Metal surface oxidation device

An oxidation device and metal surface technology, applied in the field of oxidation, can solve the problems of affecting the quality of metal processing, easy over-reaction at the bottom, difficult oxidation reaction, etc., and achieve the effect of comprehensive and thorough processing, ensuring consistency and ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

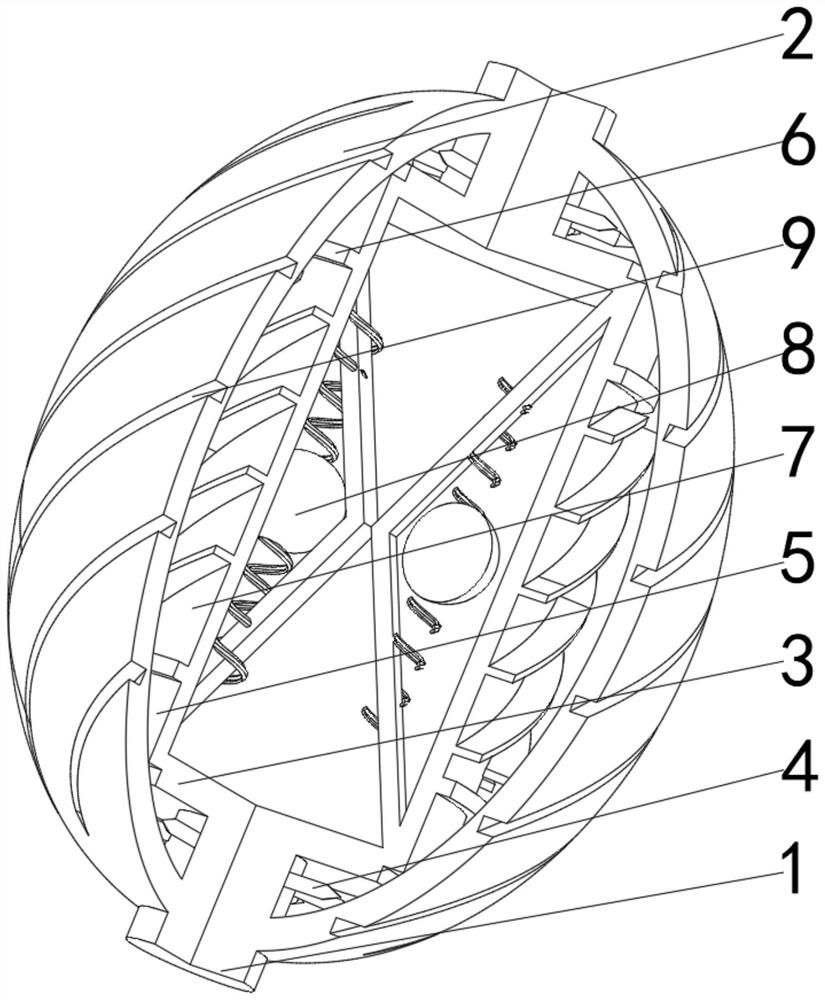

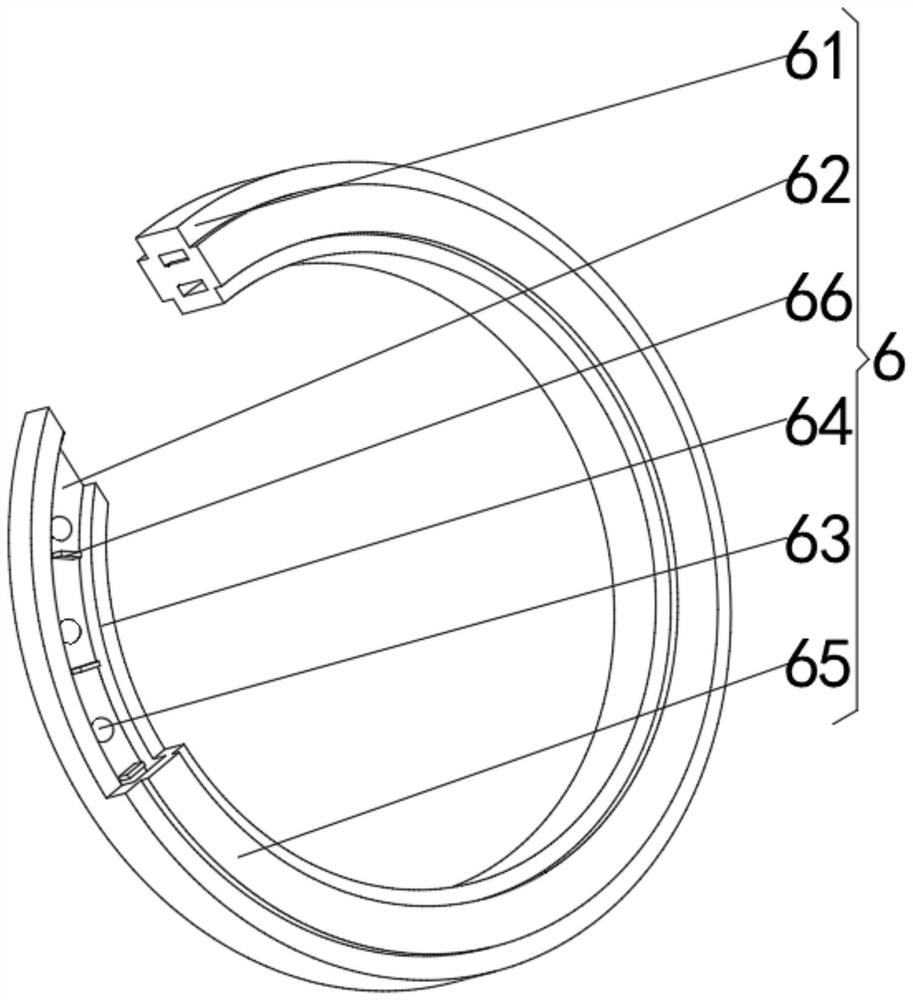

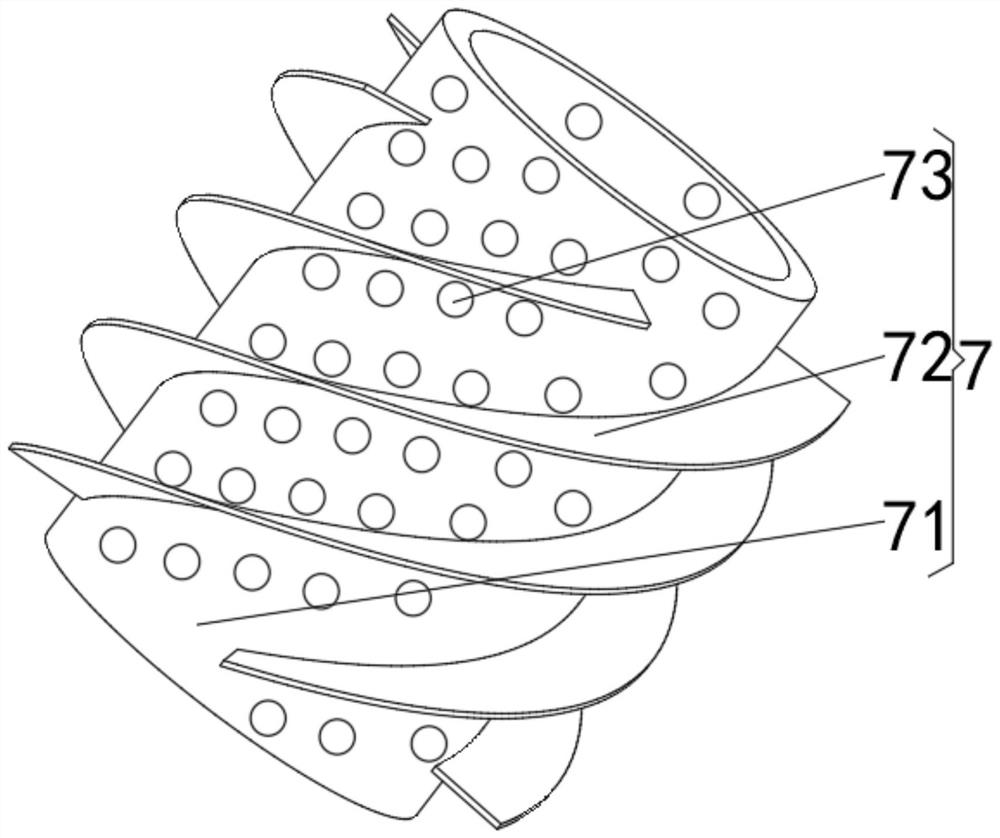

[0037] see Figure 1-6 , the present invention provides a technical solution: a metal surface oxidation device, including a mounting column 1, an ellipsoidal box 2 is rotatably connected to the middle of the outer surface of the mounting column 1, and a triboelectric plate is fixedly connected to the side of the mounting column 1 close to each other 3. The outer surface of the installation column 1 is located between the ellipsoidal box 2 and the triboelectric plate 3 and is fixedly connected with the guide needle 4, and the outer surface of the triboelectric plate 3 is movably connected with the transmission ring plate 5, and the transmission ring plate 5 is far away from the installation column 1. One side is movably connected with a differential mechanism 6, and the side of the differential mechanism 6 far away from the transmission ring plate 5 is movably connected with a dialysis mechanism 7, and the side of the transmission ring 5 far away from the ellipsoid box 2 is mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com