Method for treating waste gases containing CS2 and H2S mixed pollutants

A pollutant and exhaust gas technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of inability to realize the recovery of useful resources, achieve the effects of reducing energy consumption, simplifying the process, and improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

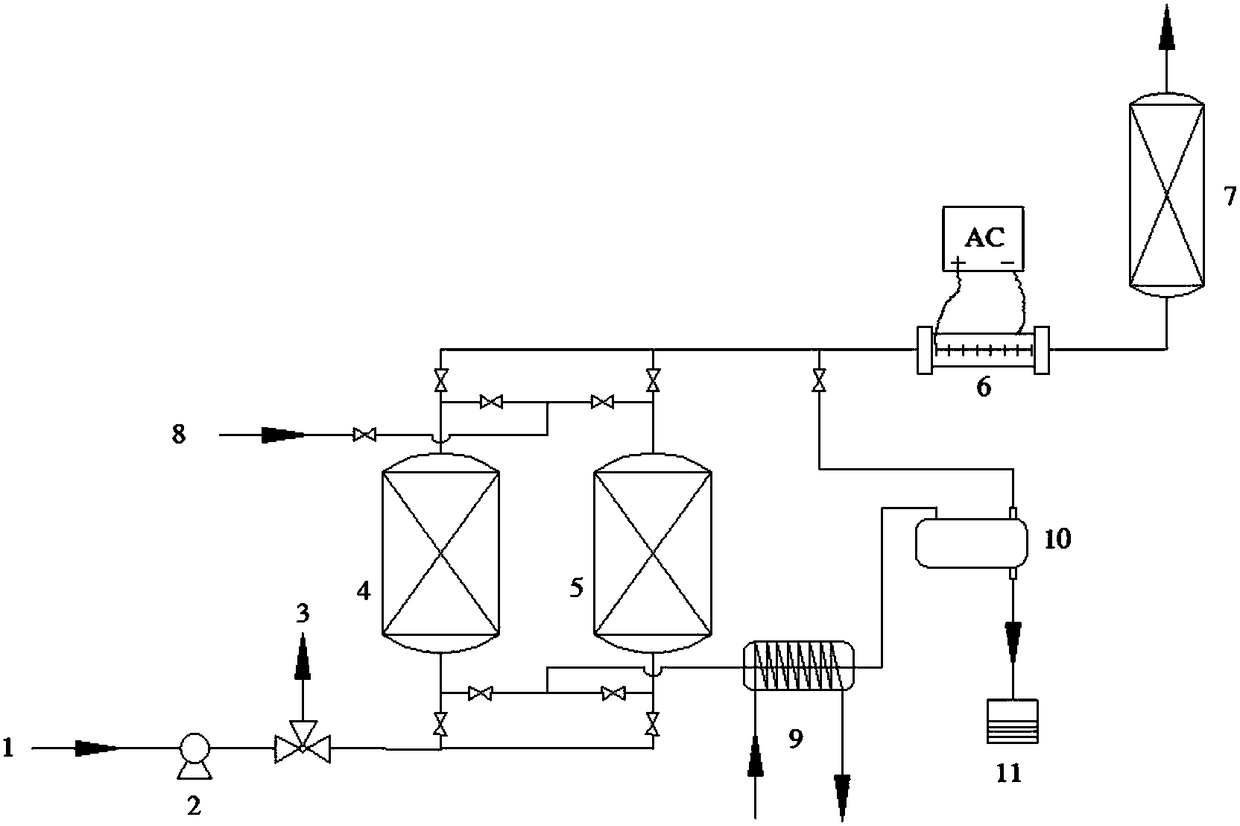

[0028] Such as figure 1 As shown, one for processing containing CS 2 and H 2 The process system of S mixed waste gas, including adsorption towers 4 and 5, low-temperature plasma treatment device 6 and lye absorption tower 7 connected in sequence, the adsorption tower 4 and the adsorption tower 5 are connected in parallel, and the adsorption and desorption processes are alternated on the two towers The switching of the adsorption and desorption processes of the two adsorption towers is automatically controlled by the PLC program. The bottom of the adsorption towers 4 and 5 is provided with an exhaust gas inlet 1, an induced draft fan 2 and an emptying device 3, and the tops of the adsorption towers 4 and 5 are provided with The water vapor enters the end 8, and the adsorption tower 4 is filled with polystyrene-based ultra-high cross-linked adsorption resin; a primary condenser 9 and a secondary condenser 10 are arranged between the adsorption tower 4 and the low-temperature pl...

Embodiment 2

[0038] Handle CS 2 with H 2 The exhaust gas of S mixture, the main parameters are: induced draft fan air volume 80CMH, CS 2 Intake concentration 5g / m 3 , H 2 S concentration 1000mg / m 3 The inlet temperature is normal temperature and the pressure is normal pressure; the diameter of the adsorber is DN=180mm, the adsorbent is ultra-high cross-linked adsorption resin NDA-150 resin, the filling height is H=300mm, the adsorption time is 90min, and the water vapor desorption time is 60min. The condenser uses circulating water at normal temperature, and the secondary condenser uses 5°C frozen brine; the low-temperature plasma adopts corona discharge mode, the voltage is 25kV, and the frequency is 20MHz; the absorption liquid is NaOH solution with a concentration of 5wt%. After the waste gas is treated by the integrated process, the CS in the exhaust gas 2 with H 2 S was not detected, and CS was recovered from the sump for 24 hours 2 9.3Kg, the recovery rate is 96.9%.

Embodiment 3

[0040] The adsorbent in embodiment 2 is changed into macroporous adsorption resin AMBERLITE TM XAD-4, other conditions remain unchanged. CS in exhaust gas 2 The concentration is 103mg / m 3 , the processing efficiency is 97.94%, H 2 S concentration was not detected. Total recovery of CS in the sump for 24 hours 2 6.9Kg, the recovery rate is 71.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com