Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Achieve interconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

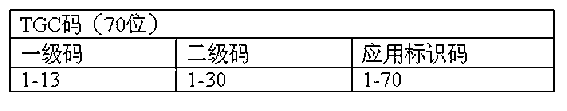

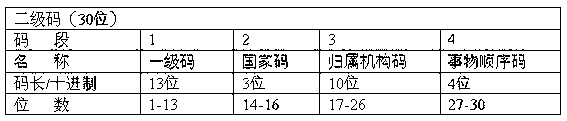

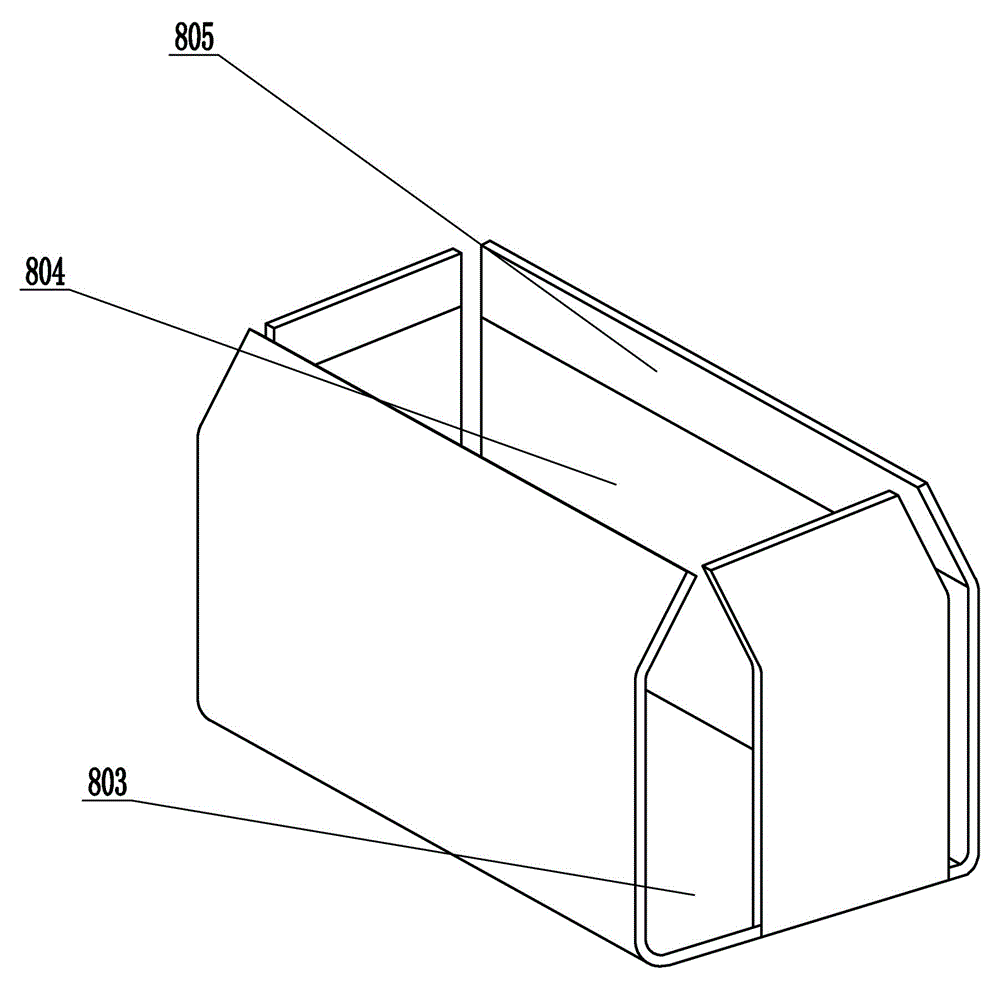

Universal identification coding system for smart city construction

InactiveCN103345478AAchieve integrationExchangeSpecial data processing applicationsIntelligent cityArtificial intelligence

The invention discloses a universal identification coding system for smart city construction. The universal identification coding system for smart city construction comprises a plurality of TGC service middle wares, a TGC data exchange system, a perfect information chain data center and a TGC universal identification coding management system, wherein the TGC service middle wares are matched with a plurality of city systems or TGC systems, and used for processing the corresponding city systems or TGC systems, the TGC data exchange system and the perfect information chain data center are connected with the all the TGC service middle wares in sequence, and the TGC universal identification coding management system is connected with the perfect information chain data center. The universal identification coding system for smart city construction can overcome the defects that structure is complex, using is inconvenient and universality is poor in the prior art, and has the advantages of being simple in structure, convenient to use and good in universality.

Owner:WUHAN TIANGANG MEDICINE SOFTWARE CO LTD

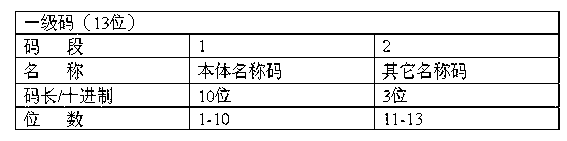

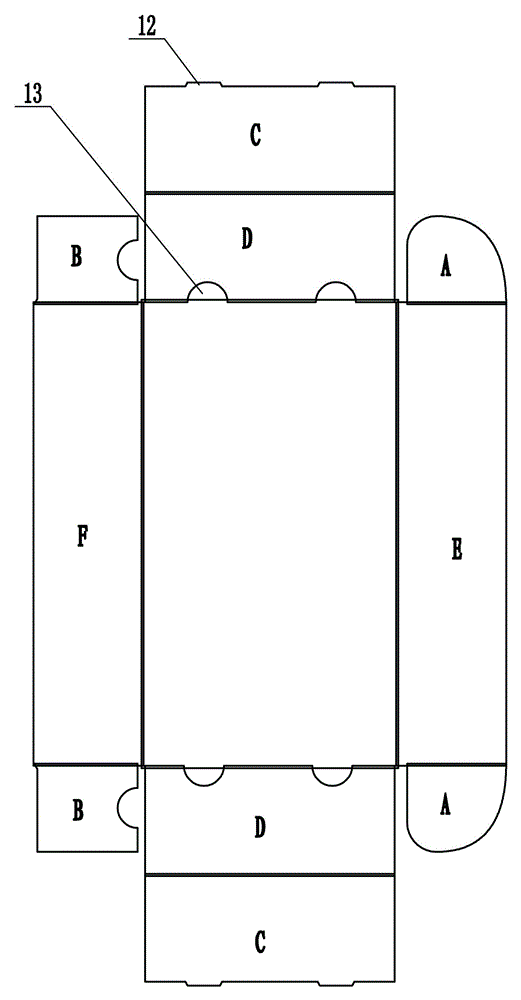

Carton folding machine

ActiveCN105128399ARealize folding box formingAchieve interconnectionBox making operationsPaper-makingMolding machineCarton

The invention provides a carton folding machine. The carton folding machine comprises a bottom board, a bracket, a paperboard feeding mechanism, a supporting mechanism, a compressing mechanism, an edge leftwards and rightwards folding mechanism, a forming mechanism, a carton push-out mechanism, an edge forwards and backwards folding mechanism and an edge forwards and backwards pressing mechanism, wherein the bracket is used for supporting the bottom of the bottom board which is provided with a forming cavity. The carton folding machine is provided with the forming cavity of the same structure as a formed package carton, the paperboard with folding lines is placed in the forming cavity, and then the bottom board of the package carton is downwards pressed to the bottom of the forming cavity and moves downwards so as to drive side boards of the package carton to be erected, so that the package carton is formed in a folded manner. According to the carton folding machine, the package carton is formed in the folded manner based on the stamping principle, and a new method is provided for folded molding of the package carton.

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD

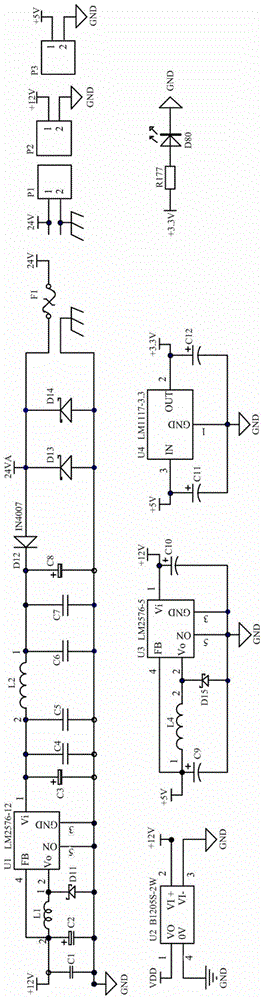

Household monitoring robot control system based on STM32

InactiveCN105234952AStrong data processing abilityFast communication speedProgramme-controlled manipulatorElectric machineryObstacle avoidance

The invention discloses a household monitoring robot control system based on an STM32. The system is composed of an upper computer, an STM32 controller, a sensor module, a wireless communication module, a motor control module and a power source module. The upper computer is used for issuing a motion instruction and receiving and displaying state information of a robot; the STM32 controller is used for receiving a motion and communication instruction issued by the upper computer and achieving communication interfaces, pulse output, I / O state management and information collecting and processing according to the instruction; the sensor module is used for monitoring the temperature and humidity, the gas concentration and the smoke concentration in a room in real time, and meanwhile, a photoelectric sensor and an ultrasonic sensor are used for obstacle avoidance of the robot; the wireless communication module is used for communication between the STM32 controller and the upper computer; the motor control module is used for controlling the robot to drive movement control over a motor and a camera pan-tilt steering engine; and the power source module is used for providing a power source for all modules.

