Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Achieve compliance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

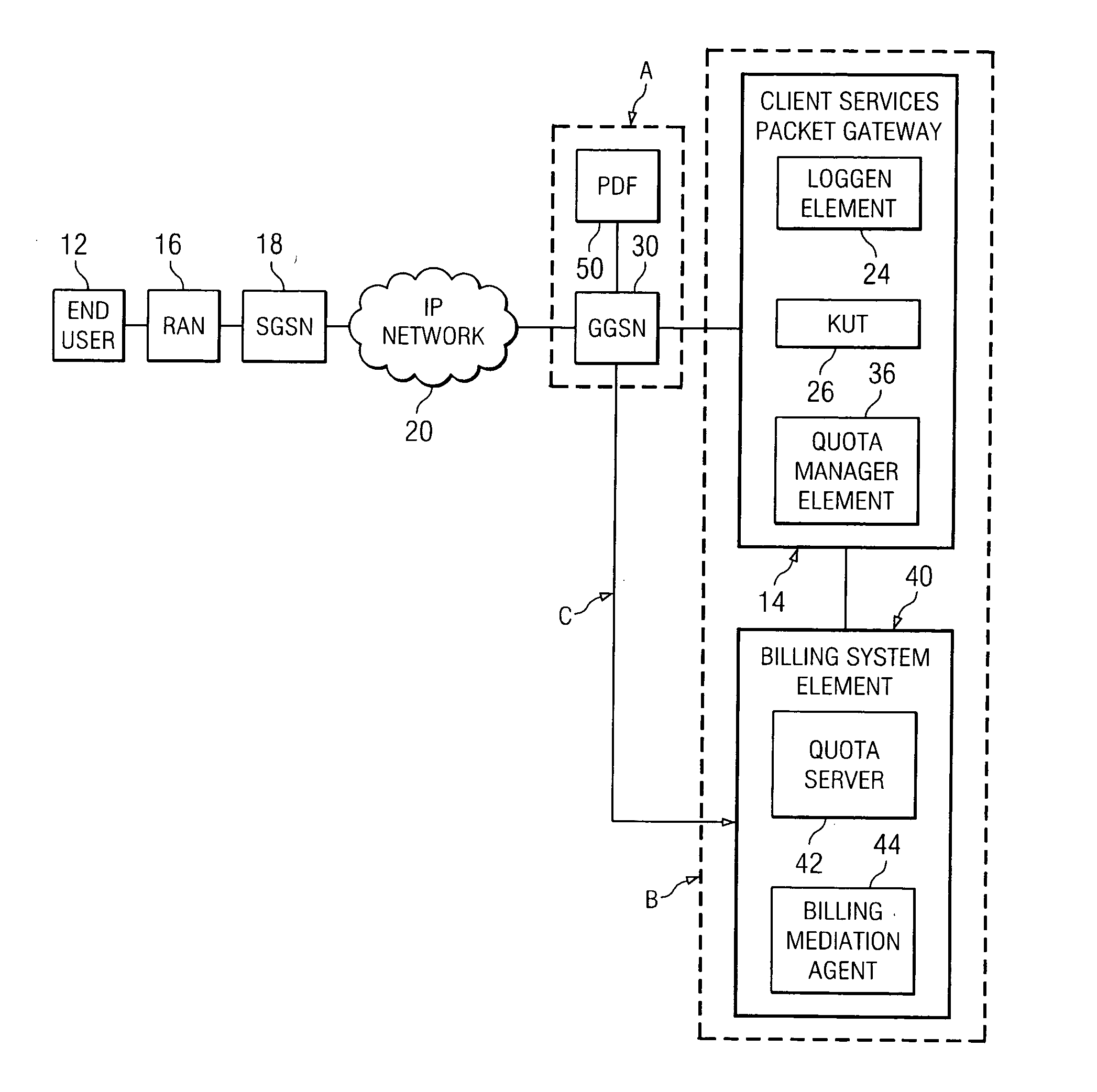

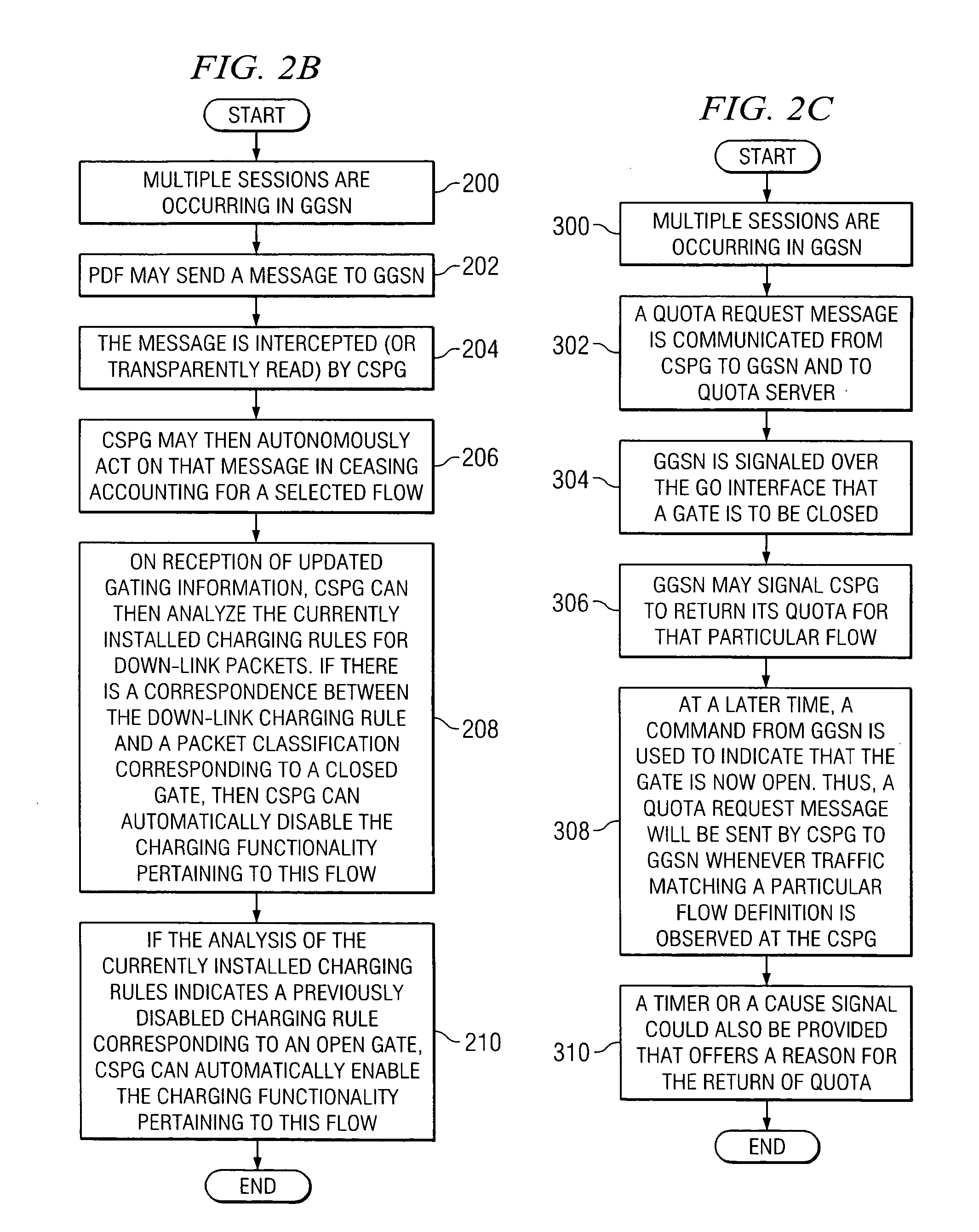

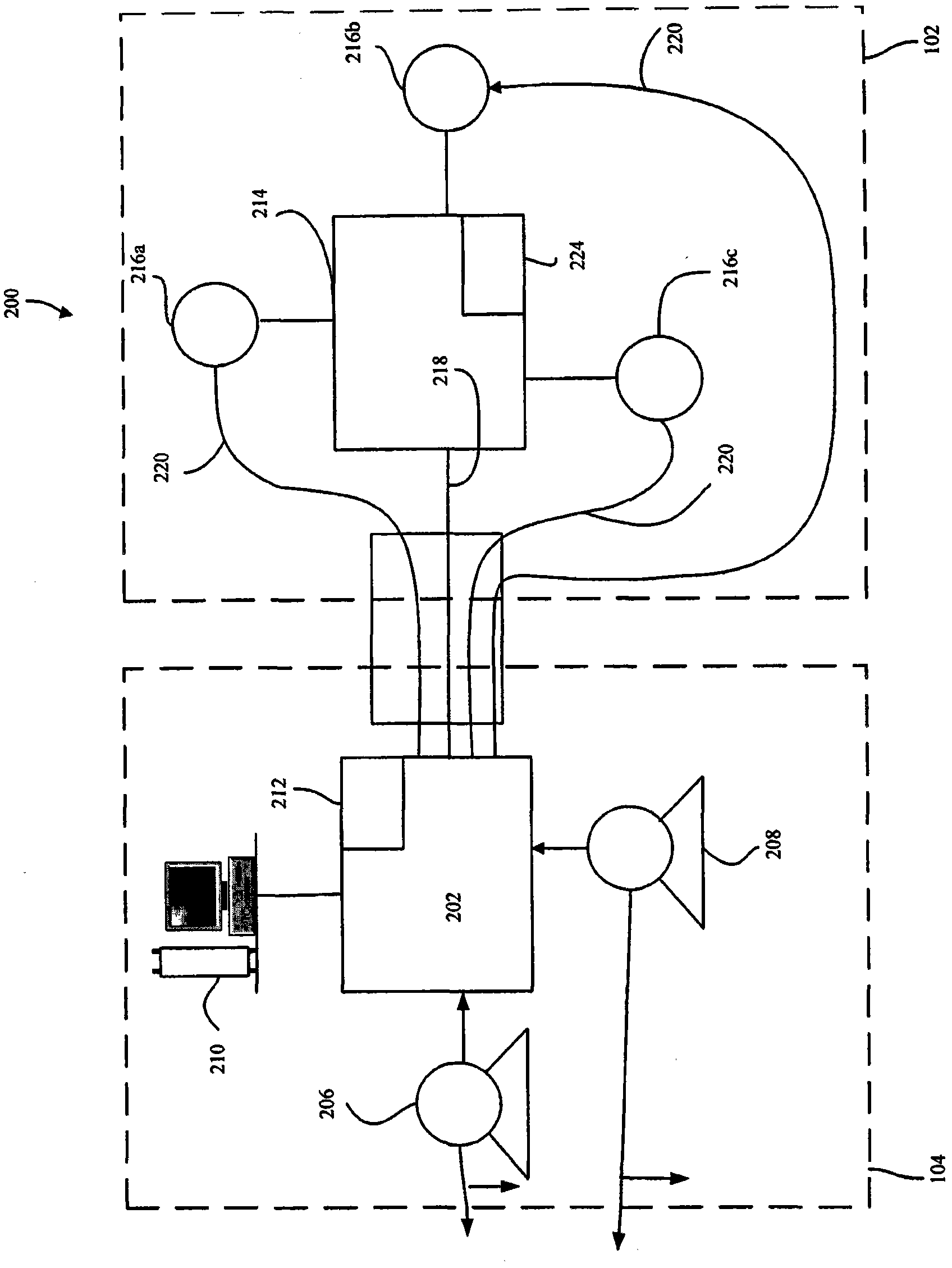

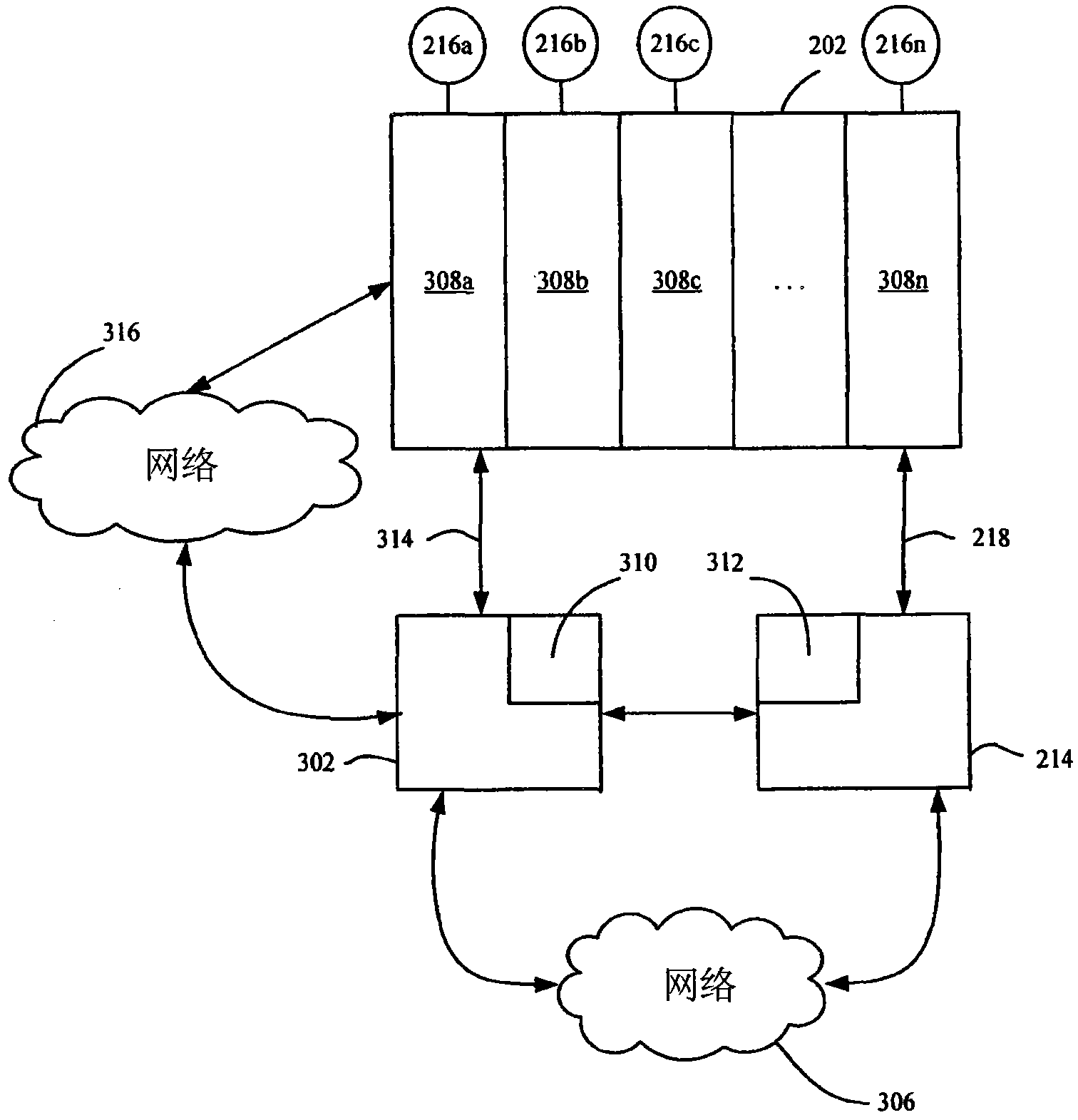

System and method for signaling information in order to enable and disable distributed billing in a network environment

ActiveUS20060029084A1Reduce disadvantagesReduce problemsMetering/charging/biilling arrangementsError preventionQuality of serviceClient-side

An apparatus for signaling information in a network environment is provided that includes an access gateway operable to establish one or more packet data protocol (PDP) links on behalf of an end user. The access gateway is operable to communicate a message associated with a change in quality of service, locale, or policy enforcement relating to a selected one of the PDP links to a client services packet gateway (CSPG). The CSPG responds to the message by providing an accounting command for the selected PDP link such that synchronization is achieved between accounting information and a state associated with the selected PDP link.

Owner:CISCO TECH INC

Dual mode display with a backlight filter for an unactivated light emitting diode (LED)

ActiveUS7025474B2Little changeSolution to short lifeTelescopesSpectral modifiersLiquid-crystal displayDual mode

A dual mode or multimode backlight containing LEDs as a light source. The backlight has light cavity containing a reflective material. The cavity has an opening to allow light to be directed to a display source such as a liquid crystal display (LCD). Two sets of LEDs are provided, one set for day mode and one set for night mode. The night mode LEDs is fitted with an NVIS filter. The day mode LEDs is fitted with a filter that suppresses the phosphorescence from the day mode LEDs. The filter suppress the IR energy and allows maximum luminance from the day mode LEDs. During night mode operation, the backlight is flooded with light. Filtered light from the NVIS LED's would impinge on the day mode LED's causing them to phosphoresce. The filter over the day mode LEDs removes the infrared energy from the phosphorescent light emitted from the day mode LEDs.

Owner:HONEYWELL INT INC

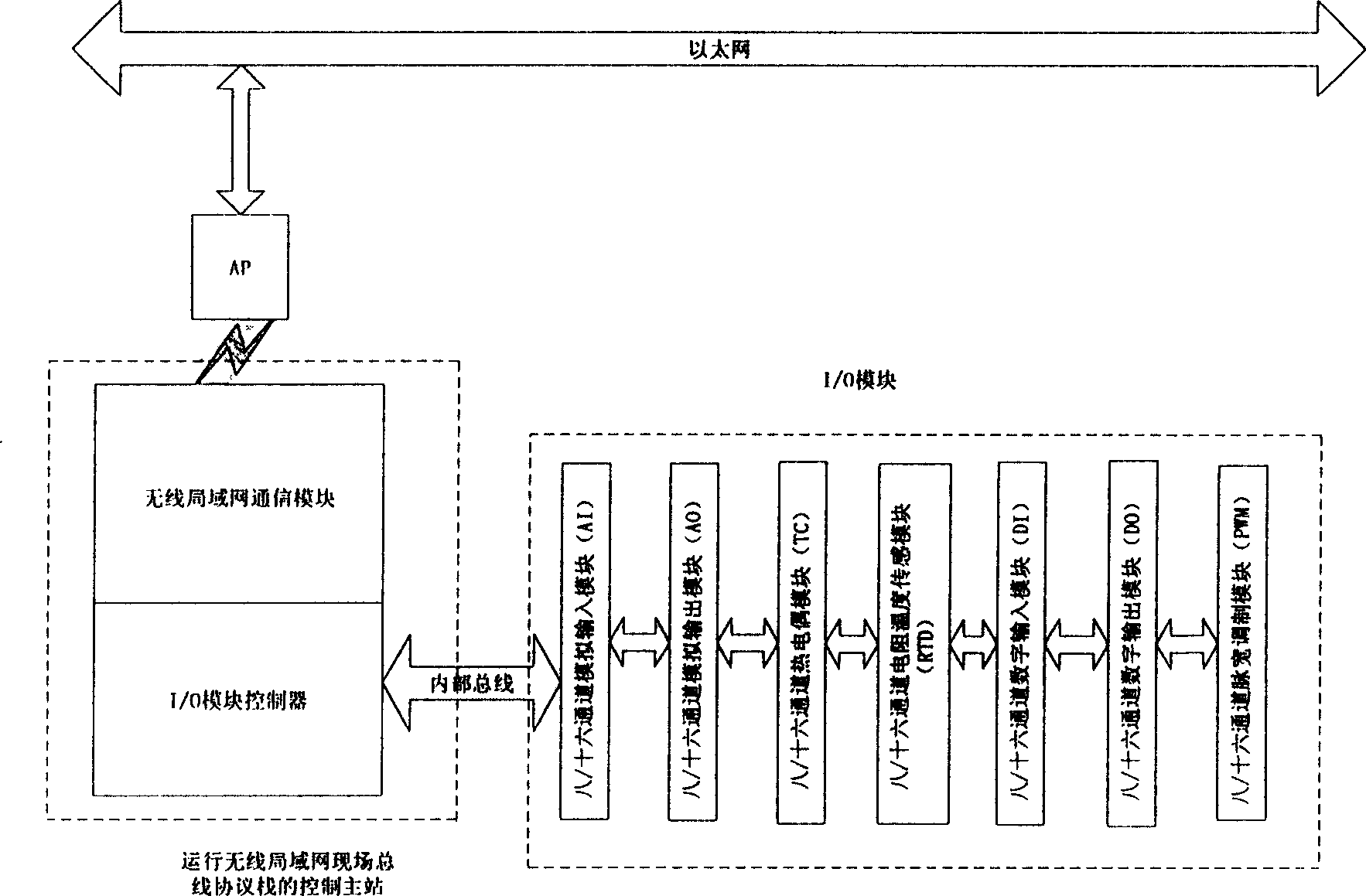

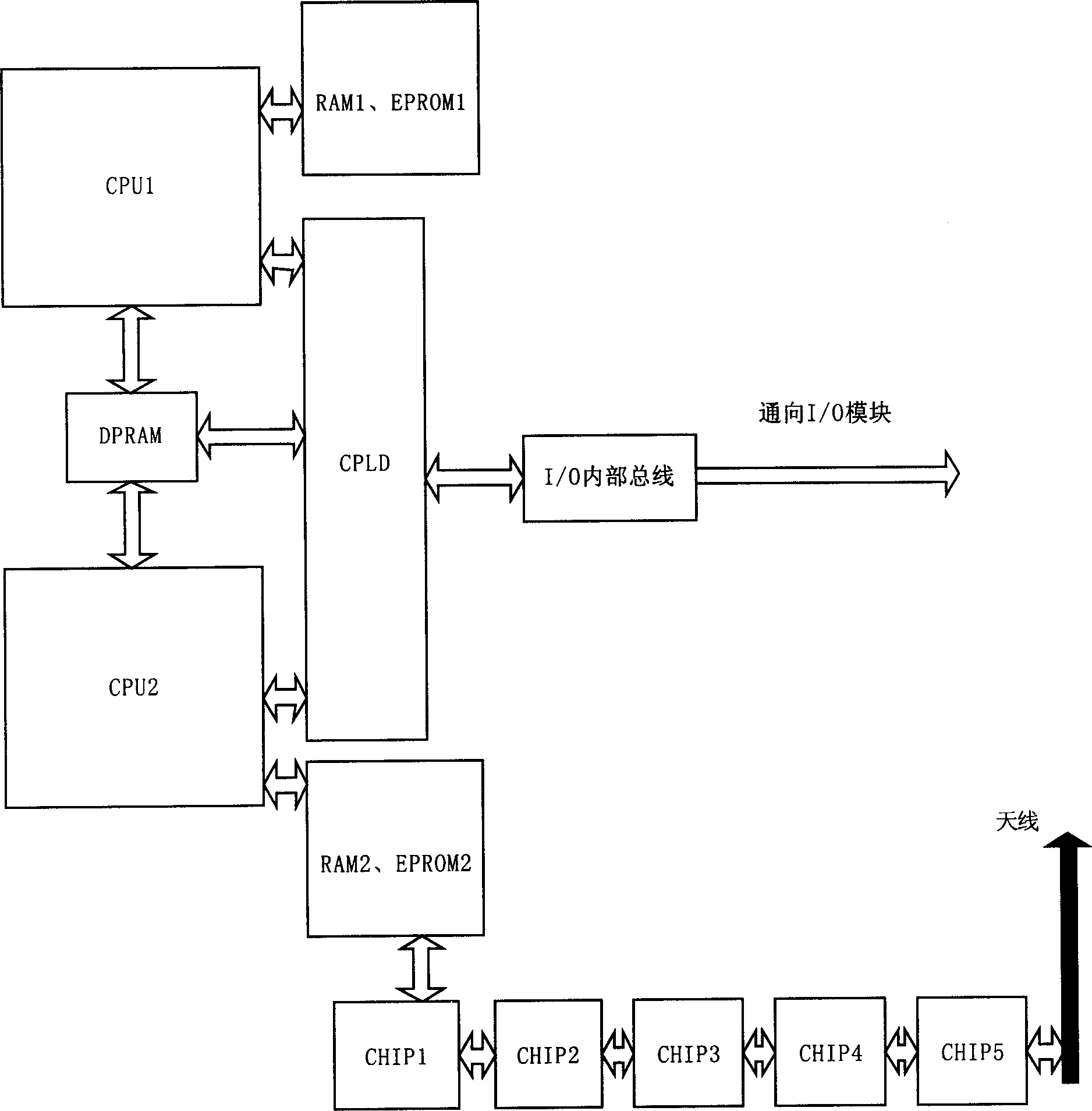

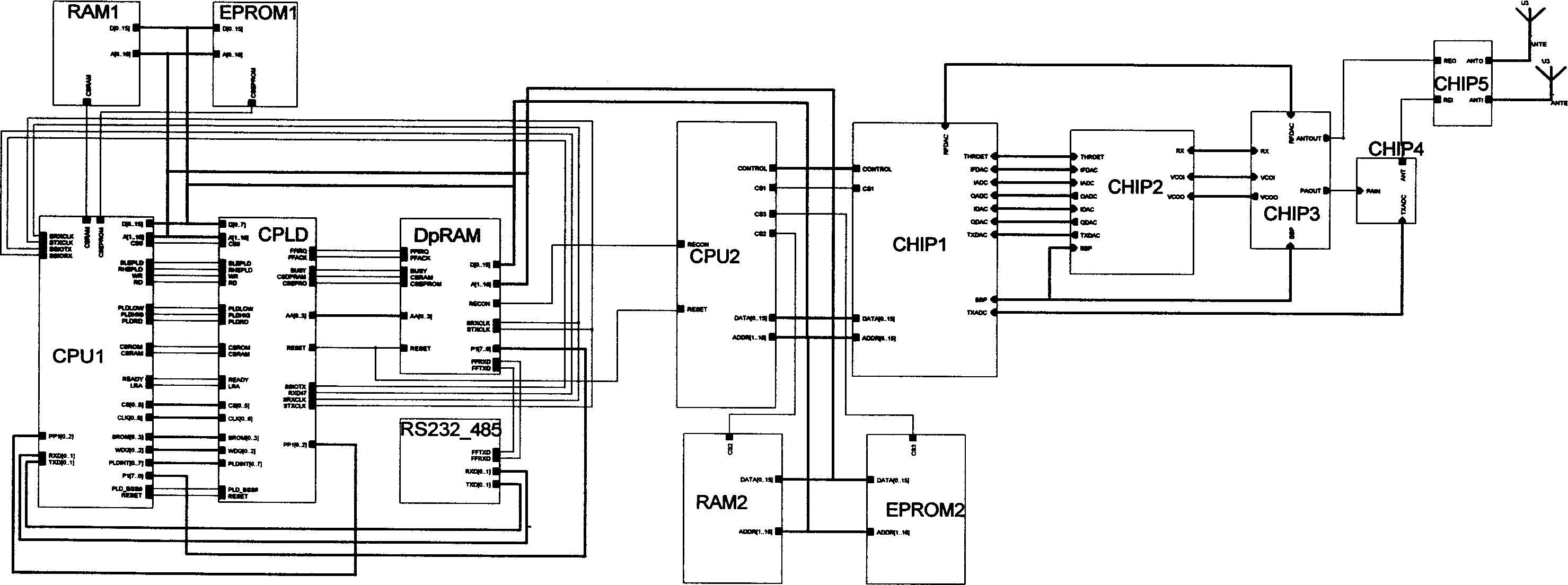

Wireless local area network on-site bus network control station

InactiveCN1567114ASupport hot swapSupport plug and play technologyTotal factory controlElectric digital data processingAutomatic controlDistributed structure

This invention relates to auto-control field, which in detail is used to a wireless LAN on-site bus net control station. It comprises main control station and I / O module, wherein, its main control station runs the wireless LAN on-site bus agreements and accomplishes the distribution I / O control through I / O module controller and receives and transmits data to Ethernet through wireless LAN transmission module. The I / O module is to accomplish the collection and conversion of the on-site signals. It is based on intelligence control device of the wireless Ethernet and turns the DCS total distributed system structure into new type of total distribution structure to completely distribute the control into the on site by network control station. This invention especially applies to old industry control system reconstruction to make it possible for old enterprises to enter the new time of on-site bus.

