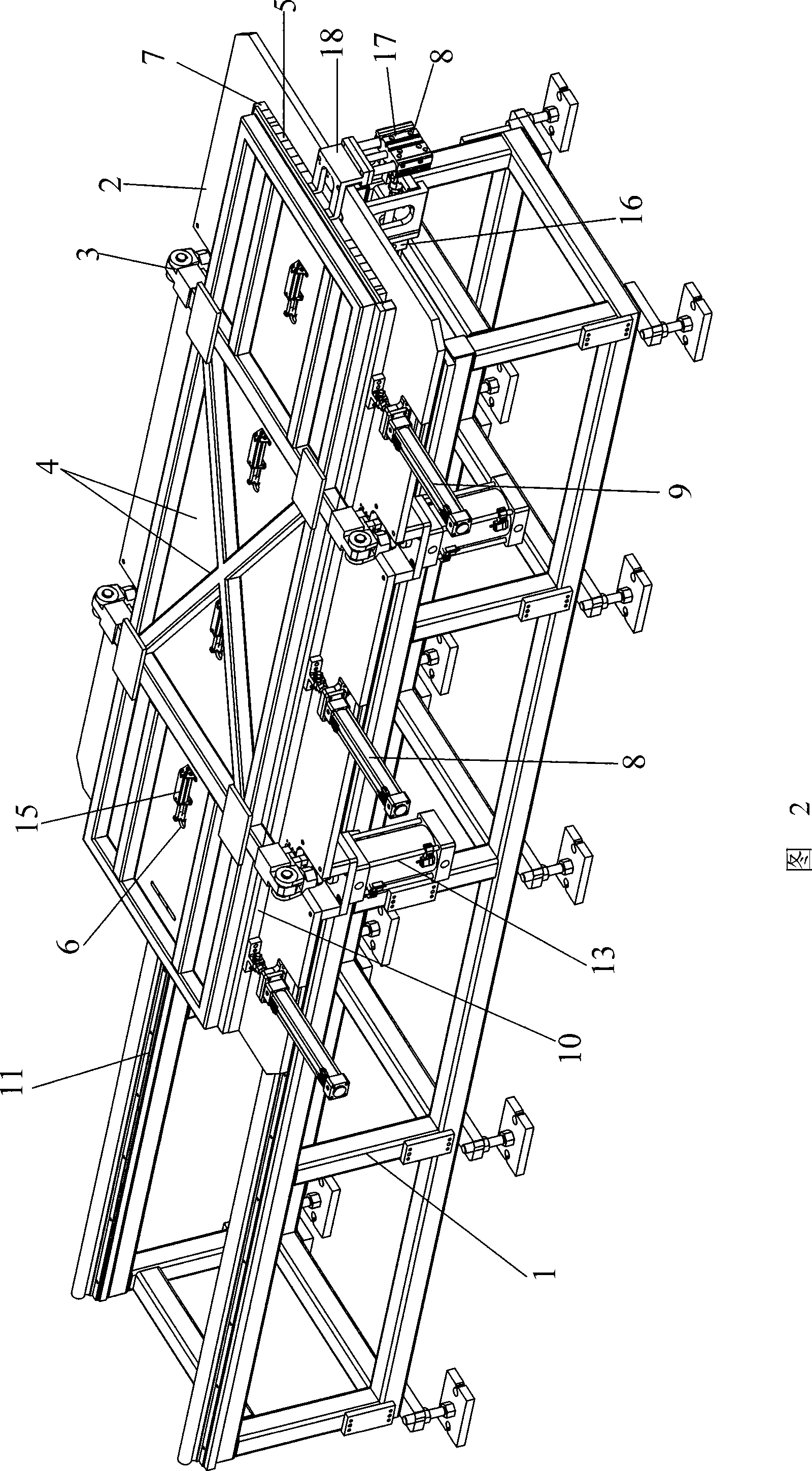

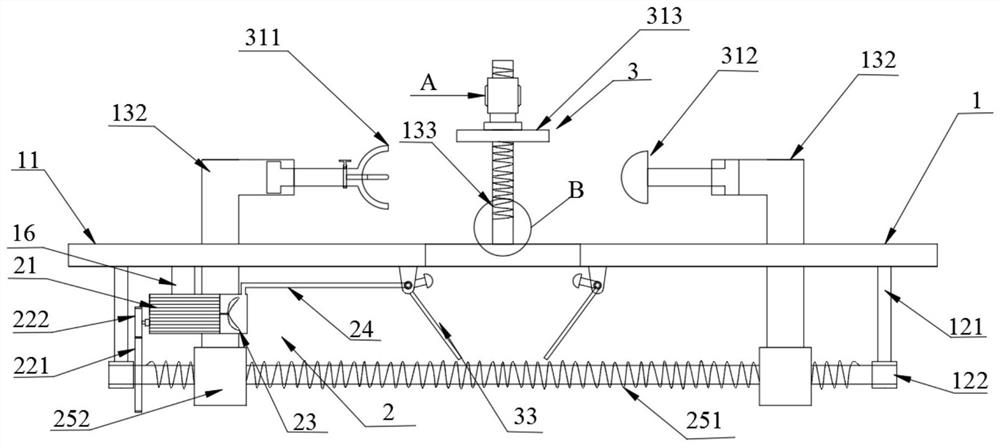

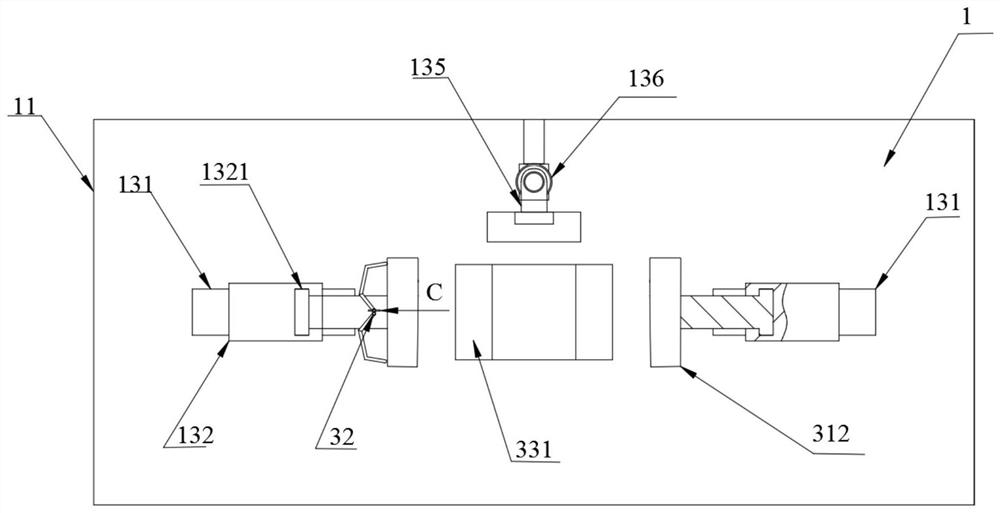

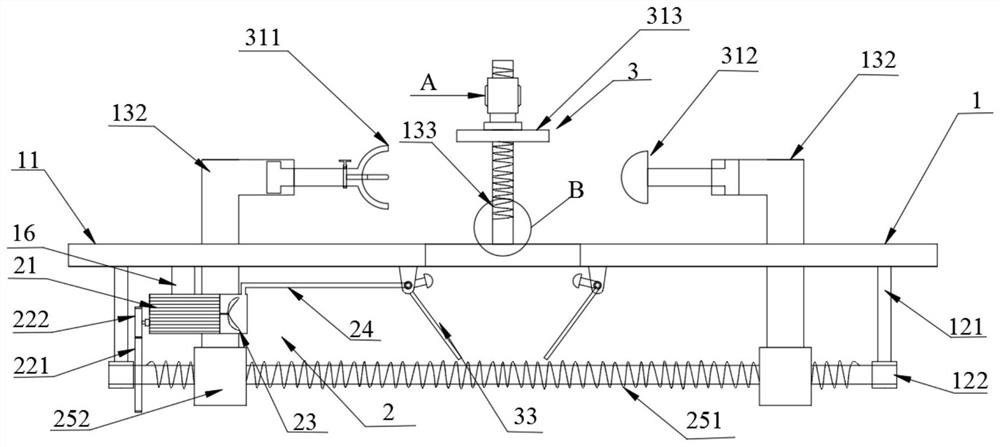

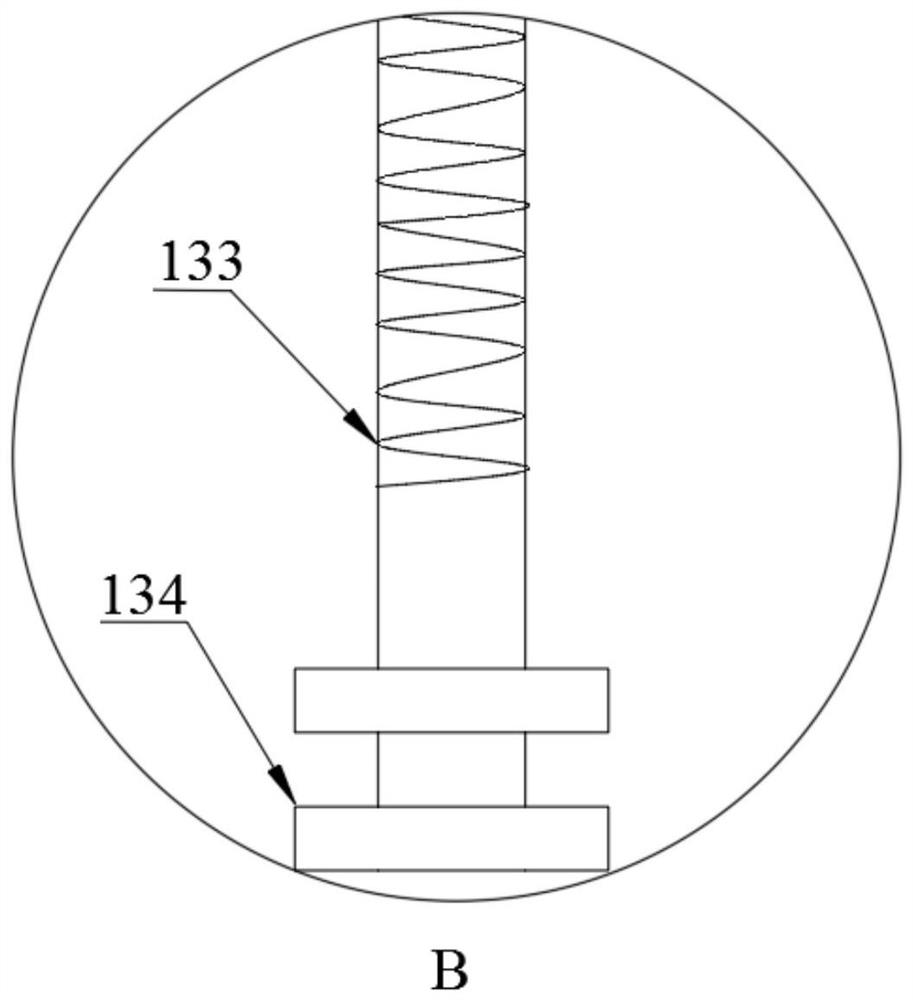

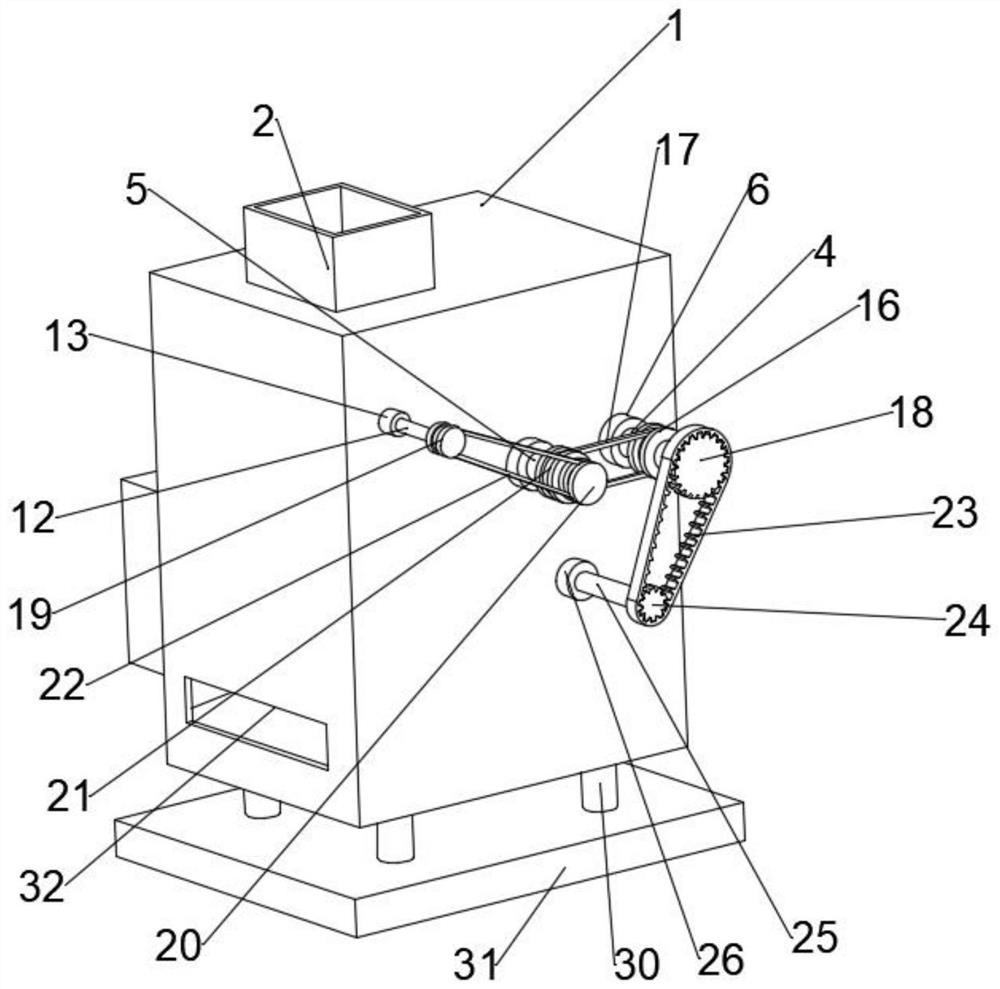

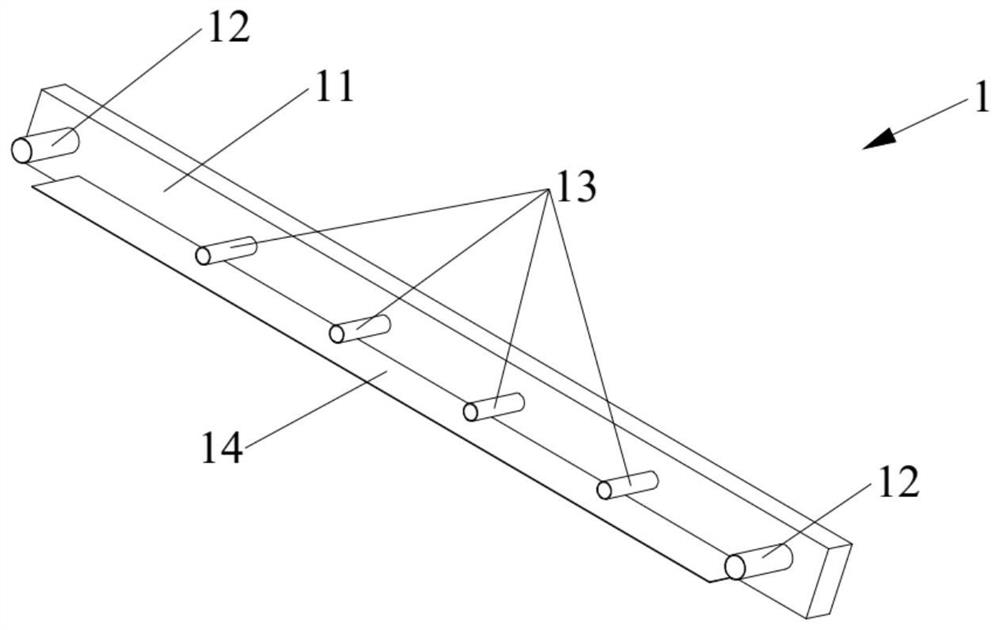

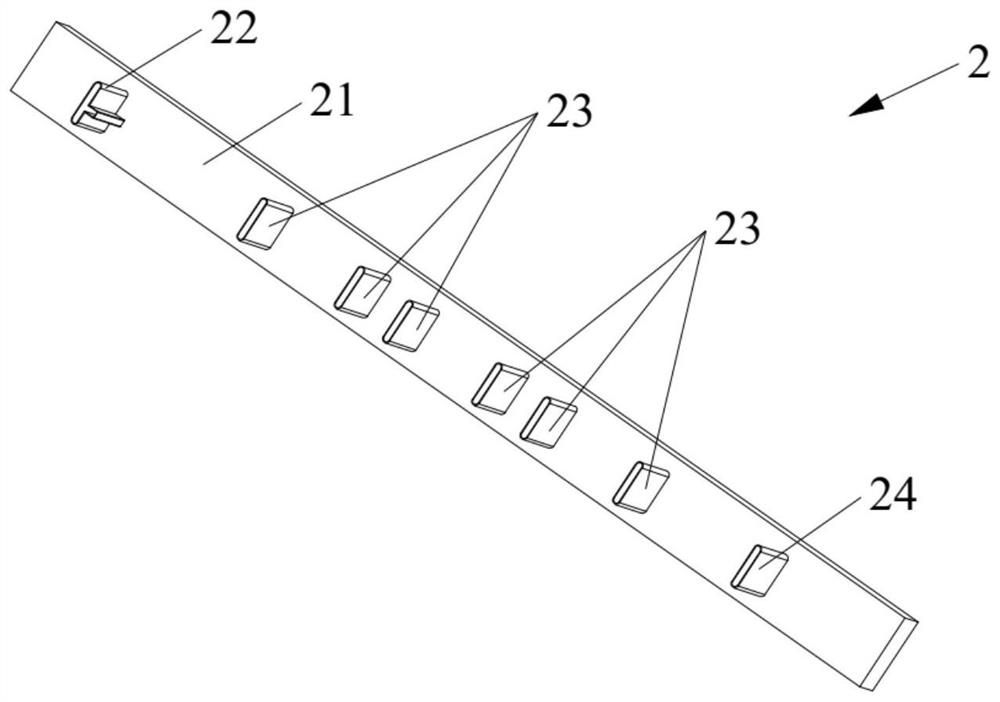

Positioning and fixing device for house plate processing

ActiveCN112621273APlay an auxiliary role in positioningMiniaturizationPositioning apparatusMaintainance and safety accessoriesStructural engineeringClip device

The invention discloses a positioning and fixing device for house plate processing, comprising a frame assembly, a power transmission device and a clamping device. The power transmission device is tightly connected with the frame assembly; the frame assembly is tightly connected with the clamping device; the