Owner:江苏拓新天机器人科技有限公司

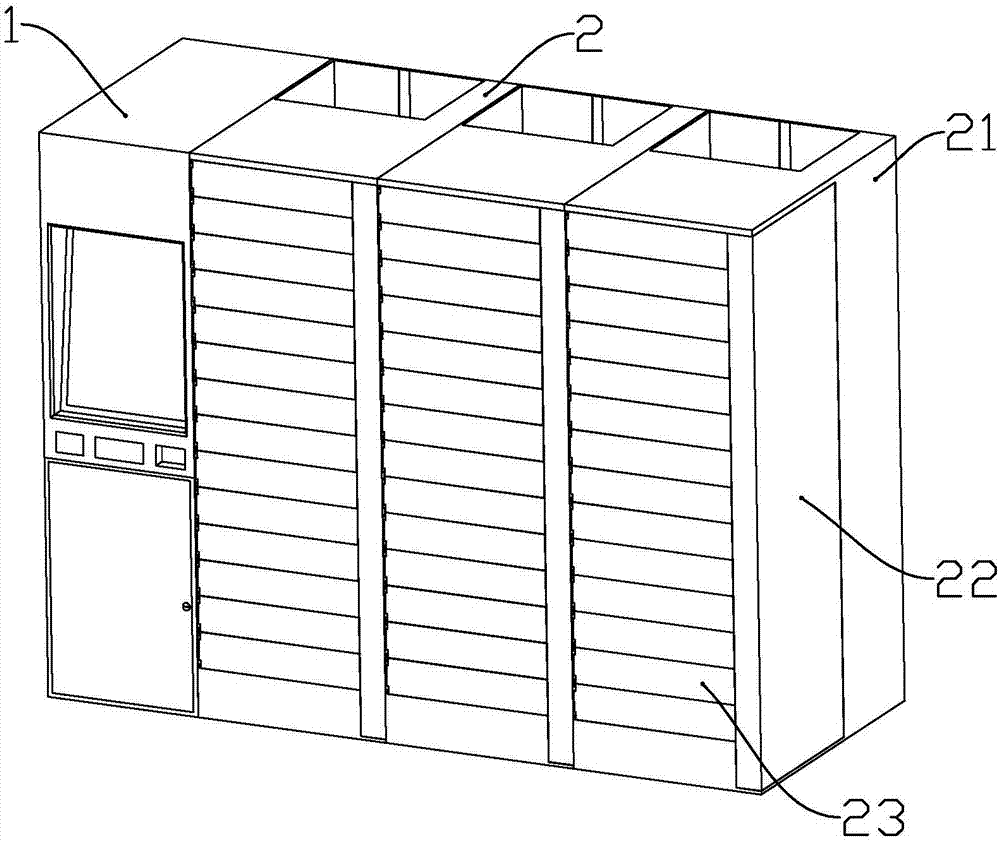

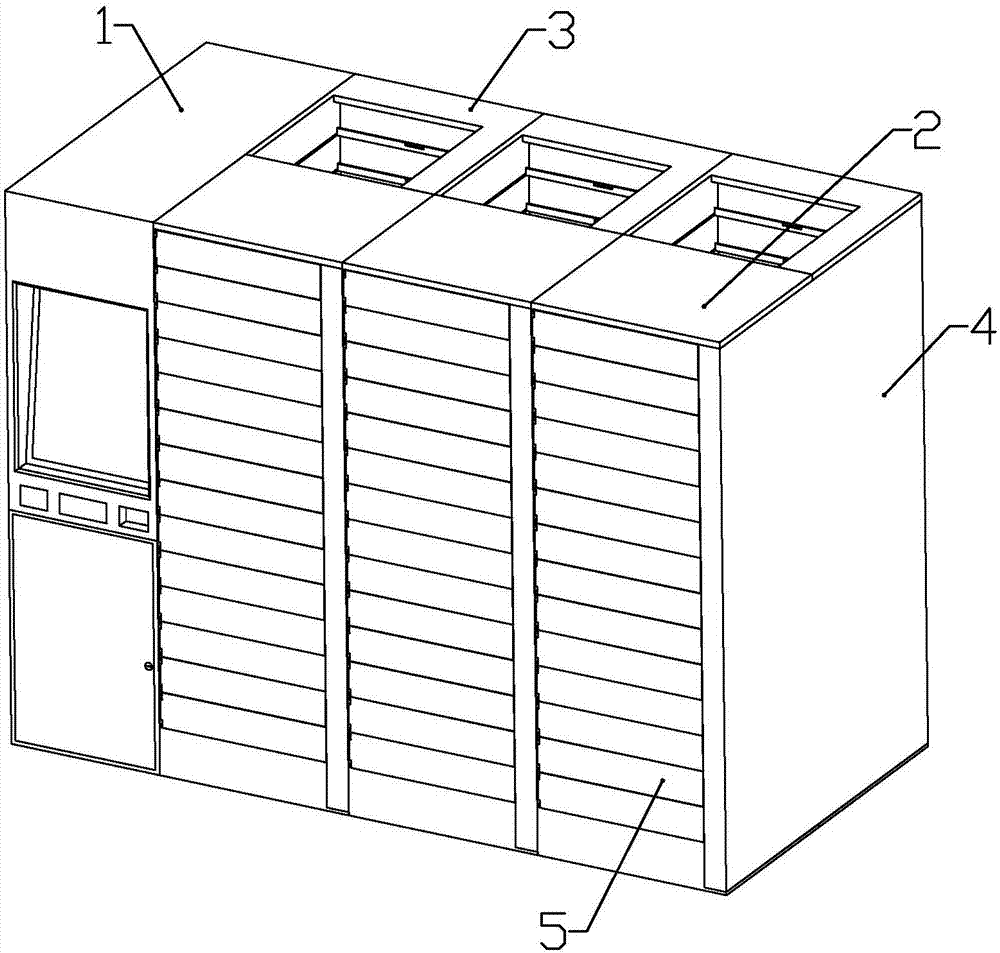

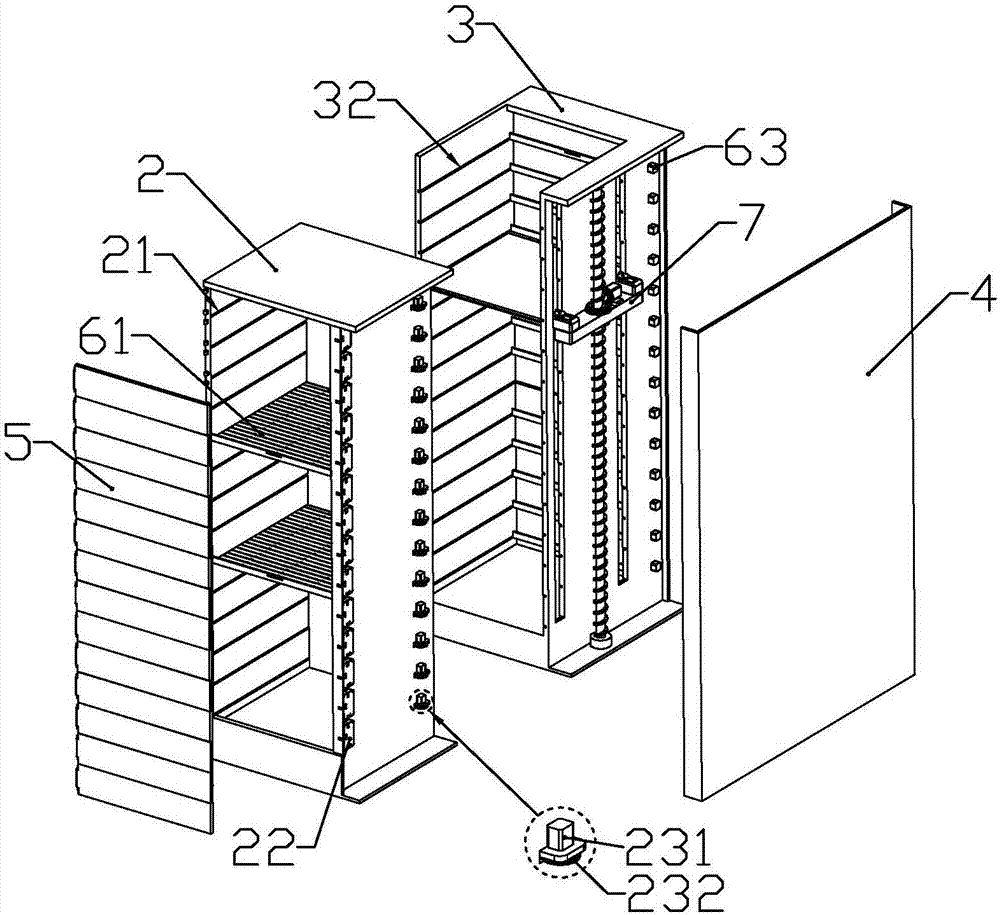

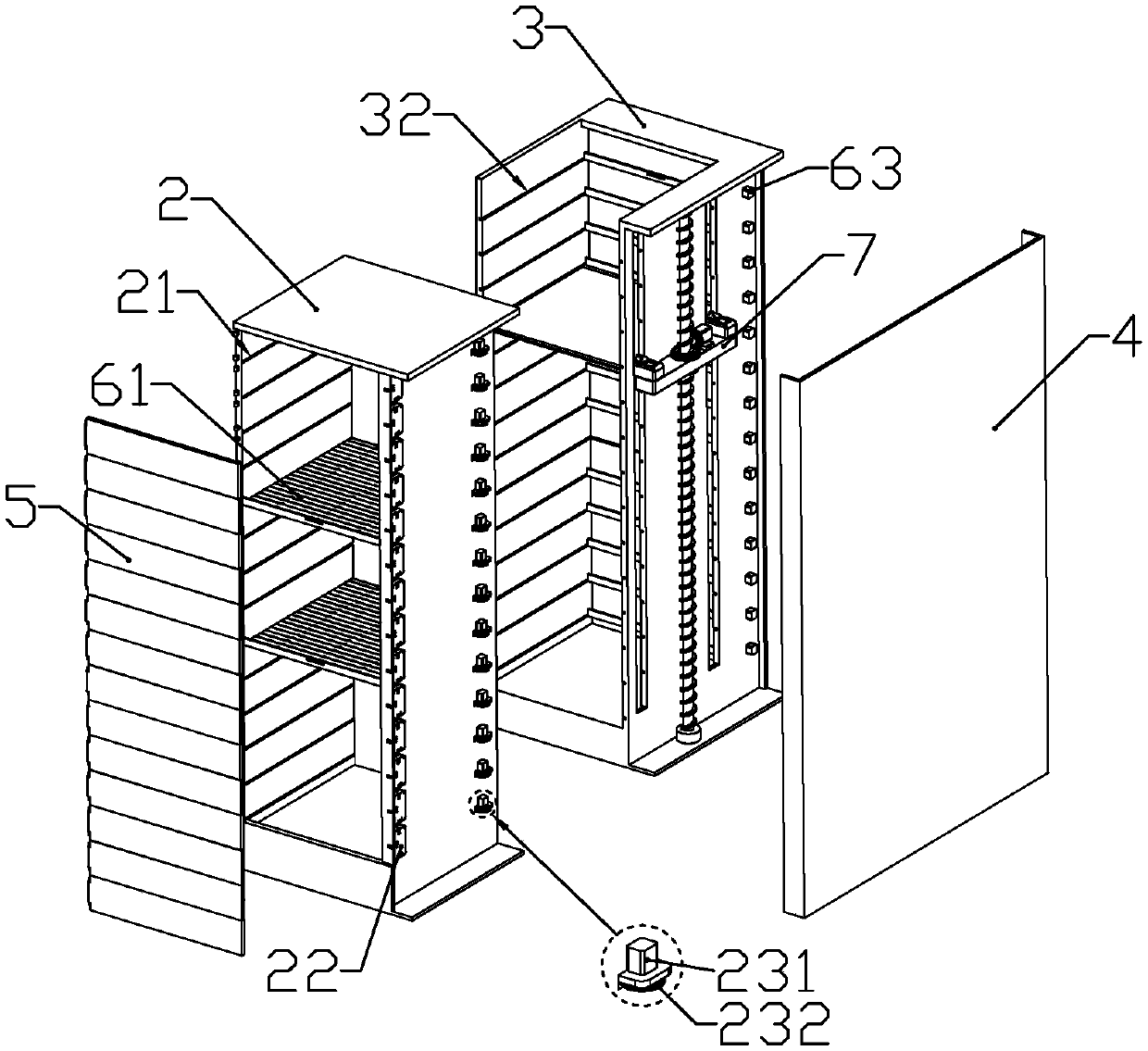

Express cabinet

ActiveCN107495675ATake advantage ofAchieve interconnectionFreight handlingCabinetsEngineeringMechanical engineering

The invention discloses an express cabinet, which comprises a plurality of cabinet body units which are arranged side by side and a control cabinet for controlling the various cabinet body units, wherein each cabinet body unit comprises a cabinet body with the interior divided into a front part and a rear part, a plurality of lifting components which are arranged at the front side of the cabinet body and are horizontally arranged and a plurality of cabinet doors which are rotatably connected to the front end of the cabinet body and are closely distributed from top to bottom. According to the express cabinet provided by the invention, the front part in each cabinet body is divided into a plurality of spaces for storing packages by virtue of the plurality of lifting components, and the storage spaces can be adjusted in accordance with the heights of the packages by controlling vertical moving of the lifting components, so that the full use of the spaces in the cabinet bodies is achieved, and human intervention can be avoided in an adjusting process.

Owner:曹县富山幼儿实木家具有限公司

Intelligent digital alarm linkage system

InactiveCN1560805AImprove reusabilityImprove scalabilityAlarmsSpecial data processing applicationsAlarm stateCommand system

The invention relates to a digital intelligent alarming linkage system. The invention solves the technology problem that: providing a digital intelligent alarming linkage system which can realize the smooth linking, fluent cooperation, integral dispatching of alarming-word recording-voice warning-image tracing-point locating. The digital intelligent alarming linkage system includes a synthesis alarm state processing device, network databank, uniform dispatching platform, audio frequency image supervising device, GIS geology information device. The invention can be applied to police supervising field, especially the 110 alarm receiving and processing arrangement system, at the same time, it can be extended to path supervising, electric supervising, environment supervising, power supervising.