Owner:无锡中科泛在信息技术研发中心有限公司

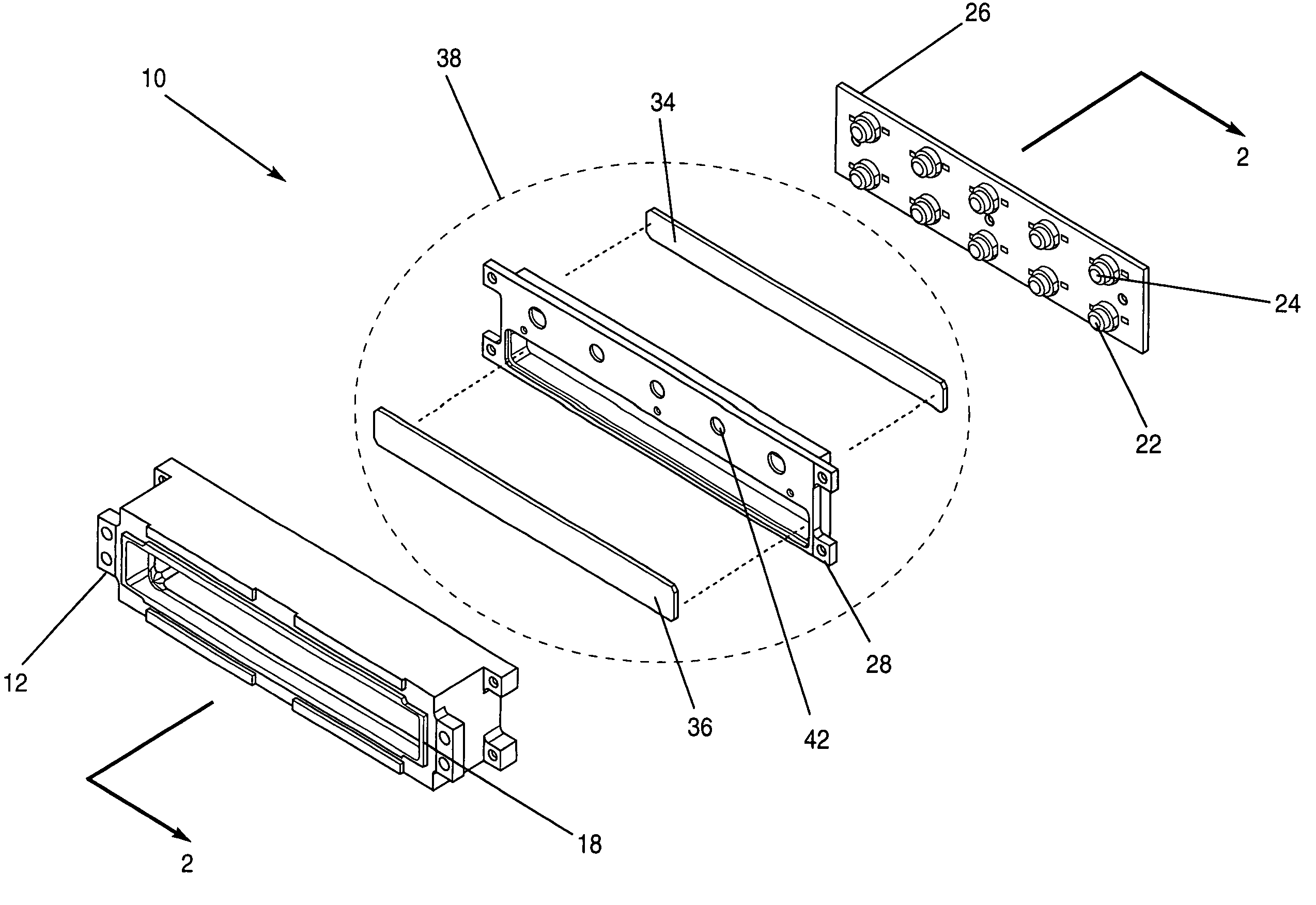

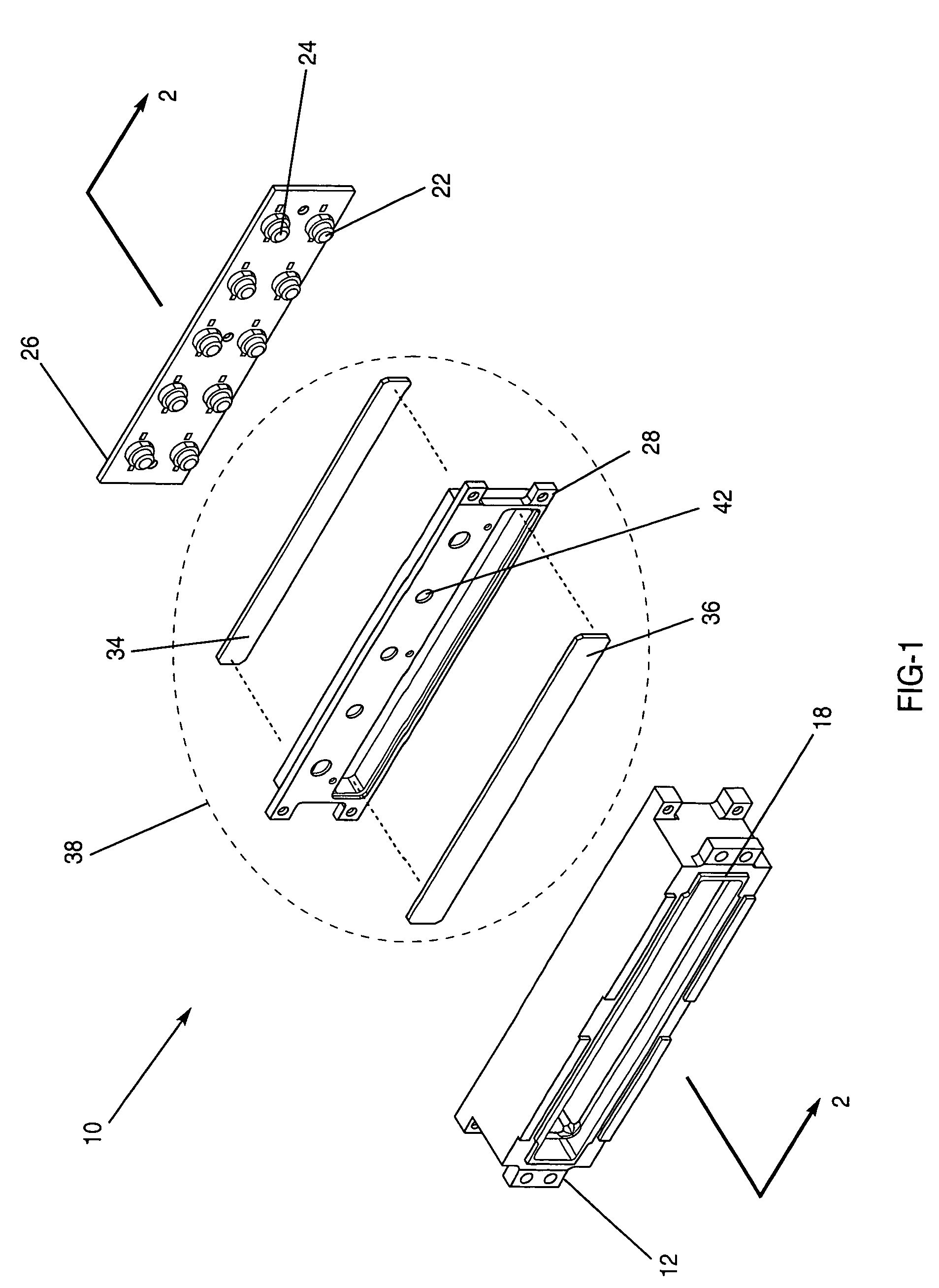

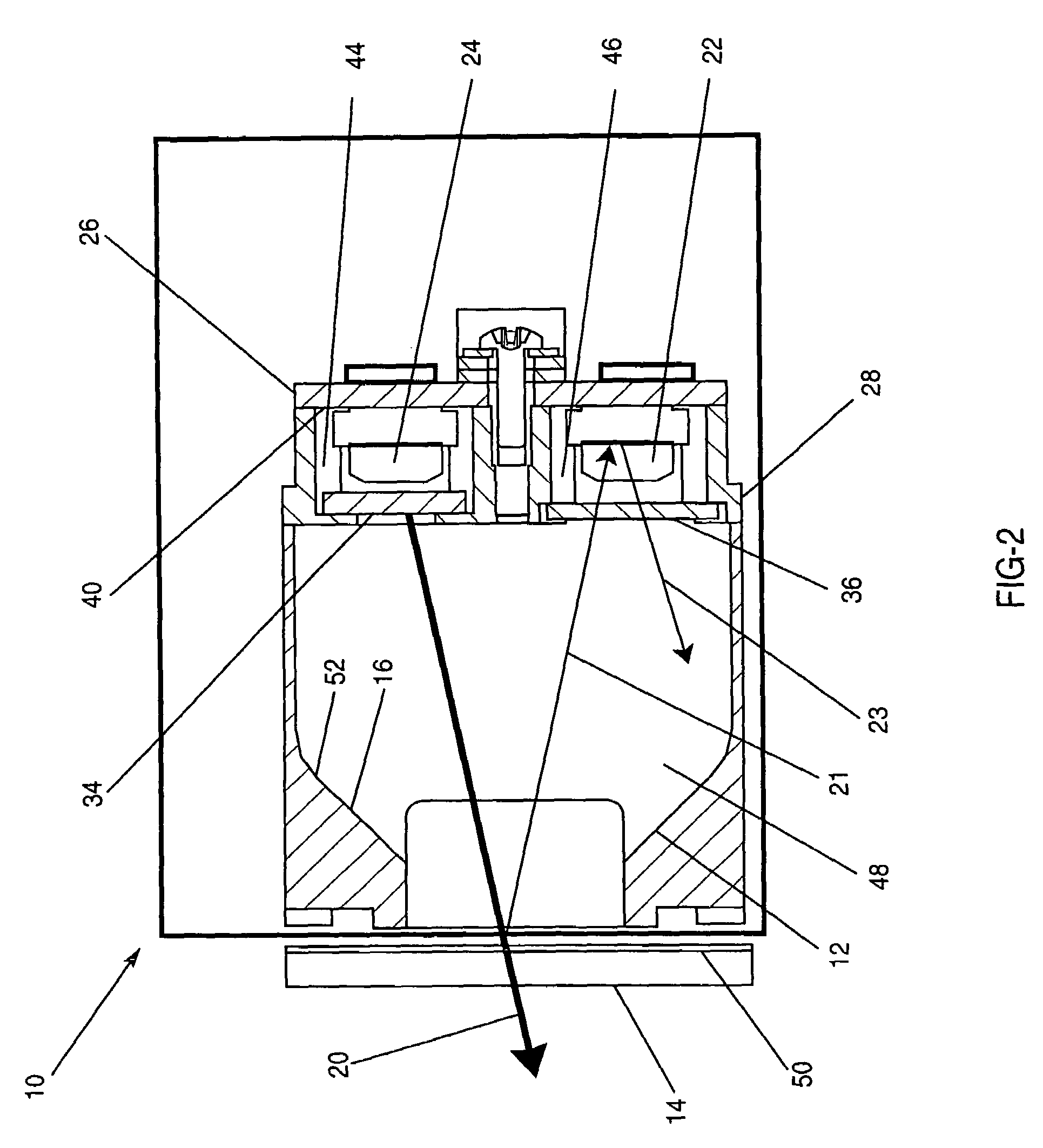

System and method for air sampling in controlled environments

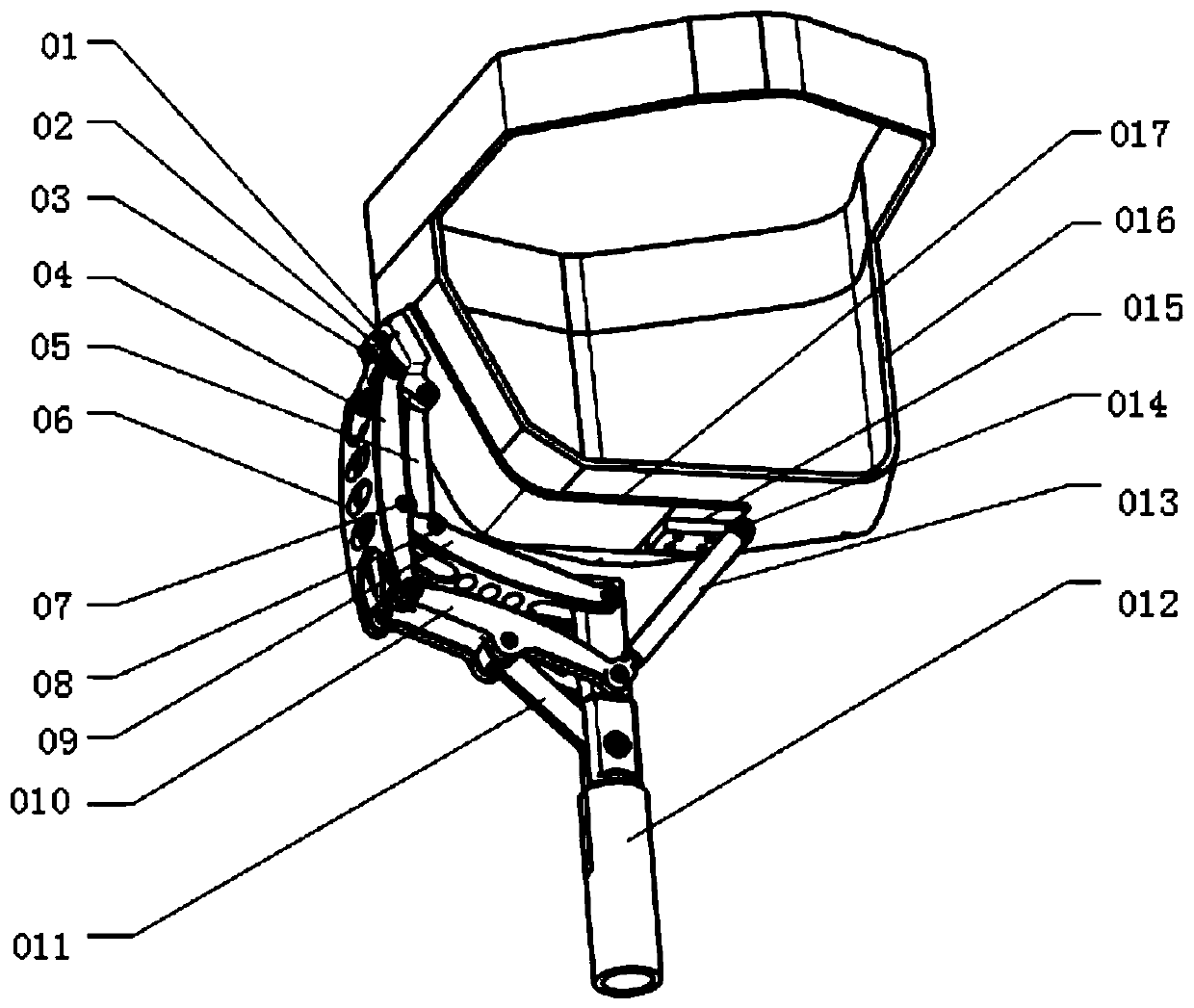

ActiveCN102066897AAchieve complianceReduce the number of penetrationsWithdrawing sample devicesThin material handlingTouchpadEngineering

A sampling system for quantifying the amount of contaminants in a controlled environment within a facility, the controller having a plurality of ports, each port having a timer circuit, a flow rate circuit, a flow switch, and a vacuum tube, wherein the flow rate circuit controls the flow switch and maintains a fluid flow through the vacuum tube at about 1 cfm. The system also includes a plurality of air sampling device located within the controlled environment, each connected to one of the plurality of ports by way of the vacuum tube. A touchpad input / output device is connected to a base station, wherein the base station comprises a communications device for wirelessly sending a start and stop signal from the touchpad to the controller.

Owner:VALTEK ASSOC INC

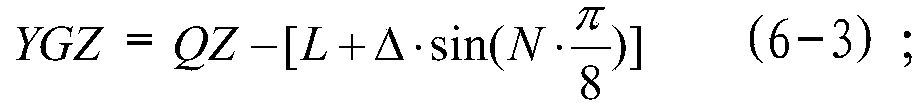

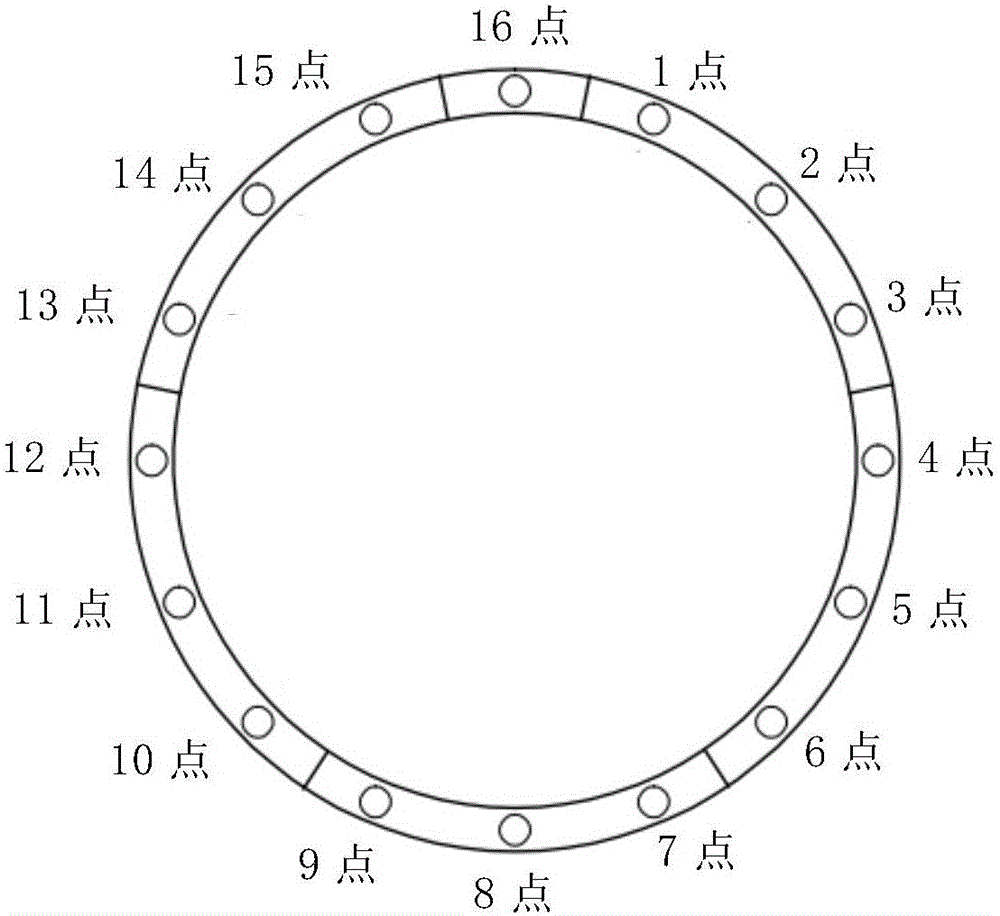

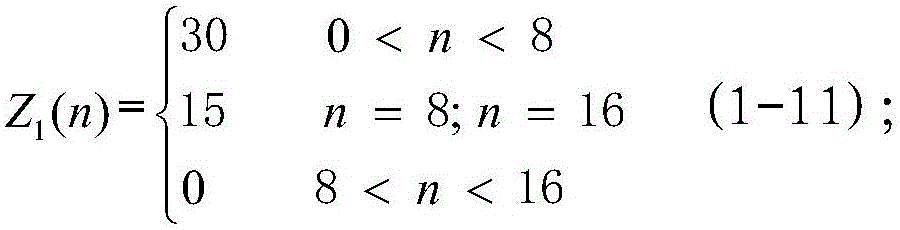

Shield general segment assembling point location determining method

ActiveCN107725067AThe method steps are simpleLow input costUnderground chambersResourcesWeight coefficientEngineering

The invention discloses a metro shield construction general segment assembling point location determining method. A shield tunneling machine is used for conducting shield tunneling construction on a construction tunnel along a tunnel central axis from back to front. After the shield tunneling construction is completed for one link, shield segment assembling construction is carried out. Before anylink of shield segment assembling construction is performed, first of all, segment assembling point locations of current shield segments are determined. Processes include the following steps that firstly, selectable assembling point locations are determined; secondly, selection influence indexes and weight coefficients of the selection influence indexes are determined, and the three selection influence indexes and the weight coefficients of the three selection influence indexes influencing segment assembling point location selection are determined separately; thirdly, the selectable assemblingpoint locations are selectively evaluated, wherein according to a weight coefficient method, the selection of all the selectable assembling point locations is evaluated separately, and the segment assembling point locations of the current shield segments are determined. The shield general segment assembling point location determining method is simple in step reasonable in design, convenient to achieve, good in using effect and capable of conveniently, fast and precisely determining the assembling point locations of the general segments.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Method for determining duct piece splicing point position of universal ring for subway shield construction

ActiveCN105673041AThe method steps are simpleLow input costData processing applicationsUnderground chambersWeight coefficientEngineering

The invention discloses a method for determining a duct piece splicing point position of a universal ring for subway shield construction. The method comprises the following steps: performing shield tunneling construction on a constructed tunnel from back to front along the central axis of the tunnel by adopting a shield tunneling machine; after a ring of the shield tunneling construction is completed, performing shield duct piece splicing construction; before any ring of shield duct piece splicing construction, determining the duct piece splicing point position of shield duct pieces of the current ring first, wherein the method for determining the duct piece splicing point position comprises the following processes: firstly, determining selectable splicing point positions; secondly, determining selection influence indexes and weight coefficients thereof: respectively determining the three selection influence indexes which influence the selection of the duct piece splicing position point and the weight coefficients thereof; thirdly, performing selectivity evaluation on the selectable splicing position points: respectively evaluating the selectivity of each selectable splicing position point according to a weight coefficient method, and determining the duct piece splicing point position of the current shield duct piece. The method disclosed by the invention is simple in step, reasonable in design, convenient to implement and good in using effect, and can determine the splicing point position of the duct pieces of the universal ring easily, conveniently and accurately.

