TiAl base alloy synergetically strengthened and toughened by carbides and titanium alloy layers, and preparation method thereof

A carbide and titanium alloy technology, applied in the field of metal materials, can solve problems such as limited improvement effect of TiAl-based alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a TiAl-based alloy synergistically strengthened and toughened by the carbide and the titanium alloy layer described in the above technical solution, comprising the following steps:

[0035] (1) mixing titanium powder, aluminum powder and TiC powder to obtain a mixed powder;

[0036] (2) Alternately stacking the mixed powder in the step (1) and the titanium alloy thin plate with a through structure layer by layer, and filling the mixed powder into the through structure to obtain a green body;

[0037] (3) Sintering the green body obtained in the step (2) to obtain a TiAl-based alloy synergistically strengthened and toughened by the carbide and the titanium alloy layer.

[0038] The invention mixes titanium powder, aluminum powder and TiC powder to obtain mixed powder. In the present invention, the mass ratio of the titanium powder, aluminum powder and TiC powder is preferably (52.58~61.81):(29.64~34.83):(3.36~17...

Embodiment 1

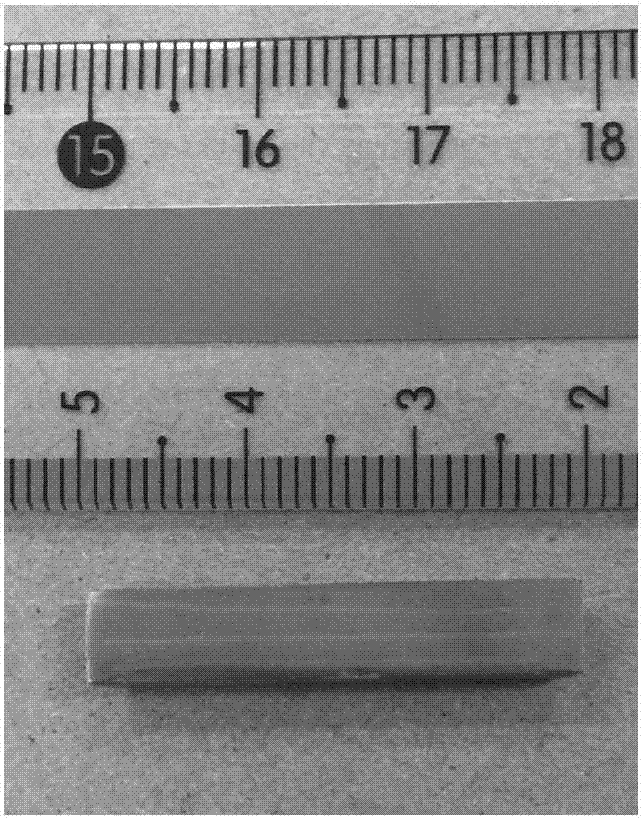

[0053] (1) if figure 1 As shown, the TC4 titanium alloy (Ti-6Al-4V) sheet with a thickness of Φ30mm and a thickness of 0.3mm is opened, the diameter of the hole is 0.5mm, and the distance between the longitudinal and transverse circular holes is 1mm, and then the porous TC4 titanium alloy thin plate is processed into Φ30mm discs by wire cutting, then pickled with 10wt% HF solution to remove the surface oxide film, then washed with distilled water, then rinsed with acetone, and vacuum dried at a vacuum degree of 0.05Pa and a temperature of 30°C 30min;

[0054] (2) Weigh the powder according to 59.77Ti-33.69Al-6.54TiC (wt%), dry mix it with a ball mill for 4 hours, the ratio of ball to material is 4:1, the speed is 500r / min, ball mill for 30min, and pass through a 200-mesh sieve after mixing spare;

[0055] (3) if figure 2 As shown, the processed titanium alloy thin plate and 59.77Ti-33.69Al-6.54TiC (wt%) mixed powder are stacked layer by layer in the graphite mold, the numb...

Embodiment 2

[0061] (1) The TC4 titanium alloy (Ti-6Al-4V) thin plate with a thickness of 0.3mm is perforated, the diameter of the hole is 0.5mm, and the distance between the longitudinal and transverse circular holes and the circular holes is 1mm, and then the porous TC4 titanium The alloy thin plate is processed into Φ30mm discs by wire cutting, and then pickled with 10wt% HF solution to remove the surface oxide film, then washed with distilled water, then rinsed with acetone, and vacuum-dried at a vacuum degree of 0.05Pa and a temperature of 40°C for 30min;

[0062] (2) Weigh the powder according to 59.77Ti-33.69Al-6.54TiC (wt%), dry mix it with a ball mill for 4 hours, the ratio of ball to material is 4:1, the speed is 500r / min, ball mill for 30min, and pass through a 200-mesh sieve after mixing spare;

[0063] (3) The processed titanium alloy sheet and 59.77Ti-33.69Al-6.54TiC (wt%) mixed powder are stacked layer by layer in a graphite mold, the titanium alloy layer is 5 layers, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com