Owner:NANWANG INFORMATION INDAL GROUP

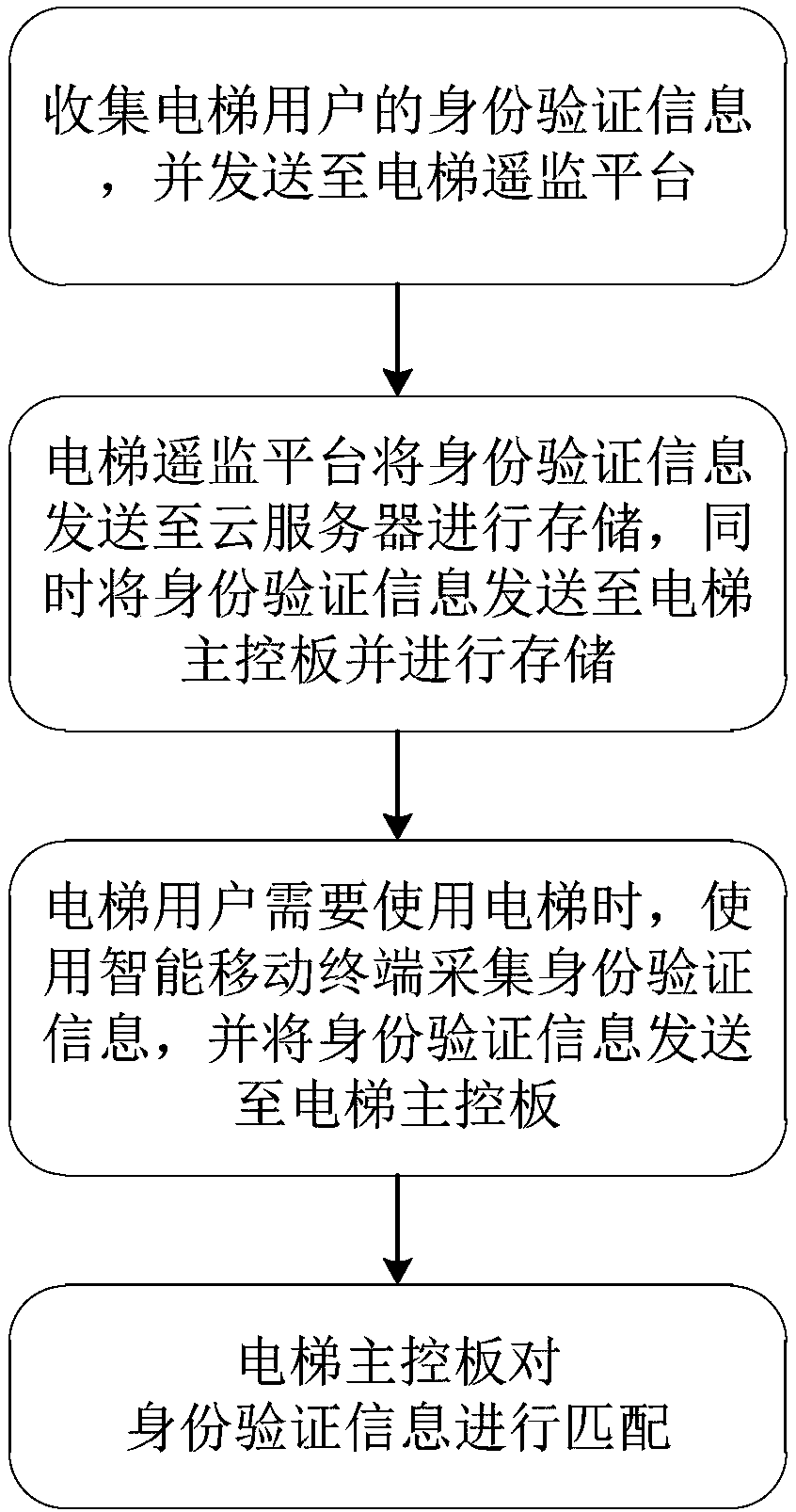

Method and system for identifying elevator user and operating elevator by employing intelligent mobile terminal

The invention discloses a method and system for identifying an elevator user and operating an elevator by employing an intelligent mobile terminal. The method comprises the following steps that identity authentication information of the elevator user is collected and transmitted to an elevator remote monitoring platform; the elevator remote monitoring platform transmits the identity authenticationinformation to a cloud server to be stored and transmits the identity authentication information to an elevator main control panel to be stored; when the elevator user requires using the elevator, the identity authentication information is acquired by using the intelligent mobile terminal and is transmitted to the elevator main control panel; and the elevator main control panel matches the transmitted identity authentication information with the prestored identity authentication information, if the matching result is consistent, the elevator user is allowed to operate the elevator, and if thematching result is not consistent, the elevator user is not allowed to operate the elevator. Personal information of the elevator user is recorded directly through the intelligent mobile terminal, and by matching the personal information with the identity authentication information prestored in the elevator main control panel, the elevator can be exclusively used by a person, and is reliable, safe and intelligent.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

Express cabinet with adjustable storage space

ActiveCN107697528ATake advantage ofAchieve interconnectionCoin-freed apparatus detailsFreight handlingEngineeringMechanical engineering

The invention discloses an express cabinet with an adjustable storage space, and the express cabinet comprises a plurality of cabinet body units and a control cabinet, wherein the cabinet body units are arranged in parallel and the control cabinet is used for controlling all the cabinet body units. Each cabinet body unit comprises a cabinet body, a plurality of lifting components, a conveying component and a plurality of cabinet doors, wherein the interior of the cabinet body is divided into a front part and a rear part, the lifting components are installed on the front portion of the cabinetbody and are arranged horizontally, the conveying component is used for conveying packages, and the cabinet doors are rotatably connected to the front end of the cabinet body and are arranged tightlyfrom top to bottom. According to the express cabinet with the adjustable storage space, the front part of each cabinet body is separated into a plurality of spaces used for storing packages by the multiple lifting components, by means of the manner that the lifting components are controlled to move up and down, the storage space can be adjusted according to the heights of packages, the space of each cabinet body is fully utilized, and the adjustment process does not require human intervention.

Owner:南通东联信息技术有限公司

Test platform and test method for methanol water reforming hydrogen production

PendingCN110018246ARealize electronic recordsEffective controlWeighing by removing componentHydrogenChemistryHydrogen concentration

The invention discloses a test platform and a test method for methanol water reforming hydrogen production. The test platform for methanol water reforming hydrogen production comprises a reforming reaction hydrogen production system, a steam-water separation system, a hydrogen purification system, a hydrogen detection system and a monitoring system, wherein the reforming reaction hydrogen production system comprises a methanol water storage container, a filter, an inlet pump, a solenoid valve, a pressure relief valve, a gasification chamber and a reformer; the steam-water separation system comprises a steam-water separator; the hydrogen purification system comprises a hydrogen purification device; the hydrogen detection system comprises a hydrogen concentration detector and a gas chromatograph; and the output end of the steam-water separator is connected to the hydrogen purification device and the gas chromatograph respectively. According to the test platform and the test method for methanol water reforming hydrogen production, the performance of the methanol water reforming hydrogen production system and the relationship between related parameters and the performance of a catalystcan be tested, and the operation condition of the catalyst under different test conditions can be tested at the same time.

Owner:向得夫

Multi-agent power distribution network planning scene simulation generation method and system

InactiveCN105046354AAchieve interconnectionAchieve independent planningForecastingLand-use planningGenetic algorithm

The invention discloses a multi-agent power distribution network planning scene simulation generation method and system. The method includes the following steps that: a power distribution network planning scheme in a region to be planned is divided into a power distribution network agent, a distributed power source agent and a load agent which operate independently; the load agent calculates load prediction information in the region to be planned according to a land use planning scheme and the historical load density data of different types of land in the region to be planned; the power distribution network agent obtains the load prediction information and an existing network framework in the region to be planned, so as to construct a target function of power distribution network line planning, and optimizes the planning scheme of the obtained network framework of a power distribution network through adopting a genetic algorithm according to the target function; and the distributed power source agent obtains the load prediction information, the optimized scheme of the power distribution network and the historical data of local climate so as to construct a target function of distributed power source planning; and the optimized planning scheme of a distributed power source is calculated according to the target function of the distributed power source planning.

Owner:STATE GRID SICHUAN ECONOMIC RES INST

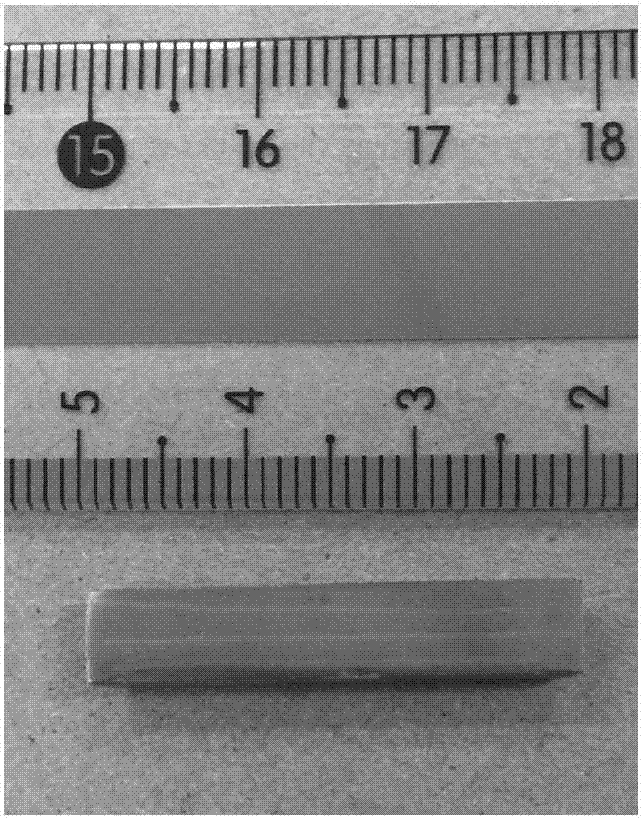

TiAl base alloy synergetically strengthened and toughened by carbides and titanium alloy layers, and preparation method thereof

The invention provides a TiAl base alloy synergetically strengthened and toughened by carbides and titanium alloy layers, and a preparation method thereof. The TiAl base alloy synergetically strengthened and toughened by the carbides and the titanium alloy layers, provided by the invention, comprises carbide-TiAl alloy layers and titanium alloy layers alternately stacked and arranged; each titanium alloy layer is internally provided with a through structure of which two openings are located on the upper and lower surface of the titanium alloy layer separately, and the through structure is filled with carbide-TiAl alloy; the carbide-TiAl alloy layers at two adjacent sides of the titanium alloy layer are connected through the carbide-TiAl alloy in the through structure; the carbide-TiAl alloy layers and the titanium alloy layer as well as the carbide-TiAl alloy and the titanium alloy in the through structure are connected though Ti3Al interface layers; carbides in the carbide-TiAl alloy layers and the carbide-TiAl alloy comprise Ti2AlC and Ti3AlC2.