power transmission device is located below the frame assembly; the clamping device comprises a positioning chuck assembly, a movable chuck assembly and a baffle assembly; the positioning chuck assembly is movably connected with the movable chuck assembly; a baffle assembly is movably connected with the frame assembly; a concave surface in the middle of a first chuck is a clamping surface; clamping planes are arranged at the two ends of the first chuck; a convex surface of a second chuck is a clamping surface; a third chuck is a plane clamping plate; the power transmission device comprises a lead screw; the two ends of the lead screw penetrate through an inner ring of a bearing; and the lead screw is rotatably connected with the bearing.

Owner:青岛亿联建设集团股份有限公司

Fabric spreading and drying device

InactiveCN111719308APlace stableGuaranteed drynessSevering textilesHeating arrangementStructural engineeringMechanical engineering

The invention discloses a fabric spreading and drying device. The fabric spreading and drying device comprises a mounting box, wherein a mounting cavity is formed in the mounting box; a removing mechanism is arranged in the mounting cavity; the removing mechanism comprises a removing shaft rotationally arranged in the front and back end walls of the mounting cavity; barrel-shaft shifting blocks are symmetrically and fixedly arranged one after the other on the removing shaft relative to the center; four shifting grooves are symmetrically formed in the shifting blocks relative to the center of circle; and shifting rods connected to the inside of the mounting cavity are arranged in the shifting grooves in a sliding way. In addition, the fabric is removed from a fabric