Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "Realize the cutting operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

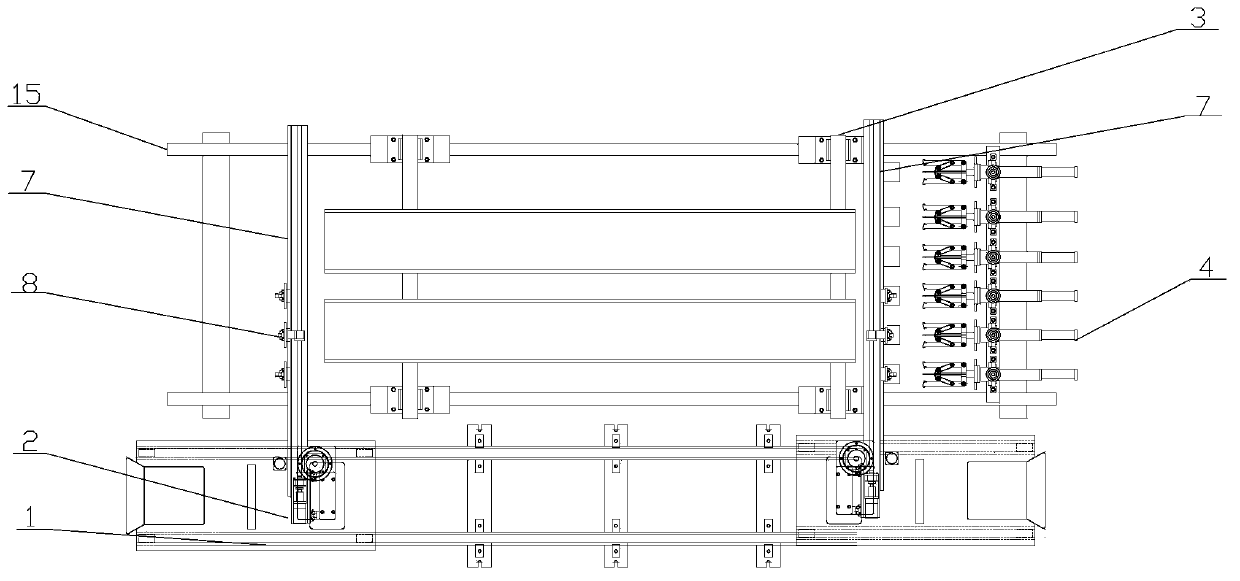

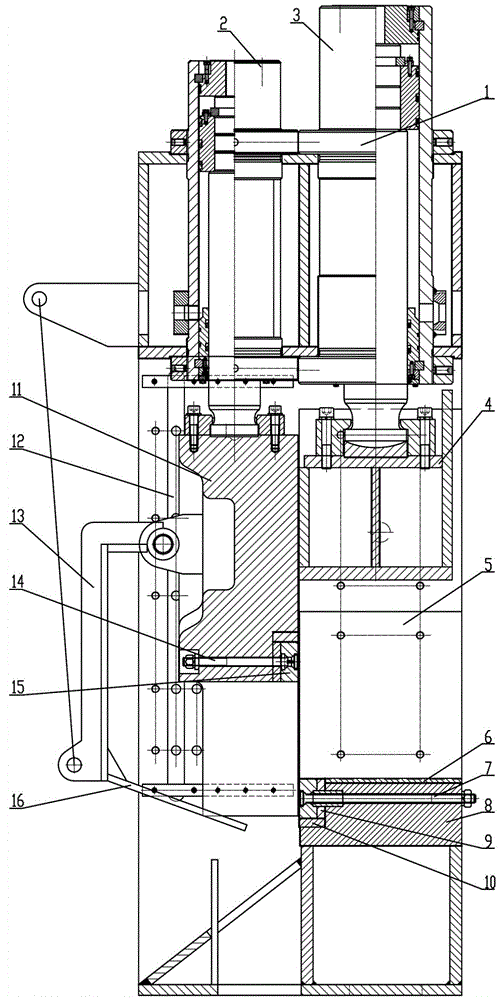

Cantilever type numerical control plasma flame structural steel three-dimensional cutting machine

ActiveCN103418881AImprove running stabilityImprove cutting accuracyWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlEngineering

The invention discloses a steel sheet cutting device, and particularly relates to a cantilever type numerical control plasma flame structural steel three-dimensional cutting machine used for cutting steel pipes. The cutting machine comprises two parallel Y-axis guide rails, two movable numerical control cutting main machines arranged on the Y-axis guide rails, a wheel overturning material frame used for storing steel pipes, and a pneumatic clamping dividing device arranged at one end of the wheel overturning material frame. Each numerical control cutting main machine comprises a walking cart, a stand column, a cantilever and a cutting gun, wherein the walking cart is driven by a Y-axis servo motor to move along the Y axis, and the stand column is provided with two parallel Z-axis guide rails. The cutting machine has the advantages that the grooving operation of the steel pipes and large-scale H-steel cutting operation can be achieved at the same time, one cutting machine can be used for multiple purposes, automatic cutting efficiency is high, operation is stable, and operation is simple and convenient.

Owner:QINGDAO EAST STEEL TOWER

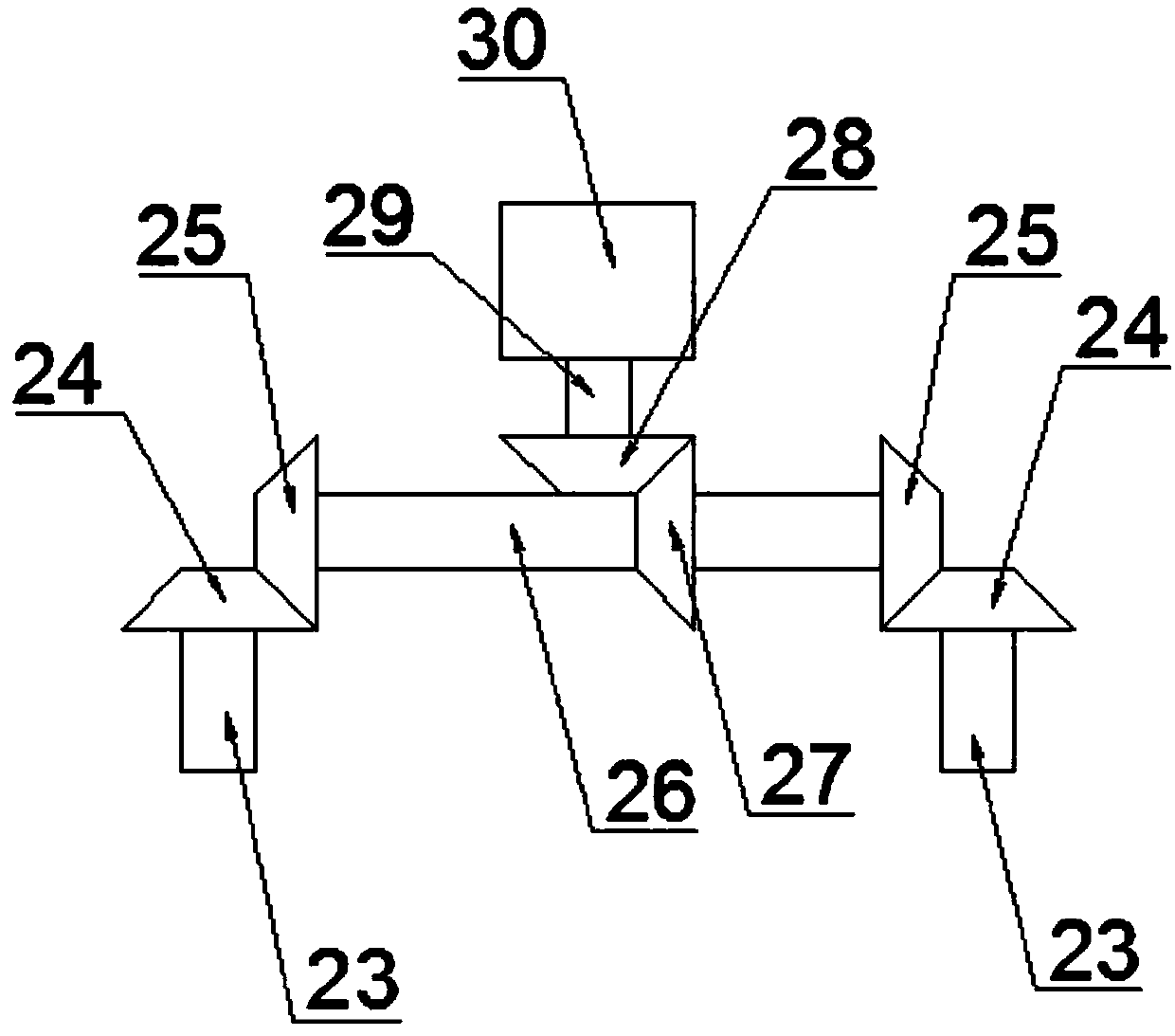

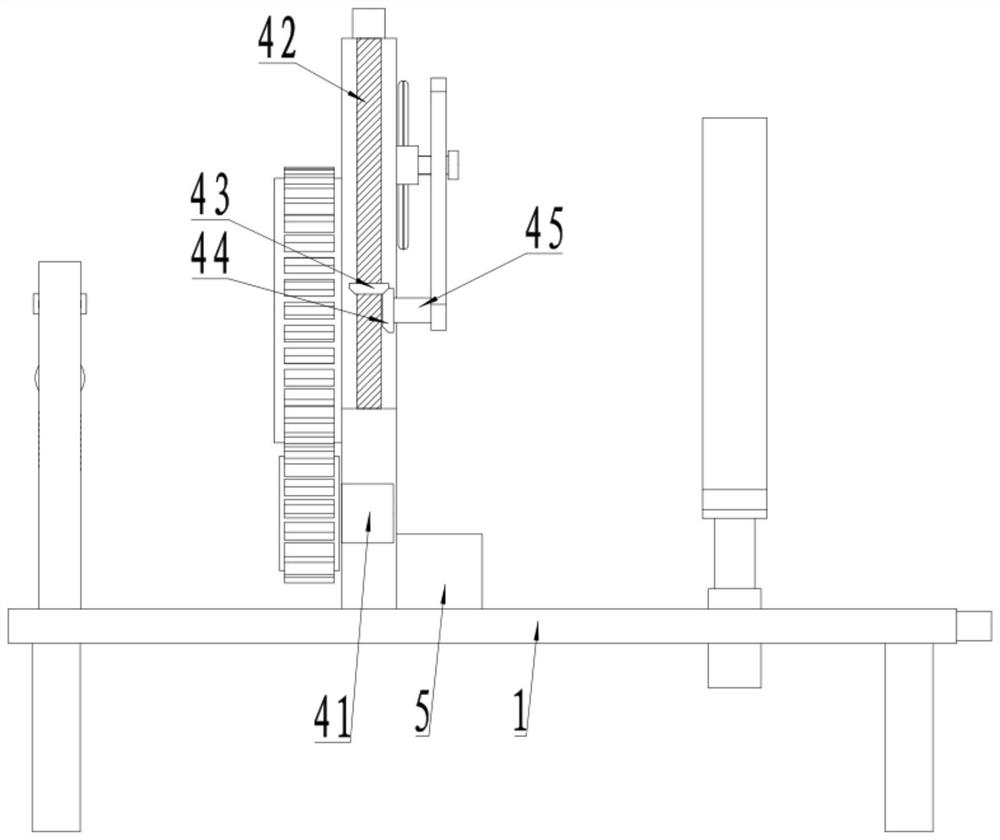

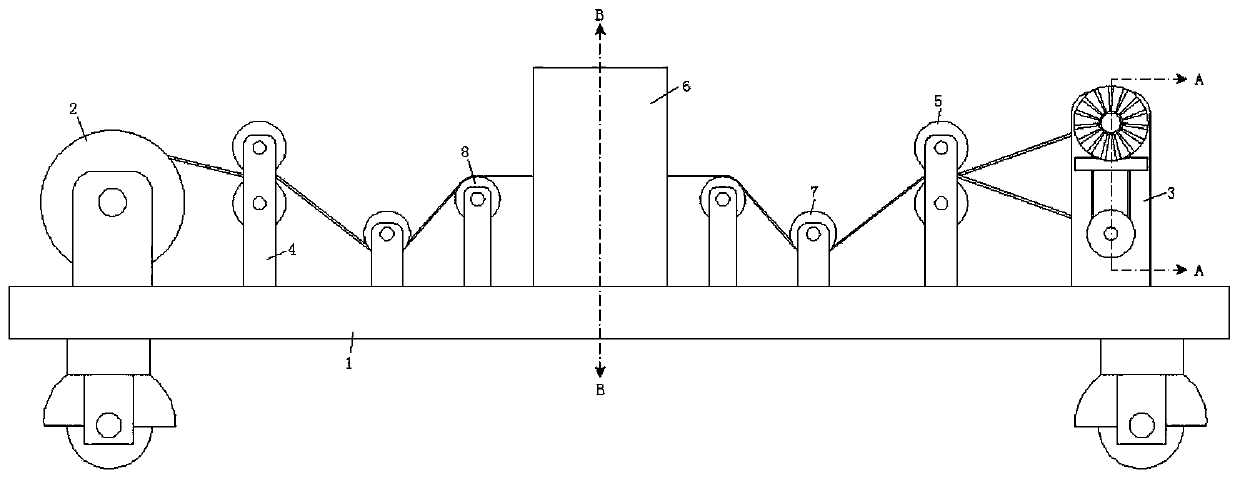

Producing, machining and cutting device for polyethylene winding structure wall pipes

ActiveCN107627331AEasy to holdRealize the cutting operationMetal working apparatusEngineeringMechanical engineering

The invention discloses a producing, machining and cutting device for polyethylene winding structure wall pipes. The producing, machining and cutting device comprises a work platform, pipeline clamping mechanisms, a supporting frame, a transverse plate, a telescopic air cylinder and a cutting mechanism. The two pipeline clamping mechanisms are arranged and connected through a power connecting mechanism. A base is arranged at the bottom of the work platform. Each pipeline clamping mechanism comprises an installing block, a through hole, a screw, a thread sleeve, a first hinge shaft, a connecting rod, a strip-shaped hole, a third hinge shaft, an arc clamping plate and a second hinge shaft. According to the producing, machining and cutting device, the polyethylene winding structure wall pipesdifferent in pipe diameter can be very conveniently clamped through the arranged pipeline clamping mechanisms, three cutting blades of the cutting mechanism conduct the joint action, the cutting efficiency is high, if one cutting blade is damaged, normal usage of the other two cutting blades is not influenced, and if one cutting blade is damaged, only the independent cutting blade needs to be replaced.