Owner:SHAANXI SCI TECH UNIV

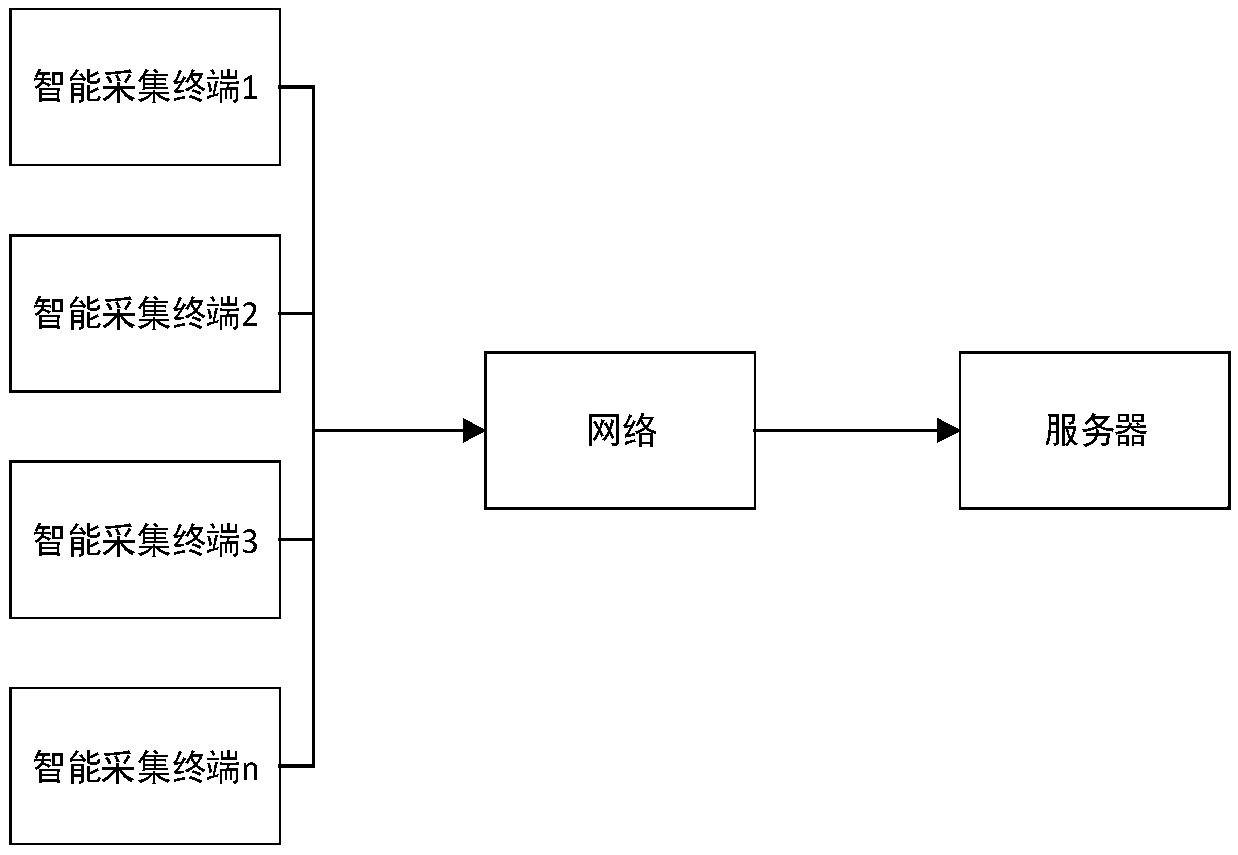

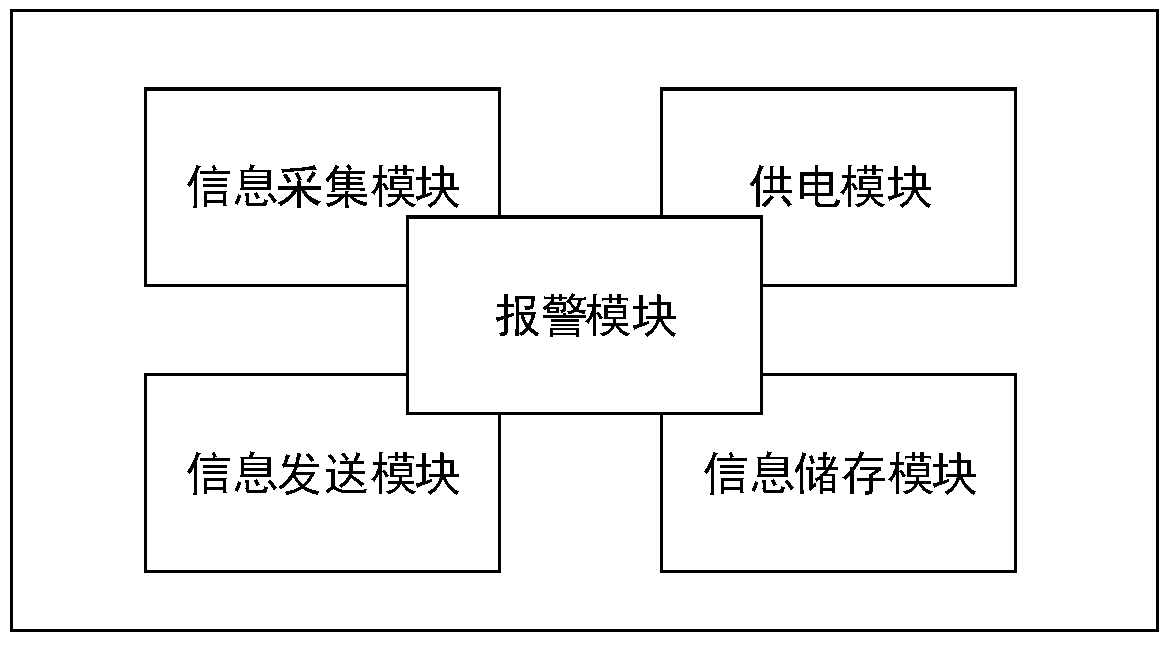

Internet of Things based welding work management method

InactiveCN109570842AGo digitalAchieve interconnectionTransmission systemsWelding/cutting auxillary devicesComputer terminalEnergy consumption

The invention discloses an Internet of Things based welding work management method, and relates to the technical field of welding work management. The method specifically comprises the following step:S1, technologically scanning codes through an intelligent acquiring terminal before the welding work so as to obtain basic welding work requirements, mainly including the welding technology parameterrequirements such as current, voltage, preheating temperature, interlayer temperature and welding speed, the welding qualification requirement, the welding material size requirement, and the weldingenvironment requirements such as temperature, humidity and air speed. With the adoption of the method, the welding data can be comprehensively monitored in the whole process in real time, so that datasupport is supported to management and decision making, and interference of human factors can be effectively decreased; the welding data are true and reliable; the welding quality is improved; the construction environment safety factors are monitored and alarmed in real time, so that the safety accident is reduced; the energy consumption equipment are adjusted, controlled and managed, so that theequipment utilization rate is increased; the equipment energy consumption is decreased; and welding materials are effectively managed and controlled.

Owner:烟台智工物联科技有限公司

Express cabinet with adjustable storage space

ActiveCN107319768ATake advantage ofAchieve interconnectionBuilding locksMovable shelf cabinetEngineeringMechanical engineering

The invention discloses an express cabinet with an adjustable storage space. The express cabinet comprises a plurality of cabinet bodies which are arranged in parallel and a control cabinet for controlling the cabinet bodies; each cabinet body comprises a front cabinet body unit, a rear cabinet unit, a lifting component, a plurality of partition plate components and a plurality of cabinet doors, wherein the front cabinet body unit and the rear cabinet unit are arranged at the front and rear portions respectively, the lifting component is installed in the rear cabinet body unit and arranged horizontally, the partition plate components are connected in the front cabinet body unit and the rear cabinet unit in a sliding mode, and the cabinet doors are rotatably connected to the front end of the cabinet body and arranged densely from top to bottom. According to the express cabinet with the adjustable storage space, when parcels are stored, the front parts of the front cabinet body units are divided into a plurality of spaces for storing the parcels by the corresponding partition plate components according to the heights of the parcels, sot that the spaces in the cabinet bodies are fully utilized.

Owner:菏泽市汇信知识产权运营有限公司

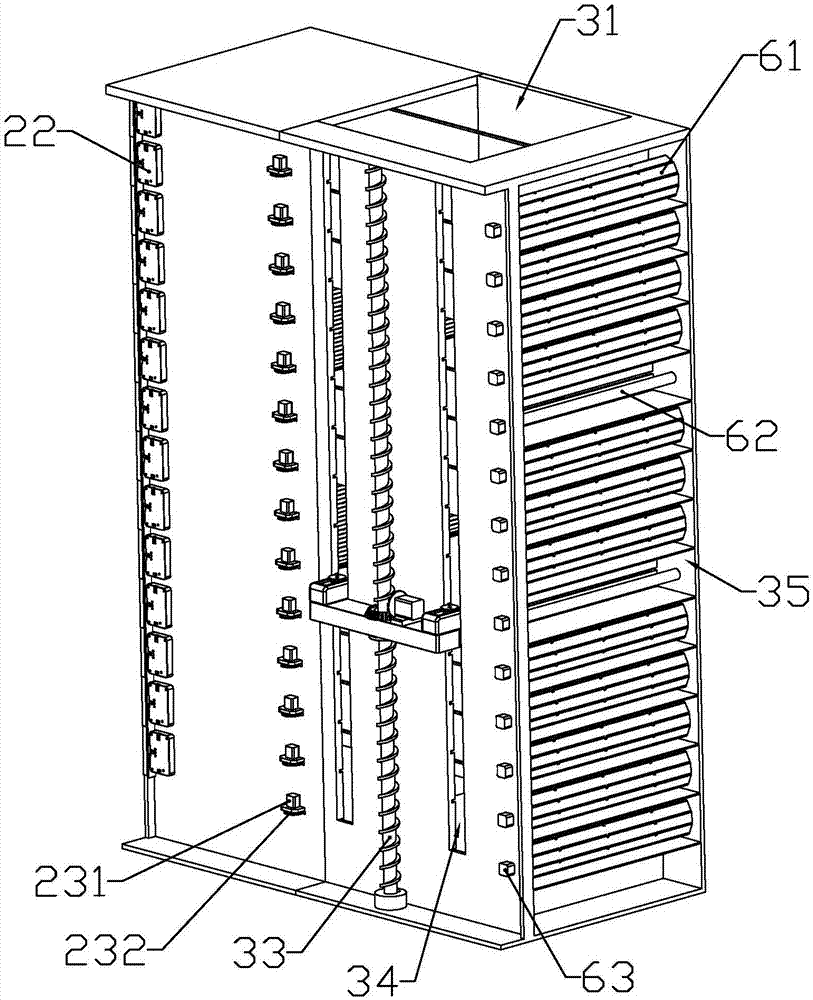

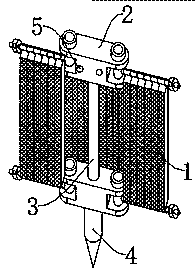

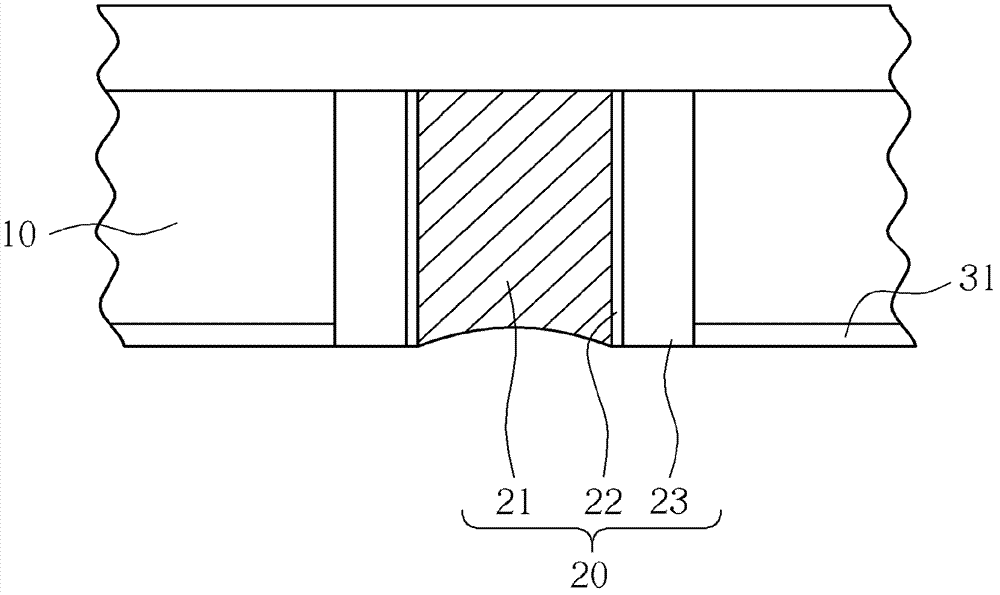

Current-assisted fuel cell ultra-thin metal bipolar plate pressure welding device and method

ActiveCN102049601AAchieve interconnectionImprove plasticityWelding electric supplyThin metalFuel cells

The invention discloses a current-assisted fuel cell ultra-thin metal bipolar plate pressure welding device and a current-assisted fuel cell ultra-thin metal bipolar plate pressure welding method in the technical field of welding. The device comprises a power supply, two electrodes, an actuator, an upper welding head and a lower welding head, wherein the actuator is mechanically connected with the upper and lower welding heads; a bipolar plate to be welded is arranged between the upper and lower welding heads; positive and negative poles of the power supply are connected with the two electrodes respectively; the first electrode is connected with the upper welding head or an upper single polar plate; and the second electrode is connected with the lower welding head or a lower single polar plate. The method comprises the following steps of: generating current by using the power supply, making the current pass through the bipolar plate so as to heat a welding area, and performing pressure welding; and after the pressure welding is finished, cooling to room temperature, and detecting the air tightness of the bipolar plate to meet the requirements of water tightness and airtightness so as to obtain a finished bipolar plate. By directly heating and performing pressure welding through the current, the thermal efficiency is high, the welding process is simple, and the produced bipolar plate has high flatness and stable performance.