Owner:CHINA RAILWAY FIRST GRP CO LTD

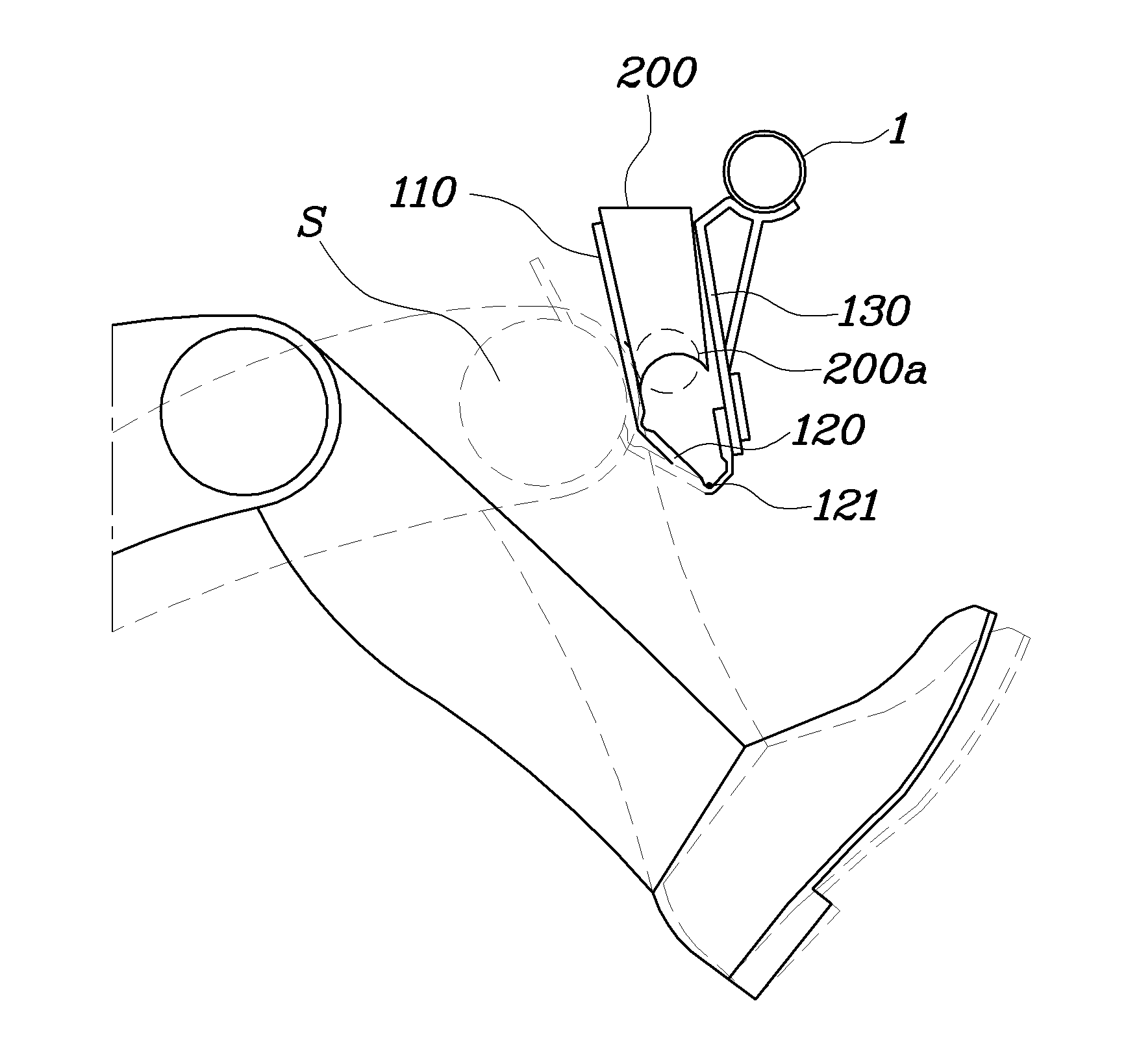

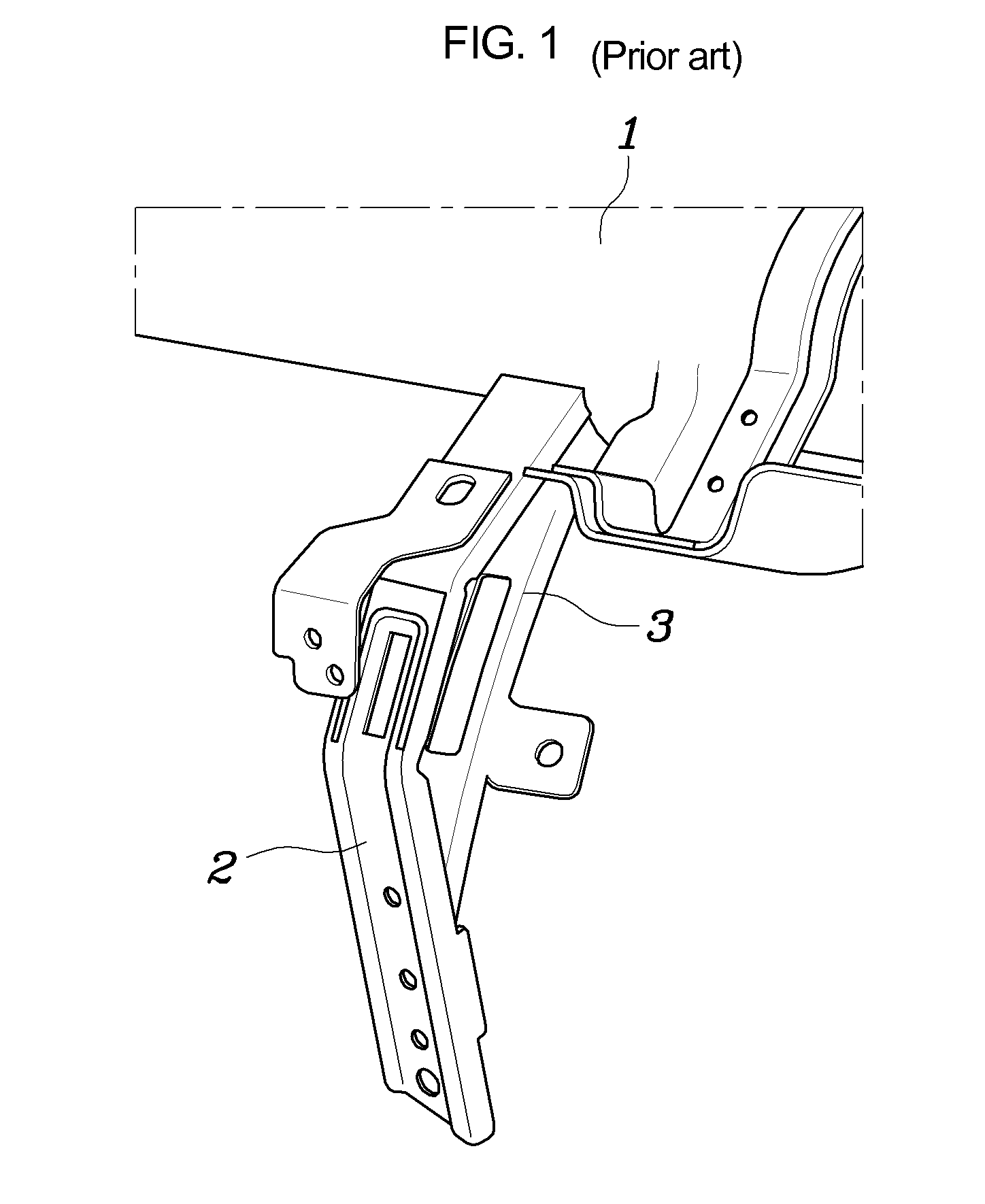

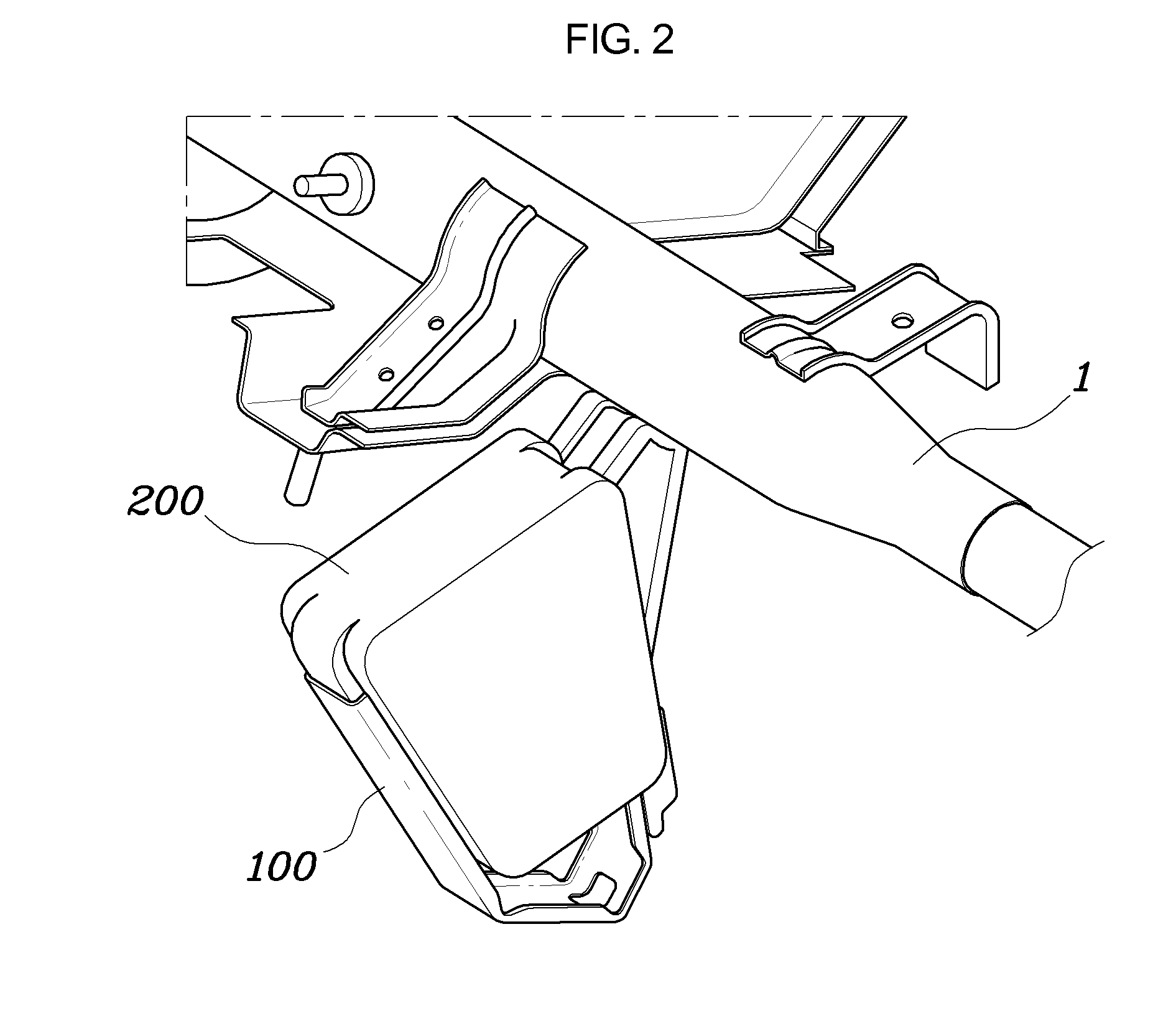

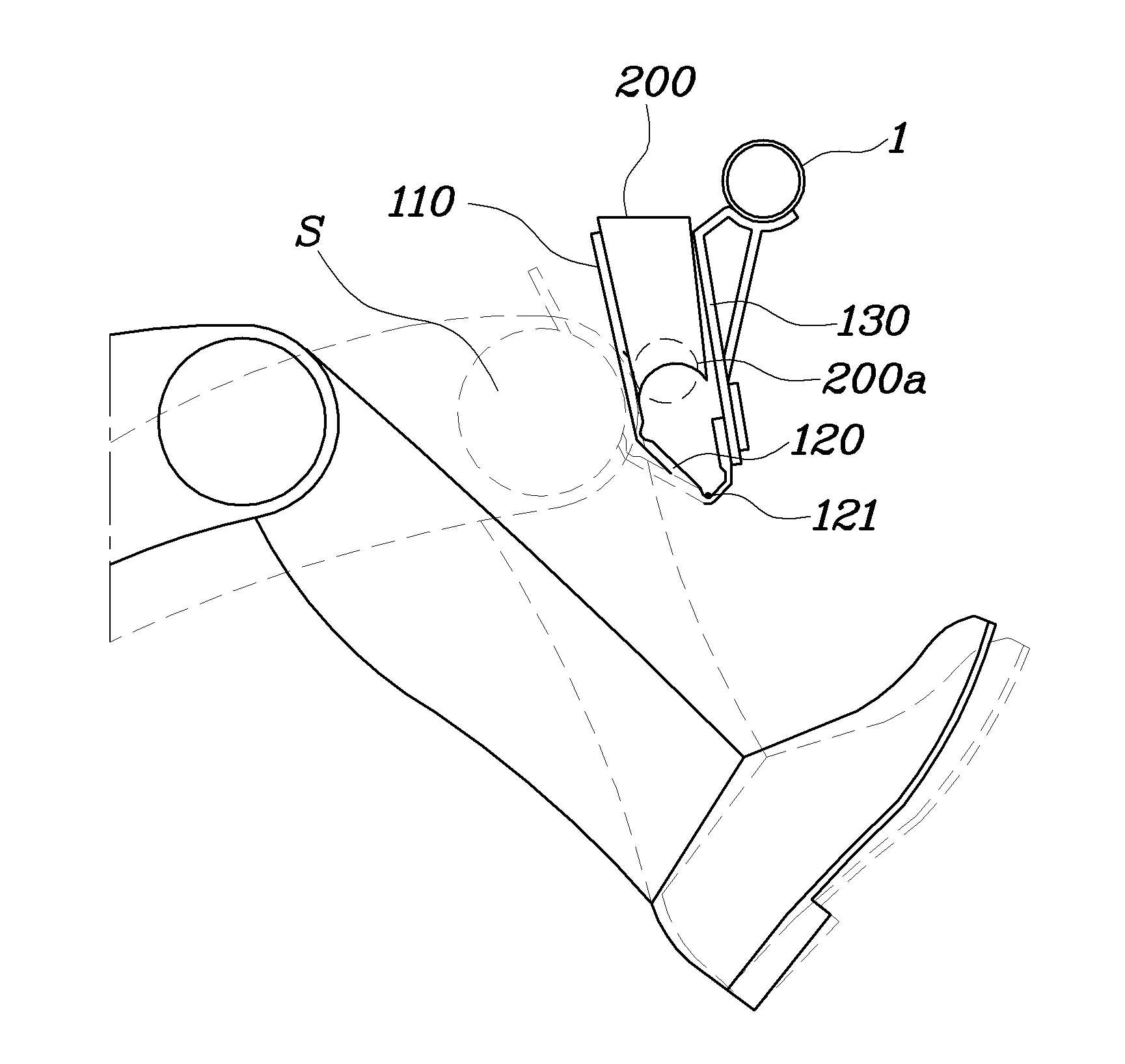

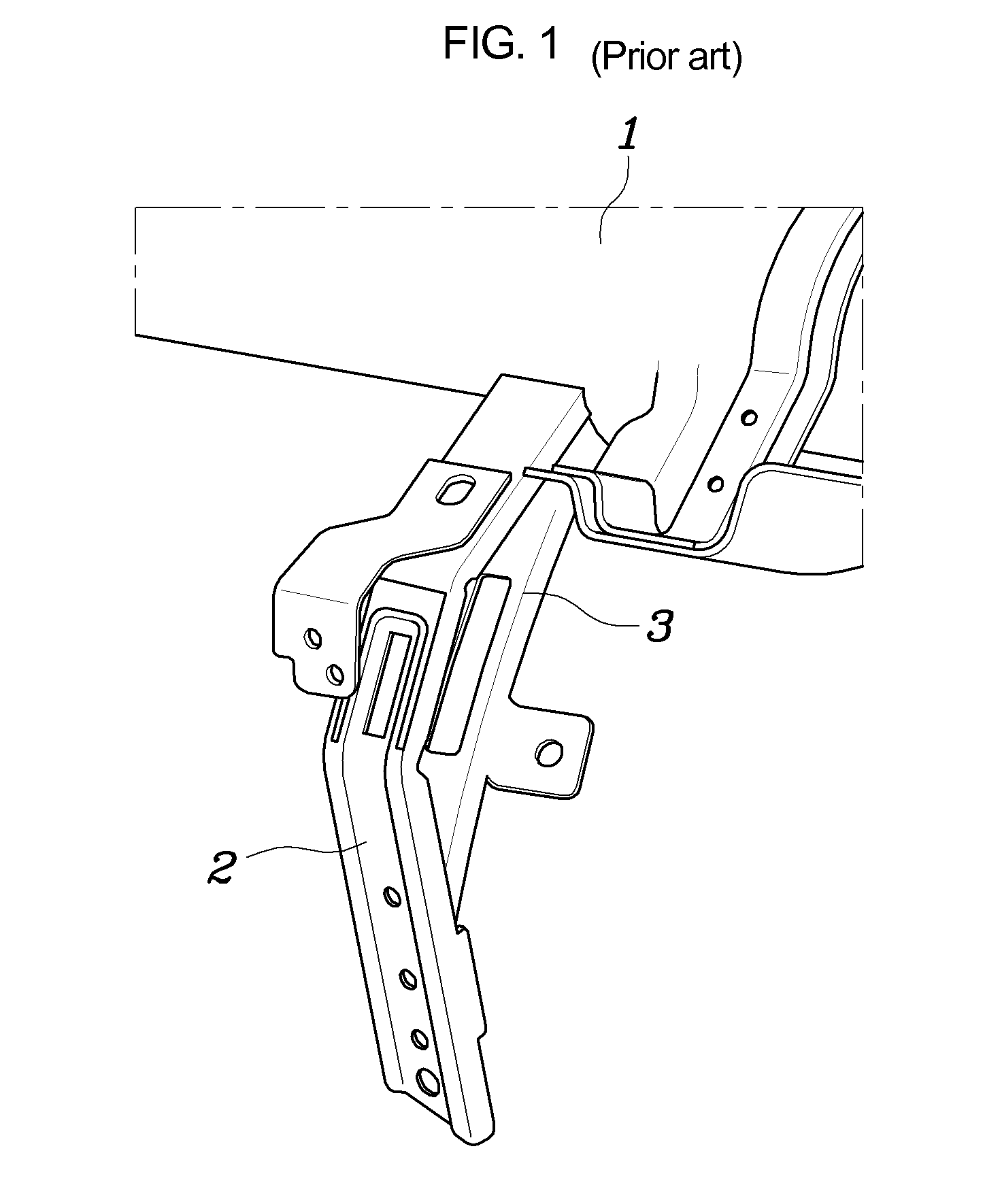

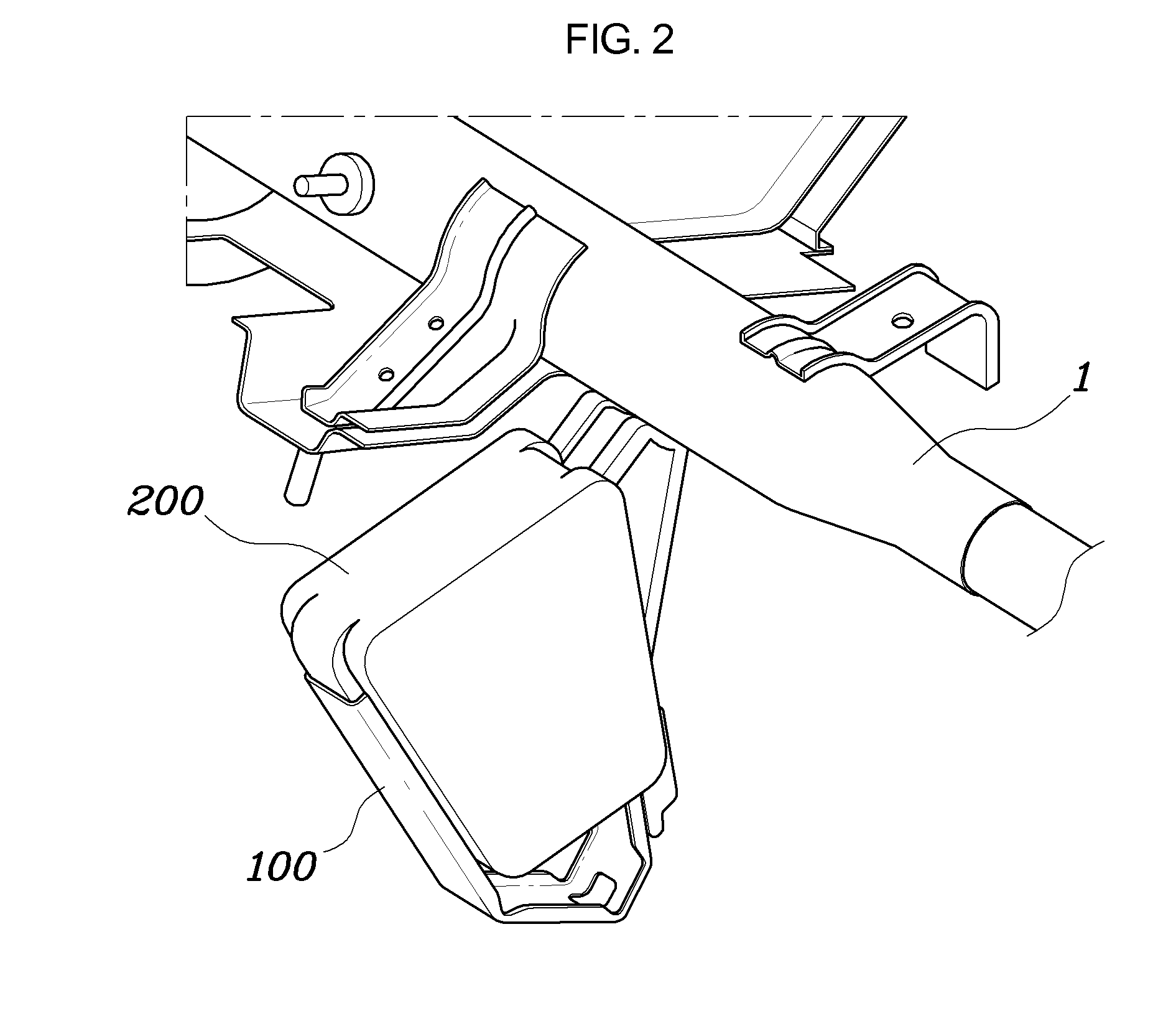

Knee bolster for vehicles

ActiveUS20120068447A1Cushion the shockAchieve compliancePedestrian/occupant safety arrangementBolsterKnee protector

A knee bolster for vehicles, which is placed inside a lower instrument panel of a vehicle and is mounted to a cowl cross bar and relieves shock applied to knees of a passenger in case of an accident, may include a U-shaped bracket mounted to the cowl cross bar and bent to form a U-shape to be deformed by an external force during the accident, thus primarily absorbing knee load of the passenger, and a shock absorbing foam mounted in the U-shaped bracket, being deformed by the external force during the accident, and sliding along inner surface of the U-shaped bracket, thus secondarily absorbing the knee load of the passenger.

