New-old road overlap joint reflective crack construction machinery and pavement construction method

A technology of reflective cracks and construction machinery, applied in the field of engineering construction, can solve problems such as low construction efficiency, road damage, reflective cracks on the road surface, etc., and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

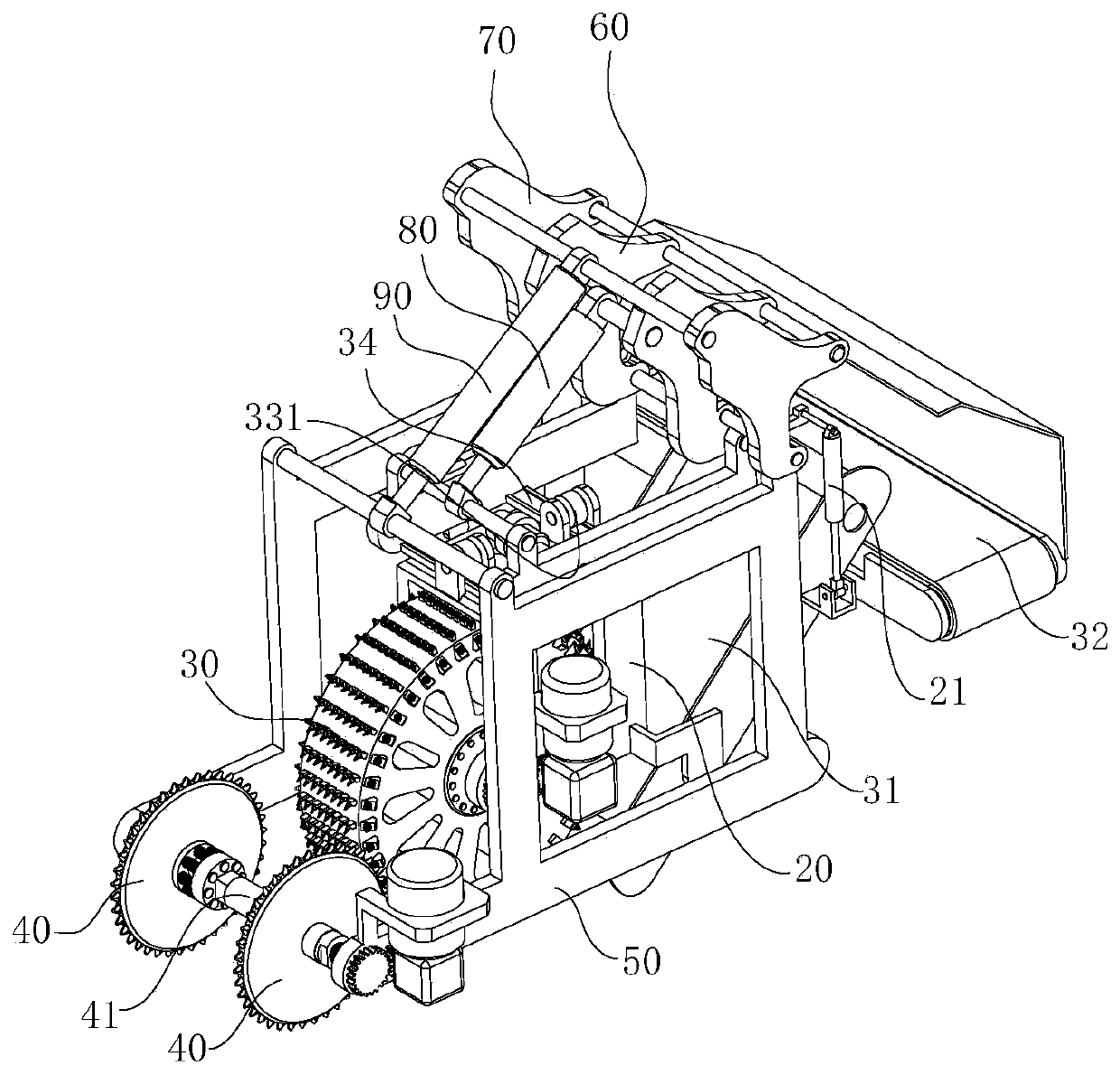

[0028] refer to Figure 1 to Figure 10 , the structural characteristics of the new and old road lap reflective crack construction machinery are described in detail as follows:

[0029] New and old road overlap reflective crack construction machinery, including a bracket arm 20 arranged on a mobile vehicle 10, a milling wheel 30 is rotatably arranged on the bracket arm 20, and the milling wheel 30 has a wheel core and is connected to a driving mechanism , the driving mechanism drives the milling wheel 30 to rotate, and the two sides in front of the milling wheel 30 are provided with cutting disc cutters 40, the disc core of the cutting disc cutter 40 is horizontal and connected with the power mechanism, and the power mechanism drives the cutting disc cutter 40 to rotate;

[0030] combine figure 1 As shown, during the moving process of the moving vehicle 10 supporting the cutting disc cutter 40, the power mechanism drives the cutting disc cutter 40 to rotate, thereby realizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com