Owner:江苏华财管道有限公司

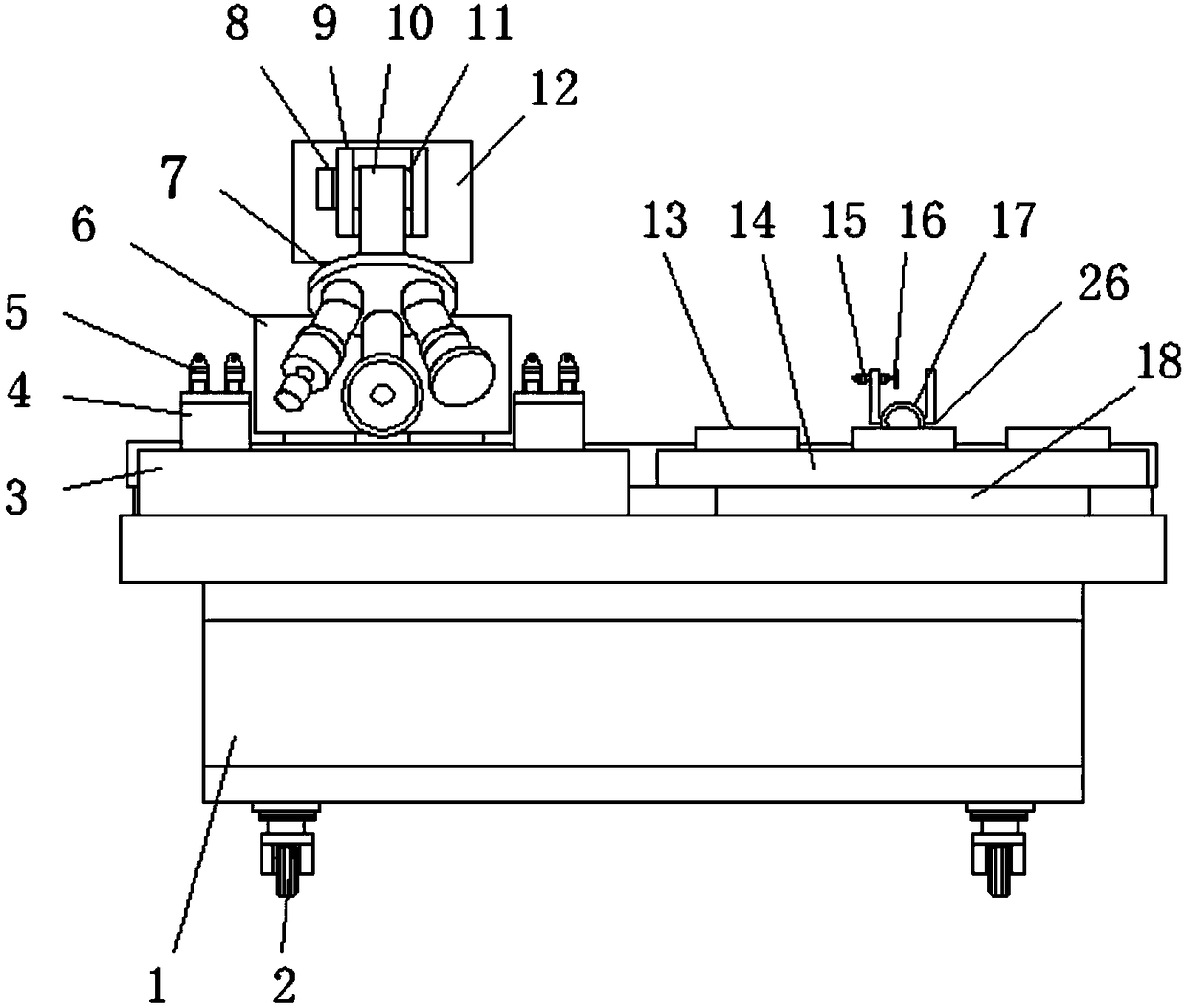

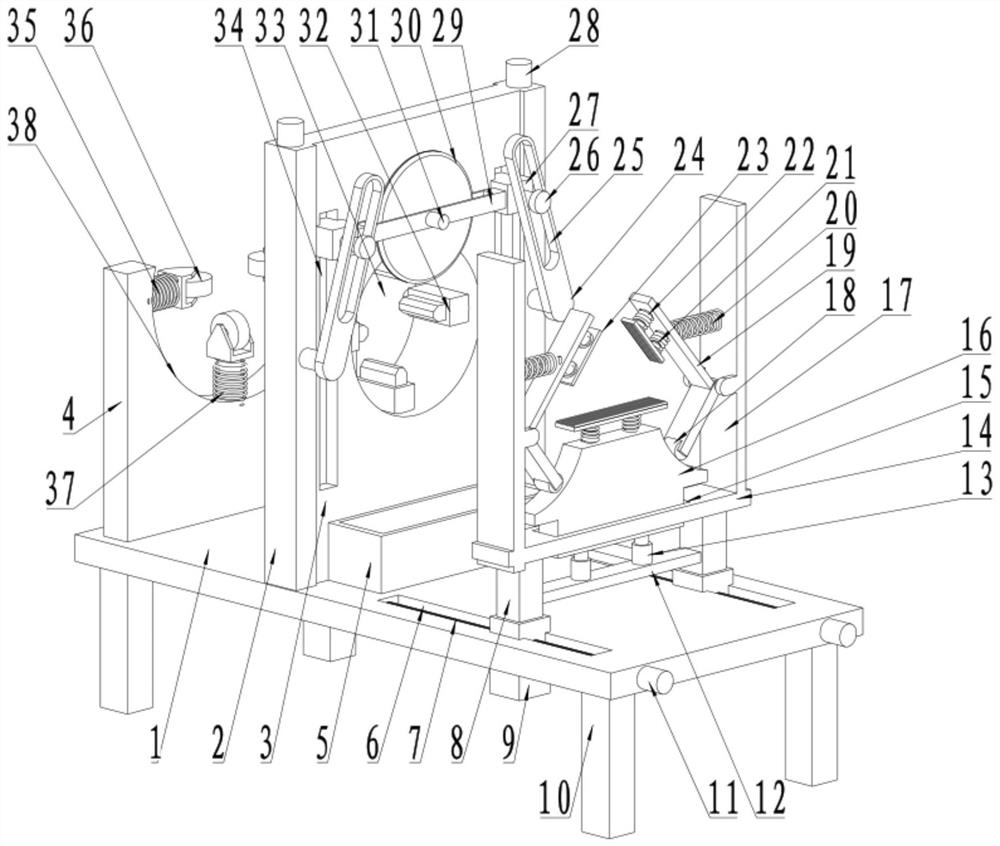

Multifunctional mechanical working table capable of working in multi-angle mode

ActiveCN108067886AVersatileFunctionalOther manufacturing equipments/toolsPneumatic cylinderEngineering

The invention discloses a multifunctional mechanical working table capable of working in multi-angle mode. The working table comprises a machine tool, a mounting plate is arranged on one side of the machine tool, and first electromagnetic sliding rails are arranged on the two sides above the mounting plate; the top of the first electromagnetic sliding rail is provided with two sets of first electromagnetic sliding blocks, and a first installation base is arranged above the first electromagnetic sliding block; an installation groove is formed in the top of the first installation base, and foursets of lifting pneumatic cylinders are arranged in the installation grooves, the top of the lifting pneumatic cylinder is provided with a piston rod, and the top of the piston rod is provided with afixing block; and a second installation base is arranged at the top of the fixed block, and an installation hole is formed in the inner side of the second installation base. The workbench is providedwith a cutting table and a grinding table, a cutting structure and a grinding structure on the mechanical table cooperate, so that the function of the working table is more comprehensive, the polishing operation of the hardware can be realized, the cutting operation of the hardware can be realized, and the functionality is stronger.