Owner:HYUNDAI MOTOR CO LTD +1

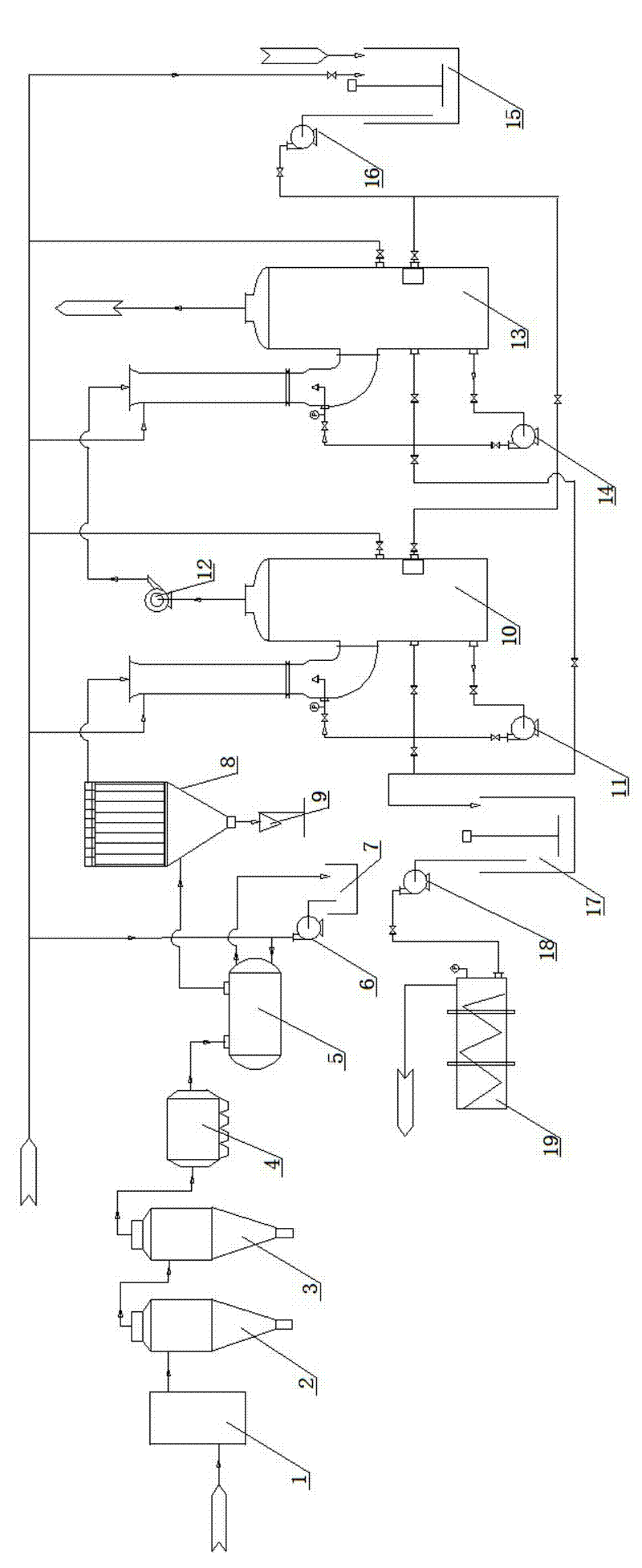

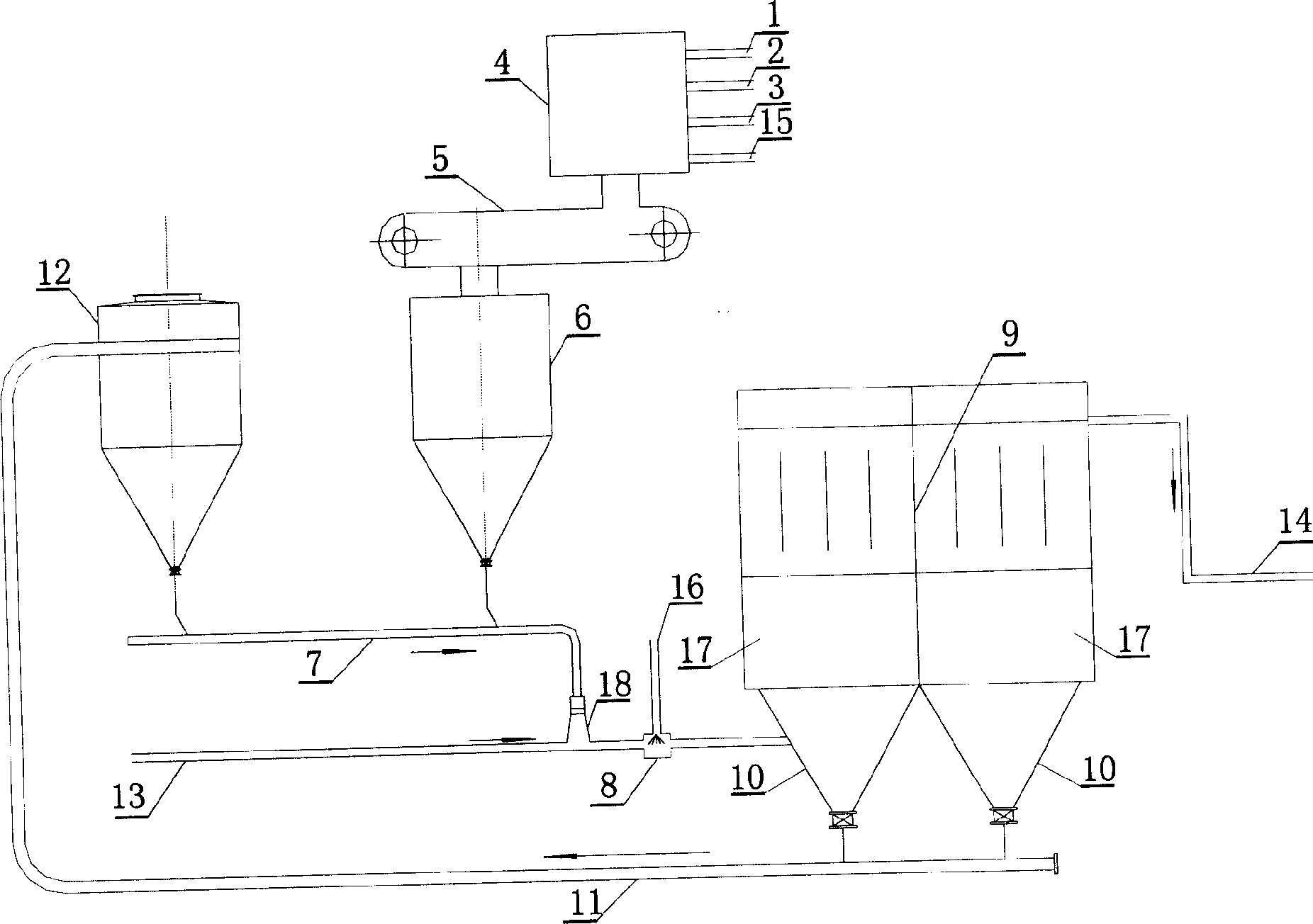

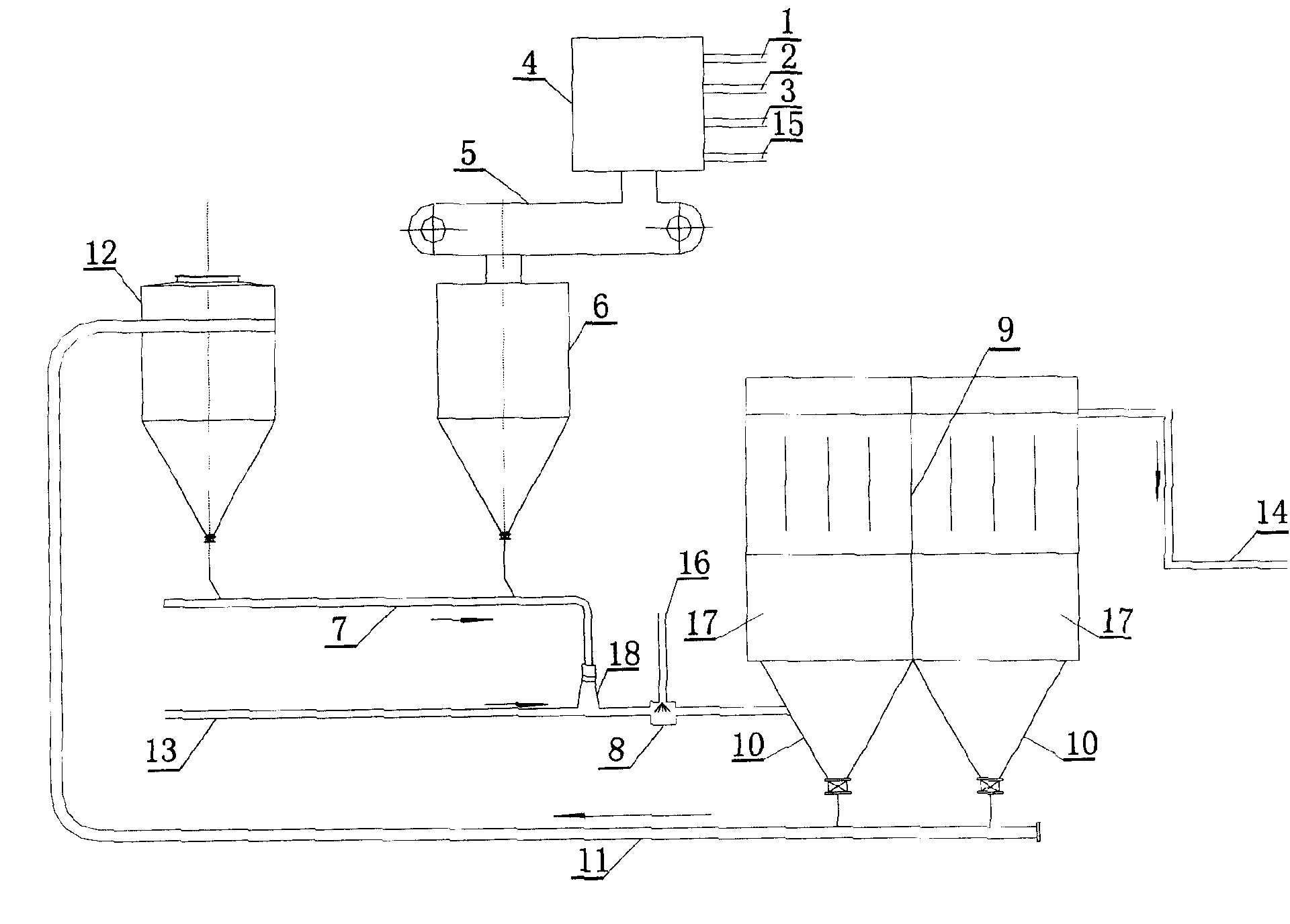

High arsenicum gold ore roasting smoke gas treatment system and method for recovering arsenicum and desulfurating

ActiveCN102350163AReduce loadGuaranteed operational safetyCombination devicesSublimationWater jacketGold ore

The invention discloses a high arsenicum gold ore roasting smoke gas treatment system and a method for recovering arsenicum and desulfurating, which can be used for mainly solving the problems that the arsenicum resource in the high arsenicum gold ore roasting smoke is wasted, and the environment is polluted by a large amount of hazardous wastes containing the arsenicum generated in wet processing. The high arsenicum gold ore roasting smoke gas treatment system comprises an arsenicum recovery system which comprises a settling chamber, a primary cyclone dust collector, a secondary cyclone dust collector, an electric dust collector, a water jacket cooler, a water circulating pump, a water circulating pond and a cloth bag arsenic collector. The high arsenicum gold ore roasting smoke gas treatment system provided by the invention also comprises a desulfurization system; and the method for recovering the arsenicum provided by the invention comprises the following steps of roasting smoke and dedusting, smoke drying cooling and arsenicum collecting by a cloth bag. The desulfurating method comprises the steps of rushing and washing. The invention has the advantages of being stable in process, high in arsonium recovery rate, high in product purity, low in gypsum arsenicum content and less in environmental pollution.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Knee bolster for vehicles

ActiveUS8333407B2Cushion the shockAchieve compliancePedestrian/occupant safety arrangementKnee supportEngineering

A knee bolster for vehicles, which is placed inside a lower instrument panel of a vehicle and is mounted to a cowl cross bar and relieves shock applied to knees of a passenger in case of an accident, may include a U-shaped bracket mounted to the cowl cross bar and bent to form a U-shape to be deformed by an external force during the accident, thus primarily absorbing knee load of the passenger, and a shock absorbing foam mounted in the U-shaped bracket, being deformed by the external force during the accident, and sliding along inner surface of the U-shaped bracket, thus secondarily absorbing the knee load of the passenger.

Owner:HYUNDAI MOTOR CO LTD +1

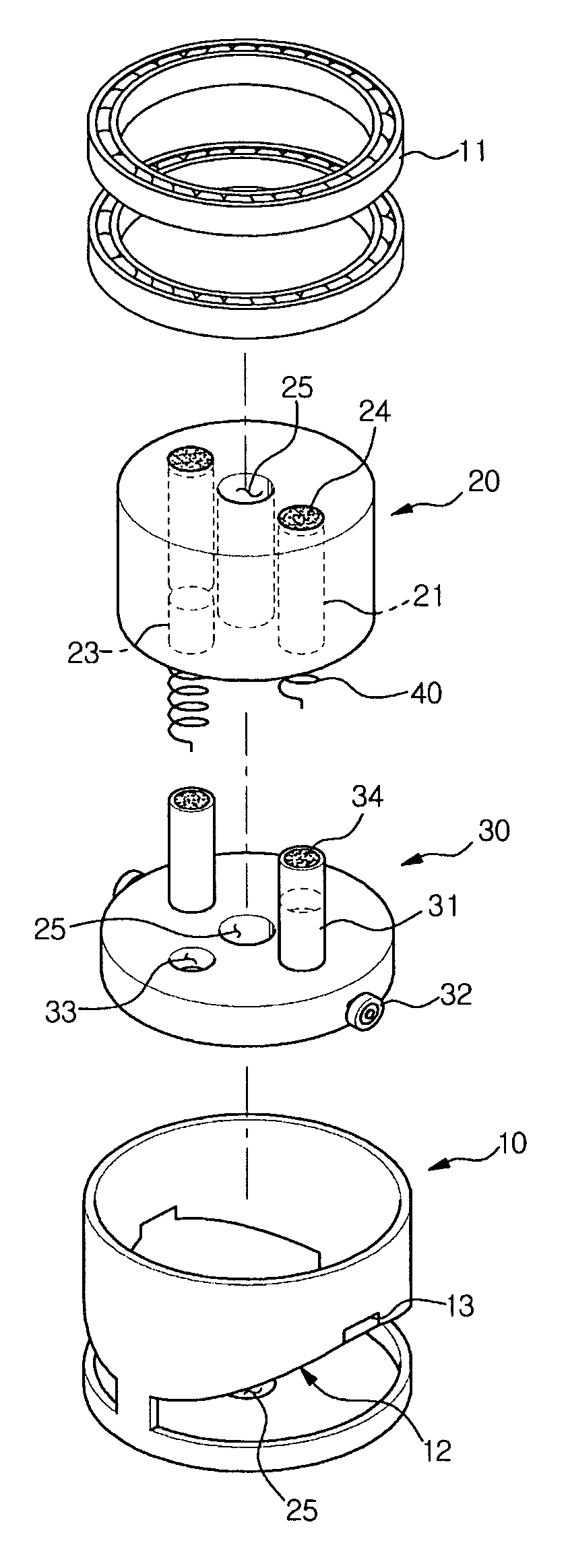

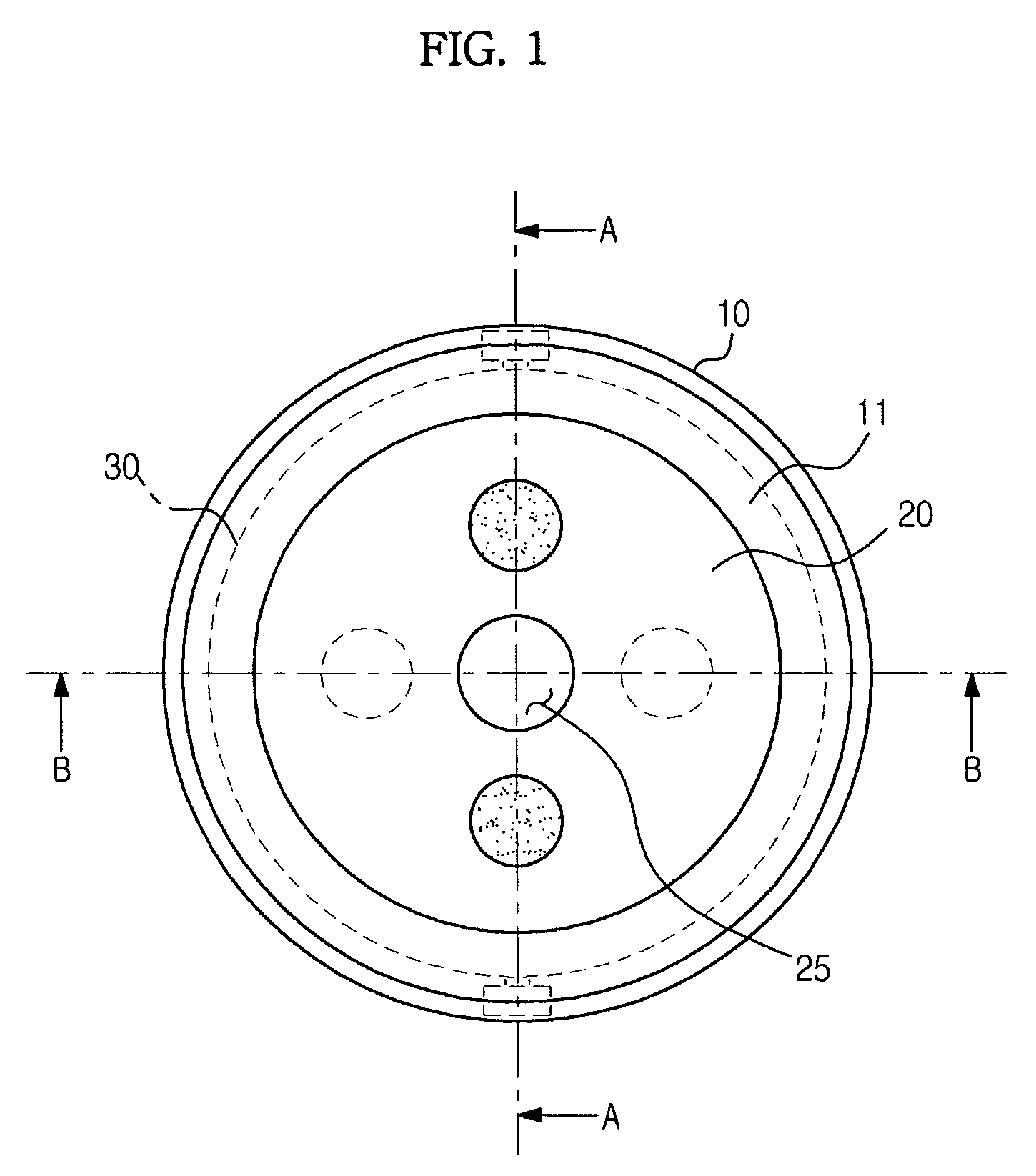

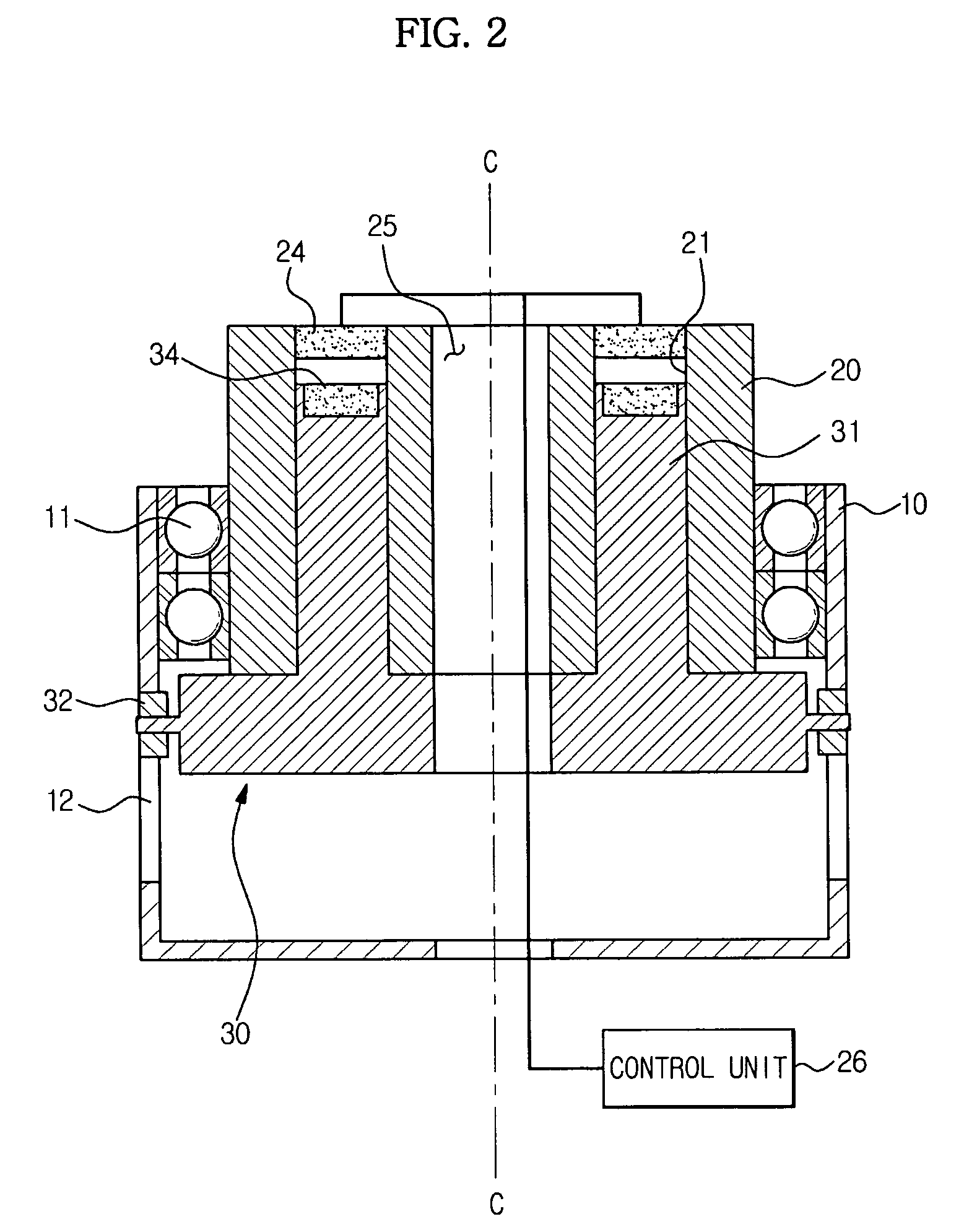

Compliant joint

Disclosed is a compliant joint achieving passive compliance. The compliant joint includes a housing and a rotating member mutually rotatably provided; and a cam provided between the housing and the rotating member, and connected to the housing and the rotating member respectively. The cam is connected to the rotating member to rotate together with the rotation of the rotating member, or be independent of the rotating member so as to move in the axial direction of the rotating member separately from the rotating member. The cam is connected to the housing such that the cam can maintain the connection with the housing when external force below a designated value is applied to the rotating member, and release the connection with the housing in the case that external force more than the designated value is applied to the rotating member.

Owner:SAMSUNG ELECTRONICS CO LTD

A 3D model verification method based on PDM system

PendingCN109472093AAchieve complianceGuaranteed availabilityDesign optimisation/simulationSpecial data processing applicationsComputer architectureUsability

The invention discloses a three-dimensional model verification method based on a PDM system, which is realized by a three-dimensional model verification system comprising a rule management module, a rule calling module, a three-dimensional model verification module and a verification report generation module. The rule management module maintains the three-dimensional model verification rules, therule calling module calls the three-dimensional model verification rules, the three-dimensional model verification module verifies the three-dimensional model, and the verification report generation module generates the three-dimensional model verification report. The invention realizes the check of conformity and conformity of the three-dimensional model design data, solves the problems that theprior method can not verify the design parameters of the three-dimensional model, can not effectively guarantee the design quality and usability of the three-dimensional model, can not automatically generate a verification report, and has high quality risk and is difficult to control.

Owner:北京机电工程总体设计部

Hair softening, repairing and caring composition and application thereof

ActiveCN111631983AAchieve compliancePromote growthCosmetic preparationsHair cosmeticsPolymer scienceStearamidopropyl dimethylamine

The invention relates to a hair softening, repairing and caring composition and application thereof. The hair softening, repairing and caring composition comprises the following components in parts byweight: 0.01 to 5 parts of lecithin, 0.01 to 5 parts of argania spinosa kernel oil, 0.1 to 5 parts of trimethylstearylammonium chloride, 0.1 to 5 parts of stearamidopropyl dimethylamine, 0.1 to 5 parts of hydrolyzed wheat protein, and 0.5 to 5 parts of silicone oil. The hair softening, repairing and caring composition has an obvious repairing effect on damaged hair after ironing and dyeing, can solve the problem of dry and frizzy hair, and achieves the effect of softening the hair.