barrel simultaneously from the two sides, so that the situation that the processing efficiency is influenced since residual fabric is not removed is avoided. Moreover, the fabric is spread and dried, so that the fabric is ina flat state, and the dryness of the fabric is ensured.

Owner:DONGYANG HAOMING CLOTHING CO LTD

An automatic rivet punching machine

ActiveCN104959514BReduce safety hazard accidentsAvoid affecting processing efficiencyPunchingSynchronous control

The invention discloses an automatic rivet punching machine. The automatic rivet punching machine comprises a workbench, a main punching arm, a bearing cross beam and a punching buffer tank; the main punching arm is installed at the right side of the workbench, the bearing cross beam is installed at the top of a connecting plate, and the punching buffer tank is installed at the bottom of a punching arm bearing block. According to the automatic rivet punching machine, the pneumatic punching nailing technique is adopted, an installed workpiece fixing machine box can be combined with a workpiece fixing rod for locating and fixing a workpiece to be machined perfectly, an installed rivet carrying box can feed rivets automatically through an ejector pin, the manual fixing, uprighting and rivet mounting are replaced effectively, the accident potential safety hazards of the punching machine are reduced, a synchronous control timer is installed in an inner cavity of the punching buffer box, it can be convenient for operators to adjust the punching time voluntarily according to the variety requirements of the workpiece, and the punching machine and the workpiece fixing machine box can be effectively made to operate in a synchronous mode.