Owner:肇庆市高要区博斯五金制品有限公司

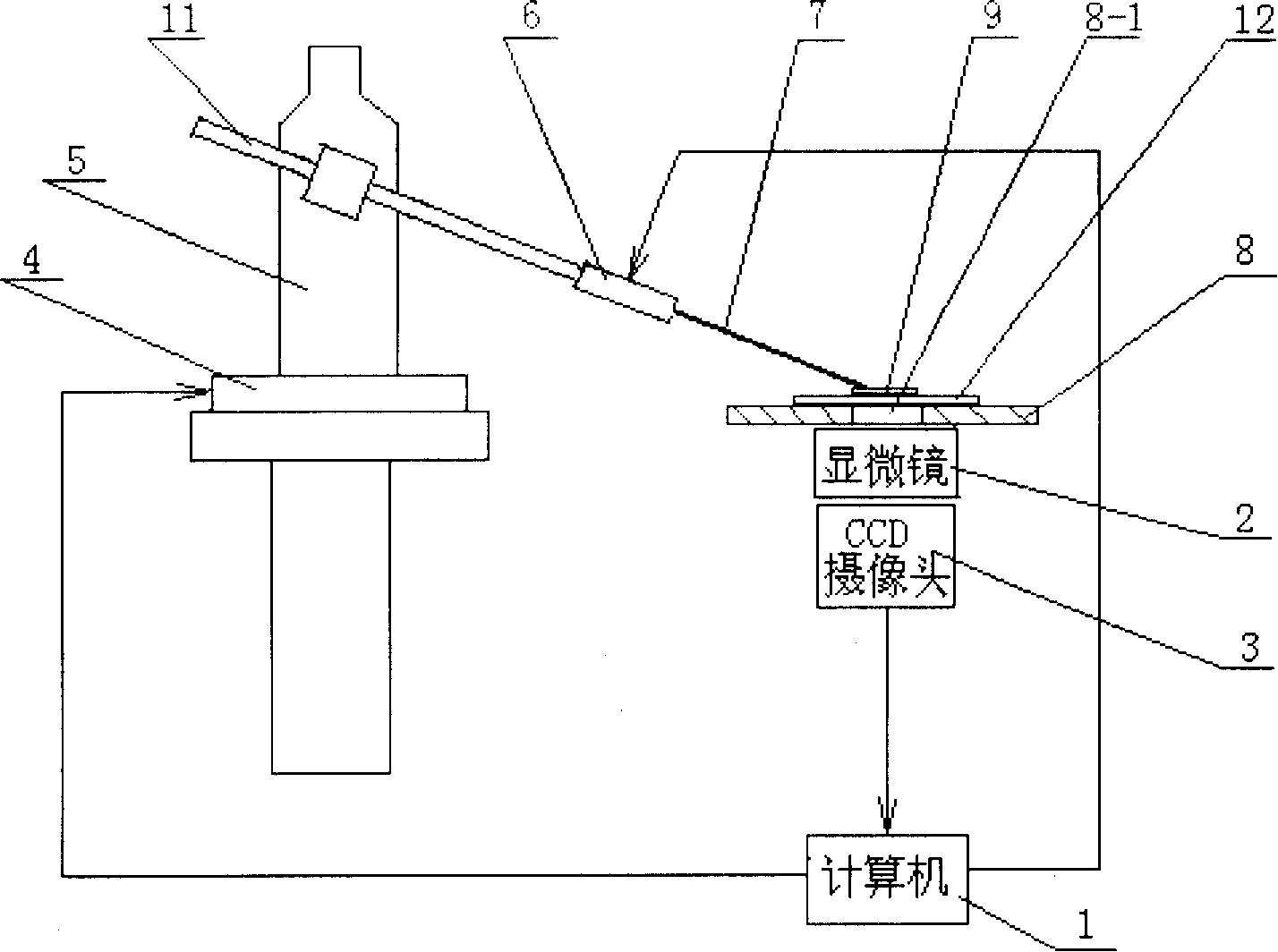

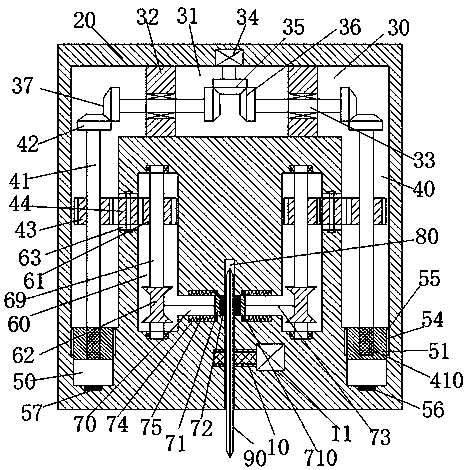

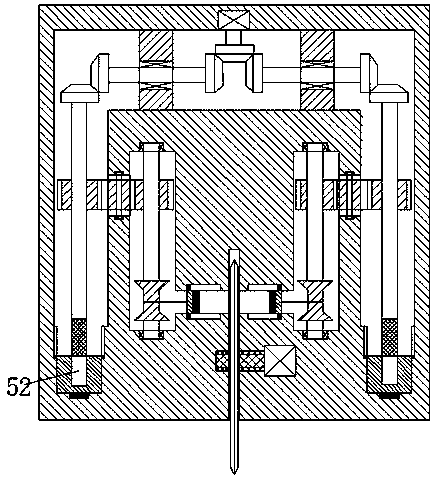

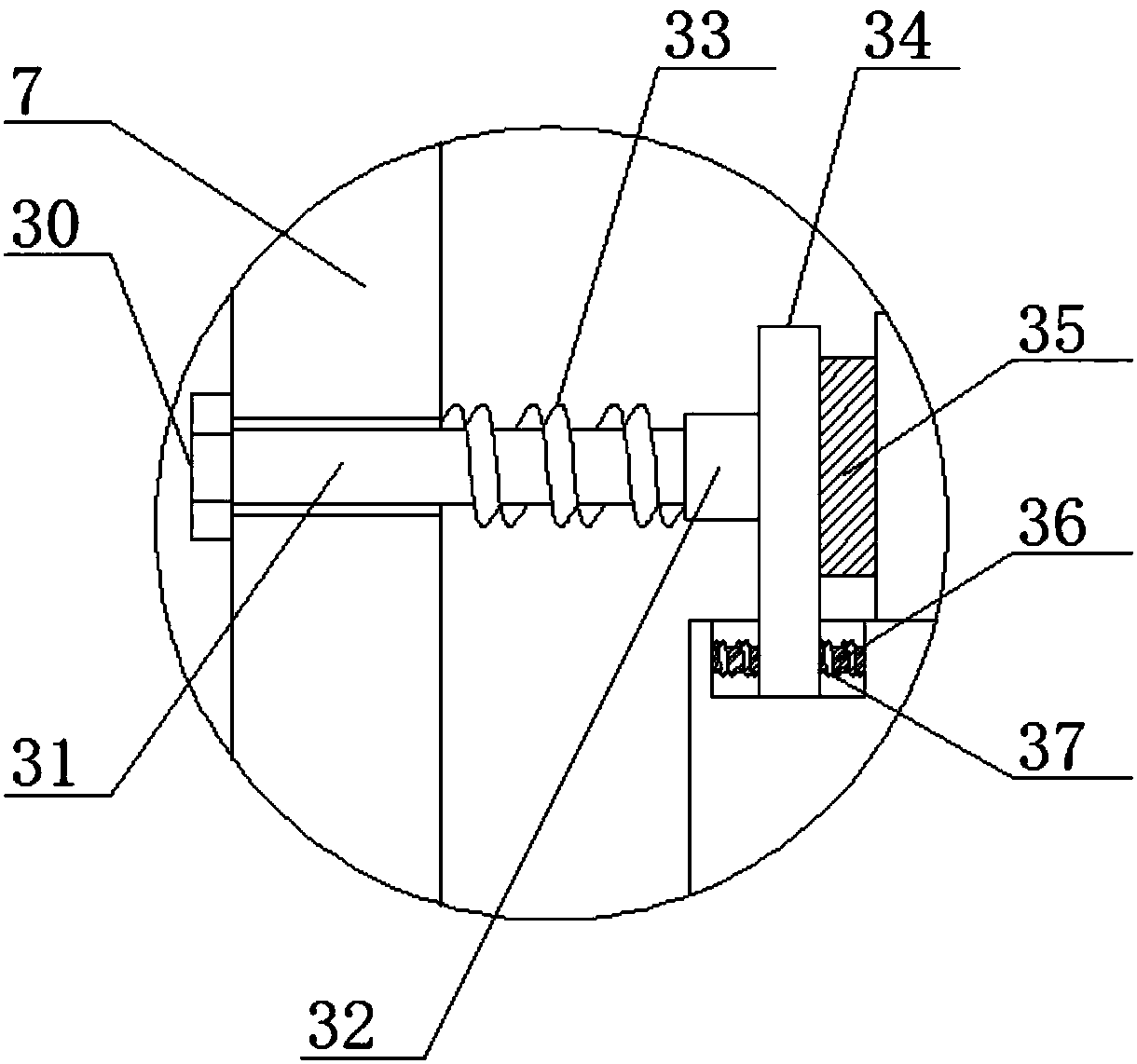

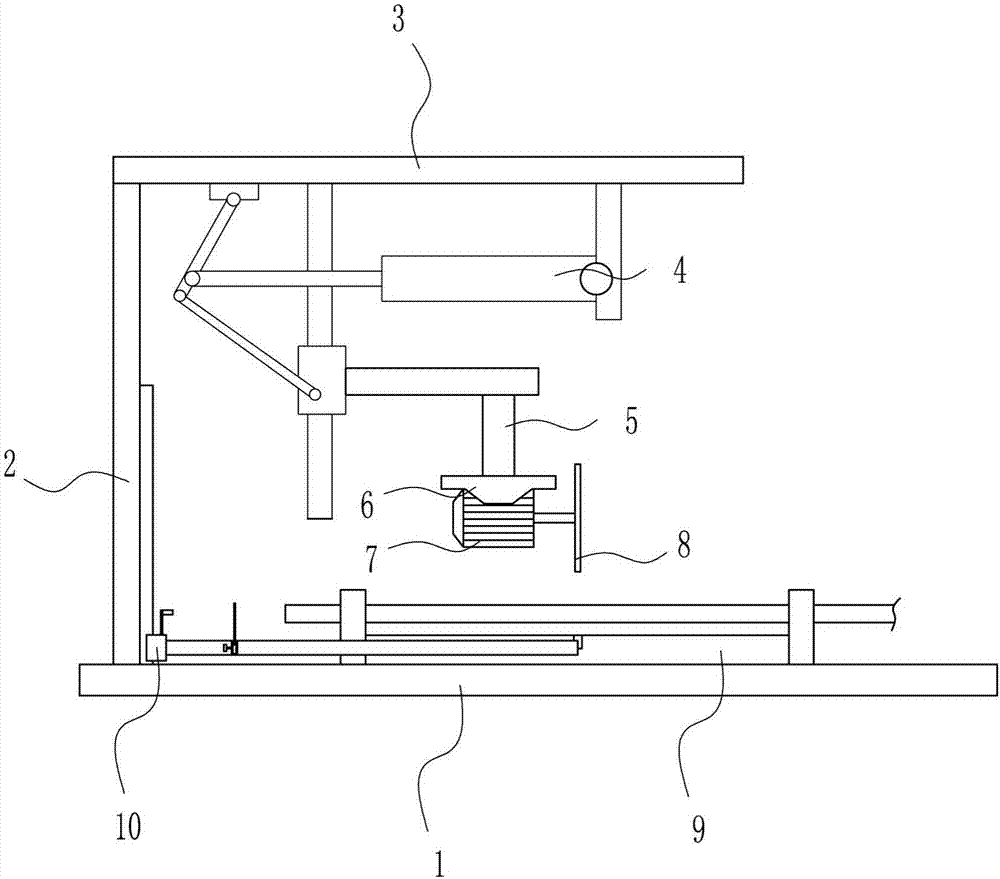

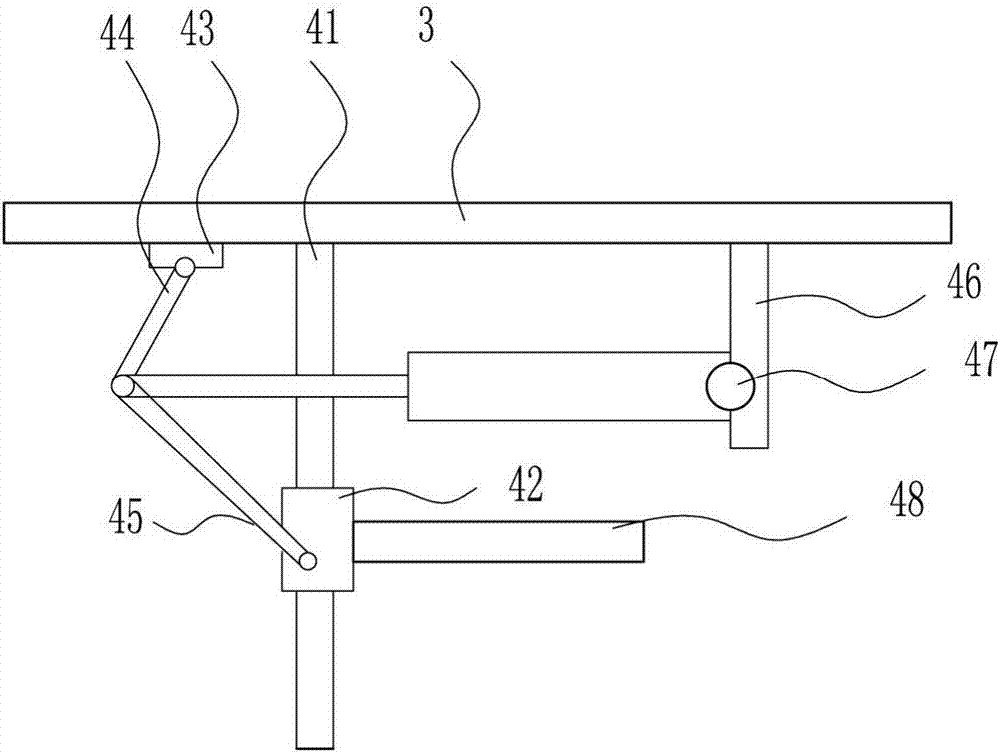

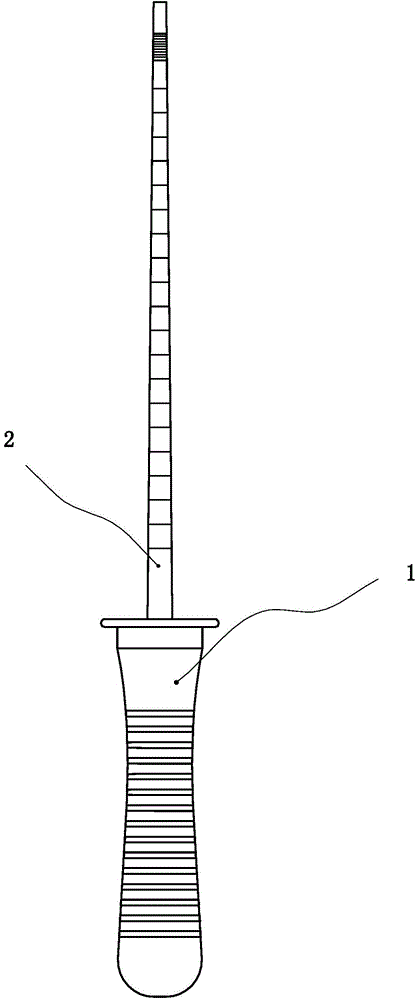

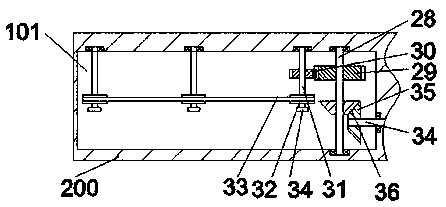

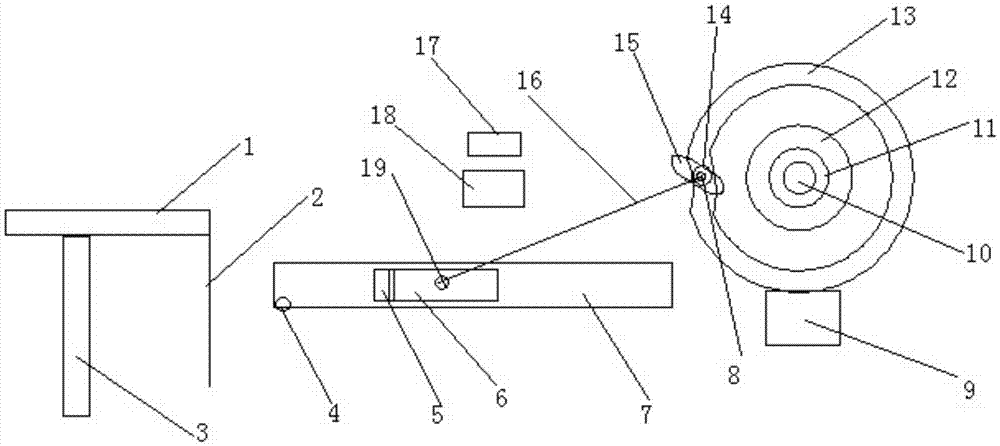

Microdissection device based on piezoelectric ultrasonic vibration

InactiveCN1875893ARealize the cutting operationMeet the vibration state requirementsWithdrawing sample devicesSurgeryCut needleEngineering

The invention relates the microscopic cutting device. The invention overcomes the defects of strong working strength, fatigability and big personal error. The device comprises computer 1, microscope 2, CCD cam 3, free mechanical micro motion desk 4, clamp 5, ultrasonic vibration emitter 6, cutting needle 7, biological section stage 8 and cutter bar. 2 is installed under 8, 3 is connected with 2 to collect the object magnified by 2, the signal output terminal of 3 is connected with signal input terminal of 1, 4 is installed at the side of 8, the signal output terminal of 1 is connected with controlling terminal of 4, 5 is fixed on the 4, 11 is fixed on the 5, one end of 11 is connected with one end of 6, the other end of 6 is connected with the butt of 7, the tip of 7 extends to the upper surface of 8, and the other signal output terminal of 1 is connected with the input terminal of 6.

Owner:HARBIN INST OF TECH

Cutting device with protection function

InactiveCN108044392ARealize the cutting operationFast limited rotationDriving apparatusEngineeringMechanical engineering

A cutting device with a protection function comprises a cutting frame. A first rotation groove extending in the transverse direction is formed in the upper portion in the cutting frame. Second rotation grooves communicating with the first rotation groove are formed in the cutting frame in a left-right symmetry manner. Fixing blocks are arranged in the first rotation groove in a left-right symmetrymanner, and an installing cavity is formed between the two fixing blocks. A first motor is arranged on the top wall in the installing cavity, an output shaft of the first motor stretches into the installing cavity, and a driving bevel gear is arranged at the tail end of the bottom. A first rotation rod is arranged in the fixing blocks in a left-right extending and rotating manner, and first bevelgears are arranged on extension sections of the two sides of the first rotation rod. Second rotation rods are rotationally arranged in the second rotation grooves, and second bevel gears stretching into the first rotation groove are fixedly arranged on the tops of the second rotation rods.

Owner:高峰

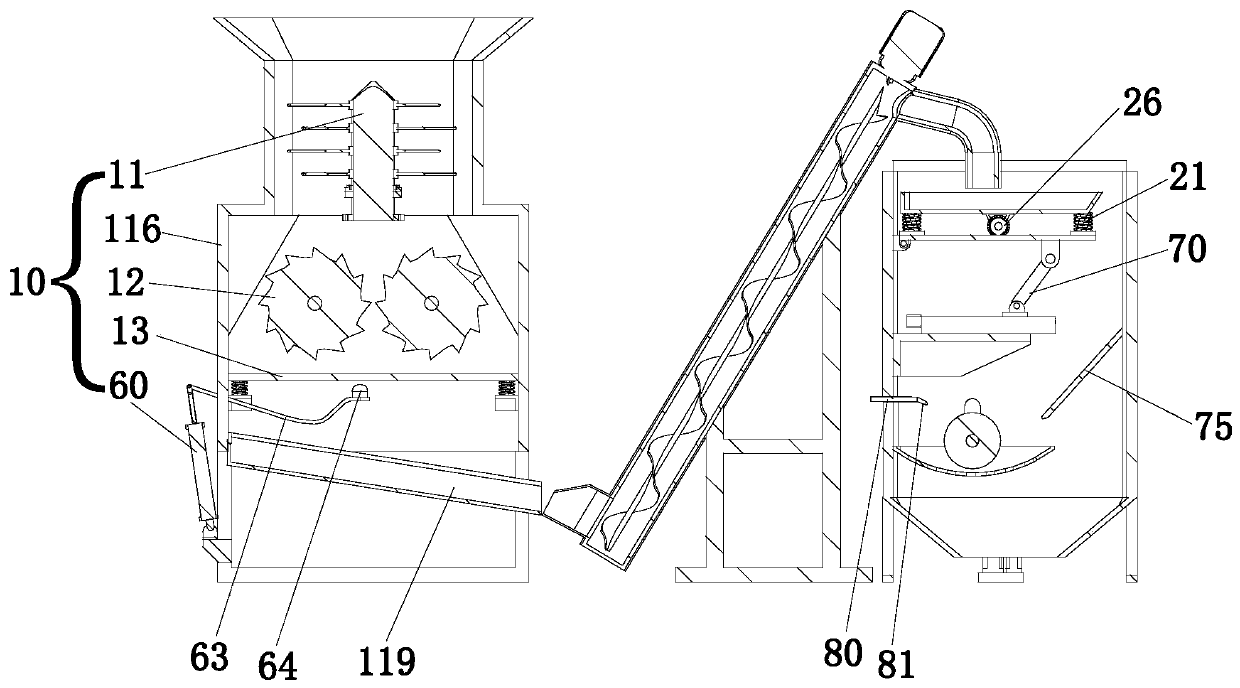

Fig fruit powder production device

The invention discloses a fig fruit powder production device, and belongs to the technical field of fig manufacturing. The fig fruit powder production device comprises a fruit crushing mechanism, a fruit particle drying mechanism, a feeding packing auger, a grinding cabinet and a fruit powdering and grinding mechanism, wherein the fruit crushing mechanism is provided with a cutting assembly, a crushing cabinet, a crushing assembly, a screening plate and a knocking vibration assembly; the top of the crushing cabinet is provided with a feeding hole and an anti-funnel; the bottom of the crushingcabinet is provided with a material conveying channel; the material conveying channel is provided with a water falling hole; the knocking vibration assembly comprises a driving air cylinder and two mounting grooves; a knocking rod is arranged in each mounting groove; a vibration hammer is arranged at the right end of each knocking rod; and a connecting rod is arranged between the left ends of thetwo knocking rods. According to the fig fruit powder production device, by knocking the vibration assembly, fig particles blocked in screening holes of a screening mesh can be vibrated out, the dryingoperation of figs can be realized through the fruit particle drying mechanism, and a drying box can be vibrated through a vibrating part, so that the figs positioned in the drying box are overturned.

Owner:义乌市昕闵日用品有限公司

Sheet material cutting method

ActiveCN101064239AEliminates the possibility of breakageRealize the cutting operationSemiconductor/solid-state device manufacturingMetal working apparatusCamber angleCaster angle

To cut a sheet in response to the size of a plate-like member in a state of sticking to the plate-like member a sheet of the size projecting from the outer periphery of the plate-like member such as a wafer. This sheet cutting method cuts the sheet S of the size projecting from the outer periphery of a semiconductor wafer W by a cutter blade 12 along the outer periphery of the semiconductor wafer W. This cutting method presets a moving locus of a blade 12B as a normal locus so that the sheet S does not project from the semiconductor wafer W, and adjusts an attitude of the cutter blade 12 so as to become a predetermined twin angle [alpha]1, a camber angle &agr;2 and a caster angle &agr;3, in a process of being approached to the normal locus, after inserting the blade 12B of the cutter blade 12 into a cutting starting position P separated from the normal locus in cutting.

Owner:LINTEC CORP

Metal cutting machine tool convenient to adjust

InactiveCN108481076AAchieve fixationAvoid offsetMaintainance and safety accessoriesDrive motorTurbine

The invention discloses a metal cutting machine tool convenient to adjust. The metal cutting machine tool comprises a base, a placing table is arranged above the base, two supporting plates are symmetrically arranged between the placing table and the base, storage boxes are fixed to the opposite side walls of the two supporting plates, two driving boxes are fixedly arranged at the lower end of theplacing table, first driving motors are fixed in the driving boxes, turbine fans are connected to the tail ends of output shafts of the first driving motors, air suction ports of the turbine fans communicate with air suction pipes, the ends, away from the turbine fans, of the air suction pipes penetrate through the driving boxes and the placing table to communicate with air suction covers, and the air suction pipes communicate with the storage boxes through communicating pipes. The metal cutting machine tool convenient to adjust is convenient to adjust and applicable to cutting metal with different thicknesses, working efficiency is improved, metal fragment treatment is timely, follow-up cutting operation is facilitated, and metal cutting quality is improved.