Owner:广州旭妆生物科技有限公司

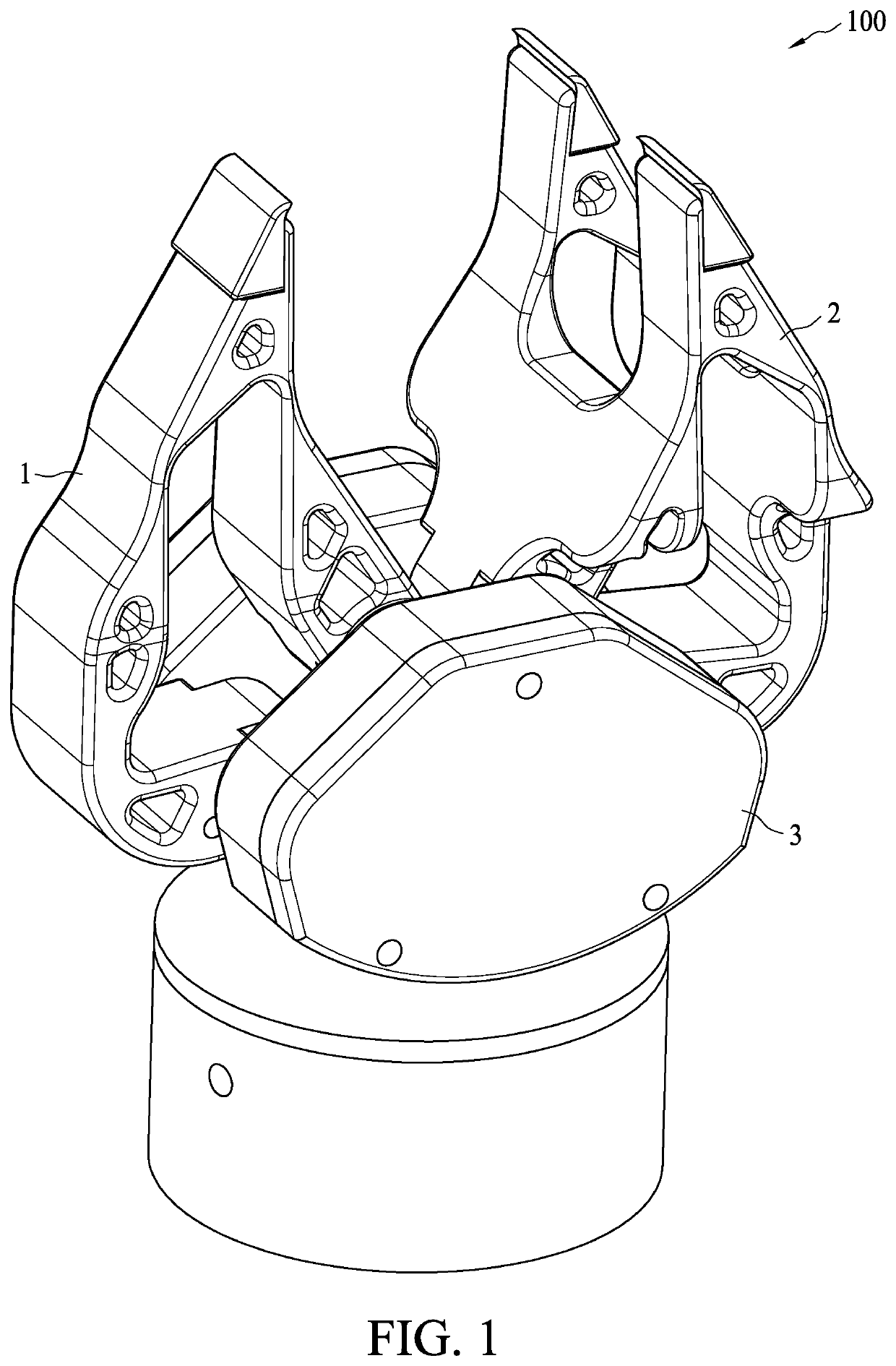

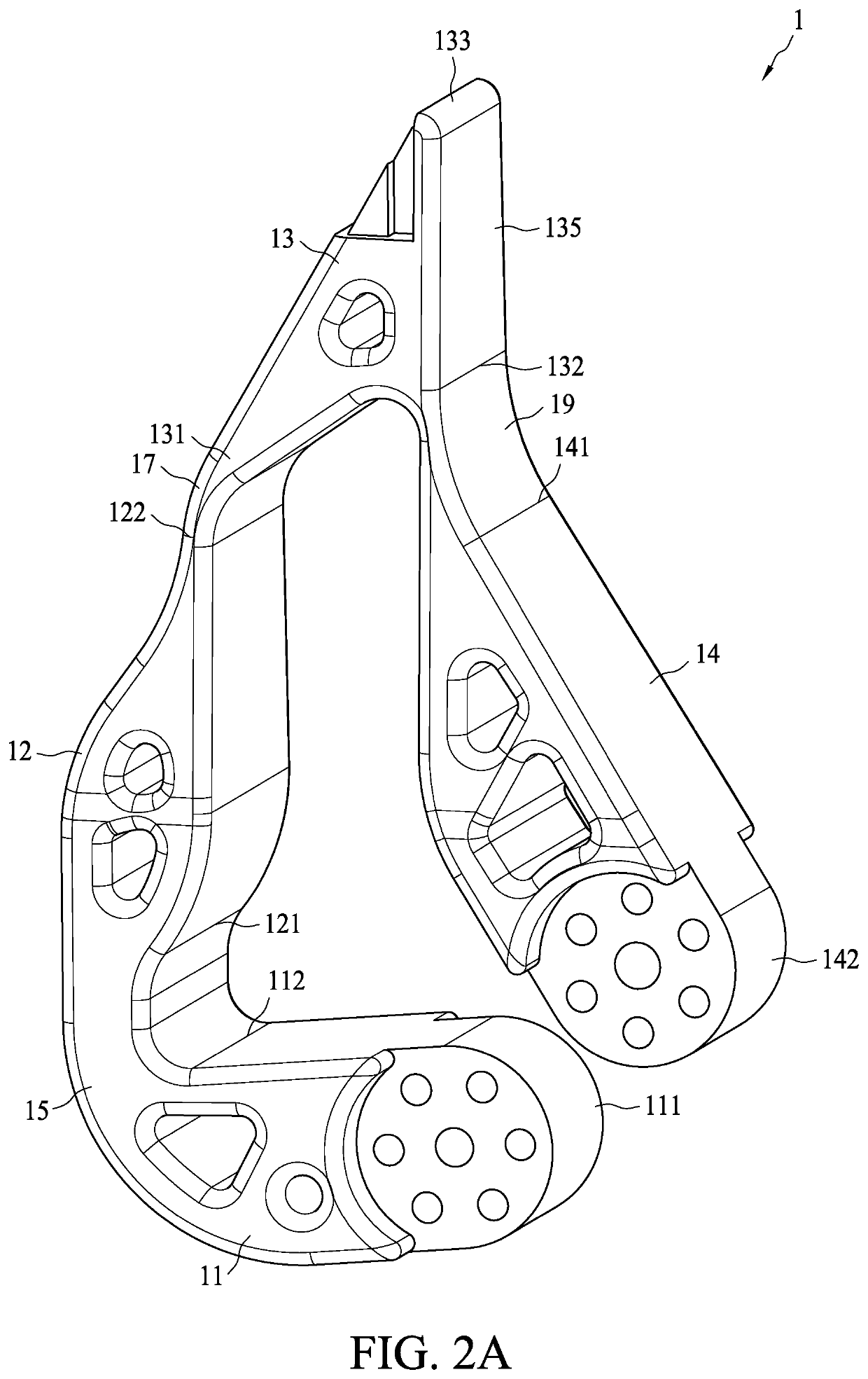

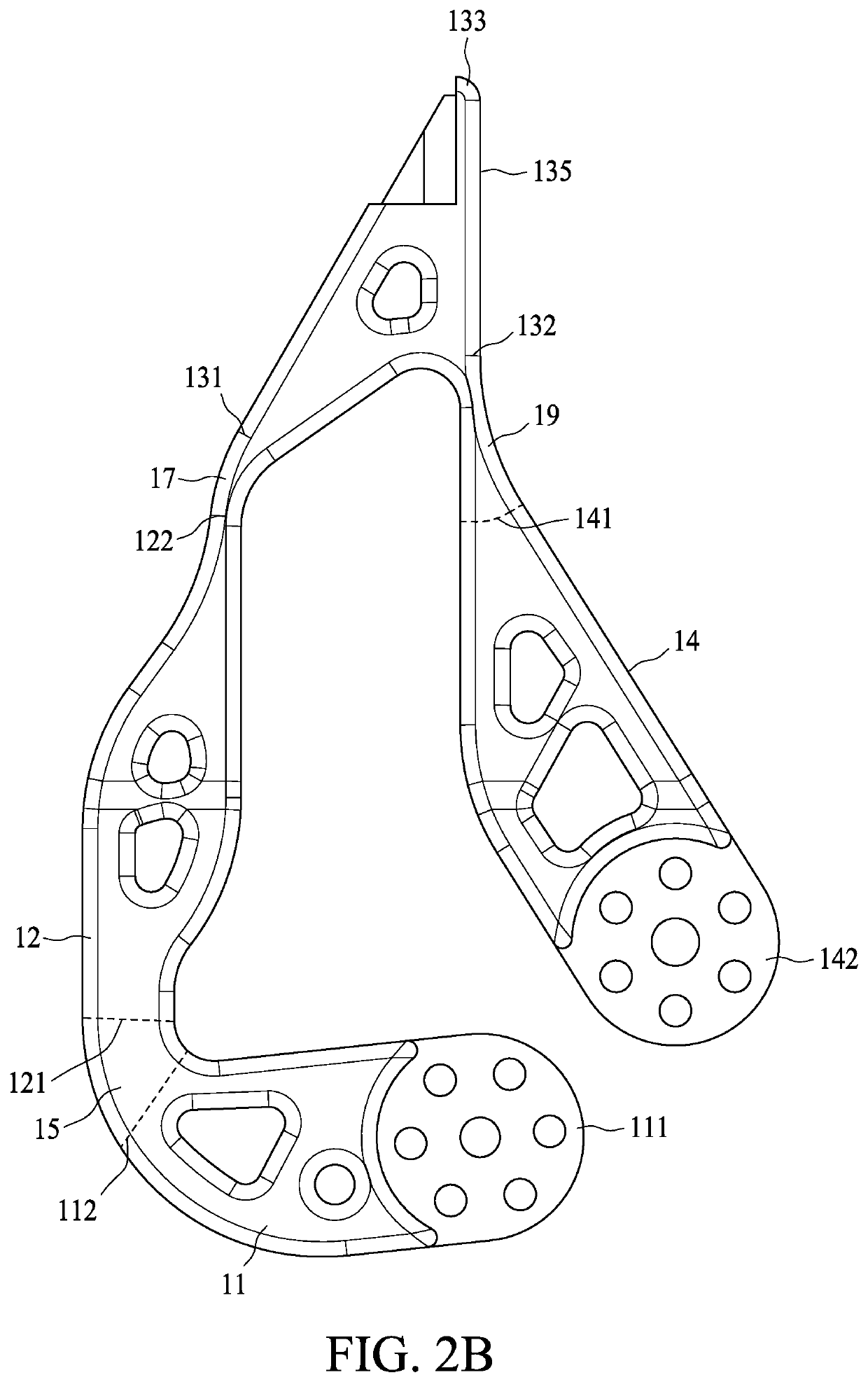

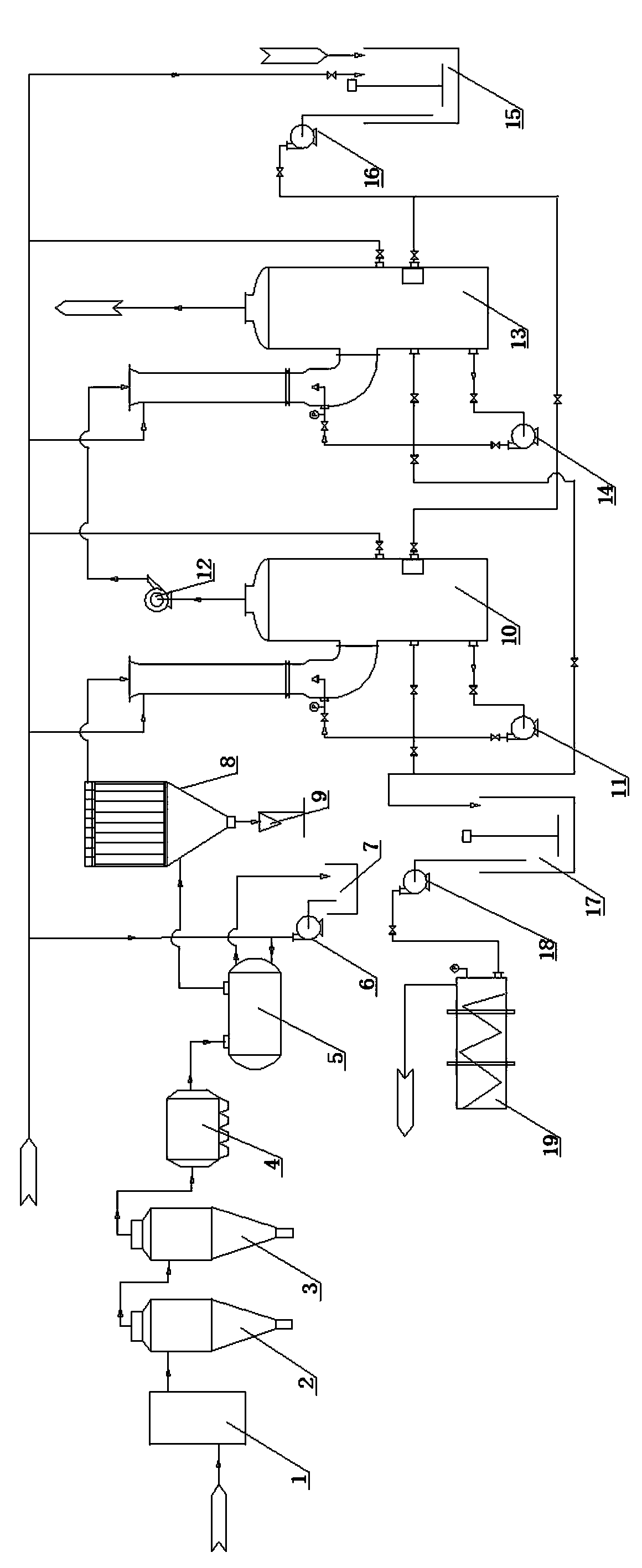

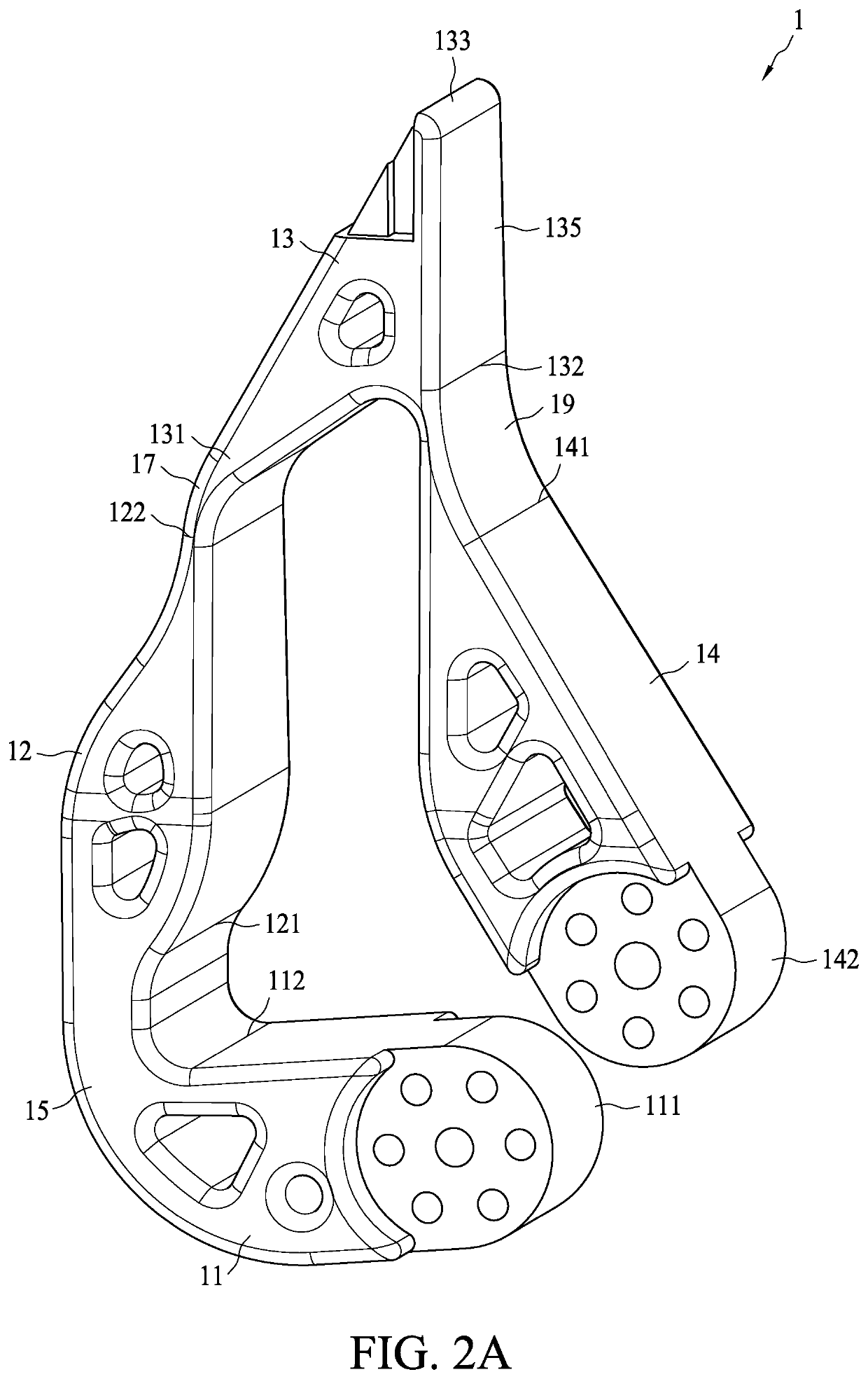

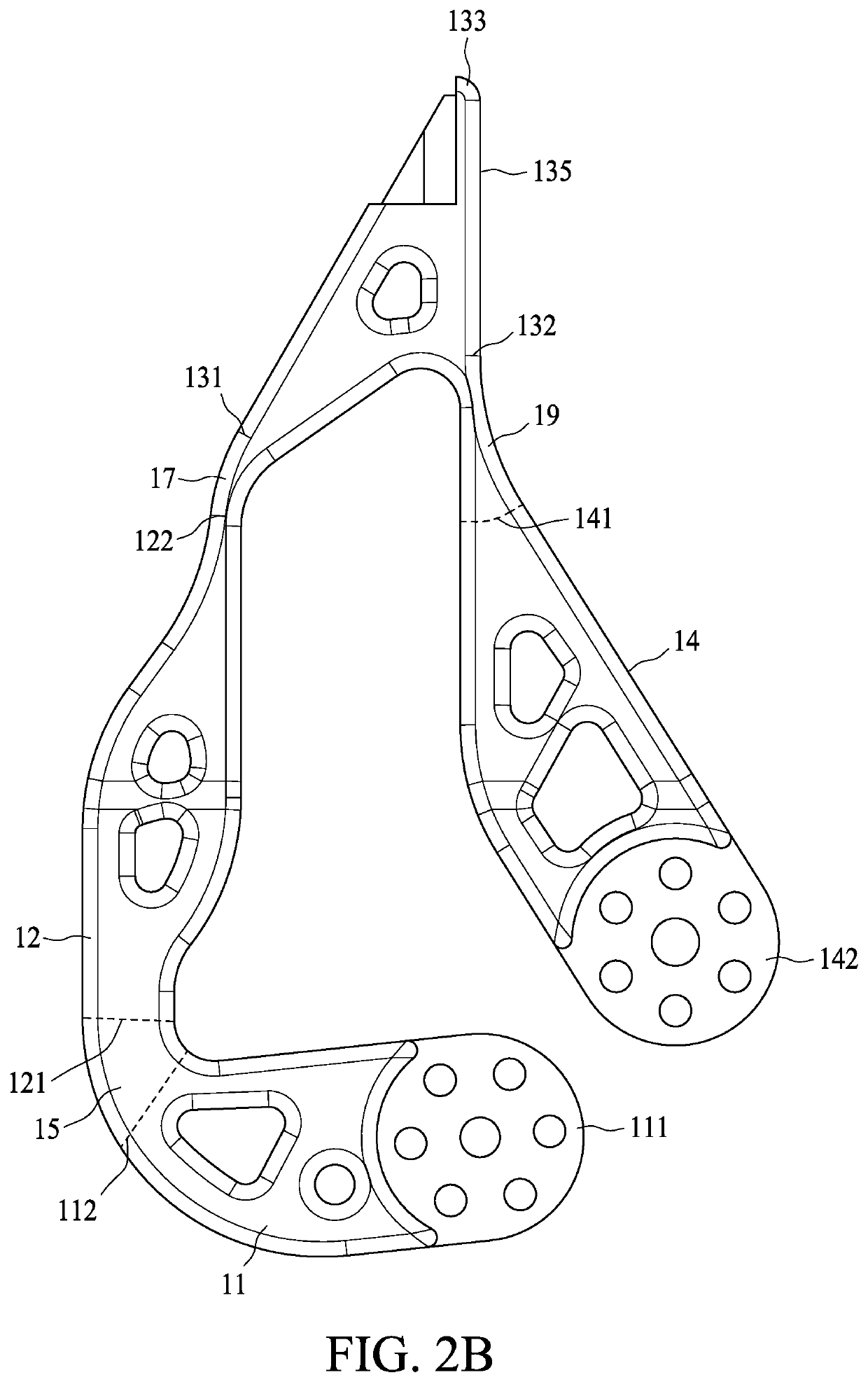

Robotic gripper

The present disclosure relates to a robotic gripper comprising a body and two robotic fingers mounted to the body. Each robotic finger includes a first link, a second link, a third link, a fourth link, a first joint, a second joint and a third joint. The first joint connects the first link and the second link, and the second joint connects the second link and the third link, and the third joint connects the third link and the fourth link. These links and these joints are comprised of elastic material and are formed in one piece.

Owner:AEOLUS ROBOTICS CORP LTD

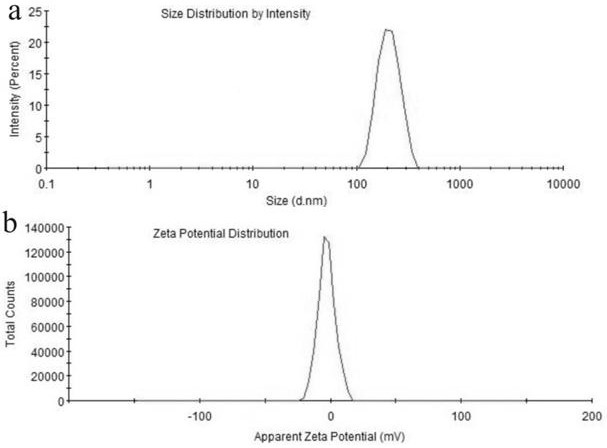

Local analgesic drug entrapped near-infrared response lipid temperature-sensitive gel

ActiveCN113663080AEliminate side effectsReduce complianceDrug photocleavageAerosol deliveryAnalgesics drugsSide effect

The invention discloses a local analgesic drug entrapped near-infrared response lipid temperature-sensitive gel, which can reduce and eliminate the toxic and side effects of the existing temperature-sensitive gel, prolong the slow release period, realize responsiveness and adjustable release, enable a patient to autonomously adjust the administration, greatly improve the treatment effect of pain and reduce the compliance of the patient. The composite drug delivery system is of a grid structure, the liposome is embedded in the system, the average particle size ranges from 150 nm to 200 nm, and the potential is about -2.88 mV; singlet oxygen is generated under the action of near infrared rays, so that a light response release behavior can be realized; the release behavior is first sudden release and then slow release, the slow release effect is obvious, meanwhile, near-infrared response can be achieved, the release rate is increased, and the analgesic concentration of ropivacaine is increased within a certain period of time.

