Integral intelligent industrial wastewater treatment system

A technology for industrial waste water and treatment systems, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, agriculture, etc., can solve the problems of loss and waste of nitrogen and phosphorus resources, lack of attention and management, and high concentration of pollutants. Achieve the effect of convenient construction, low cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

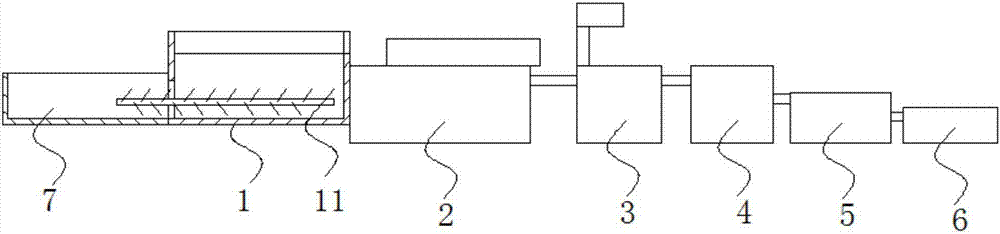

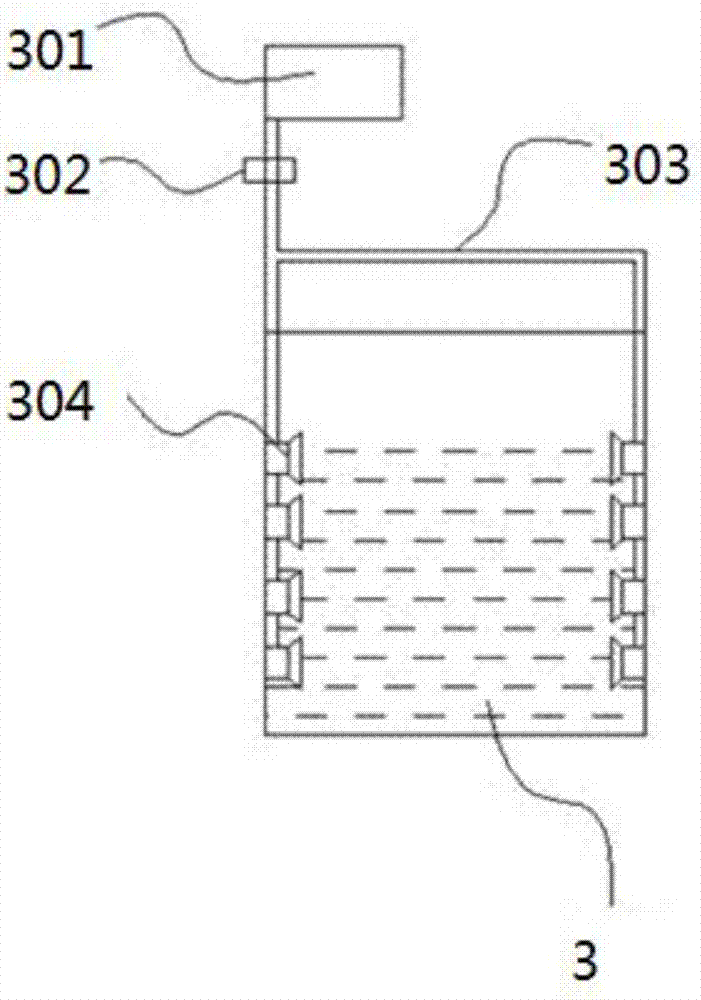

[0024] As shown in the figure, an integrated intelligent industrial wastewater treatment system includes dry-wet separation tank 1, primary treatment tank 2, hydrolysis treatment tank 3, contact oxidation tank 4, sedimentation tank 5, clear water tank 6 and sludge fermentation tank 7 , primary treatment tank 2, hydrolysis treatment tank 3, contact oxidation tank 4, sedimentation tank 5 and clean water tank 6 are connected in turn through pipelines, dry-wet separation tank 1 and sludge fermentation tank 7 are connected through pipelines, dry-wet separation tank 1 and primary The treatment tanks 2 are set to be connected together, and the position of the primary treatment tank 2 is 0.5m lower than that of the dry-wet separation tank 1; A mud bucket 11 is provided. The top of the hydrolysis treatment tank 3 is provided with a liquid storage tank 301, the liquid storage tank 301 is connected with the water pump 302 through the pipeline 303, and the pool wall of the hydrolysis trea...