Owner:TANGSHAN ZHENGFENG IRON & STEEL CO LTD

A positioning and fixing device for plate processing for houses

ActiveCN112621273BReduce frictionAvoid swingingPositioning apparatusMaintainance and safety accessoriesStructural engineeringClip device

Owner:青岛亿联建设集团股份有限公司

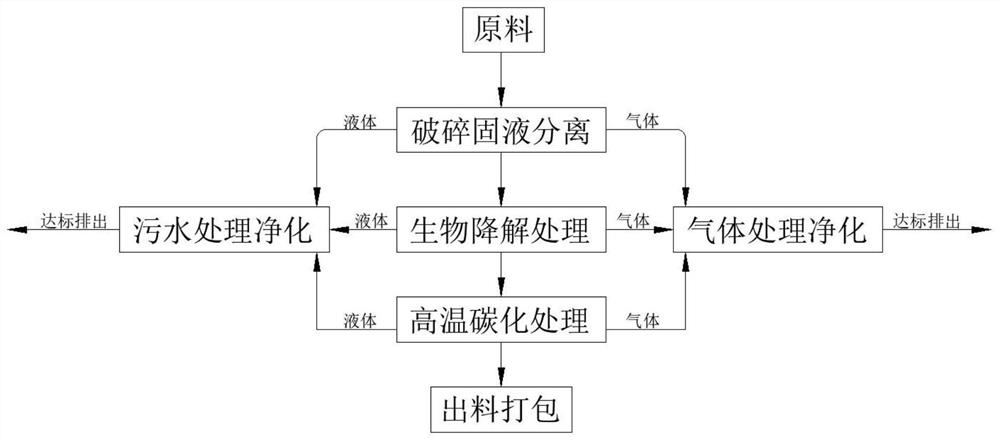

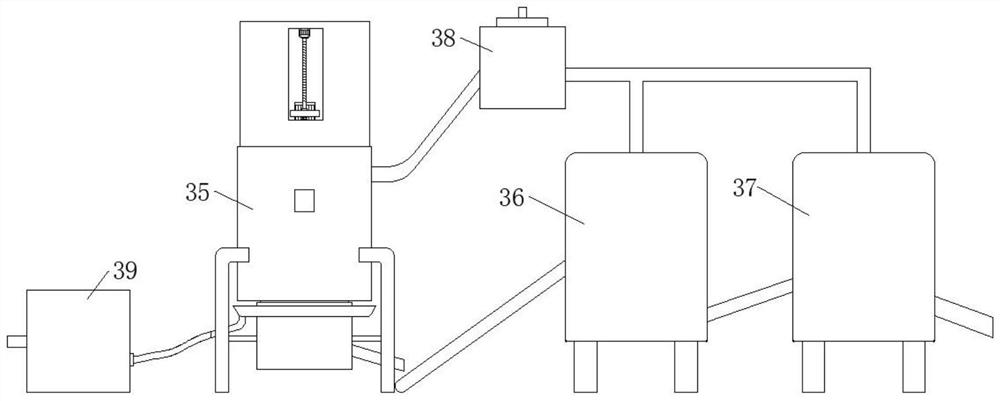

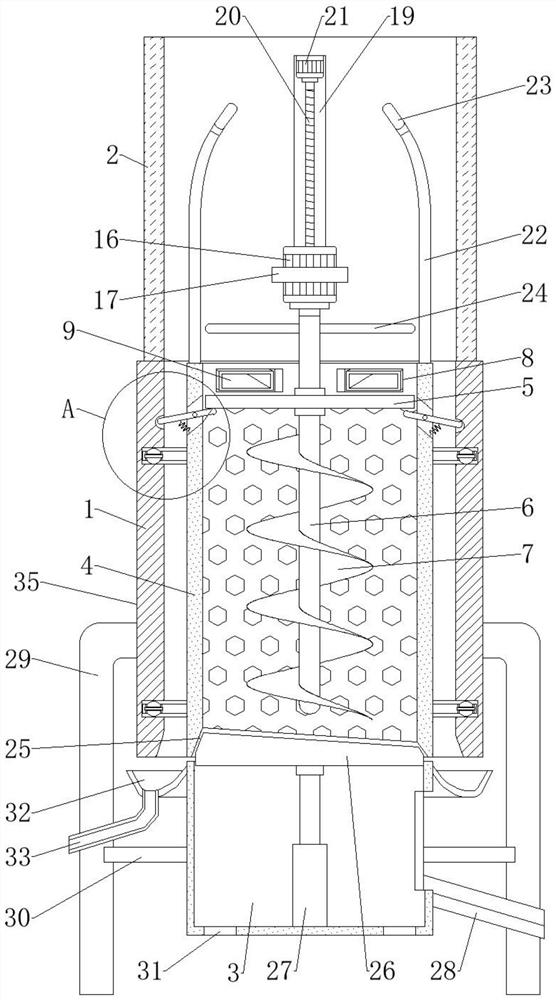

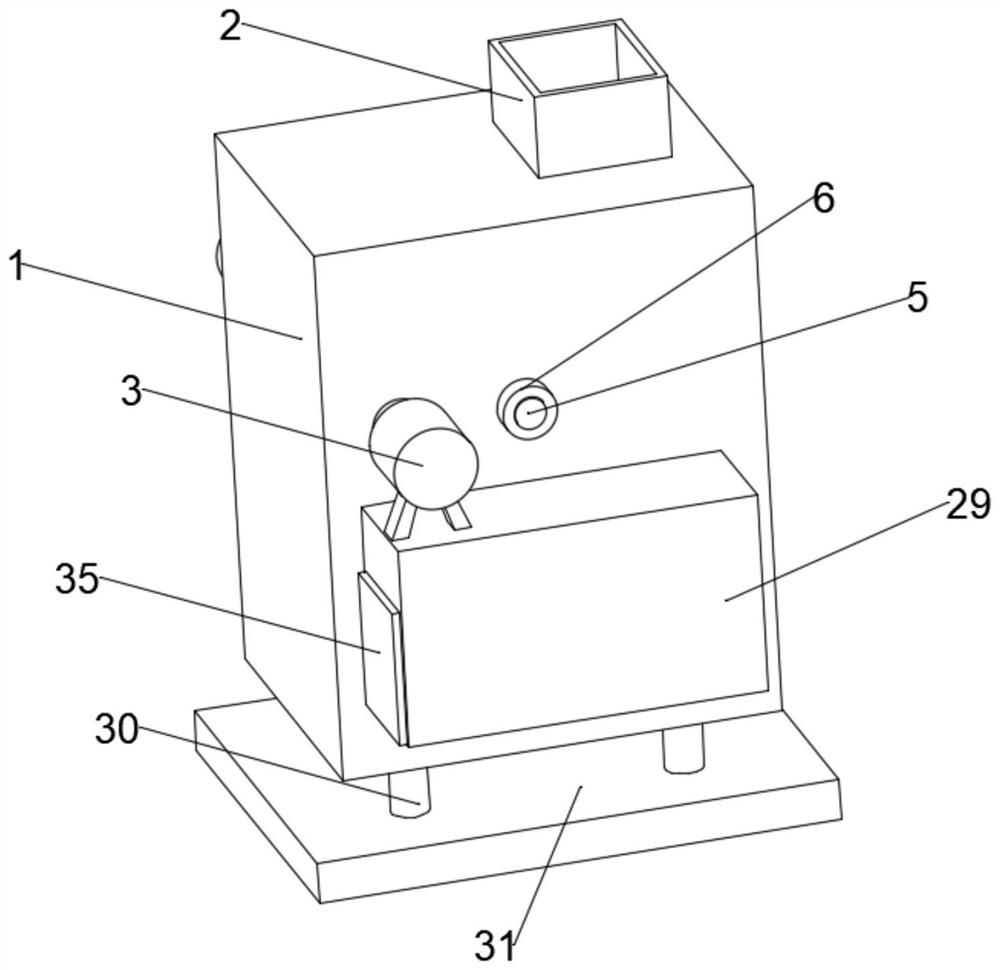

Technology and system for harmless treatment of diseased livestock and poultry based on high temperature carbonization

ActiveCN112871340BRealize processing utilizationAvoid pollutionTransportation and packagingSolid waste disposalCarbonizationExhaust fumes

The invention discloses a process and system for the harmless treatment of diseased livestock and poultry based on high-temperature carbonization, and relates to the technical field of harmless treatment of diseased livestock and poultry. In the treatment device and the sewage treatment device, the discharge port of the crushing treatment device is communicated with the feed hopper of the biodegradation device, and the discharge port of the biodegradation device is communicated with the feed hopper of the high temperature carbonization device. The harmless treatment process and system for diseased livestock and poultry based on high-temperature carbonization, through the set crushing treatment device, biodegradation device, high-temperature carbonization device, waste gas treatment device and sewage treatment device. Quickly degrade and carbonize raw materials of livestock and poultry carcasses into stable, pollution-free and odorless particles, which can be used as fertilizers, soil conditioners, etc., to realize waste treatment and utilization, and to avoid environmental pollution caused by livestock and poultry carcasses.