Owner:JILIN UNIV

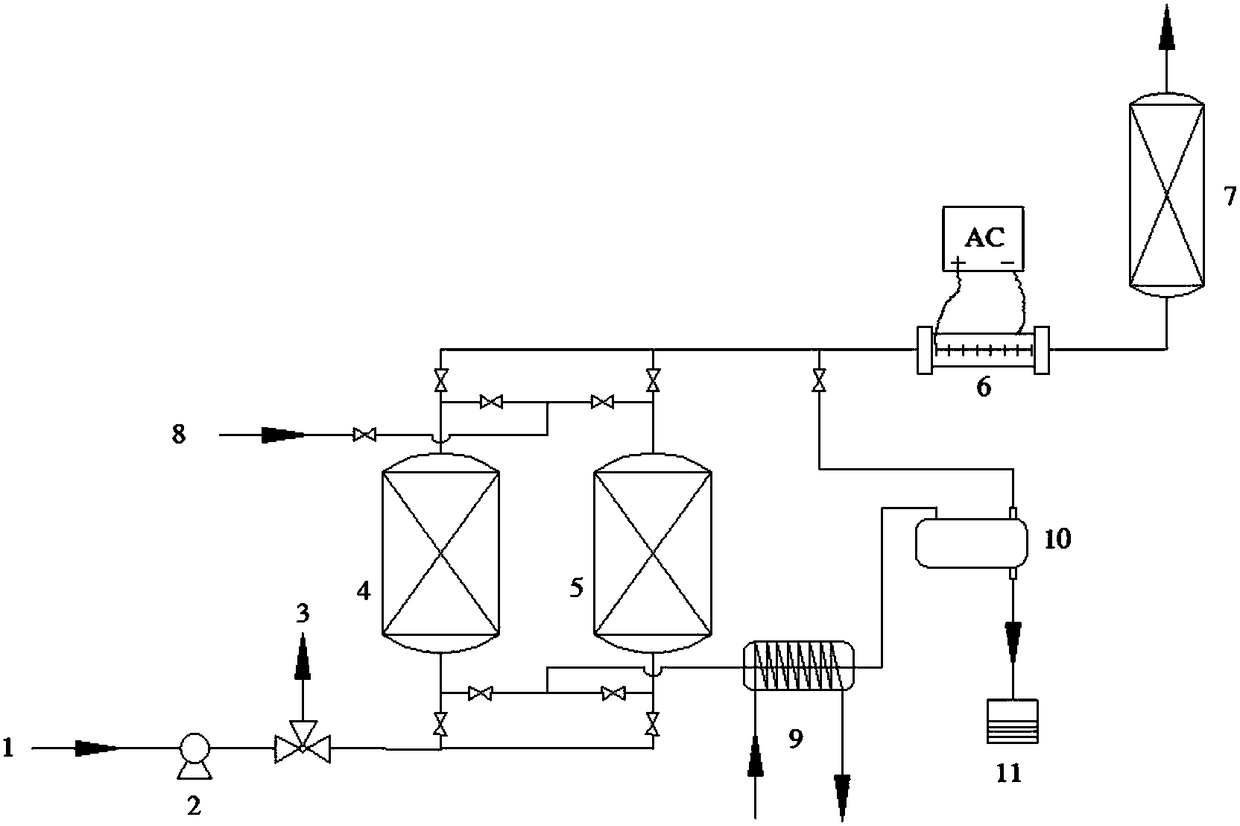

Method for treating waste gases containing CS2 and H2S mixed pollutants

ActiveCN108114570AImprove recycling efficiencyRaise H <sub>2<</sub> Gas treatmentDispersed particle separationCross-linkLow temperature plasma

The invention discloses a method for treating waste gases containing CS2 and H2S mixed pollutants and belongs to the technical field of waste gas treatment. Aiming at waste gases containing CS2 and accompanying with traced H2S discharged in the production process in industries such as synthetic fibers, leather, pharmacy and the like, a treatment method adopting an adsorption-low temperature plasmaoxidation-absorption integrated process is disclosed. A hyper-cross-linked polymeric adsorbent has high selective adsorption capacity on the CS2, the CS2 can be recovered by 99% or higher, and wasteof resources is avoided; and due to low temperature plasma, the trace H2S and CS2 can be efficiently oxidized into CO2, H2O and SO2, foul odor in the waste gas can be completely eliminated, and the SO2 in the tail gas is absorbed with alkali liquor, so that the H2S, CS2 and SO2 can achieve complete up-to-standard discharge.

Owner:NANJING UNIV

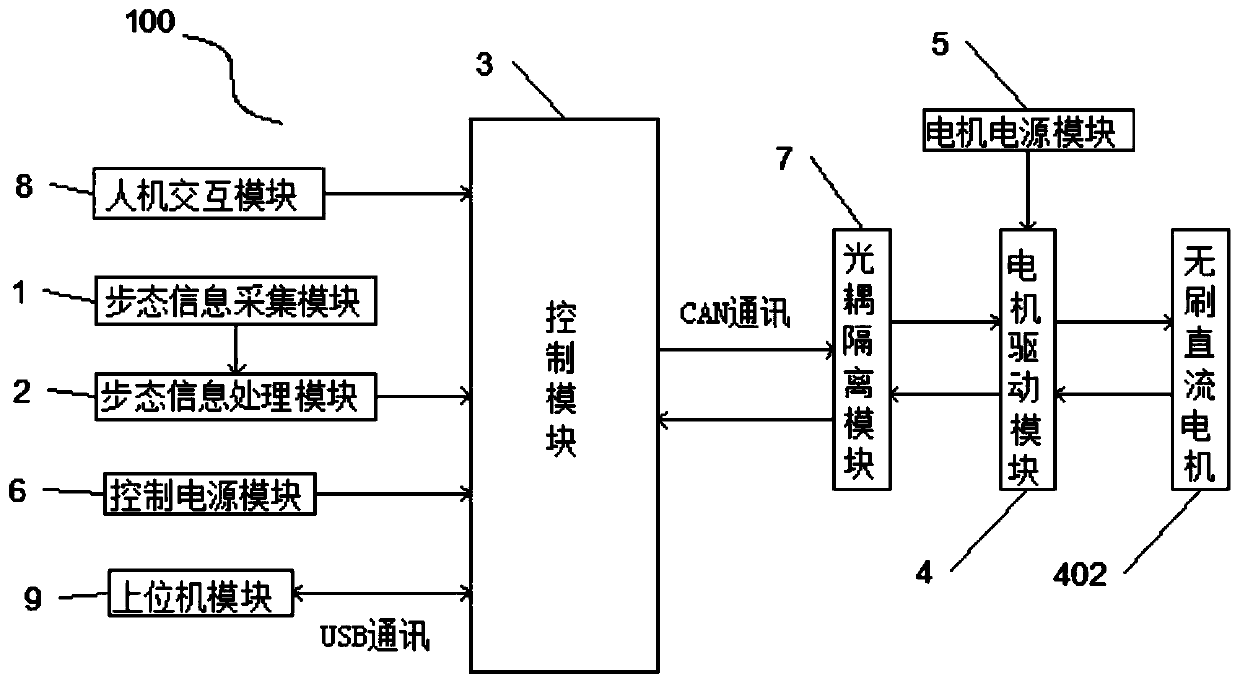

Dynamic hip joint prosthesis control system

InactiveCN111110411ASolve the control lag behind the human body movement intentionAchieve speedProsthesisInformation processingControl signal

The invention relates to the field of rehabilitative prosthetics and orthotics, in particular to a dynamic hip joint prosthesis control system. The dynamic hip joint prosthesis control system comprises a gait information collection module, a gait information processing module, a control module, a motor driving module, a communication module, a motor power supply module, a control power supply module, a photo coupler isolation module and a Kalman filtering module; and the control system receives plantar pressure information and knee joint and hip joint flexion and extension information, collected by the gait information collection module, through the communication module, the received information is processed to generate a control signal, and the motor driving device (module) receives the control signal through the communication module to drive a dynamic hip joint prosthesis to run, so as to drive a patient to walk. The provided dynamic hip joint prosthesis control system has the advantage that strength needed by the patient to walk is reduced so that the patient can walk conveniently.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

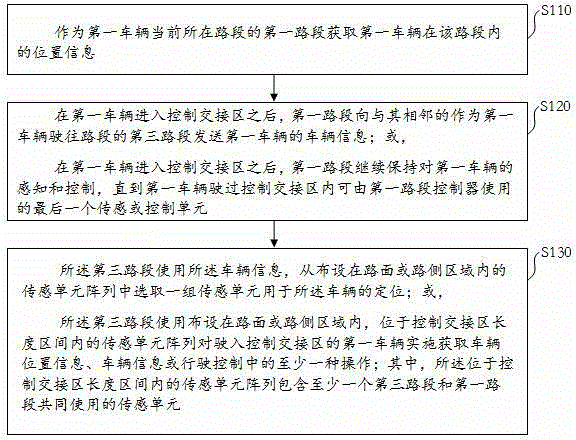

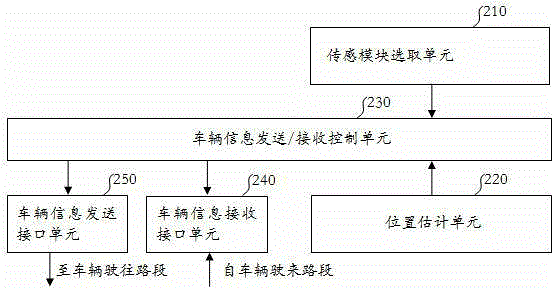

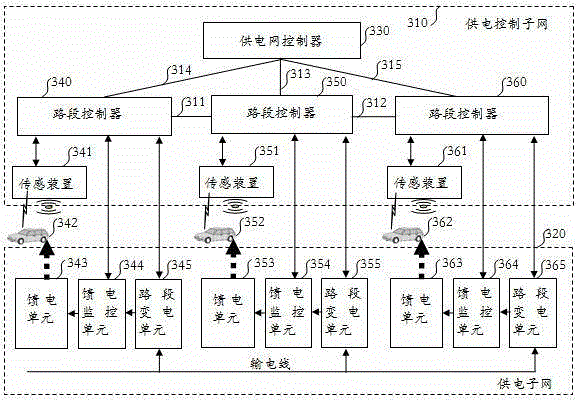

Vehicle zone-crossing control method, device and system

InactiveCN105313708AFast transferImprove continuityDetection of traffic movementPower supply linesElectricityEngineering

The invention provides a vehicle zone-crossing control method, device and system and used for overcoming one or more defects that in the prior art, it is difficult to guarantee consistency and compliance of vehicle electricity receiving / vehicle sensing before and after zone crossing. The vehicle zone-crossing control method includes the steps that after a first vehicle enters a control cross connecting zone, a first road segment sends vehicle information of the first vehicle to a third road segment which is adjacent to the first road segment and to which the first vehicle drives; or, after the first vehicle enters the control cross connecting zone, the first road segment continues sensing and control over the first vehicle till the first vehicle drives out of the control cross connecting zone; the vehicle information is used by the road segment to which the vehicle drives, and a sensor element group is selected from a sensor element array arranged in the road surface zone or a road side zone for positioning the vehicle; or the road segment to which the vehicle drives uses the sensor element array which is arranged in the road surface zone or the road side zone and located in a length range of the control cross connecting zone for conducting one or more operation of obtaining the vehicle position information, obtaining the vehicle information or conducting driving control on the first vehicle driving into the control cross connecting zone. By means of the method and device, rapid transmission of vehicle information between road segments can be achieved, consistency and compliance of vehicle electricity receiving / vehicle sensing before and after zone crossing can be achieved, and practicability is achieved.

Owner:刁心玺

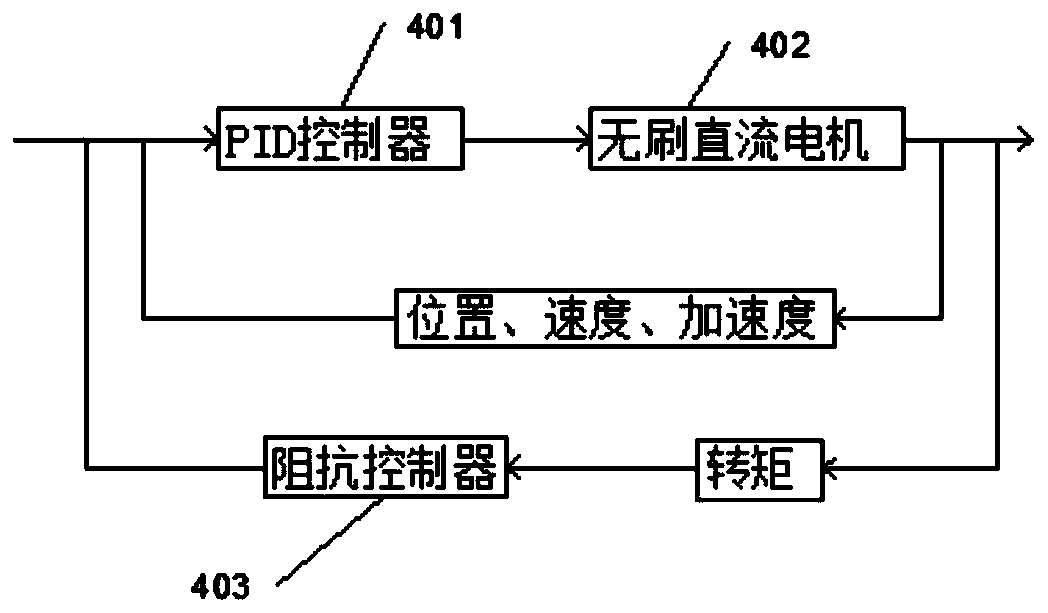

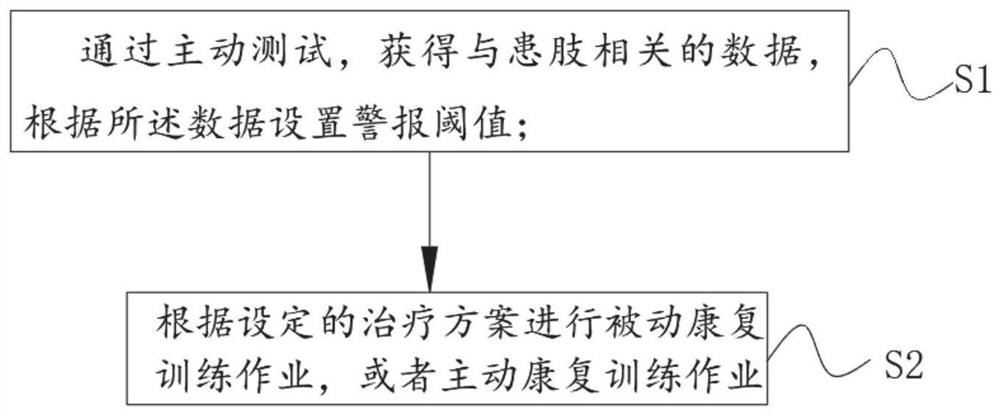

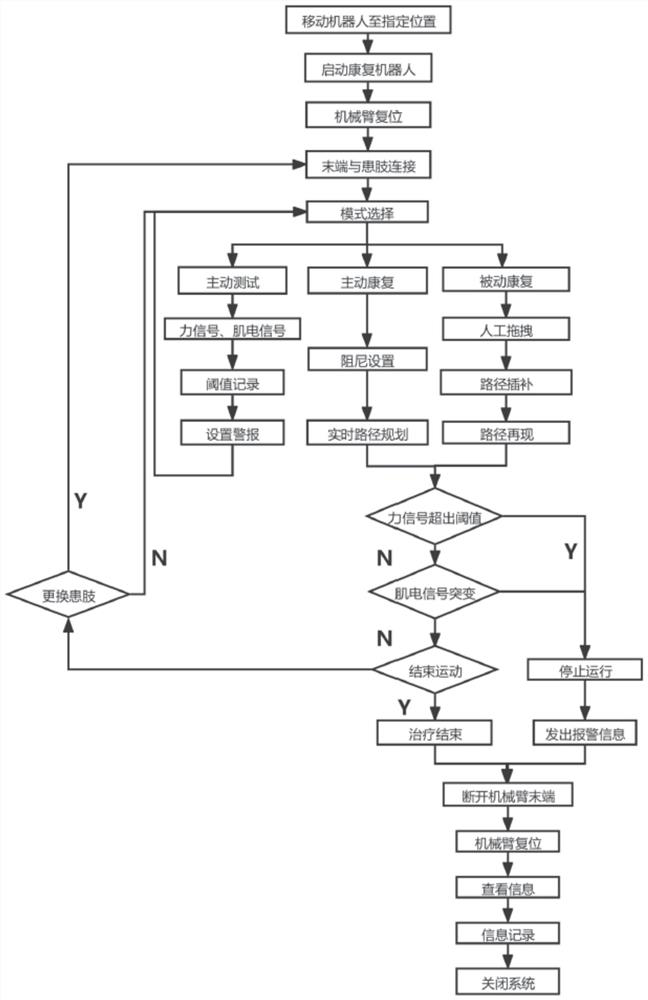

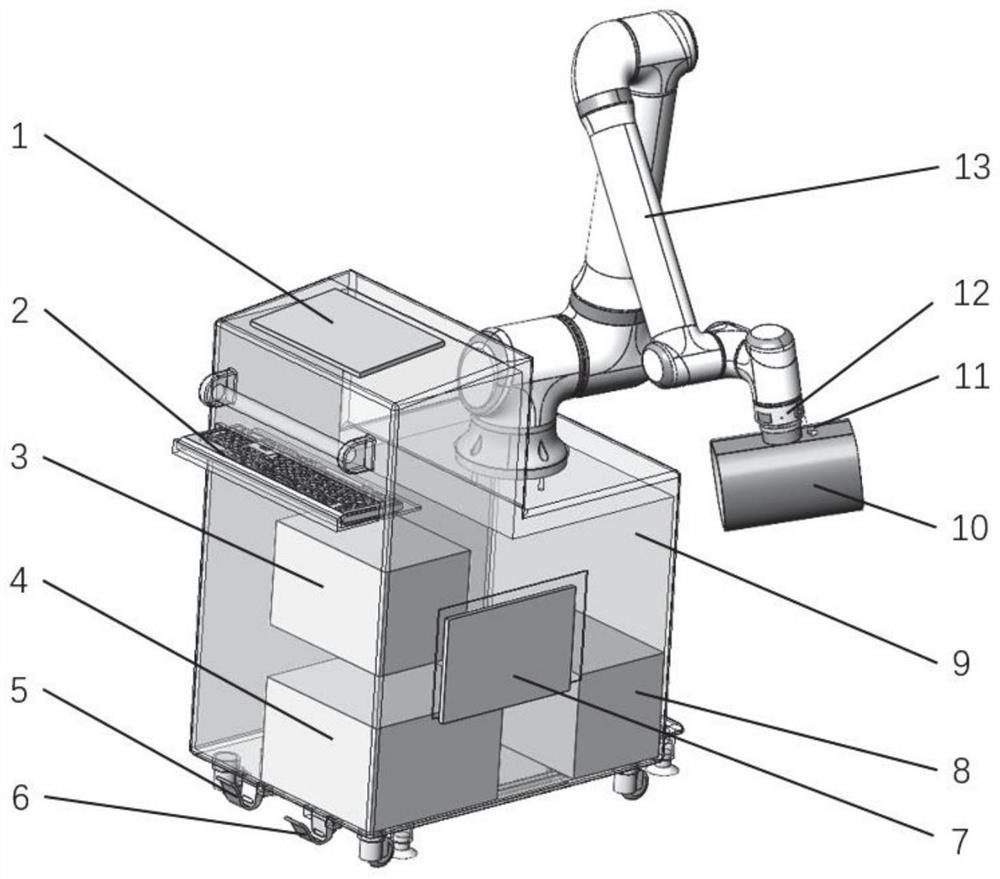

Upper and lower limb rehabilitation robot, control method, medium and computer equipment

PendingCN114652566APrecise rehabilitation training processLess training and hands-onDiagnosticsChiropractic devicesComputer deviceMedical practitioner

The invention relates to an upper and lower limb rehabilitation robot, a control method, a medium and computer equipment. The upper and lower limb rehabilitation robot comprises a mechanical arm and a control system thereof, and the execution tail end of the mechanical arm is provided with a quick-release clamp, a six-dimensional force sensor and an electromyographic signal sensor; the quick-release clamp is used for being connected with an affected limb; the control method comprises the steps that data related to an affected limb is obtained through active testing, and an alarm threshold value is set according to the data; according to a set treatment scheme, the mechanical arm is controlled to drive the affected limb to move along a set path for passive rehabilitation training, or the affected limb overcomes damping force to drive the mechanical arm to move along the set path for active rehabilitation training. When the moving path of the affected limb deviates from the set path, the affected limb moves back to the set path through self-adaptive impedance control. The device can replace or assist doctors in upper and lower limb rehabilitation training, provides a more personalized and more accurate upper and lower limb rehabilitation scheme, and meets the requirements of patients for rehabilitation training.

Owner:SOUTHEAST UNIV +1

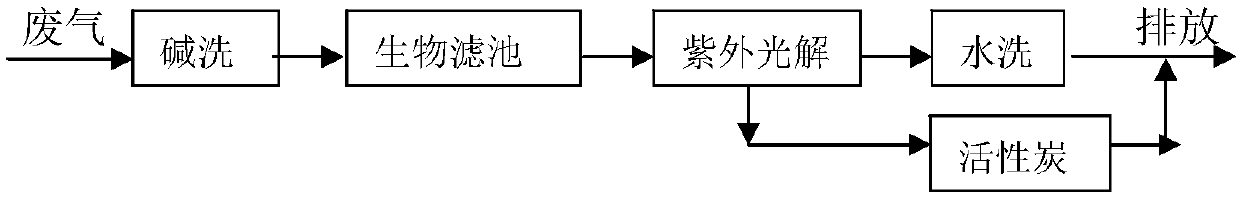

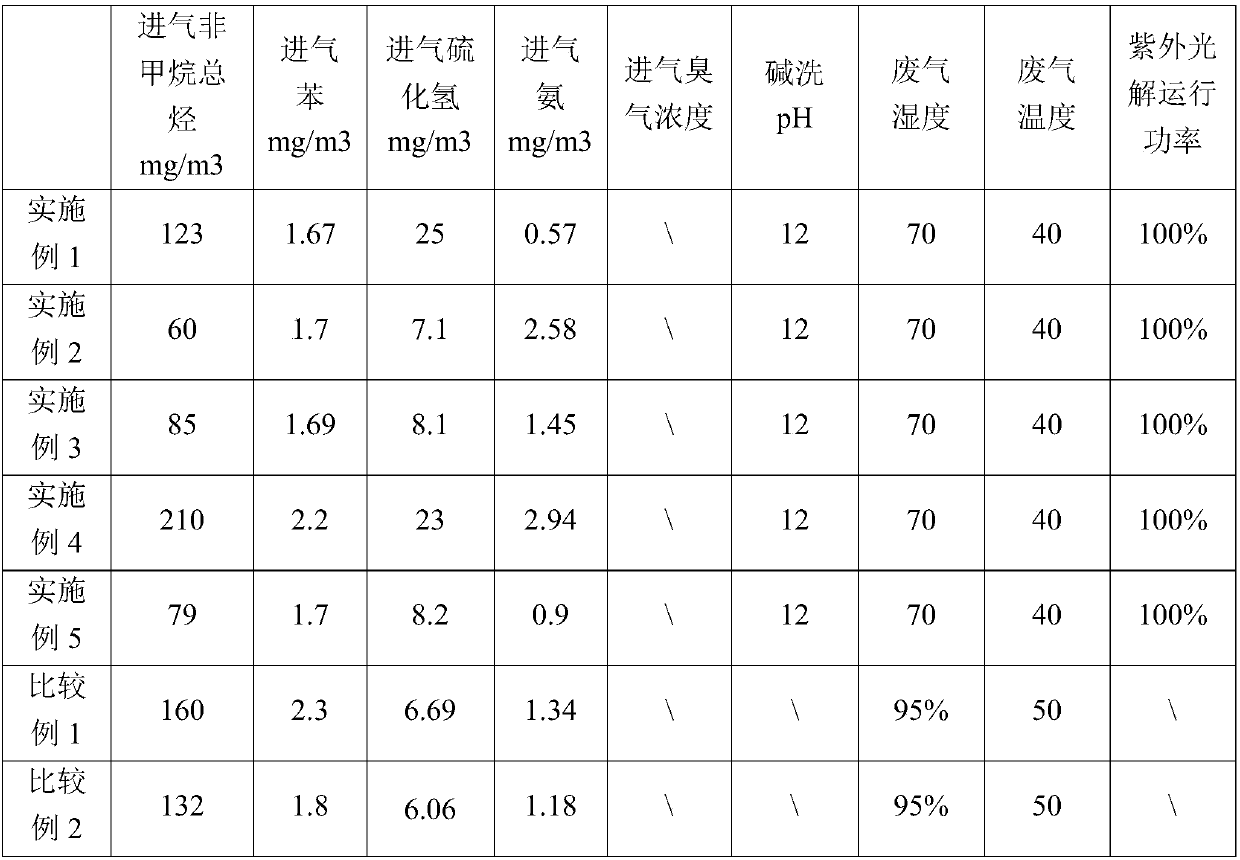

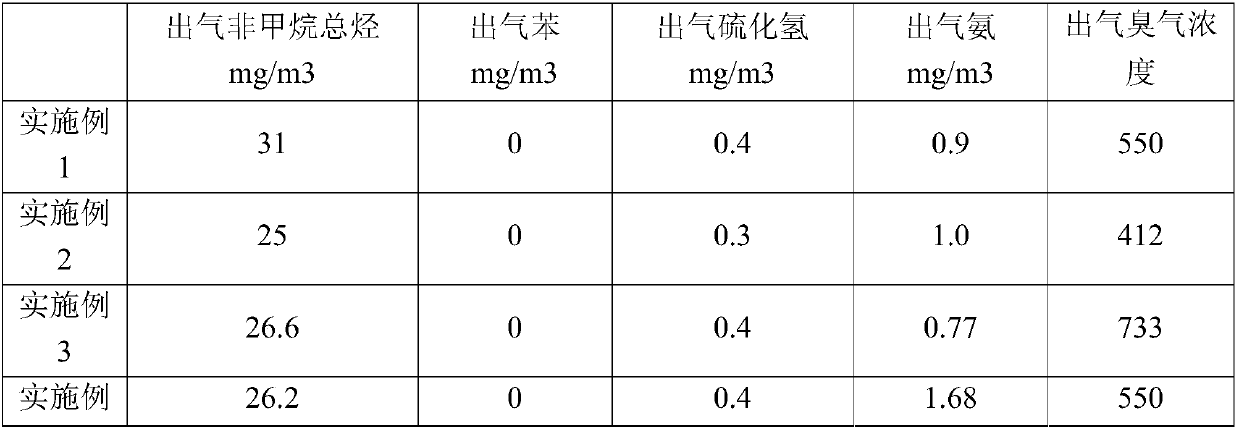

Method for treating waste gas of refined terephthalic acid sewage plant

PendingCN111318146AAchieve removalAchieve complianceGas treatmentDispersed particle separationActivated carbonBiological filter

The invention belongs to the technical field of waste gas treatment, and particularly relates to a treatment method for waste gas generated in a PTA sewage plant. Waste gas generated by a PTA sewage treatment plant is treated by adopting a combined process of alkali washing, biological filter processing, ultraviolet photolysis, water washing and activated carbon processing, and meanwhile, a dehumidification and demisting pretreatment facility is additionally arranged before an ultraviolet photolysis process, and thus the ultraviolet photolysis system can perform oxidation reaction under optimal temperature and humidity conditions. Compared with the prior art, the method has the beneficial effects that various indexes of PTA sewage plant waste gas, which is difficult to process, reach the latest emission standard requirements (national standard GB 31571-2015 and Shanghai standard DB31 / 1025-2016) through a complete set of combined treatment process.