Owner:苏州治臻新能源装备有限公司

Boron nitride-graphene oxide hybrid material with three-dimensional structure, preparation method of boron nitride-graphene oxide hybrid material and application as filler in heat conducting composite

The invention discloses a boron nitride-graphene oxide hybrid material with a three-dimensional structure, a preparation method of the boron nitride-graphene oxide hybrid material and an application as filler in a heat conducting composite. The boron nitride-graphene oxide hybrid material with the three-dimensional structure has a three-dimensional grid structure and is composed of boron nitride and graphene oxide, and the graphene oxide is uniformly distributed on boron nitride sheets. The invention also provides the heat conducting composite which has excellent performance and contains the boron nitride-graphene oxide hybrid material with the three-dimensional structure as the filler. The heat conducting composite is composed of the boron nitride-graphene oxide hybrid material with the three-dimensional structure as the filler and an epoxy resin mixture as a matrix, and has high heat conductivity coefficient and good electrical insulation performance, the heat conductivity coefficient is 0.7W / (m.K)-5.1W / (m.K), and volume resistivity is 2.0*10<12> omega.cm-4.0*10<14> omega.cm.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Power transmission equipment

InactiveCN105958428AAchieve interconnectionEasy to distinguish between maintenanceCable fittingsElectric power transmissionEngineering

The invention discloses power transmission equipment, which comprises cables, a cover body and a bottom shell, wherein the cover body and the bottom shell are symmetric in structure; a plurality of clamping grooves which are arranged at intervals are arranged in the middle parts of the cover body and the bottom shell respectively; the clamping grooves in the inner sides of the cover body and the bottom shell are corresponding in position; two cable connectors are arranged in each clamping groove in the bottom shell; the upper ends of the two cable connectors are clamped into the corresponding clamping groove in the cover body and the lower ends of the two cable connectors are clamped into the corresponding clamping groove in the bottom shell; wire through grooves communicating with each clamping groove are arranged in two sides of the clamping groove; the number of the wire through grooves is equal to that of the clamping grooves; the cables are located at the inner sides of the wire through grooves respectively; and the cables which are corresponding in position are connected to the corresponding cable connectors respectively. By the power transmission equipment, the cable connectors can be distinguished and fixed after the cables are connected, so that the structure is more reliable; and convenience can be carried out more conveniently.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

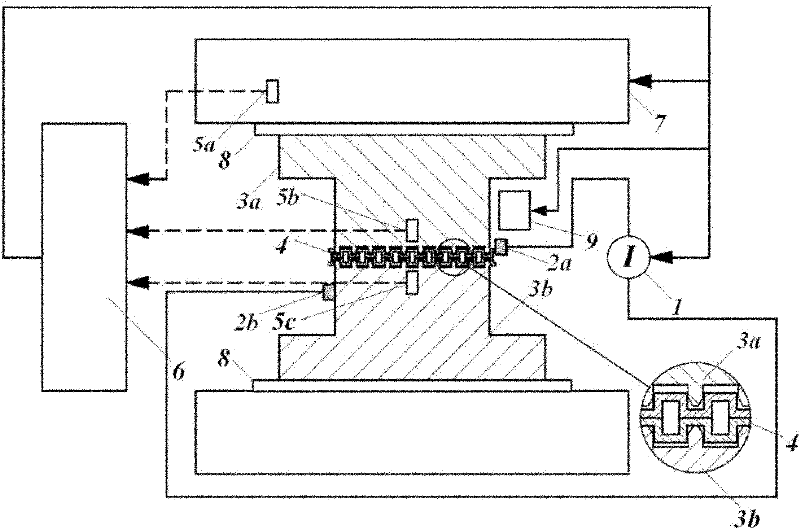

Gateway device and control device

InactiveCN101185307AAchieve interconnectionEasy to makeNetworks interconnectionHome automation networksService informationOperating system

Provided is a gateway device for opening information on devices or services to a device to be connected with the networks of protocols of different kinds. The gateway device (11) includes a device description creation processing unit (24), a device description template holding unit (25), a service description creation processing unit (26) and a service description template holding unit (27). The service description creation processing unit (26) classifies the services and attributes corresponding to the individual devices, into property types or corresponding control models, and creates the service information description or the public information automatically, according to the rules regulated for every property types.

Owner:PANASONIC CORP

Power Internet of Things IP-based fusion terminal and communication method thereof

The invention discloses an electric power Internet of Things IP-based fusion terminal and a communication method thereof, and the method comprises the steps: obtaining the information of each piece ofequipment in a power system, wherein the equipment comprises power equipment and sensing equipment, and the equipment information comprises equipment ID and equipment communication types; establishing an equipment IP library and an equipment communication protocol sharing library according to the acquired equipment information, and sending the equipment IP library to a cloud platform, wherein theequipment IP library comprises a one-to-one correspondence relationship between equipment IDs and IP addresses, and the equipment communication protocol sharing library comprises a one-to-one correspondence relationship between equipment information and protocol analysis programs; collecting original data sent by the equipment; determining a protocol analysis program according to the equipment IDin the original data, and analyzing the original data according to the determined protocol analysis program to obtain communication data; and generating a data frame satisfying an IPv6 protocol fromthe extracted equipment ID and the determined communication data, and sending the data frame to the cloud platform, so that the cloud platform obtains the communication data based on the equipment IPlibrary and the equipment ID. According to the method, interconnection and intercommunication, comprehensive perception and ubiquitous access of the power equipment are achieved.

Owner:黑龙江省电工仪器仪表工程技术研究中心有限公司 +2

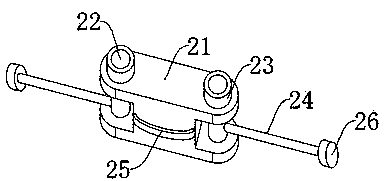

Connecting device

InactiveCN107366668ASimple interconnectionAchieve interconnectionSnap-action fastenersEngineeringMechanical engineering

The invention provides a connecting device, which includes a connecting piece, a connected piece and a resisting assembly; a limiting groove is opened on the connecting surface of the connecting piece; an accommodating groove is opened on the connected piece; A through hole is opened on the side wall, and the through hole communicates with the accommodating groove. The resisting assembly includes a limit column, a sliding pin, a sliding button and a return spring, and the limit column is accommodated in the In the receiving groove, a receiving hole is opened on it, one end of the sliding pin is received in the receiving hole through the through hole, the other end is fixedly connected with the sliding button, and one end of the return spring is connected to the The limit column is in contact with each other, and the other end is in contact with the bottom of the accommodating groove; by operating the sliding button, the limit column can be driven to slide into or out of the limit groove. The connecting device of the present invention can realize the interconnection of two parts simply and quickly, without special tools, and improves the efficiency.

Owner:陈亮

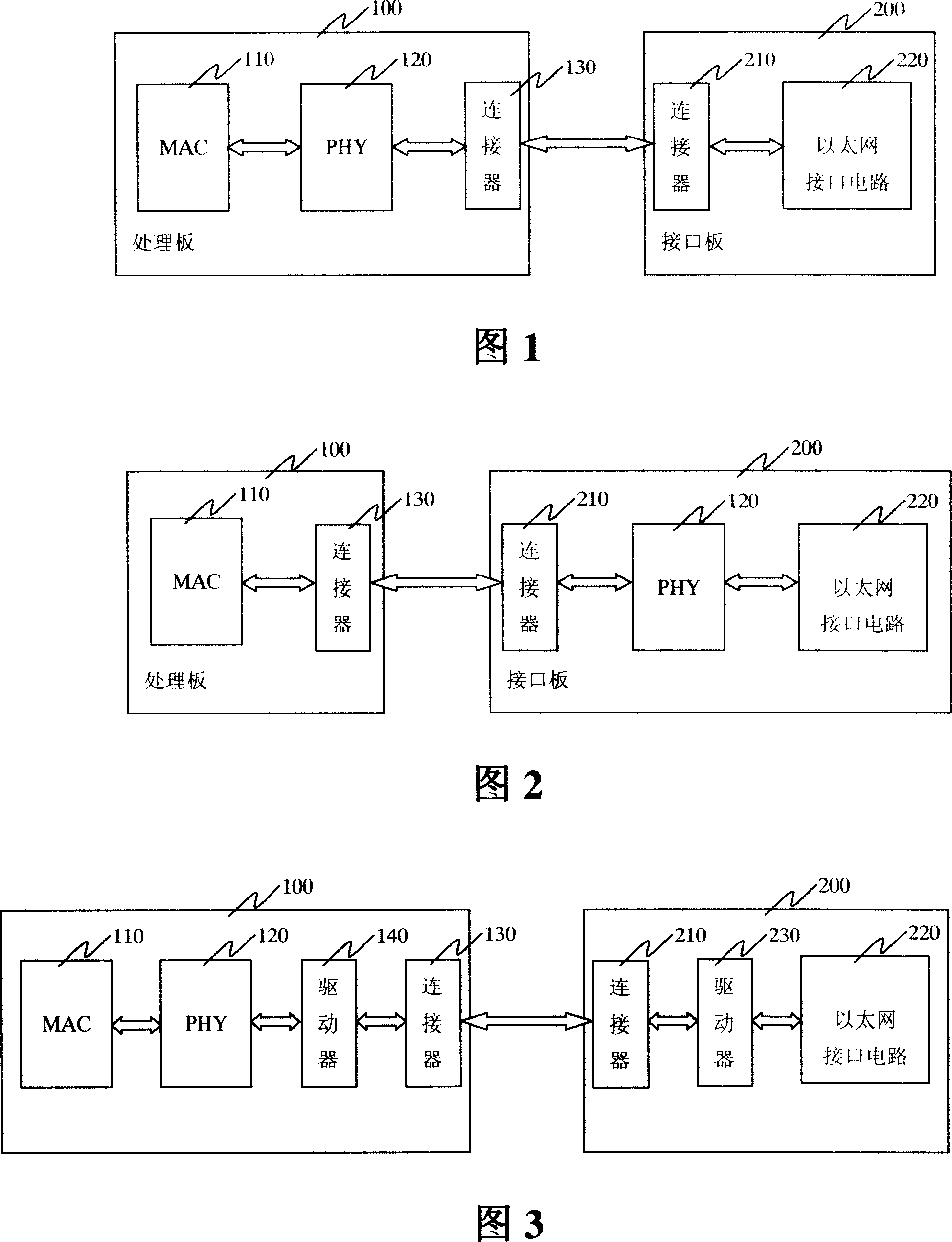

Device for long-distance transmitting Ethernet physical layer interface signal

InactiveCN1983934AAchieve interconnectionReduce development costsData switching detailsPhysical layerEthernet

The invention is concerned with the equipment that achieves long distance transmission by using Ethernet physical layer signal, includes: the processing board and the interface board, the processing board consists of the control chip access with the Ethernet medium, the Ethernet signal driver and the information connector, the medium accesses into the control chip connecting with the physical layer chip, the physical layer chip and the signal driver, the signal diver and the signal connector connect with the interface through the Ethernet physical layer; the interface board includes the Ethernet interface electric circuit, the Ethernet signal driver and the signal connector, the interface electric circuit and the signal driver, the signal driver and the signal connector connect with the interface through the Ethernet physical layer.