Owner:由佳

Rice husking device

InactiveCN112108206AAchieve separationEffectively absorbs vibrationGrain huskingGrain polishingGear wheelAgricultural engineering

The invention discloses a rice husking device. The rice husking device comprises a base, a supporting column and a shell, the shell is fixed to the upper portion of the base through the supporting column, a first guide plate is arranged in the shell, the left end of the first guide plate is rotationally connected with a vertical plate fixed to the upper portion in the shell, the right end of the first guide plate penetrates through an L-shaped connecting plate fixed to the upper portion in the shell to be fixedly connected with a first spring, a first rubber roller and a second rubber roller are arranged on the lower portion of the left side of the first guide plate, first rotating shafts are arranged at the two ends of the first rubber roller and rotationally connected with the shell through first bearing seats, second rotating shafts are arranged at the two ends of the second rubber roller, the second rotating shafts are rotationally connected with the shell through the first bearingseats, the first rotating shaft at the front end is rotationally connected with a driving motor, and a first guide rail block and a first gear are installed on the first rotating shaft at the rear end. The rice husking device is simple in structure, reasonable in design and capable of effectively solving the problem that the processing efficiency is influenced by rice accumulation at a feeding port.

Owner:王天理

A kind of foam glue manufacturing device and foam glue manufacturing process

ActiveCN108748396BSimple structureAvoid affecting processing efficiencyLamination ancillary operationsLaminationYarnPolymer science

The invention belongs to the technical field of foam glue, and discloses a foam glue manufacturing device, comprising a first mold assembly for cutting and forming a first foam assembly and a second mold assembly for cutting and forming a second foam assembly, The step-by-step processing of different molds simplifies the structure of the molds and avoids the problem of foam glue being stuck in the gap between the cutting knives that is easy to occur in one-time processing. The invention also discloses a foam glue manufacturing process, including: bonding and cutting the first base film, the first double-sided adhesive tape and the mesh to form the first foam component; combining the second base film with the second double-sided adhesive The surface adhesive is bonded and cut to form the second foam component; the second double-sided adhesive is bonded to the mesh, so that the first foam component and the second foam component are bonded together. The present invention can reduce the cutting thickness of the mold by dividing the foam glue into the first foam component and the second foam component, thereby avoiding the problem that the edge of the hole and the cutting edge are easily deformed.

Owner:DONGGUAN MAXRON IOT TECH CO LTD

Brazing flux coating device for cutter brazing

PendingCN114453702AReduce labor intensityPrevent cooling and solidificationOther manufacturing equipments/toolsMetal working apparatusEngineeringWorkbench

The invention relates to the technical field of cutter machining, and discloses a brazing flux coating device for cutter brazing, which comprises a workbench, a first slideway and a second slideway which are arranged in parallel are arranged on the workbench, the first slideway is sequentially provided with a brazing flux coating station for coating a brazing flux and a copper sheet station for mounting a copper sheet, and the second slideway is sequentially provided with a brazing flux coating station for coating a brazing flux and a copper sheet mounting station for mounting a copper sheet. The second slide way is sequentially provided with an insert station for mounting inserts and a discharging station; the workbench is further provided with a feeding mechanism, a pushing mechanism, a discharging mechanism and a spraying unit used for spraying brazing flux on a tool blank. The feeding mechanism can sequentially push a cutter blank, a copper sheet and an insert to the soldering flux coating station, the copper sheet station and the insert station. The pushing mechanism can convey the cutter blanks on the soldering flux coating station, the copper sheet station and the sheet embedding station to the next station in sequence. And the discharging mechanism can be used for discharging the cutter blanks loaded with the copper sheets and the inserts. The purpose of automatically coating the brazing flux can be achieved, and the labor intensity of an operator is relieved.

Owner:重庆派斯克刀具制造股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com