Owner:CHINA PETROLEUM & CHEM CORP +1

High arsenicum gold ore roasting smoke gas treatment system and method for recovering arsenicum and desulfurating

ActiveCN102350163BEmission reductionSolve the problem of reducing the recovery rate of arsenic trioxideCombination devicesSublimationGold depositWater jacket

The invention discloses a high arsenicum gold ore roasting smoke gas treatment system and a method for recovering arsenicum and desulfurating, which can be used for mainly solving the problems that the arsenicum resource in the high arsenicum gold ore roasting smoke is wasted, and the environment is polluted by a large amount of hazardous wastes containing the arsenicum generated in wet processing. The high arsenicum gold ore roasting smoke gas treatment system comprises an arsenicum recovery system which comprises a settling chamber, a primary cyclone dust collector, a secondary cyclone dust collector, an electric dust collector, a water jacket cooler, a water circulating pump, a water circulating pond and a cloth bag arsenic collector. The high arsenicum gold ore roasting smoke gas treatment system provided by the invention also comprises a desulfurization system; and the method for recovering the arsenicum provided by the invention comprises the following steps of roasting smoke and dedusting, smoke drying cooling and arsenicum collecting by a cloth bag. The desulfurating method comprises the steps of rushing and washing. The invention has the advantages of being stable in process, high in arsonium recovery rate, high in product purity, low in gypsum arsenicum content and less in environmental pollution.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Robotic gripper

ActiveUS11312027B2Avoid time costLow costGripping headsPhysical medicine and rehabilitationRobot hand

The present disclosure relates to a robotic gripper comprising a body and two robotic fingers mounted to the body. Each robotic finger includes a first link, a second link, a third link, a fourth link, a first joint, a second joint and a third joint. The first joint connects the first link and the second link, and the second joint connects the second link and the third link, and the third joint connects the third link and the fourth link. These links and these joints are comprised of elastic material and are formed in one piece.

Owner:AEOLUS ROBOTICS CORP LTD

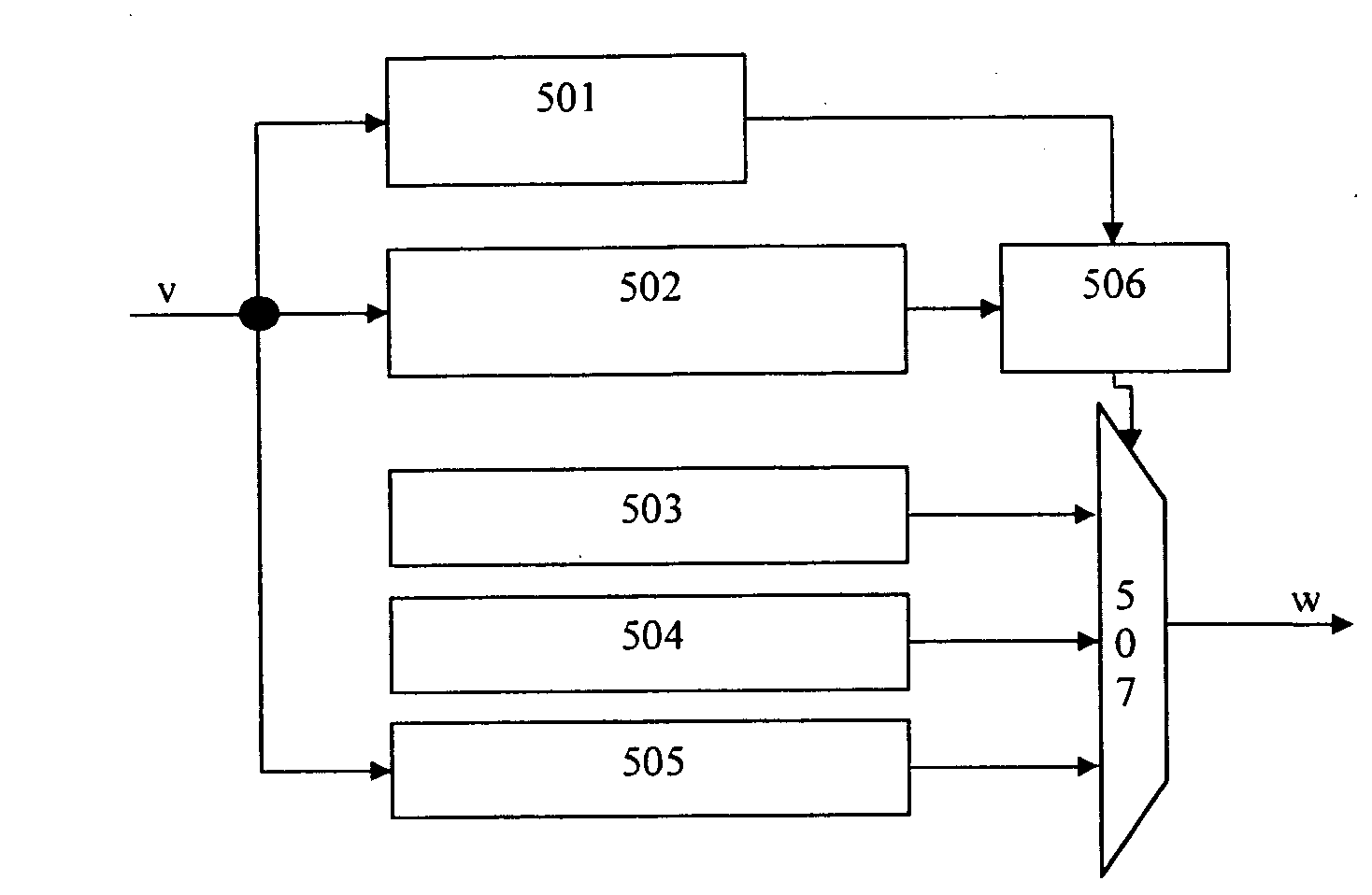

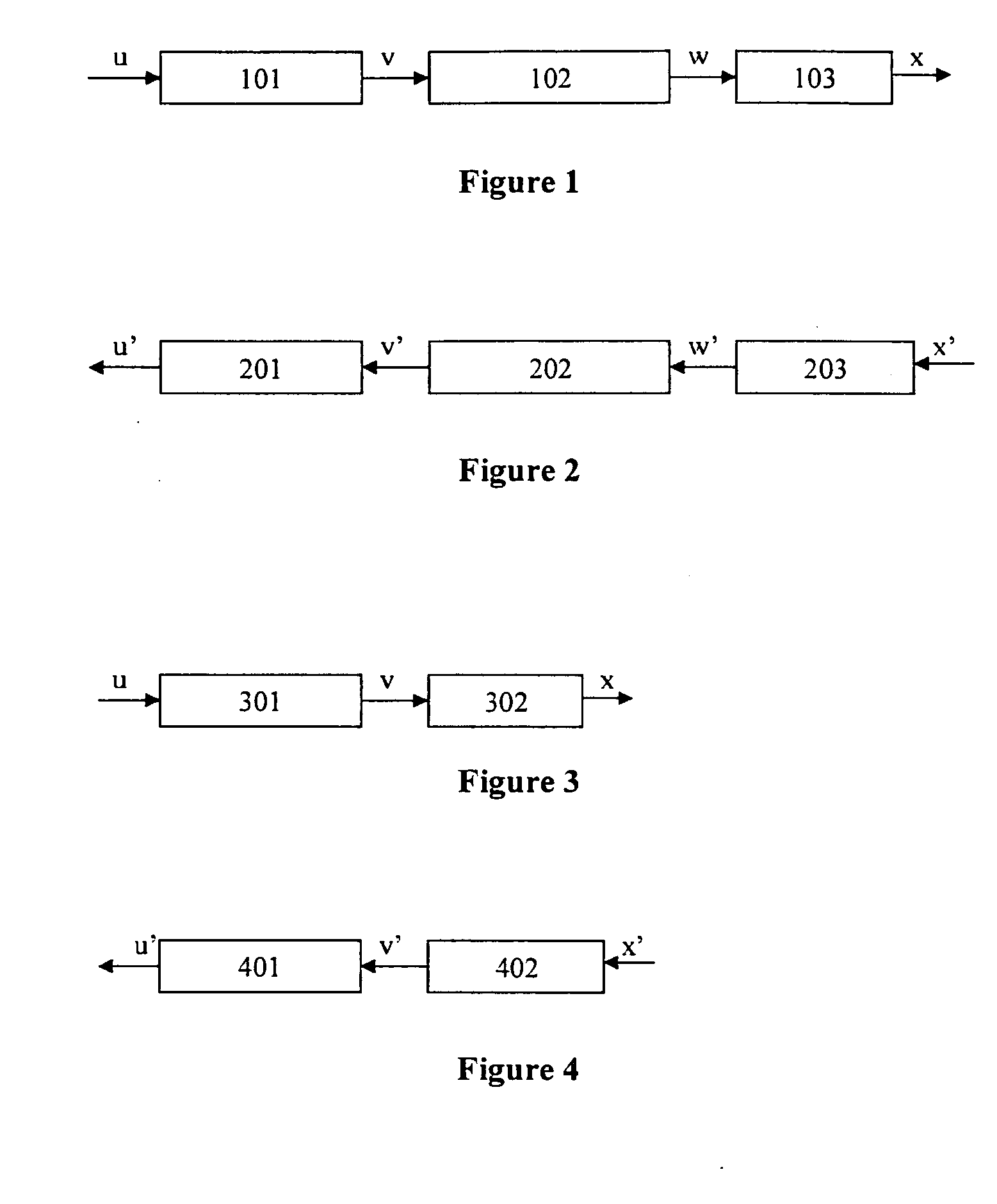

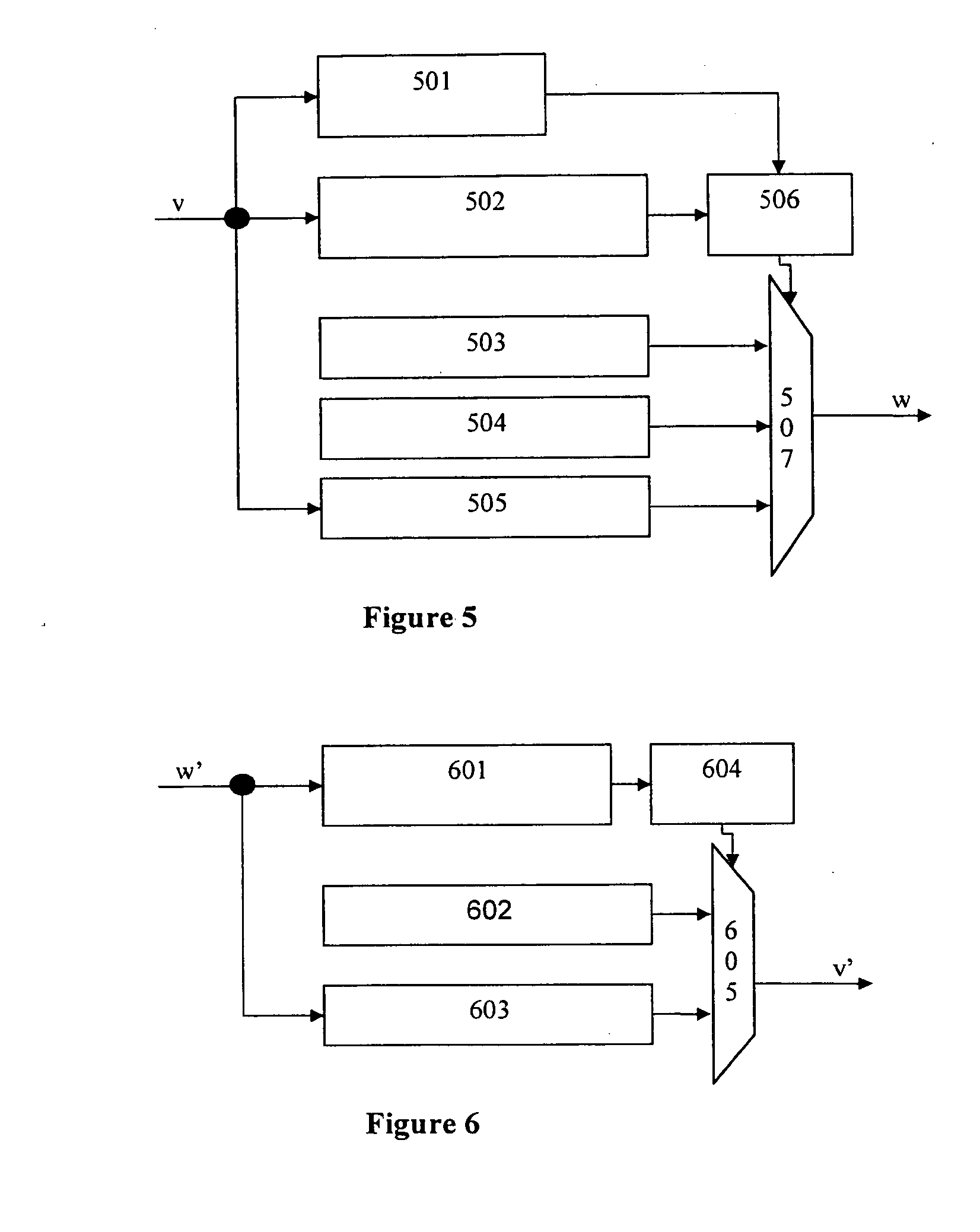

Method and apparatus for channel coding and decoding

InactiveUS20080272940A1Achieve complianceIndividual digits conversionCoding detailsComputer scienceChannel encoding

In a channel encoder comprising a dk-encoder stage and a precoding stage, obeyance of a repeated minimum transition runlength constraint is achieved because, between the dk-encoder and the precoder, data are passed through an RMTR encoder which replaces occurrences of a forbidden pattern by a current replacement pattern having the same length as the forbidden pattern. By appropriately selecting current replacement patterns from a predefined set of two different replacement patterns, DC-control can be achieved for the encoder output. The corresponding decoder is described, which also employs pattern replacement.

Owner:THOMSON LICENSING SA

Wet purification method and device for coal oxygen-enriched fly ash melting tail gas

PendingCN114353108AAchieve complianceLess investmentLighting and heating apparatusIndirect carbon-dioxide mitigationElectrostatic precipitatorFlue gas

The invention discloses a wet purification method and device for coal oxygen-enriched fly ash melting tail gas, and belongs to the technical field of purification. High-temperature tail gas released by the coal oxygen-enriched fly ash melting furnace is cooled to 120-150 DEG C or below through a quench tower; sequentially entering a water washing tower for dust pre-removal and acid removal, and cooling to below 80 DEG C; deeply removing dust through a wet electrostatic dust collector; carrying out denitration, desulfurization and demercuration through an oxidation absorption tower, and cooling to 50-70 DEG C; further deacidification is carried out through an alkaline washing tower, and finally purified tail gas is discharged into a chimney through an induced draft fan; and respectively purifying the wastewater discharged from the water washing tower and the oxidation absorption tower to obtain metal chlorine salt, sulfate and nitrate, and recycling the metal chlorine salt, sulfate and nitrate. According to the invention, the advantages of deacidification, denitration, demercuration and dust removal integrated cooperative treatment can be fully and effectively exerted, and the flue gas can reach the standard and even be discharged in an ultra-clean manner; recyclable salts are obtained through wastewater purification treatment, and resource utilization is achieved.

Owner:BEIJING RUNYU ENVIRONMENTAL PROTECTION ENG

Method of integrated dust removal and desulfur of smoke and its equipment

InactiveCN1190256CAchieve complianceAchieve clean emissionsDispersed particle filtrationIt equipmentControl system

A process for dedusting and desulfurizing fume at the same time includes such steps as granulating the mixture of catalyst, desulfurizing agent and water-bearing agent, moistening and activating by high-temp. steam, reaction and adsorption in fume and pre-reacting chamber, entering bag-type deduster along with fume to generate a granule layer on the filter material, further removing dust and adsorbing SO2, and feeding the dust in ash cabin back to the circulating ash cabin for cyclic use. Its advantages are high efficiency, and synchronization of dedusting with desulfurizing.

Owner:TSINGHUA UNIV +1

Method for reducing the emission of volatile organic compounds made of wood materials, and wood materials

ActiveUS10596720B2Reduced responseEmission reductionFlat articlesDomestic articlesBisulphite saltCellulose

The present invention relates to a method for producing wood materials from lignocellulose-containing crushed products, in particular for producing wooden insulating panels or OSB boards, wherein in order to decrease or reduce the emission of volatile organic compounds (VOC) and, if relevant, very volatile organic compounds (VVOC), including terpenes, acids and aldehydes, said wood materials are treated with a combination of additives during production. According to the invention, the treatment is carried out with a first component made of porous carbon and a second component, a hydrogen sulphite salt. The invention further relates to wood materials that can be obtained using the method according to the invention, having reduced emissions of VOCs, including terpenes, acids and aldehydes. Finally the present invention relates to the use of a combination of additives, formed by a first component with a porous carbon and a second component made of hydrogen sulphide salt, for decreasing or reducing the emission of VOCs from wood materials during or after production thereof from lignocellulose-containing crushed products.

Owner:KRONOTEC

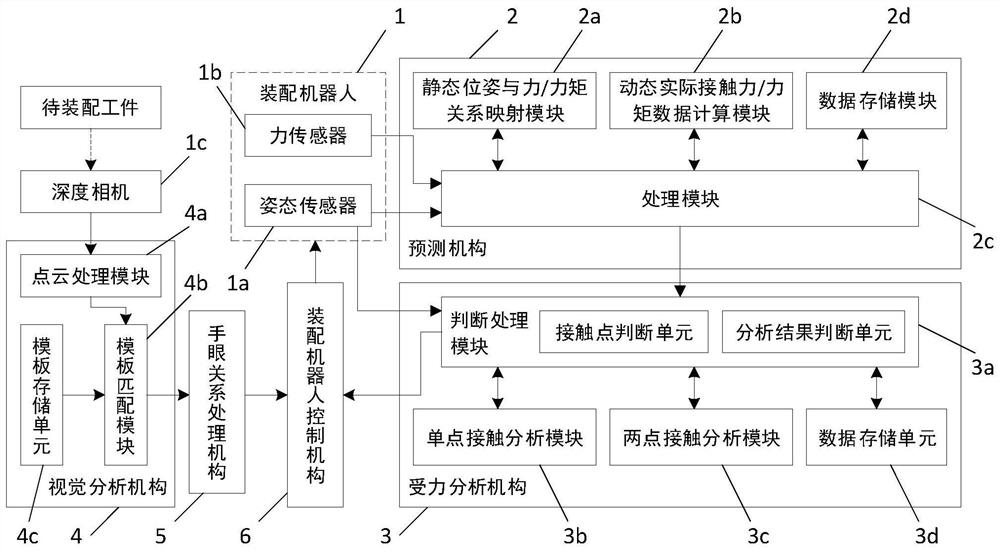

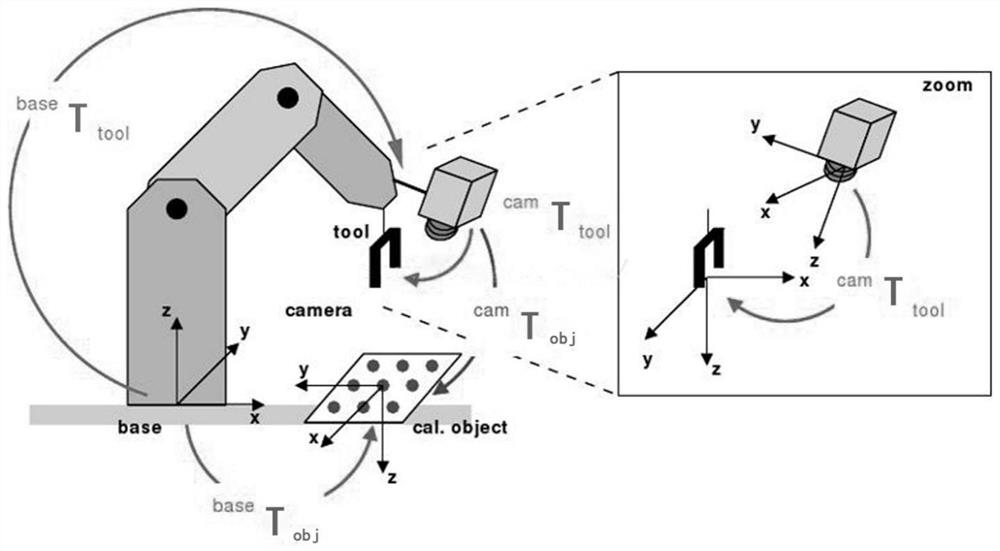

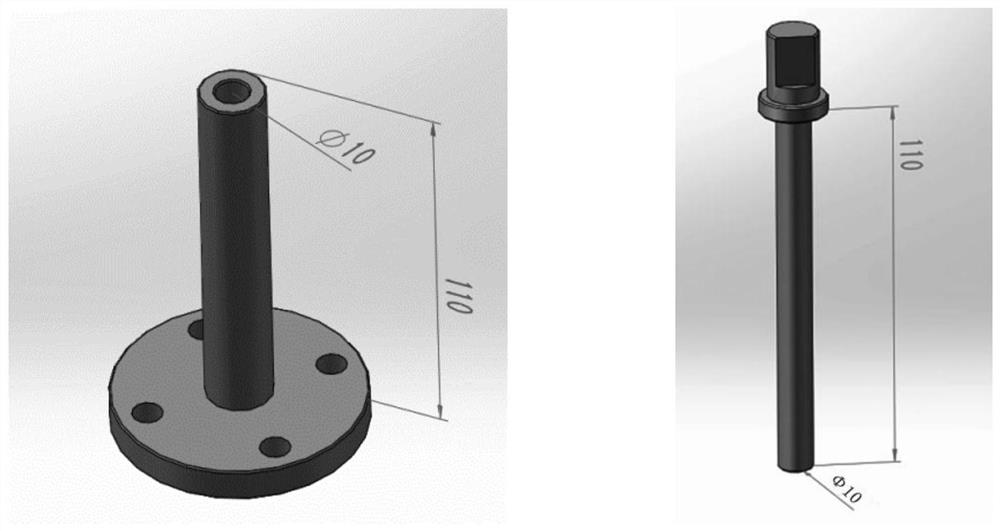

Compliant assembly system and method integrating 3D vision and contact force analysis

ActiveCN109940605BPrecisely formulatedAchieve complianceProgramme-controlled manipulatorMathematical modelSimulation

The invention discloses a compliant assembly system and method that integrates three-dimensional vision and contact force analysis, establishes a compliant assembly platform that integrates three-dimensional vision, a six-dimensional force sensor, and a six-degree-of-freedom robot system. Convert it into the position information of the assembly point, and then calibrate the position through the hand-eye relationship processing mechanism, so that the control mechanism of the assembly robot can accurately formulate the action. During the action execution process, by establishing an accurate mathematical model, and then solving the parameters through the collected data , the data pairs collected under different conditions will be used to train the neural network model and establish its mapping relationship, to achieve accurate prediction of force and moment, and after the prediction, accurately analyze whether the assembly is accurate through the force of the large aspect ratio shaft during the assembly process There are deviations, thereby providing analytical support for precise control of assembly movements.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