Owner:佛山市顺德星烨金属制品有限公司

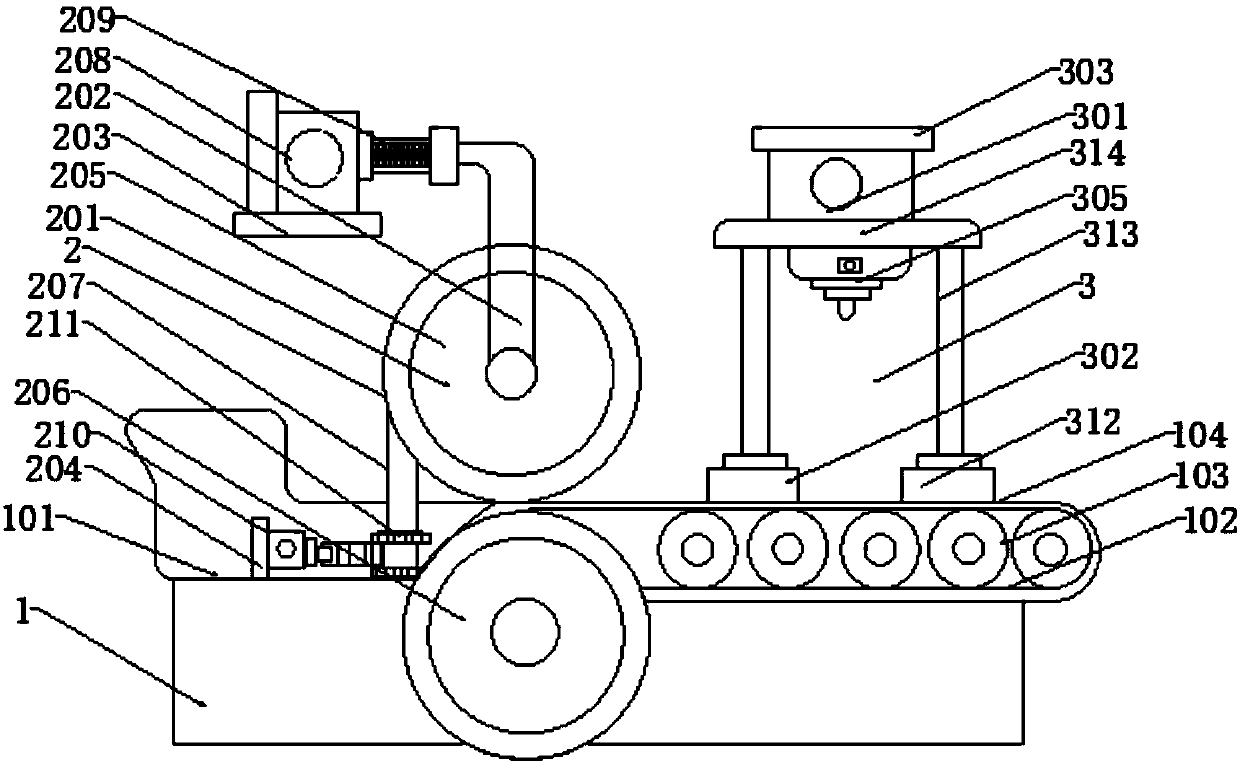

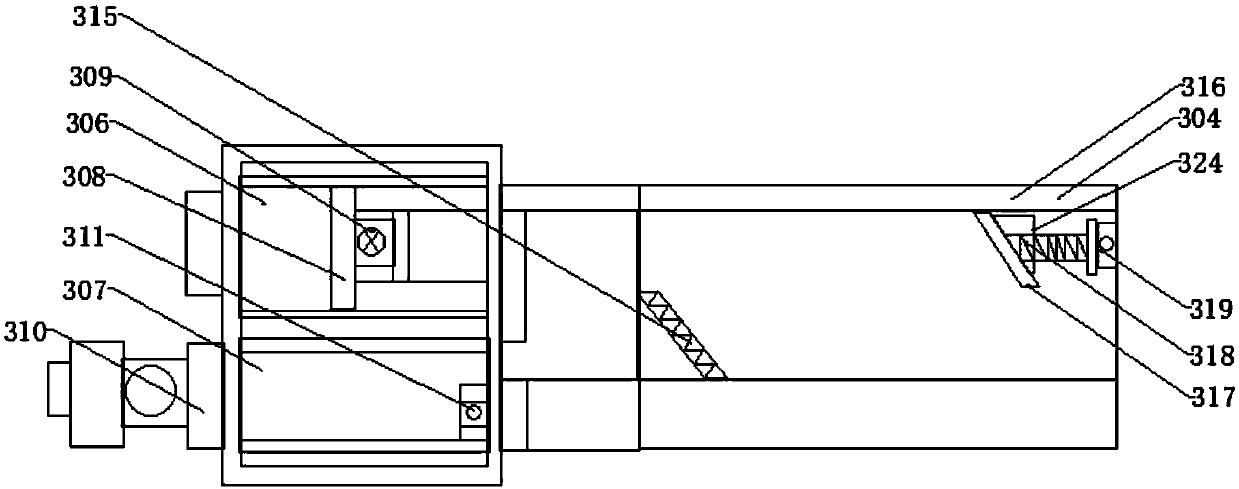

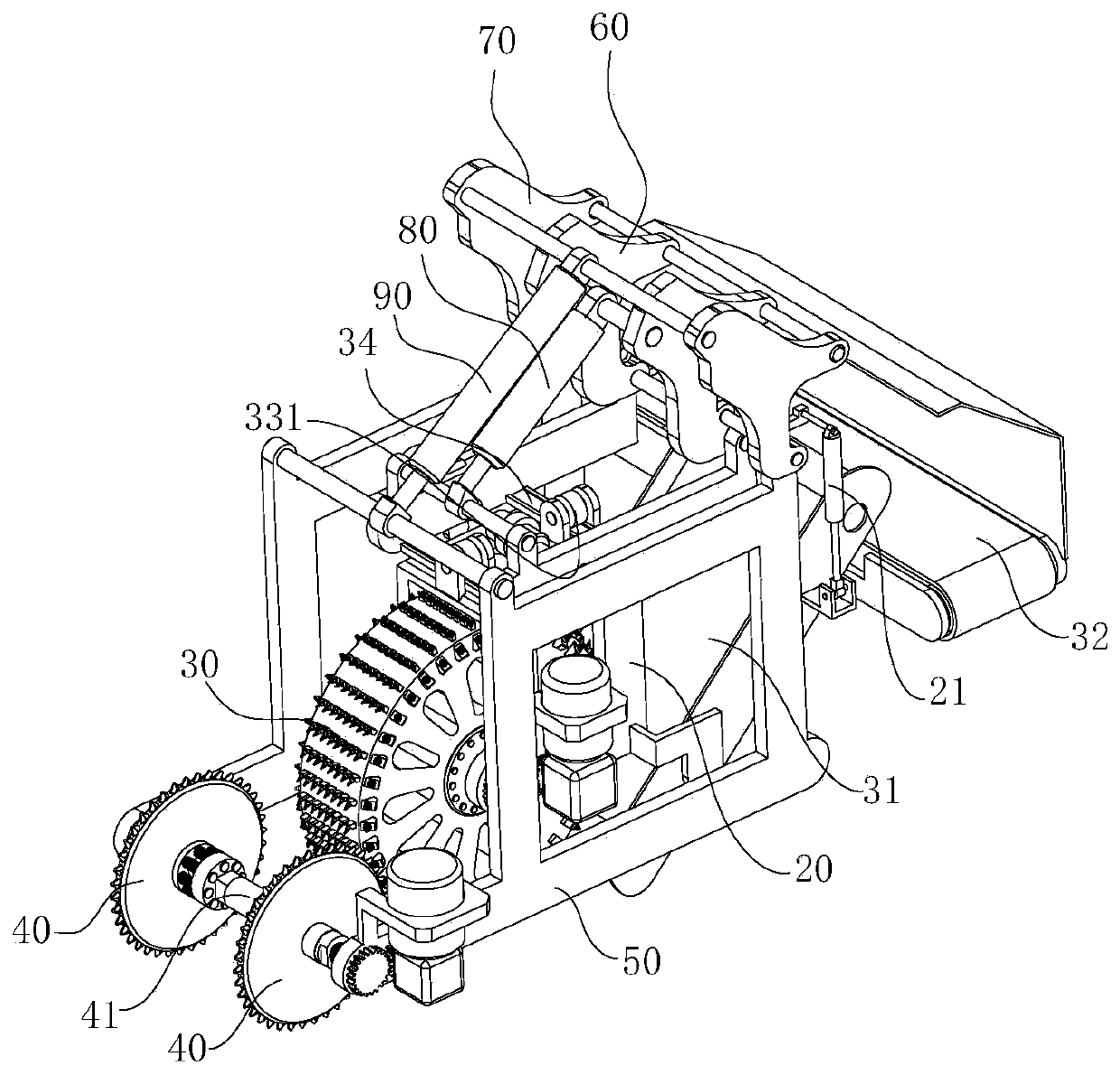

Garlic root hair cutting system

ActiveCN108991568AImprove processing efficiencyPrevent quality degradationFood treatmentEngineeringMechanical engineering

The invention relates to a garlic root hair cutting system, which comprises a conveying device, wherein a discharging port of the conveying device is connected with a feeding port of a sieving device,the sieving device is used for separating garlic into a plurality of size classes, the sieving device is provided with a plurality of discharging ports, the plurality of discharging ports of the sieving device are connected with a feeding port of a vibration adjusting device, the vibration adjusting device is used for making heads of garlic face the same direction, the vibration adjusting deviceis further used for transferring the garlic to a feeding port of a cutting device in sequence, and the cutting device is used for implementing garlic stem segment and root hair cutting on the garlic.The garlic root hair cutting system has the effects that the harvested heads of garlic are input into the conveying device, the garlic is exported to the sieving device by means of the conveying device and divided into multiple classes according to the size, the vibration adjusting device is used for adjusting attitudes of the heads of garlic, so that the attitudes of the heads of garlic orient tothe same state, the cutting device is activated to realize the cutting operation of the root hairs and garlic stems of garlic, and the garlic root hair cutting system can improve the processing efficiency of garlic.

Owner:胡转香

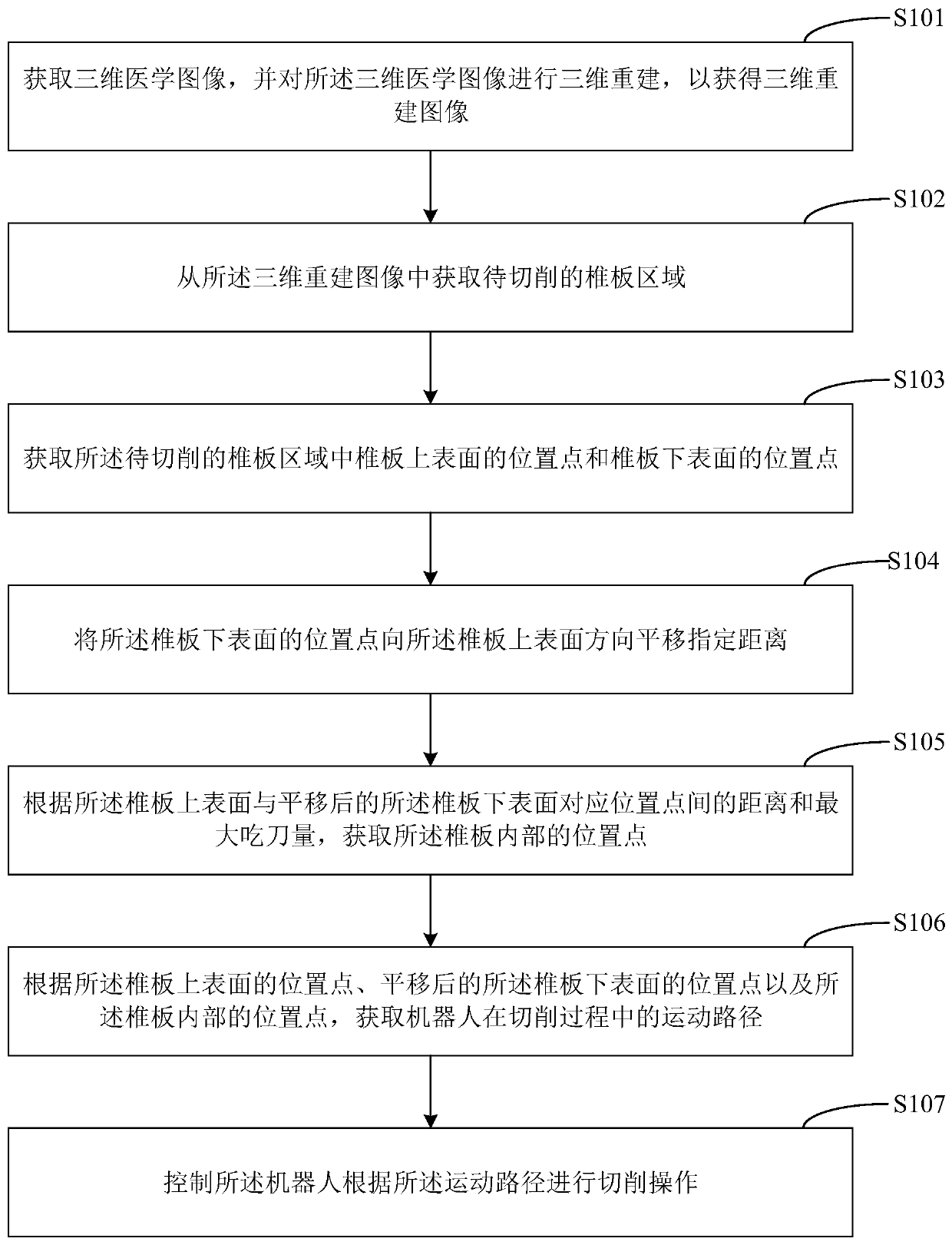

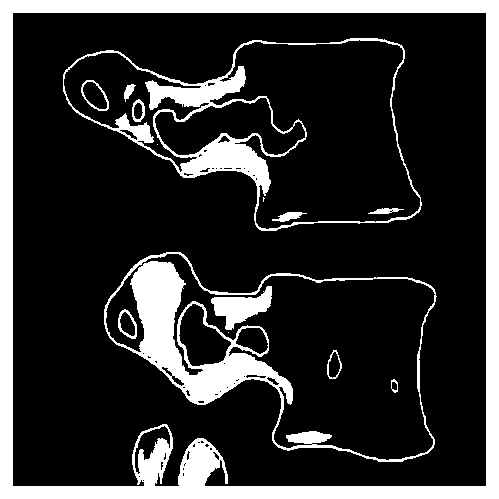

Robot control method, robot control device and robot

InactiveCN110154019ARealize the cutting operationAvoid overcuttingProgramme-controlled manipulatorPhysical medicine and rehabilitationLaminectomy procedure

The invention is suitable for the technical field of robots and provides a robot control method, a robot control device, a robot and a computer readable storage medium. The robot control method comprises the steps that a three-dimensional medical image is obtained, and three-dimensional reconstruction is performed on the three-dimensional medical image to obtain a three-dimensional reconstructionimage; a vertebral plate area to be cut is obtained from the three-dimensional reconstruction image; position points of the upper surface of the vertebral plate and the position points of the lower surface of the vertebral plate are obtained; the position points of the lower surface of the vertebral plate are translated a specified distance towards the direction of the upper surface of the vertebral plate; the position points inside the vertebral plate are obtained according to the distances between the corresponding position points of the upper surface of the vertebral plate and the translated lower surface of the vertebral plate and the maximum engagement of the cutting edge; a moving path of the robot in the cutting process is obtained according to all the position points of the vertebral plate; and the robot is conteolled to perform cutting operations according to the moving path. By means of the robot control method, the robot control device, the robot and the computer readable storage medium, the robot can be conteolled to perform vertebral plate laminectomy, the cutting quality is improved, and spinal nerve injury caused by overcutting and other risks are reduced.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

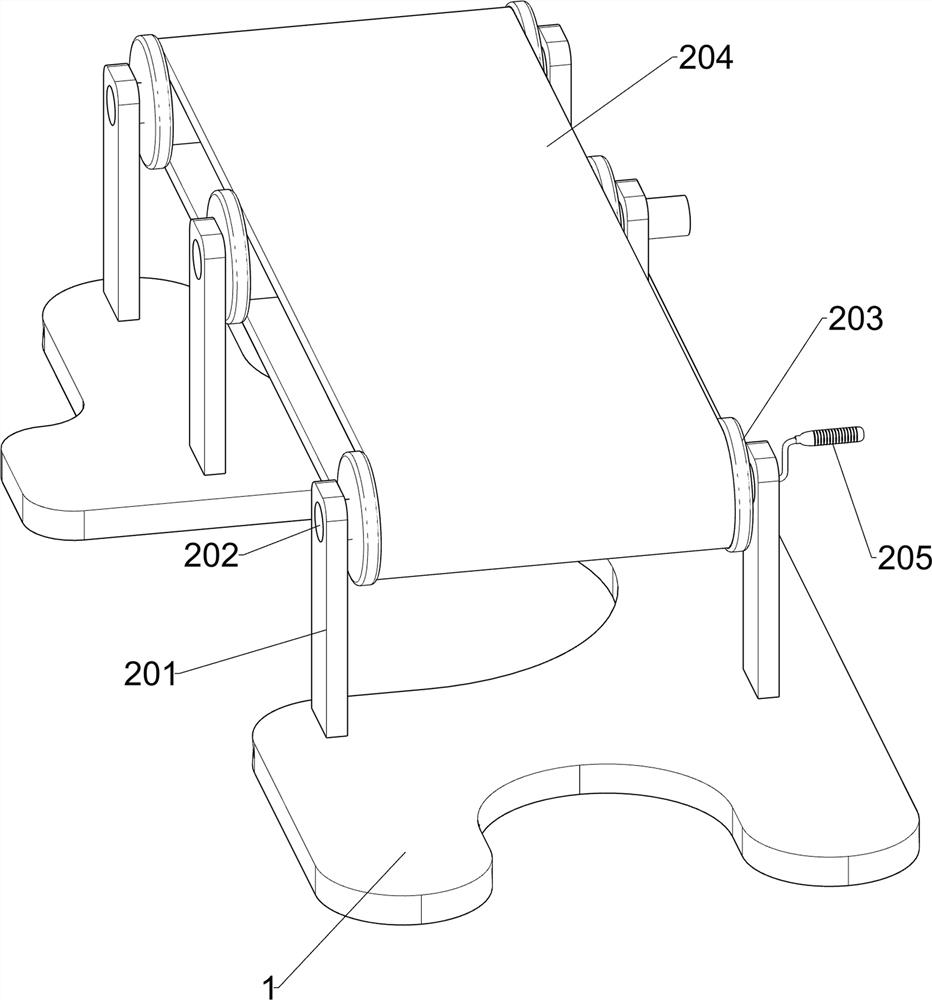

Calendering and directional cutting integrated equipment for automobile plates

ActiveCN108672949ARealization of automatic calenderingAchieve regulationLaser beam welding apparatusLight guideLaser cutting

The invention discloses calendering and directional cutting integrated equipment for automobile plates. The equipment comprises an automatic feeding mechanism, an automatic calendering mechanism and adirectional cutting mechanism. The automatic calendering mechanism comprises a hedging calendering roller, a curved bar connection shaft is connected with the center of a roller shaft of the hedgingcalendering roller in a penetrating mode, the other end of the curved bar connection shaft is connected with a pressing roller adjusting system, the side edge of the hedging calendering roller is further provided with a roller drum position adjusting device, the directional cutting device comprises a laser cutting system and an omni-directional supporting mechanism, the laser cutting system comprises a laser generator used for producing cutting laser light, a laser beam outlet of the laser generator is connected with a sealed light guide pipe used for stably transmitting light, and an output port of the sealed light guide pipe is connected with a laser cutting head. Calendering stretching and directional cutting operation for the automobile plates can be achieved, the good automatic adjusting function is achieved, the requirements of different plates are met, machining precision is high, and cutting in complex shapes can be achieved.