Owner:ZTE CORP

Intelligent identification data statistics system and insect attack monitoring device provided with same

InactiveCN105868824ARealize acquisitionAchieving summaryCounting mechanisms/objectsInsect catchers and killersInfraredTrapping

The present invention proposes an intelligent identification data statistics system, which includes an intelligent chip, a miniature camera lens, an infrared transceiver device and a sensing device. The smart chip includes a control module, a timing imaging module, a communication module and a data statistics module. The sensing device Includes light sensor and humidity sensor. The present invention also provides a pest monitoring device equipped with the intelligent identification data statistics system, including a housing, an automatic screening device arranged inside the housing, a miniature camera lens, an infrared transceiver device, a sensing device and an intelligent chip, and a set Insect trap light tube above the housing. Using the invention, agricultural and forestry technicians can remotely monitor the occurrence of pests in the area under their jurisdiction, without having to travel long distances to the site for manual operations, greatly improving work efficiency and monitoring accuracy, and can control the risk of pests to a minimum.

Owner:SHANGHAI XINGRANG IND

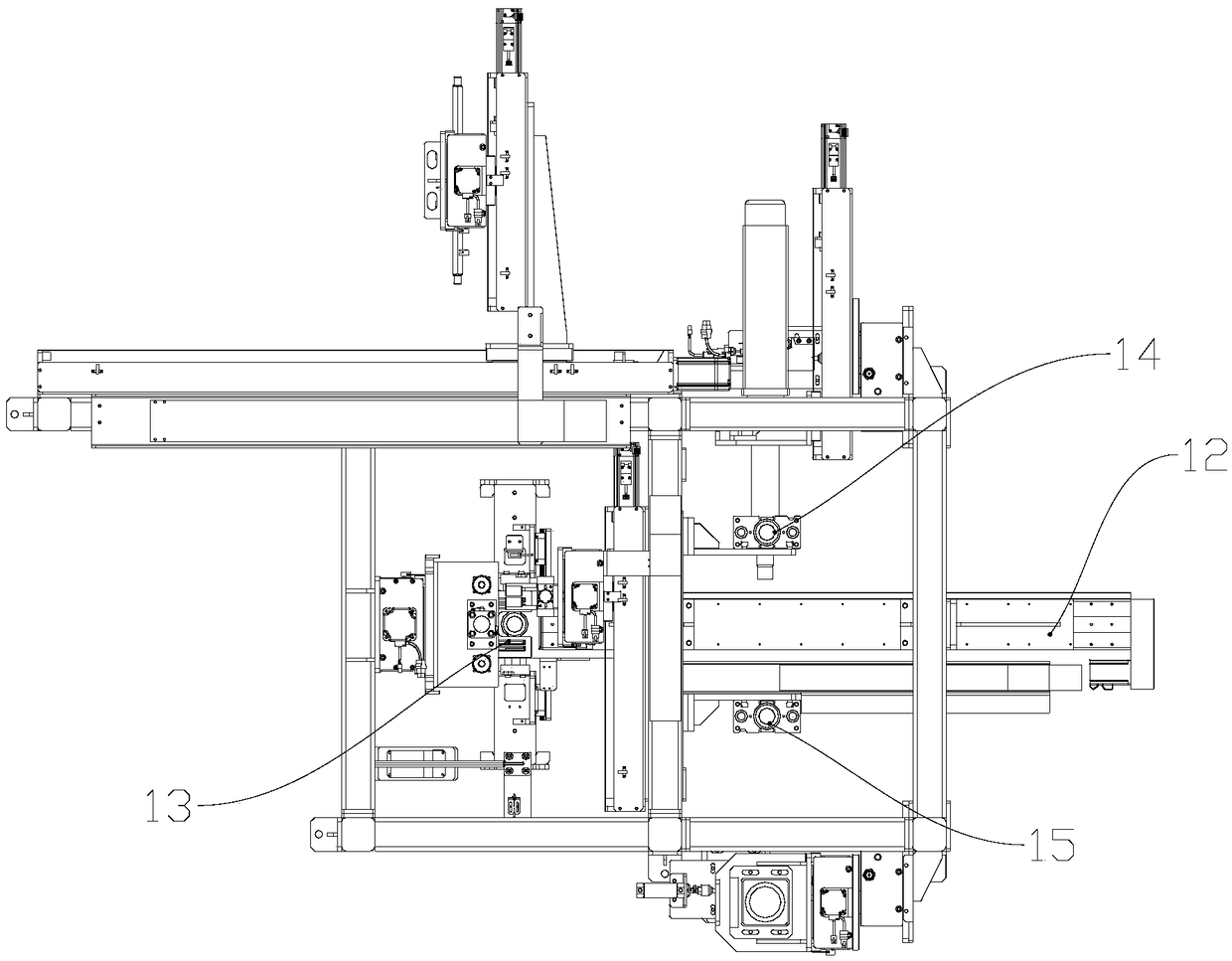

Track shoe assembly assembling device

ActiveCN108945133AAchieve interconnectionIncrease productivityEndless track vehiclesEngineeringElectrical and Electronics engineering

The invention provides a track shoe assembly assembling device. The track shoe assembly assembling device comprises a track shoe conveying line, a track pin mounting mechanism, two sets of nut mounting mechanisms and a first positioning mechanism; the track pin mounting mechanism comprises a pin hole positioning mechanism and a plug pin mechanism which are arranged on the two sides of the track shoe conveying line; the pin hole positioning mechanism comprises a first driving mechanism and a guiding pin connected with the first driving mechanism, the plug pin mechanism comprises a second driving mechanism and a jacking shaft connected with the second driving mechanism, when track pins enter pin holes of the track shoes adjacent in the front-rear direction, the first driving mechanism drivesthe guiding pin to move rearwards, the guiding pin moves rearwards while the track shoes go forwards until the ends of the track pins penetrate through the pin holes of the track shoes adjacent in the front-rear direction, and thus mounting of the track shoes is completed; and the first positioning mechanism is located between the two sets of nut mounting mechanisms and used for clamping and positioning the track shoes adjacent in the front-rear direction and operating to the nut mounting mechanisms, and nuts are mounted at the two ends of the track pins through the two sets of nut mounting mechanisms correspondingly. According to the track shoe assembly assembling device, the multiple track shoes can be automatically connected.

Owner:滁州明匠智能系统有限公司 +1

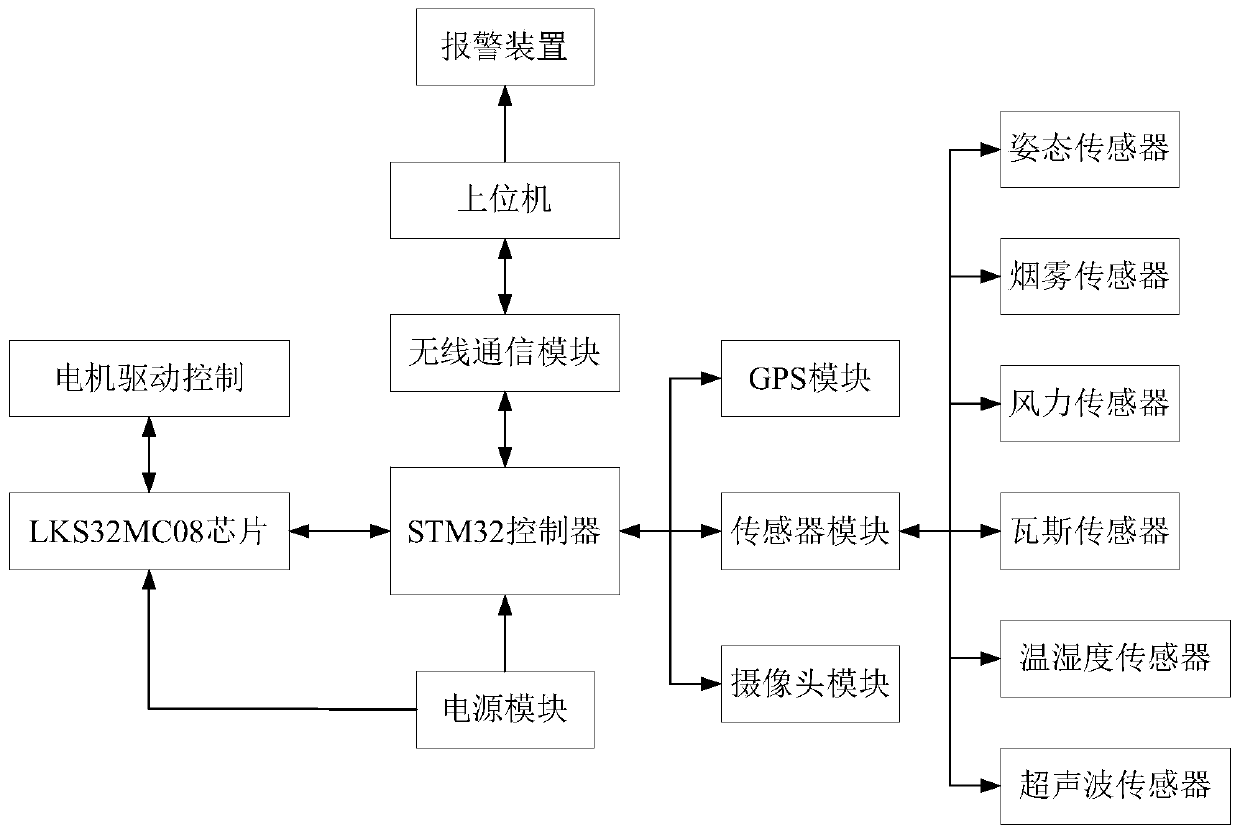

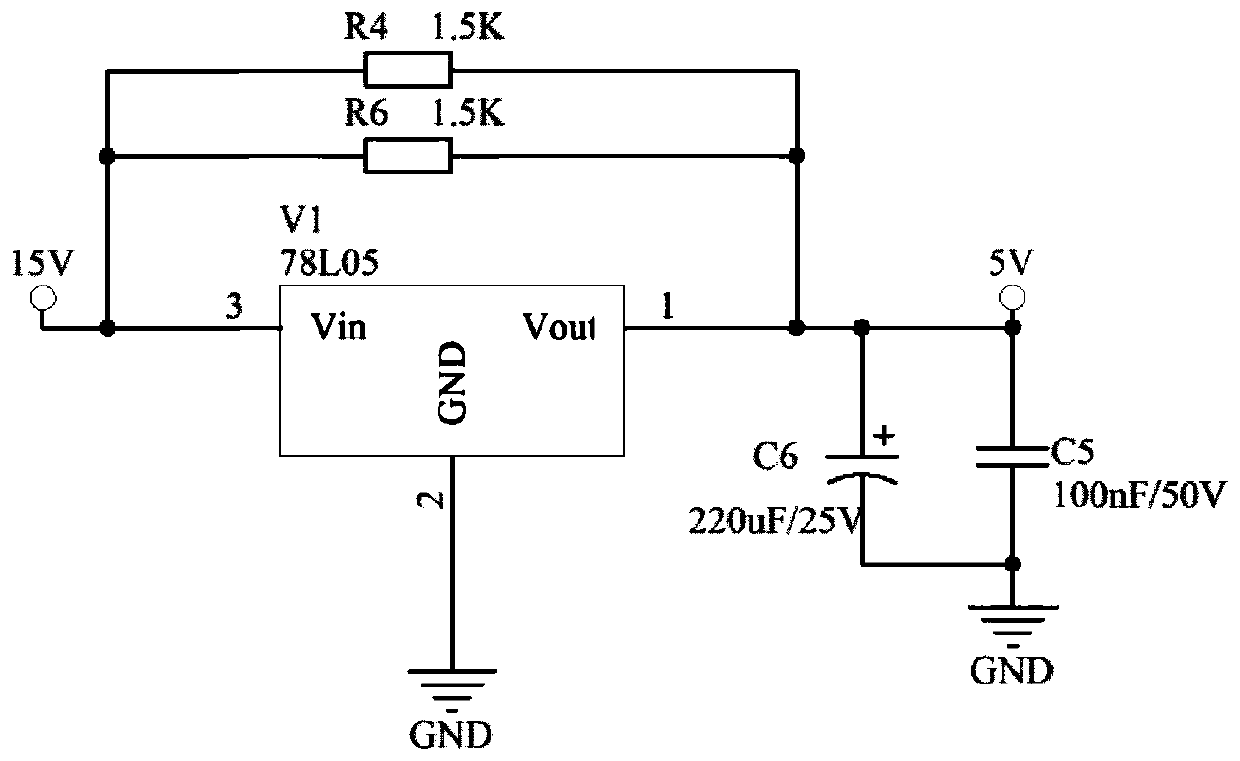

Mine survey robot control system based on STM 32

ActiveCN110757466AProcessing speedHighly integratedProgramme-controlled manipulatorMotor driveControl system