Embodiment 2

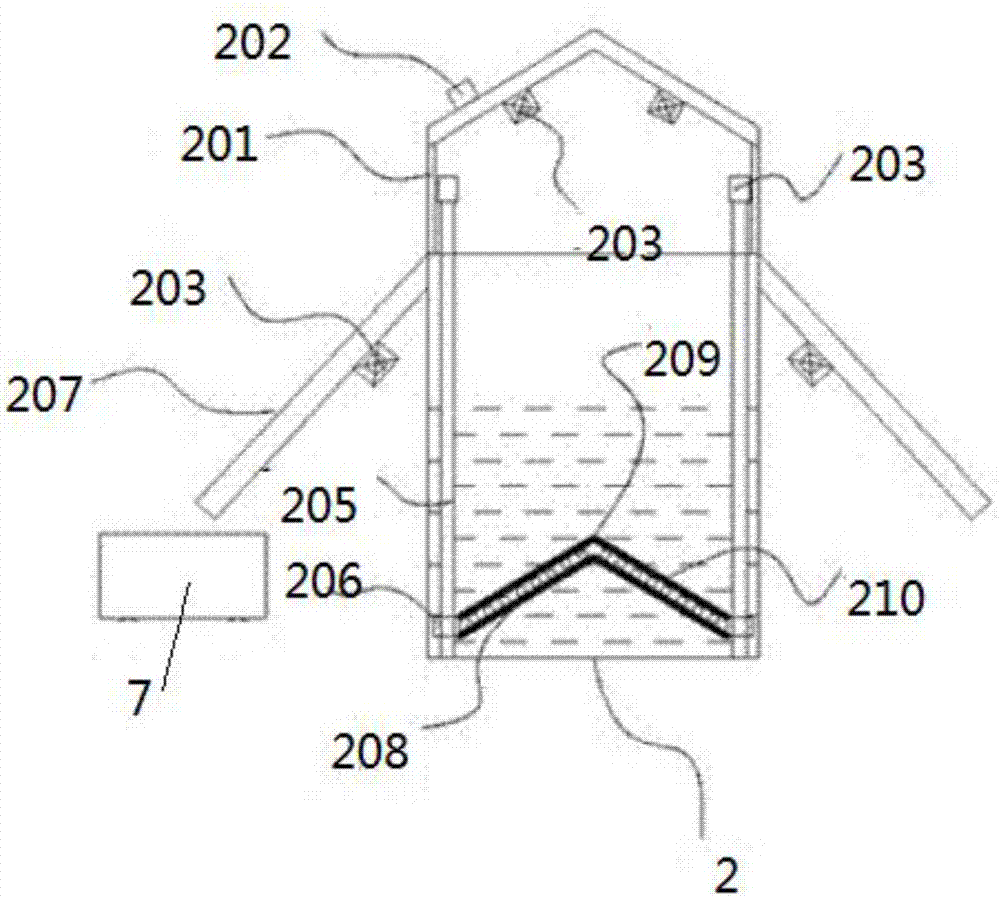

[0028] On the basis of Embodiment 1, as shown in the figure, a support column 201 is provided on both sides of the upper part of the primary treatment tank 2 of an integrated intelligent industrial wastewater treatment system. The support column 201 is provided with an inverted V-shaped bracket. A controller 202 and a vibration mechanism 203 are provided. An automatic slag removal unit is provided in the primary treatment tank 2. The automatic slag removal unit includes an inverted V-shaped fixed frame 208 consistent with the support, a filter screen 210, a screw nut 206, and a screw rod 205. And motor 204, the bottom of the primary treatment pool 2 is provided with two screw mandrels 205 parallel to the pool wall, and the screw mandrel 205 is provided with a screw mandrel nut 206, and one end of the screw mandrel 205 is connected with the motor 204, and an inverted V-shaped fixed mount 208 The two ends of each are connected with the screw mandrel 208, and the inverted V-shaped...

Embodiment 3

[0033] On the basis of Embodiment 2, as shown in the figure, a liquid storage tank is arranged above the hydrolysis treatment tank of an integrated intelligent industrial wastewater treatment system, and the liquid storage tank is connected to the water pump through a pipeline. A nozzle is provided, and the nozzle is connected with a water pump through a pipeline.

[0034] The working principle of this embodiment is: the industrial wastewater and dung produced by the agricultural and animal husbandry product processing plant are collected into the dry-wet separation tank 1 through pipelines, the dry-wet separation tank 1 and the primary treatment tank 2 are connected together, and the primary treatment tank 2 The location is 0.5m lower than the dry-wet separation tank 1, that is, the industrial wastewater and feces fill the dry-wet separation tank 1 and overflow directly into the primary treatment tank 2, because the primary treatment tank 2 is lower than the dry-wet separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com