Owner:芜湖众梦电子科技有限公司

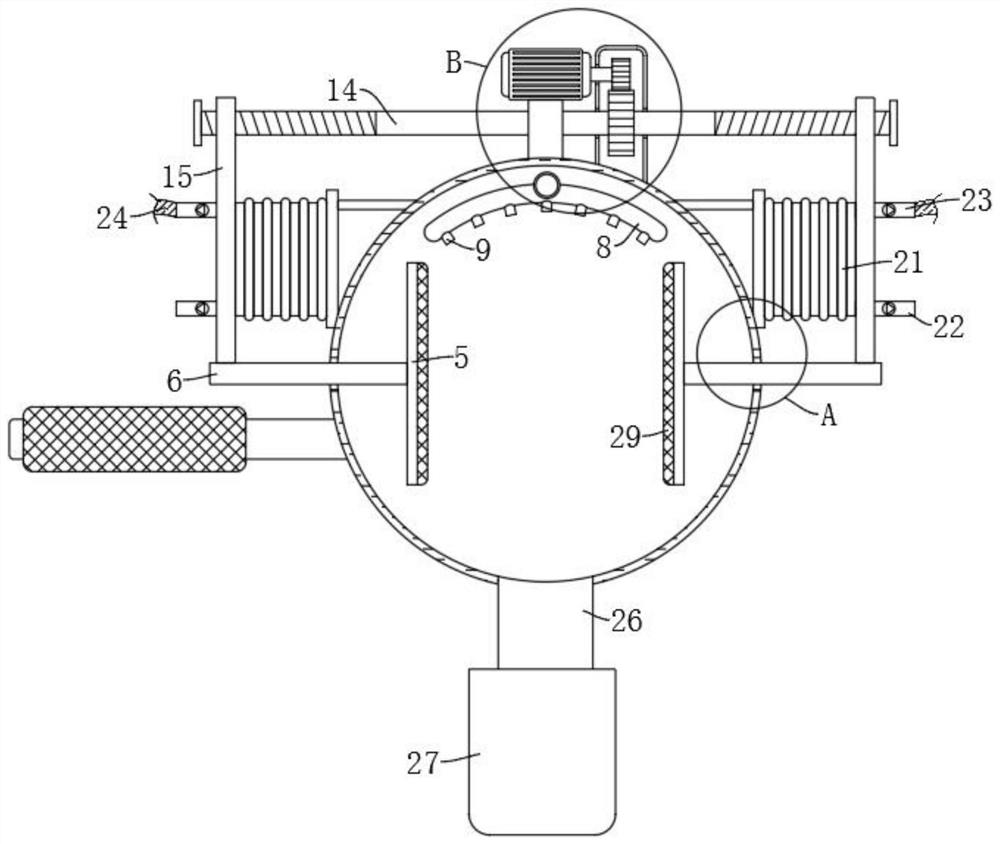

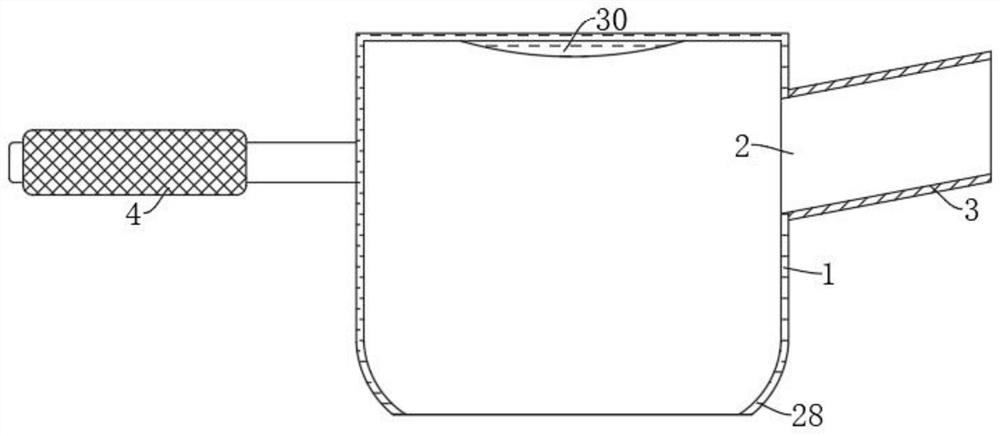

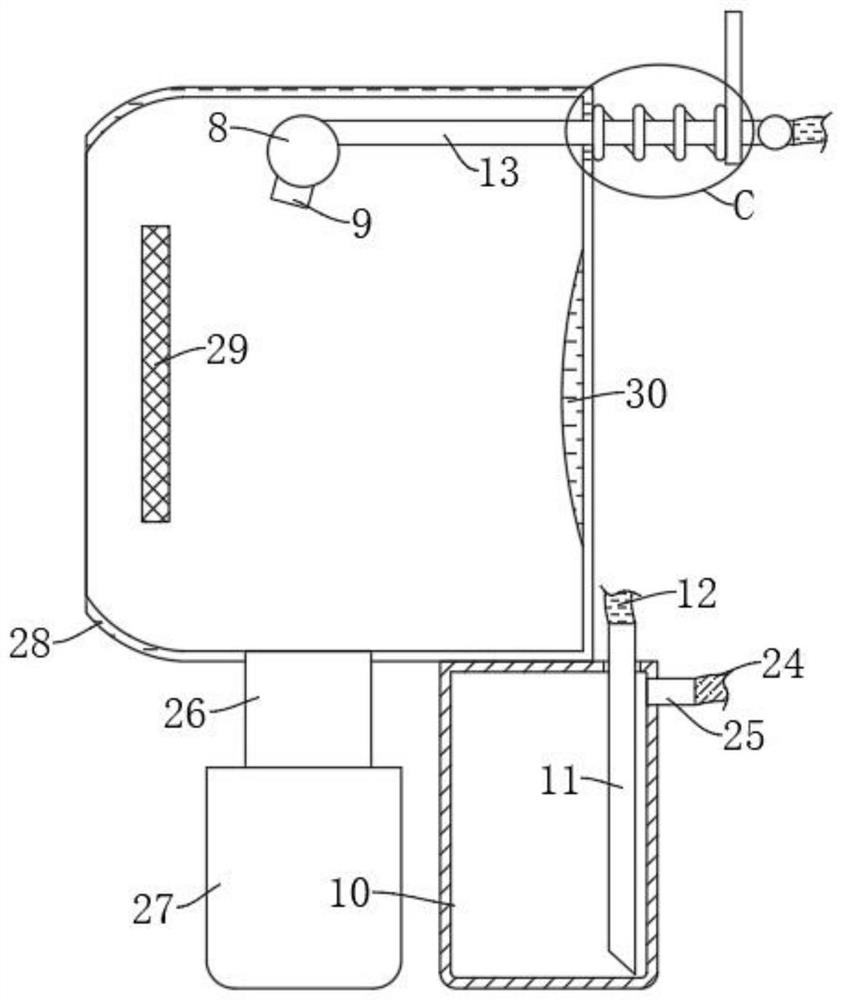

Glass fiber crushing equipment and waste wire processing method

The invention discloses glass fiber crushing equipment and a waste wire processing method. The glass fiber crushing equipment comprises a cutting device, the cutting device is arranged in a cylinder of the glass fiber crushing equipment, the cylinder is in a round table shape with the small upper and lower ends and the large middle, a feeding opening is formed in the upper end of the cylinder, a discharging pipe is arranged at the lower end of the cylinder and connected with a crushing device, and small-size fiber glass after cutting by the cutting device is guided out through the dischargingpipe and enters the crushing device to be crushed. According to the glass fiber crushing equipment, a fixed disc and a rotating disc rotate relatively, the waste wire falls on a cutting piece, under the rotation of the rotating disc, the waste wire of the cutting piece and the cutting piece move relatively, and the cutting of the waste wire by the cutting piece is achieved accordingly.

Owner:旌德县源远新材料有限公司

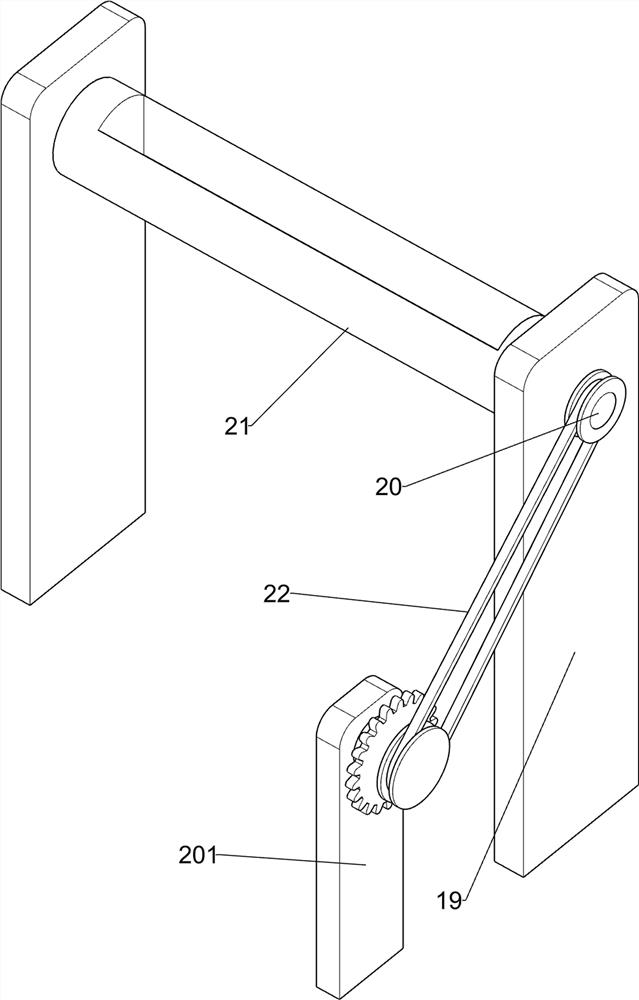

Traffic road handrail efficient cutting equipment

InactiveCN107150142ARealize the cutting operationAvoid blockingShearing machinesMaintainance and safety accessoriesEngineeringRoad traffic

The invention belongs to the technical field of traffic road construction, and in particular relates to a high-efficiency dividing device for traffic road railings. The technical problem to be solved by the present invention is to provide a high-efficiency cutting device for traffic road railings with high cutting efficiency and easy measurement. In order to solve the above-mentioned technical problems, the present invention provides such a high-efficiency separation equipment for traffic road railings, which includes a bottom plate, a left frame, a top plate, a lifting device, a connecting rod, a first mounting plate, a first motor, etc.; There is a left frame, the top of the left frame is provided with a top plate, the bottom of the top plate is provided with a lifting device, the bottom of the lifting device is provided with a connecting rod, the bottom of the connecting rod is provided with a first mounting plate, the bottom of the first mounting plate is provided with a first motor, and the first motor The output shaft is provided with a cutting knife. The invention achieves the effects of high cutting efficiency and easy measurement. The invention has novel structure, convenient measurement and movement, good cutting effect and strong practicability.

Owner:ZHEJIANG NORMAL UNIVERSITY

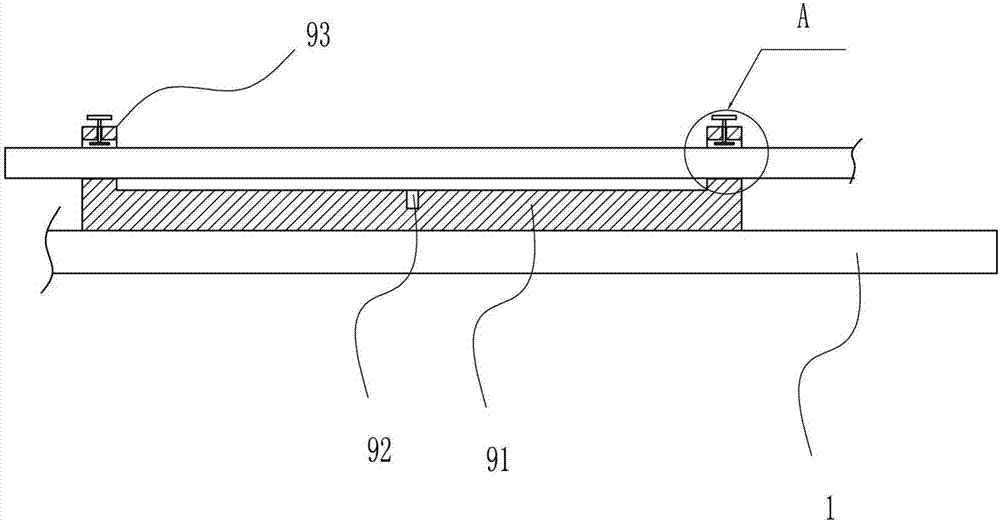

New-old road overlap joint reflective crack construction machinery and pavement construction method

PendingCN110004808AImplement mining operationsRealize the cutting operationRoads maintainenceMobile vehicleRoad surface

The invention relates to new-old road overlap joint reflective crack construction machinery. The new-old road overlap joint reflective crack construction machinery comprises a bracket arm arranged ona moving vehicle, the bracket arm is rotatably provided with a milling wheel, a wheel core of the milling wheel is horizontally arranged and connected with a drive mechanism, the drive mechanism drives the milling wheel to rotate, cutting disc cutters are arranged on the two sides of the front of the milling wheel, disc cores of the cutting disc cutters are horizontally arranged and connected witha power mechanism, the power mechanism drives the cutting disc cutters to rotate, in the process of the moving vehicle supporting and sending the cutting disc cutters to move, the power mechanism drives the cutting disc cutters to rotate, thus joint cutting operation is achieved, the drive mechanism drives the milling wheel to rotate, thus excavation operation of pavement between two cracks is achieved, after joint cutting is completed by the cutting disc cutters, a crack groove used for overlapping of a new pavement and an old pavement can be formed, and thus the construction efficiency canbe effectively improved through the construction machinery.

Owner:ANHUI KAIYUAN HIGHWAY & BRIDGE +1

Aluminum alloy section bar cutting device

InactiveCN111482661AReasonable structureIncrease the scope of applicationLarge fixed membersPositioning apparatusElectric machineryDrive motor

The invention discloses an aluminum alloy section bar cutting device. The aluminum alloy section bar cutting device comprises a bracket and a cutting platform, wherein a cutting base is arranged on asupporting plate; a drive motor is arranged on the cutting base; a cutting tool is fixedly arranged on the main shaft of the drive motor; a bearing table is arranged in a lifting concave cavity; a lifting hydraulic cylinder is fixedly arranged between the bearing table and the bottom wall of the lifting concave cavity; a T-shaped regulating slide slot is formed in a supporting plate; the top surface of the cutting base is integrally formed with a T-shaped slide block; a positioning screw is arranged on the T-shaped slide block; a rotary circular hole is formed in the bottom surface of the cutting base; an inverted-H-shaped rotary shaft rod is arranged in the rotary circular hole; the bottom end of the inverted-H-shaped rotary shaft rod is fixedly provided with a motor bracket; and a locking screw is fixedly arranged on the cutting base. The aluminum alloy section bar cutting device is reasonable in structure setting, can effectively and quickly realize cutting operation of an aluminumalloy section bar, can regulate the position of the cutting tool according to needs to realize cutting operation on different cutting lines, meets cutting on different cutting lines of different section bars, and is high in practicability.