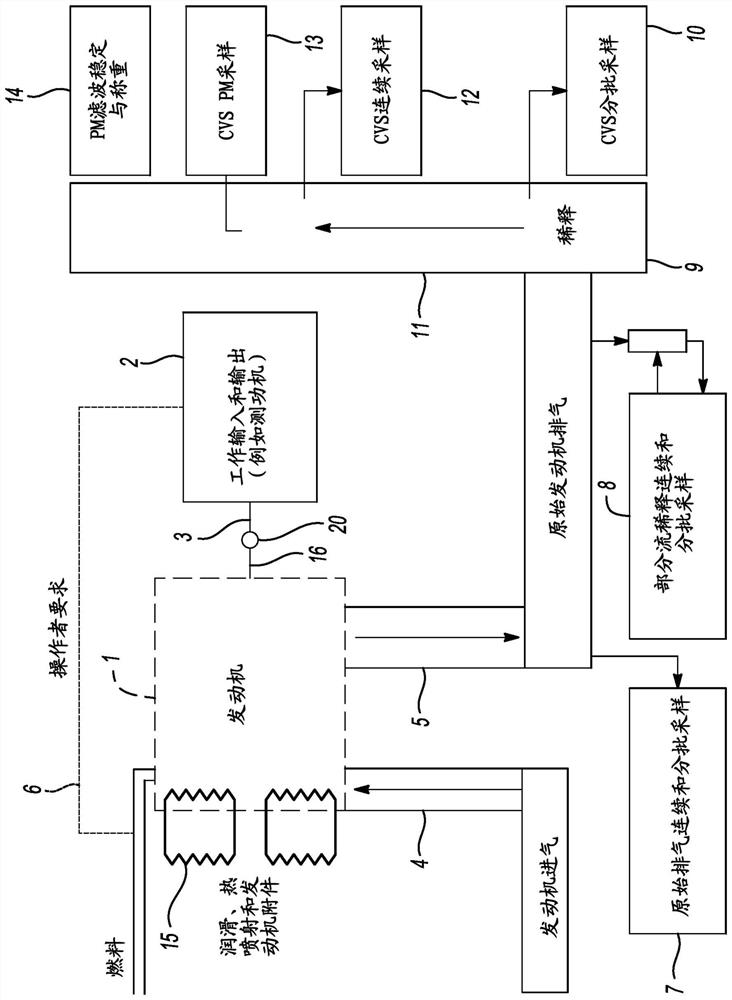

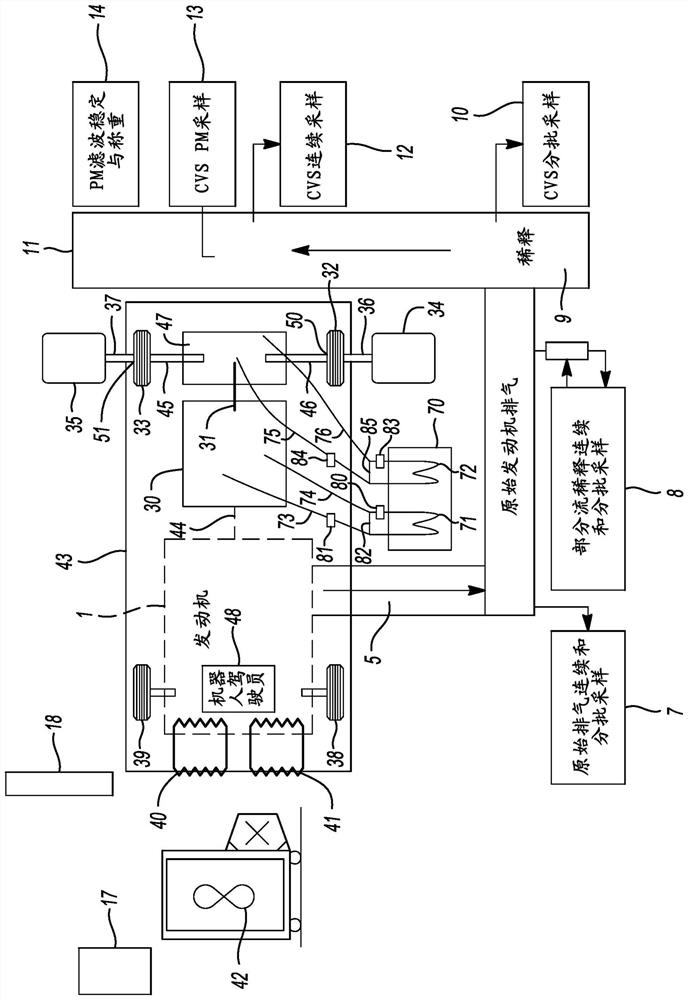

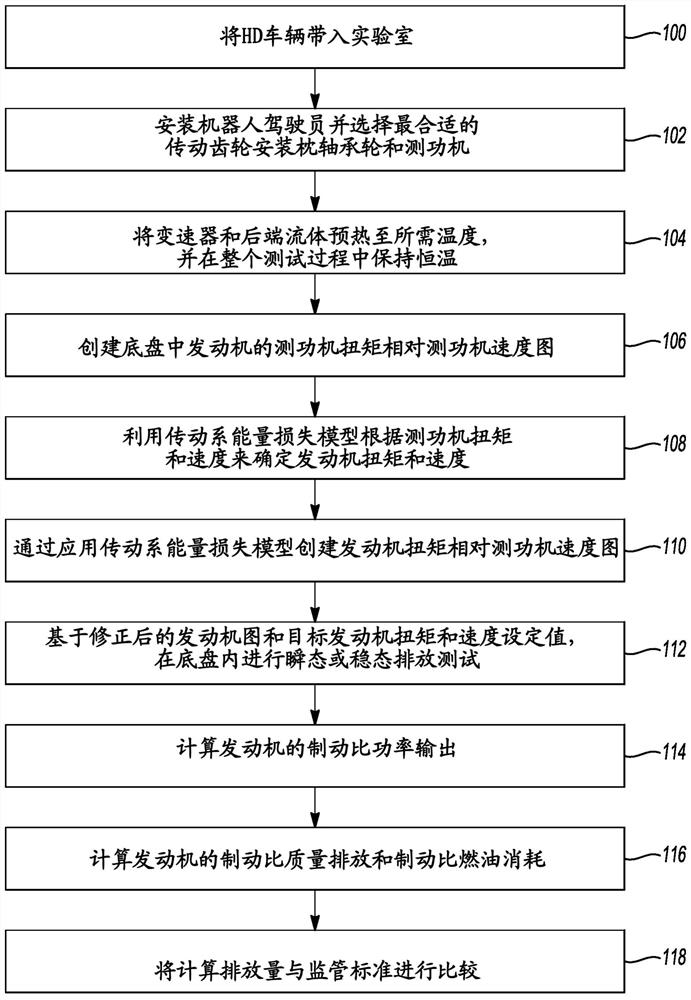

Heavy duty engine regulatory testing apparatus and method

PendingCN114072653AAchieve complianceInternal-combustion engine testingMachine gearing/transmission testingHeat transmissionControl theory

A method for testing an engine in a vehicle includes arranging a bath separated from the vehicle and configured to cool a driveline component of the vehicle, adjusting a temperature of the driveline component to a target temperature, and responsive to the driveline component achieving the target temperature, operating the engine according to a mapping procedure, and controlling the bath to maintain the temperature of the driveline component at the target temperature during the operating. The method further includes measuring heat transfer from the driveline component to the bath during the operating, and calculating torque loss or energy loss of the driveline component during the operating based on the heat transfer.

Owner:HORIBA INSTR

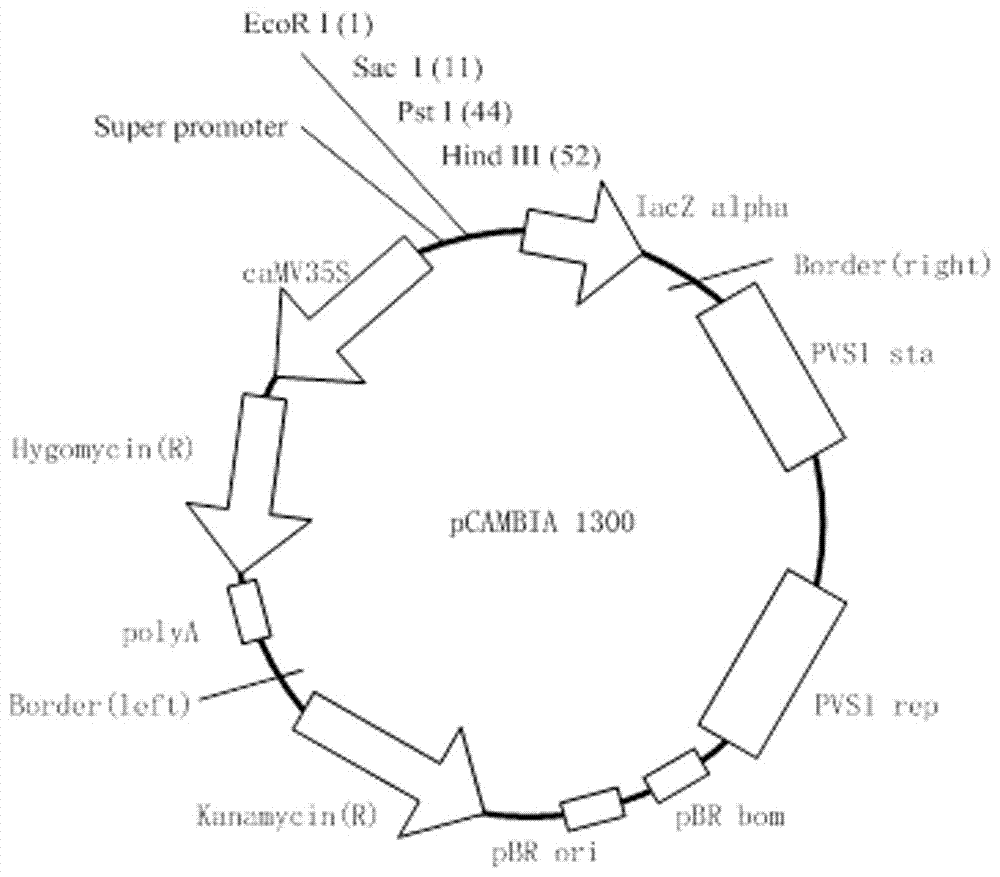

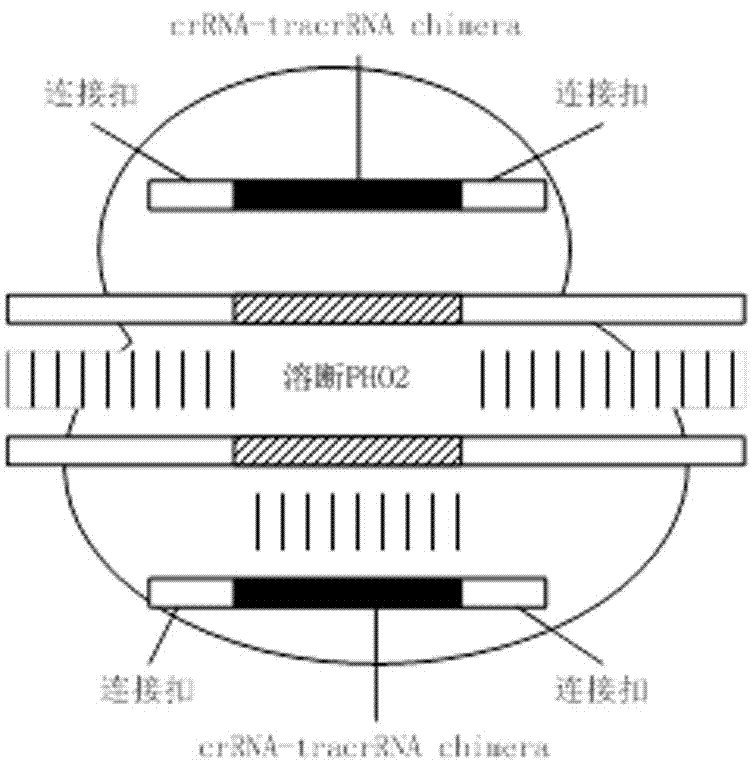

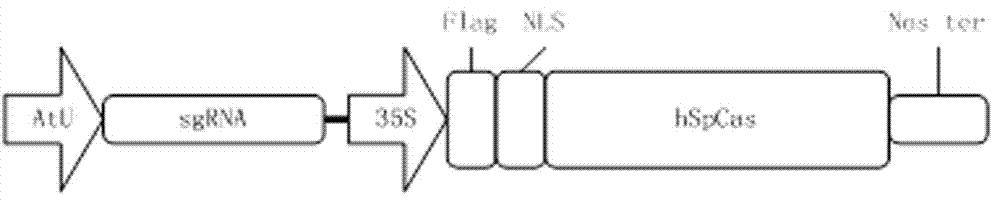

Method of improving phosphorus-enriching ability of aquatic plant

InactiveCN106868040AIncreased rate of phosphorus uptakeAchieve compliancePlant peptidesFermentationTranscription factorGenetically modify

The invention relates to a method of improving phosphorus-enriching ability of an aquatic plant. The method improves the phosphorus-enriching ability by increasing overexpression of a PHR1 transcription factor and wiping out a PHO2 gene. The method specifically comprises the following two steps: (1) increasing overexpression of the PHR1 transcription factor; and (2) wiping out the PHO2 gene. By genetically modifying the aquatic plant and copying and cultivating the aquatic plant by means of the method, the aquatic plant which reaches a certain quantity is placed in a to-be-repaired phosphorus-enriching water body to excessive absorb phosphorus in the water body; and in the absorption process, vegetables are bred massively, so that the phosphorus-absorbing rate is increased, and therefore, phosphorus meeting the standard is realized.

Owner:ZHEJIANG JUNE5 ENVIRONMENT TECH CO LTD

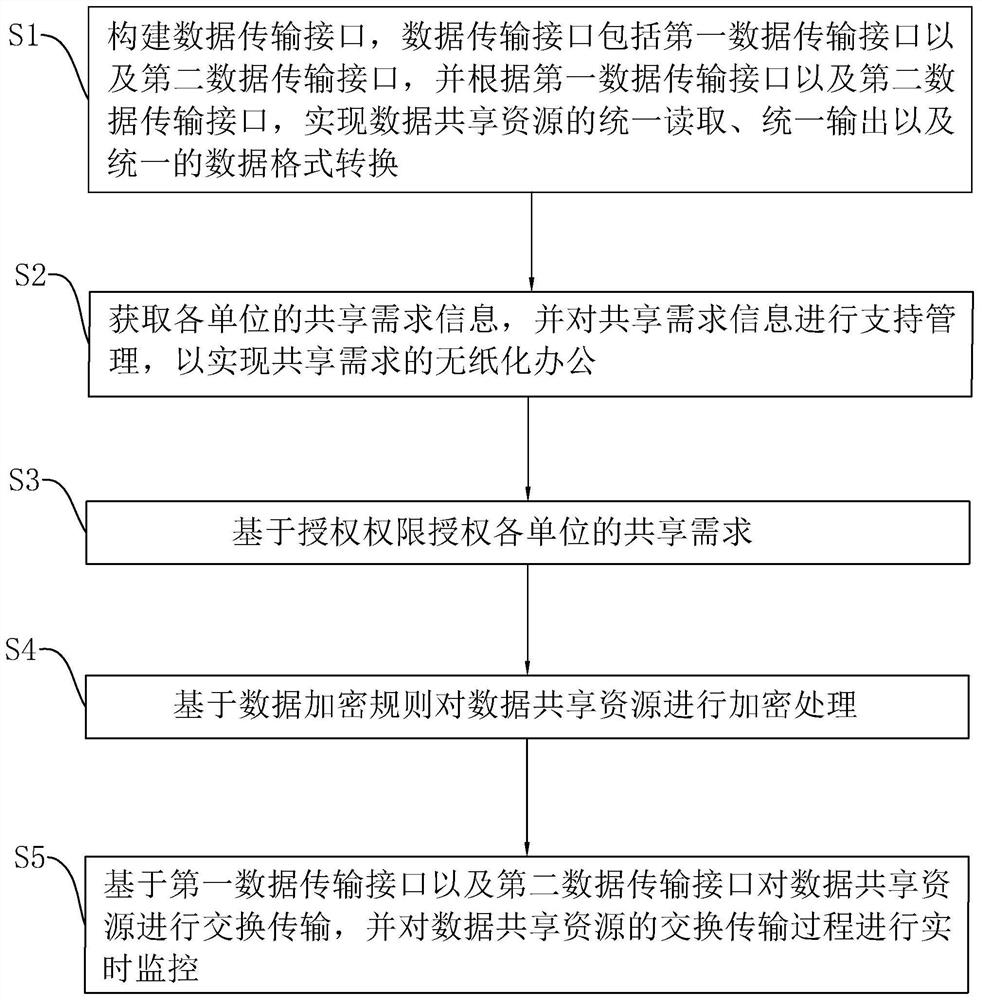

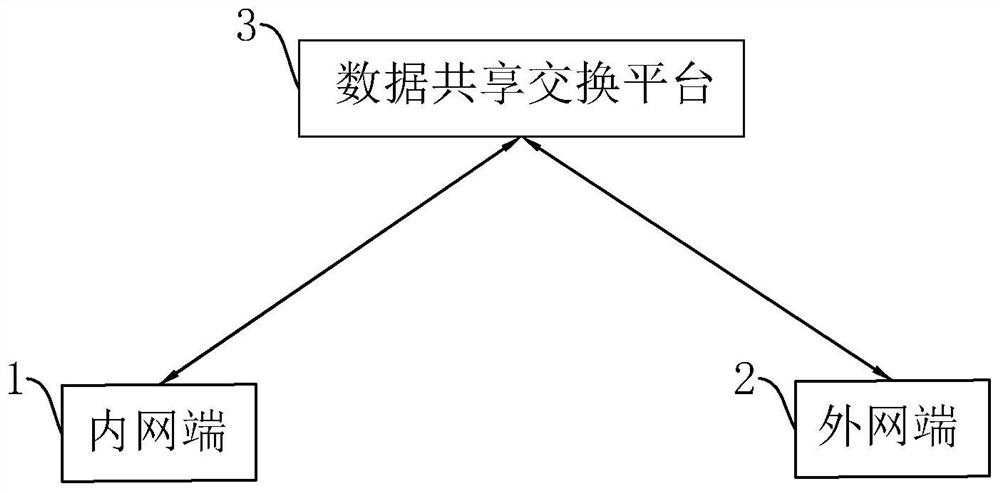

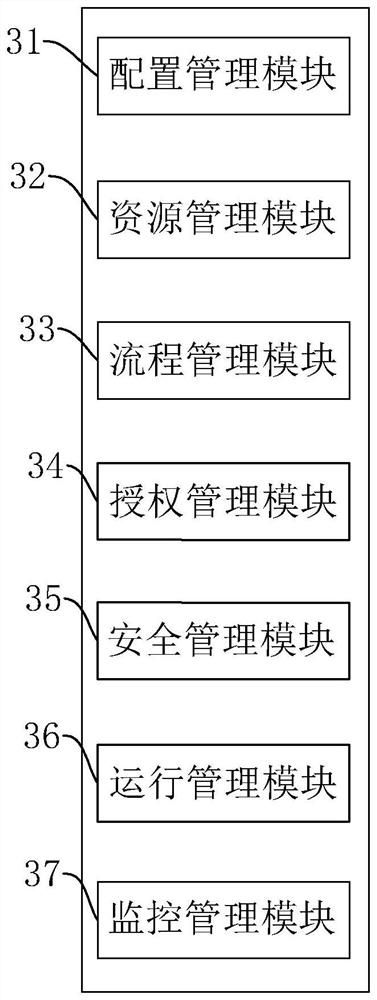

Network security data interaction method, system and device and storage medium

PendingCN114443594AAdd encrypted transmissionEnhanced Access ControlDigital data information retrievalDigital data protectionEngineeringData transmission

The invention relates to the field of data interaction, in particular to a network security data interaction method, system and device and a storage medium, the method comprises the following steps: constructing data transmission interfaces, the data transmission interfaces comprising a first data transmission interface and a second data transmission interface, and according to the first data transmission interface and the second data transmission interface, performing data interaction on the first data transmission interface and the second data transmission interface; unified reading, unified output and unified data format conversion of data sharing resources are realized; acquiring sharing demand information of each unit, and performing support management on the sharing demand information to realize paperless office of sharing demands; authorizing the sharing demand of each unit based on the authorization authority; carrying out encryption processing on the data sharing resource based on the data encryption rule; and carrying out exchange transmission on the data sharing resources based on the first data transmission interface and the second data transmission interface, and carrying out real-time monitoring on the exchange transmission process of the data sharing resources.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

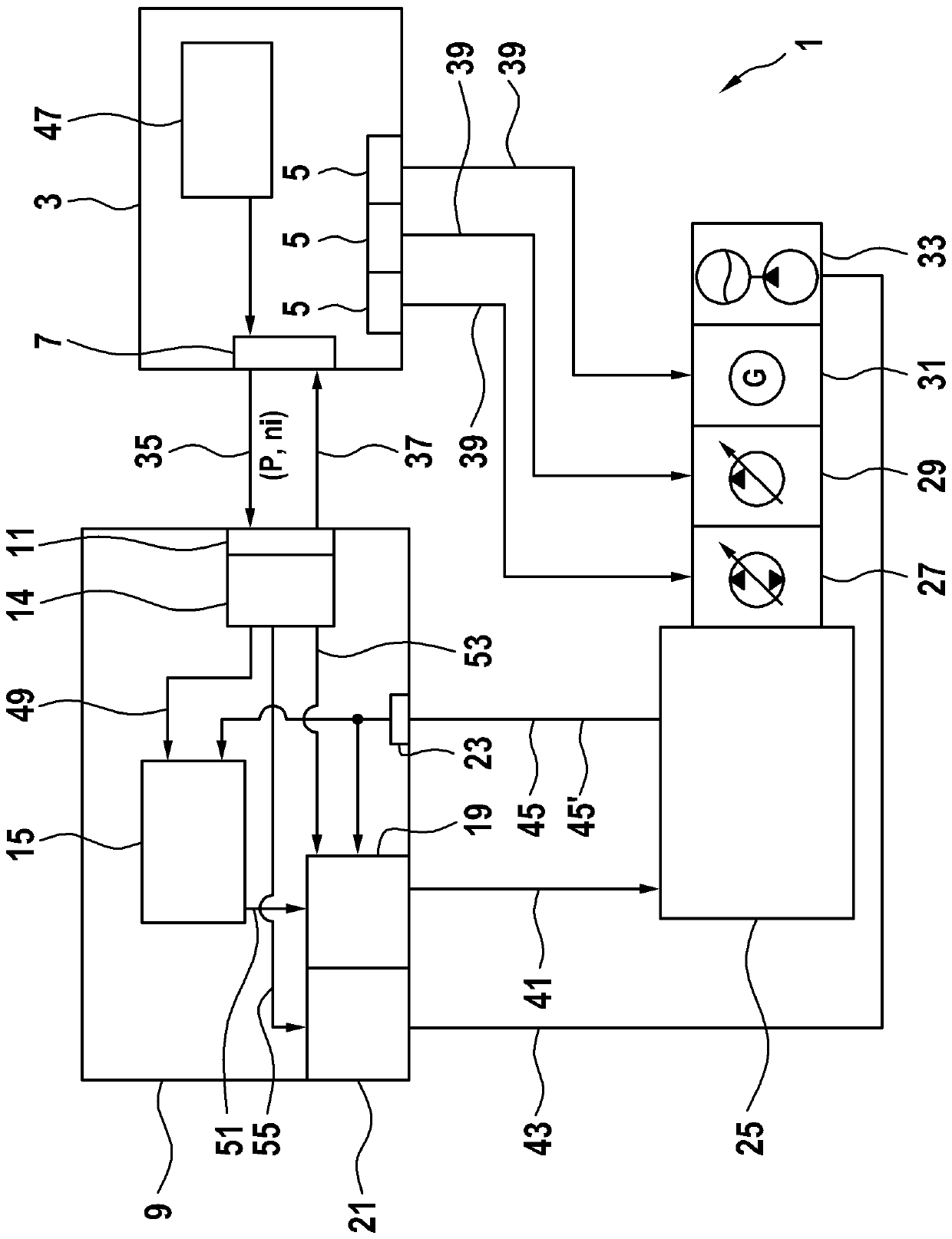

Drive control arrangement for a mobile working machine and interface

InactiveCN110725750AAnticipating regulatory behaviorAchieve complianceProgramme controlElectrical controlControl signalControl theory

A drive control arrangement, for driving of consumers of a mobile working machine with a Diesel engine, includes a Diesel engine controller, vehicle controller, and interface. The engine controller isconfigured to actuate the Diesel engine via a first control signal. The vehicle controller is configured to (i) control the consumers via at least one second control signal, (ii) transfer a power demand, via the interface, to the engine controller, and (iii) receive feedback, via the interface, with reference to an available power from the Diesel engine. The interface is configured such that thepower demand includes a value for a mechanical power and at least one speed interval value. When the engine is delivering a power according to the value of the power demand and / or with reference to the feedback, the engine controller is further configured to control a speed of the engine in a speed interval with reference to the at least one speed interval value.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com