Walking beam furnace walking beam original point calibration method

A calibration method and walking beam technology, applied in lighting and heating equipment, furnaces, furnace components, etc., can solve problems such as calibration errors, unfamiliar modified values, affecting normal production, etc., achieving high accuracy and solving calibration calculation errors. , The effect of reducing downtime maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

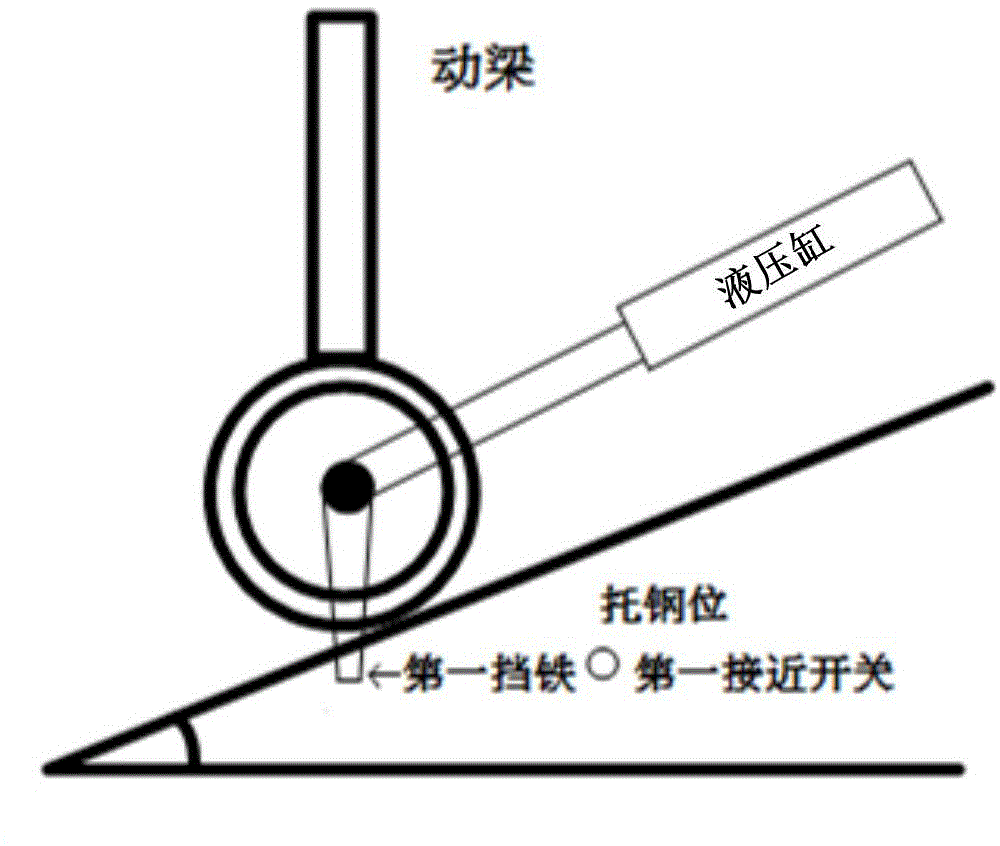

[0016] figure 1 It shows the first stop iron on the lifting hydraulic cylinder of the walking beam and the first proximity switch fixed at the supporting steel position. Wherein, the first iron stopper is installed on one side of the movable axle of the hydraulic cylinder, and the first proximity switch is installed on the position where the walking beam stops at the supporting steel position.