Owner:王菊明

Multi-functional hatchet knife

InactiveCN104942835ARealize the cutting operationFunction increaseMetal working apparatusEngineeringKnife handles

The invention discloses a multi-functional hatchet knife. The multi-functional hatchet knife integrates a knife, an axe, a saw and a hook, and the multi-functional hatchet knife is used for achieving multiple kinds of cutting actions. The multi-functional hatchet knife comprises a knife body and a knife handle, wherein a protection plate is arranged at the contact portion of the knife handle and the knife body, one side of the knife body is provided with saw teeth, the other side of the knife body is provided with a straight knife edge, and the free end, close to the straight knife edge, of the knife body is provided with a knife tip. The multi-functional hatchet knife is characterized in that the installation end of the knife body is detachably connected with the knife handle, the knife tip is in a circular arc shape, a curved knife edge is arranged at the inner side of the knife tip, and a top knife edge is arranged at the top of the free end of the knife body. The multi-functional hatchet knife integrates the knife, the axe, the saw and the hook, multiple kinds of cutting operations can be achieved, functions are various, and the use in outdoor traveling is facilitated.

Owner:UNIV OF JINAN

Wood cutting and polishing device for gardens

InactiveCN112496979ARealize clamping and fixing operationRealize the cutting operationGrinding carriagesGrinding drivesStructural engineeringWood processing

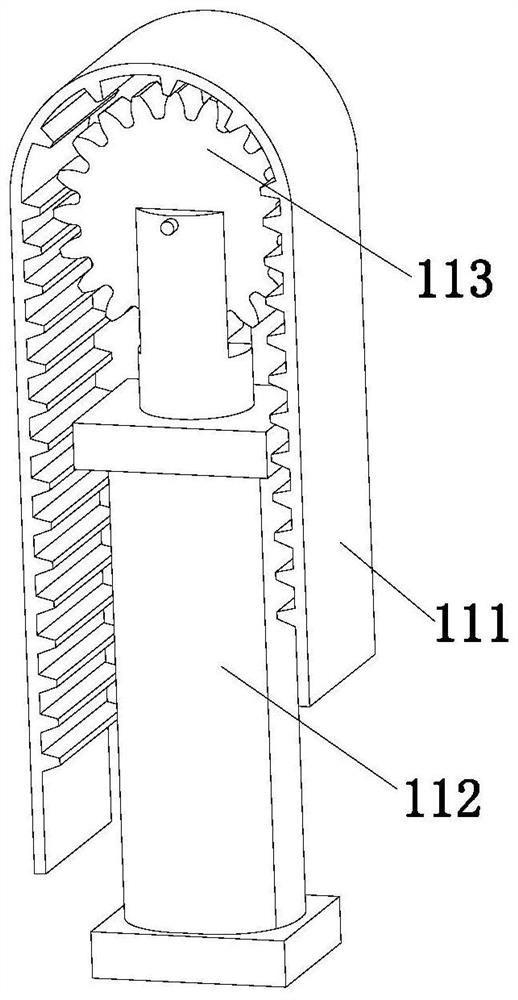

The invention discloses a wood cutting and polishing device for gardens, and relates to the technical field of wood processing equipment for gardens. The wood cutting and polishing device for gardenscomprises a bottom plate, supporting legs are fixedly connected to four corners of the bottom of the bottom plate, a first mounting plate is fixedly connected to the bottom plate, a mounting opening is formed in the first mounting plate, a mounting gear ring is rotatably connected to the position, on one side of the mounting opening, of the first mounting plate, a driving gear is rotationally connected to the position, below the mounting gear ring, of the side wall of the first mounting plate, polishing devices are arranged in the mounting gear ring, the polishing devices are arranged on the mounting gear ring at equal radian intervals, a sliding groove is formed in the first mounting plate and on the side, away from the mounting gear ring, of the mounting opening, mounting blocks are slidably connected into the sliding groove, a mounting frame is fixedly connected between the mounting blocks, the mounting frame is of a cavity structure with two through sides, and a cutting disc is rotationally connected into the mounting frame. The device is reasonable in structural principle design and strong in practicability.

Owner:倪婷

Novel cutting device

InactiveCN108044663ARealize the cutting operationFast limited rotationMetal working apparatusElectric machineryEngineering

The invention discloses a novel cutting device which comprises a cutting frame; a first rotation groove which transversely extends is arranged at the upper side in the cutting frame; second rotation grooves which communicate with the first rotation groove are arranged in the cutting frame in a left-right symmetry manner; fixed blocks are arranged in the first rotation groove in the left-right symmetry manner; a mounting cavity is arranged between the two fixed blocks; a first motor is arranged on the top wall in the mounting cavity; an output shaft of the first motor extends into the mountingcavity; a driving conical wheel is arranged at the tail end of the bottom of the output shaft; a first rotary shaft is rotatably arranged in each fixed block and extends from left to right; first conical wheels are arranged at the extension sections of the two sides of each first rotary rod respectively; a second rotary rod is rotatably arranged in each second rotation groove; and a second conicalwheel which extends into the first rotation groove is fixedly arranged on the top of each second rotary rod.

Owner:高峰

High-end plastic thin film conveying device

InactiveCN109319555ASimple structureHigh degree of automationArticle deliveryWebs handlingThin membraneEngineering

The invention discloses a high-end plastic thin film conveying device comprising an outer rack, a conveying device and a cutting device. The conveying device is located in a first cavity which is formed in the right side of the outer rack and is provided with a rightward opening, and the cutting device is located in a sliding cavity in the left side of the outer rack; a gear housing is fixed to the top wall of the interior of the first cavity, a mounting cavity is formed in the gear housing, a first rotating shaft is rotatably arranged in the front and rear end walls of the first cavity, the first rotating shaft is fixedly provided with a mounting disc and a first belt wheel located behind the mounting disc, a second rotating shaft extending front and back is connected to the rightmost side of the interior of the mounting cavity in a matched manner, the front side extending end of the second rotating shaft is connected with the end wall of the front side of the mounting cavity in a rotary fit manner, the rear side extending section of the second rotating shaft is in power connection with a first motor fixedly arranged in the end wall of the back side of the mounting cavity, and thesecond rotating shaft is fixedly provided with a second belt wheel connected to the first belt wheel through a first belt.

Owner:广州雅隆自动化设备有限公司

Auxiliary device for wart cutting in dermatology department

InactiveCN113331914AEasy cutting workRealize the cutting operationEnemata/irrigatorsDiagnosticsDermatology departmentSpray nozzle

The invention discloses an auxiliary device for wart cutting in the dermatology department, and belongs to the field of the dermatology department. The auxiliary device for wart cutting in the dermatology department comprises a cylindrical transparent cover, and further comprises a handle fixedly installed on the outer wall of the cylindrical transparent cover, an operation groove, two symmetrically arranged clamping plates and a spray pipe. The operation groove is formed in the outer wall of the cylindrical transparent cover, and an obliquely-arranged operation pipe is fixedly installed in the operation groove. The two symmetrically arranged clamping plates are arranged in the cylindrical transparent cover, are connected with the cylindrical transparent cover through a clamping mechanism and are used for clamping a part to be cut. Spray nozzles are arranged on the side wall of the spray pipe, and the spray pipe is arranged in the cylindrical transparent cover, connected with the cylindrical transparent cover through an adjusting mechanism and used for adjusting the position of the spray pipe. According to the auxiliary device for wart cutting, a cutter can cut warts more safely and conveniently, and cut wounds can be disinfected and flushed conveniently.

Owner:申明

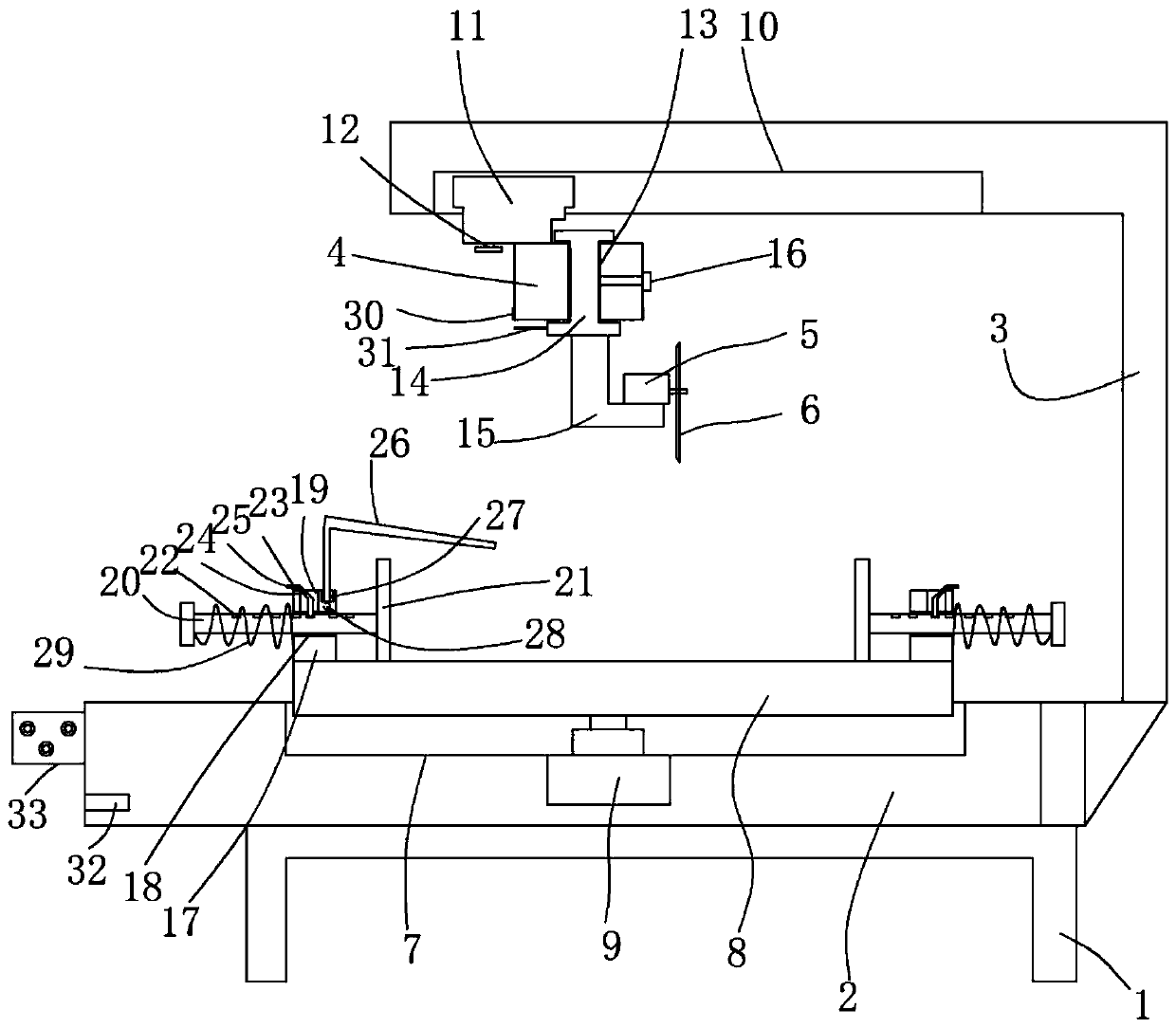

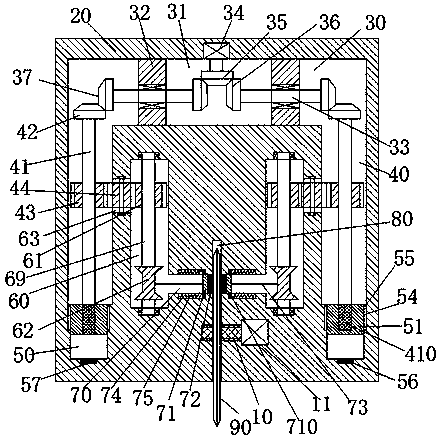

Locating and conveying cutting equipment of eraser strip

ActiveCN106042057ARealize automatic printingRealize the cutting operationMetal working apparatusReciprocating motionBarrel Shape

The invention relates to the technical field of eraser producing and machining, in particular to locating and conveying cutting equipment of an eraser strip. The locating and conveying cutting equipment comprises a stamping device, a guide-in device and a stroke detection unit. The stamping device comprises a stamping die and an intermittent feed mechanism. The stamping die comprises a barrel-shaped tool. The barrel-shaped tool does reciprocating motion in the vertical direction and is used for obtaining eraser blocks on the flat eraser strip in a blanking manner. The intermittent feed mechanism is used for conveying the flat eraser strip to feed the flat eraser strip intermittently towards the portion below the stamping die; and according to the specific process, the flat eraser strip is fed forwards when the barrel-shaped tool ascends, and feeding of the flat eraser strip is stopped when the barrel-shaped tool descends. According to the locating and conveying cutting equipment, automatic printing and cutting operation of an eraser can be achieved, no manual operation is needed in the production process, and the production efficiency is greatly improved.

Owner:宿州市超晟文具有限公司

Agricultural garlic auxiliary cutting device

ActiveCN111941504ARealize interval feedingRealize blanking at intervalsMetal working apparatusAgricultural scienceAgricultural engineering

The invention relates to an agricultural cutting device, in particular to an agricultural garlic auxiliary cutting device. The agricultural garlic auxiliary cutting device can automatically conduct discharging, can cut root hairs and garlic sprouts at a time, and meanwhile can conduct batch cutting. The agricultural garlic auxiliary cutting device comprises a bottom plate, supporting rods, a discharging hopper, elastic catches and a cutting device, wherein the supporting rods are symmetrically arranged on one side of the top of the bottom plate with respect to the feeding device, the discharging hopper is arranged between the upper parts of the two supporting rods, the elastic catches are arranged on the side, close to the center of the feeding device, of the discharging hopper, and the cutting device is arranged on the side, away from the discharging hopper, of the bottom plate. According to the agricultural garlic auxiliary cutting device, the effects that the automatic discharging can be achieved, the root hairs and the garlic sprouts can be cut at a time, and meanwhile the batch cutting can be achieved.