The invention discloses a mine survey robot control system based on STM 32. The mine survey robot control system comprises an upper computer, a wireless communication module, a STM 32 controller, a sensor module, a camera module, a GPS module, a motor drive control module and a power supply module; the upper computer communicates with the STM 32 controller through the wireless communication module, the upper computer issues an instruction to the STM 32 controller, and the upper computer receives data uploaded by the STM 32 controller; the STM 32 controller collects information of the sensor module, the camera module and the GPS module and transmits the information to the upper computer, and the STM 32 controller receives the instruction of the upper computer to control a mine survey robot;and the motor drive control module is installed in the mine survey robot and receives an instruction of the STM 32 controller to control the mine survey robot to work. The mine survey robot control system fully utilizes the characteristics of fast processing speed, rich interface and the like of the STM 32 controller, and the mine survey robot control system realizes accurate control of the minesurvey robot while improving the integration degree of the control system.

Owner:南京凌鸥创芯电子有限公司

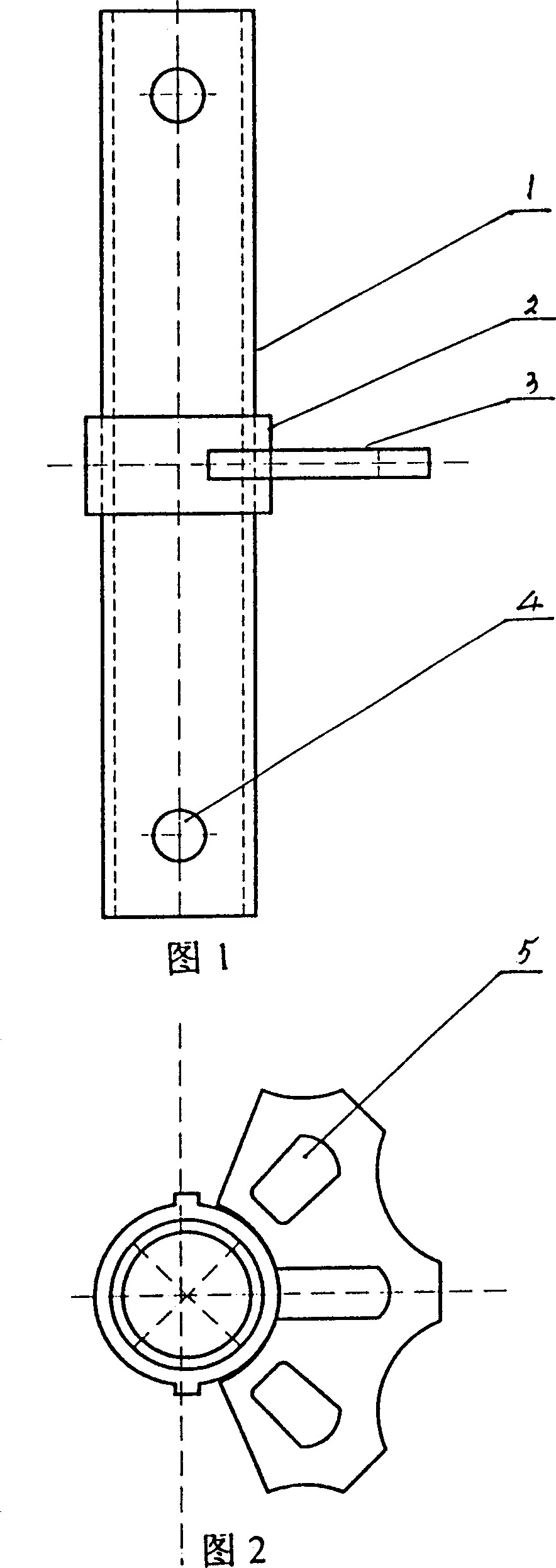

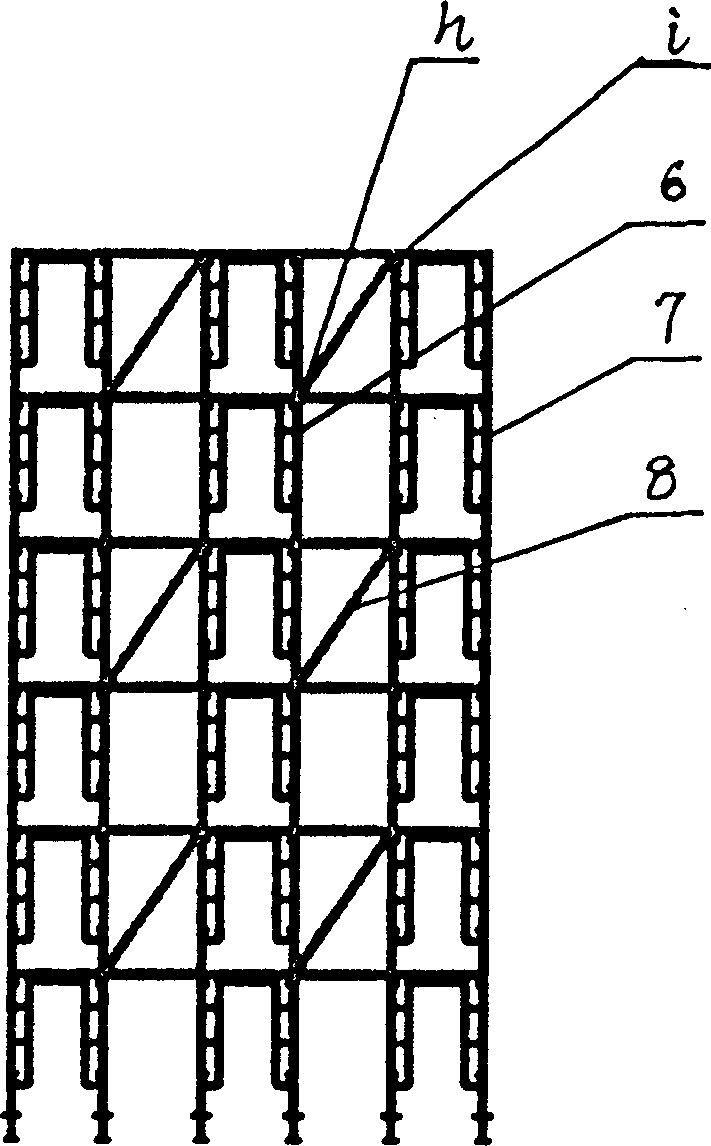

Socket discs and connecting bars components and their use combined with gantry scaffold

InactiveCN1490481AImprove construction stabilityComposite applicationScaffold connectionsElectrical and Electronics engineering

A connecting rod unit used for scaffold is composed of connecting rod and insertion plate with sectorial or rectangular insertion hole whose width is greater than the thickness of wedge pin. A sleeve ring is welded to the connecting rod and said insertion plate is welded to the sleeve ring. With said connecting rod units, the scaffold can be easily connected together.

Owner:于国杰

Convenient nest casting equipment for aquaculture

InactiveCN108834987AGuaranteed stabilityAdjustable lengthFishing netsClimate change adaptationEngineeringFishing net

The invention discloses convenient nest casting equipment for aquaculture. The equipment comprises two rotary mechanisms, the rotary mechanisms comprise fixing plates, rotary columns, nuts, first telescopic columns, supporting rods and baffle blocks, two rotary columns are symmetrically arranged on both left and right sides of each of the fixing plates, the two connecting columns are connected through a second telescopic column, the bottom face of the fixing plate located below is connected with fixing columns, the rotary columns are fixed to the fixing plates through the nuts, the rotary columns are connected with one end of the first telescopic columns, the other end of the first telescopic columns are fixedly connected with the baffle blocks, the side faces of the first telescopic columns are movably sleeved with pull rings on a fish net, the pull rings at the two ends of the fish net are fixed to the two baffle blocks respectively, the pull rings in the middle of the fish net are fixed to the supporting rods, and the supporting rods are fixed to the front end faces of the fixing plates. By means of the equipment, the casting and recovering of the fish net are convenient, the equipment is more conformed to actual situations, and the adaptability is high.

Owner:安徽省鑫龙渔业有限公司

Building safety protective net

InactiveCN107882347ANovel structureEasy to installBuilding material handlingSafety netInterconnection

The invention discloses a building safety protection net, which comprises a plastic net, cloth strips are connected around the outside of the plastic net, a circular ring is arranged on the plastic net, and a clamping device is connected to the circular ring. The connecting device includes an upper clip body and a lower clip body, a hook is provided above one side of the upper clip body, a connecting block is provided under one side of the lower clip body, and a sleeve is fixedly connected to one side of the connecting block, so A block is provided on one side of the sleeve, and one end of the block is rotatably connected to the inside of the sleeve, and a torsion spring is connected between the block and the sleeve. Through the setting of the upper clamp body and the lower clamp body, the clamping device is connected with the ring. Through the setting of the torsion spring, the sleeve and the clamping block, the clamping block can be flexibly rotated, and the hook can be hung on the scaffold, or the The connection between the hooks means that the protective nets are connected to each other, and the flexible rotation of the hooks is realized through the setting of the connecting pins, which improves the flexibility of the hooks in use.

Owner:成都千里之行科技有限公司

Method for exposing through silicon via

InactiveCN103367236AThere will be no obvious shallow dish phenomenonObvious shallow dish phenomenonSemiconductor/solid-state device manufacturingElectrical conductorDielectric layer

The invention discloses a method for exposing a through silicon via. The method comprises the steps of firstly forming a through silicon via in a semiconductor substrate, wherein the through silicon via comprises a copper metal layer, a barrier layer and an insulating layer; covering a dielectric layer on the bottom surface of the semiconductor substrate and the through silicon via; forming a sacrificial layer on the dielectric layer; abrading and removing a part of the sacrificial layer, the dielectric layer, the insulating layer and the barrier layer so as to expose the surface of the copper metal layer; etching a part of the insulating layer and the dielectric layer, and forming a concave region around the through silicon via; and finally removing the left sacrificial layer.