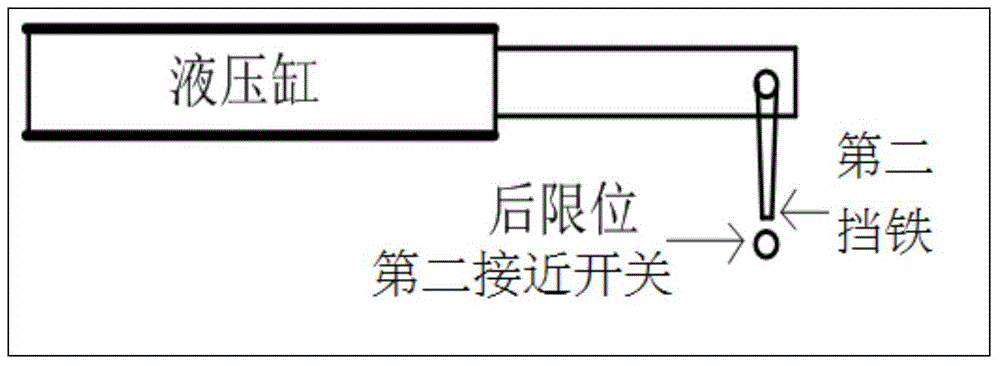

[0017] figure 2 Shown is the second stopper on the horizontal hydraulic cylinder of the walking beam and the second proximity switch fixed at the rear limit. Wherein, the second iron stopper is installed on the telescopic side of the hydraulic cylinder, and the second proximity switch is installed at the position where the walking beam stops at the rear limit position.

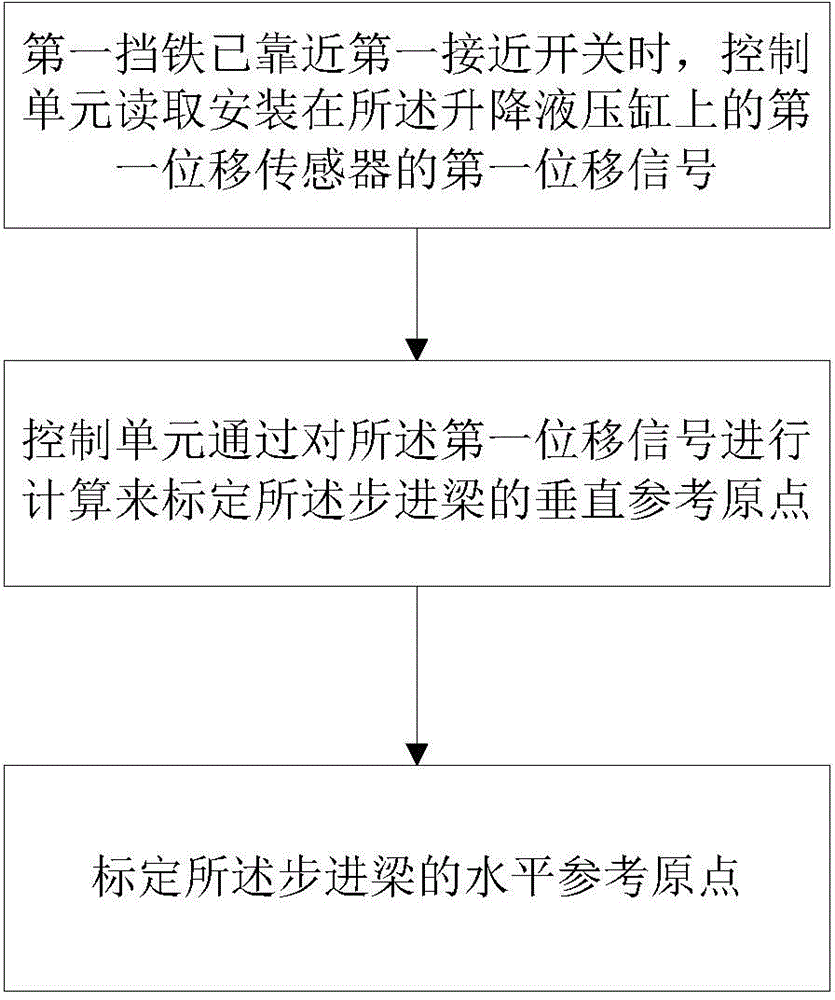

[0018] image 3 A flowchart indicating an embodiment of a method for calibratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com