Owner:天辰兰德(山东)科技服务有限公司

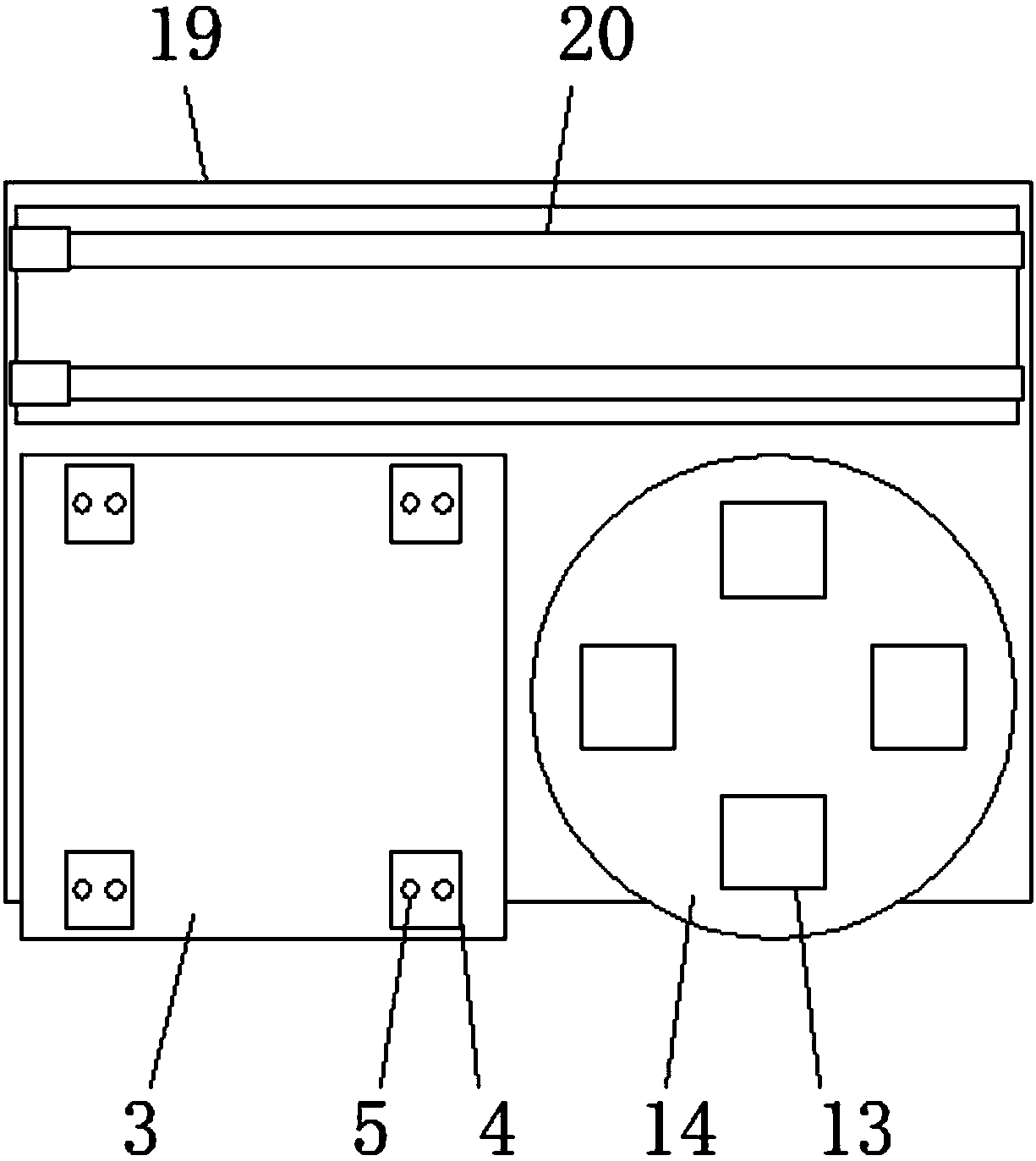

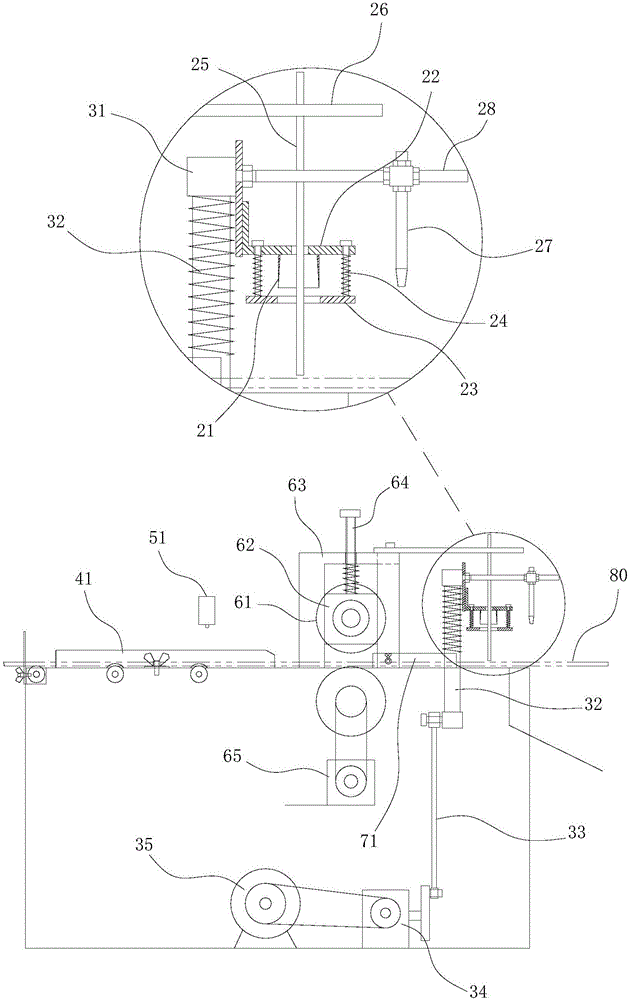

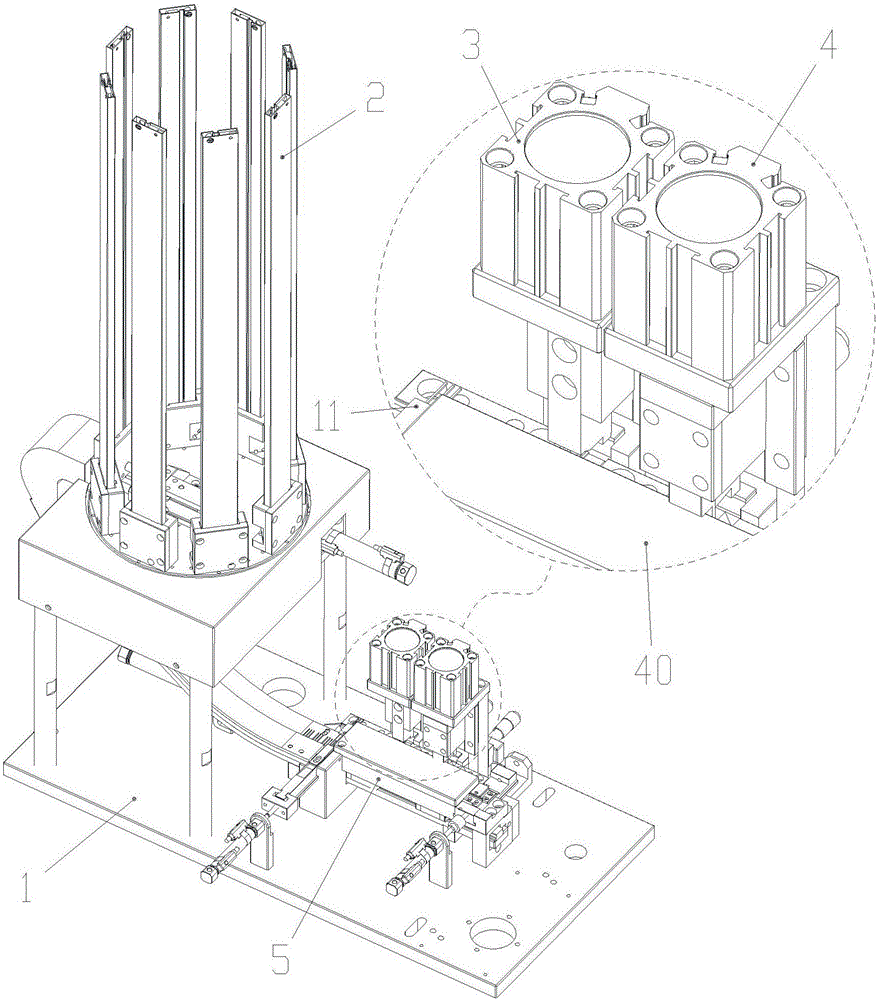

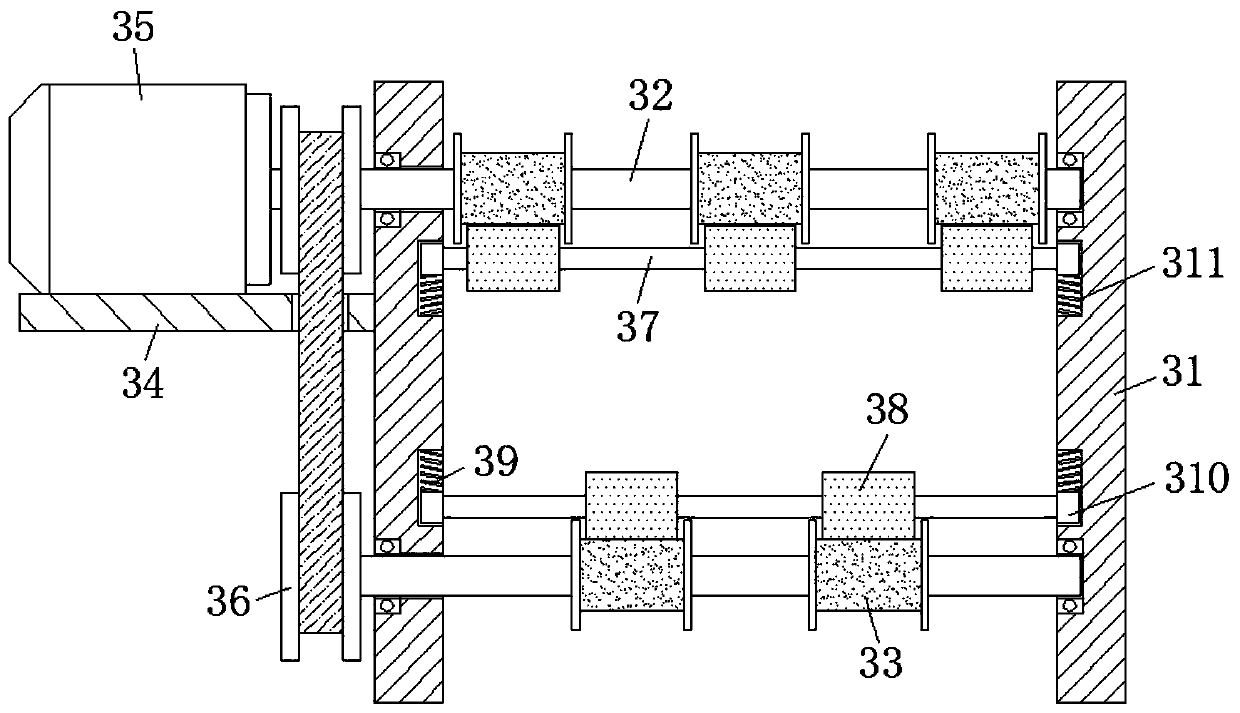

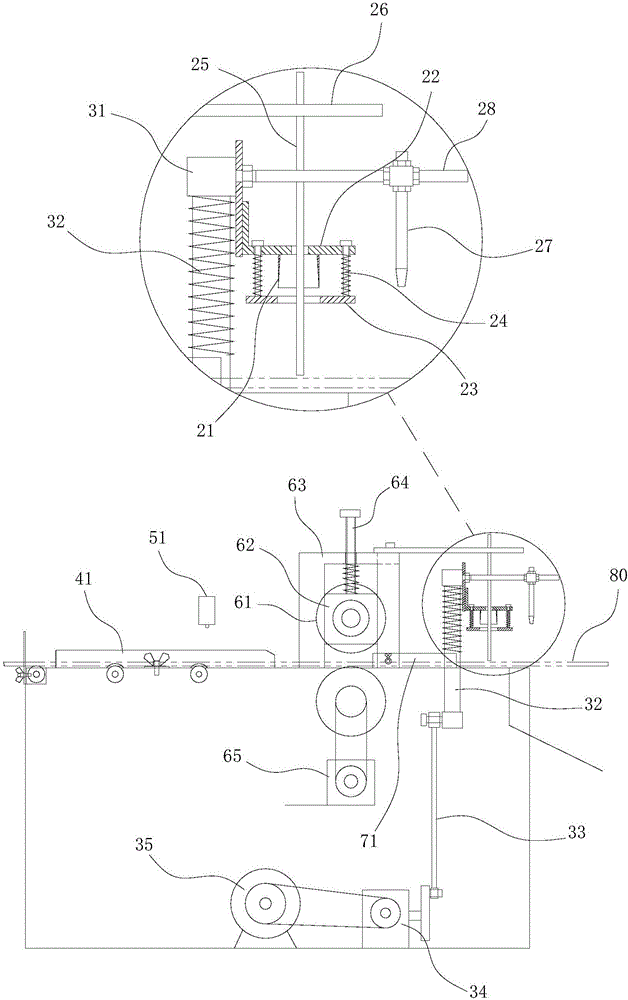

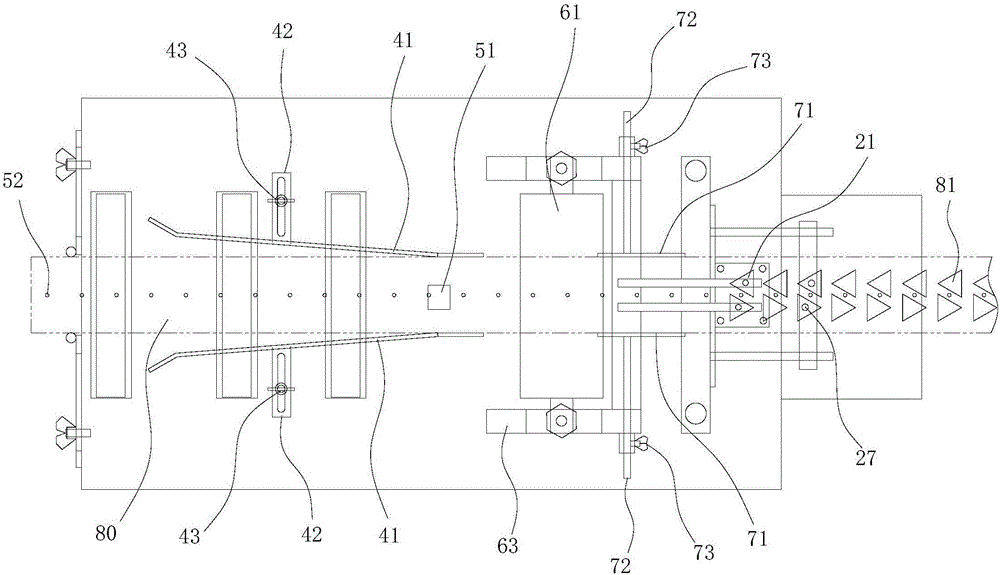

Chip pin intelligent assembly line machining complete equipment

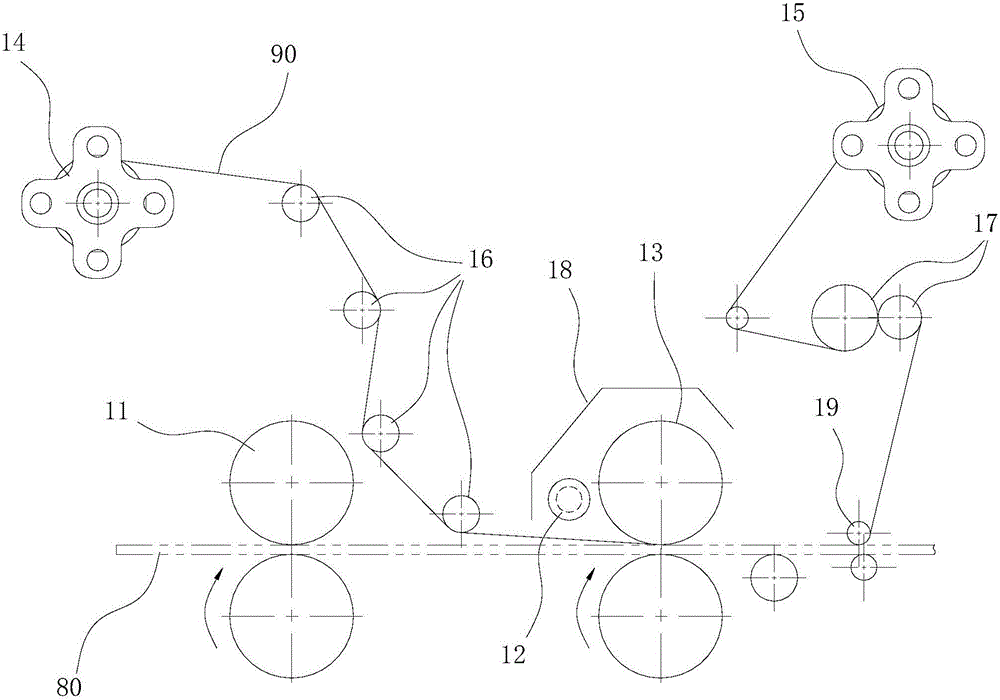

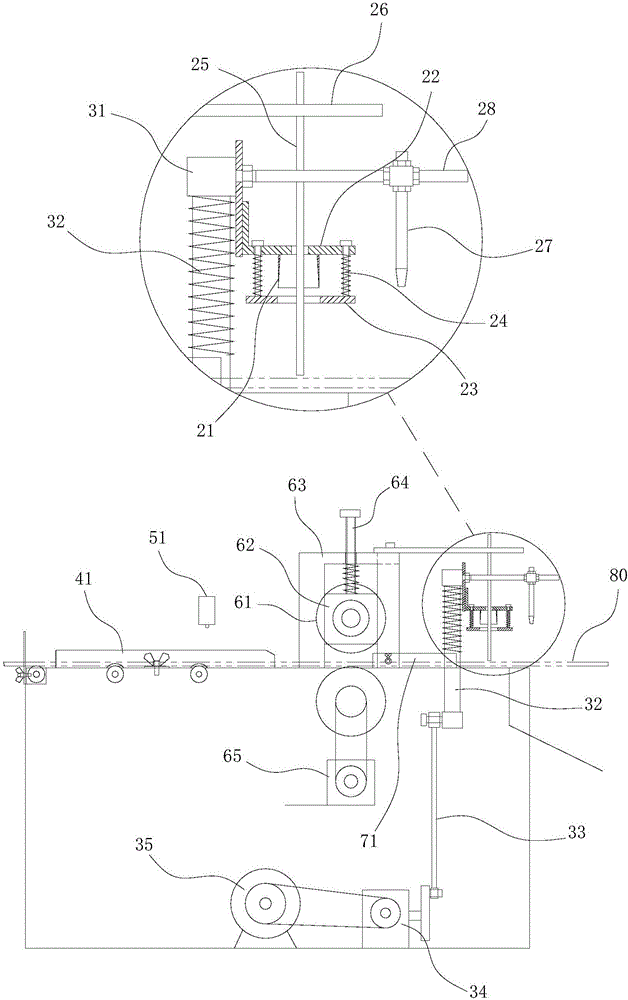

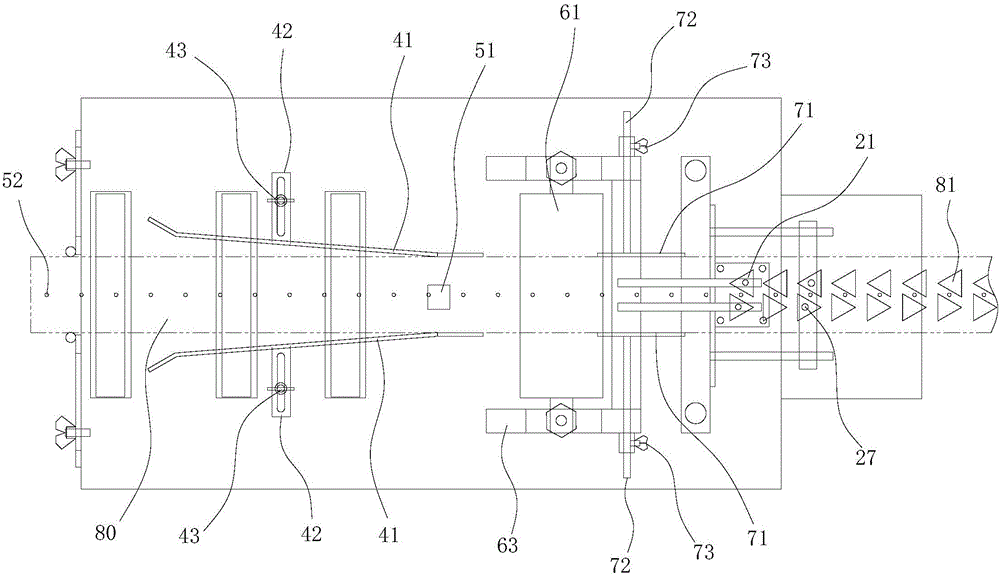

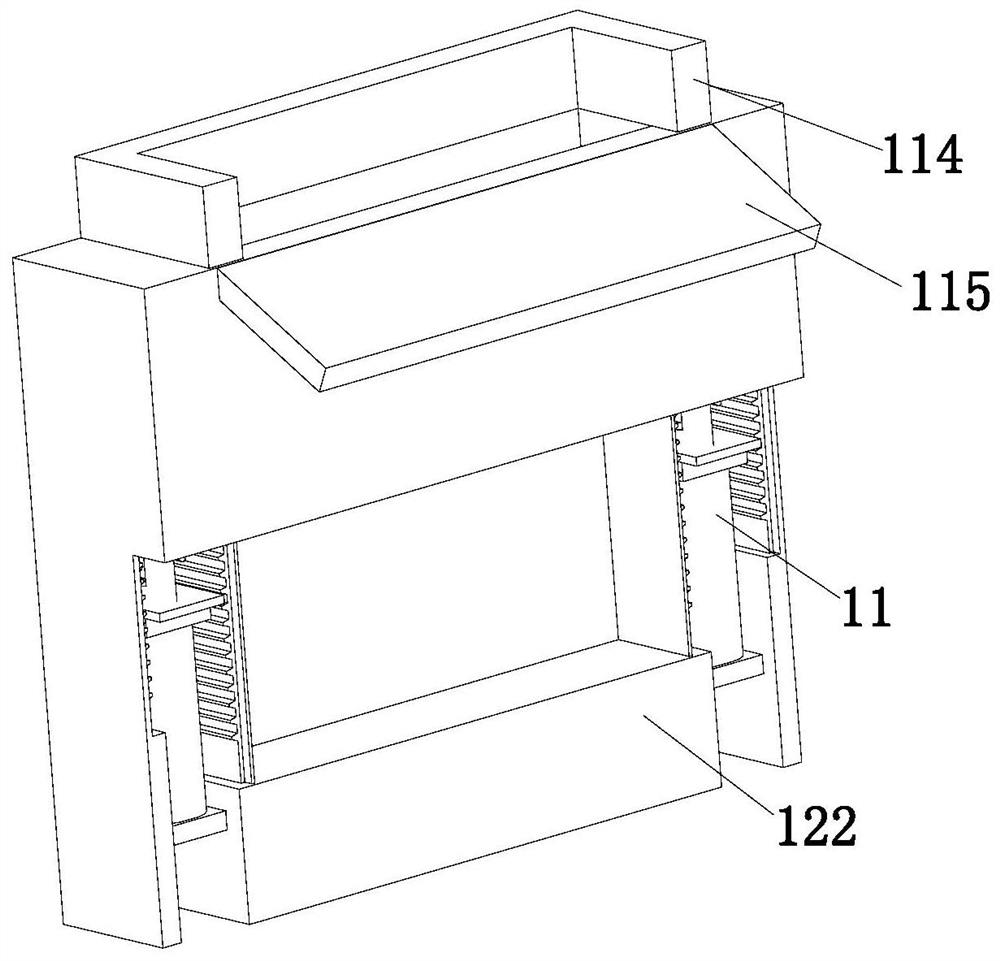

InactiveCN106799594AFully automaticRealize automatic feedingOther manufacturing equipments/toolsMetal working apparatusAssembly lineElectrical and Electronics engineering

The invention relates to industrial manufacturing equipment, in particular to special equipment for achieving machining operation on pins of power chips. The chip pin intelligent assembly line machining complete equipment comprises a working table, a feeding mechanism used for providing the power chips, a bending mechanism for bending the pins of the power chips, a shearing mechanism for shearing the pins and a stepping feeding mechanism for carrying the power chips; and the feeding mechanism is fixedly connected to the working table, a rail of the feeding mechanism is connected to the stepping feeding mechanism, and the side edge of the stepping feeding mechanism is provided with the bending mechanism and the shearing mechanism. The chip pin intelligent assembly line machining complete equipment is used for achieving full-automatic bending and shearing of the pins of the power chips, unmanned operation is achieved, the working efficiency is high, and the molding accuracy is high.

Owner:WENZHOU BEIJIAFU AUTOMATIC TECH CO LTD

Automatic tassel cutting device

InactiveCN106914939ARealize the cutting operationAdjust speedMetal working apparatusTasselMotor shaft

The invention belongs to the technical field of agricultural machine food processing devices and particularly relates to an automatic tassel cutting device. The automatic tassel cutting device comprises a conveying belt, a cutting plate, a support, a sensor, a cutter, a sliding block, a sliding rail, a roller shaft, a mounting platform, a motor shaft, a coupler, a motor, an annular track, a roller, a mounting block, a connecting rod, a switch, a controller and a pin shaft. The conveying belt is fixed on the support. The cutting plate is arranged on the side face of the conveying belt. The sliding rail is perpendicular to the cutting plate face. The sliding block is arranged inside the sliding rail. The cutter is arranged at the front end of the sliding block. According to the automatic tassel cutting device, the structure is reasonable, pertinence is high, intermittent reciprocating rectilinear motion of the cutter is achieved through the mechanical connecting rod so as to cut material, and the automatic tassel cutting device has high market application value.

Owner:YISUBAIHUO TIANJIN TECH CO LTD

Shearing and recycling device for waste liquid gas storage tank

InactiveCN105127751AImprove work efficiencyReduce labor intensitySolid waste disposalShearing machinesKnife bladesLiquid gas

The invention relates to a shearing and recycling device for a waste liquid gas storage tank. The shearing and recycling device comprises a main machine body. A shearing cylinder and a material pressing cylinder are perpendicularly arranged on the top of the main machine body. A material pressing head is arranged at the bottom of a piston rod of the material pressing cylinder and is used in cooperation with a bottom protection plate for achieving the material pressing work. A shear slide base is fixedly arranged at the bottom of a piston rod of the shearing cylinder and is in slide fit with a guide rail plate. A blade is fastened and arranged at the bottom of the shear slide base through a tool bit bolt and is used in cooperation with a vertical cutter pad for completing the shearing work. By means of the shearing and recycling device, automatic feeding can be conducted on the waste liquid gas storage tank, a tank body can be compressed, the flattened tank body is sheared through the shearing device so that the tank body can be sheared into two parts, and finally waste angle materials obtained after shearing are recycled.

Owner:YICHANG CITY RUIYANG MACHINERY MFG

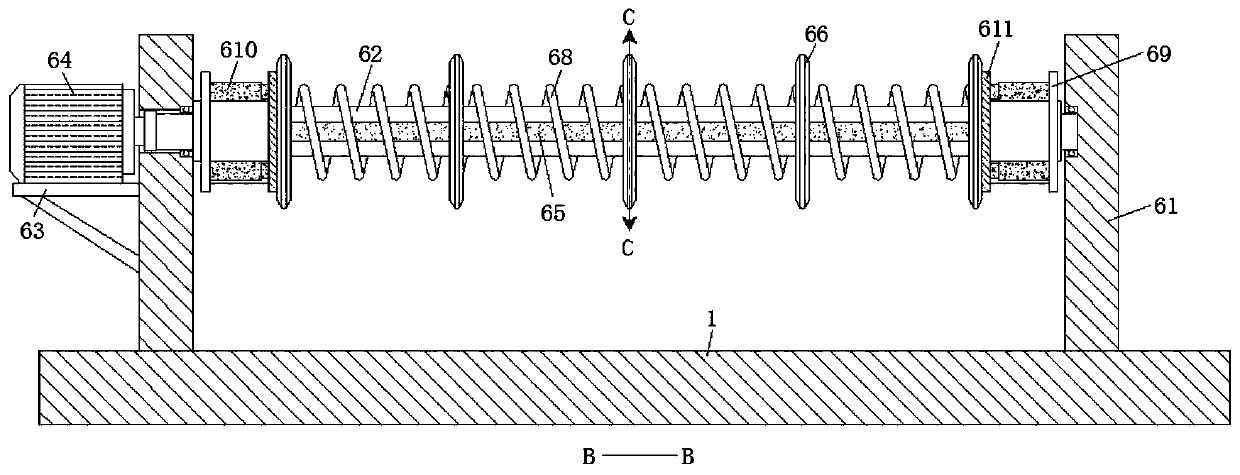

Thin film precise slitting device for thin-film capacitor processing

ActiveCN111438748ACutting stabilityGood cutting effectMetal working apparatusFilm capacitorThin membrane

The invention discloses a thin film precise slitting device for thin-film capacitor processing. The device comprises a base, wherein universal wheels are mounted at four corners of the lower end faceof the base respectively, a pay-off roller and a take-up mechanism are fixedly connected to two sides of the upper end face of the base respectively, the take-up mechanism comprises two first mountingseats, mounting rods are rotationally connected between the two first mounting seats through rolling bearings, coiling disks are fixedly connected to outer walls of the mounting rods respectively, ahorizontal plate is fixedly connected to the upper portion of the first mounting seat at the rear end, a first servo motor is fixedly connected to the upper end of the horizontal plate through screws,rear ends of the two mounting rods both penetrate through the first mounting seats and are rotationally connected through a conveying belt, the output end of the first servo motor is connected with the mounting rod at the upper end through screws, and pressing rods are arranged at close ends of the two mounting rods respectively. Through the thin film precise slitting device, capacitor thin filmcutting is stable, the cutting effect is good, efficiency is high, cutting operation on capacitor thin films with multiple specifications can be realized, and therefore the device is wide in application range.

