Positioning and fixing device for house plate processing

A fixing device and plate processing technology, which is applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of relatively high processing accuracy, inability to guarantee the accuracy of the plate, and unfavorable positioning accuracy, so as to avoid residues Splash, avoid affecting processing performance, and facilitate the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0030]The present invention provides the following technical solutions:

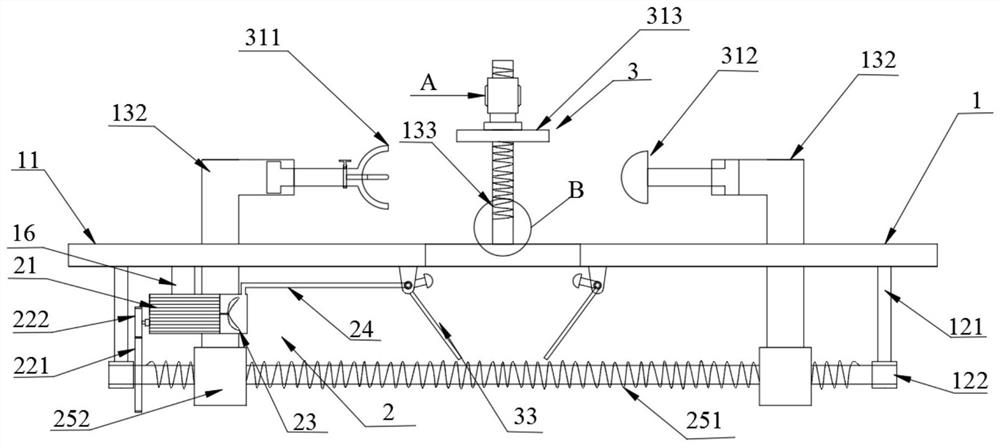

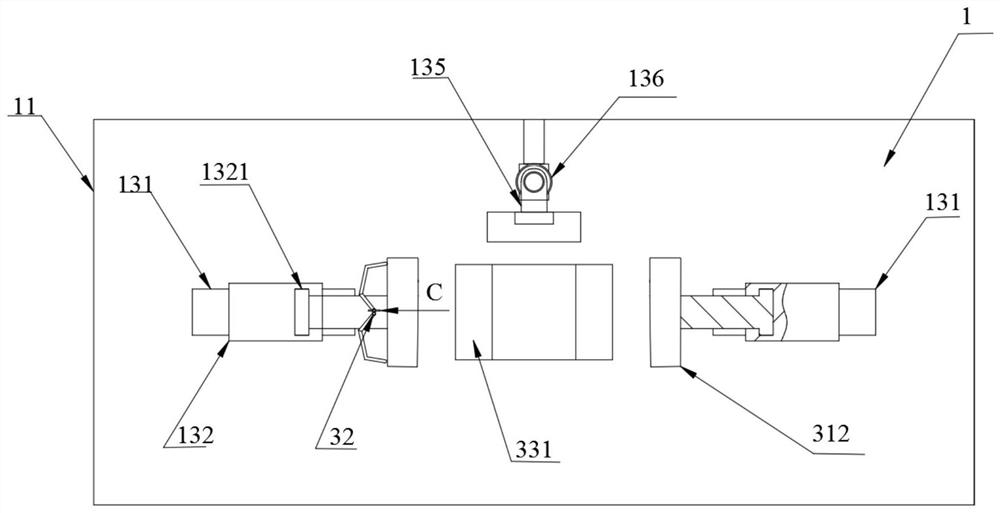

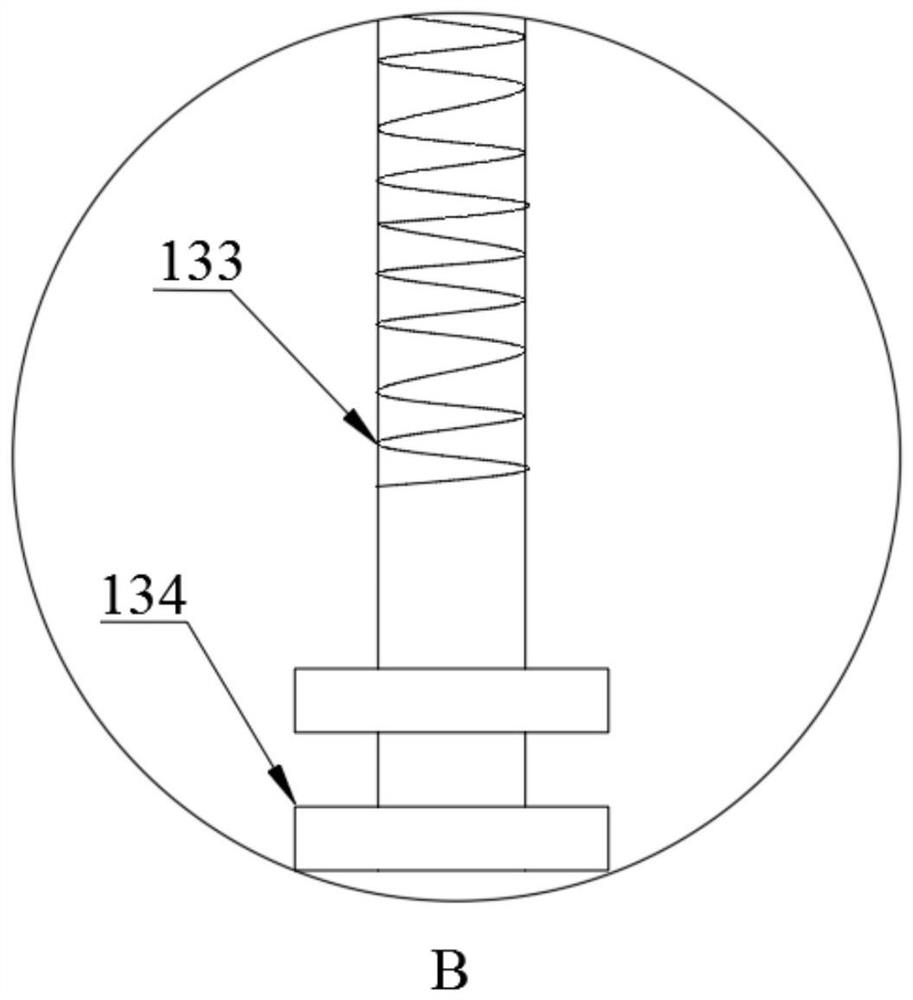

[0031]Such asFigure 1 ~ 6 As shown, a house is machined with a plate material, including the frame assembly 1, the power transmission 2, and the assembly device 3, the power transmission 2 and the frame assembly 1 fastening connection, the frame assembly 1 and the assembly device 3 is tight. Solid connection, the power transmission 2 is located below the frame assembly 1, and the assembly device 3 includes a positioning collet assembly 31, a moving collet asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com