Owner:NAN YA TECH

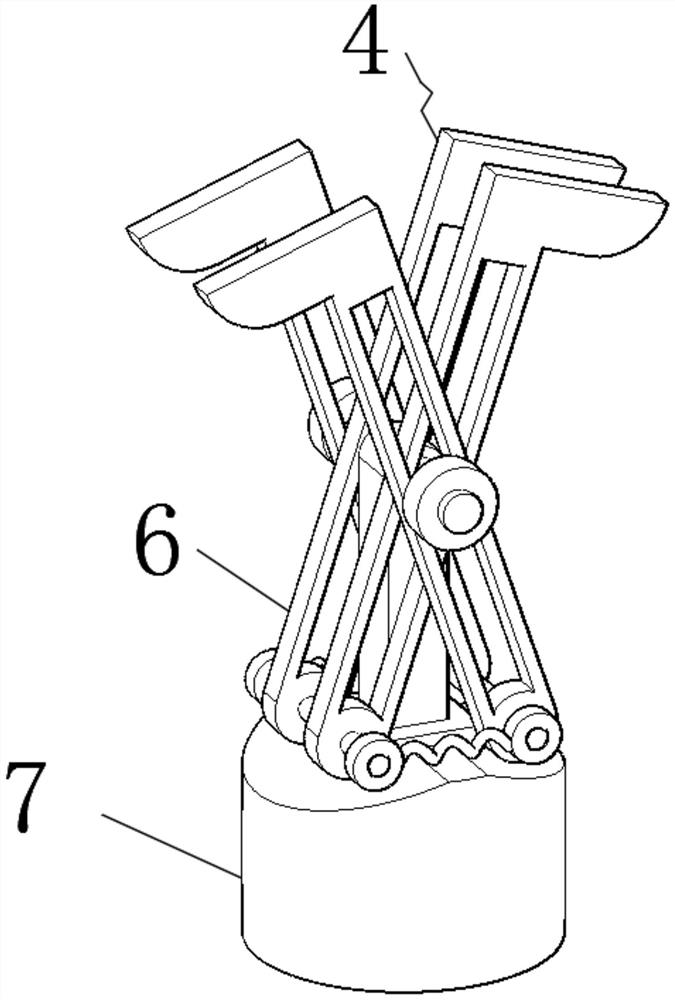

Multi-section type fastening structure for machining and connecting annular parts

PendingCN112108918AAdjust expansion areaAchieve Bottom StretchPositioning apparatusMetal-working holdersStructural engineeringMechanical engineering

The invention discloses a multi-section type fastening structure for machining and connecting annular parts. The multi-section type fastening structure comprises a fastening structure body, a fastening device is arranged in the center of the inner end of the fastening structure body, and a sleeving device sleeves the outer end of the fastening device. The fastening device comprises an adjusting part and a driving part, the driving part is arranged at the bottom of the inner end of the fastening device, and the adjusting part is telescopically connected to the upper end position of the drivingpart. The adjusting part comprises a linkage frame body and an adjusting frame body, the adjusting frame body is arranged at the bottom of the inner end of the adjusting part, and the upper end of theadjusting frame body is telescopically connected with the linkage frame body. The linkage frame body comprises a first clamping frame, a second clamping frame, a first connecting rod, a shaft frame,a spring, a sleeve rod, a fastening shaft, a second connecting rod, a third clamping frame and a fourth clamping frame, and the first clamping frame, the second clamping frame, the third clamping frame and the fourth clamping frame are symmetrically arranged. According to the multi-section type fastening structure for machining and connecting the annular parts, the purpose of fastening the inner end is achieved by arranging the fastening device.

Owner:肖慈敏

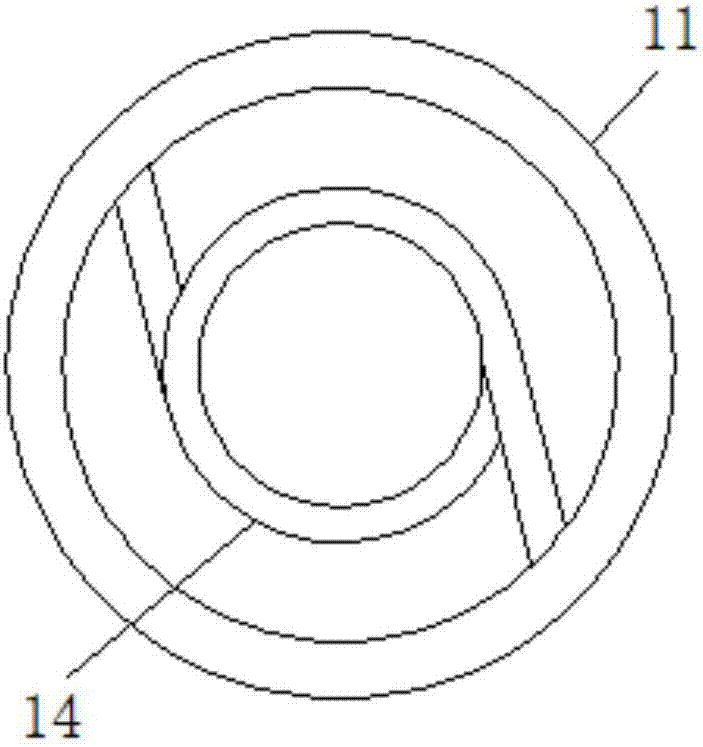

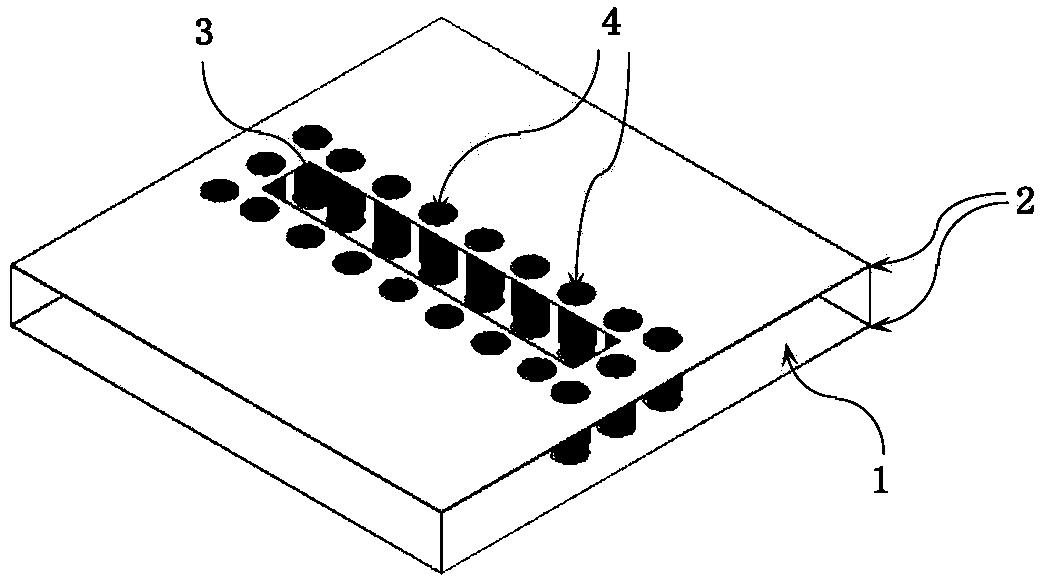

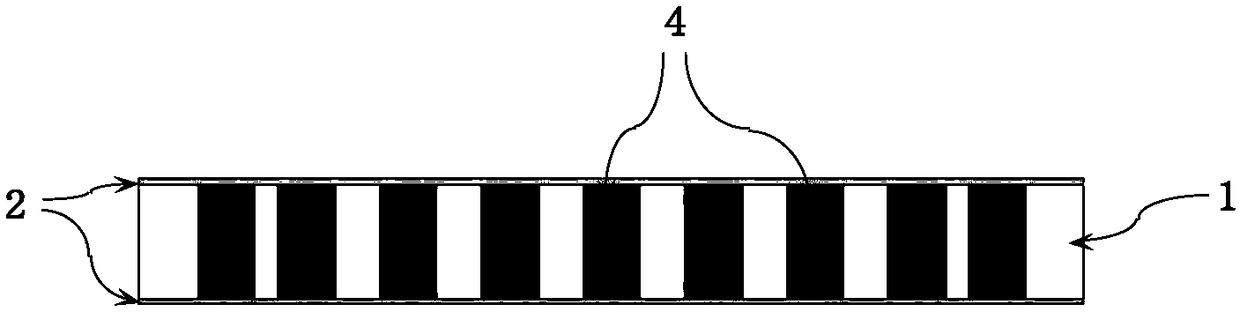

Vertical substrate integrated waveguide and vertical connection structure including the waveguide

ActiveCN105958167BRealize vertical transmissionAchieve interconnectionWaveguidesDielectric substrateWaveguide

The invention discloses a vertical substrate integrated waveguide and a vertical connection structure comprising the waveguide. The vertical substrate integrated waveguide comprises a dielectric substrate and metal layers, wherein the metal layers are attached to upper and lower surfaces of the dielectric substrate; the upper and lower surfaces of the dielectric substrate are parallel; multiple metalized through holes vertical to the dielectric substrate are formed in the dielectric substrate; the metal layers on the upper and lower surfaces cover the metalized through holes, and are etched with aperture structures which are the same and are corresponding upward and downward; and the metalized through holes are enclosed to form a closed structure along the aperture structures. The vertical substrate integrated waveguide can realize the vertical transmission of electromagnetic energy in the multilayer dielectric substrate.

Owner:BEIJING JIAOTONG UNIV

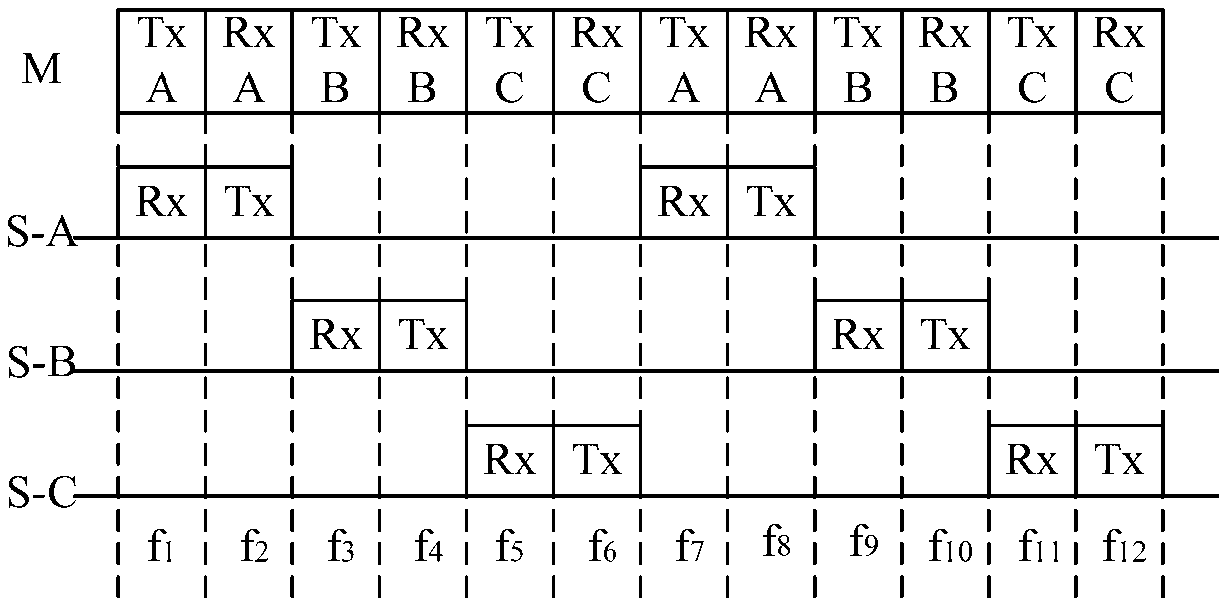

A data transmission method, device and system

ActiveCN106211810BReduce overheadAchieve interconnectionConnection managementShort range communication serviceWearable eegNetwork overhead

The embodiment of the invention discloses a data transmission method, device and system, relates to the technical field of communication, provides a more flexible network topology structure, and reduces network overhead. The method provided by the embodiment of the present invention includes: the first wearable device sends a first broadcast message to the second wearable device; if the first wearable device detects the second broadcast message sent by the second wearable device , then determine whether the second wearable device supports processing the service data of the first wearable device; if the first wearable device determines that the second wearable device supports processing service data, establish an Connect, and send service data to the second wearable device on the allocated time slot for sending and receiving.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com