Owner:ANHUI MASCOTOP ELECTRONICS

Eraser machining equipment

ActiveCN106113459AIncrease productivityRealize automatic printingMetal working apparatusEngineeringMachining

The invention relates to the technical field of eraser production and machining, in particular to eraser machining equipment. The eraser machining equipment comprises a pattern pasting device, a stamping device, a leading-in device, a holding mechanism, a stroke detection unit and a stamping die driving mechanism. The stamping device comprises a stamping die and an intermittent feeding mechanism. The stamping die comprises a cylindrical tool. The cylindrical tool moves back and forth in the vertical direction and is used for cutting eraser blocks from a flat eraser strip through blanking. The intermittent feeding mechanism is used for conveying the flat eraser strip and feeding the flat eraser strip to the position below the stamping die intermittently. Specifically, when the cylindrical tool is lifted, the flat eraser strip is fed forwards; and when the cylindrical tool falls, the flat eraser strip stops being fed. By the adoption of the eraser machining equipment, automatic printing and cutting of erasers can be achieved, manual operation is not needed in the production process, and the production efficiency is greatly improved.

Owner:宿州市超晟文具有限公司

Automatic cutting and grinding equipment for slag ingots and dummy ingot plates

InactiveCN112318131ASmart device designSmooth connectionFeeding apparatusOther manufacturing equipments/toolsGrindingSlag

The invention discloses automatic cutting and grinding equipment for slag ingots and dummy ingot plates, and belongs to the technical field of slag ingot and dummy ingot plate machining. The equipmentcomprises a platform, feeding devices, a conveying belt, a supporting device, two limiting devices, a grabbing device, a cutting device, a grinding device, a dust suction device and a discharging device, wherein the feeding devices, the conveying belt, the supporting device, the two limiting devices, the grabbing device, the cutting device, the grinding device, the dust suction device and the discharging device are all mounted on the platform. A feeding box is arranged at one end of the conveying belt, the number of the feeding devices is two, the two feeding devices are symmetrically arranged on the two sides of the feeding box, feeding blocks connected with the output ends of the two feeding devices correspondingly are further arranged in the feeding box, a connecting rod is arranged onthe conveying belt, and sliding grooves allowing the connecting rod to slide are formed in the two sides of the conveying belt. By means of the equipment, automatic feeding, clamping, limiting, supporting, cutting, grinding, dust collecting and discharging steps can be conducted on electroslag ingots and dummy ingot plates, the practicability is high, the automation degree is high, and the remarkable economic value is achieved.

Owner:许水荣

Comprehensive eraser processing equipment

ActiveCN106113152ARealize automatic printingRealize the cutting operationTransfer printingMetal working apparatusMechanical engineeringEngineering

The invention relates to the technical field of eraser producing and processing, in particular to comprehensive eraser processing equipment which comprises a pattern pasting device, a stamping device, a guiding-in device, a holding mechanism and a travel detecting unit. The stamping device comprises a stamping die and an intermittent feeding mechanism; the stamping die comprises a cylindrical tool which reciprocates in the vertical direction and is used for stamping eraser blocks out of a flat eraser strip; and the intermittent feeding mechanism is used for conveying the flat eraser strip and feeding the flat eraser strip to the position below the stamping die in an intermittent mode, specifically, when the cylindrical tool is lifted, the flat eraser strip is fed forwards, and when the cylindrical tool falls, the flat eraser strip is stopped feeding. By means of the comprehensive eraser processing equipment, automatic printing and cutting of erasers can be achieved, manual operation is not needed in the production process, and the production efficiency is greatly improved.

Owner:宿州市超晟文具有限公司

Cutting device

ActiveCN108968120AGuarantee processing qualityImprove processing efficiencySievingGas current separationEngineeringDisc cutter

The invention relate to a garlic cutting device. The garlic cutting device is characterized in that an arc-shaped extension block is arranged at the discharge outlet of a vibration adjusting device, avertical extension block is arranged at the lower end of the arc-shaped extension block, a third guide groove is arranged in the vertical extension block, third retaining rods are vertically arrangedat the lower ends of two second retaining rods, and the bottom of the third guide groove is provided with an opening; a cutting device body comprises two disc cutters, the disc faces of the disc cutters are vertical and arranged on two sides of the opening, the disc cutters protrude out of the opening and extend towards the third retaining rods, the opposite disc faces of the two disc cutters arelocated on the inner sides of the two third retaining rods and are close to each other, and a drive unit drives the two disc cutters to rotate synchronously. The cutting device has the advantages that by starting the two disc cutters of the cutting device body, garlic stalks and fibrils can be accurately and reliably cut, garlic processing quality is guaranteed, and garlic processing efficiency can be increased.

Owner:山东星链信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com